clock MITSUBISHI DIAMANTE 1900 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 329 of 408

SUSPENSION AND STEERING 8-33

*Matchmark the pinion input shaft of the

rack to the lower steering column joint for in-

stallation purposes.

6. Remove the pinch bolt holding the lower

steering column joint to the rack and pinion input

shaft.

7. Remove the cotter pins and disconnect the tie

rod ends from the steering knuckle.

8. Remove the rack and pinion steering assem-

bly and its rubber mounts from the right side of the

vehicle.

To install: 9. Align the matchmarks of the input shaft and

install the rack to the vehicle.

10. Secure the rack using the retainer clamps and

bolts. Tighten the bolts to 51 ft. Ibs. (70 Nm).

11. Tighten the steering column pinch bolt to 13

ft. Ibs. (18 Nm).

12. Install the center member.

13. Install the front exhaust pipe.

14. Connect the HO$ sensor.

15. Connect the tie rod ends to the steering

knuckles and tighten the castle nuts to 25 ft. Ibs. (34

Nm). Install new cotter pins.

16. Install the wheels and connect the negative

battery cable.

17. Have a front end alignment performed.

REMOVAL &INSTALLATION

Diamante

FRONT

*Prior to removal of the steering gear box,

center the front wheels and remove the igni-

tion key. Failure to do so may damage the

SRS clock spring and render SRS system in-

operative.

1. Disconnect the negative battery cable.

2. Disconnect the front exhaust pipe.

3. If equipped with AWD, remove the transfer

case assembly.

4. Remove the bolt holding the lower steering

column joint to the rack and pinion input shaft.

5. Remove the cotter pins and disconnect the tie

rod ends.

6. Remove the left and right frame members.

7. Remove the stabilizer bar bracket.

8. If equipped with four-wheel steering, discon-

nect the lines going to the rear pump.

9. Remove the rack and pinion steering assem-

bly and its rubber mounts. Move the rack to the right

to remove it from the crossmember.

To install: IO. Install the rack and mounting bolts. Tighten

the bolts to 51 ft. Ibs. (70 Nm). When installing the

rubber rack mounts, align the projection of the

mounting rubber with the indentation in the cross:

member. Install the pinch bolt.

11. Connect the pressure and return lines to the

rack and to the rear pump, if equipped.

12. Install the frame members and tighten the

bolts to 43-51 ft. Ibs. (60-70 Nm).

13. Connect the tie rods and install new cotter

pins. 14. Install the transfer case and front exhaust

pipe.

15. Refill the reservoir and bleed the system.

16. Have a front end alignment performed.

REAR

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Drain the power steering fluid.

4. Remove the main muffler assembly.

5. Remove the rear shock absorber lower

mounting bolts.

6. Using the proper equipment, support the

weight of the rear differential. Remove the 2 small

crossmember brackets.

7. Remove the large self-locking crossmember

mounting nuts on the differential side.

8. Remove the oil line clamp bolts.

9. Remove the pressure tubes.

IO. Hold the tie rod ends stationary and remove

the tie rod end nuts. Remove the tie rod ends from

the trailing arms.

11. Remove the mounting bolts and remove the

rear steering gear.

To install: 12. Secure the unit to the crossmember. Move

the power cylinder piston rod over its full stroke to

determine its neutral position.

13. Align the tie rod ends with the holes in the

trailing arms and install the nuts. Adjust the length of

the tie rods with the nuts if necessary. The difference

in length between the 2 tie rod ends should not ex-

ceed 0.04 in. (1 mm). The nuts’ torque specification is

42 ft. Ibs. (58 Nm).

14. Replace the O-rings and install the pressure

tubes. Clamp in place.

15. Install the large self-locking crossmember

mounting nuts on the differential side. Tighten to

80-94 ft. Ibs. (110-130 Nm).

16. Remove the support equipment.

17. Install the 2 small crossmember brackets.

18. Install the shock mounting bolts.

19. Install the muffler assembly.

20. Refill the reservoir and bleed the system.

21. Have a front end alignment performed. _

Galant

1990-93 MODELS

1. Disconnect the negative battery cable.

2. Drain the power steering fluid.

3. Raise the vehicle and support safely.

4. Remove the bolt holding lower steering col-

umn joint to the rack and pinion input shaft.

5. Remove the transfer case, if equipped.

6. Remove the cotter pins and using the proper

tools, separate the tie rod ends from the steering

knuckle.

7. Locate the triangular brace near the stabilizer

bar brackets on the crossmember and remove both

the brace and the stabilizer bar bracket.

8. Support the center crossmember.

9. Remove the through-bolt from the round roll

stopper and remove the rear bolts from the center

crossmember.

10. Disconnect the front exhaust pipe, if

equipped with FWD.

11. Disconnect the power steering fluid pressure

pipe and return hose from the rack fittings. Plug the

fittings to prevent excess fluid leakage. 12. Lower the crossmember slightly.

13. Remove the rack and pinion steering assem-

bly and its rubber mounts. Move the rack to the right

to remove from the crossmember. Tilt the assembly

downward and remove from the left side of the vehi-

cle. Use caution to avoid damaging the boots.

To install: 14. Install the rack and install the mounting bolts. Tighten the mounting bolts to 43-58 ft. Ibs. (60-80

Nm). When installing the rubber rack mounts, align

the projection of the mounting rubber with the inden-

tation in the crossmember.

15. Connect the power steering fluid lines to the

rack.

16. Connect the exhaust pipe, if removed.

17. Raise the crossmember into position. Install

the center member mounting bolts and tighten to 72

ft. Ibs. (100 Nm). Install the roll stopper bolt and new

nut. Tighten nut to 47 ft. Ibs. (65 Nm).

