clock MITSUBISHI DIAMANTE 1900 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 228 of 408

CHASSIS ELECTRICAL 6-25

ove the socket from ig. 118 Pull the bulb straight out to remove

6. Install the cover lens until its retaining tabs are

properly engaged. ’

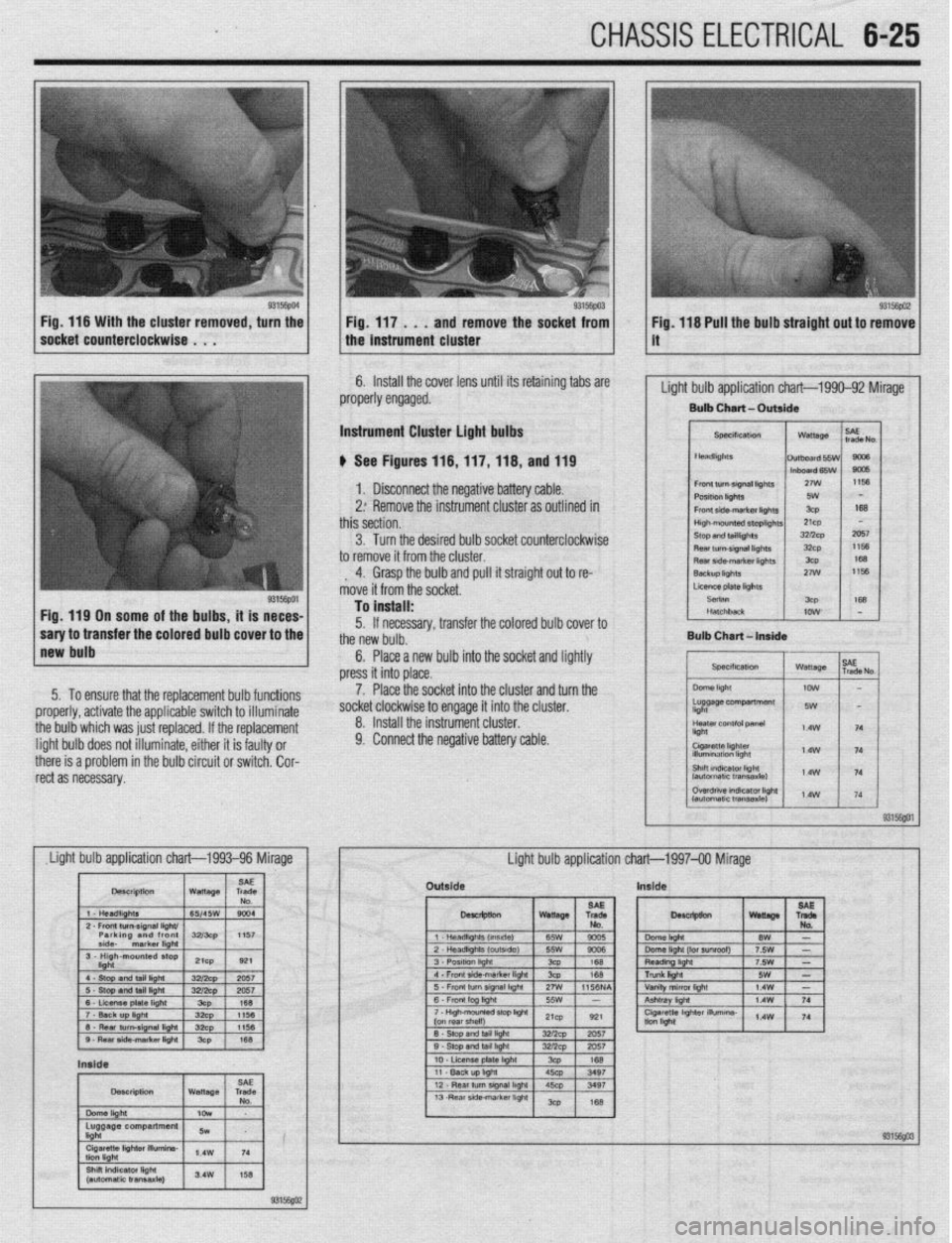

Light bulb application chart-1990-92 Mirage

Bulb Chart - Outaide

Instrument Cluster light bulbs

b See Figures 116,llf,ll8, and 119

1. Disconnect the negative battery cable.

2: Remove the instrument cluster as outlined in

this section.

3. Turn the desired bulb socket counterclockwise

to remove it from the cluster.

, 4. Grasp the bulb and pull it straight out to re-

move it from the socket.

I 1 Lmelatel~hls

Fig. 119 On some of the bulbs, it is neces-

1 ;;tbqrlrnsferthe colore ’ ’ ” . .’ ’

1 EL&

!a OUID cover IO me

Bulb Chart-In

*__. . __.

, , JvR,,Is~,,o~

press i+ in+n n,app

II llll” ~“UVV.

To install:

5. If necessary, transfer the colored bulb cover to

the new bulb.

6. Place a new bulb into the socket and lightly

Place the socket into the cluster and turn the

,“. II pithpr it ic faldtv nr 9. Connect the negative battery cable.

I

Outside Inside

Page 232 of 408

CHASSIS ELECTRlCiL 6-29

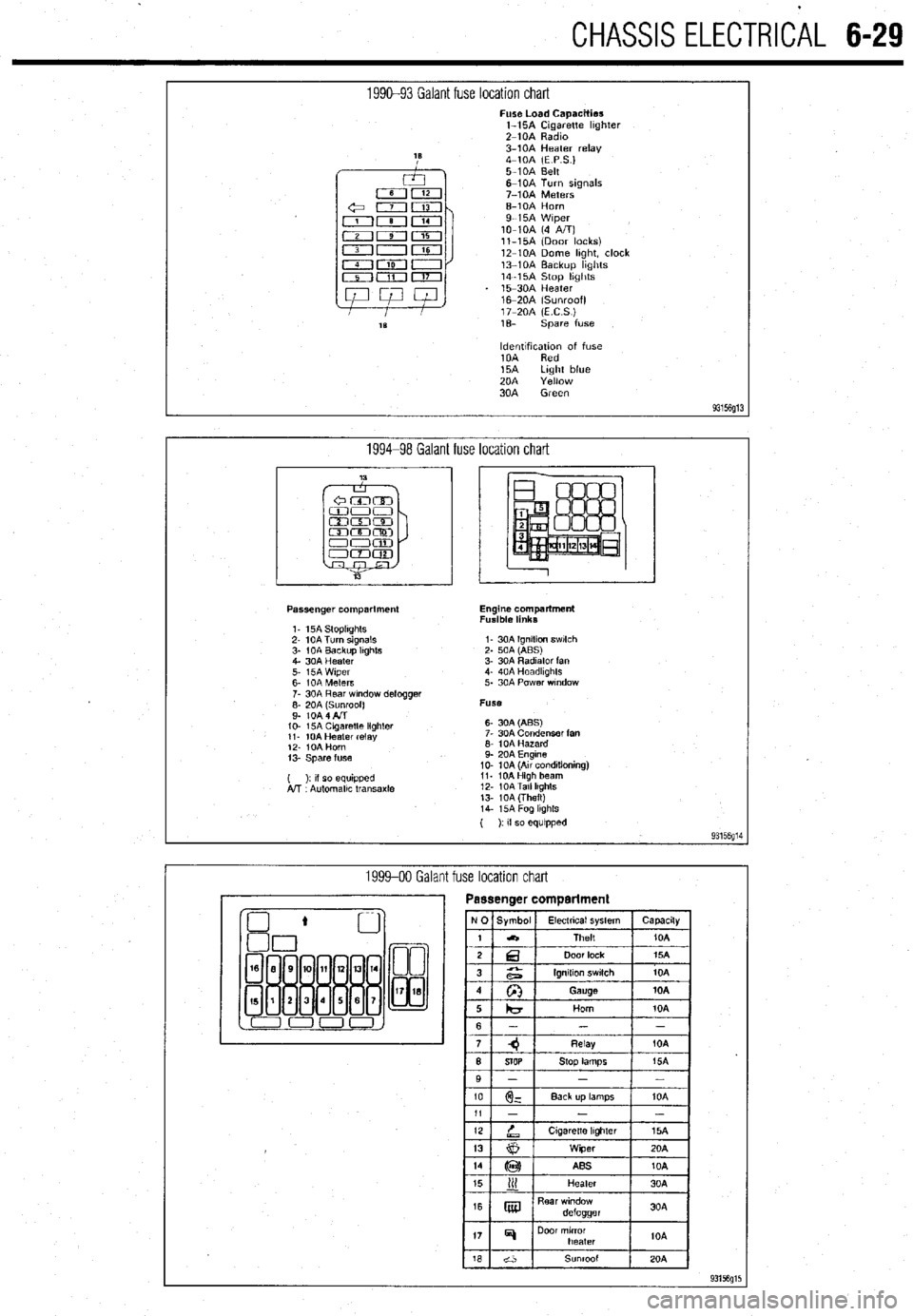

1990-93 Galant fuse location chart Fuse Load Capacities

l-15A Cigarette hghter

Z-10A Radm

3-10A Heater relay

4-10A (E P S.)

