check engine light MITSUBISHI DIAMANTE 1900 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 60 of 408

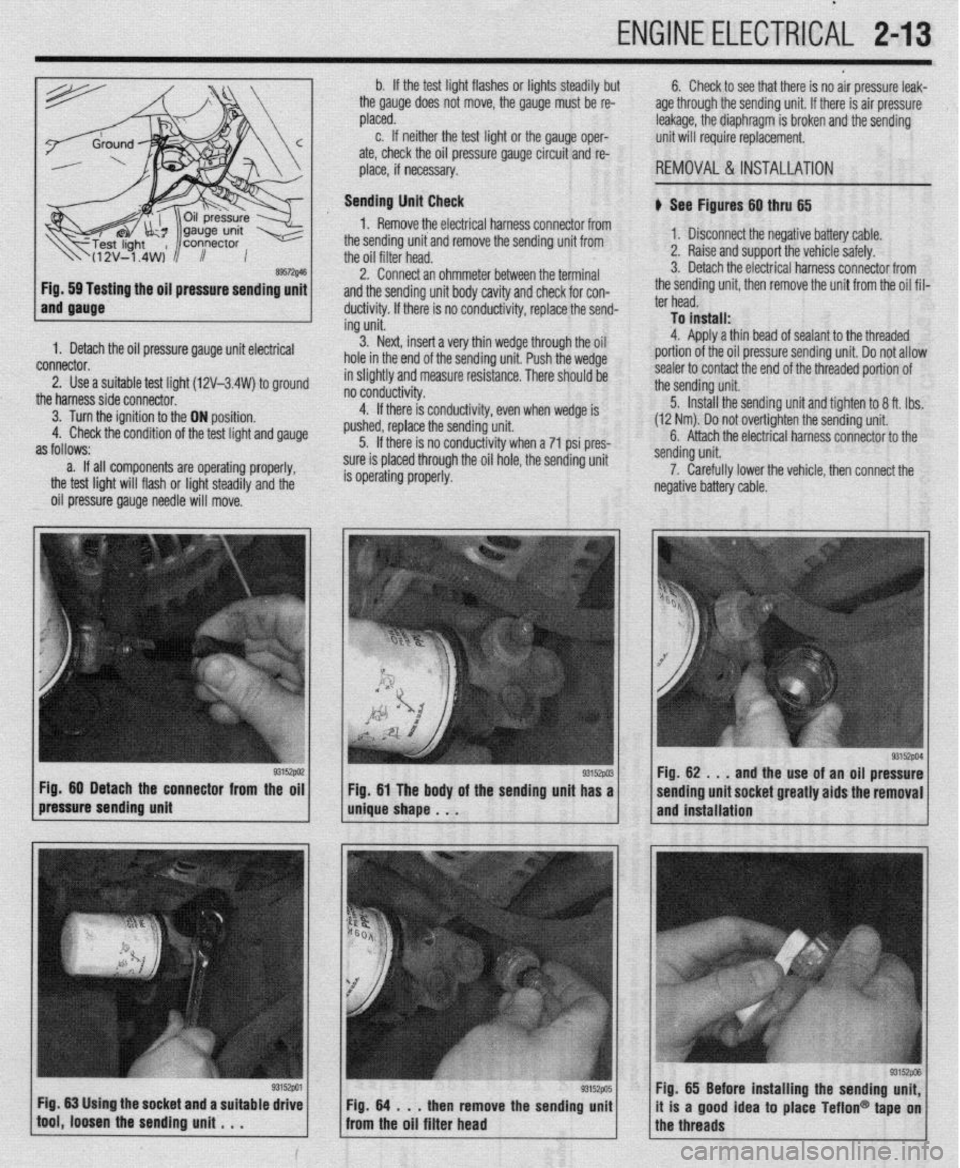

ENGINE ELECTRlCiL 2-13

ing the oil pressure sending unit

1. Detach the oil pressure gauge unit electrical

connector.

2. Use a suitable test lioht (12V-3.4W) to around

the harnesssideconnecto~ ’ ’ -

3. Turn the ignition to the ON position.

4. Check the condition of the test light and gauge

as follows:

a. If all components are operating properly,

the test light will flash or light steadily and the

oil pressure gauge needle will move. b. If the test light flashes or lights steadily but

the gauge does not move, the gauge must be re-

placed.

c. If neither the test light or the gauge oper-

ate, check the oil pressure gauge circuit and re-

place, if necessary.

Sending Unit Check

1. Remove the electrical harness connector from

the sending unit and remove the sending unit from

the oil filter head.

2. Connect an ohmmeter between the terminal

and the sending unit body cavity and check for con-

ductivity. If there is no conductivity, replace the send-

ing unit.

3. Next, insert a very thin wedge through the oil

hole in the end of the sending unit. Push the wedge

in slightly and measure resistance. There should be

- - -- d . . . .

no conoucovey.

4. If there is conductivity, even when wedge is

pushed, replace the sending unit.

5. If there is no conductivity when a 71 psi pres-

sure is placed through the oil hole, the sending unit

is operating properly. 6. Check to see that there is no air pressure leak-

age through the sending unit. If there is air pressure

leakage, the diaphragm is broken and the sending

unit will require replacement.

REMOVAL &INSTALLATION

b See Figures 60 thru 65

1. Disconnect the negative battery cable.

2. Raise and support the vehicle safely.

3. Detach the electrical harness connector from

the sending unit, then remove the unit from the oil fil-

ter head.

To install:

4. Aoolv a thin bead of sealant to the threaded

portion of the oil pressure sending unit. Do not allow

sealer to contact the end of the threaded portion of

the sending unit.

5. Install the sending unit and tighten to 8 ft. tbs.

(12 Nm). Do not over-tighten the sending unit.

6. Attach the electrical harness connector to the

/pressure sending unit g3’9wi / m&e shape . . . Fig 60 Detach the connector from the oil

g3152w Fig 61 The body of the sending unit has a sending unit.

7. Carefully lower the vehicle, then connect the

negative battery cable.

93152PM Fig. 62 . , .

and the use of an oil pressure

sending unit socket greatly aids the removal

and installation

Fig. 65 Before installing the sending unit,

it is a good idea to place Teflon@ tape on

the threads

Page 61 of 408

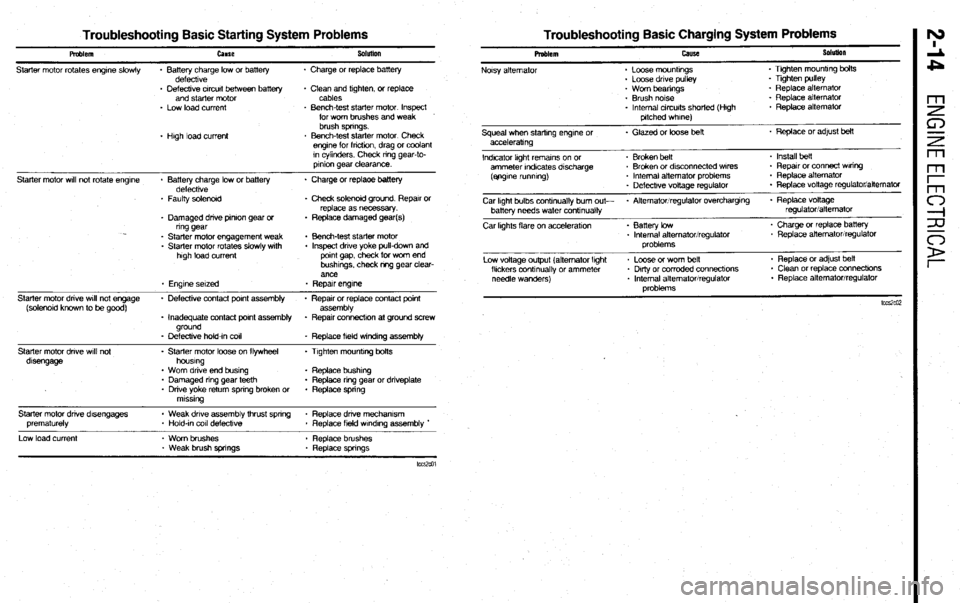

Troubleshooting Basic Starting System Problems Troubleshooting Basic Charging System Problems

Pmblem

Starter motor rotates engrne slowly cause

* Battery charge low or battery

defecttve Sobnlon

. Charge or replace battery

- Defective crrcurt between battery

and starter motor

* Low load current

* Hugh load current + Clean and ttghten, or replace

cables

* Bench-test starter motor Inspect

for wom brushes and weak

brush springs.

. Bench-test starter motor Check

engtne for fncbon, drag or coolant

rn cylinders. Check nng gear-to-

prnton gear clearance.

Starter motor wrll not rotate engrne

Starter motor dnve wrll not engage

(solenotd known to be good)

Starter motor dnve wtli not

dtsengage * Battery charge low or battery * Charge or replaoe battery

defecttve

* Faulty solenord . Check solenoid ground Reparr or

replace as necessary.