18. Install the stabilizer bar brackets and brace.

19. Connect the tie rod ends and tighten nuts to

25 ft. Ibs. (34 Nm).

20. Install the transfer case, if removed. Check

and fill fluid.

21. Refill the reservoir with power steering fluid

and bleed the system.

22. Have a front end alignment performed.

1994-M MODELS

+ See Figure 96

Prior to removal of the steering gear box,

center the front wheels and remove the igni-

tion key. Failure to do so may damage the

SRS clock spring and render SRS system in-

operative.

1. Disconnect the negative battery cable.

2. Raise and properly support the vehicle.

3. Remove both front wheel assemblies.

4. Remove the bolt holding lower steering col-

umn joint to the rack and pinion input shaft.

5. Remove the stabilizer bar.

6. Remove the cotter pins, and using joint sepa-

rator MB991 113 or equivalent, disconnect the tie rod

ends from the steering knuckle.

7. On vehicles equipped with Electronic Control

Power steering (EPS), detach the wiring harness from

the solenoid connector.

8. Locate the two triangular braces near the

crossmember and remove both.

9. Support the center crossmember. Remove the

through-bolt from the front round roll stopper and re-

move the bolts securing the center crossmember.

10. Remove the center crossmember. ,

Il. Properly support the engine and remove the

rear roll stopper through-bolt.

12. Disconnect the power steering fluid pressure

pipe and return hose from the rack fittings. Plug the

fittings to prevent excessive fluid leakage.

13. Remove the clamp bolts and the two bolts se-

curing the rack assembly to the chassis.

14. Remove the rack and pinion steering assem-

bly and its rubber mounts.

*When removing the rack and pinion as-

sembly, tilt the assembly to the vehicle side

of the compression lower arm and remove

from the left side of the vehicle.

Page 331 of 408

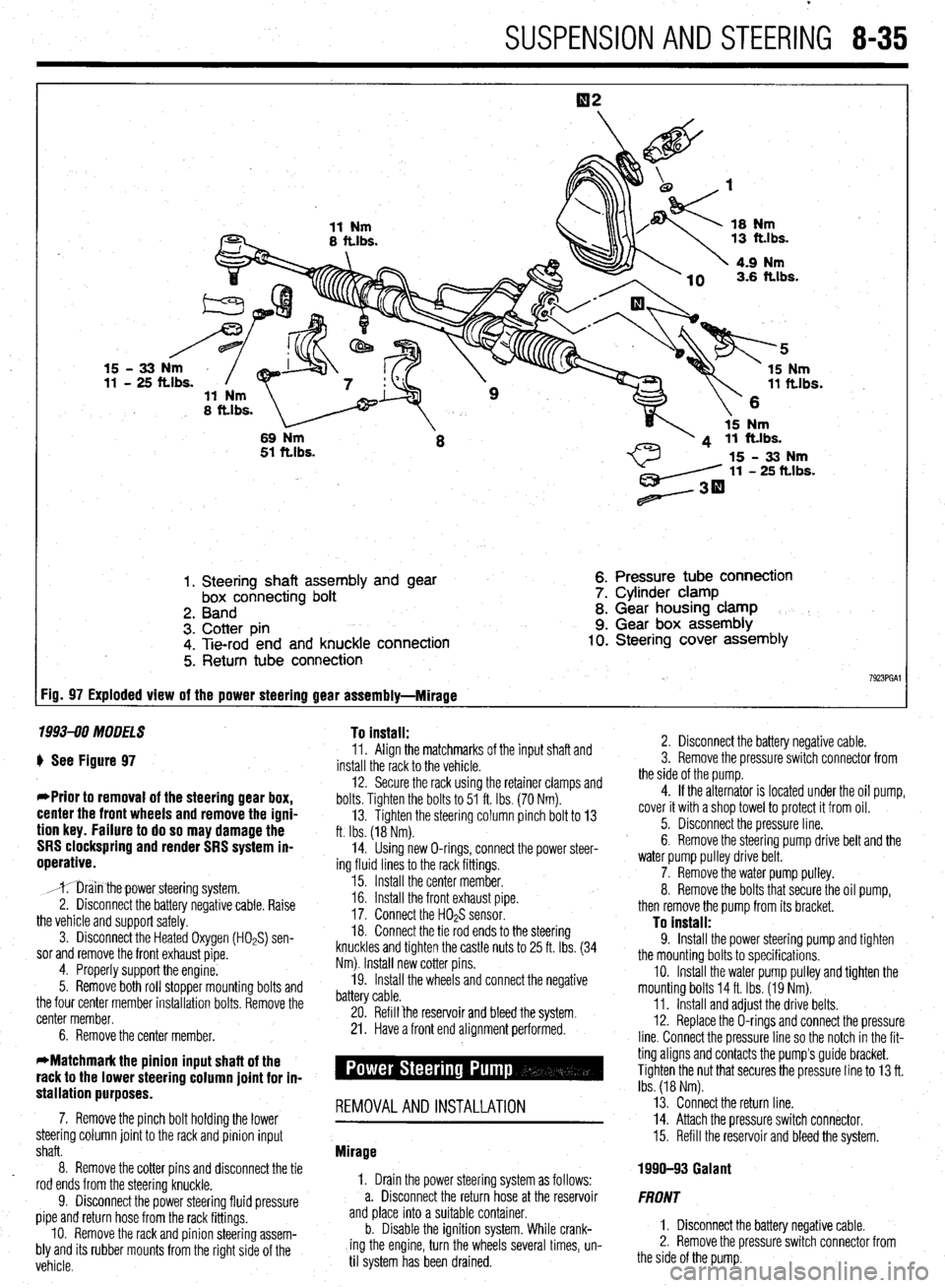

SUSPENSION AND STEERING 8-35

1. Steering shaft assembly and gear

box connecting bolt

2. Band

3. Cotter pin

4. Tie-rod end and knuckle connection

5. Return tube connection 6. Pressure tube connection

7. Cylinder clamp

8. Gear housing clamp

9. Gear box assembly 10. Steering cover assembly

7923PGAl FiD= 97 Exploded view of the power steering gear assembly-Mirage

1993-90 MODELS To install:

) See Figure 97

*Prior to removal of the steering gear box,

center the front wheels and remove the igni-

tion key. Failure to do so may damage the

SRS clockspring and render SRS system in-

operative.

