clock MITSUBISHI DIAMANTE 1900 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 111 of 408

.

3-50 ENGINEANDENGINEOVERHALJL

F

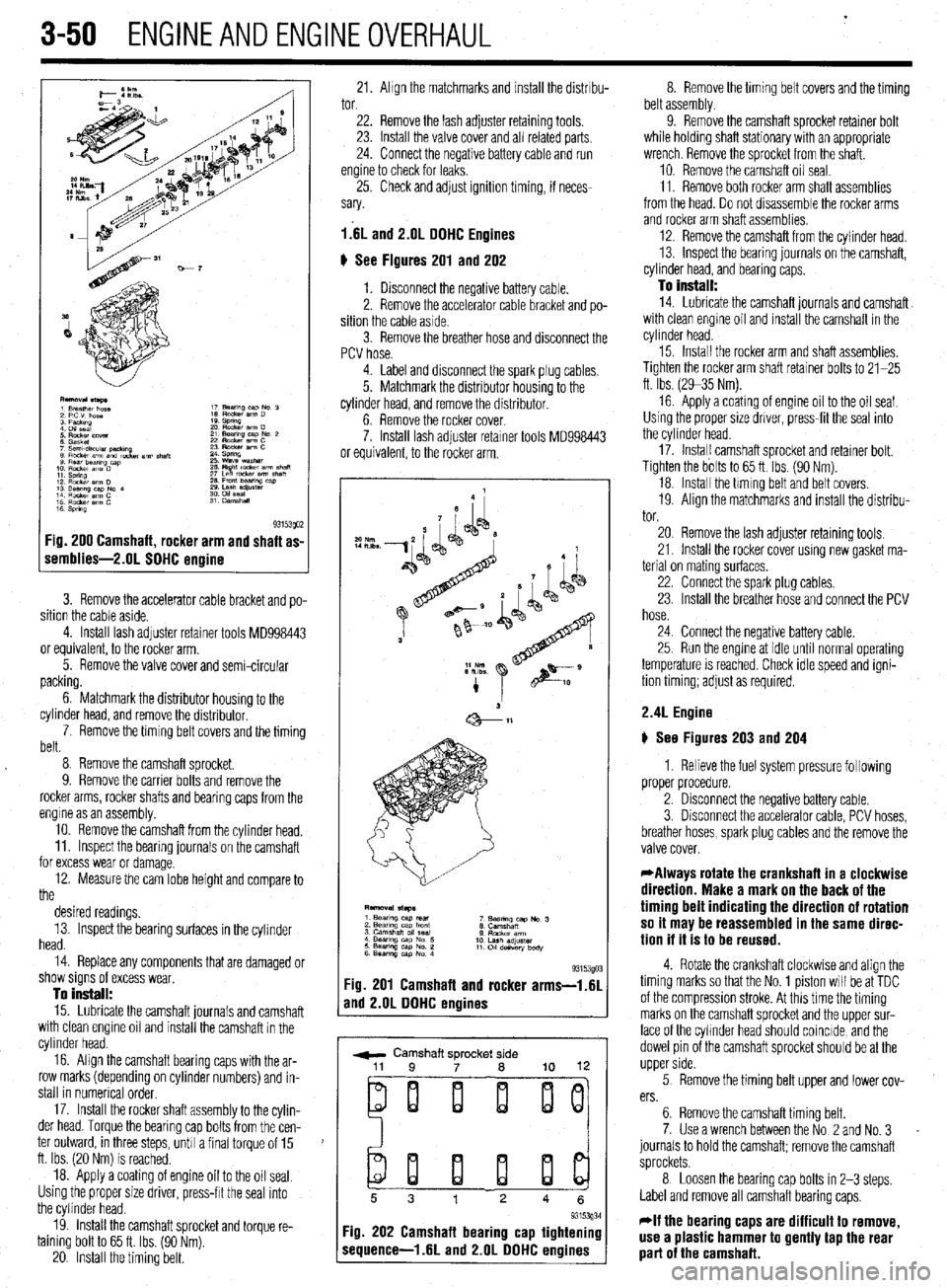

1 s 93153QO2 :ig. 200 Camshaft, rocker arm and shaft as-

iemblies-2.01 SOHC ermine

3. Remove the accelerator cable bracket and po-

sition the cable aside.

4. Install lash adjuster retainer tools MD998443

or equivalent, to the rocker arm.

5. Remove the valve cover and semi-circular

packing.

6. Matchmark the distributor housing to the

cylinder head, and remove the distributor,

7. Remove the timing belt covers and the timing

belt.

8 Remove the camshaft sprocket.

9. Remove the carrier bolts and remove the

rocker arms, rocker shafts and bearing caps from the

engine as an assembly.

10. Remove the camshaft from the cylinder head.

11. Inspect the bearing journals on the camshaft

for excess wear or damage.

12. Measure the cam lobe height and compare to

the

desired readings.

13. Inspect the bearing surfaces in the cylinder

head.

14. Replace any components that are damaged or

show signs of excess wear,

To install:

15. Lubricate the camshaft journals and camshaft

with clean engine oil and install the camshaft in the

cylinder head.

16. Align the camshaft bearing caps with the ar-

row marks (depending on cylinder numbers) and in-

stall in numerical order,

17. Install the rocker shaft assembly to the cylin-

der head. Torque the bearing cap bolts from the cen-

ter outward, in three steps, unh a final torque of 15

ft. Ibs. (20 Nm) is reached.

18. Apply a coating of engine oil to the oil seal.

Using the proper size driver, press-frt the seal into

the cylinder head.

19. install the camshaft sprocket and torque re-

taining bolt to 65 ft. Ibs. (90 Nm).

20. Install the timing belt. 21. Ahgn the matchmarks and install the distrrbu- 8. Remove the timing belt covers and the timing

tor. belt assembly.

22. Remove the lash adjuster retaining tools.

23. Install the valve cover and all related parts

24. Connect the negative battery cable and run

engine to check for leaks,

25. Check and adjust ignition timing, if neces-

sary.