5-10A Belt

6-10A Turn signals

7-10A Meters

6-10A Horn

9-15A Wiper

lo-10A (4 A/T)

ll-15A (Door locks)

12-10A Dome hght, clock

13-10A Backup hghts

14-15A Stop hghts

15-30A Heater

16m20A (Sunroof)

17-20A (ECS)

1% spare fuse

ldentlfxation of fuse

10A Red

15A Light blue

20A Yellow

30A Green

93156g13

1994-98 Galant fuse location chart

Passenger compartment

1. 15A StoplIghts

2- 10A Turn signals

3- 1 OA Backup Itghts

4. 30A Heater

5. i5A Wiper

6- IOA Meters

7. 30A Rear wndow defogger

;: fo& fl$oof)

IO- 15A Cagaretle lighler

11. 10A Heater relay

12. IOA Horn

13. Spare fuse

( ): II so equipped

A!T Automallc transaxle Engine compartment

Fusible links

I- 30A Ignition swlch

2. 50A (ABS)

3. 30A Radiator fan

4. 40A Headkghts

5. 30A Power wndow

Fuse

6- 30A (ABS)

7. 30A Condenser fan

6. 10A Hazard

9. 20A Engine

10. 10A (Au conditioning)

11. 10AHigh beam

12. 10ATall lkghts

13. 10A (Theft)

14. i5A Fog lkghls

( ): If so equipped

93156g14

1999-00 Galant fuse location chart

Page 233 of 408

6-30 CHASSIS ELECTRICAL

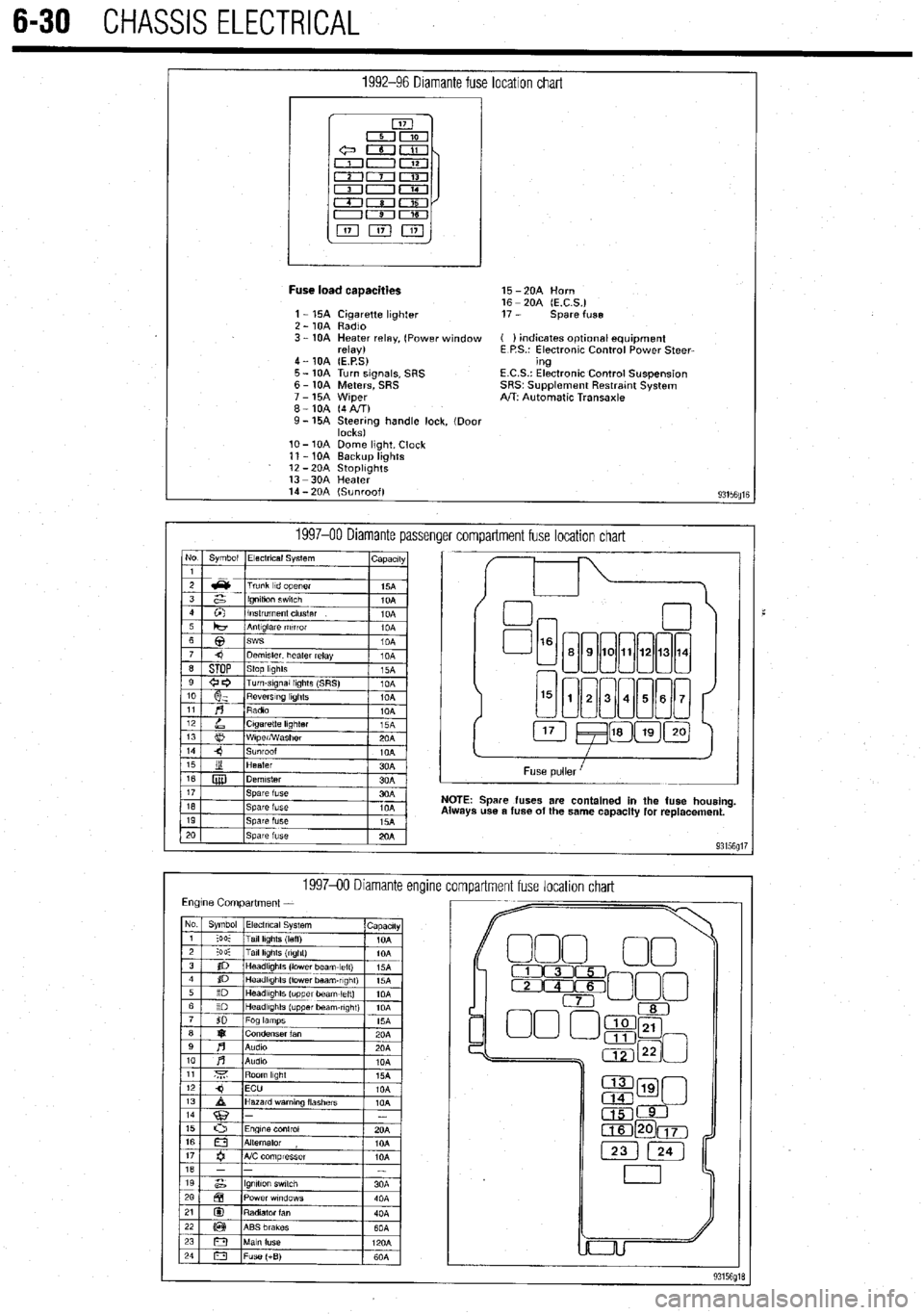

1992-96 Diamante fuse location chart

I

Fuse load caaacities 15 -2OA Horn

16 - 20A (E.C.S.)

1 - 15A Cigarette lighter 17 - spare fuse

2 - 10A Radio

3 - 10A Heater relay, (Power window ( ) indicates optlonal equipment

relay) E P.S.: Electronic Control Power Steer-

4 - 10A (E.P.S) ing

5 - 10A Turn signals, SRS E.C.S.: Electronic Control Suspension

6 - 10A Meters, SRS SRS~ Supplement Restratnt System

7 - 15A Wiper A/T: Automatic Transaxle

8-10A (4AIT)

9- 15A Steering handle lock, (Door

locks)

lo- 10A Dome light, Clock

11 - 10A Backup lights

12 -2OA StoplIghts

13 -3OA Heater

14 - 20A (Sunroof)

93156fllE

1997-00 Diamante passenger compartment fuse location chart No Symbol Electrical System

I capactty

I

Spare fuses are contained in the fuse housing

use a fuse of the same capacity for replacement.