,mr;iin thepower steering system.

2. Disconnect the battery negative cable. Raise

the vehicle and support safely.

3. Disconnect the Heated Oxygen (HOPS) sen-

sor and remove the front exhaust pipe.

4. Properly support the engine.

5. Remove both roll stopper mounting bolts and

the four center member installation bolts. Remove the

center member.

6. Remove the center member. 11. Align the matchmarks of the input shaft and

install the rack to the vehicle.

12. Secure the rack using the retainer clamps and

bolts. Tighten the bolts to 51 ft. Ibs. (70 Nm).

13. Tighten the steering column pinch bolt to 13

ft. Ibs. (18 Nm).

14. Using new O-rings, connect the power steer-

ing fluid lines to the rack fittings.

15. Install the center member.

16. Install the front exhaust pipe.

17. Connect the H02S sensor.

18. Connect the tie rod ends to the steering

knuckles and tighten the castle nuts to 25 ft. Ibs. (34

Nm). Install new cotter pins.

19. Install the wheels and connect the negative

battery cable.

20. Refill ‘the reservoir and bleed the system.

21. Have a front end alignment performed.

stallation purposes. -

7. Remove the pinch bolt holding the lower REMOVALANDINSTALLATION

steering column joint to the rack and pinion input

shaft.

8. Remove the cotter pins and disconnect the tie

rod ends from the steering knuckle.

9. Disconnect the power steering fluid pressure

pipe and return hose from the rack fittings.

IO. Remove the rack and pinion steering assem-

bly and its rubber mounts from the right side of the

vehicle. Mirage

1, Drain the power steering system as follows:

a. Disconnect the return hose at the reservoir

and place into a suitable container.

b. Disable the ignition system. While crank-

ing the engine, turn the wheels several times, un-

til system has been drained. 2. Disconnect the battery negative cable.

3. Remove the pressure switch connector from

the side of the pump.

4. If the alternator is located under the oil pump,

cover it with a shop towel to protect it from oil.

5. Disconnect the pressure line.

6. Remove the steering pump drive belt and the

water pump pulley drive belt.

7. Remove the water pump pulley.

8. Remove the bolts that secure the oil pump,

then remove the pump from its bracket.

To install: 9. Install the power steering pump and tighten

the mounting bolts to specifications.

IO. Install the water pump pulley and tighten the

mounting bolts 14 ft. Ibs. (19 Nm).

11. Install and adjust the drive belts.

12. Replace the O-rings and connect the pressure

line. Connect the pressure line so the notch in the fit-

ting aligns and contacts the pump’s guide bracket.

Tighten the nut that secures the pressure line to 13 ft.

Ibs. (18 Nm).

13. Connect the return line.

14. Attach the pressure switch connector.

15. Refill the reservoir and bleed the system.

1990-93 Galant

FRONT

1. Disconnect the battery negative cable.

2. Remove the pressure switch connector from

the side of the pump.

