check engine light MITSUBISHI DIAMANTE 1900 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 99 of 408

3-38 ENGINEANDENGINEOVERHAUL

1.61&? 2.OL (Non-Turbo) DOHC Engines

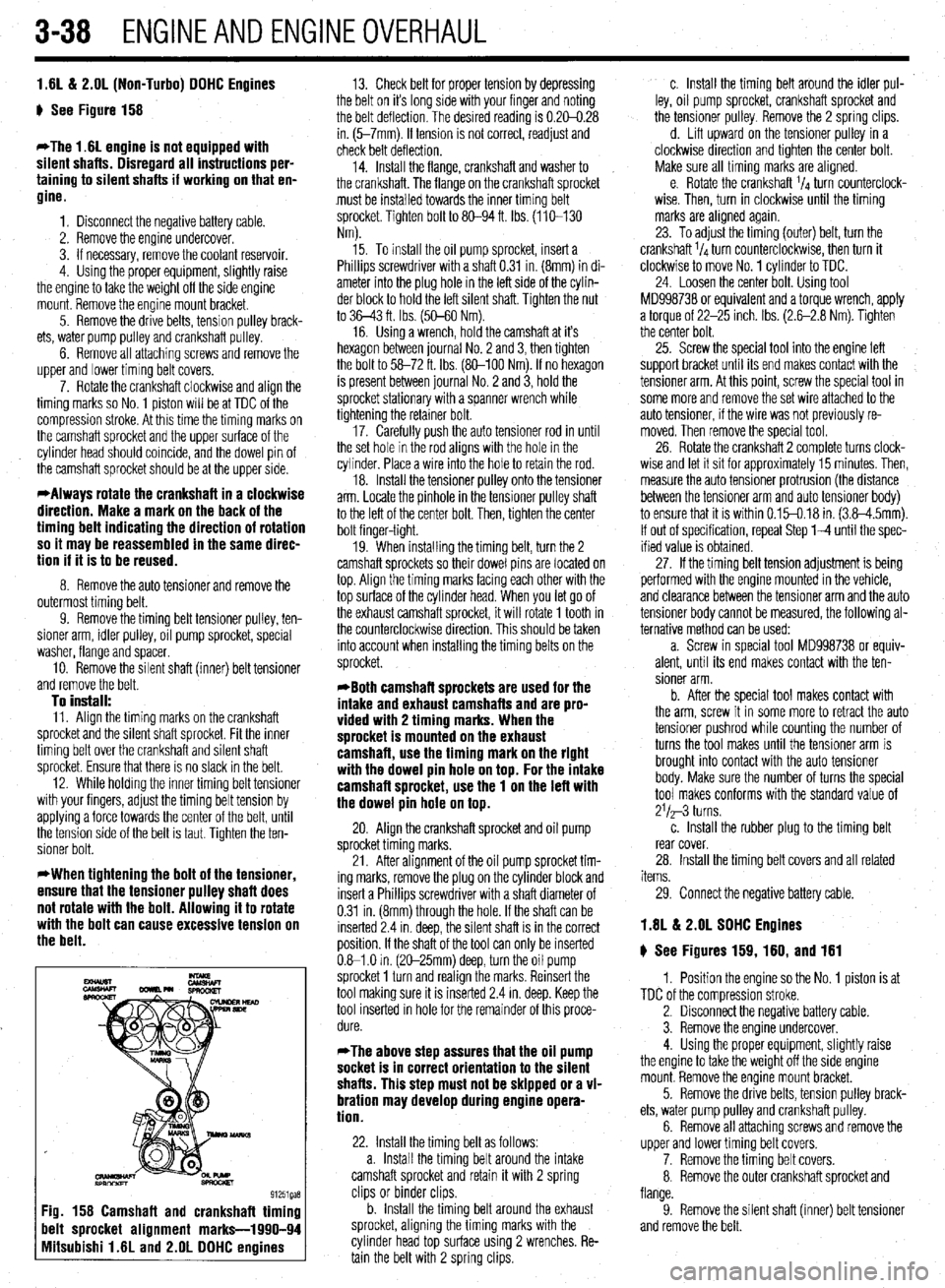

g See Figure 158

*The 1.6L engine is not equipped with

silent shafts. Disregard all instructions per-

taining to silent shafts if working on that en-

gine.

1. Disconnect the negative battery cable.

2. Remove the engine undercover.

3. If necessary, remove the coolant reservoir.

4. Using the proper equipment, slightly raise

the engine to take the weight off the side engine

mount. Remove the engine mount bracket.

5. Remove the drive belts, tension pulley brack-

ets, water pump pulley and crankshaft pulley.

6. Remove all attaching screws and remove the

upper and lower timing belt covers.

7. Rotate the crankshaft clockwise and align the

timing marks so No. 1 piston will be at TDC of the

compression stroke. At this time the timing marks on

the camshaft sprocket and the upper surface of the

cylinder head should coincide, and the dowel pin of

the camshaft sprocket should be at the upper side.

*Always rotate the crankshaft in a clockwise

direction. Make a mark on the back of the

timing belt indicating the direction of rotation

so it may be reassembled in the same direc-

tion if it is to be reused.

8. Remove the auto tensioner and remove the

outermost timing belt.

9. Remove the timing belt tensioner pulley, ten-

sioner arm, idler pulley, oil pump sprocket, special

washer, flange and spacer.

10. Remove the silent shaft (inner) belt tensioner

and remove the belt.

To install: 11. Align the timing marks on the crankshaft

sprocket and the silent shaft sprocket. Fit the inner

timing belt over the crankshaft and silent shaft

sprocket. Ensure that there is no slack in the belt.

12. While holding the inner timing belt tensioner

with your fingers, adjust the timing belt tension by

applying a force towards the center of the belt, until

the tension side of the belt is taut. Tighten the ten-

sioner bolt.

*When tightening the bolt of the tensioner,

ensure that the tensioner pulley shaft does

not rotate with the bolt. Allowing it to rotate

with the bolt can cause excessive tension on

the belt.

13. Check belt for proper tension by depressing

the belt on it’s long side with your finger and noting

the belt deflection. The desired reading is 0.20-0.28

in. (5-7mm). If tension is not correct, readjust and

check belt deflection.

14. Install the flange, crankshaft and washer to

the crankshaft. The flange on the crankshaft sprocket

must be installed towards the inner trming belt

sprocket. Tighten bolt to 80-94 ft. Ibs. (110-130

Nm).

15. To install the oil pump sprocket, insert a

Phillips screwdriver with a shaft 0.31 in. (8mm) in di-

ameter into the plug hole in the left side of the cylin-

der block to hold the left silent shaft. Tighten the nut

to 36-43 ft. Ibs. (50-60 Nm).

16. Using a wrench, hold the camshaft at it’s

hexagon between journal No. 2 and 3, then tighten

the bolt to 58-72 ft. Ibs. (80-100 Nm). If no hexagon

is present between journal No. 2 and 3, hold the

sprocket stationary with a spanner wrench while

tightening the retainer bolt.

17. Carefully push the auto tensioner rod in until

the set hole in the rod aligns with the hole in the

cylinder. Place a wire into the hole to retain the rod.

18. Install the tensioner pulley onto the tensioner

arm. Locate the pinhole in the tensioner pulley shaft

to the left of the center bolt. Then, tighten the center

bolt finger-tight.

19. When installing the timing belt, turn the 2

camshaft sprockets so their dowel pins are located on

top. Align the timing marks facing each other with the

top surface of the cylinder head. When you let go of

the exhaust camshaft sprocket, it will rotate 1 tooth in

the counterclockwise direction. This should be taken

into account when installing the timing belts on the

sprocket.

*Both camshaft sprockets are used for the

intake and exhaust camshafts and are pro-

vided with 2 timing marks. When the

sprocket is mounted on the exhaust

camshaft, use the timing mark on the right

with the dowel pin hole on top. For the intake

camshafl sprocket, use the 1 on the left with

the dowel pin hole on top.

20. Align the crankshaft sprocket and oil pump

sprocket timing marks.

21. After alignment of the oil pump sprocket tim-

ing marks, remove the plug on the cylinder block and

insert a Phillips screwdriver with a shaft diameter of

0.31 in. (8mm) through the hole. If the shaft can be

inserted 2.4 in. deep, the silent shaft is in the correct

position. If the shaft of the tool can only be inserted

0.61 .O in. (2C-25mm) deep, turn the oil pump

sprocket 1 turn and realign the marks. Reinsert the

tool making sure it is inserted 2.4 in. deep. Keep the

tool inserted in hole for the remainder of this proce-

dure.

*The above step assures that the oil pump

socket is in correct orientation to the silent

shafts. This step must not be skipped or a vi-

bration may develop during engine opera-

tion.

22. Install the timing belt as follows:

a. Install the timing belt around the intake

camshaft sprocket and retain it with 2 spring

clips or binder clips.

b. Install the timing belt around the exhaust

sprocket, aligning the timing marks with the

cylinder head top surface using 2 wrenches. Re-

tain the belt with 2 spring clips. c. Install the timing belt around the idler pul-

ley, oil pump sprocket, crankshaft sprocket and

the tensioner pulley. Remove the 2 spring clips.

d. Lift upward on the tensioner pulley in a

clockwise direction and tighten the center bolt.

Make sure all timing marks are aligned.

e. Rotate the crankshaft ‘14 turn counterclock-

wise. Then, turn in clockwise until the timing

marks are alrgned again.

23. To adjust the timing (outer) belt, turn the

crankshaft ‘14 turn counterclockwise, then turn it

clockwise to move No. 1 cylinder to TDC.

24. Loosen the center bolt. Using tool

MD998738 or equivalent and a torque wrench, apply

a torque of 22-25 inch. Ibs. (2.6-2.8 Nm). Tighten

the center bolt.

25. Screw the special tool into the engine left

support bracket until its end makes contact with the

tensioner arm. At this point, screw the special tool in

some more and remove the set wire attached to the

auto tensioner, if the wire was not previously re-

moved. Then remove the specral tool.

26. Rotate the crankshaft 2 complete turns clock-

wise and let it sit for approximately 15 minutes. Then,

measure the auto tensioner protrusion (the distance

between the tensioner arm and auto tensioner body)

to ensure that it is within 0.15-0.18 in. (3.8-4.5mm).

If out of specification, repeat Step l-4 until the spec-

ified value is obtained.

27. If the timing belt tension adjustment is being

performed with the engine mounted in the vehicle,

and clearance between the tensioner arm and the auto

tensioner body cannot be measured, the following al-

ternative method can be used:

a. Screw in special tool MD998738 or equiv-

alent, until its end makes contact with the ten-

sioner arm.

b. After the special tool makes contact with

the arm, screw it in some more to retract the auto

tensioner pushrod while counting the number of

turns the tool makes until the tensioner arm is

brought into contact with the auto tensioner

body. Make sure the number of turns the special

tool makes conforms with the standard value of

21/a-3 turns.

c. Install the rubber plug to the timing belt

rear cover.