l.‘6L and 2.lJL DOHC Engines

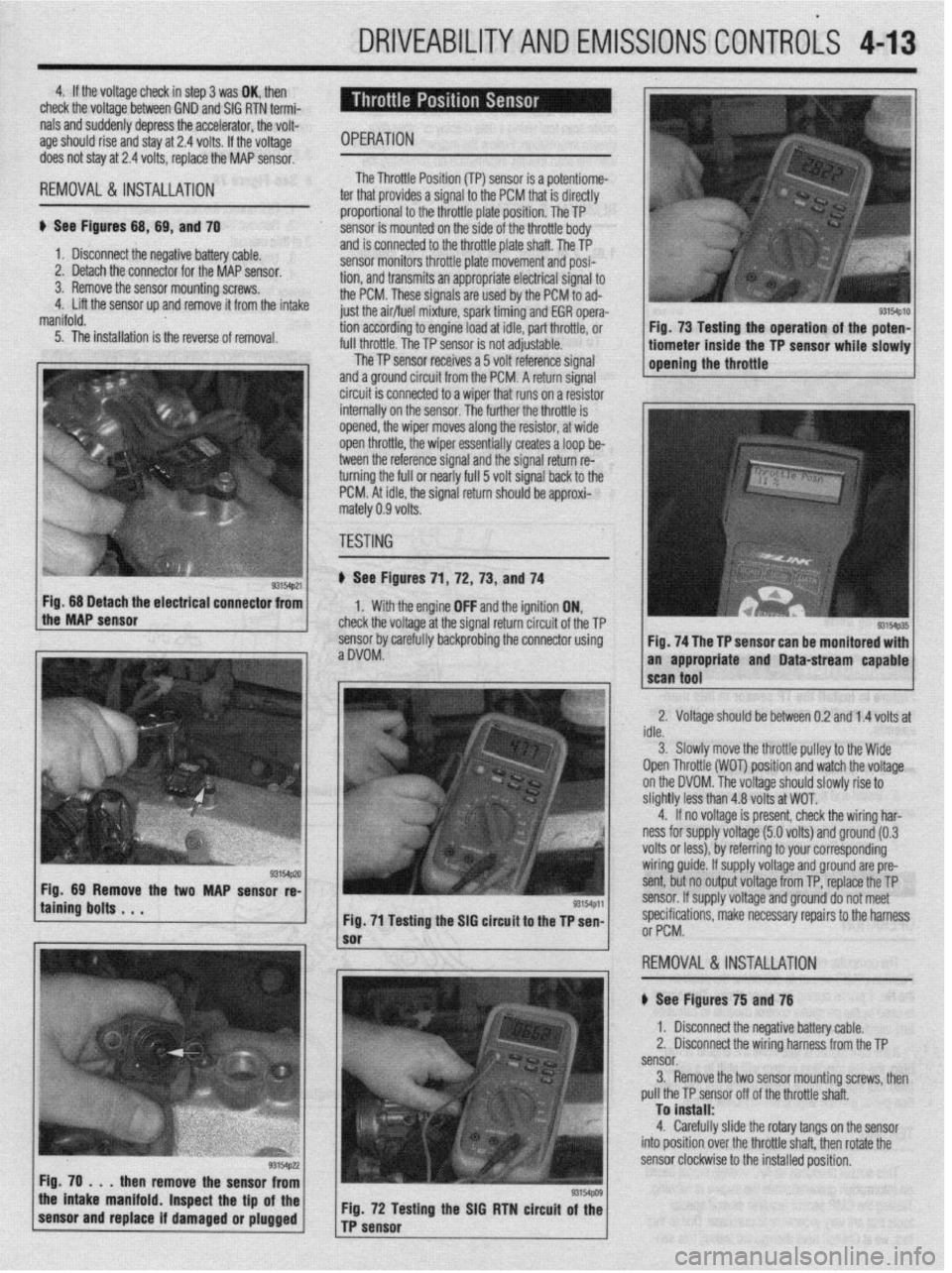

6 See Figures 201 and 202

1. Disconnect the negative battery cable.

2. Remove the accelerator cable bracket and po-

sition the cable aside.

3. Remove the breather hose and disconnect the

PCV hose. 9. Remove the camshaft sprocket retainer bolt

while holding shaft stationary with an appropriate

wrench. Remove the sprocket from the shaft.

10. Remove the camshaft oil seal.

11. Remove both rocker arm shaft assemblies

from the head. Do not drsassemble the rocker arms

and rocker arm shaft assemblies.

12. Remove the camshaft from the cylinder head.

13. inspect the bearing journals on the camshaft,

cylinder head, and bearing caps.

To install:

14. Lubricate the camshaft journals and camshaft

with clean engine oil and install the camshaft in the

cylinder head.

4. Label and disconnect the spark plug cables.

5. Matchmark the distributor housing to the

cylinder head, and remove the distributor.

6. Remove the rocker cover.

7. Install lash adjuster retarner tools MD998443

or equivalent, to the rocker arm. 15. Install the rocker arm and shaft assemblies.

Tighten the rocker arm shaft retainer bolts to 21-25

ft. Ibs. (2935 Nm).

16 Apply a coating of engine oil to the oil seal.

Using the proper size driver, press-fit the seal into

the cylinder head.

17. Instal! camshaft sprocket and retainer bolt.

Tighten the bolts to 65 ft. Ibs. (90 Nm).

18. Install the hming belt and belt covers.

19. Align the matchmarks and install the distribu-

tor.

93153gO: :ig. 201 Camshaft and rocker arms-i.61

rnd 2.OL DOHC engines

r ,

w Camshaft sprocket side

ei i i ij

20. Remove the lash adjuster retaining tools,

21. Install the rocker cover using new gasket ma-

terial on mating surfaces,

22. Connect the spark plug cables.

23. Install the breather hose and connect the PCV

hose.

24. Connect the negative battery cable.

25. Run the engme at idle until normal operating

temperature is reached. Check idle speed and igni-

tion timing; adjust as required.

2.4L Engine

) See Figures 203 and 204

1. Relieve the fuel system pressure following

proper procedure.

2. Disconnect the negative battery cable.

3. Disconnect the accelerator cable, PCV hoses,

breather hoses, spark plug cables and the remove the

valve cover.

*Always rotate the crankshaft in a clockwise

direction. Make a mark on the back of the

timing belt indicating the direction of rotation

so it may be reassembled in the same direc-

tion if it is to be reused.

4. Rotate the crankshaft clockwise and align the

timing marks so that the No. 1 piston will be at TDC

of the compression stroke. At this time the timing

marks on the camshaft sprocket and the upper sur-

face of the cyhnder head should coincide, and the

dowel pin of the camshaft sprocket should be at the

upper side.

5 Remove the timing belt upper and lower cov-

ers.

6. Remove the camshaft timing belt.

7. Use a wrench between the No 2 and No. 3

journals to hold the camshaft; remove the camshaft

sprockets.

8 Loosen the bearing cap bolts in 2-3 steps.

Label and remove all camshaft bearing caps,

*If the bearing caps are difficult to remove,

use a plastic hammer to gently tap the rear

part of the camshaft.

Page 156 of 408

DRIVEABILITYAND EMISSIONS CONTROiS 4-13

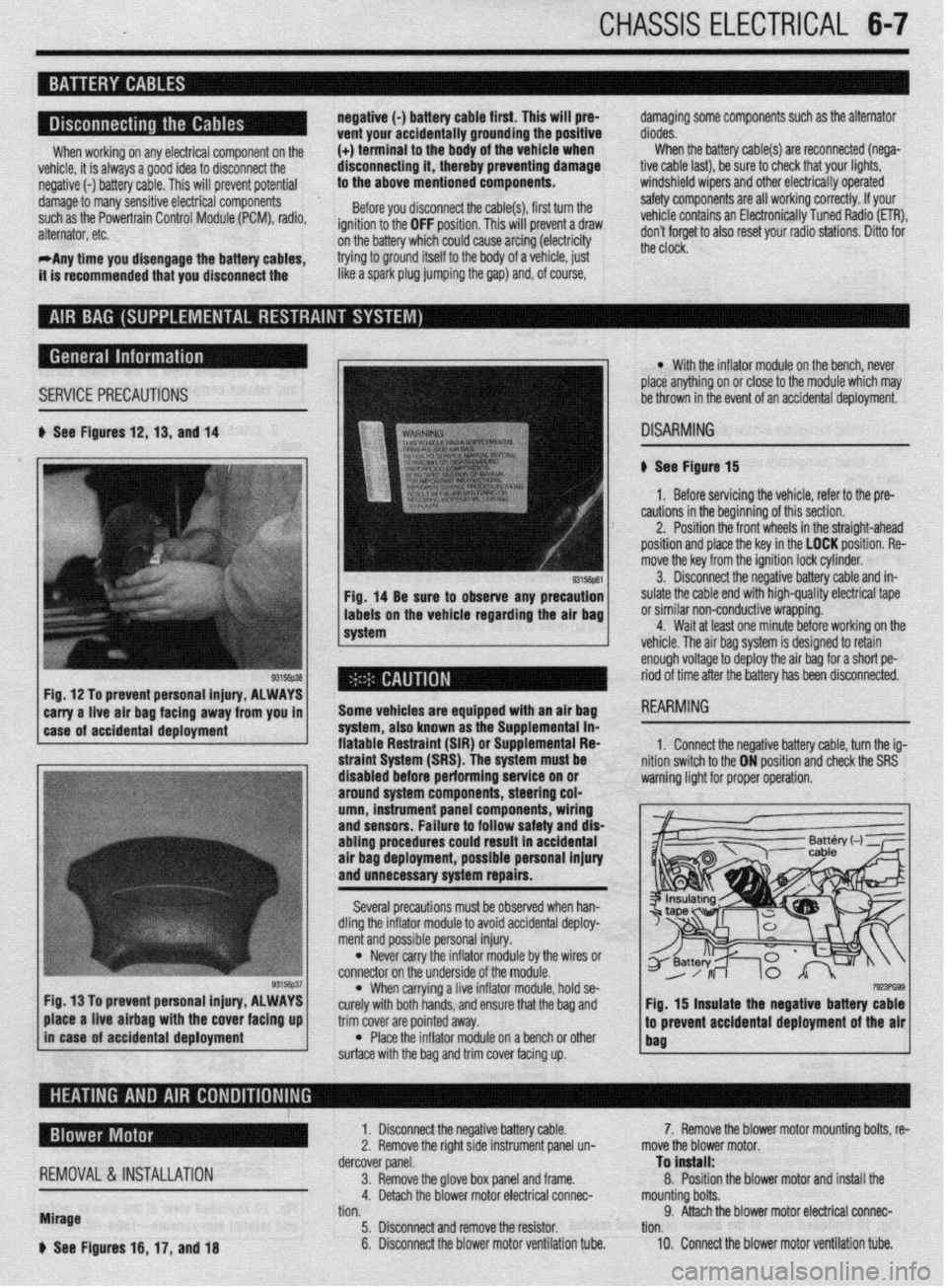

4. If the voltaoe check in sbo 3 was OK. then

check the voltage-between GND’and SIG RTN termi-

nals and suddenly depress the accelerator, the volt-

age should rise and stay at 2.4 volts. If the voltage

OPERATION does not stay at 2.4 volts, replace the MAP sensor.