Page 352 of 408

t

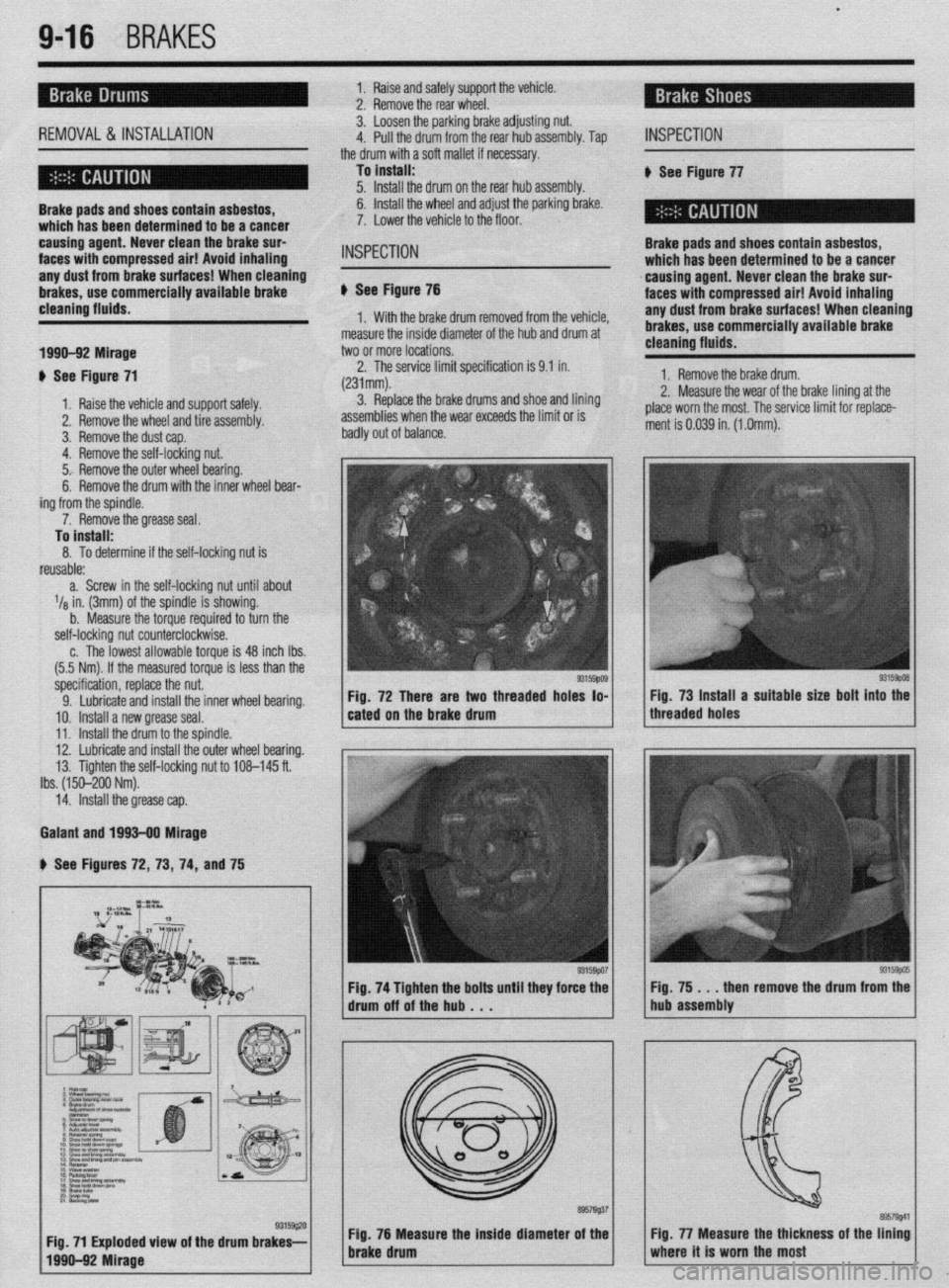

9-16 BRAKES

1. Raise and safely support the vehicle.

2. Remove the rear wheel.

: REMOVAL&INSTALLATION 3. Loosen the parking brake adjusting nut.

4. Pull the drum from the rear hub assembly. Tap INSPECTION

the drum with a soft mallet if necessary.

To install:

u See Figure 77

5. Install the drum on the rear hub assembly.

Brake pads and shoes contain asbestos, 6. Install the wheel and adjust the parking brake.

which has been determined to be a cancer 7. Lower the vehicle to the floor.

causing agent. Never clean the brake sur-

'INSPECTION Brake pads and shoes contain asbestos,

faces with compressed air! Avoid inhaling

which has been determined to be a cancer

any dust from brake surfaces! When cleaning

‘b See Figure 76 causing agent. Never clean the brake sur-

brakes, use commercially available brake

faces with compressed air! Avoid inhaling

cleaning fluids.

1. With the brake drum removed from the vehicle, any dust from brake surfaces! When cleaning

measure the inside diameter of the hub and drum at brakes, use commercially available brake

1996-92 Mirage two or more locations. cleaning fluids.

: $ See Figure 71 2. The service limit specification is 9.1 in.

(231mm). 1. Remove the brake drum.

1. Raise the vehicle and support safely. 3. Replace the brake drums and shoe and lining 2. Measure the wear of the brake lining at the

2. Remove the wheel and tire assembly. assemblies when the wear exceeds the limit or is place worn the most. The service limit for replace-

3. Remove the dust cap. badly out of balance. ment is 0.039 in. (1 .Omm).

4. Remove the self-locking nut.

5.. Remove the outer wheel bearing.

’ 6. Remove the drum with the inner wheel bear-

ing from the spindle.

7. Remove the grease seal.

To install:

8. To determine if the self-locking nut is

reusable:

a. Screw in the self-locking nut until about

l/e in. (3mm) of the spindle is showing.

b. Measure the torque required to turn the

self-locking nut counterclockwise.

c. The lowest allowable torque is 48 inch Ibs.

(5.5 Nm). If the measured torque is less than the

specification, replace the nut.

9. Lubricate and install the inner wheel bearing.

10. Install a new grease seal.

11. Install the drum to the spindle.

12. Lubricate and install the outer wheel bearing.

13. Tighten the self-locking nut to 108-145 ft.

Ibs. (150-200 Nm).