* Damaged drive pnron gear or * Replace damaged gear(s)

ring gear

* Starter motor engagement weak . Bench-test starter motor

. Starter motor rotates slowly wtth . Inspect dnve yoke pull-down and

high load current pornt gap, check for worn end

bushtngs. check m-g gear clear-

ance

. Engine setzed * Repatr engk7e

. Defecbve contact pant assembly * Reparr or replace contact pornt

assembly

. Inadequate contact pornt assembly + Repatr connectron at ground screw

ground

- Defeckve hold-In co11

* Replace field w~ndrng assembly

- Starter motor loose on flywheel . Ttghten mounttng bolts

houstng

. Worn drive end bustng . Replace bushtrg

* Damaged nng gear teeth . Replace ring gear or dnveplate

* Drive yoke return spnng broken or . Replace spnng

mtsstng

Starter motor dnve d&engages

prematurely

Low load current * Weak drive assembly thrust spnng * Replace dnve mechamsm

* Hold-tn co11 defeckve

. Replace field wtndtng assembly *

- Worn brushes . Replace brushes

* Weak brush springs * Replace spnngs Problem

Noisy alternator cause

* Loose mounbngs

. Loose drive pulley SoluIion

. Ttghten mountrng bolts

. Tighten pulley

. Worn beanngs

* Brush notse

* Internal circuits shorted (Hugh

pitched whrne) * Replace alternator

. Replace alternator

. Replace alternator

Squeal when starting engtne or . Glazed or loose belt * Replace or adfust belt

acceleratmg

Indicator light rematns on or . Broken belt . Install heft

ammeter rndrcates drscharge . Broken or dksconnected wares - Repatr or connect Waring

(ejrgrne runmng) * Internal aitemator problems * Replace alternator

. Defectrve voltage regulator . Replace vottage regulator/alternator

Car Irght bulbs contmually bum out- * Alternator/regulator overchargtng . Replace voltage

batter-v needs water conbnually regulatoriatternator

Car kghts flare on acceleratton . Battery low

. Internal alternator/regulator

problems * Charge or replace battery

. Replace alternator/regulator

Low voltage output (alternator lght

fltckers conbnually or ammeter

needle wanders) * Loose or worn belt

* Dkly or corroded connecttons

* Internal alternator/regulator

oroblems . Replace or adjust beit

. Clean or replace connecttons

* Replace alternator/regulator

Page 66 of 408

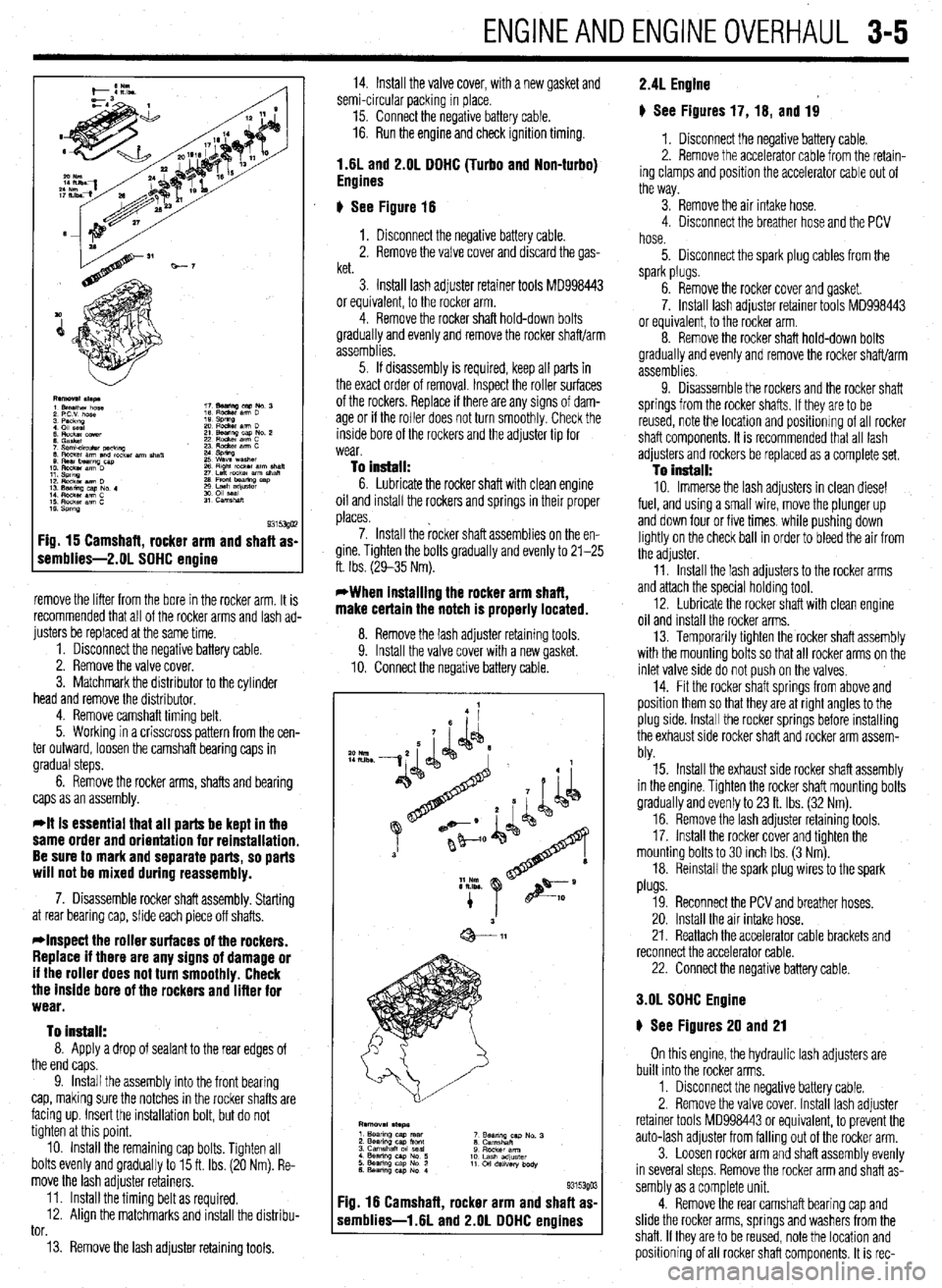

ENGINEANDENGINEOVERHALJL 3-5

Fig. 15 Camshaft, rocker arm and shaft as-

remblies-2.01 SOHC engine

remove the lifter from the bore in the rocker arm. It is

recommended that all of the rocker arms and lash ad-

justers be replaced at the same time.

1. Disconnect the negative battery cable.

2. Remove the valve cover.

3. Matchmark the distributor to the cylinder

head and remove the distributor.

4. Remove camshaft timing belt.

5. Working in a crisscross pattern from the cen-

ter outward, loosen the camshaft bearing caps in

gradual steps.

6. Remove the rocker arms, shafts and bearing

caps as an assembly.

*It is essential that all parts be kept in the

same order and orientation for reinstallation.

Be sure to mark and separate parts, so parts

will not be mixed during reassembly.

7. Disassemble rocker shaft assembly. Starting

at rear bearing cap, slide each piece off shafts.

*Inspect the roller surfaces of the rockers.

Replace if there are any signs of damage or

if the roller does not turn smoothly. Check

the inside bore of the rockers and lifter for

wear.

To install:

8. Apply a drop of sealant to the rear edges of

the end caps.

9. Install the assembly into the front bearing

cap, making sure the notches in the rocker shafts are

facing up. Insert the installation bolt, but do not

tighten at this point.

10. Install the remaining cap bolts. Tighten all

bolts evenly and gradually to 15 ft. Ibs. (20 Nm). Re-

move the lash adjuster retainers.

11. Install the timing belt as required.

12. Align the matchmarks and install the distribu-

tor.

13. Remove the lash adjuster retaining tools. 14. Install the valve cover, with a new gasket and

semi-circular packing in place.

15. Connect the negative battery cable.

16. Run the engine and check ignition timing.

1.6L and 2.OL DOHC (Turbo and Non-turbo)

Engines

6 See Figure 16

1. Disconnect the negative battery cable.

2. Remove the valve cover and discard the gas-

ket.

3. Install lash adjuster retainer tools MD998443

or equivalent, to the rocker arm.

4. Remove the rocker shaft hold-down bolts

gradually and evenly and remove the rocker shaft/arm

assemblies.

5. If disassembly is required, keep all parts in

the exact order of removal. Inspect the roller surfaces

of the rockers. Replace if there are any signs of dam-

age or if the roller does not turn smoothly. Check the

inside bore of the rockers and the adjuster tip for

wear.

To install: 6. Lubricate the rocker shaft with clean engine

oil and install the rockers and springs in their proper

places.

7. Install the rocker shaft assemblies on the en-

gine. Tighten the bolts gradually and evenly to 21-25

ft. Ibs. (29-35 Nm).

*When installing the rocker arm shaft,

make certain the notch is properly located.

8. Remove the lash adiuster retainina tools

9. Install the valve cover with a new gasket.

10. Connect the negative battery cable.

F :ig. 16 Camshaft, rocker arm and shaft as

s iemblies-1.6L and 2.OL DOHC engines

*o Nm

IILlbs -

9315390 3

2.4L Engine

# See Figures 17, 16, and 19

1. Disconnect the negative battery cable.

2. Remove the accelerator cable from the retain-

ing clamps and position the accelerator cable out of

the way.

3. Remove the air intake hose.

4. Disconnect the breather hose and the PCV

hose.

5. Disconnect the spark plug cables from the

spark plugs.

6. Remove the rocker cover and gasket.

7. Install lash adjuster retainer tools MD998443

or equivalent, to the rocker arm.

8. Remove the rocker shaft hold-down bolts

gradually and evenly and remove the rocker shaft/arm

assemblies.

9. Disassemble the rockers and the rocker shaft

springs from the rocker shafts. If they are to be

reused, note the location and positionrng of all rocker

shaft components. It is recommended that all lash

adjusters and rockers be replaced as a complete set.

To install: 10. Immerse the lash adjusters in clean diesel

fuel, and using a small wire, move the plunger up

and down four or five times. while pushing down

lightly on the check ball in order to bleed the air from

the adjuster.

11. Install the lash adjusters to the rocker arms

and attach the special holding tool.

12. Lubricate the rocker shaft with clean engine

oil and install the rocker arms.

13. Temporarily tighten the rocker shaft assembly

with the mounting bolts so that all rocker arms on the

inlet valve side do not push on the valves,

14. Fit the rocker shaft springs from above and

position them so that they are at right angles to the

plug side. Install the rocker springs before installing

the exhaust side rocker shaft and rocker arm assem-

bly.