REMOVAL&INSTALLATION '

ti See Figures 68, 69, and 70

1. Disconnect the negative bat lery cable.

2. Detach the connector for thl e MAP sensor.

3. Remove the sensor mountir ig screws.

4. Lift the sensor up and remove it from the intake

manifold. The Throttle Posii

ti-* \*. Inn ITPl smsnr is 8 Dotentiome- , WI...,". *., . ter that provides a si gnal to the PCM that is directly

proportion: il to the throttle plate position. The TP

sensor is rr iounted on the side of the throttle body

and is connected to the throttle plate shaft. The TP

sensor monitors throttle plate movement and posi-

tion, and transmits an appropriate electrical signal to

the PCM. These signals grp IIQX-I hv rho PCM to ad-

just the air/flnI mivtlI “-- ------li

5. The installation is the reverse of removal. WI I dLfUl U full throttle The TP c

UyI ,,,,,,,:re, spark timing and EGR opera-

ng to engine load at idle, part throttle, or

The TP sensor is not adjustable.

..-

lensor receives a 5 volt reference signal

and a ground circuit from the PCM. A return signal

circuit is connected to a wiper that runs on a resistor

internally on the sensnr ThP fmth@r rho throttle is

opined the winnr mr oP -*lY”, .I,” ..,y’V, 111 Jves along the resistor, at wide

en throttle, the wiper essentially creates a loop be-

tween the reference signal and the signal return re-

turning the full or nearly full 5 volt signal back to the

PCM. At idle, the signal return should be approxi-

rnz

rtely 0.9 volts.

TF

iSTING

) See Figures 71 ,72, 73, and 74

1. With the engine OFF and the ignition ON,

check the voltage at the signal return circuit of the TP

sensor bv carefullv backorobina the connector using

aDVOM: . ” Fig. 68 Detach the electrical connector from

the MAP sensor

taining bolts . . . WMp,l

Fig. 71 Testing the SIG circuit to the TP sen-

then remove the sensor from

the intake manifold. Inspect the tip of the

sensor and replace if damaged or plugged Fig. 72 Testing the SIG RTN circuit of the

TP sensor

sm4p10 I Fig. 73 Testing the operation of the poten- 1

tiometer inside the TP sensor while slowly 1

opening the throttle

Fig. 74 The TP sensor can be monitored with

an appropriate and Data-stream capable

2. Voltage should be between 0.2 and 1.4 volts at

idle.

3. Slowlv move the throttle oullev to the Wide

Open Throttle (WOT) position and watch the voltage

on the DVOM. The voltage should slowly rise to

slightly less than 4.8 volts at WOT.

4. If no voltage is present, check the wiring har-

ness for supply voltage (5.0 volts) and ground (0.3

volts or less), by referring to your corresponding

wiring guide. If supply voltage and ground are pre-

sent, but no output voltage from TP, replace the TP

sensor. If supply voltage and ground do not meet

specifications, make necessarv reoairs to the harness

or PCM.

,

REMOVAL&INSTALLATION

# See Figures 75 and 76

1. Disconnect the negative battery cable.

2. Disconnect the wiring harness from the TP

sensor.

3. Remove the two sensor mounting screws, then

pull the TP sensor off of the throttle shaft.

To install:

4. Carefully slide the rotary tangs on the sensor

into position over the throttle shaft. then rotate the

sensor clockwise to the installed position.

Page 210 of 408

I I

CHASSIS ELECTRICAL 6-7

When working on any electrical component on the

vehicle, it is always a good idea to disconnect the

negative (-) battery cable. This will prevent potential

damage to many sensitive electrical components

such as the Powertrain Control Module (PCM), radio,

alternator, etc.

*Any time you disengage the battery cables,

it is recommended that you disconnect the negative (-) battery cable first. This will pre-

vent your accidentally grounding the positive

(+) terminal to the body of the vehicle when

disconnecting it, thereby preventing damage

to the above mentioned components.

Before you disconnect the cable(s), first turn the

ignition to the OFF position. This will prevent a draw

on the battery which could cause arcing (electricity

trying to ground itself to the body of a vehicle, just

like a spark plug jumping the gap) and, of course, damaging some components such as the alternator

diodes.

When the battery cable(s) are reconnected (nega-

tive cable last), be sure to check that your lights,

windshield wipers and other electrically operated

safety components are all working correctly. If your

vehicle contains an Electronically Tuned Radio (ETR),

don’t forget to also reset your radio stations. Ditto for

the clock.

SERVICE PRECAUTIONS

b See Figures 12,13, and 14

Fig, 14 Be sure to observe any precaution

labels on the vehicle regarding the air bag

system

Fig. 12 To prevent personal injury, ALWAYS

*

carry a-live -ah bag fac!ng away from you in 1

1 case of accidental deployment Some vehicles are equipped wtth an air bag

-.-‘--

syr1em, aiscl Known as I11 -I-- ‘------- -- sLe Supplemental in- fiatable Restraint (SIR) o r Suouiementai Fiea

l With the inflator module on the bench, never

place anything on or close to the module which may

be thrown in the event of an accidental deployment.

DISARMING

# See Figure 15

1. Before servicing the vehicle, refer to the pre-

cautions in the beginning of this section.

2. Position the front wheels in the straight-ahead

position and place the key in the LOCK position. Re-

move the key from the ignition lock cylinder.

3. Disconnect the negative battery cable and in-

sulate the cable end with high-quality electrical tape

or similar non-conductive wrapping.

4. Wait at least one minute before working on the

vehicle. The air baa svstem is desianed to retain

enough voltage to deploy the air bag for a short pe-

riod of time after the battery has been disconnected.

1. Connect the neoative batters cable. turn the ia-

3, hold se-

e bag and

trim cover are pointed away.

l Place the inflator module on a bench or other

surface with the bag and trim cover facing up.

7!r!3PG93 Fig. 15 insulate the negative battery cable

.I

to prevent accidental deployment of the air

bag place a live airbag with the cover facing up

in case of accidental deployment

REMOVAL &INSTALLATION

Mirage

b See Figures 16, 17, and 18 1. Disconnect the negative battery cable.

2. Remove the right side instrument panel un-

dercover panel.

3. Remove the glove box panel and frame.

4. Detach the blower motor electrical connec-

tion.

5. Disconnect and remove the resistor.

6. Disconnect the blower motor ventilation tube. 7. Remove the blower motor mounting bolts, re-

move the blower motor.

To install:

8. Position the blower motor and install the

mounting bolts.

9. Attach the blower motor electrical connec-

tion.

10. Connect the blower motor ventilation tube.

Page 214 of 408

CHASSIS ELECTRICAL 6-11

45. Install the heater hoses under the hood.

46. Install the mstrument panel by reversing its

removal procedure.

47. Install the center console.

48. install the upper and lower steering column

covers.

49. Install the center panel undercover.

50. Install the small column panel.

51. Install the steering wheel.

52. Fill the cooling system.

53. Connect the negative battery cable and check

the entire climate control system for proper operation

and leaks.