14. Install the grease cap.

Galant and 1993-90 Mirage

b See Figures 72, 73, 74, and 75

Fig. 76 Measura the inside diameter of the

brake drum

Page 375 of 408

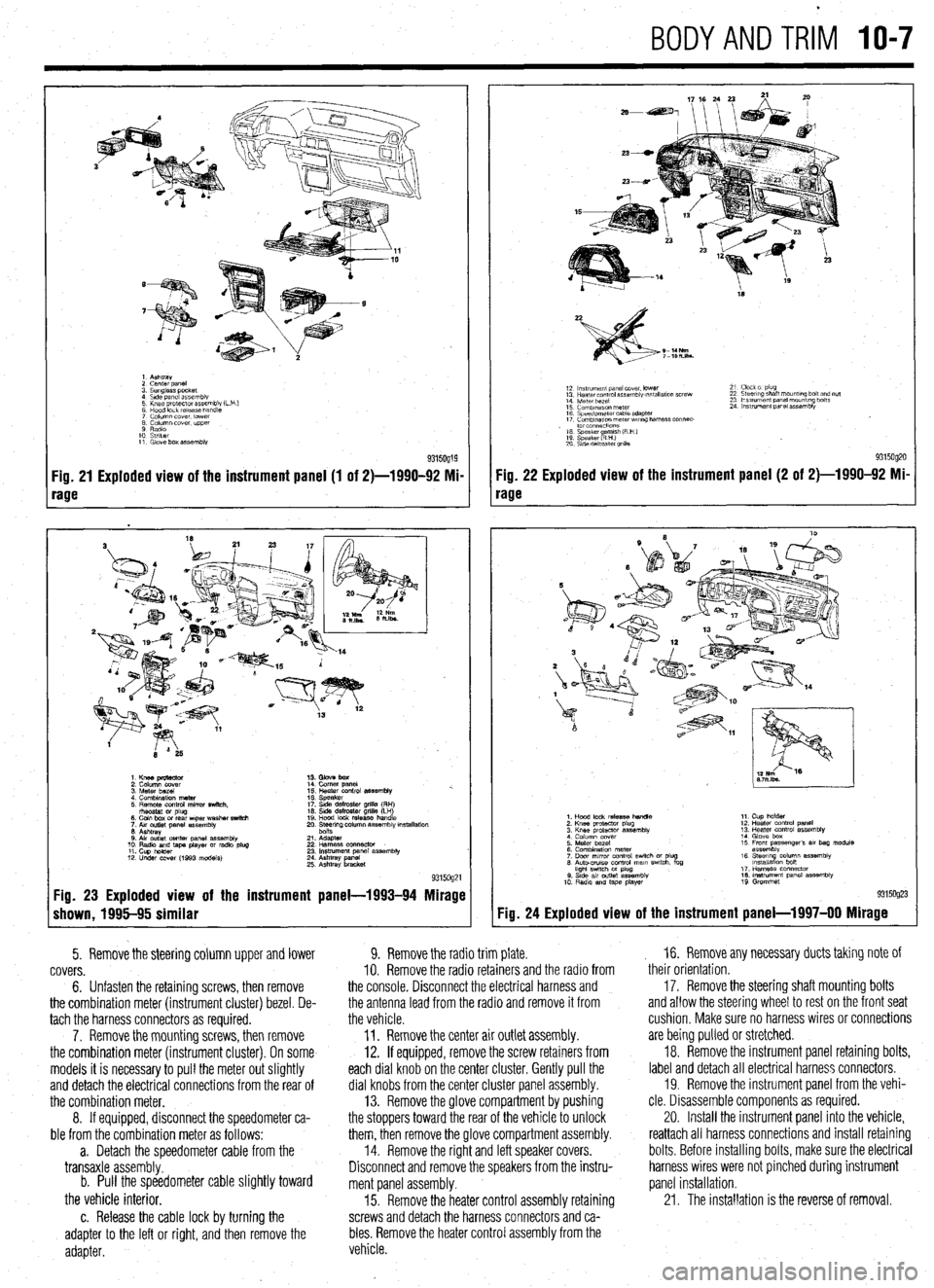

BODYANDTRIM IO-7

1. Ashtray

2 cenrer DaneI

3. Sunglass pocket

4 Side panel assembly

5 Knee protector assembly (L

6 Hood lock release handle

7 Column cover. lower

8 Column cover. upper

9 Radio

10 Striker

11. Glove box assembly

Fig. 21 Exploded view of the instrument panel (1 of 2)-1990-92 Mi-

rage

1. Knee pmtector

2. Column cover

3. Meter bezel

4. Combination meter

5. Remote control mirror switch.

rhsostat or plug

6. Coin box or rear wper washer switch

7. Aw outlet panel assembly

6. Ashtray

0. Air outlet center panel assembly

10. Radio and tape player or radio plug

11. Cup holder

12. Under COW (1993 models) 14. Comer panel

15. Heater control assembly %.

16. Speaker

17. Side defroster grille (RH)

16. Side defroster grille (LH)

19. Hood lock release handle

20. Ee$ng column assembly mstallation

21. Adapter

22 Harness oonnector

23. Instrument panel assembly

24. Ashtray panel

25. Ashtray bracket

9315og21 Fig. 23 Exploded view of the instrument panel-1993-94 Mirage

shown, 1995-95 similar

5. Remove the steering column upper and lower

covers.

6. Unfasten the retaining screws, then remove

the combination meter (instrument cluster) bezel. De-

tach the harness connectors as required.

7. Remove the mounting screws, then remove

the combination meter (instrument cluster). On some

models it is necessary to pull the meter out slightly

and detach the electrical connections from the rear of

the combination meter.

8. If equipped, disconnect the speedometer ca-

ble from the combination meter as follows:

a. Detach the speedometer cable from the

transaxle assembly.

b. Pull the speedometer cable slightly toward

the vehicle interior.

c. Release the cable lock by turning the

adapter to the left or right, and then remove the

adapter.

18

S-14Nm

7-lOh.lbs.

12 ln~v~rnent panel cover. lower

13 Hearer control assembly w,tallatlon screw

14 Meter bezel

15 Combination meter

16 Speedometer cable adapter

17 Comblnawn meterwr~ng harness connec-

. to1 co”“ectlo”s

16 Speaker amlsh (R H )

19 Speaker RHI e

20 S\de defroster grllla 21 Clock 01 plug

22 Steering shaft mount,ng bolt and nut

23 Ins!rument panel mounting bolts

24 Instrument panel assembly

9315og20 Fig. 22 Exploded view of the instrument panel (2 of 2)-1990-92 Mi-

rage

Fig. 24

1. Hood lock release handle

2. Knee protactor plug

3. Knee protector assembly

4 Column cover

5. Meter bezel

6. Combination meter

7. Door mrror control swich or plug

6. Auto-CNISO control mam swtch. fog

hght swtch M plug

0. Stde av outlet assembly

10 Radio and tape player 11. Cup holder

12. Heater control panel

13. Heater control assembly

14. Glove box

15 Front passenger’s 81, bag module

assembly

16. Steerq column assembly

lnstallatlon bon

17. Harness connector

16. Instrument panel assembly

19 Grommet

Exploded view of the instrument panel-l 997-00 Mirage

9. Remove the radio trim plate.

IO. Remove the radio retainers and the radio from

the console. Disconnect the electrical harness and

the antenna lead from the radio and remove it from

the vehicle.