15. Install the exhaust side rocker shaft assembly

in the engine. Tighten the rocker shaft mounting bolts

gradually and evenly to 23 ft. Ibs. (32 Nm).

16. Remove the lash adjuster retaining tools.

17. Install the rocker cover and tighten the

mounting bolts to 30 inch Ibs. (3 Nm).

18. Reinstall the spark plug wires to the spark

plugs.

19. Reconnect the PCV and breather hoses.

20. Install the air intake hose.

21. Reattach the accelerator cable brackets and

reconnect the accelerator cable.

22. Connect the negative battery cable.

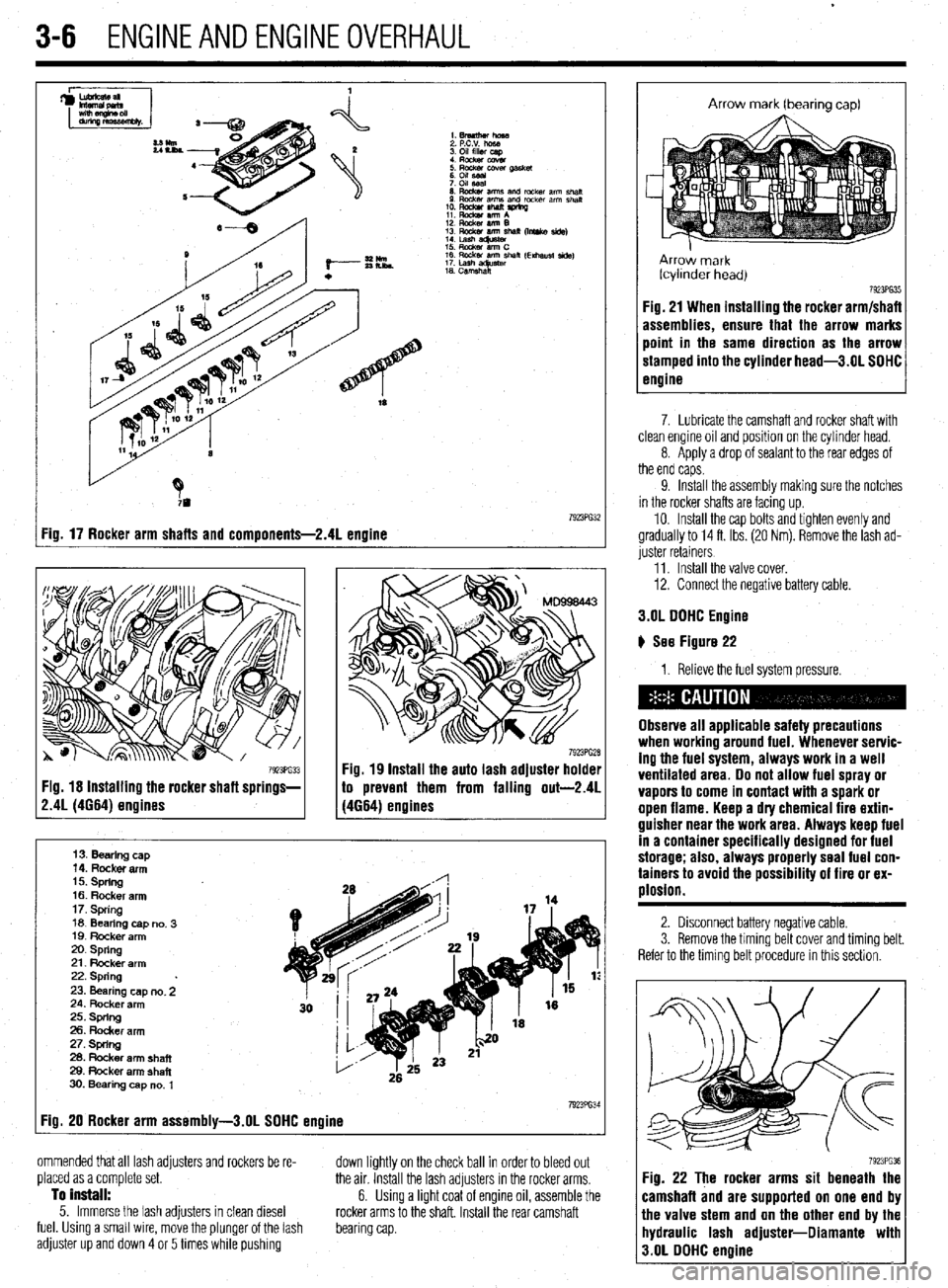

3.OL SOHC Engine

6 See Figures 20 and 21

On this engine, the hydraulic lash adjusters are

built into the rocker arms,

1. Disconnect the negative battery cable.

2. Remove the valve cover. Install lash adjuster

retainer tools MD998443 or equivalent, to prevent the

auto-lash adjuster from falling out of the rocker arm.

3. Loosen rocker arm and shaft assembly evenly

in several steps. Remove the rocker arm and shaft as-

sembly as a complete unit.

4. Remove the rear camshaft bearing cap and

slide the rocker arms, springs and washers from the

shaft. If they are to be reused, note the location and

positioning of all rocker shaft components. It is rec-

Page 67 of 408

.

3-6 ENGINEANDENGINEOVERHAUL

I Fig. 17 Rocker arm shafts and components-2.41 engine

Fig. 18 Installing the rocker shaft springs- 79231632

13. Bearing cap

14. Rocker arm

15. spring

16. Rocker arm

17. Spring

16 Bearing no. cap 3

IQ. Rocker arm

20. spring

21. Rocker arm

22. Spring

23. Bearing no. cap 2

24. Rocker arm

25. spring

26. Rocker arm

27. Spring

28. Rocker arm shaft

29. Rocker arm shaft

30. Bearing no. cap 1

Fig. 20 Rocker arm assembly-3.01 SOHC engine 7923PG3

ommended that all lash adjusters and rockers be re-

placed as a complete set.

To install:

5. Immerse the lash adjusters in clean diesel

fuel. Using a small wire, move the plunger of the lash

adjuster up and down 4 or 5 times while pushing down lightly on the check ball in order to bleed out

the air. Install the lash adjusters in the rocker arms.

6. Using a light coat of engine oil, assemble the

rocker arms to the shaft. Install the rear camshaft

bearing cap.

Arrow mark (bearing cap)

Arrow mark

fcyllnder head)

7923PG35 Fig. 21 When installing the rocker arm/shafi

assemblies, ensure that the arrow marks

point in the same direction as the arrow

stamped into the cylinder head-3.01 SOHC

engine

7. Lubricate the camshaft and rocker shaft with

clean engine oil and position on the cylinder head.

8. Apply a drop of sealant to the rear edges of

the end caps.

9. Install the assembly making sure the notches

in the rocker shafts are facing up.

10. Install the cap bolts and tighten evenly and

gradually to 14 ft. Ibs. (20 Nm). Remove the lash ad-

juster retainers

11. Install the valve cover.

12. Connect the negative battery cable.

3.OL OOHC Engine

) See Figure 22

1. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. 00 not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dty chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable.

3. Remove the timino belt cover and timina belt.

Refer to the timing belt procedure in this section.