199740 Diamante encline

compartment fuse location chart

Page 256 of 408

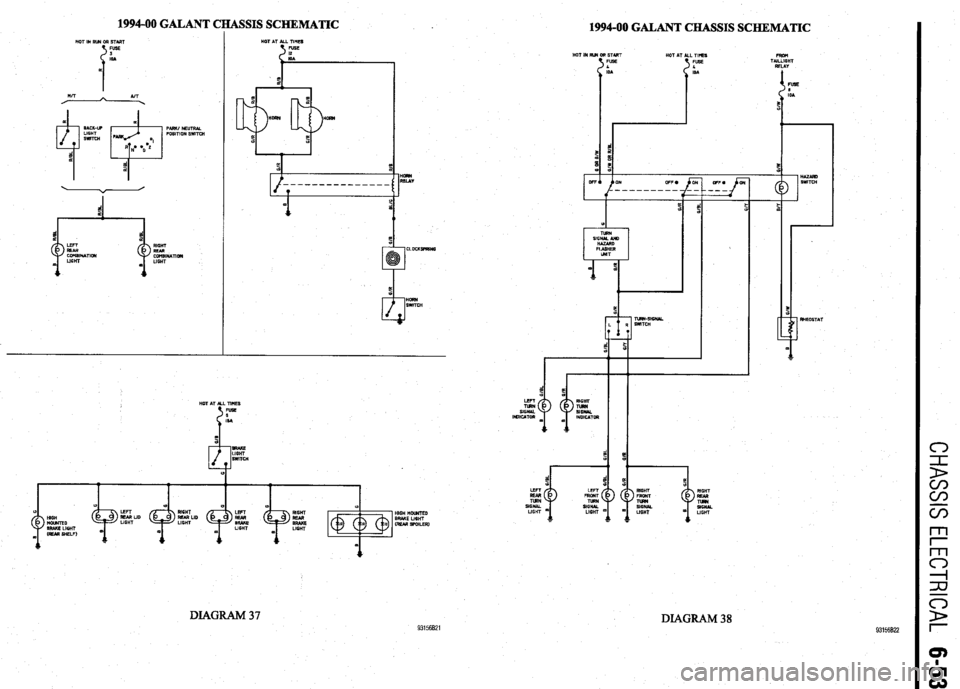

1994-00 GALANT CHASSIS SCHEMATIC

PARK! NEUTRAL

POGITION SWITCH

RIGHT

REAB

cctmiN*noI(

LIGHT

a @

CLoCKGPRlNG

HIGH HOlMTl?D

BRWE LIGHT

GEAR SPOILER)

DIAGRAM 37 93156621

1994-00 GALANT CHASSIS SCHEMATIC

DIAGRAM 38 93156822

Page 288 of 408

DRIVETRAIN 7-9

*When adjusting the clutch pedal height or

the clutch pedal clevis pin play, be careful

not to push the pushrod toward the master

cylinder.

d. Check that when the clutch pedal is de-

pressed all the way, the interlock switch switches

over from ON to OFF.

ADJUSTMENT

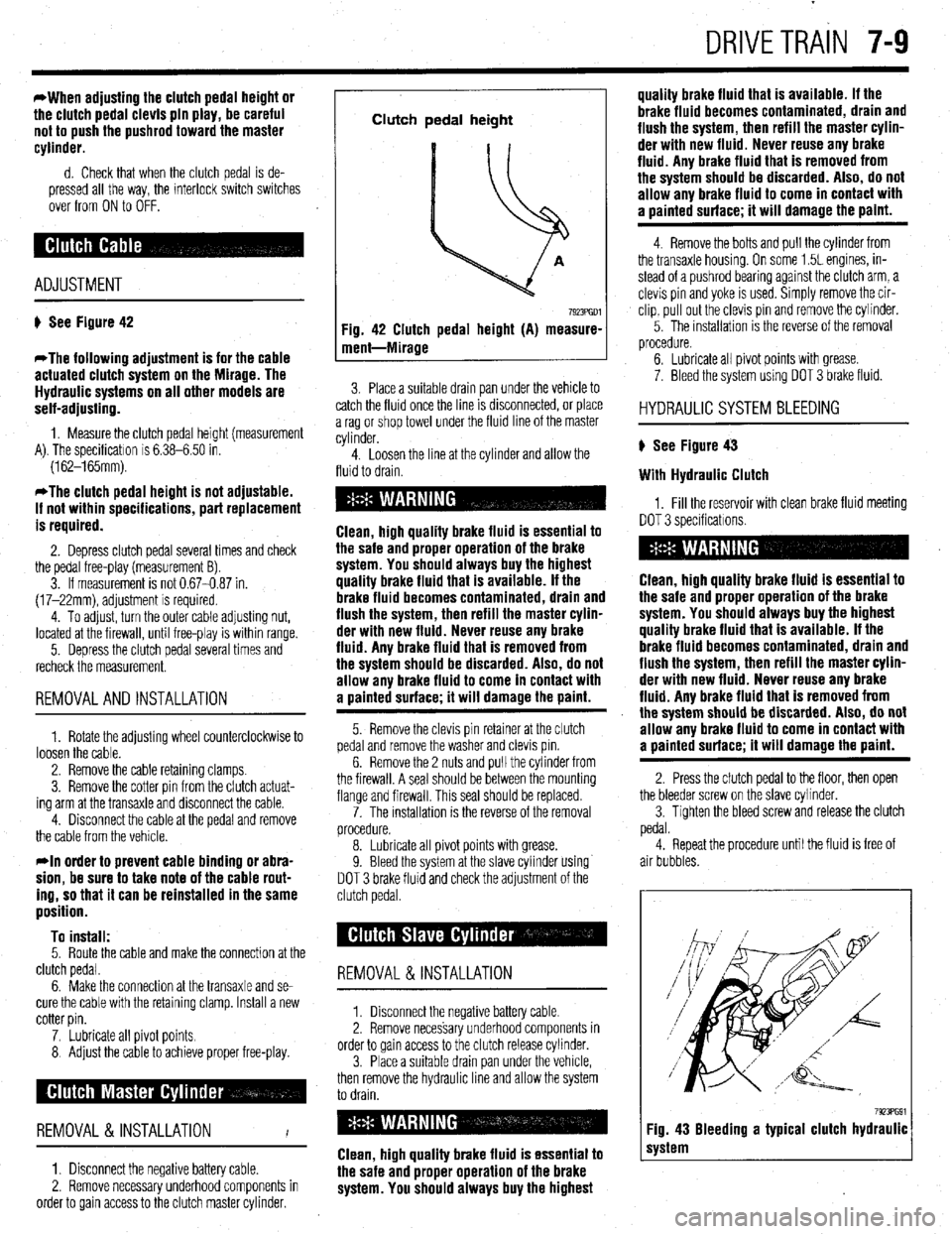

# See Figure 42

*The following adjustment is for the cable

actuated clutch system on the Mirage. The

Hydraulic systems on all other models are

self-adjusting.

1. Measure the clutch pedal height (measurement

A). The specificatron is 6.38-6.50 in.

(162-165mm).

*The clutch pedal height is not adjustable.

If not within specifications, part replacement

is required.

2. Depress clutch pedal several times and check

the pedal free-play (measurement B).

3. If measurement is not 0.67-0.87 in.

(17-22mm), adjustment is required.

4. To adjust, turn the outer cable adjusting nut,

located at the firewall, until free-play is within range.

5. Depress the clutch pedal several times and

recheck the measurement.

REMOVALANDINSTALLATION

1. Rotate the adjusting wheel counterclockwise to

loosen the cable.

2. Remove the cable retaining clamps.

3. Remove the cotter pin from the clutch actuat-

ing arm at the transaxle and disconnect the cable.

4. Disconnect the cable at the pedal and remove

the cable from the vehicle.

rln order to prevent cable binding or abra-

sion, be sure to take note of the cable rout-

ing, so that it can be reinstalled in the same

position.

To install:

5. Route the cable and make the connection at the

clutch pedal.

6. Make the connection at the transaxle and se-

cure the cable with the retaining clamp. Install a new

cotter pin.

7. Lubricate all pivot points.

8 Adjust the cable to achieve proper free-play.

REMOVAL &INSTALLATION

I

1. Disconnect the negative battery cable.

2. Remove necessary underhood components in

order to gain access to the clutch master cylinder.

Clutch pedal height

Fig. 42 Clutch pedal height (A) measure-

ment-Mirage

7923PGDl

3. Place a suitable drain pan under the vehicle to

catch the fluid once the line IS drsconnected, or place

a rag or shop towel under the fluid line of the master

cylinder.

4. Loosen the line at the cylinder and allow the

fluid to drain.

Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest

quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake

fluid. Any brake fluid that is removed from

the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a oainted surface; it will damage the paint.

5. Remove the clevis pin retainer at the clutch

pedal and remove the washer and clevis pm.

6. Remove the 2 nuts and pull the cylinder from

the firewall. A seal should be between the mounting

flange and firewall. This seal should be replaced.

7. The installation is the reverse of the removal

procedure.

8. Lubricate all pivot points with grease.

9. Bleed the system at the slave cylinder using

DOT 3 brake fluid and check the adjustment of the

clutch pedal.

REMOVAL &INSTALLATION

1. Disconnect the negative battery cable

2. Remove necessary underhood components in

order to gain access to the clutch release cylinder.