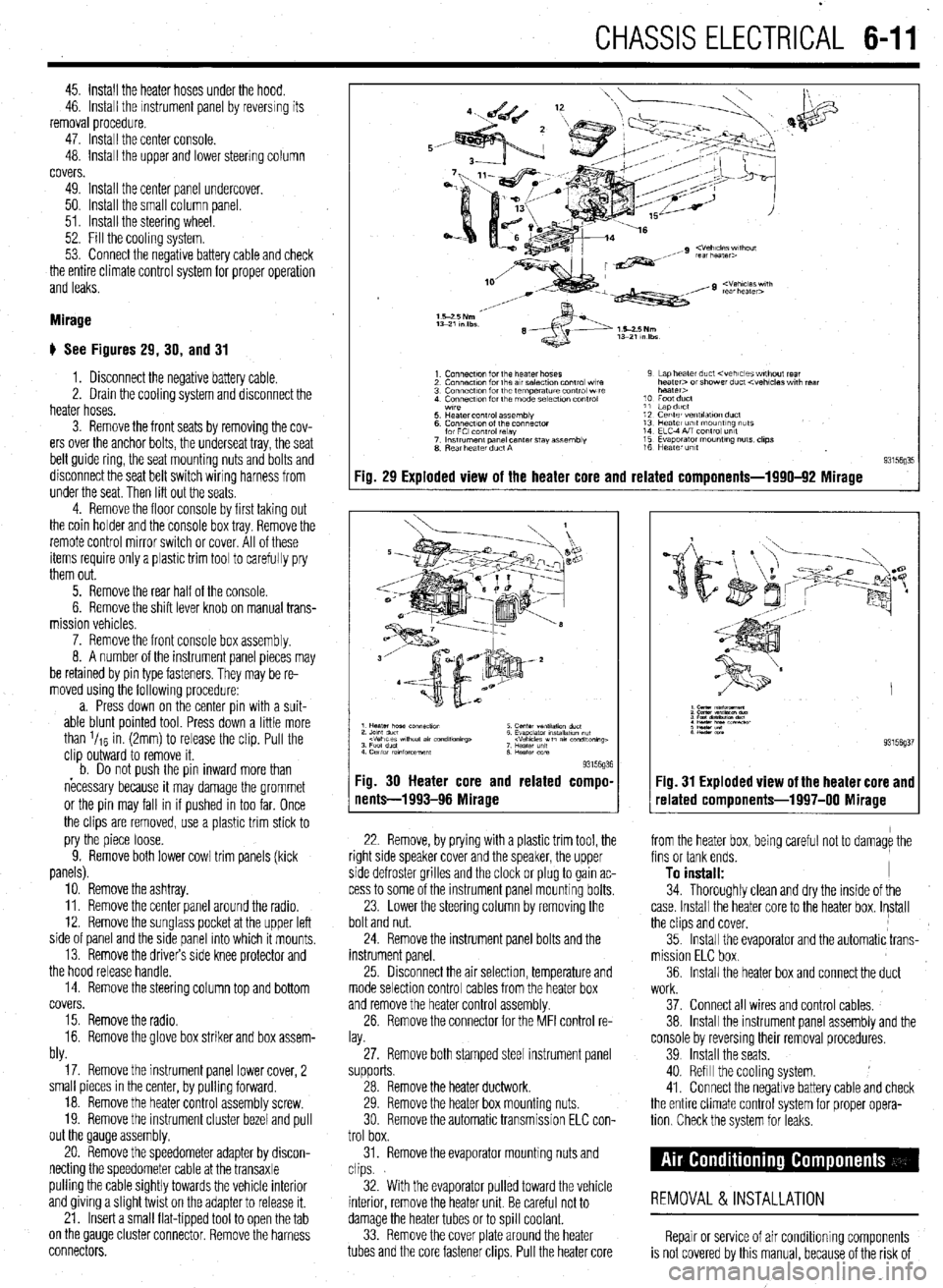

Mirage

# See Figures 29, 30, and 31

1. Disconnect the negative battery cable.

2. Drain the cooling system and disconnect the

heater hoses.

3. Remove the front seats by removing the cov-

ers over the anchor bolts, the underseat tray, the seat

belt guide ring, the seat mounting nuts and bolts and

disconnect the seat belt switch wiring harness from

under the seat. Then lift out the seats

4. Remove the floor console by first taking out

the coin holder and the console box tray. Remove the

remote control mirror switch or cover. All of these

items require only a plastic trim tool to carefully pry

them out.

5. Remove the rear half of the console.

6. Remove the shift lever knob on manual trans-

mission vehicles.

7. Remove the front console box assembly.

8. A number of the instrument panel pieces may

be retamed by pin type fasteners. They may be re-

moved using the following procedure:

a. Press down on the center pin with a suit-

able blunt pointed tool. Press down a little more

than l/re in. (2mm) to release the clip. Pull the

clip outward to remove it.

b. Do not oush the oin inward more than

necessary because it may damage the grommet

or the pin may fall in if pushed in too far. Once

the clips are removed, use a plastic trim stick to

pry the piece loose.

9. Remove both lower cowl trim panels (kick

panels).

10. Remove the ashtray.

11. Remove the center panel around the radio.

12. Remove the sunglass pocket at the upper left

side of panel and the side panel into which it mounts,

13. Remove the drivers side knee protector and

the hood release handle.

14. Remove the steering column top and bottom

covers.

15. Remove the radio.

16. Remove the glove box striker and box assem-

bly.

17. Remove the instrument panel lower cover, 2

small pieces in the center, by pulling forward.

18. Remove the heater control assembly screw.

19. Remove the instrument cluster bezel and pull

out the Qauge assembly.

20. Remove the speedometer adapter by discon-

necting the speedometer cable at the transaxle

pulling the cable Sightly towards the vehicle interior

and giving a Slight twist on the adapter to release it.

21. Insert a small flat-tipped tool to open the tab

on the QauQe cluster connector. Remove the harness

connectors.

Fig. 29 Exploded view of the heater core and related components-1990-92 Mirage

93l%Q% Fig. 30 Heater core and related compo-

nents-1993-96 Mirage

22. Remove, by prying with a plastic trim tool, the

right side speaker cover and the speaker, the upper

side defroster grilles and the clock or plug to gain ac-

cess to some of the instrument panel mounting bolts.

23. Lower the steering column by removing the

bolt and nut.

24. Remove the instrument panel bolts and the

instrument panel.

25 Drsconnect the air selection, temperature and

mode selection control cables from the heater box

and remove the heater control assembly.

26. Remove the connector for the MFI control re-

lay.

27. Remove both stamped steel instrument panel

supports.

28. Remove the heater ductwork.

29. Remove the heater box mounting nuts.

30 Remove the automatic transmission ELC con-

trol box.

31. Remove the evaporator mounting nuts and

clips.

32. With the evaporator pulled toward the vehicle

interior, remove the heater unit. Be careful not to

damage the heater tubes or to spill coolant.

33. Remove the cover plate around the heater

tubes and the core fastener clips. Pull the heater core 34. Thoroughly clean and dry the inside of the

case. Install the heater core to the heater box. Install

the clips and cover,

35. Install the evaporator and the automatic trans-

mission ELC box.

36. Install the heater box and connect the duct

Fig. 31 Exploded view of the heater core and

related components-1997-00 Mirage

from the heater box, being careful not to damage the

fins or tank ends.

To install: I

work.

37. Connect all wires and control cables,

38. Install the instrument panel assembly and the

console by reversmg their removal procedures.

39 Install the seats.

40. Refill the cooling system.

41. Connect the negative battery cable and check

the entire climate control system for proper opera-

tion Check the system for leaks.

REMOVAL &INSTALLATION

Repair or service of air Conditioning components

is not covered by this manual, because of the risk of

Page 222 of 408

CHASSIS ELECTRICAL 6-19

1. Disconnect the negative battery cable.

are all built into 1 multi-function combination

2. Remove the instrument cluster, as outlined 1. Disconnect the negative battery cable.

earlier in this section. switch that is mounted on the steering col-

2. Using a small screwdriver or other suitable

umn. Refer to Section 8 for procedures re-

3. Remove the retaining screws for the instrument tool, carefully pry the retaining clips from either side

garding the combination switch.

cluster lens and cover assembly. Remove the cover of the switch trim plate.

3.

and lens. Carefully pull the switch and trim plate out of

,

4. Remove the retaining screws for the gauge or the instrument panel.

4. Detach the electrical connectors and remove

warning lamp to be replaced, then remove the gauge

the switch.

or warning lamp.

REMOVAL&INSTALLATION : 5. The installation is the reverse of removal.

To install:

5. Place the gauge or warning lamp into place

and tighten the retaining screws. 1. Disconnect the negative battery cable.

6. Install the instrument cluster lens and cover 2. Using a suitable prytool, disengage the switch

assembly. retaining tabs.

REMOVAL &INSTALLATION 7. Install the instrument cluster. 3. Gently pull the switch from the instrument

8. Connect the negative battery cable. panel.

4. Detach the electrical connector and remove the *On all models the headlights, turn signals,

switch. and on some models, the cruise control func-

5. The installation is the reverse of removal. tion are all built into 1 multi-function combi-

nation switch that is mounted on the steerinq

REMOVAL &INSTALLATION column. Refer to Section 8 for procedures 6

garding the combination switch.