7923PG3 Fig. 22 The rocker arms sit beneath the

camshaft and are supported on one end bl

the valve stem and on the other end by the

hydraulic lash adjuster-Oiamante wit1

3.OL OOHC engine

Page 68 of 408

ENGINEANDENGINEOVERHAUL 3-7

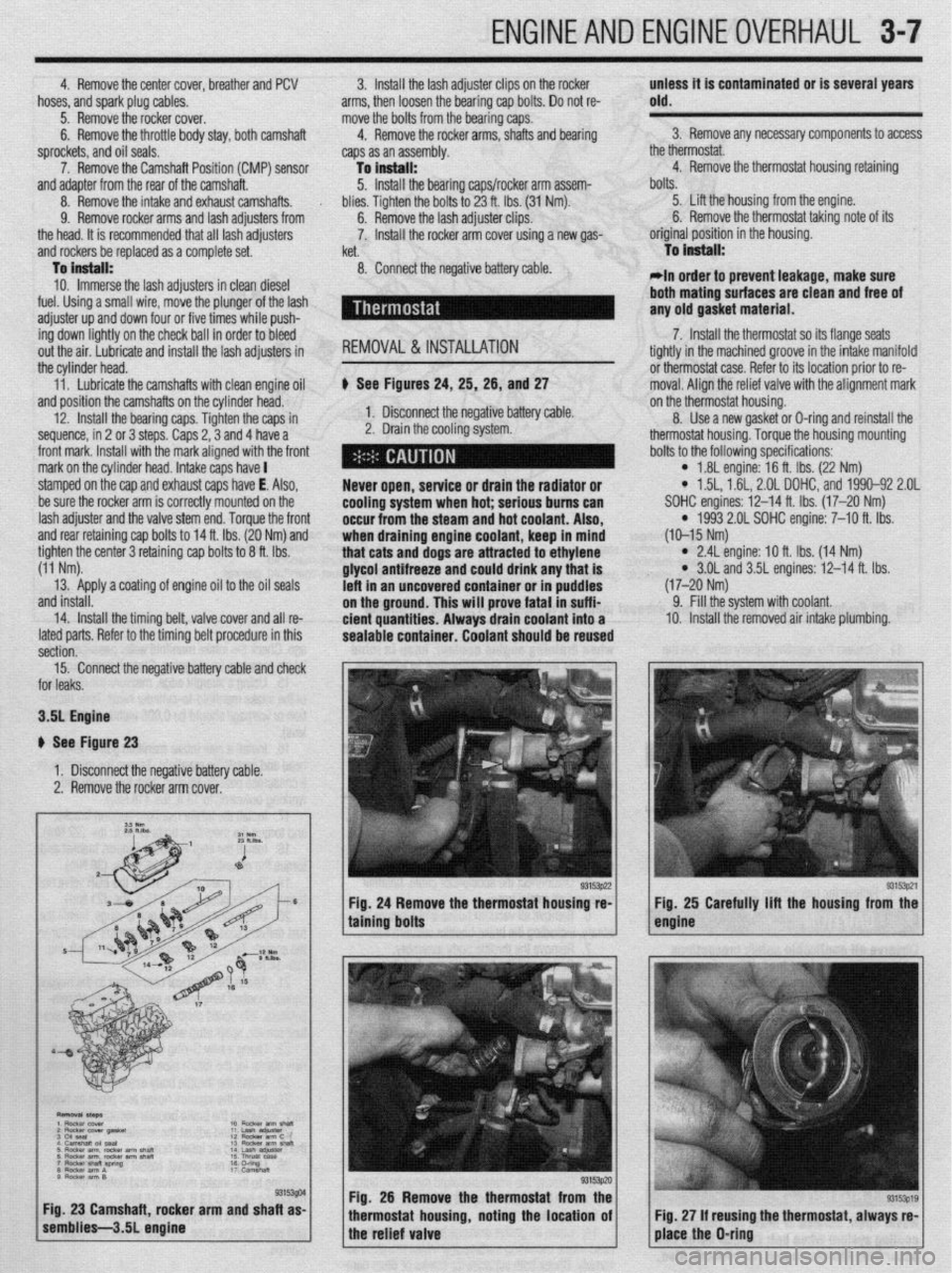

4. Remove the center cover, breather and PCV

hoses, and spark plug cables.

5. Remove the rocker cover.

6. Remove the throttle body stay, both camshaft

sprockets, and oil seals.

7. Remove the Camshaft Position fCMP) sensor 3. install the lash adjuster clips on the rocker

arms, then loosen the bearing cap bolts. Do not re-

move the bolts from the bearing caps.

4. Remove the rocker arms, shafts and bearing

caps as an assembly.

lo hlstall: unless it is contaminated or is several years old.

3. Remove any necessary components to access

the thermostat.

4. Remove the thermostat housinq retaininq

nd adapter from the rear of the camshah. ’

8. Remove the intake and exhaust camshafts.

9. Remove rocker arms and lash adjusters from

he head. It is recommended that all lash adjusters

md rockers be replaced as a complete set.

To Install:

10. Immerse the lash adjusters in clean diesel

uel. Using a small wire, move the plunger of the lash

tdjuster up and down four or five times while push-

ng down lightly on the check ball in order to bleed

jut the air. Lubricate and install the lash adjusters in

he cylinder head.

11. Lubricate the camshafts with clean enqine oil

nd position the camshafts on the cylinder head.

12. Install the bearing caps. Tighten the caps in

sequence, in 2 or 3 steps. Caps 2,3 and 4 have a

ront mark. Install with the mark aligned with the front

nark on the cylinder head. Intake caps have I

stamped on the cap and exhaust caps have E. Also,

)e sure the rocker arm is correctly mounted on the

ash adjuster and the valve stem end. Torque the front

md rear retaining cap bolts to 14 ft. Ibs. (20 Nm) and

ighten the center 3 retaining cap bolts to 8 ft. Ibs.

11 Nm).

13. Apply a coating of engine oil to the oil seals

md install.

14. Install the timing belt, valve cover and all re-

ated parts. Refer to the timing belt procedure in this

;ection. 5. Install the bearing caps/rocker arm assem-

blies. Tighten the bolts to 23 ft. Ibs. (31 Nm).

6. Remove the lash adjuster clips.

7. Install the rocker arm cover using a new gas-

ket.

8. Connect the negative battery cable.

REMOVAL &INSTALLATION

b See Figures 24, 25, 26, and 27

1. Disconnect the negative battery cable.

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious bums can

occur from the

steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused bolts.

5. Lift the housing from the engine.

6. Remove the thermostat taking note of its

original position in the housing.

To Install:

*In order to prevent leakage, make sure

both mating

surfaces are clean and free of

any old gasket material.

7. Install the thermostat so its flange seats

tightly in the machined groove in the intake manifold

or thermostat case. Refer to its location prior to re-

moval. Aliqn the relief valve with the alignment mark

on the thermostat housing.

8. Use a new gasket or D-ring and reinstall the

thermostat housing. Torque the housing mounting

bolts to the following specifications:

l 1.8L engine: 16 ft. Ibs. (22 Nm) l 1.5L, 1.61, 2.OL DOHC, and 1990-92 2.OL

SOHC engines: 12-14 ft. Ibs. (17-20 Nm)

l 1993 2.01 SOHC engine: 7-10 ft. Ibs.

(10-15 Nm)

l 2.4L engine: IO ft. Ibs. (14 Nm) l 3.OL and 3.5L engines: 12-14 ft. Ibs.

(17-20 Nm)

9. Fill the system with coolant.

10. Install the removed air intake plumbing.

15. Connect the negative battery cable and check

or leaks.

3.51 Engine

I See Figure 23

1. Disconnect the negative battery cable.

2. Remove the rocker arm cover.

g. 26 Remove the thermostat from the

ousing, noting the location of using the thermostat, always re-

Page 74 of 408

ENGINEANDENGINEOVERHAUL 3-13

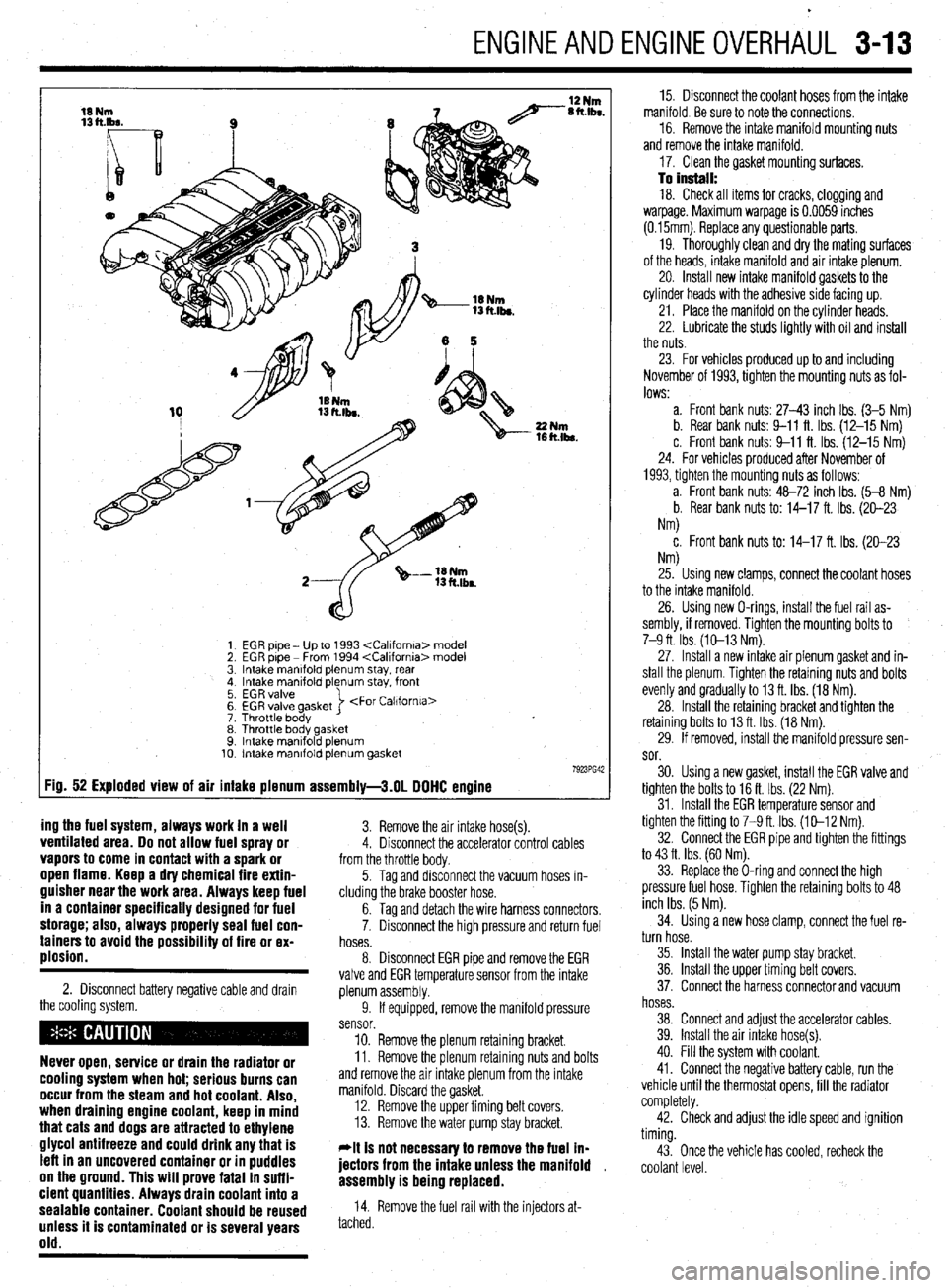

EGR pipe - Up to 1993

EGR pipe - From 1994

Intake manlfold plenum stay, rear

Intake manifold plenum stay. front

EGR valve

EGR valve gasket

Throttle body >

Throttle body gasket

Intake mantfold plenum

Intake manifold plenum gasket

:ig. 52 Exploded view of air intake plenum assembly-3.01 DOHC engine

ing the fuel system, always work in a well

3. Remove the air intake hose(s). ventilated area. Do not allow fuel spray or 4. Disconnect the accelerator control cables vapors to come in contact with a spark or from the throttle body. open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable and drawn

the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

5. Tag and disconnect the vacuum hoses in-

cluding the brake booster hose.