3. Place a suitable drain pan under the vehicle,

then remove the hydraulic line and allow the system

to drain.

Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake

fluid. Any brake fluid that is removed from

the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a uainted surface; it will damage the paint.

4. Remove the bolts and pull the cylinder from

the transaxle housing. On some 1.5L engines, in-

stead of a pushrod bearing against the clutch arm, a

clevis pin and yoke is used. Simply remove the cir-

clip, pull out the clevis pin and remove the cylinder.

5. The installation IS the reverse of the removal

procedure.

6. Lubricate all pivot points with grease.

7. Bleed the system using DOT 3 brake fluid.

HYDRAULIC SYSTEM BLEEDING

) See Figure 43

With Hydraulic Clutch

1, Fill the reservoir with clean brake fluid meeting

DOT 3 specificatrons.

Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest

quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake

fluid. Any brake fluid that is removed from

the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a painted surface; it will damage the paint.

2. Press the clutch pedal to the floor, then open

the bleeder screw on the slave cvlinder.

3. Tighten the bleed screw and release the clutch

pedal.

4. Repeat the procedure until the fluid is free of

air bubbles.

7923PG91 Fig. 43 Bleeding a typical clutch hydraulic

system

Page 322 of 408

8-26 SUSPENSION AND STEERING

torqued to specifications. The wheel bearings are

sealed units and are not adjustable. If defective, re-

placement is the only option.

REMOVAL &INSTALLATION

Mirage

7996-92 MODELS

1. Raise the vehicle and support safely.

2. Remove the tire and wheel assembly.

3. If equipped with rear disc brakes, remove the

caliper from the disc and remove the brake disc.

4. Remove the dust cap and bearing nut. Do not

use an air gun to remove the nut.

5. Remove the outer wheel bearing.

6. Remove the drum and/or axle hub with the

inner wheel bearing and the grease seal.

7. Remove the grease seal and remove the inner

bearing.

To install: 8. Lubricate the inner bearing and install to the

drum or hub.

9. Install a new grease seal.

10. To determine if the self-locking nut is

reusable:

a. Screw in the self-locking nut until about

0.07-0.11 in. (2-3mm) of thread is visible under

the nut.

b. Measure the torque required to turn the

self-locking nut counterclockwise.

c. The lowest allowable torque is 48 inch Ibs.

(6 Nm). If the measured torque is less than the

specification, replace the nut.

11. Install the drum and/or hub to the vehicle.

12. Lubricate and install the outer wheel bearing

to the spindle.

13. Tighten the self-locking nut to 108-145 ft.

Ibs. (150-200 Nm).

14. Set up a dial indicator and measure the end-

play while moving the hub or drum in and out. If the

endplay exceeds 0.008 in. (0.002mm) retorque the

nut. If still beyond the limit, replace the bearings.

15. Install the grease cap and wheel assembly.

7993-60 MODELS

*Never disassemble the rear hub bearing.

The wheel bearing is serviced by replace-

ment of the hub.

1. If equipped with ABS, remove the wheel

speed sensor.

2. Raise and safely support the vehicle.

3. Remove the rear wheel.

4. Remove the caliper and brake disc or brake

drum.

5. Remove the dust cap and flange nut.

6. Remove the rear hub assembly.

To install: 7. Install the rear hub assembly using a new

flange nut. Tighten the flange nut to 130 ft. Ibs. (180

Nm).

8. install the dust cap.

9. Install the wheel speed sensor if removed.

The air gap should be 0.012-0.035 in. (0.3-0.9mm).

10. Install the brake disc and caliper, or brake

drum.

11. Install the rear wheel assembly and lower the

vehicle to the floor.

1990-93 Galant

DRUM BRAKE VEHICLES

1. Raise the vehicle and support it safely.

2. Remove the wheel and tire assemblies.

3. Remove the grease cap and the hub nut.

4. Remove the brake drum. The outer bearing

will fall out while the drum is coming off. Do not drop

it. Remove the hub and rotor assembly.

5. Pry out and discard the oil seal.

6. Remove the inner bearing.

*Check the bearing races. If any scoring,

heat checking or damage is noted, they

should be replaced. When bearing or races

need replacement, replace them as a set.

7. If the bearings and races are to be replaced,

drive out the race with a brass drift.

To install: 8. Before installing new races, coat them with

wheel bearing grease. Drive into place with proper

size driver. Make sure they are fully seated.

9. Thoroughly pack the bearings and lubricate

the hubs with wheel bearing grease. Install the inner

bearing and coat the lip and rim of the grease seal

with grease. Drive the seal into place with a seal dri-

ver.

10. Install the drum assembly on the axle.

11, Lubricate and install the outer wheel bearing,

washer and nut. To properly adjust the wheel bearing

preload:

a. Tighten the wheel bearing nut to 20 ft. Ibs.

(27 Nm) while rotating the drum.

b. Back off the adjusting nut to remove the

preload, then tighten it to 7 ft. Ibs. (10 Nm).

c. Install the nut lock and a new cotter pin.

12. Install the wheel and lower the vehicle.

O/SC BRAKE VEHICLES

1. Raise the vehicle and support safely.

2. Remove the tire and wheel assembly.

3. Remove the bolt(s) holding the speed sensor

bracket to the knuckle and remove the assembly from

the vehicle.

The speed sensor has a pole piece projecting

from it. This exposed tip must be protected

from impact or scratches. Do not allow the

oole oiece to contact the toothed wheel dur-

in0 removal or installation.

4. Remove the caliper from the brake disc and

suspend with a wire.

5. Remove the brake rotor.

6. Remove the grease cap, locking nut and

tongued washer.

7. Remove the rear hub and bearing assembly.

*The rear hub assembly can not be disas-

sembled. If bearing replacement is required,

replace the assembly as a unit.

8. If replacing the hub assembly, remove the

two bolts securing the speed sensor ring to the hub.

To install: 9. Install the speed sensor to the hub and bear-

ing assembly. Tighten the mounting bolts to 8 ft. Ibs.

(11 Nm). 10. Install the hub and bearing assembly to the

axle shaft.

11, Install the tongued washer and a new locking

nut. Tighten the locknut to 144-188 ft. Ibs. (200-260

Nm). Once the locknut has been properly torqued,

crimp the nut flange over the slot in the spindle, and

install the grease cap.

12. Install the brake caliper and rotor.

13. Install the speed sensor and tighten the

mounting bolt to 8 ft. Ibs. (11 Nm).

14. Install the tire and wheel assembly.

Be sure to pump the brake pedal until it’s

firm, before moving vehicle.