28. Install the timing belt covers and all related

items.

29. Connect the negative battery cable.

1.8L & 2.OL SOHC Engines

g See Figures 159, 160, and 161

1. Position the engine so the No. 1 piston is at

TDC of the compression stroke.

2. Disconnect the negative battery cable.

3. Remove the engine undercover.

4. Using the proper equipment, slightly raise

the engine to take the weight off the side engine

mount. Remove the engine mount bracket.

5. Remove the drive belts, tension pulley brack-

ets, water pump pulley and crankshaft pulley.

6. Remove all attaching screws and remove the

upper and lower timing belt covers.

7. Remove the timing belt covers.

8. Remove the outer crankshaft sprocket and

flange.

9. Remove the silent shaft (inner) belt tensioner

and remove the belt.

Page 101 of 408

l

3-40 ENGINEANDENGINEOVERHAUL

Counterbaiance

19235861

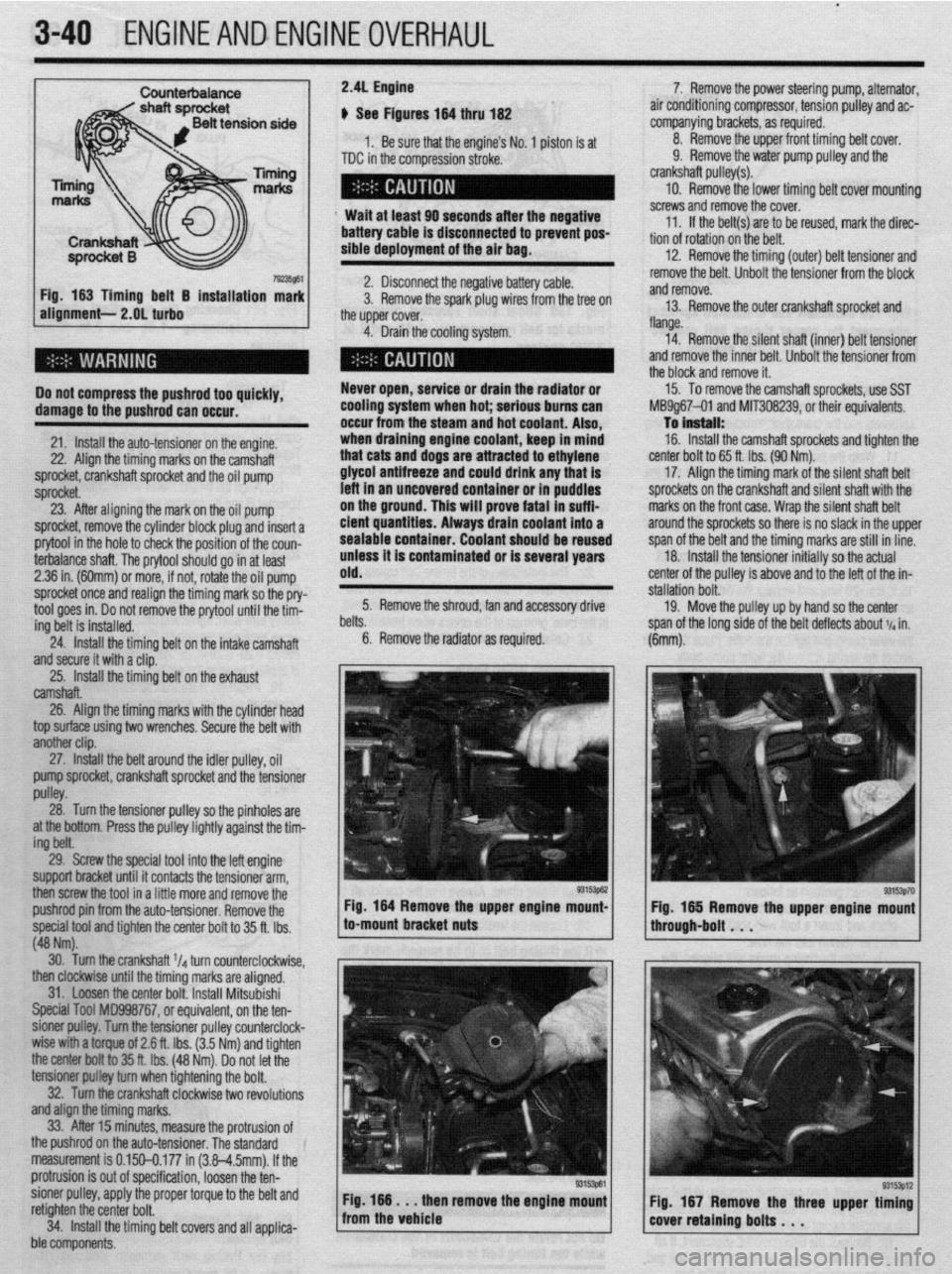

Fig. 163 Timing belt 5 installation mark

alignment- 2.OL turbo

Do not compress the pushrod too quickly,

damage to the pushrod can occur.

21. Install the auto-tensioner on the engine.

22. Align the timing marks on the camshaft

sprocket, crankshaft sprocket and the oil pump

sprocket.

23. After aligning the mark on the oil pump

: sprocket, remove the cylinder block plug and insert a

prytool in the hole to check the position of the coun-

terbalance shaft. The orvtool should ao in at least 7. Remove the power steering pump, alternator

air conditioning compressor, tension pulley and ac-

companying brackets, as required.

8 Remove the upper front timing belt cover.

9. Remove the water pump pulley and the

crankshaft pulley(s).

10. Remove the lower timing belt cover mountinf

screws and remove the cover.

11. If the belt(s) are to be reused, mark the direc.

tion of rotation on the belt.

12. Remove the timing (outer) belt tensioner and

remove the belt. Unbolt the tensioner from the block

and remove.

13. Remove the outer crankshaft sprocket and

flange.

14. Remove the silent shaft (inner) belt tensioner

and remove the inner belt. Unbolt the tensioner from

the block and remove it.

15. To remove the camshaft sprockets, use SST

Ml39g67-01 and MlT308239, or their equivalents.

To in!3tall:

16. Install the camshaft sprockets and tighten thr

center bolt to 65 ft. Ibs. (90 Nm).

17. Align the timing mark of the silent shaft belt

sprockets on the crankshaft and silent shaft with the

marks on the front case. Wrap the silent shaft belt

around the sprockets so there is no slack in the uppe

!

I span of the belt and the timing marks are still in line.

18. Install the tensioner initially so the actual

:enter of the pulley is above and to the left of the in-

jtallation bolt. 2.36 in. (60mm) or more, if not, rotai;! the oil pump

sprocket once and realign the timing mark so the pry-

24. Install the timing belt on the intake camshaft

and secure it with a clip. .

25. Install the timina belt on the exhaust old. 2.41 Engine

I: # See Figures 164 thru 162

1. Be sure that the engine’s No. 1 piston is at

TDC in the compression stroke.

Wait at least 90 seconds after the negative

battery cable is disconnected to prevent pos-

sible deployment of the air bag.

2. Disconnect the negative battery cable.

3. Remove the spark plug wires from the tree on

the upper cover.

4. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious bums can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always dram coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

tool goes in. Do not remove the on/ool until the tfrn- 5. Remove the shroud, fan and accessory drive

ing belt is installed. lelts.

6. Remove the radiator as required. 19. Move the pulley up by hand so the center

jpan of the lona side of the belt deflects about 11~ in.

camshaft.

26. Align the timing marks with the cylinder head

top surface using two wrenches. Secure the belt with

another clip.

27. tnstatf the belt around the idler pulley, oil

pump sprocket, crankshaft sprocket and the tensioner

pulley.

28. Turn the tensioner pulley so the pinholes are

at the bottom. Press the pulley lightly against the tim-

ing belt.

29. Screw the special tool into the left engine

support bracket until it contacts the tensioner arm,

then screw the tool in a little more and remove the

pushrod pin from the auto-tensioner. Remove the

special tool and tighten the center bolt to 35 ft. Ibs.

(48 Nm). Fig 164 Remove the upper engine mount-

to-mount bracket nuts al%@]

Pm3p70 Fig. 165 Remove the upper engine mount

through-bolt . . .

30. Turn the crankshaft ‘Id turn counterclockwise,

then clockwise until the timing marks are aligned.

31. Loosen the center bolt. Install Mitsubishi

Special Tool MD998767, or equivalent, on the ten-

sioner p&y. Turn the tensioner pulley counterclock-

wise with a torque of 2.6 ft. Ibs. (3.5 Nm) and tighten

the center boftto 35 ft. tbs. (48 Nm). Do not let the

tensioner pUtFey turn when tightening the bolt.

32. Turn the crankshaft clockwise two revolutions

and align the timing marks.

33. After 15 minutes, measure the protrusion of

the pushrod on the auto-tensioner. The standard

measurement is 0.150-0.177 in (3.8-4.5mm). If the

I protrusion is out of specification, loosen the ten-

I sioner pulley, apply the proper torque to the belt and

: retighten the center bolt.

34. Install the timing belt covers and all applica-

i ble components.

Page 103 of 408

.