6. Tag and detach the wire harness connectors,

7. Disconnect the high pressure and return fuel

hoses.

8. Disconnect EGR pipe and remove the EGR

valve and EGR temperature sensor from the intake

plenum assembly.

9. If equipped, remove the manifold pressure

sensor.

10. Remove the plenum retaining bracket.

11. Remove the plenum retaining nuts and bolts

and remove the air intake plenum from the intake

manifold. Discard the gasket.

12. Remove the upper timing belt covers.

13. Remove the water pump stay bracket.

*It is not necessav to remove the fuel ln-

jectors from the intake unless the manifold ,

assembly is being replaced.

14. Remove the fuel rail with the injectors at-

tached. 15. Disconnect the coolant hoses from the intake

manifold. Be sure to note the connections.

16. Remove the intake manifold mounting nuts

and remove the intake manifold.

17. Clean the gasket mounting surfaces.

To install: 18. Check all items for cracks, clogging and

warpage. Maximum warpage is 0.0059 inches

(0.15mm). Replace any questionable parts.

19. Thoroughly clean and dry the mating surfaces

of the heads, intake manifold and air intake plenum.

20. Install new intake manifold gaskets to the

cylinder heads with the adhesive side facing up.

21. Place the manifold on the cylinder heads.

22. Lubricate the studs lightly with oil and install

the nuts.

23. For vehicles produced up to and including

November of 1993, tighten the mounting nuts as fol-

lows:

a. Front bank nuts: 27-43 inch Ibs. (3-5 Nm)

b. Rear bank nuts: 9-11 ft. Ibs. (12-15 Nm)

c. Front bank nuts: 9-11 ft. Ibs. (12-15 Nm)

24. For vehicles produced after November of

1993, tighten the mounting nuts as follows:

a. Front bank nuts: 48-72 inch Ibs. (5-8 Nm)

b. Rear bank nuts to: 14-17 ft. Ibs. (20-23

Nm)

c. Front bank nuts to: 14-17 ft. Ibs. (20-23

NM

25. Using new clamps, connect the coolant hoses

to the intake manifold.

26. Using new O-rings, install the fuel rail as-

sembly, if removed. Tighten the mounting bolts to

7-9 ft. Ibs. (10-13 Nm).

27. Install a new intake air plenum gasket and in-

stall the plenum. Tighten the retaining nuts and bolts

evenly and gradually to 13 ft. Ibs. (18 Nm).

28. Install the retaining bracket and tighten the

retaining bolts to 13 ft. Ibs. (18 Nm).

29. If removed, install the manifold pressure sen-

sor.

30. Using a new gasket, install the EGR valve and

tighten the bolts to 16 ft. Ibs. (22 Nm).

31. Install the EGR temperature sensor and

tighten the fitting to 7-9 ft. Ibs. (10-12 Nm).

32. Connect the EGR pipe and tighten the fittings

to 43 ft. Ibs. (60 Nm).

33. Replace the O-ring and connect the high

pressure fuel hose. Tighten the retaining bolts to 48

inch Ibs. (5 Nm).

34. Using a new hose clamp, connect the fuel re-

turn hose.

35. Install the water pump stay bracket.

36. Install the upper timing belt covers.

37. Connect the harness connector and vacuum

hoses.

38. Connect and adjust the accelerator cables.

39. Install the air intake hose(s).

40. Fill the system with coolant.

41. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely.

42. Check and adjust the idle speed and ignition

timing.

43. Once the vehicle has cooled, recheck the

coolant level.

Page 79 of 408

l

3-18 ENGINEANDENGINEOVERHAUL

bolt and gaskets that connect the oil feed line to the

turbo center section and the water cooling lines. The

water line under the turbo has a threaded connection.

8. Remove the exhaust pipe nuts and gasket and

lift off the exhaust manifold. Discard the gasket,

9. Remove the 2 through bolts and 2 nuts that 16. If removed, install the power steering pump

and bracket.

17. Install the heat shields, air outlet hose, waste-

gate hose and air intake bellows.

18. Install the oil dipstick tube and dipstick. In-

stall the oxyqen sensor. cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Disconnect the overflow tube. Some vehicles

hold the exhaust manifold to the turbocharger,

10. Remove the 2 capscrews from the oil return

line (under the turbo). Discard the gasket. Separate

the turbo from the exhaust manifold. The 2 water

pipes and oil feed line can still be attached. 19. In&h the radiator assembly.

20. Fill the engine with oil, fill the cooling system

and reconnect the negative battery cable.

11. Visually check the turbine wheel (hot side)

and compressor wheel (cold side) for cracking or

other damage. Check whether the turbine wheel and

the compressor wheel can be easily turned by hand.

Check for oil leakaae. Check whether or not the Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

wastegate valve remains open. If any problem is .

found, replace the part. Inspect oil passages for re- #I , I

striction or deposits and clean as required,

12. The wasteaate can be checked with a ores-

REMOVAL & INSTALLATION sure tester. Apply approximately 9 psi to the&h&or

and make sure the rod moves. Do not apply more

than 10.3 psi or the diaphragm in the wastegate may

be damaged. Vacuum applied to the wastegate actua-

tor should be maintained, replace if leaks vacuum,

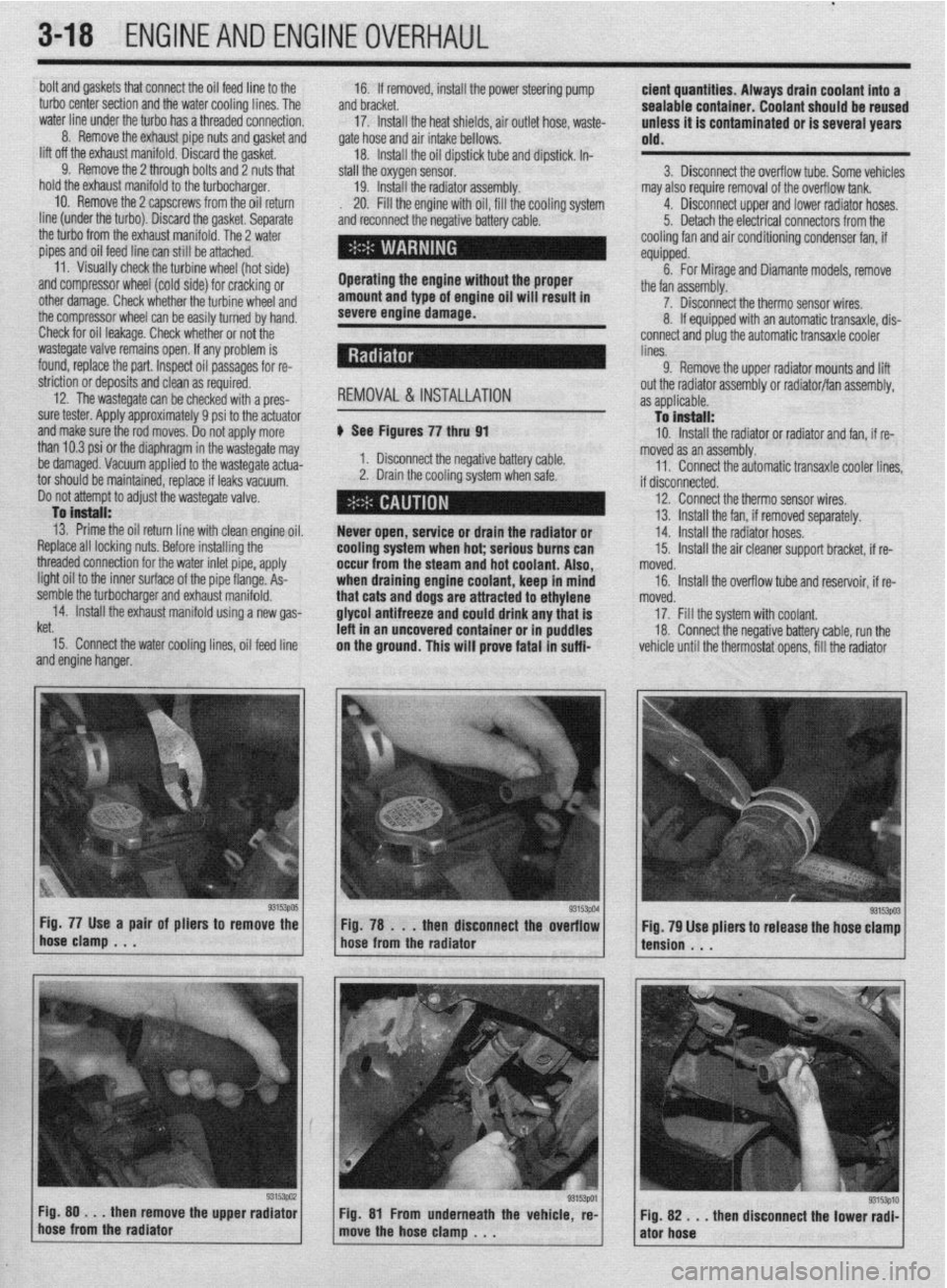

Do not attempt to adjust the wastegate valve. $ See Figures 77 thru 91

I. Disconnect the negative battery cable.

2. Drain the cooling system when safe.

To

install: 13. Prime the oil return line with clean engine oil.

Replace all locking nuts. Before installing the

threaded connection for the water inlet pipe, apply

light oil to the inner surface of the pipe flange. As-

semble the turbocharger and exhaust manifold.

14. Install the exhaust manifold using a new gas-

ket.

15. Connect the water cooling lines, oil feed line

and engine hanger. Never open, service or drain the radiator or

cooling system when hot: serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glyeol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

Fig. 77 Use a pair of pliers to remove the

Fig. 78 . . .

then disconnect the overflow

hose clamp . . .

hose from the radiator may also require removal of the overflow tank.