1994-00 Galant

DRUM BRAKE VEHICLES

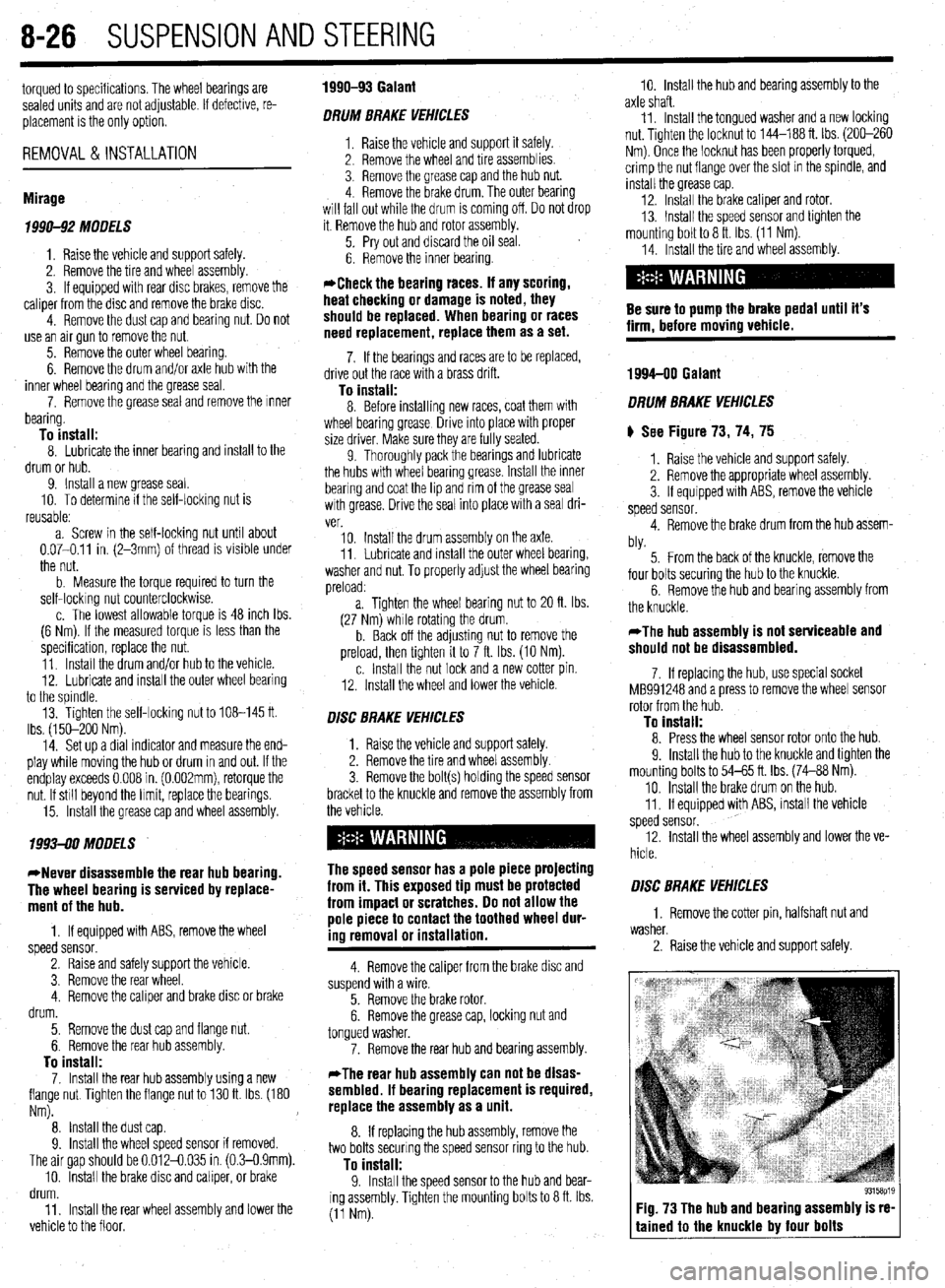

) See Figure 73, 74, 75

1. Raise the vehicle and support safely.

2. Remove the appropriate wheel assembly.

3. If equipped with ABS, remove the vehicle

speed sensor.

4. Remove the brake drum from the hub assem-

bly.

5. From the back of the knuckle, remove the

four bolts securing the hub to the knuckle.

6. Remove the hub and bearing assembly from

the knuckle.

*The hub assembly is not serviceable and

should not be disassembled.

7. If replacing the hub, use special socket

MB991248 and a press to remove the wheel sensor

rotor from the hub.

To install: 8. Press the wheel sensor rotor onto the hub.

9. Install the hub to the knuckle and tighten the

mounting bolts to 54-65 ft. Ibs. (74-88 Nm).

10. Install the brake drum on the hub.

11. If equipped with ABS, install the vehicle

speed sensor.

12. Install the wheel assembly and lower the ve-

hicle.

O/SC BRAKE VEHICLES

1. Remove the cotter pin, halfshaft nut and

washer.

2. Raise the vehicle and support safely.

Fig. 73 The hub and bearing assembly is re-

tained to the knuckle by four bolts

Page 324 of 408

. . . ,.x ..-~ .-....,, _s_s”., .._ ” *

8-28 SUSPENSION AND STEERING

REMOVAL&INSTALLATION

199%93 Mirage 1994-00 Mirage and Galant

b See Figures 76 thru 85 the NEUTRAL mark on the clockspring with the mat-

f ing mark on the casing. Then, install the steering

wheel and tighten the new retaining nut to 29 ft. Ibs.

(40 Nm).

8. Install the air bag module.

1. Disconnect the negative battery cable.

2. Remove the horn pad from the steering wheel,

by pulling the lower end of the pad upward. Detach I

If aqui

arm it --.-.- ---.-...= .-r-.‘- -.. _..- ._.. - -

Failure to do so could result in severe per-

sonal injury and damage to vehicle. pped with an air bag, be sure to dls- hnfnra sfarfinn rmairs on the vehicle.

9. Connect the negative battery cable, turn the key

to the ON position; the SRS warning light should illu-

minate for seven seconds and go out.

1990-93 Galant

hbin butin connector.

3. Remove steering wheel retaining nut:

. . . .‘ .

a. .a I <.

4. Matcnmarlc me steering wneel to me snan.

5. Use a steering wheel puller to remove the

steering wheel.

Do not hammer on steering wheel to remove

it. The collapsible column mechanism may

ha rlsmwmd.

To install:

6. Line up the matchmarks and install the steer-

ing wheel to the shaft.

7. Ti flhten the steering wheel attaching nut to 29

ft. Ibs. (40 Nm).

8. Reconnect the horn connector and install the

horn pad.

9. Connect the neaative battetv cable. 1. Disarm the SRS system as outlined in Section 6.

^ m *I

sand the air bag module

.,A +L. m++-,g w,,eel,

*. I z. Remove me cover

mounting nut from behill” ~IK ~(G~G!I

3. To detach the connector of the clocKsprmfl

from the air bag module, press the air bag’s lock to-

ward the module to spread the lock open. While

holding lock in this position, use a small tipped pry-

ing tool to gently pry the connector from the module.

4. Remove the air bag module and store in a

clean, dry place with the pad cover facing up.

5. Matchmark the steering wheel to the shaft.

6. Remove the steering wheel retaining nut and

use a steering wheel puller to remove the wheel. Do

not use a hammer, or the collapsible mechanism in

the column could be damaged.

To install:

7. Confirm that the front wheels are in a straight-

ahead position. Center the clocksprinfl by aligning 1. Disconnect the negative battery cable.

2. Remove the horn oad from the steerino wheel

as follows:- - - - r d

a. For 1990-91 models only, the horn pad is

removed by pushing the pad upward, to release

the pad from the retaining clips. Detach horn but-

ton connector and remove the pad.

b.

For 1992-93 models only, remove the

screw from the bottom of the pad and push the

pad upward, to release the pad from the retaining

clips. Detach horn button connector and remove

the pad.

3. Remove steering wheel retaining nut.

4. Matchmark the steering wheel to the shaft.

5. Use a steering wheel puller to remove the

steering wheel.