11. Remove the center air outlet assembly.

12. If equipped, remove the screw retainers from

each dial knob on the center cluster. Gently pull the

dial knobs from the center cluster panel assembly.

13. Remove the glove compartment by pushing

the stoppers toward the rear of the vehicle to unlock

them, then remove the glove compartment assembly.

14. Remove the right and left speaker covers.

Disconnect and remove the speakers from the instru-

ment panel assembly.

15. Remove the heater control assembly retaining

screws and detach the harness connectors and ca-

bles. Remove the heater control assembly from the

vehicle. , 16. Remove any necessary ducts taking note of

their orientation,

17. Remove the steering shaft mounting bolts

and allow the steering wheel to rest on the front seat

cushion, Make sure no harness wires or connections

are being pulled or stretched.

18. Remove the instrument panel retaining bolts,

label and detach all electrical harness connectors.

19. Remove the instrument panel from the vehi-

cle. Disassemble components as required.

20. Install the instrument panel into the vehicle,

reattach all harness connections and install retaining

bolts. Before installing bolts, make sure the electrical

harness wires were not pinched during instrument

panel installation.

21. The installation is the reverse of removal.

Page 376 of 408

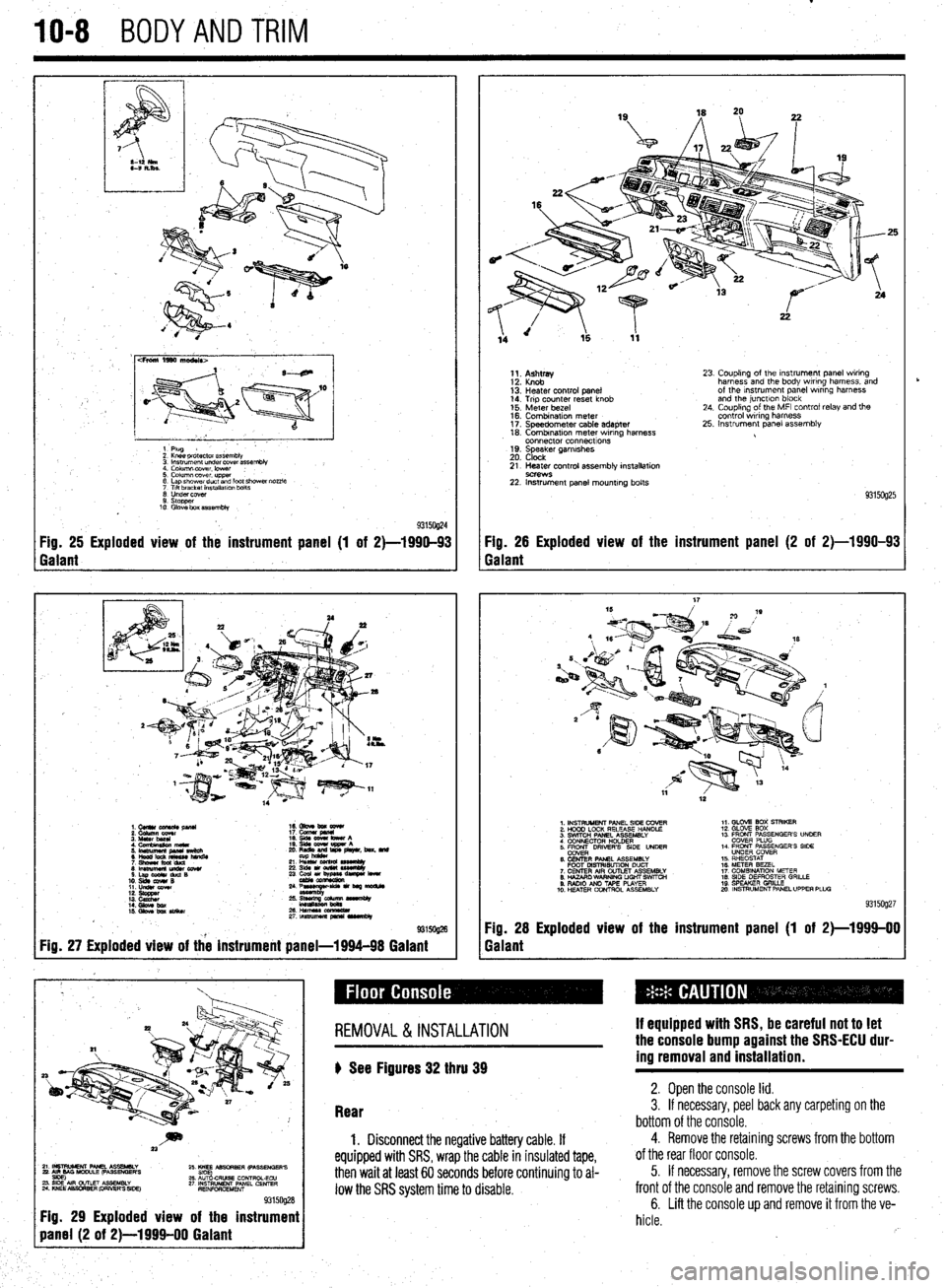

IO-8 BODYANDTRIM

cFroni 1990 ma&Is>

1 Plug

2 Knee pr&ctor assembb

3 lnsuumen~ under covet assembly

4. Column lxwer. lower :

5. Column cover upper

6 Lap shower duct and foot shcwai nozzle

7 Ttlt bracket installalm bolts

0 Undercover

9. stopper

10 Glove box assembly

93150@4 Fig. 25 Exploded view of the instrument panel (1 of 2)-1990-93 Fig. 26 Exploded view of the instrument panel (2 of 2)-1990-93