4. Disconnect upper and lower radiator hoses.

5. Detach the electrical connectors from the

cooling fan and air conditioning condenser fan, if

equipped.

6. For Mirage and Diamante models, remove

the fan assembly.

7. Disconnect the therm0 sensor wires,

8. If equipped with an automatic transaxle, dis-

connect and plug the automatic transaxle cooler

lines.

9. Remove the upper radiator mounts and lift

out the radiator assembly or radiator/fan assembly,

as applicable.

To install:

10. Install the radiator or radiator and fan, if re-

moved as an assembly.

11. Connect the automatic transaxle cooler lines

if disconnected.

12. Connect the therm0 sensor wires,

13. Install the fan, if removed separately.

14. Install the radiator hoses.

15. Install the air cleaner support bracket, if re-

noved.

16. Install the overflow tube and reservoir, if re-

noved.

17. Fill the system with coolant.

18. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

93153003 Fig. 79 Use pliers to release the hose clamp

tension . . .

Fig. 80 . . .

then remove the upper radiator

hose from the radiator Fig. 81 From underneath the vehicle, re-

move the hose clamp , . . ”

then disconnect the lower radi- Fig. 82 . . .

ator hose

Page 87 of 408

3-26 ENGINEANDENGINEOVERHAUL

18. Remove the self-locking nuts and the small

retaining bolt holding the exhaust pipe to the bottom

of the exhaust manifold. Separate the pipe from the

manifold and remove the gasket.

19. Remove the bolts holding the support brace

to the bottom of the intake manifold.

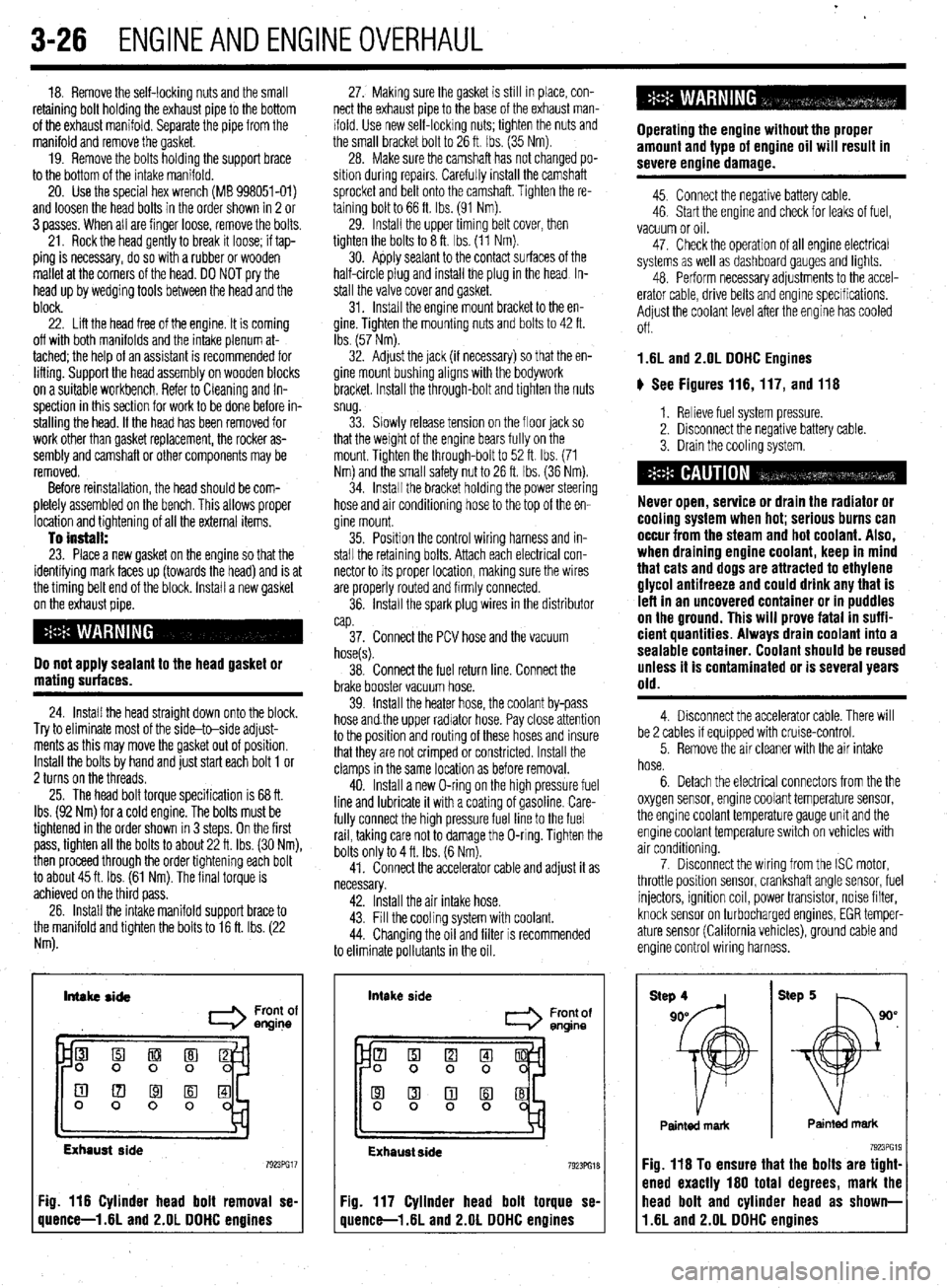

20. Use the special hex wrench (MB 998051-01)

and loosen the head bolts in the order shown in 2 or

3 passes. When all are finger loose, remove the bolts.

21. Rock the head gently to break it loose; if tap-

ping is necessary, do so with a rubber or wooden

mallet at the corners of the head. DO NOT pry the

head up by wedging tools between the head and the

block.

22. Lift the head free of the engine. It is coming

off with both manifolds and the intake plenum at-

tached; the help of an assistant is recommended for

lifting. Support the head assembly on wooden blocks

on a suitable workbench. Refer to Cleaning and In-

spection in this section for work to be done before in-

stalling the head. If the head has been removed for

work other than gasket replacement, the rocker as-

sembly and camshaft or other components may be

removed.

Before reinstallation, the head should be com-

pletely assembled on the bench. This allows proper

location and tightening of all the external items.

To install: 23. Place a new gasket on the engine so that the

identifying mark faces up (towards the head) and is at

the timing belt end of the block. Install a new gasket

on the exhaust pipe.

Do not apply sealant to the head gasket or

mating surfaces.

24. Install the head straight down onto the block.

Try to eliminate most of the side-to-side adjust-

ments as this may move the gasket out of position.

Install the bolts by hand and just start each bolt 1 or

2 turns on the threads.

25. The head bolt torque specification is 68 ft.

Ibs. (92 Nm) for a cold engine. The bolts must be

tightened in the order shown in 3 steps. On the first

pass, tighten all the bolts to about 22 ft. Ibs. (30 Nm),

then proceed through the order tightening each bolt

to about 45 ft. Ibs. (61 Nm). The final torque is

achieved on the third pass.

26. Install the intake manifold support brace to

the manifold and tighten the bolts to 16 ft. Ibs. (22

Nm). 27. Making sure the gasket is still in place, con-

nect the exhaust pipe to the base of the exhaust man-

ifold. Use new self-locking nuts; tighten the nuts and

the small bracket bolt to 26 ft. Ibs. (35 Nm).

28. Make sure the camshaft has not changed po-

sition during repalrs. Carefully install the camshaft

sprocket and belt onto the camshaft. Tighten the re-

taining bolt to 66 ft. Ibs. (91 Nm).

29. Install the upper timing belt cover, then

tighten the bolts to 8 ft. Ibs. (11 Nm).

30. Apply sealant to the contact surfaces of the

half-circle plug and install the plug in the head In-

stall the valve cover and gasket.

31. Install the engine mount bracket to the en-

gine. Tighten the mounting nuts and bolts to 42 ft.

Ibs. (57 Nm).

32. Adjust the jack (if necessary) so that the en-

gine mount bushing aligns with the bodywork

bracket. Install the through-bolt and tighten the nuts

snug.

33. Slowly release tension on the floor jack so

that the weight of the engine bears fully on the

mount. Tighten the through-bolt to 52 ft. Ibs. (71

Nm) and the small safety nut to 26 ft. tbs. (36 Nm).

34. Install the bracket holding the power steering

hose and air conditioning hose to the top of the en-

gine mount.

35. Position the control wiring harness and in-

stall the retaining bolts. Attach each electrical con-

nector to its proper location, making sure the wires

are properly routed and firmly connected.

36. Install the spark plug wires in the distributor

cap.

37. Connect the PCV hose and the vacuum

hose(s).

38. Connect the fuel return line. Connect the

brake booster vacuum hose.

39. Install the heater hose, the coolant by-pass

hose and.the upper radiator hose. Pay close attention

to the position and routing of these hoses and insure

that they are not crimped or constricted. Install the

clamps in the same location as before removal.

40. Install a new O-ring on the high pressure fuel

line and lubricate it with a coating of gasoline. Care-

fully connect the high pressure fuel line to the fuel

rail, taking care not to damage the O-ring. Tighten the

bolts only to 4 ft. Ibs. (6 Nm).

41. Connect the accelerator cable and adjust it as

necessary.

42. Install the air intake hose.

43. Fill the cooling system with coolant.

44. Changing the oil and filter is recommended

to eliminate pollutants in the oil.

Intake side

I Front of

engine

Exhaust side

Fig. 116 Cylinder head bolt removal se-

quence-l .6L and 2.OL DDHC engines intake

side

Front of

entine

Exhaust side 7923PG18

Fig. 117 Cylinder head bolt torque se-

quence-l .6L and 2.OL DDHC engines Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

45. Connect the negative battery cable.

46. Start the engine and check for leaks of fuel,

vacuum or oil.