3-42 ENGINEANDENGINEOVERHAUL

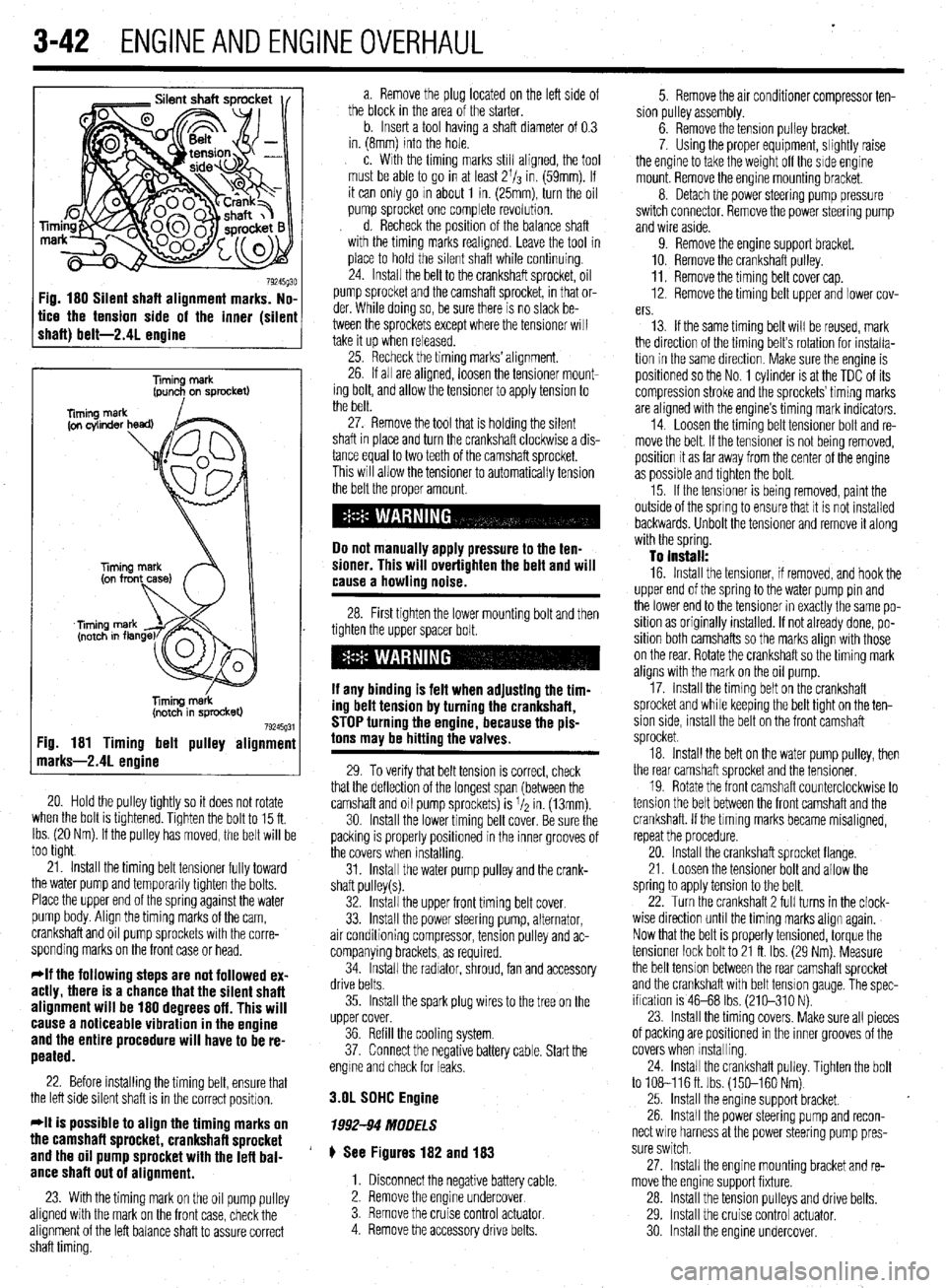

Fig. 180 Silent shaft alignment marks. No,

tice the tension side of the inner (silen

shaft) belt-2.41 enaine

Timing merk

(pun+ on sprocket)

liming m&k

(notch in sprocket)

79245g31 :ig. 181 Timing belt pulley alignmenl

narks-2.41 enoine

20. Hold the pulley tightly so it does not rotate

when the bolt is tlghtened. Tighten the bolt to 15 ft.

Ibs. (20 Nm). If the pulley has moved, the belt will be

too tight

21. Install the timing belt tensioner fully toward

the water pump and temporarily tighten the bolts.

Place the upper end of the spring against the water

pump body. Align the timing marks of the cam,

crankshaft and oil pump sprockets with the corre-

sponding marks on the front case or head.

*If the following steps are not followed ex-

actly, there is a chance that the silent shaft

alignment will be 180 degrees off. This will

cause a noticeable vibration in the engine

and the entire procedure will have to be re-

peated.

22. Before installing the timing belt, ensure that

the left side silent shaft is in the correct position.

*It is possible to align the timing marks on

the camshaft sprocket, crankshaft sprocket

and the oil pump sprocket with the lefl bal-

ance shaft out of alignment.

23. With the timing mark on the oil pump pulley

aligned with the mark on the front case, check the

alignment of the left balance shaft to assure correct

shaft timing. a. Remove the plug located on the left side of

the block in the area of the starter.

b. Insert a tool having a shaft diameter of 0.3

in. (8mm) into the hole.

c. With the timing marks still aligned, the tool

must be able to go in at least 2l/s in. (59mm). If

it can only go m about 1 in. (25mm), turn the oil

pump sprocket one complete revolution.

d. Recheck the position of the balance shaft

with the timing marks reahgned. Leave the tool in

place to hold the silent shaft while continuing.

24. Install the belt to the crankshaft sprocket, oil

pump sprocket and the camshaft sprocket, in that or-

der. While doing so, be sure there is no slack be-

tween the sprockets except where the tensioner will

take it up when released.

25. Recheck the timing marks’ alignment.

26. If all are aligned, loosen the tensioner mount-

ing bolt, and allow the tensioner to apply tension to

the belt.

27. Remove the tool that is holding the silent

shaft in place and turn the crankshaft clockwise a dis-

tance equal to two teeth of the camshaft sprocket.

This will allow the tensioner to automatically tension

the belt the proper amount.

Do not manually apply pressure to the ten-

sioner. This will overtighten the belt and will

cause a howling noise.

28. First tighten the lower mounting bolt and then

tighten the upper spacer bolt.

If any binding is felt when adiustino the tim-

ing delt tension by turning th;! crankshaft,

STOP turning the engine, because the pis-

tons may be hitting the valves.

29. To verify that belt tension is correct, check

that the deflection of the longest span (between the

camshaft and oil pump sprockets) is I/* in. (13mm).

30. Install the lower timing belt cover. Be sure the

packing is properly positioned in the inner grooves of

the covers when installing.

31. Install the water pump pulley and the crank-

shaft pulley(s).

32. Install the upper front timing belt cover.

33. Install the power steering pump, alternator,

air conditioning compressor, tension pulley and ac-

companying brackets, as required.

34. Install the radiator, shroud, fan and accessory

drive belts.

35. Install the spark plug wires to the tree on the

upper cover.

36. Refill the cooling system.

37. Connect the negative battery cable. Start the

engme and check for leaks.

3.OL SDHC Engine

1992-94 MODELS

# See Figures 182 and 183

1. Disconnect the negative battery cable.

2. Remove the engine undercover

3. Remove the cruise control

actuator 4. Remove the accessory drive belts. 5. Remove the air conditioner compressor ten-

sion pulley assembly.

6. Remove the tension pulley bracket.

7. Using the proper equipment, slightly raise

the engine to take the weight off the side engine

mount. Remove the engine mounting bracket.

8. Detach the power steering pump pressure

switch connector. Remove the power steering pump

and wire aside.

9. Remove the engine support bracket.

10. Remove the crankshaft pulley.

11. Remove the timing belt cover cap.

12. Remove the timing belt upper and lower cov-

ers.

13. If the same timing belt will be reused, mark

the direction of the timing belt’s rotation for installa-

tion in the same direction. Make sure the engine is

positioned so the No. 1 cylinder is at the TDC of its

compression stroke and the sprockets’ timing marks

are aligned with the engine’s timing mark indicators.

14. Loosen the timing belt tensioner bolt and re-

move the belt. If the tensioner is not being removed,

position it as far away from the center of the engine

as possible and tighten the bolt.

15. If the tensioner is being removed, paint the

outside of the spring to ensure that it is not installed

backwards. Unbolt the tensioner and remove it along

with the spring.

To install:

16. Install the tensioner, if removed, and hook the

upper end of the spring to the water pump pin and

the lower end to the tensioner in exactly the same po-

sition as originally installed. If not already done, po-

sition both camshafts so the marks align with those

on the rear. Rotate the crankshaft so the timing mark

aligns with the mark on the oil pump.

17. Install the timing belt on the crankshaft

sprocket and while keeping the belt tight on the ten-

sion side, install the belt on the front camshaft

sprocket.

18. Install the belt on the water pump pulley, then

the rear camshaft sprocket and the tensioner.

19. Rotate the front camshaft counterclockwise to

tension the belt between the front camshaft and the

crankshaft. If the tlmlng marks became misaligned,

repeat the procedure.

20. Install the crankshaft sprocket flange.

21. Loosen the tensioner bolt and allow the

spring to apply tension to the belt.

22. Turn the crankshaft 2 full turns in the clock-

wise direction until the timing marks align again.

Now that the belt is properly tensioned, torque the

tensioner lock bolt to 21 ft. Ibs. (29 Nm). Measure

the belt tension between the rear camshaft sprocket

and the crankshaft with belt tension gauge, The spec-

ification is 46-68 Ibs. (210-310 N).

23. Install the timing covers. Make sure all pieces

of packing are positioned in the inner grooves of the

covers when Installing.

24. install the crankshaft pulley. Tighten the bolt

to 108-116ft. Ibs. (150-160 Nm)

25. Install the engine support bracket.

26. Install the power steering pump and recon-

nect wire harness at the power steering pump pres-

sure switch.

27. Install the engine mounting bracket and re-

move the engine support fixture.

28. Install the tension pulleys and drive belts.

29. Install the cruise control actuator.

30 Install the engine undercover.

Page 105 of 408

.