*The headlights, turn signals, dimmer

switch, horn switch, windshield

REMOVAL &INSTALLATION

wiper/washer, intermittent wiper switch and *

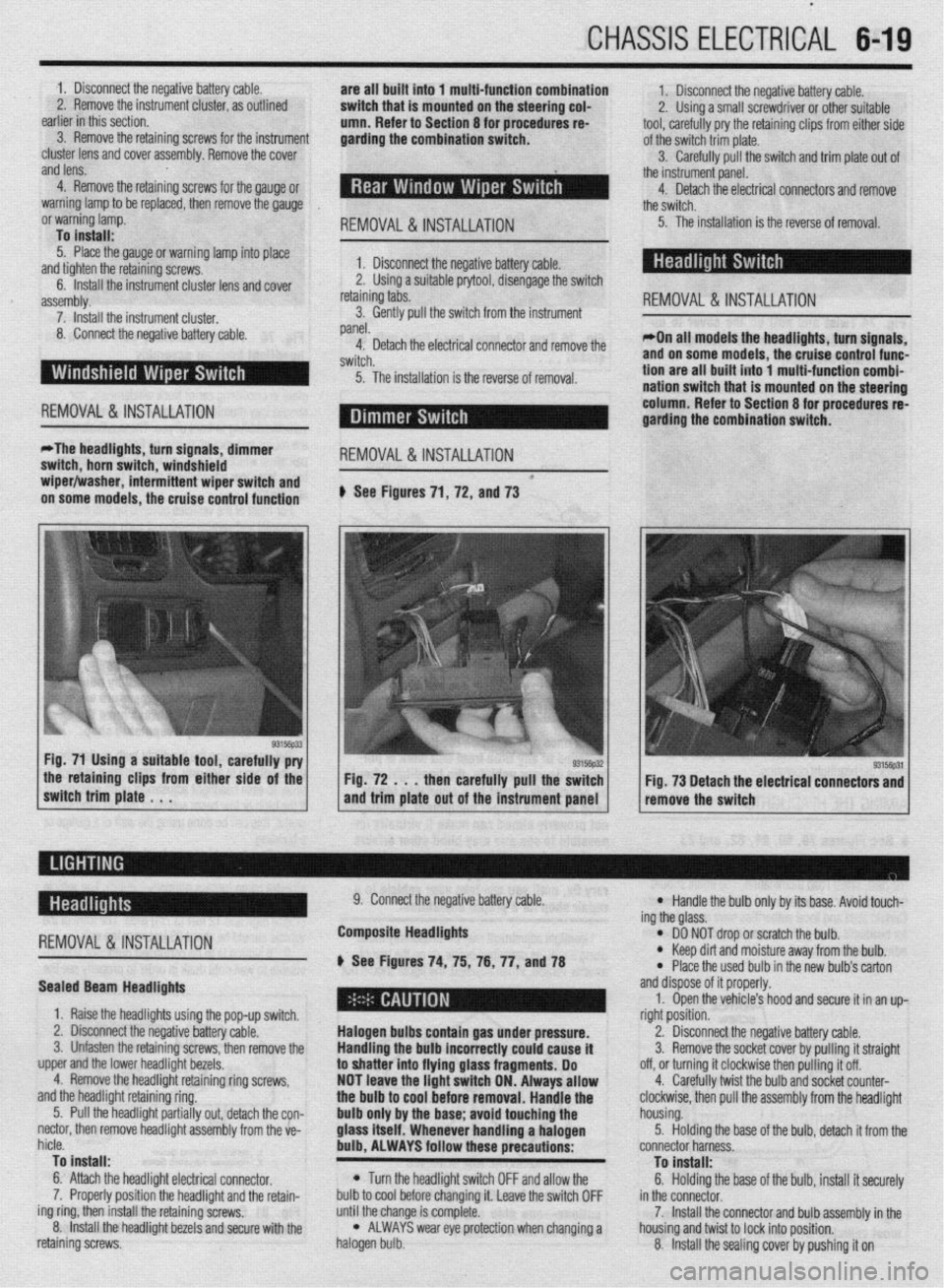

on some models, the cruise control function # See Figures 71, 72, and 73

the retaining clips from either side of the

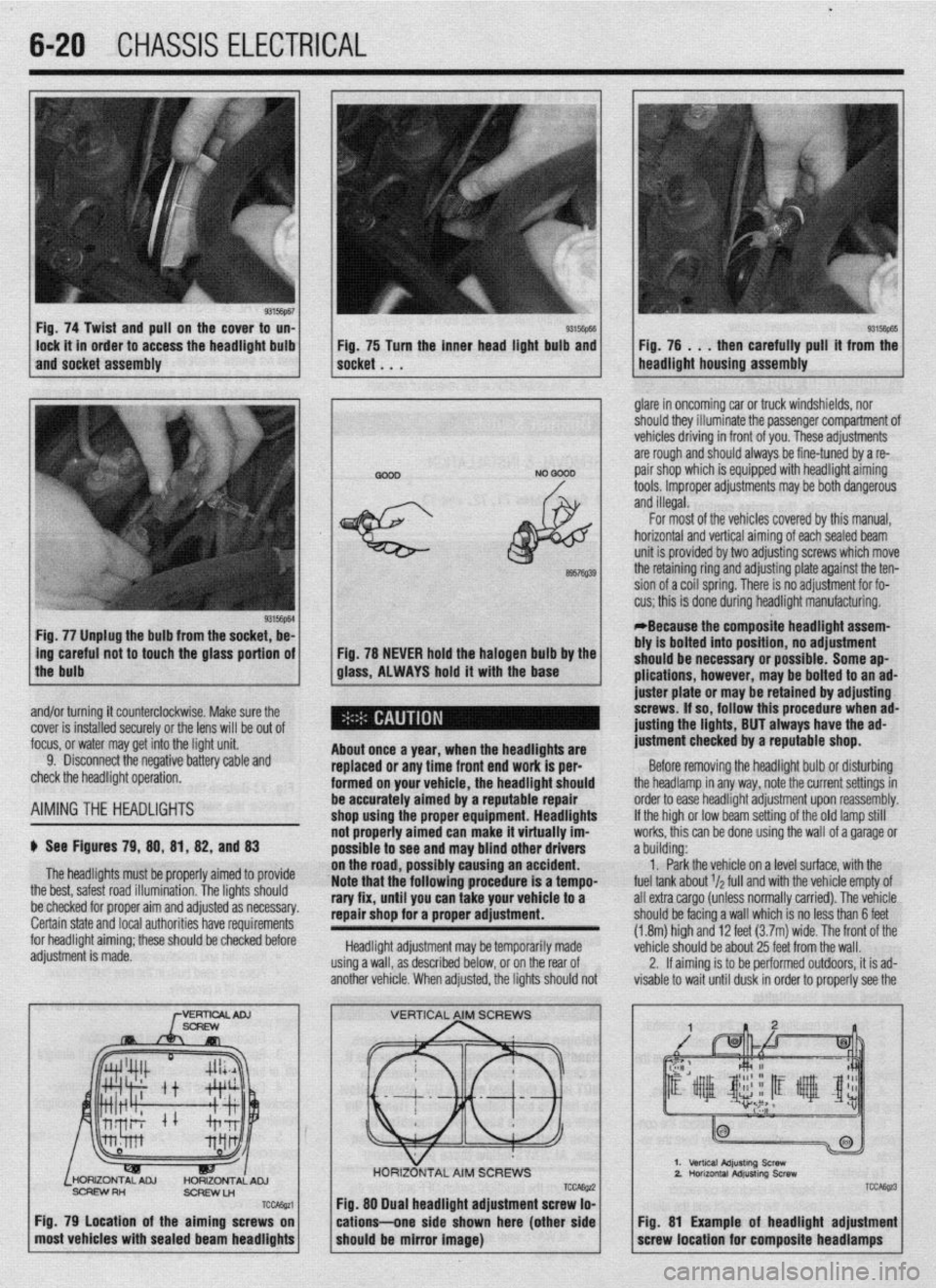

switch trim plate . . . Fig. 72 . . . then carefully pull the switch

and trim plate out of the instrument panel Fig. 73 Detach the electrical connectors and

remove the switch

-

REMOVAL &INSTALLATION

Sealed Beam Headlights

1. Raise the headlights using the pop-up switch.

2. Disconnect the negative battery cable.

3. Unfasten the retaining screws, then remove the

upper and the lower headlight bezels.

4. Remove the headlight retaining ring screws,

and the headlight retaining ring.

5. Pull the headlight partially out, detach the con-

nectar, then remove headlight assembly from the ve-

hicle.

To install:

6. Attach the headlight electrical connector.

7. Properly position the headlight and the retain-

ing ring, then install the retaining screws.

8. Install the headlight bezels and secure with the

retaining screws. 9. Connect the negative battery cable.