47. Check the operation of all engine electrical

systems as well as dashboard gauges and lights.

48. Perform necessary adjustments to the accel-

erator cable, drive belts and engine specifications.

Adjust the coolant level after the engine has cooled

Off.

1.6L and 2.OL DDHC Engines

ti See Figures 116,117, and 116

1. Relieve fuel system pressure.

2. Disconnect the negative battery cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4. Disconnect the accelerator cable. There will

be 2 cables if equipped with cruise-control.

5. Remove the air cleaner with the air intake

hose.

6. Detach the electrical connectors from the the

oxygen sensor, engine coolant temperature sensor,

the engine coolant temperature gauge unit and the

engine coolant temperature switch on vehicles with

air conditioning.

7. Disconnect the wiring from the ISC motor,

throttle position sensor, crankshaft angle sensor, fuel

injectors, ignition coil, power transistor, noise filter,

knock sensor on turbocharged engines, EGR temper-

ature sensor (California vehicles), ground cable and

engine control wiring harness.

Painted mark Painted mark

Fig. 116 To ensure that the bolts are tight-

ened exactly 160 total degrees, mark the

11.6L and 2.OL DDHC engines head bolt and cylinder head as shown-

Page 97 of 408

3-36 ENGINEANDENGINEOVERHAUL

The EPA warns that urolonaed contact with

used engine oil may cause”a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to

used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to

used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

4. Remove the solash shield from the wheel

93153p65 93153p60 well.

5. Remove the oil filter adapter.

6. Remove the lower and upper oil pans.

7. Remove the lower baffle, oil pump pick-up

and upper baffle.

8. Remove the oil pump case mounting bolts

and the oil pump case.

9. Remove the oil pump gear cover.

10. Make matchmarks on the oil pump rotors be-

fore removing them.

,,. r.-- -IL- -.( -L.11---‘I --. IL- -.I _ --

nemove me cranksnarr sear rrom me 011 pump

case.

To instell:

12. Install a new crankshaft seal in the oil pump

cover.

13. Apply engine oil to the rotors, then align the

matchmarks and install the rotors in the oil pump Fig. 153 Remove the fasteners, then re-

move the side inner fender splash shield

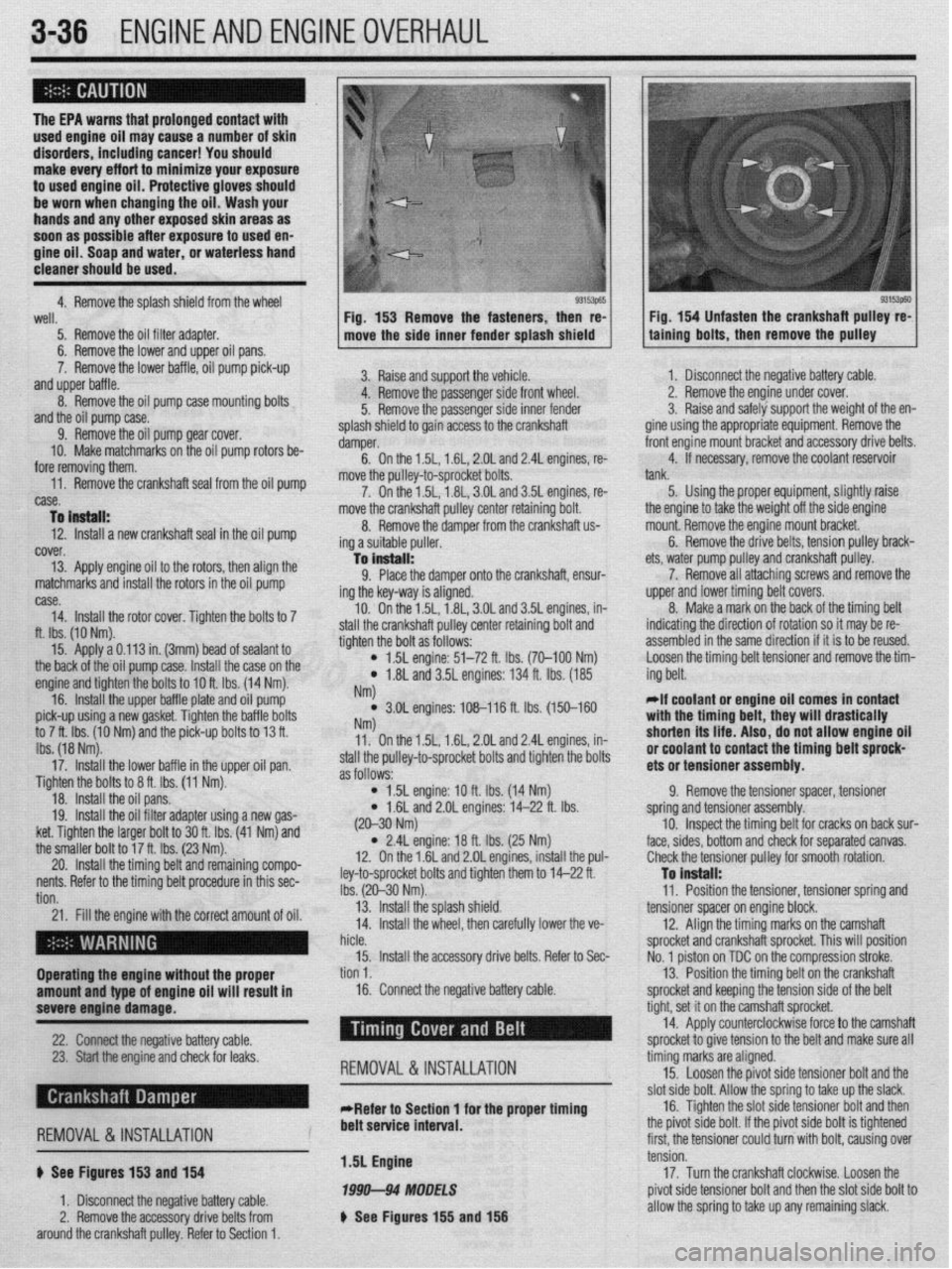

3. Raise and support the vehicle.

4. Remove the passenger side front wheel.

5. Remove the passenger side inner fender

splash shield to gain access to the crankshaft

damper.

6. On the 1.5L, 1.6L, 2.OL and 2.4L engines, re-

move the oullev-to-sorocket bolts.

7. On thei .5L, i .8L, 3.OL and 3.5L engines, re-

move the crankshaft pulley center retaining bolt.

8. Remove the damper from the crankshaft us

ing a suitable puller.

-la install:

9. Place the damper onto the crankshaft, ensur-

ing the key-way is aligned.

10. On the 1.5L, 1.8L, 3.OL and 3.5L engines, in-

e crankshaft pulley center retaining bolt and

the bolt as follows: Fig. 154 Unfasten the crankshaft pulley re-

talning bolts, then remove the pulley

case.

14. Install the rotor cover. Tighten the bolts to 7

ft. Ibs. (10 Nm).

15. Apply a 0.113 in. (3mm) bead of sealant to

the back of the oil pump case. I[ -‘-‘I IL -~-- IL-

nsrall me ca

se on me engine and tighten the bolts to IOft Ihc 11 ,,, -. , .4 Nm).

16. Install the upper baffle r tlal te and oil pump

pick-up using a new gasket. Tic fhtti,, ,,lG va,,,ti ““a,., an tha hafflc, hnltc to 7 ft. Ibs. (10 Nm) and the pit k-up bolts to 13 ft.

Ibs. (18 Nm).

17. Install the lower baffle in the upper oil pan.

Tighten the bolts to 8 ft. Ibs. (11 Nm).

18. Install the oil pans.

19. Install the oil filter adapter using a new gas-

ket. Tighten the larger bolt to 30 ft. Ibs. (41 Nm) and

the smaller bolt to 1’ u ‘L- Inn ‘I--’ stall thl

tighten

4

) 1.5L engine: 51-72 ft. Ibs. (70-100 Nm)

l 1.8L and 3.5L engines: 134 ft. Ibs. (185

NM

l 3.OL engines: 108-116 ft. lbs. (150-160 NW 11. On the 1.5L, 1.6L, 2.OL and 2.4L engines, in-

stall the pulley-to-sprocket bolts and tighten the bolts

as follows:

l 1.5L engine: 10 ft. Ibs. (14 Nm)

* 1.6L and 2.OL engines: 14-22 ft. Ibs. 1. Disconnect the negative battery cable.

2. Remove the engine under cover.

3. Raise and safely support the weight of the en-

gine using the appropriate equipment. Remove the

front engine mount bracket and accessory drive belts.

4. If necessary, remove the coolant reservoir

tank.

5. Using the proper equipment, slightly raise

ets, water pump pulley

7. Remove all attr

upper and lower timin{

8. Make a mark o

indicating the directior

assembled in the same the engine to take the weight off the side engine

mount. Remove the engine mount bracket.

6. Remove the drive belts, tension pulley brack-

and crankshaft pulley.

aching screws and remove the

J belt covers.

n the back of the timing belt

I of rotation so it may be re-

! direction if it is to be reused.

tensioner and remove the tim-

Loosen the timing belt

ing belt.

*If coolant or engine oil comes in contact

with the timing bplt thaw will r(mcti~~llv Wll L, .,,s,, n,,, u,uu.,vu,,,

shorten its life. A ,IS o, do not allow engine oil

#.I nn..lr”* In rind In,

“I IruuI(IIIL Lu Irulll&t the timing belt sprock-

ets or tensioner assembly.

9. Remove the tensioner spacer, tensioner

spring and tensioner assembly.

cracks on back sur-

;eoarated canvas.

20. Install the tilllIllY uljllOllu IclllallllllY ~ullIPV-

:

nents. Refer to the timing belt procedure in this sec-

: tion.