Galant Galant

1.CUllUCU+RC&pllU 16. Gbve bm eewr

i: iiiikz!!T 17. cucw gmnl

4. Cfnnbinuion meta 19. qds cww bww A

5 ‘~fiJzg%L L: ,“zr&, beat. md

21 L% sssemuy

8lmwmemu&cowr 236&1ou(W~

S.LapOdrduQB

10. slds cw4# B 23 ~u,~e-

11. LIdsI corn

::: s%ZZ

14. Gbw bx / ;:+q-=:-

kmasa

IS. Gkw ba SIiikw 2&HWSSCCl!ZL

2rtnsmlmuapr*lrvrnbly

@ma

Fig. 27 Exploded view of the instrument panel-1994-98 Galant

1;. p;;w

13: Heater control panel

14. Trip counter reset knob

15. Meter bezel

16. Combination meter

17. Speedometer cable adapter

18. Combrnatron meter wiring harness

connector connecttons

19. Speaker garnrshes

20. Clock 23. Coupling of the Instrument panel wiring

harness and the body wiring harness, and

of the Instrument panel wrring harness

and the junctlon block

24. Coupling of the MFI control relay and the

control wiring harness

25. Instrument panel assembly

21. Heater control assembly installation

9C?WS 22. Instrument panel mounting bolts

93150925

1. INSTRUMENT PANEL SIDE COVER

2. HOOD LOCK RELEASE HANDLE

3. SWITCH PANEL ASSEMBLY

4 CONNECTOR H+DER

5. ER DRIVERS SIDE UNDER

6. CENTER PANEL ASSEMBLY

FOOT MSTRISUTION DUCT

7. CENTER AIR OUTLET ASSEMBLY

8. HAZARO WARNING LIGHT SWfTCti

9. RADIO AN0 TAPE PLAYER

10. H!ZATER CONTROL ASSEMBLY 1,. GLOV2 BOX STRIKER

12. GLOVE SOX

13 FRONT PASSENGER’S UNOER

COVER PLUG

14. FRONT PASSENGER’S SIDE

UNDER COVER

15. RHEOSTAT

16. METER BEZEL

17. COMBINATION METER

18. SIDE DEFROSTER GRILLE

19 SPEAKER GRILLE

mo. INSTRUMENT PANEL UPPER PLUG

93159927

Fig. 28 Exploded view of the instrument panel (1 of 2)-1999-00

Galant

~~~~~~~~~

Fig. 29 Exploded view of the instrument

REMOVAL &INSTALLATION

) See Figures 32 thru 39 If equipped with SRS, be careful not to let

the console bump against the SRS-ECU dur-

ing removal and installation.

Rear 2. Open the console lid. 3. If necessary, peel back any carpeting on the

bottom of the console.

1. Disconnect the negative battery cable. If

equipped with SRS, wrap the cable in insulated tape,

then wait at least 60 seconds before continuing to al-

low the SRS system time to disable.

4. Remove the retaining screws from the bottom

of the rear floor console.

5. If necessary, remove the screw covers from the

front of the console and remove the retaining screws.

6. Lift the console up and remove it from the ve-

hicle.

rb

Page 380 of 408

.

1042 BODYANDTRIM

P

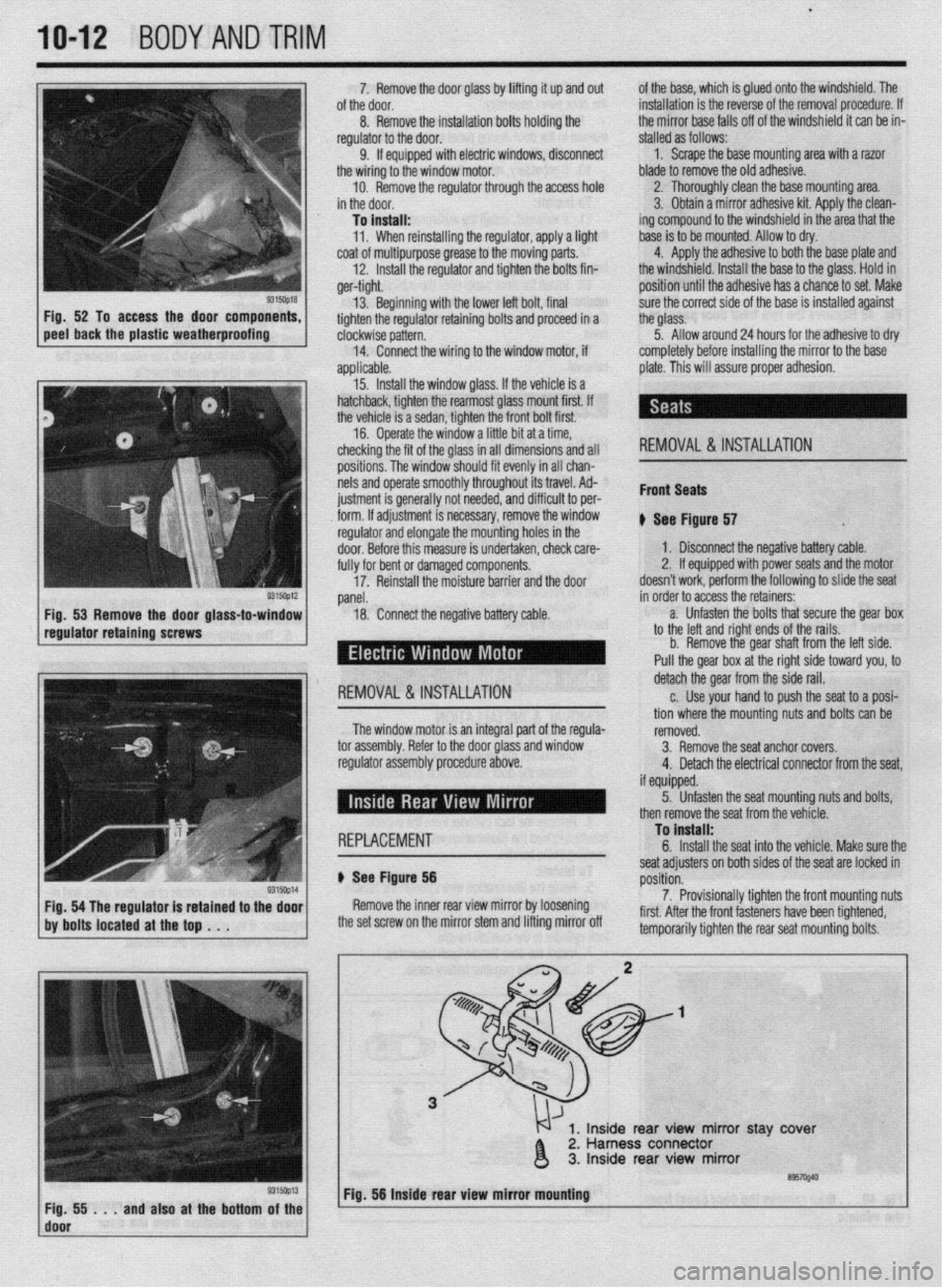

I. i%lllUVt: LIE UUUI yldbb Uy lllllll!J It up ana out ot me ease, wnicn IS glueo onto tne wmasnlela. 1 ne

of the door.

installation is the reverse of the removal procedure. If

8. Remove the installation bolts holding the

the mirror base falls off of the windshield it can be in-

regulator to the door.

stalled as follows:

I

9. If equipped with electric windows discnnnad

1. Scrape the base mounting area with a razor

LllC vvllllly L” t,te Wlll”“W lll”l”l.

blade to remove the old adhesive.

I 10. Remove the regulator through the access hole

2. Thoroughly clean the base mounting ara.

’ in the door.

3. Obtain a mirror adhesive kit. Apply the clean-

To install:

ing compound to the windshield in the area that the