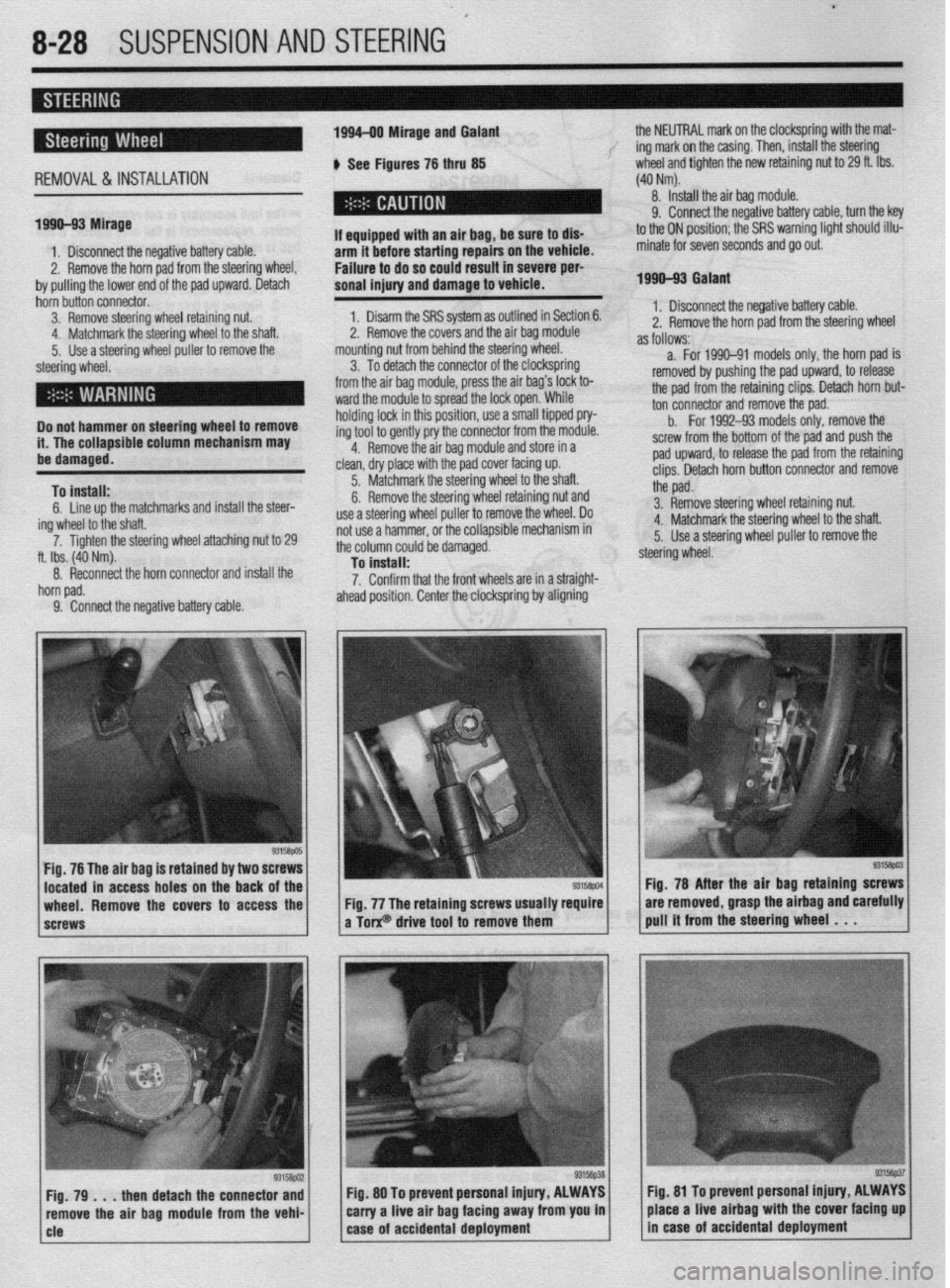

Fig. 76 The air bag is retained by two 8

located in access holes on the back

wheel. Remove the covers to access the

screws Fig. 78 After the air baa

retainino screws

Fig. 77 The retaining screws usually require are removed, grasp the airbag andiarefully

a Torx@ drive tool to remove them pull it from the steering wheel . . .

then detach the connector and Fig. 80 To prevent personal injury, ALWAYS fig. 81 To prevent personal Injury, ALWAYS

ove the air bag module from the vehi- carry a live air bag facing away from you in place a live airbag with the cover facing up

Page 325 of 408

SUSPENSION AND STEERING 8-29

i ’

Do not hamme i4 l-ha nnlhnr !r on steering wheel to remove

,,. , II= ,,,,,,Jfble column mechanism may REMOVALANDINSTALLATION

I

be damaged.

To install:

ing

7.

6. Line up the matchmarks and install the steer-

/heel to the shaft.

Tighten the steering wheel attaching nut to

25-33 ft. Ibs. (35-45 Mm).

8. Attach the horn connector and install the horn

pad.

9. Connect the negative battery cable.

Diamante The air bag system (SRS or SIR) must be dis-

armed before removing the steering wheel.

Failure to do so may cause accidental de-

ployment, property damage or personal in-

MY.

1 Rscnnnnd the nnmtivn hattm rJhle . I._“” . ..I_. . ..I *.-~ _...” ““.‘“‘, _““._. 2. If equipped, disable the air bag system.

3. Remove the steering wheel as outlined earlier

in this section.

Be sure to disarm the SRS (air bag

before starting repairs OI

to do so could result in p

death. DO NOT perform ;

cle until after 90 seconds has passed. The ai

bag system is designed to retain enough

short term voltage to make air bag deploy-

ment possible; I) system,

n the vehicle. Failure

lersonal injury or

any work on the vehi-

ir 4. For Diamante models, remove the hood lock

release handle.

5. Remove the knee protector panel under the

steering column, then the upper and lower column

covers.

6. For Diamante models, remove the lap cooler

and foot blower duct work as necessary. Carefully de-

non

b. 1. Disarm the SRS system as outlined in Sec-

. . ^ I assembly. tach the combination switch connecto&.

8. -

7. For Mirage models, detach all connectors,

For Galant models, if equipped, remove the remove the wiring clip and remove the column switch

2. Remove the air bag module mounting nut

from behind the steering wheel.

3. Matchmark the steering wheel.

4. Detach the connector of the clockspring from

the air baq module, press the air baa’s lock towards four screws retaining the cruise control slip ring to

the switch.

9. For Galant models, remove the two retaining

screws from the combination switch and remove the

switch from the column.

Tn install: the modub to spread the lock open:While holding

lock in this position, use a small tipped prying tool to

gently pry the connector from the module.

5. Store the air bag module in a clean, dry place

..# ,I I I .

ut.

Iaft. wlrn me paa cover racmg up.

6. Remove the steering wheel retaining nl

7. Matchmark the steering wheel to the sl

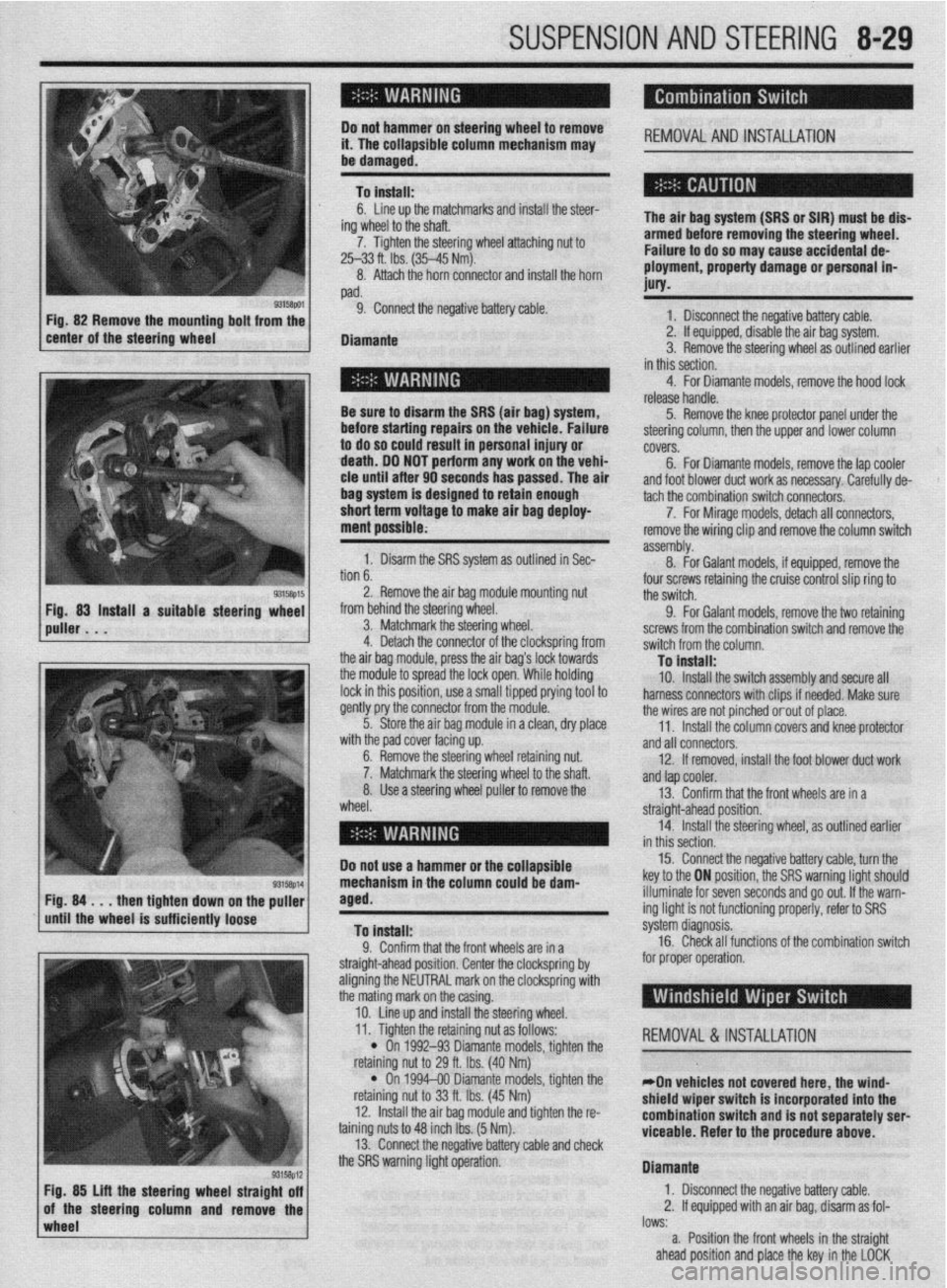

8. Use a steering wheel puller to remove the

wheel. - . . - _-. . _

10. Install the switch assembly and secure all

harness connectors with clips if needed. Make sure

the wires are not pinched orout of place.