21. Fill the engine with the correct amount of oil.

I . (20-30 Nm)

l 2.4L engine: 18 ft. Ibs. (25 Nm)

12. On the 1.6L and 2.OL engines, install the pul-

ley-to-sprocket bolts and tighten them to 14-22 ft.

Ibs. (20-30 Nm).

13. Install the splash shield.

14. Install the wheel, then carefully lower the ve- 10. Inspect the timing belt for I

face, sides, bottom and check for ! (

Check the tensioner pulley for smooth rotation.

To install:

11. Position the tensioner, tensioner spring and

tensioner spacer on engine block.

12. Align the timing marks on the camshaft

ft sprocket. This will position

tn the comoression stroke.

I hicle.

sprocket and cranksha

15. Install the accessory drive belts. Refer to Sec-

No. 1 piston on TDC o

Operating the engine without the proper tion 1.

13. Position the timing belt on the crankshaft

amount and type of engine oil will result in 16. Connect the negative battery cable.

sprocket and keeping the tension side of the bolt

severe engine damage.

-

22. -s

Chrmxt the nenntive h;lttm cnhle --, , I” ,.-J XL.._ I -..-., --I.-.

23. Start the engine and check for leaks.

REMOVAL &INSTALLATION

tight, set it on the cam, shaft sprocket.

14. Apply counterc Yockwise force to the camshaft

snrnckd tn nive tensin In -r .__.._. ._ J..- ._ - _ to the belt and make sure all

timing marks are aligned.

15. Loosen the pivot side tensioner bolt and the

clnt

&In hnlt Allnur thn rnrinn tn tdm III-I thn slack, cl then , d I, I’ r),“I 44”” ““IL. “ll”sl LllU .y”“yj L” L”I\U Low Ul” L .-Refer to Section 1 for the proper timing 16. Tighten the slot side tensioner bolt ark

., , , , ,, ,, ,, , , , , ,, . ,, ,~

REMOVAL &INSTALLATION

6 See Figures 153 and 154

1. Disconnect the negative battery cable.

2. Remove the accessory drive belts from

around the crankshaft pulley. Refer to Section 1. belt service interval.

1.5L Engine

1999-94 MODELS

b See Figures 155 and 156 me p~vor sloe DOI~. IT me p~vor sloe OOII

IS ogntened

first, the tensioner could turn with bolt, causing over

tension.

17. Turn the crankshaft clockwise. Loosen the

pivot side tensioner bolt and then the slot side bolt to

allow the spring to take up any remaining slack.

Page 98 of 408

ENGINEANDENGINEOVERHAUL 3-37

1. Ben

2. Power4teerlna Dump 7. washer

8. Crankshaft pullet

9. Damper pulls

10. upper ccwer

11. Lowercowr

12. llmingbeil

13. crsnkshat? E#ocket 14. Flsnge

i 5. Tensbner spacer

16. Tef~kner WkW

1; Tgibnrr

19: camehan sprocket

91251ga

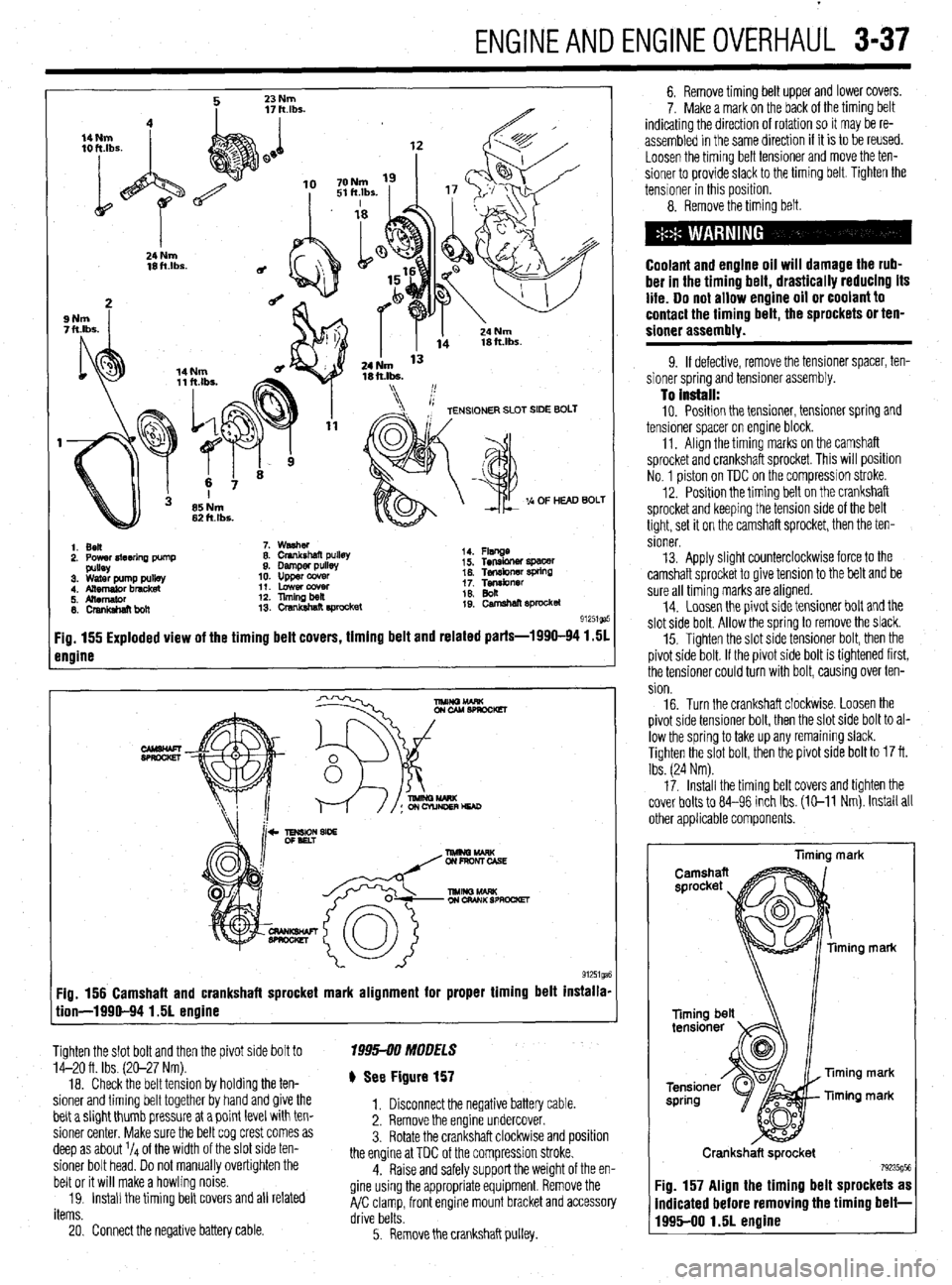

Fig. 155 Exploded view of the timing belt covers, timing belt and related parts-1990-94 1.51

engine

Fig. 156 Camshaft and crankshaft sprocket mark alignment for proper timing belt installa-

tion-1990-94 1.51 engine

Tighten the slot bolt and then the pivot side bolt to

14-20 ft. Ibs. (20-27 Nm).

18. Check the belt tension by holding the ten-

sioner and timing belt together by hand and give the

belt a slight thumb pressure at a point level with ten-

sioner center. Make sure the belt cog crest comes as

deep as about l/4 of the width of the slot side ten-

sioner bolt head. Do not manually overtighten the

belt or it will make a howling noise.

19. Install the timing belt covers and all related

items. 1995-00 MOOFLS

) See Figure 157

1. Disconnect the negative battery cable.

2. Remove the engine undercover.

3. Rotate the crankshaft clockwlse and position

the engine at TDC of the compression stroke.

4. Raise and safely support the weight of the en-

gine using the appropriate equipment. Remove the

A/C clamp, front engine mount bracket and accessory

drive belts.

20. Connect the negative battery cable.

5. Remove the crankshaft pulley. 6. Remove timing belt upper and lower covers.

7. Make a mark on the back of the timing belt

indicating the direction of rotation so it may be re-

assembled in the same direction if it is to be reused.

Loosen the timing belt tensioner and move the ten-

sioner to provide slack to the timing belt. Tighten the

tensioner in this position.

8. Remove the timing belt.

Coolant and engine oil will damage the rub-

ber in the timing belt, drastically reducing its

life. Do not allow engine oil or coolant to

contact the timing belt, the sprockets or ten-

sioner assembly.

9. If defective, remove the tensioner spacer, ten-

sioner spring and tensioner assembly.

To install: 10. Position the tensioner, tensioner spring and

tensioner spacer on engine block.

11. Align the timing marks on the camshaft

sprocket and crankshaft sprocket. This will position

No. 1 piston on TDC on the compression stroke.

12. Position the timing belt on the crankshaft

sprocket and keeping the tension side of the belt

tight, set it on the camshaft sprocket, then the ten-

sioner.

13. Apply slight counterclockwise force to the

camshaft sprocket to give tension to the belt and be

sure all timing marks are aligned.

14. Loosen the pivot side tensioner bolt and the

slot side bolt. Allow the spring to remove the slack.

15. Tighten the slot side tensioner bolt, then the

pivot side bolt. If the pivot side bolt is tightened first,

the tensioner could turn with bolt, causing over ten-

sion.

16. Turn the crankshaft clockwise. Loosen the

pivot side tensioner bolt, then the slot side bolt to al-

low the spring to take up any remaining slack.

Tighten the slot bolt, then the pivot side bolt to 17 ft.

Ibs. (24 Nm).

17. Install the timing belt covers and tighten the

cover bolts to 84-96 inch Ibs. (E-11 Nm). Install all

other applicable components.

liming mark

ming mark

Timing mark

Timing mark

Crankshaft sprocket

79235g5t Fig. 157 Align the timing belt sprockets as

indicated before removing the timing belt-

1995-00 1.51 engine