3-44 ENGINEANDENGINEOVERHALJL

31. Connect the negative battery cable.

32. Road test the vehicle.

EXCEPT 1992-94 MODELS

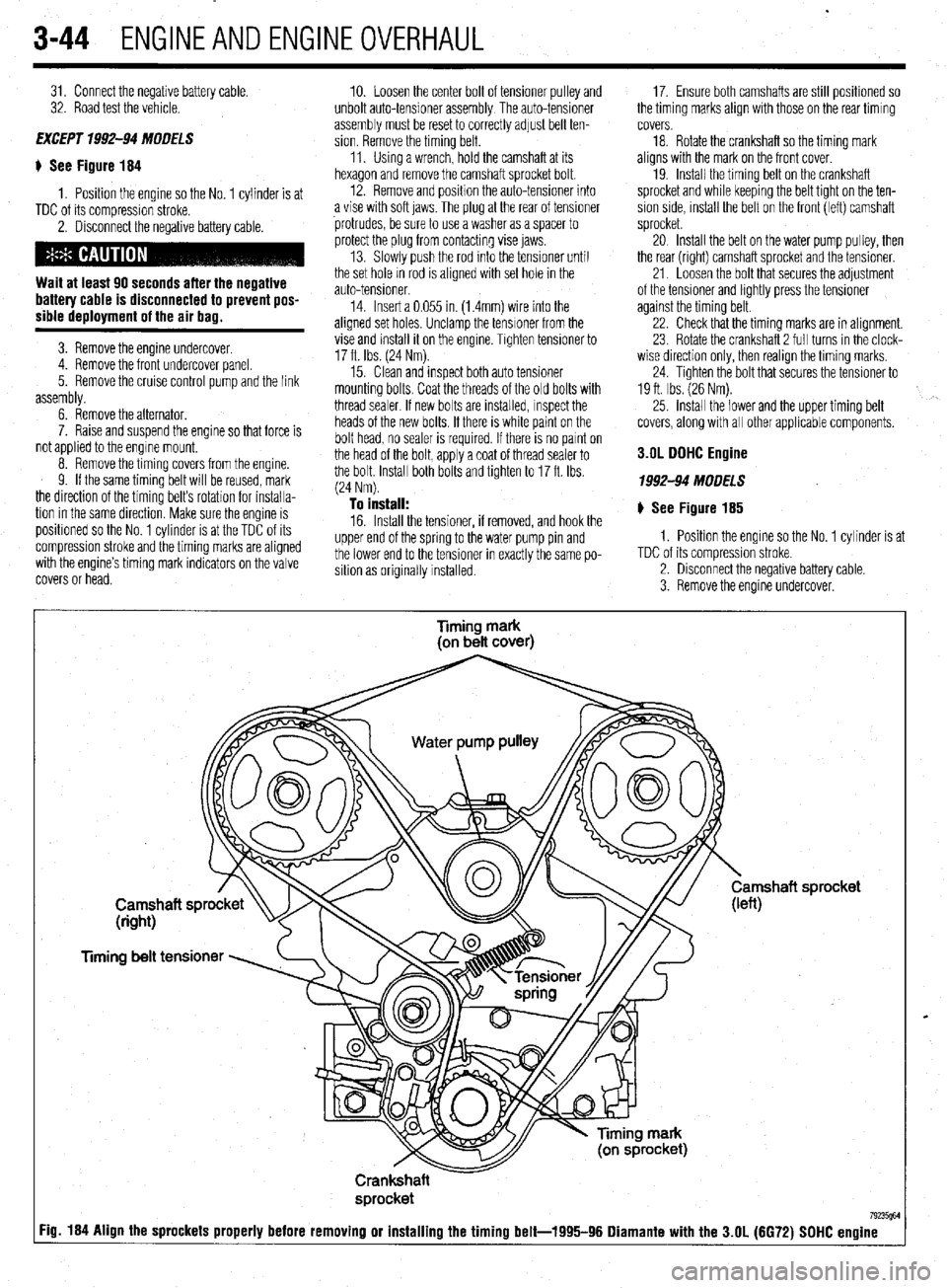

$ See Figure 184

1. Position the engine so the No. 1 cylinder is at

TDC of its compression stroke.

2. Disconnect the negative battery cable.

Wait at least 90 seconds after the negative

battery cable is disconnected to prevent pos-

sible deployment of the air bag.

3. Remove the engine undercover.

4. Remove the front undercover panel.

5. Remove the cruise control pump and the link

assembly.

6. Remove the alternator.

7. Raise and suspend the engine so that force is

not applied to the engme mount,

8. Remove the timing covers from the engine.

9. If the same timing belt will be reused, mark

the direction of the timing belt’s rotation for installa-

tion in the same direction. Make sure the engine is

positroned so the No. 1 cylinder is at the TDC of its

compression stroke and the timing marks are aligned

with the engine’s timing mark indicators on the valve

covers or head. 10. Loosen the center bolt of tensioner pulley and

unbolt auto-tensioner assembly The auto-tensioner

assembly must be reset to correctly adjust belt ten-

sion. Remove the timing belt.

11. Using a wrench, hold the camshaft at its

hexagon and remove the camshaft sprocket bolt.

12. Remove and position the auto-tensioner into

a vise with soft jaws. The plug at the rear of tensioner

protrudes, be sure to use a washer as a spacer to

protect the plug from contacting vise jaws.

13. Slowly push the rod Into the tensioner until

the set hole rn rod is aligned with set hole in the

auto-tensioner.

14. Insert a 0.055 in. (1.4mm) wire into the

aligned set holes. Unclamp the tensioner from the

vise and install it on the engine. Trghten tensroner to

17 ft. Ibs. (24 Nm).

15. Clean and inspect both auto tensioner

mounting bolts. Coat the threads of the old bolts with

thread sealer. If new bolts are installed, Inspect the

heads of the new bolts. If there is white paint on the

bolt head, no sealer is required. If there is no parnt on

the head of the bolt, apply a coat of thread sealer to

the bolt. Install both bolts and tighten to 17 ft. Ibs.

(24 Nm).

To install: 16. Install the tensioner, if removed, and hook the

upper end of the spring to the water pump pin and

the lower end to the tensioner in exactly the same po-

sition as originally installed. 17. Ensure both camshafts are still positioned so

the timing marks align with those on the rear timing

covers.

18. Rotate the crankshaft so the timing mark

aligns with the mark on the front cover.

19. Install the timing belt on the crankshaft

sprocket and while keeping the belt tight on the ten-

sion side, mstall the belt on the front (left) camshaft

sprocket.

20 Install the belt on the water pump pulley, then

the rear (right) camshaft sprocket and the tensioner.

21. Loosen the bolt that secures the adjustment

of the tensioner and lightly press the tensioner

against the timing belt.

22. Check that the timing marks are in alignment.

23 Rotate the crankshaft 2 full turns in the clock-

wise direction only, then realign the timing marks,

24. Tighten the bolt that secures the tensioner to

19 ft. Ibs. (26 Nm).

25. install the lower and the upper timing belt

covers, along with all other applicable components.

3.OL DDHC Engine

1992-94 MODELS

# See Figure 185

1. Position the engine so the No. 1 cylinder is at

TDC of its compression stroke.

2. Disconnect the negative battery cable.

3. Remove the engine undercover.

Timing mark

(on belt cover)

Timing belt tensioner

Crankshaft

sprocket

7923W :ig. 184 Align the sprockets properly before removing or installing the timing belt-1995-96 Diamante with the 3.OL (6672) SDHC engine

Page 108 of 408

ENGINEANDENGINEOVERHAUL 3-47

DO NOT rotate or turn the camshafts when re-

moving the sprockets or severe engine dam-

age will result from internal component in-

terference.

22. Align the mark on the crankshaft sprocket

with the mark on the front case. Then, move the

crankshaft sprocket 1 tooth counterclockwise.

23. Align the timing marks of the camshafts with

the marks on the rear covers.

24. Using large paper clips to secure the timing

belt to the sprockets, install the timing belt in the fol-

lowing order. Be sure camshafts-to-cylinder heads

and crankshaft-to-front cover timing marks are

aligned. Install the timing belt around the pulleys in

the following order:

a. Exhaust camshaft sprocket (front bank).

b. Intake camshaft sprocket (front bank).

c. Water pump pulley.

d. Intake camshaft sprocket (rear bank).

e. Exhaust camshaft sprocket (rear bank).

f. Tensioner pulley.

g. Crankshaft pulley.

h. Idler pulley.

*Since the camshaft sprockets turn easily,

secure them with box wrenches when in-

stalling the timing belt.

25. Align all timing marks on the crankshaft and

raise the tensioner pulley against the belt to remove

slack, snug tensioner bolt.

26. Check the alignment of all the timing marks

and remove the clips that secure the timing belt to the

camshaft sprockets.

27. Rotate the engine 1/4 turn counterclockwise,

then rotate the engine clockwise to align the timing

marks. Check that all the timing marks are in align-

ment.

28. Loosen the center bolt on the tensioner pul-

ley.

29. Using tool MD998752 or equivalent and a

torque wrench, apply 84 inch Ibs. (10 Nm) to the tool

on the tensioner. Tighten the tensioner bolt to 35 ft.

Ibs. (49 Nm) and be sure the tensioner does not ro-

tate with the bolt. 30. Rotate the crankshaft two complete turns

clockwise and let it sit for approximately five minutes.

Then, check that the set pin can easily be inserted

and removed from the hole in the auto-tensioner.

31. Remove the set wire attached to the auto-ten-

sioner

32. Measure the auto-tensioner protrusion (the

distance between the tensioner arm and auto-ten-

sioner body) to ensure that it is within 0.15-0.18 in.

(3.8-4.5mm). If out of specification, repeat adjust-

ment procedure until the specified value is obtained.

33. Check again that the timing marks on all

sprockets are in proper alignment.

34. Install the timing belt covers and all other ap-

plicable components.

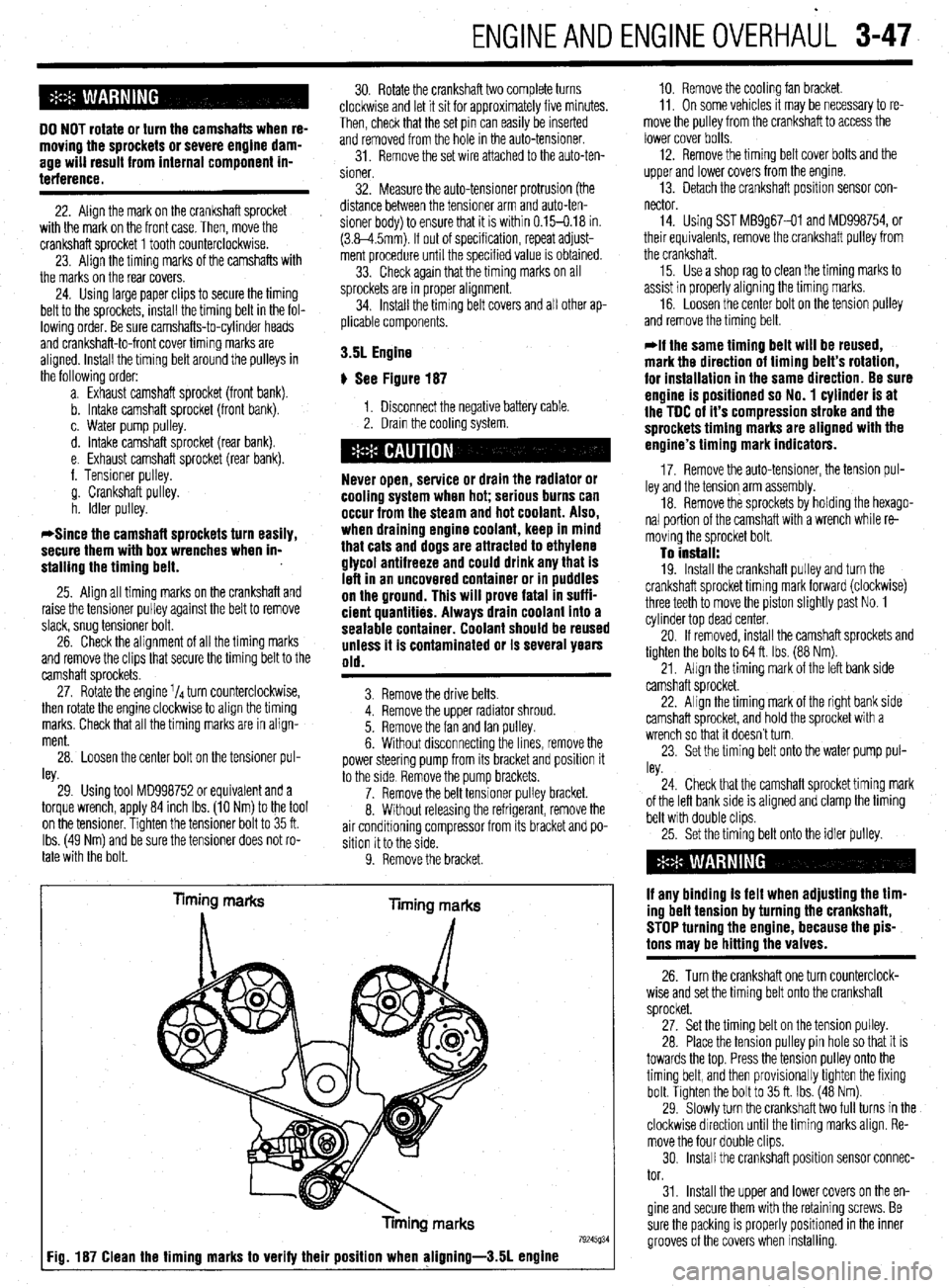

3.51 Engine

p See Figure 187

1. Disconnect the negative battery cable.

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

giycoi antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the drive belts.