Composite Headlights

6 See Figures 74, 75, 76, 77, anU78

Halogen bulbs contain gas under pressure.

Handling the

bulb incorrectly could cause it

to shatter into flying glass fragments. Do

NOT leave the light switch ON. Always allow

the bulb to cool before removal. Handle the

bulb only by the base; avoid touching the

glass itself. Whenever handling a halogen

bulb, ALWAYS follow these precautions:

l Turn the headlight switch OFF and allow the

bulb to cool before changing it. Leave the switch OFF

until the change is complete.

l ALWAYS wear eye protection when changing a

halogen bulb.

l Handle the bulb only by its base. Avoid touch-

ing the glass.

l DO NOT drop or scratch the bulb. l Keep dirt and moisture away from the bulb.

* Place the used bulb in the new bulb’s carton

and dispose of it properly.

1. Open the vehicle’s hood and secure it in an up-

right position.

2. Disconnect the negative battery cable.

3. Remove the socket cover by pulling it straight

off, or turning it clockwise then pulling it off.

4. Carefully twist the bulb and socket counter-

clockwise, then pull the assembly from the headlight

housing.

5. Holding the base of the bulb, detach it from the

connector harness.

To install:

6. Holding the base of the bulb, install it securely

in the connector.

7. Install the connector and bulb assembly in the

housing and twist to lock into position.

8. Install the sealing cover by pushing it on

Page 223 of 408

.

6-20 CHASSIS ELECTRICAL

Fig. 74 Twist and pull on the cover to un-

lock it in order to access the headlight bulb

and socket assembly 93Mm Fig, 75 Turn the inner head light bulb and then carefully pull’ it from the

NO 0000 . glare in oncoming car or truck windshields, nor

should they illuminate the passenger compartment of

vehicles driving in front of you. These adjustments

are rough and should always be fine-tuned by a re-

pair shop which is equipped with headlight aiming

tools. Improper adjustments may be both dangerous

and illegal.

Fig. 77 Unplug the bulb from the socket, be-

L

ing careful not to touch the glass portion of

the bulb

I

6957Q39

Fig. 78 NEVER hold the halogen bulb by the

glass, ALWAYS hold it with the base

,

About once a year, when the headllgftts are

replaced or any time front end work is per-

formed on your vehicle, the headlight should

be accurately aimed by a reputable repair

shop uslng the proper equipment. Headlights

not properly aimed can make it virtually im-

possible to see ar Id may blind other drivers

ibly causing an accident.

Note that the’following procedure is a tempo-

rary fix, until you can take your vehicle to a

repair shop for a proper adjustment.

Headlight adjustment may be temporarily made

using a wall, as described below, or on the rear of

another vehicle. When adjusted, the lights should not For most of the vehicles covered by this manual,

horizontal and vertical aiming of eachsealed beam

unit is provided by two adjusting screws which move

the retaining ring and adjusting plate against the ten-

sion of a coil spring. There is no adjustment for fo-

cus; this is done during headlight manufacturing.

*Because the composite headlight assem-

bly is bolted into position, no adjustment

should be necessary or possible. Some ap-

plications, however, may be bolted to an ad-

juster plate or may be retained by adjusting

screws. If so, follow this procedure when ad-

@sting the lights, BUT always have the ad-

justment checked by a reputable shop.

Before removing the headlight bulb or disturbing

the headlamp in any way, note the current settings in

order to ease headlight adjustment upon reassembly.

If the high or low beam setting of the old lamp still

works, this can be done using the wall of a garage or

a building:

1. Park the vehicle on a level surface, with the

fuel tank about r/a full and with the vehicle empty of

all extra cargo (unless normally carried). The vehicle

should be facing a wall which is no less than 6 feet

(1.8m) high and 12 feet (3.7m) wide. The front of the

vehicle should be about 25 feet from the wall.

2. If aiming is to be performed outdoors, it is ad-

visable to wait until dusk in order to properly see the

% and/or turning it counterclockwise. Make sure the

cover is installed securely or the lens will be out of

focus, or water may get into the light unit.

9. Disconnect the negative battery cable and

check the headlight operation.

AIMINGTHE HEADLIGHTS

$ See Figures 79, 88, 81, 82, and 83

The headlights must be proper’ ’ ’ ’

the best, safest road illumination. ’ ’

ly armea IO provrae

The lights should

:.__1__1 __ - -___-_-. on the road, POSSI

be checked for proper aim and adfusreu as IlweSYdly. Certain state and local authorities have requirements

for headlight aiming; these should be checked before

adjustment is made.

SCFEWRH

ScFlEwLn

TCcAssa

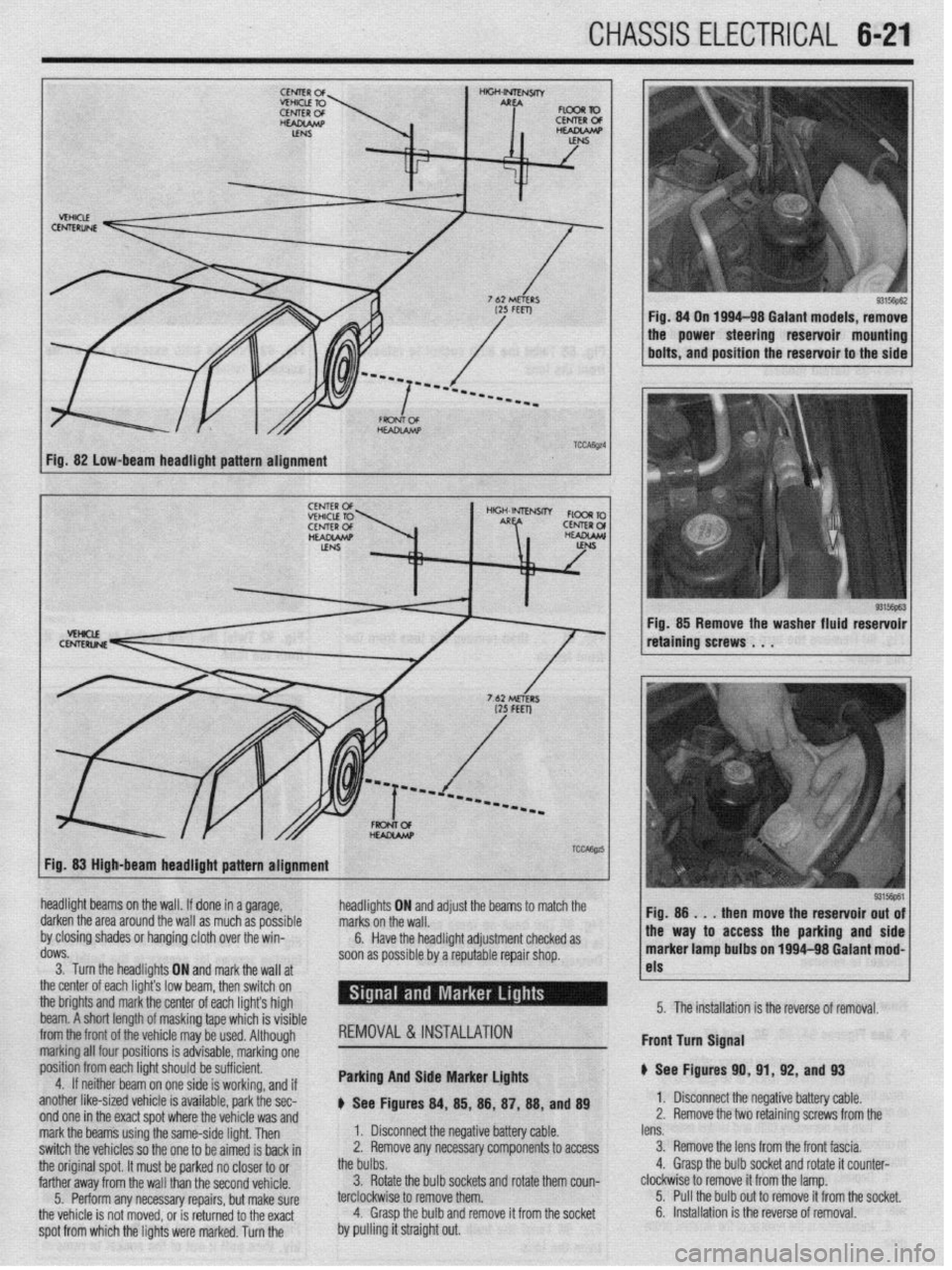

Fig. 79 Location of the aiming screws on

most vehicles with sealed beam headlights

TCCAE@ Fig. 88 Dual headlight adjustment screw lo-

cations--one side shown here (other side

should be mirror image)

2.