11. Install the column covers and knee protector

and all connectors.

12. If removed, install the foot blower duct work

anfl tan cnnler -..- .-

r --- ”

13. Confirm that the front wheels are in a

straight-ahead position.

14. Install the steering wheel, as outlined earlier

in thir

Do not use a hammer or the ~r”---‘~‘- 15. Connect the negative battery cable, turn the

key to the ON position, the SRS warning light should

NW down

rinntlv

wImpl* the puller

iem Fig. 84 . . . then tighte

until the wheel is suffL,,,,, lVvoV

To install:

0 Pnnfirm that thn frnnt whnalc ,?A in , .I. ““llllllll u,a, ,110 ll”lll I.ll~rJlJ CnIj 111 a

straight-ahead position. Center the clockspring by

aligning the NEUTRAL mark on the clockspring with

the mating mark on the casing.

10. Line up and install the steering wheel. illuminate for seven seconds and go out. If the warn-

ing light is not functioning properly, refer to SRS

s’ .’ ystem cllagnosls.

16. Check all functions of the combination switch

for proper operation.

wheel lows:

a. Position the front wheels in the straight

ahead position and place the key in the LOCK

93158p12 Fig. 85 Lift the steering wheel straight off

of the steering column and remove the 11. Tighten the retaining nut as follows:

REMOVAL &INSTALLATION

l On 1992-93 Diamante models, tighten the

nut to 29 ft. Ibs. (40 Nm) retammg I

l On

retaining I

12. lnstal

taining nuts 1

13. Conn

“... . ..” .‘“J...*.” ‘&.“WSJ Y..“.” . ..rn” VII”“..

the SRS warning light operation. 1994-00 Diamante models, tighten the

iut to 33 ft. Ibs. (45 Nm)

II the air bag module and tighten the r&

:o 48 inch Ibs. (5 Nm).

wt the rwnative hatim rahle ami rhwk

*On vehicles not covered here, the wind-

shield wiper switch is incorporated into the

combination switch and is not separately serl

viceable. Refer to the procedure

above.

Diamante

1. Disconnect the negative battery cable.

2. If equipped with an air bag, disarm as fol-

I” .L

Page 326 of 408

8-30 SUSPENSION AND STEERING

position. Remove the key from the ignition lock

cylinder.

b. Disconnect the negative battery cable and

insulate the cable end with high-quality electrical

tape or similar non-conductive wrapping.

c. Wait at least 1 minute before working on

the vehicle. The air bag system is designed to re-

tain enough voltage to deploy the air bag for a

short period of time even after the battery has

been disconnected.

3. Remove the steering wheel. as outlined ear-

lier in this section.

4. Remove the hood lock release handle.

5. Remove the switches from the knee protector

below the steering column, and remove the exposed

retaining screws. Then remove the knee protector.

6. Remove the column covers.

7. Remove necessary duct work and detach the

windshield wiper switch connectors. +

8. Remove the retaining screws and remove the

windshield wiper switch assembly from the steering

column.

To install: 9. Install the wiper switch to the steering col-

umn and connect the connectors.

IO. Install any removed duct work.

11. Install the column covers.

12. Install the knee protector and switches.

13. Install the hood release handle.

14. Confirm that the front wheels are in a straight

ahead position. Install the steering wheel, as outlined

earlier in this section.

15. Connect the negative battery cable and check

the windshield wiper and washer for proper opera-

tion

REMOVAL &INSTALLATION

The air bag system (SRS or SIR) must be dis-

armed before removing the steering wheel.

Failure to do so may cause accidental de-

ployment, property damage or personal in-

jury.

1. If equipped, properly disarm the air bag sys-

tern:

2. Disconnect the negative battery cable.

3. Remove the hood lock release lever from the

lower panel.

4. Remove the lower instrument panel knee pro-

tector.

5. Remove the ductwork with the lower knee

panel and remove the steering wheel assembly.

Use proper steering wheel puller equipment

when removing the steering wheel. The use

of a hammer for removal could damage the

collapsible mechanism within the column.

6. Remove the lower and upper steering column

covers.

7. For Diamante models, remove the lap cooler

and foot shower duct work.

8. If necessary, remove the clip that holds the

wiring harness against the steering column. 9. Detach all necessary connectors.

10. For Galant and Diamante models, remove the

retaining screws, then remove the entire column

switch/clockspring assembly from the left side of the

steering column.

11. For Diarnante models, remove the mounting

screws from the ignition switch and pull the switch

from the interlock cylinder.

12. Insert the key into the steering lock cylinder

and turn to the

ACC position.

13. With a small, pointed tool, push the lock pin

of the steering lock cylinder inward and pull the lock

cylinder out.

14. Remove the key reminder switch, if equipped.

To install: 15. For Mirage, install the lock cylinder in the

lock cylinder bracket. Make sure the cylinder oper-

ates properly before breaking off the heads of the

special bolts, if the bracket was replaced.

16. For Galant and Diarnante models, install the

lock cylinder into the interlock housing. Be sure the

lock pin snaps into place. Install the ignition switch

into the interlock housing. Align the keyway of the ig-

nition switch with the lock cylinder and secure with

the mounting screws.

17. For Galant and Diamante models, install the

column switch/clockspring assembly to the and con-

nect the harness.

18. install the key reminder switch, if equipped.

19. Attach the harness connections and install

the wiring clip.

20. If removed, install the lap cooler and foot

shower duct work.

21. Install the steering column upper and lower

covers.

22. If necessary, install the knee protector and the

steering wheel.

23. Install the hood lock release lever.

24. Connect the negative battery cable, enable the

air bag system, and check the ignition switch and

lock for proper operation.

REMOVALANDINSTALLATION

Mirage and Galant

I. Disconnect the negative battery cable. If

equipped, disarm the air bag system.

2. Remove the hood lock release lever from the

lower panel.

3. Remove the lower instrument panel knee pro-

tector.

4. Remove the ductwork with the lower knee

panel and remove the steering wheel assembly.

*Use proper steering wheel puller equip-

ment when removing the steering wheel. The

use of a hammer for removal could damage

the collapsible mechanism within the col-

umn.

5. Remove the lower steering column cover.

6. Remove the upper steering column cover.

7. Remove the clip that holds the wiring harness

against the steering column.

8. For Galant models, insert the key into the

steering lock cylinder and turn to the ACC position.

9. For Galant models, using a small pointed

tool, push the lock pin of the steering lock cylinder

inward and pull the lock cylinder out. IO. For Galant models, remove the key reminder

switch, if equipped.

11. Unplug the ignition switch harness connec-

tor. Remove the ignition switch mounting screws and

pull the switch from the steering lock cylinder.

*Vehicles equipped with automatic

transaxle have safety-lock systems and will

have a key interlock cable installed in a slide

lever on the side of the key cyfinder. Care-

fully unhook the interlock cable from the lock

cylinder while withdrawing the cylinder from

the lock housing.

To install:

*To remove the steerlng lock, use a hack-

saw or equivalent to cut the special bolts

through the bracket. The bracket and bolts

must be replaced with new ones.

12. With the ignition key removed, install the

slide lever and the interlock cable to the steering lock

cylinder. Apply grease to the interlock cable and in-

stall the cylinder into the lock housing. Check for

normal operation of the interlock system.

13. Install the ignition switch into the rear of the

lock cylinder housing. Be sure to align the keyway of

the ignition switch with interlock cylinder.

14. Attach the harness connections and install

the wiring clip.

15. Install the steering column upper and lower

covers.

16. Install the knee protector.

17. Connect the negative battery cable, enable the

air

bag system (if equipped) and check the ignition

switch and lock for proper operation.