4. Remove the upper radiator shroud.

5. Remove the fan and fan pulley.

6. Without disconnecting the lines, remove the

power steering pump from its bracket and position it

to the side Remove the pump brackets.

7. Remove the belt tensioner pulley bracket.

8. Without releasing the refrigerant, remove the

air conditioning compressor from its bracket and po-

sition it to the side.

9. Remove the bracket.

Timing marks

liming marks

Tinning marks

79245934 Fig. 187 Clean the timing marks to verify their position when aligning-3.51 engine

10. Remove the cooling fan bracket.

11, On some vehicles It may be necessary to re-

move the pulley from the crankshaft to access the

lower cover bolts.

12. Remove the timing belt cover bolts and the

upper and lower covers from the engme.

13. Detach the crankshaft position sensor con-

nector

14. Using SST MB9g67-01 and MD998754, or

their equivalents, remove the crankshaft pulley from

the crankshaft.

15. Use a shop rag to clean the timing marks to

assist in properly aligning the timing marks.

16. Loosen the center bolt on the tension pulley

and remove the timing belt.

@if the same timing belt will be reused,

mark the direction of timing belt’s rotation,

for installation in the same direction. Be sure

engine is positioned so No. 1 cylinder is at

the TDC of it’s compression stroke and the

sprockets timing marks are aligned with the

engine’s timing mark indicators.

17. Remove the auto-tensioner, the tension pul-

ley and the tension arm assembly.

18. Remove the sprockets by holding the hexago-

nal portion of the camshaft with a wrench while re-

moving the sprocket bolt.

To install: 19. Install the crankshaft pulley and turn the

crankshaft sprocket timing mark forward (clockwise)

three teeth to move the piston slightly past No. 1

cylinder top dead center.

20. If removed, install the camshaft sprockets and

tighten the bolts to 64 ft. Ibs. (88 Nm).

21, Align the timing mark of the left bank side

camshaft sprocket.

22. Align the timing mark of the right bank side

camshaft sprocket, and hold the sprocket with a

wrench so that it doesn’t turn.

23. Set the timing belt onto the water pump pul-

ley.

24. Check that the camshaft sprocket timing mark

of the left bank side is aligned and clamp the timing

belt with double clips.

25. Set the timing belt onto the idler pulley.

if any binding is felt when adjusting the tim-

ing belt tension by turning the crankshaft,

STOP turning the engine, because the pis-

tons may be hitting the valves.

26. Turn the crankshaft one turn counterclock-

wise and set the timing belt onto the crankshaft

sprocket.

27. Set the timing belt on the tension pulley.

28. Place the tension pulley pin hole so that it is

towards the top. Press the tension pulley onto the

timing belt, and then provisionally tighten the fixing

bolt. Tighten the bolt to 35 ft. Ibs. (48 Nm).

29. Slowly turn the crankshaft two full turns in the

clockwise direction until the timing marks align. Re-

move the four double clips.

30. Install the crankshaft position sensor connec-

tor.

31. Install the upper and lower covers on the en-

gine and secure them with the retaining screws. Be

sure the packing is properly positioned in the inner

grooves of the covers when installing.

Page 112 of 408

ENGlNEANDENGlNEOVERHALiL 3-51

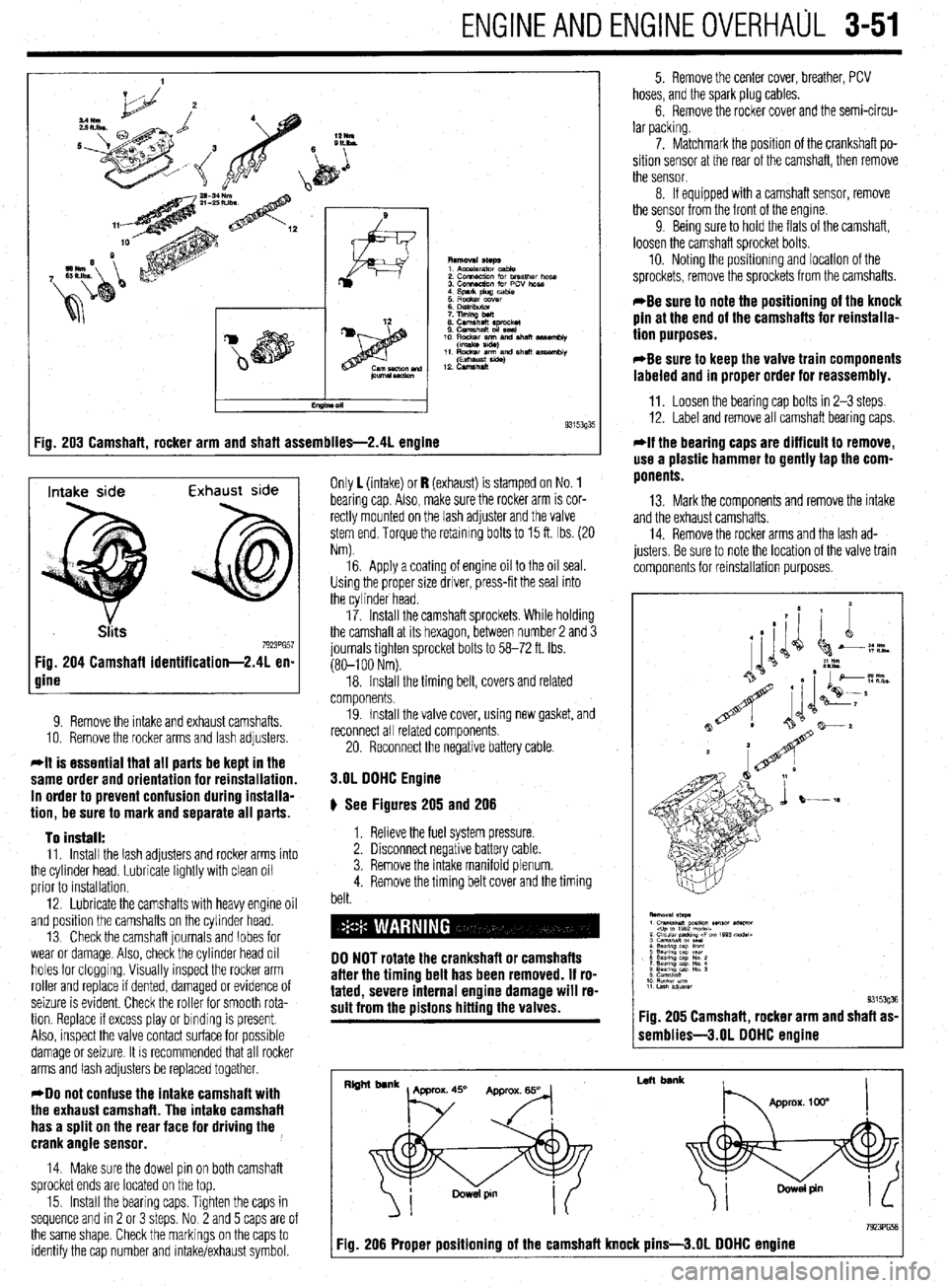

:ig. 203 Camshaft, rocker arm and shaft assemblies-2.41 engine 9315393'

Intake side Exhaust side

7923PG57 Fig. 204 Camshaft identification-2.41 en-

gine

9. Remove the intake and exhaust camshafts.

10. Remove the rocker arms and lash adjusters

*It is essential that all parts be kept in the

same order and orientation for reinstallation.

In order to prevent confusion during installa-

tion, be sure to mark and separate all parts.

To install:

11. Install the lash adjusters and rocker arms into

the cylinder head. Lubricate lightly with clean oil

prior to installation.

12. Lubricate the camshafts with heavy engine oil

and position the camshafts on the cylinder head.

13 Check the camshaft journals and lobes for

wear or damage. Also, check the cylinder head oil

holes for clogging. Visually inspect the rocker arm

roller and replace if dented, damaged or evidence of

seizure is evident. Check the roller for smooth rota-

tion. Replace If excess play or binding is present.

Also, inspect the valve contact surface for possible

damage or seizure. It is recommended that all rocker

arms and lash adjusters be replaced together.

*Do not confuse the intake camshaft with

the exhaust camshaft. The intake camshaft

has a split on the rear face for driving the ,

crank angle sensor.

14. Make sure the dowel pin on both camshaft

sprocket ends are located on the top.

15. Install the bearing caps. Tighten the caps in

sequence and rn 2 or 3 steps. No 2 and 5 caps are of

the same shape. Check the markings on the caps to

identify the cap number and intake/exhaust symbol. Only 1 (intake) or I? (exhaust) is stamped on No. 1

bearing cap Also, make sure the rocker arm is cor-

rectly mounted on the lash adjuster and the valve

stem end. Torque the retaining bolts to 15 ft. Ibs. (20

Nm).

16. Apply a coating of engine oil to the oil seal.

Using the proper size driver, press-fit the seal into

the cylinder head.

17. Install the camshaft sprockets. While holding

the camshaft at its hexagon, between number 2 and 3

journals tighten sprocket bolts to 58-72 ft. Ibs.

(80-l 00 Nm).

18. Install the timing belt, covers and related

components.

19. Install the valve cover, using new gasket, and

reconnect all related components

20. Reconnect the negative battery cable.

3.OL DOHC Engine

# See Figures 205 and 206

1. Relieve the fuel system pressure.

2. Disconnect negative battery cable.

3. Remove the intake manifold plenum.

4. Remove the timing belt cover and the timing

belt.

DO NOT rotate the crankshaft or camshafts

after the timing belt has been removed. If ro-

tated, severe internal engine damage will re-

sult from the pistons hitting the valves.

5. Remove the center cover, breather, PCV

hoses, and the spark plug cables.

6. Remove the rocker cover and the semi-circu-

lar packing.

7. Matchmark the position of the crankshaft po-

sition sensor at the rear of the camshaft, then remove

the sensor.

8. If equipped with a camshaft sensor, remove

the sensor from the front of the engine.

9 Being sure to hold the flats of the camshaft,

loosen the camshaft sprocket bolts.

10. Noting the positionmg and location of the

sprockets, remove the sprockets from the camshafts.

*Be sure to note the positioning of the knock

pin at the end of the camshafts for reinstalla-

tion purposes.

*Be sure to keep the valve train components

labeled and in proper order for reassembly.

11. Loosen the bearing cap bolts in 2-3 steps.

12. Label and remove all camshaft bearing caps.

*If the bearing caps are difficult to remove,

use a plastic hammer to gently tap the com-

ponents.