TCC&z3

Fig. 81 Example of headlight adjustment

screw location for composite headlamps

Page 224 of 408

CHASSIS ELECTRICAL 6-21

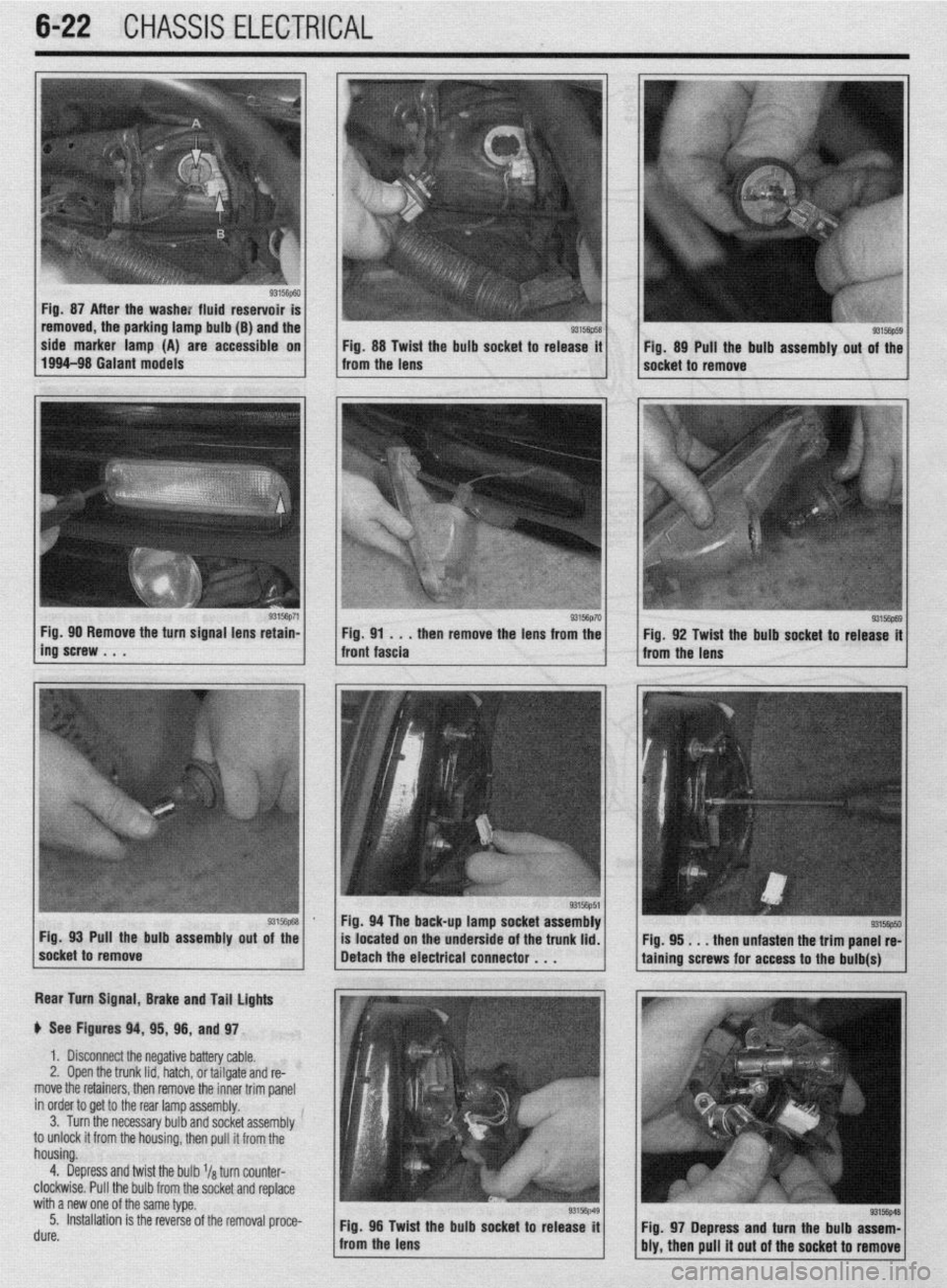

Fig. 82 low-beam headlight pattern alignment

93156pE.3 Fig. 85 Remove the washer fluid reservoir

retaining screws . . .

Fig. 83 High-beam headlight pattern alignment

headlight beams on the wall. If done in a garage,

darken the area around the wall as much as possible

by closing shades or hanging cloth over the win-

dows.

3. Turn the headlights ON and markthe wall at

the center of each light’s low br ram, then switch on

the brights and mark the center of each lights high

beam. A short length of maskin g tape which is visible

from the front of the

whir+ ma . ._..._._ . .._ y be used. Although

marking all four po:

sitions is advisable, marking one

position from each

light should be sufficient.

4. If neithar he; ~. __

Irn on one side is working, and if

another like-sized vehicle is available, park the sec-

nnri nm in the wart cnnt whrw the whirlo um md

headli! jhts ON and adjust the beams to marcn me

I. Disconnect the negative battery cable. marks on the wall.

2. Remove any necessary components to access 6.

the bulbs. Have the headlight adjustment checked as

soon as possible by a reputable repair shop.

3. Rotate the bulb sockets and rotate them coun-

terclockwise to remove them.

4. Grasp the bulb and remove it from the socket REMOVAL&INSTALLATION

Parking And Side Marker Lights

p See Figures 84, 85, 88, 87, 88, and 89 !ss the parking and side

1~ nn loo4-98 Galant mod-

I

1 I-

5315@61

lens. 1 Fio. 8

then move the reservoir out of

3. Remove the lens from the front fascia.

4. Grasp the bulb socket and rotate it counter- marker lamp bult, _.. ._“~-

clockwise to remove it from the lamp.

5. Pull the bulb out to remove it from the socket. 5. The installation is the reverse of removal.

6. Installation is the reverse of removal. Front turn Signal

p See Figures 91

1. Disconnect tl

2. Remove the t 0, 91, 92, and 93

I(? n,-.nn+:.m b.Hnn, nnL.L

z Ill7yau”e “allcly ul”IC. 10 retainino screws from the

spot from which the lights were marked. Turn the . ..I_ WIIY I.8 %,I” V”UVL”fdYI T.II”IU Lll” “VlllUlY ,.UU U,,” mark the beams using the same-side light. Then

switch the vehicles so the one to be aimed is back in

the original spot. It must be parked no closer to or

farther away from the wall than the second vehicle.

5. Perform any necessary repairs, but make sure

the vehicle is not moved, or is returned to the exact

by pulling it straight out.

Page 225 of 408

6-22 CHASSIS ELECTRICAL

b

Fig. 87 After the washe: fluid reservoir

removed, the parking lamp bulb (B) and the

side marker lamp (A) are accessible on

Fig. 88 Twist the bulb socket to release it

1994-98 Galant models

from the lens Fig. 89 Pull the bulb assembly out of the

socket to remove

g3156p71 / Fig 90 Remove the turn signal lens retain-

ing’screw . . . . then remove the lens from the

Rear Turn Signal, Brake and Tail lights

p See Figures 94, 95, 96, and 97.

1. Disconnect the negative battery cable.

2, Open the trunk lid, hatch, or tailgate and re-

move the retainers, then remove the inner trim panel

in order to get to the rear lamp assembly.

3. Turn the necessary bulb and socket assembly

to unlock it from the housing, then pull it from the

housing.

4. Depress and twist the bulb l/a turn counter-

clockwise. Pull the bulb from the socket and replace

with a new one of the same type.

5. Installation is the reverse of the removal proce-

rl. ._^

UUIt?. Fig. 96 Twid

: the bulb socket to release it

from the lens

93156p69 Fig. 92 Twist the bulb socket to release it

from the lens

I

Fig. 94 The back-up lamp socket assembly

Pull the bulb assembly

out of the

located on the underside of the trunk lid.