Diamante

Work MUST NOT be started until at least 90

seconds after the ignition switch is turned to

the LOCK position and the negative battery

cable is disconnected from the battery. This

will allow time for the air bag system backup

power supply to deplete its stored energy

preventing accidental air bag deployment

which could result in unnecessary air bag

system repairs and/or personal injury.

I. Disconnect the negative battery cable.

2. Disarm the air bag system, as outlined in

Section 6.

3. Remove the steering wheel, as outlined ear-

lier in this section.

4. Remove the hood lock release handle.

5. Remove the switches from the knee protector

below the steering column and remove the exposed

retaining screws. Then remove the knee protector.

6. Remove the steering column upper and lower

covers. Use care removing the covers to prevent

breakage of alignment tabs.

7. Remove lap cooler and foot shower

duct work. Detach the ignition switch harness connectors.

8. Remove mounting screws from the ignition

switch and pull switch from interlock cylinder.

To install: 9. Install ignition switch into interlock housing.

Align keyway of ignition switch with lock cylinder and

secure with mounting screws.

IO. Connect the ignition switch electrical harness

Plug.

Page 328 of 408

.

8132 SUSPENSION AND STEERING

(42 Nm) on Mirage and 36-39 ft. tbs. (49-53 Nm)

on Galant and Diamante models.

19. Have the front end alignment checked, and

adjusted if necessary.

Inner Tie Rods

11. Loosen the inner tie rod end nut from the

steering gear and remove the inner tie rod end.

To install: 12. Using a new lock plate, install the tie rod end

and tighten the tie rod to 65 ft. Ibs. (90 Nm). REMOVAL &INSTALLATION 13. Bend the tabs of the new lock plate to secure

1. Raise the front of the vehicle and support it

on jackstands.

2. Remove the wheel.

3. Remove the cotter pin and the outer tie rod

ball joint stud nut. Note the position of the steering

linkage.

4. Wire brush the threads on the tie rod shaft

and lubricate with penetrating oil.

5. Using a suitable ball joint separator tool, re-

move the tie rod ball joint from the steering knuckle.

6. Loosen the locknut and remove the tie rod

end from the tie rod. Count the number of complete

turns it takes to completely remove it.

7. Remove the tie rod-to-steering gear locknut.

8. Remove the clamps that secure the flexible

boot to the steering gear.

9. Slide the boot from the inner tie rod and re-

move the boot.

IO. Bend the lock plate tabs from the inner tie rod

end nut. the inner tie rod end.

14. Slide the boot onto the steering gear and se-

cure it with new clamps.

15. Install the outer tie rod end to the steering

gear locknut.

16. Install the outer tie rod end, turning it in ex-

actly as many turns as it was to remove the old one.

Make sure it is correctly positioned in relationship to

the steering linkage.

22. Have a front end alignment performed. 17. Connect the outer tie rod end to the steering

knuckle and install the castle nut. Tighten the nut to

25 ft. Ibs. (34 Nm,) on the Mirage and 21 ft. Ibs. (29

Nm) on the Galant and Diamante models.

18. Install a new cotter pin to the castle nut.

19. Tighten the tie rod end locking nut to 30 ft.

Ibs. (42 Nm) on the Mirage and 36-39 ft. Ibs. (49-53

Nm) on the Galant and Diamante models.

20. Install the wheel and tire assembly.

21. Lower the vehicle.

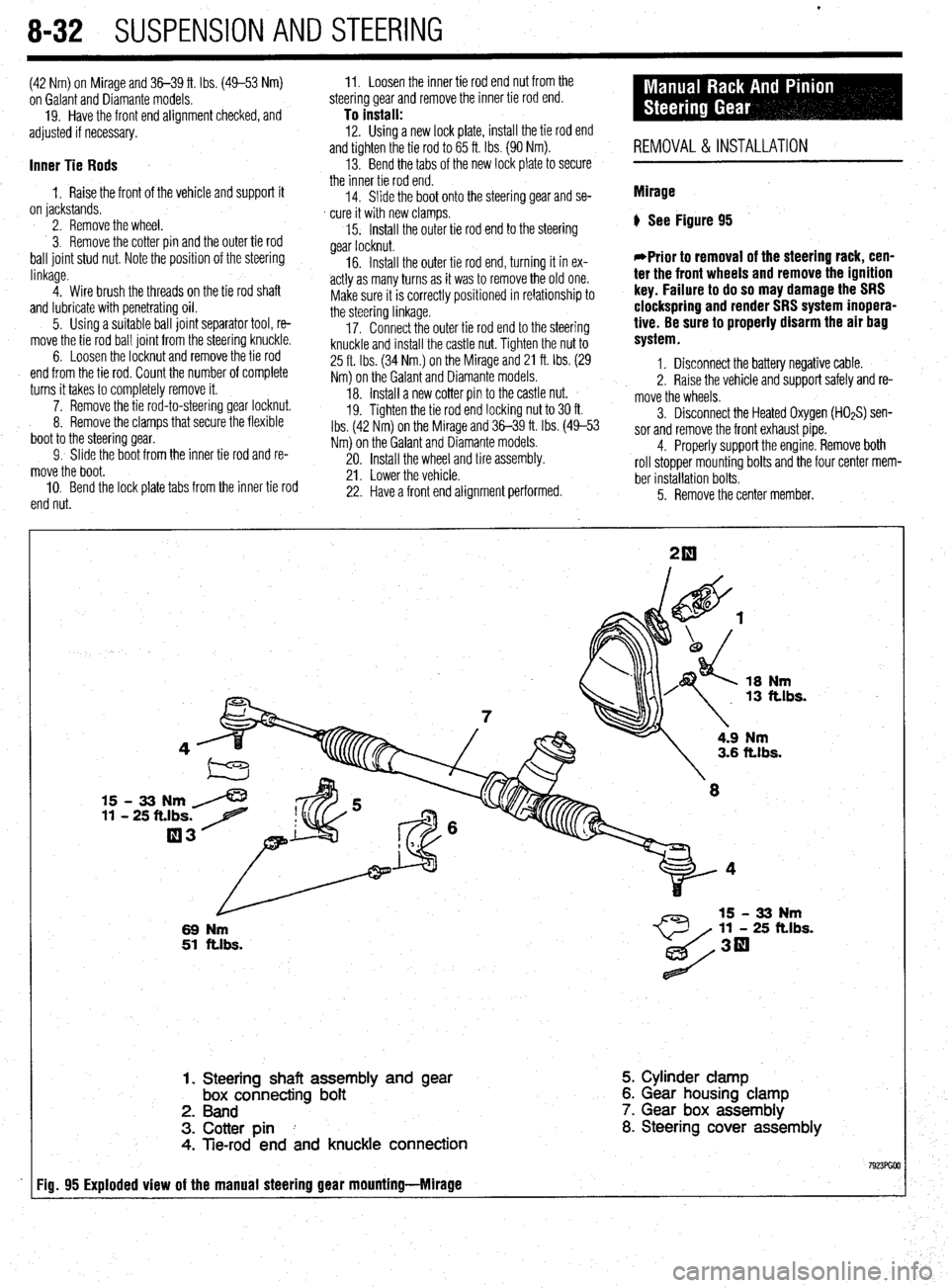

Mirage

) See Figure 95

*Prior to removal of the steering rack, cen-

ter the front wheels and remove the ignition

key. Failure to do so may damage the SRS

clockspring and render SRS system inopera-

tive. Be sure to properly disarm the air bag

system.

1. Disconnect the battery negative cable.

2. Raise the vehicle and support safely and re-

move the wheels.

5. Remove the center member. 3. Disconnect the Heated Oxygen (HOzS) sen-

sor and remove the front exhaust pipe.

4. Properly support the engine. Remove both

roll stopper mounting bolts and the four center mem-

ber installation bolts.

18

Nm 13 ft.lbs.

15 - 33 Nm /

11 - 25 ft.lbs. 7

03

L

69 Nm

51 ftlbs.

4.9 Nm 3.6 ft.lbs.

11 - 25 ft.lbs.

1. Steering shaft assembly and

gear box connecting bolt

2. Band

3. Cotter pin I

4. Tie-rod end and knuckle connection 5. Cylinder clamp

6. Gear housing clamp

7. Gear box assembly

8. Steering cover assembly

Fig. 95 Exploded view of the manual steering gear mounting-Mlrage