13. Mark the components and remove the intake

and the exhaust camshafts.

14. Remove the rocker arms and the lash ad-

justers. Be sure to note the location of the valve train

components for reinstallation purposes.

1 semblies-3.01 DOHC engine

I

Left bank

7923PG58 Fig. 206 Proper positioning of the camshaft knock pins-3.01 DOHC engine

Page 118 of 408

ENGINEANDENGINEOVERHAUL 3-57

Anything that generates heat and/or friction WIII

eventually burn or wear out (for example, a light bulb

generates heat, therefore its life span is limited). With

this in mind, a running engine generates tremendous

amounts of both; friction is encountered by the mov-

ing and rotating parts inside the engine and heat is

created by friction and combustion of the fuel How-

ever, the engine has systems designed to help reduce

the effects of heat and friction and provide added

longevrty. The oiling system reduces the amount of

friction encountered by the moving parts inside the

engine, while the cooling system reduces heat cre-

ated by friction and combustion If either system is

not maintained, a break-down will be inevitable.

Therefore, you can see how regular maintenance can

affect the service life of your vehicle, If you do not

drain, flush and refill your cooling system at the

proper intervals, deposits WIII begin to accumulate in

the radiator, thereby reducing the amount of heat it

can extract from the coolant The same applies to

your oil and filter; If it is not changed often enough it

becomes laden with contaminates and is unable to

properly lubricate the engine. This increases friction

and wear.

There are a number of methods for evaluating the

condition of your engine. A compression test can re-

veal the condition of your pistons, piston rings,

cylinder bores, head gasket(s), valves and valve

seats. An oil pressure test can warn you of possible

engine bearing, or oil pump failures. Excessrve oil

consumption, evidence of oil in the engine air intake

area and/or bluish smoke from the tailpipe may indi-

cate worn piston rings, worn valve guides and/or

valve seals. As a general rule, an engine that uses no

more than one quart of oil every 1000 miles is in

good condition. Engines that use one quart of oil or

more in less than 1000 miles should first be checked

for oil leaks. If any oil leaks are present, have them

fixed before determining how much oil is consumed

by the engine, especrally if blue smoke is not visible

at the tailpipe

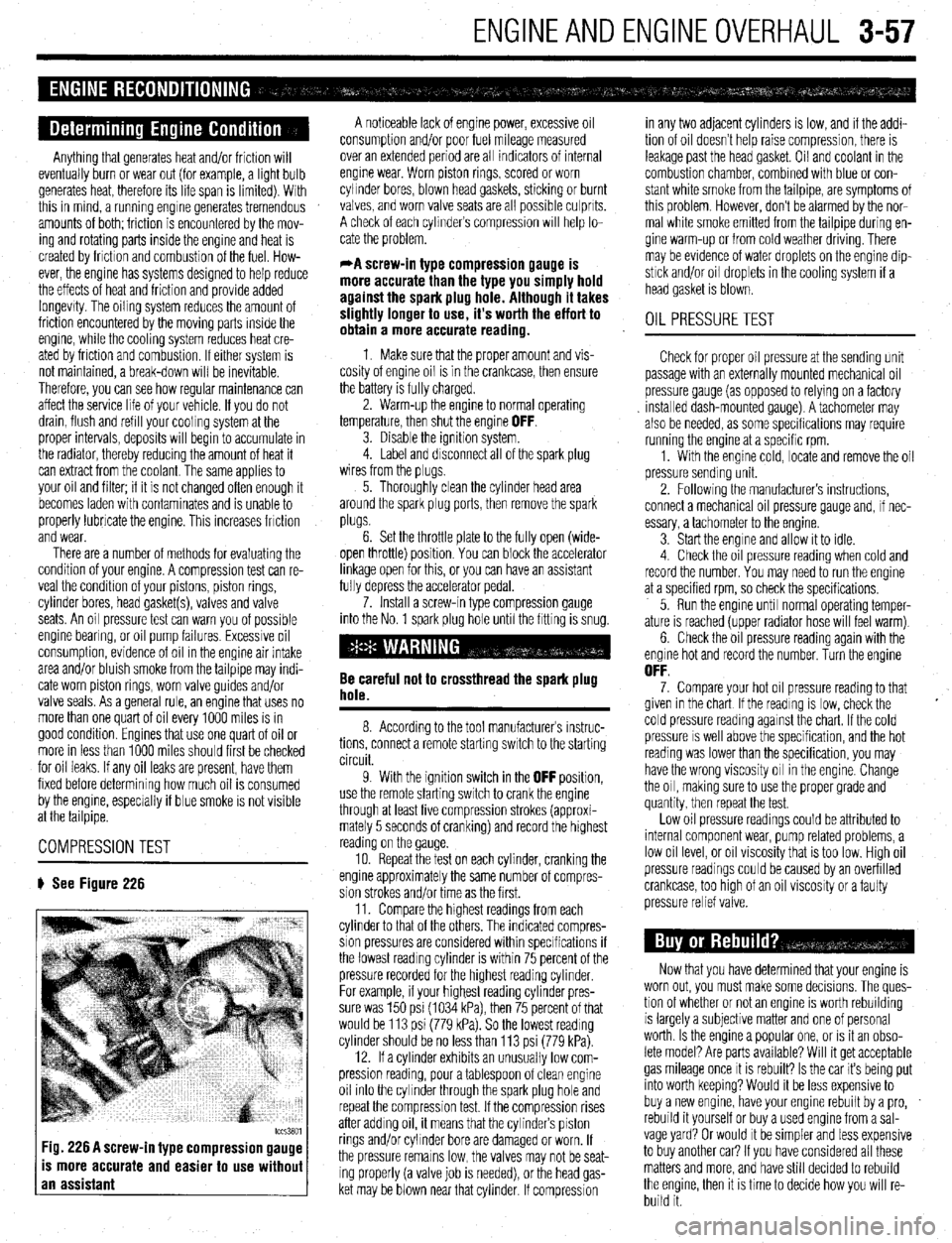

COMPRESSION TEST

# See Figure 226

tccs3801 Fig. 226 A screw-in type compression gauge

is more accurate and easier to use without

an assistant

A noticeable lack of engine power, excessive oil

consumption and/or poor fuel mileage measured

over an extended period are all indicators of internal

engine wear. Worn piston rings, scored or worn

cylinder bores, blown head gaskets, sticking or burnt

valves, and worn valve seats are all possible culprits.

A check of each cylinders compression WIII help lo-

cate the problem.

*A screw-in type compression gauge is

more accurate than the type you simply hold

against the spark plug hole. Although it takes

slightly longer to use, it’s worth the effort to

obtain a more accurate reading.

1 Make sure that the proper amount and vis-

cosity of engine oil is in the crankcase, then ensure

the battery is fully charged.

2. Warm-up the engine to normal operating

temperature, then shut the engine

OFF. 3. Disable the ignition system.

4. Label and disconnect all of the spark plug

wires from the plugs,

5. Thoroughly clean the cylinder head area

around the spark plug ports, then remove the spark

plugs.

6. Set the throttle plate to the fully open (wide-

open throttle) position You can block the accelerator

linkage open for this, or you can have an assistant

fully depress the accelerator pedal.

7. Install a screw-in type compression gauge

into the No. 1 spark plug hole until the fitting is snug.

Be careful not to crossthread the spark plug

hole.

8. According to the tool manufacturers instruc-

tions, connect a remote starting switch to the starting

circuit.

9. With the ignition switch in the

OFF position,

use the remote starting switch to crank the engine

through at least five compression strokes (approxi-

mately 5 seconds of cranking) and record the highest

reading on the gauge

10. Repeat the test on each cylinder, cranking the

engine approximately the same number of compres-

sion strokes and/or time as the first.

11. Compare the hrghest readings from each

cylinder to that of the others. The indicated compres-

sion pressures are considered within specifications if

the lowest reading cylinder is within 75 percent of the

pressure recorded for the highest reading cylinder

For example, if your highest reading cylinder pres-

sure was 150 psi (1034 kPa), then 75 percent of that

would be 113 psi (779 kPa). So the lowest reading

cylinder should be no less than 113 psi (779 kPa).

12. If a cylinder exhibits an unusually low com-

pression reading, pour a tablespoon of clean engine

oil into the cylinder through the spark plug hole and

repeat the compression test. If the compression rises

after adding oil, it means that the cylinder’s piston

rings and/or cylinder bore are damaged or worn, If

the pressure remains low, the valves may not be seat-

ing properly (a valve job is needed), or the head gas-

ket may be blown near that cylinder. If compression in any two adjacent cylinders is low, and if the addi-

tion of oil doesn’t help raise compression, there is

leakage past the head gasket. Oil and coolant in the

combustion chamber, combined with blue or con-

stant white smoke from the tailpipe, are symptoms of

this problem. However, don’t be alarmed by the nor-

mal white smoke emitted from the tailpipe during en-

gine warm-up or from cold weather driving. There

may be evidence of water droplets on the engine dip-

stick and/or oil droplets in the cooling system if a

head gasket is blown.

OIL PRESSURETEST

Check for proper oil pressure at the sending unit

passage with an externally mounted mechanical oil

pressure gauge (as opposed to relying on a factory

Installed dash-mounted gauge). A tachometer may

also be needed, as some specifications may require

running the engine at a specific rpm.

1. With the engine cold, locate and remove the oil

pressure sending unit.

2. Followrng the manufacturers instructions,

connect a mechanical oil pressure gauge and, if nec-

essary, a tachometer to the engine.

3 Start the engine and allow it to idle.

4 Check the oil pressure reading when cold and

record the number. You may need to run the engine

at a specified rpm, so check the specifications,

5. Run the engine until normal operating temper-

ature is reached (upper radiator hose will feel warm)

6. Check the oil pressure reading again with the

engine hot and record the number. Turn the engine

OFF. 7. Compare your hot oil pressure reading to that

given in the chart If the reading is low, check the

cold pressure reading against the chart. If the cold

pressure IS well above the specification, and the hot

reading was lower than the specification, you may

have the wrong viscosity oil in the engine. Change

the oil, making sure to use the proper grade and

quantity, then repeat the test.

Low oil pressure readings could be attributed to

internal component wear, pump related problems, a

low oil level, or oil viscosity that is too low. High oil

pressure readings could be caused by an overfilled

crankcase, too htgh of an oil viscosity or a faulty

pressure relief valve.

Now that you have determined that your engine is

worn out, you must make some decisions. The ques-

tion of whether or not an engine IS worth rebuilding

is largely a subjective matter and one of personal

worth. Is the engine a popular one, or IS it an obso-

lete model? Are parts available? Will it get acceptable

gas mileage once It is rebuilt? Is the car its being put

into worth keeping? Would it be less expensive to

buy a new engine, have your engine rebuilt by a pro,

rebuild it yourself or buy a used engine from a sal-

vage yard? Or would It be simpler and less expensive

to buy another car? If you have considered all these

matters and more, and have still decided to rebuild

the engine, then it is time to decide how you will re-

build it.