. . . then unfasten the trim panel re-

Fig. 97 Depress and turn the bulb assem-

bly, then pull it out of the socket to remove

Page 226 of 408

![MITSUBISHI DIAMANTE 1900 Owners Manual CHASSIS ELECTRlCiL 6-23

93156P57 Fig. 98 The back-up lamp socket assembly Fig. 99 Twist the bulb socket to release the

is located on the underside of the trunk lid locking tabs from the lens *1W5y] MITSUBISHI DIAMANTE 1900 Owners Manual CHASSIS ELECTRlCiL 6-23

93156P57 Fig. 98 The back-up lamp socket assembly Fig. 99 Twist the bulb socket to release the

is located on the underside of the trunk lid locking tabs from the lens *1W5y]](/img/19/57096/w960_57096-225.png)

CHASSIS ELECTRlCiL 6-23

93156P57 Fig. 98 The back-up lamp socket assembly Fig. 99 Twist the bulb socket to release the

is located on the underside of the trunk lid locking tabs from the lens *1W5y] Fig 100 Pull the bulb assembly straight out

of the socket to remove it

Back-up light

u See Figures 98, 99, and 100

1 I Disconnect the negative battery cable.

2. Open the trunk lid.

3. If equipped, remove the trim on the underside

of the trunk lid.

4. Turn the socket counterclockwise ‘14 of a turn

to release it from the lens.

5. Pull the bulb out to remove it from the socket,

6. The installation is the reverse of removal.

7. Connect the negative battery cable.

8. Verify the operation of the lamp.

Side Marker light

# See Figures 101, lOi, 103, and 104 I. Remove the two retaining screws from the 2. Open the trunk lid and detach the electrical

lens. connector from the lamp assembly.

2. Remove the lens from the rear fascia. 3. Remove the retaining screw holding the lamp

’ 3. Grasp the bulb socket and rotate it counter- assembly.

clockwise to remove it from the lamp. 4. Lower the lamp assembly from the lamp lens.

4. Pull the bulb out to remove it from the’socket. 5. Rotate the bulb clockwise while pushing it

5. Installation is the reverse of removal. gently inward to remove it from the socket.

6. The installation is the reverse of removal. .

High-mount Brake light

199fH6 MIllAGE, 1990-93 GALANT, AND

799446 GALANT 7992-96 DlAMANTE

p See Figures 105, 106, 107, 108, and 109 1, Disconnect the negative battery cable.

2. On the Mirage and Galant, remove the square

1. Disconnect the negative battery cable.

*The lamp assembly is accessible from the

trunk underneath the package shelf. retainer clips or bolts from the high-mount brake

light cover and remove the cover.

3. On the Diamante, press gently inward on the

sides of the liaht cover and remove it from the lamp.

1 taining screw . ~ . 93156p73 1 Fig 101 Remove the side marker light re-

93156p75 1 / ;;x,;;:,sdhen puii the lens awaG;:: 1 1 fror;l the iens Fig 103 Twist the bulb socket to release it

Fig. 104 Pull the bulb assembly straight out

of the socket to remove Fig. 105 Detach the high-mount brake

light electrical connector Fig. 106 Remove the lamp retaining screws

. a *

Page 227 of 408

.

6-24 CHASSIS ELECTRICAL

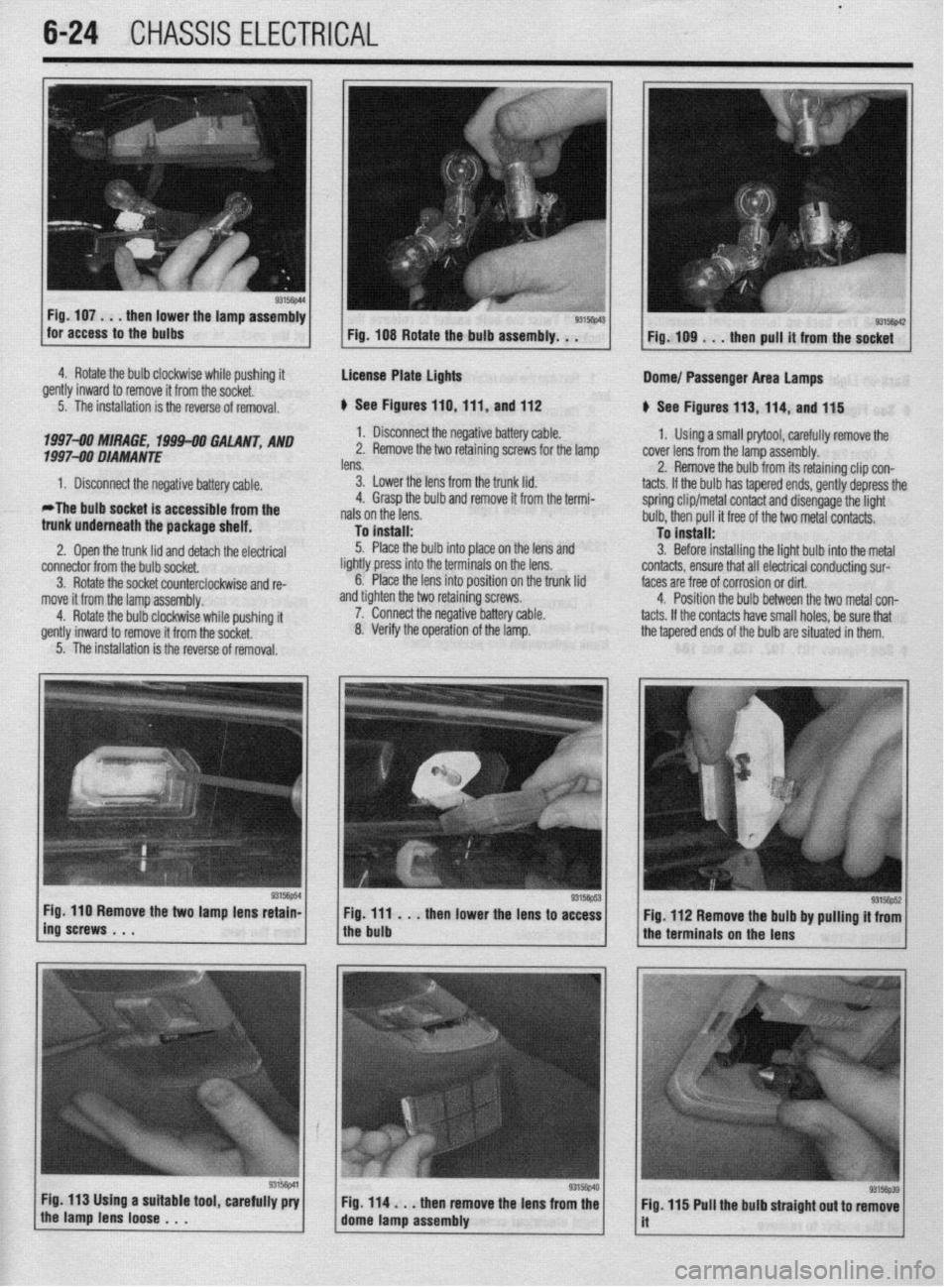

Fig. 107

. . . then lower the lamp assembly

for access to the bulbs

4. Rotate the bulb clockwise while pushing it

.,

gently inward to remove it from the socket.

5. The installation is the reverse of removal.

1997-00 MIRAGE, 1994-00 GALANT, AND

f 997-90 DIAMANTE

1. Disconnect the negative battery cable.

*The bulb socket is accessible from the

trunk underneath the package shelf.

2. Ooen the trunk lid

and detach the elwtrical connector from the bulb socket,

3. Rotate the socket counterclockwise and re-

move it from the lamp assembly.

4. Rotate the bulb clockwise while pushing

it gently inward to remove it from the socket. Fig. 108 Rotate the bulb assembly. . .

License Plate lights

p See Figures 110,111, and 112

1. Disconnect the negative battery cable.

2. Remove the two retaining screws for the lamp

lens.

3. Lower the lens from the trunk lid.

4. Grasp the bulb and remove it from the termi-

nals on the lens.

To install:

5. Place the bulb into place on the lens and

lightly press into the terminals on the lens.

6. Place the lens into position on the trunk lid

and tighten the two retaining screws.

7. Connect the negative battery cable.

8. Verify the operation of the lamp. Dome/ Passenger Area lamps

p See Figures 113, 114, and 115

1, Using a small prytool, carefully remove the

cover lens from the lamp assembly.

2. Remove the bulb from its retaining clip con-

tacts. If the bulb has tapered ends, gently depress the

spring clip/metal contact and disengage the light

bulb, then pull it free of the two metal contacts.

To install:

3. Before installing the light bulb into the metal

contacts, ensure that all electrical conducting sur-

faces are free of corrosion or dirt.

4. Position the bulb between the two metal con-

tacts. If the contacts have small holes, be sure that

the tapered ends of the bulb are situated in them.

5. The installation is the reverse of removal.

Fig. 110 Remove the two lamp lens retain-

ing screws . . . Fig. ill . . .

then lower the lens to access

the bulb Fig. 112 Remove the bulb by pulling it from

the terminals on the lens