11. When reinstalling the regulator, apply a light

base is to be mounted. Allow to dry.

coat of multipurpose grease to the moving parts.

4. Apply the adhesive to both the base plate and

12. Install the regulator and tighten the bolts fin-

the windshield. Install the base to the glass. Hold in

ger-tight.

position until the adhesive has a chance to set. Make

5315oQ18 Fig. 52 To access the door components,

peel back the plastic weatherproofing 13. Beginning with the lower left bolt, final

tighten the regulator retaining bolts and p

clockwise pattern.

14.

applic

+r roceed in a

Connect the wiring to the window motor, if

able.

Install the window glass. If the vehicle is a

lack, tighten the rearmost glass mount first. If

hicle is a sedan, tighten the front bolt first.

.

13. hatcht

the ve’

16. Uperate the window a little bit at a time,

checking the fit of the glass in all dimensions and all

positions. The window should fit evenly in all chan-

nels and operate smoothly throughout its travel. Ad-

ius~ment is rener;IIIv not needed. and diffirlllf +n nor- . ._ ~ _.._. - ., _.

___.-, - - _ lll”“ll I” pm

i&h. If adiustment is necessarv, remove thp win&N I..” . . . ..“1.. regulator and elongate the mointing holes in the

door. Before this measure is undertaken, check care-

fully for bent or damaged components.

17. Reinstall the moisture barrier and the door sure the correct side of the base is installed against

the glass.

5. Allow around 24 hours for the adhesive to dry

completely before installing the mirror to the base

plate. This will assure proper adhesion.

REMOVAL & INSTALLATION

Front Seats

* err ei

I ovv rlgure 57 .

1, Disconnect the negative battery cable.

2. If equipped with power seats and the motor

doesn’t work, perform the following to slide the seat

panel.

18. Conned the negative battery Cable. in order to acdess the retainers:

-

a. Unfasten the bolts that secure the gear box

to the left and right ends of the rails.

b. Remove the gear shaft from the left side.

Pull the gear box at the right side toward you, to

I REMOVAL & INSTALLATION detach the gear from the side rail.

c. Use your hand to push the seat to a posi-

tion where the mounting nuts and bolts can be

The window motor is an integral part nf the renlrla-

romnvPrl

-’ .“- ‘-J-.- tor assembly. Refer to the door Glass and window

regulator assembly procedure above. IYII,“.““. 3. Remove the seat anchor covers.

4. Detach the electrical connector from the seat,

if m~innd I I, “y”y~Y”. 5. Unfasten the seat mountina nuts and bolts.

1 REPLACEMENT To install:

c

b Ser f Floure 56

Yap- ~~

Remove the inner rear view mirror by loosening

the set screw on the mirror stem and lifting mirror off seat adjusters on both sides of the seat are locked in

rmritinn p”3111”ll.

7. Provisionally tighten the front mounting nuts

first. After the front fasteners have been tightened,

tomnnr.,rilw tinhton thn co.-ar co.,+ m qunting bolts. then remove the seat from the vehicle.

1, Inside rear view mirror stay ‘cover

2. Harness connector

3. Inside rear view mirror

’ ~;f!i!i...andalsoatthebottom~~~~ Fig. 56 Inside rear view mirror mbuntlng

I