Page 121 of 408

3-60 ENGINE/

-w

remove any covers remaining on the engine such as

on today’s automobiles: the Overhead Valve (OHV)

and the Overhead Camshaft (OHC). The latter can

also be broken down into two subgroups: the Single the rocker arm, front or timing cover and oil pan.

Overhead Camshaft (SOHC) and the Dual Overhead

Camshaft (DOHC). Generally, if there is only a single

camshaft on a head. it is iust referred to as an OHC Some front covers may require the vibration damper

and/or crank pulley to be removed beforehand. The

idea is to reduce the engine to the bare necessities

(cylinder head(s), valve train, engine block, crank-

shaft, pistons and connecting rods), plus any other

‘in block’ components such as oil pumps, balance

shafts and auxiliary shafts.

Finally, remove the cylinder head(s) from the en-

gine block and carefully place on a bench. Disassem-

bly instructions for each component follow later in

this section.

There are two basic types of cylinder heads used

Most cylinder heads these days are made of an

aluminum alloy due to its light weight, durability and

L--L I _--- 1^- _..^ I:,:^^ I I ^...^. .^_ ^^^I :_-_ ..^^ ,L- same environment. The same goes for any other unchanged. One aspect to pay attention to is careful

component on the cylinder head. Think of it as an in- labeling of the parts on the dual camshaft cylinder

“’ surance policy against future problems related to that head. There will be an intake camshaft and followers

component. as well as an exhaust camshaft and followers and

Unfortunately, the only way to find out which com- they must be labeled as such. In some cases, the

ponents need replacing, is to disassemble and care- components are identical and could easily be in-

fully check each piece. After the cylinder head(s) are stalled incorrectly. DO NOT MIX THEM UP! Deter-

disassembled, thoroughly clean all of the compo- mining which is which is very simple; the intake

nents. camshaft and components are on the same side of

DISASSEMBLY the head as was the intake manifold. Conversely, the

exhaust camshaft and components are on the same

side of the head as was the exhaust manifold.

ti See Figures 237 and 238

Whether it is a single or dual overhead camshaft Cup Type Camshaft Followers

cylinder head, the disassembly procedure is relatively 6 See Figures 239, 240, and 241

t “” ““’ 1 Most cylinder heads with cup type camshaft fol-

1 1 head. Also, an engine with an OHV cylinder head is j:, ’

I also known as a pushrod engine. : .; :-,

_I lowers will have the valve spring, retainer and locks

recessed within the followers bore. You will need a

C-clamp style valve spring compressor tool, an OHC

spring removal tool (or equivalent) and a small mag-

net to disassemble the head.

1. If not already removed, remove the camshaft(s)

and/or followers, Mark their positions for assembly.

2. Position the cylinder head to allow use of a C-

clamp style valve spring compressor tool.

IIRN il~llSlt?l ~Lldll~l~S. IlUWttVtJ, MS1 11011 W8S lilt: material of choice in the past, and is still used on

many vehicles today. Whether made from aluminum

or iron, all cylinder heads have valves and seats.

Some use fwo valves per cylinder, while the more hi-

tech engines will utilize a multi-valve configuration

using 3‘4 and even 5 valves per cylinder. When the

valve contacts the seat, it does so on precision ma-

chined surfaces, which seals the combustion cham-

ber, All cylinder heads have a valve guide for each

valve. The auide centers the valve to the seat and al-

lows it to move up and down within it. The clearance

between the valve and guide can be critical. Too

much clearance and the engine may consume oil,

lose vacuum and/or damaae the seat. Too little. and

the valve can stick in the guide causing the engine to

run poorly if at all, and possibly causing severe dam-

age. The last component all cylinder heads have are

valve springs. The spring holds the valve against its

seat. It also returns the valve to this position when

the valve has been opened by the valve train or

camshaft. The spring is fastened to the valve by a re-

tainer and valve locks (sometimes called keepers).

Aluminum heads will also have a valve spring shim

to keep the spring from wearing away the aluminum. Fig, 237 Exploded view of a valve, seal,

1 cylinder head ----r- 1 spring, retamer and locks from an OHC

An ideal method of rebuilding the cylinder head

would involve replacing all of the valves, guides,

seats, springs, etc. with new ones. However, depend-

ing on how the engine was maintained, often this is

not necessary. A major cause of valve, guide and seat

wear is an improperly tuned engine. An engine that is

~~f~t~~ rich, will often wash the lubricating oil

out ofthe guide with gasoline, causing it to wear

~~fdfy. lonely, an engine which is running too

lean wifl pface higher combustion temperatures on

Me valves and seats allowing them to wear or even

bum. Springs fall victim to the driving habits of the

f~~iduaf. A driver who often runs the engine rpm to

tfre redfine will wear out or break the springs faster

then one tfrat stays well below it. Unfortunately,

mileage takes it tot1 on all of the parts. Generally, the

valves, guides, springs and seats in a cylinder head

can be machined and re-used, saving you money.

.However, if a valve is burnt, it may be wise to replace

all of the valves, since they were all operating in the oi a multi-valve cylinder

t has 2 intake

and 2 ex-

At is preferred to position the cylinder head lasket’surtace facing you with tee valve

springs facing the opposite direction and the

lead laying horizontal.

3. With the OHC spring removal adapter tool po-

,itioned inside of the follower bore, compress the

alve spring using the C-clamp style valve spring

:ompressor.

tcca3p51 fig. 239 C-clamp type spring compressor

and an OHC spring removal tool (center) for

cup type followers

Fig. 240 Most cup type follower cylinder

/ heads retain the camshaft using bolt-on

bearing caps

Page 123 of 408

.

3-62 ENGINEANDENGINEOVERHAUL

lge. To accurately inspect them, you will need some

,pecialized tools:

l A O-l in. micrometer for the valves l A dial indicator or inside diameter gauge for

he valve guides

l A spring ressure test gau e

If you do no P Yl have access to t e proper tools,

‘ou may want to bring the components to a shop

hat does.

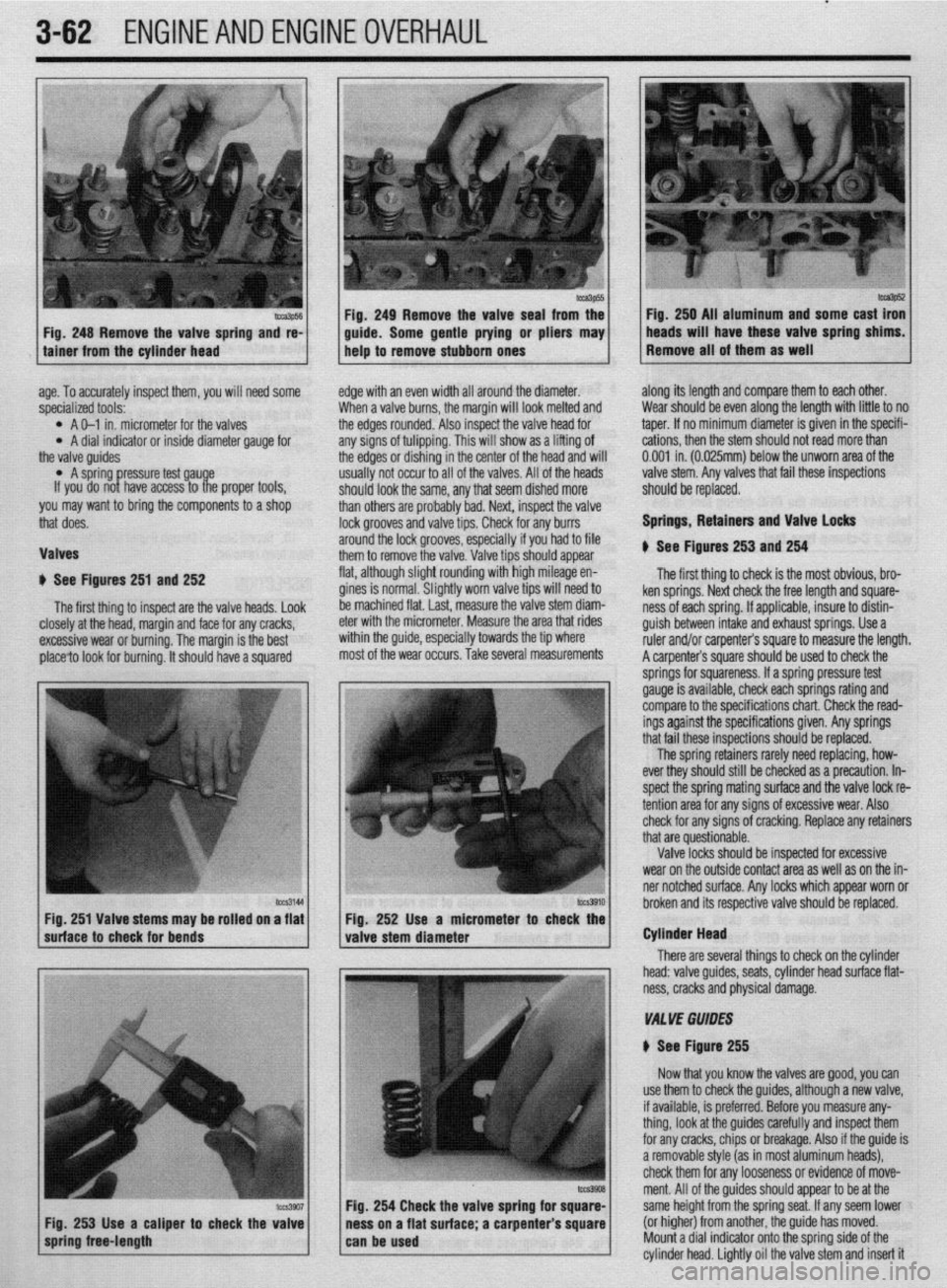

lalves

1 See Figures 251 and 252

The first thing to inspect are the valve heads. Look

E :losely at the head, margin and face for any cracks,

rxcessive wear or burning. The margin is the best

)lace?o look for burning. It should have a squared E

c

edge with an even width all around the diameter.

When a valve burns, the margin will look melted and

the edges rounded. Also inspect the valve head for

any signs of tulipping. This will show as a lifting of

the edges or dishing in the center of the head and will

usually not occur to all of the valves. All of the heads

should look the same, any that seem dished more

than others are probably bad. Next, inspect the valve

lock grooves and valve tips. Check for any burrs

around the lock grooves, especially if you had to file

them to remove the valve. Valve tips should appear

flat, although slight rounding with high mileage en-

gines is normal. Slightly worn valve tips will need to

be machined flat. last, measure the valve stem diam-

eter with the micrometer. Measure the area that rides

within the guide, especially towards the tip where

most of the wear occurs. Take several measurements along its length and compare them to each other.

Wear should be even along the length with little to no

taper. If no minimum diameter is given in the specifi-

cations, then the stem should not read more than

0.001 in. (0.025mm) below the unworn area of the

valve stem. Any valves that fail these inspections

should be replaced.

Springs, Retainers and Valve Locks

$ See Figures 253 and 254

The first thing to check is the most obvious, bro-

ken springs. Next check the free length and square-

ness of each spring. If applicable, insure to distin-

guish between intake and exhaust springs. Use a

ruler and/or carpenter’s square to measure the length.

A carpenter’s square should be used to check the

lCZS3144

I I hrnknn itc Fig. 251 Valve stems may be rolled on a flat Fio. 252 Use a micrometer

suhace to check for bends

valve stem diameter r to check the

I

There are seve Cylinder Head

ral things to check on the cylinder

head: valve guides, seats, cylinder head surface flat-

ness, cracks and physical damage.

VA1 YE GUIDES

N See Figure 255

Now that you know the valves are good, you can

254 Check the valve spring fo

s on a flat surface; a carpenter use them to check the guides, although a new valve,

if available, is preferred. Before you measure any-

thing, look at the guides carefully and inspect them

for any cracks, chips or breakage. Also if the guide is

a removable style (as in most aluminum heads),

check them for any looseness or evidence of move-

ment. All of the guides should appear to be at the

same height from the spring seat. If any seem lower

(or higher) from another, the guide has moved.

Mount a dial indicator onto the sorina side of the

cylinder head. Lightly oil the valve stem and insert it

Page 124 of 408

ENGINEANDENGINEOVERHAUL 3-63

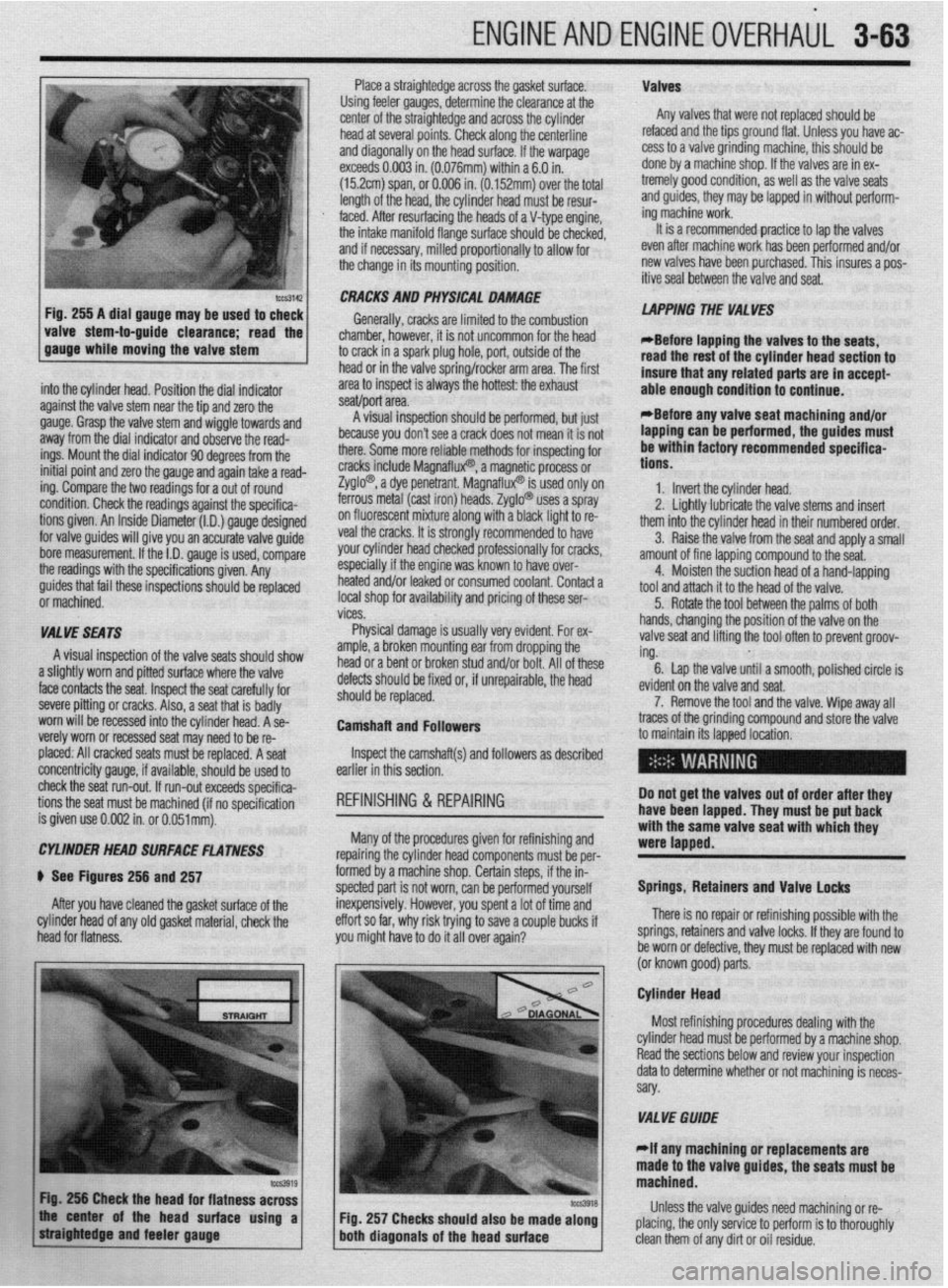

Place a straightedge across the gasket surface. Valves

Using feeler gauges, determine the clearance at the

center of the straightedge and across the cylinder Any valves that were not replaced should be

head at several points. Check along the centerline refaced and the tips ground flat. Unless you have ac-

and diagonally on the head surface. If the warpage cess to a valve grinding machine, this should be

exceeds 0.003 in. (0.076mm) within a 6.0 in. done by a machine shop. If the valves are in ex-

(152cm) span, or 0.006 in. (0.152mm) over the total tremely good condition, as well as the valve seats

length of the head, the cylinder head must be resur- and guides, they may be lapped in without petform-

,

I mg macnme worK.

4

It is a recnmmended practice to lap the valves faced. After resurfacing the heads of a V-type engine

the intake manifold flange surface should be checker,

and if necessary, milled proportionally to allow for

the change in its mounting position. _ - _ _ _ .- - - _

even after machine work has been p&formed and/or

new valves have been purchased. This insures a pos-

itive seal between the valve and seat.

-guide clearance; the 1

read

. .

into the cylinder head. Position the dial indicator

against the valve stem near the tie and zero the

gauge. Grasp the valve stem and’wiggle towards and

away from the dial indicator and observe the read-

ings. Mount the dial indicator 90 degrees from the

initial point and zero the gauge and again take a read-

ing. Compare the two readings for a out of round

condition. Check the readings against the specifica-

tions given. An Inside Diameter (I.D.) gauge designed

for valve guides will give you an accurate valve guide

bore measurement. If the I.D. gauge is used, compare

the readings with the specifications given. Any CRACKS AND PHYSICAL DAMAGE

Generally, cracks are limited to the combustion

chamber, hbwever, it is not uncommon for the head

to crack in a spark plug hole, port, outside of the

head or in the valve spring/rocker arm area. The first

area to inspect is always the hottest: the exhaust

.I *

seawpon area.

8 I .,“““I llly”Lv”l~ .ml”“l” - plr”llll”“, ““I ,“a’

because you don’t see a crack does not mean it is not

there. Some more reliable methods for inspecting for

cracks include Magnaflux? a magn$i,c process or

Zyglo? a dye penetrant. Ma{ -’

InatluxW IS used only on

ferrous metal (cast iron) heat Is. Zyglo@ uses a spray

on fluorescent mixture along with a black light to re-

veal the cracks. It is strongly recommended to have

your cylinder head checked professionally for cracks,

especially if the engine was known to have over-

I .* I,. ..^.. LAPPING THE VALVES

*Before iaoaino the valves to the seats,

read the rest of the cylinder head section to

insure that any related parts are in accept-

able enough condition to continue.

*Before anv valve seat machining and/or

lapping can be performed, the guides must

be within factory recommended specifica-

tions.

1. Invert the cylinder head.

2. Linhtlv Iuhrir;rB the valve stems and insert

-. _ ~ . . . . . .--.._-._

them into the cylinder head in their numbered order.

3. Raise the valve from the seat and apply a small

amount of fine lanninn compound to the seat.

4.

i guides that fail these inspections should be replaced nearea analor ieaKea or consumea coolant. Contact a Moisten the suction head of a hand-lapping

tool and attach it to the head of the valve.

i or machined. local shop for availability and pricing of these ser-

5. Rotate the tool between the palms of both

I vices.

I

VALVE SEATS Physical damage is usually very evident. For ex- hands, changing the position of the valve on the

valve seat and lifting the tool often to prevent groov-

A visual inspection of the valve seats should show

amnb P hrnbn mntlntinn ear from dropping the I and/or bolt. All of these ing.

.a,... . 6. Lap the valve until a smooth, polished circle is

a slightly worn and pitted surface where the valve

face contacts the seat. Inspect the seat carefully for

severe pitting or cracks. Also, a seat that is badly

worn will be recessed into the cylinder head. A se-

verely worn or recessed seat may need to be re- uetecIs SIIOUIO oe nxea or, IT unrepairaole, me neaa

should be replaced.

Camshaft and Followers evid

7

traces of the grinding corn

to maintain its lapped loca lent on the valve and seat.

‘. Remove the tool and the valve. Wipe away all

pound and store the valve

placed: All cracked seats must be replaced. A seat

concentricity gauge, if available, should be used to

check the seat run-out. If run-out exceeds specifica-

tions the seat must be machined (if no soecification

is given use 0.002 in. or O.O51mt$. Inspect the camshaft(s) and followers as described

earlier in this section.

REFINISHING & REPAIRING Do not get the valves out of order after they

have been lapped. They must be put back

: ..^^ I... --I:^:-L!-- --A

Many of the procedures gIveI

WI WIIIIISIIIIIIJ ~IIU repairing the cylinder head components must be per-

formed by a machine shop. Certain steps, if the in-

spected part is not worn, can be performed yourself

inexpensively. However, you spent a lot of time and

effort so far, why risk trying to save a couple bucks if

you might have to do it all over again?

I- with the same valve seat with which they

were lapped.

Springs, Retainers and Valve locks

There is no repair or refinishing possible with the

springs, retainers and valve locks. If they are found to

be worn or defective, they must be replaced with new

lor known nnod narts CYLtNDEt? HEAD SURFACE FLATNESS

) See Figures 256 and 257

After you have cleaned the gasket surface of the

cylinder head of any old gasket material, check the

head for flatness.

\- - a---r r- .-.

Cylinder Head

Most refinishing procedures dealing with the

VALVE GWDE

elf any machining or replacements are

e valve guides, the seats must be

Fig. 257 Checks should also be made along Unless the valve guides need machining or re-

placing, the only service to perform is to thoroughly‘

clean them of any dirt or oil residue.