check engine MITSUBISHI DIAMANTE 1900 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 84 of 408

ENGlNEANDENGlNEOVERHAiL 3-23

8. Remove the camshaft and silent shaft timing

belts. Refer to the timing belt procedure in this sec-

tion

9. Remove the A/C belt idler pulley and pulley

bracket.

10. Remove the alternator brace,

11. Remove the water pump, gasket and O-ring

where the water inlet pipe(s) joins the pump.

To install:

12. Thoroughly clean both gasket surfaces of the

water pump and block.

13. Install a new O-ring into the groove on the

front end of the water inlet pipe and wet with clean

antifreeze only. Do not apply oils or grease to the O-

ring.

14. Using a new gasket, install the water pump

assembly. Tighten bolts with the head mark 4 to 10

ft Ibs. (14 Nm) and bolts with the head mark 7 to 18

ft. Ibs. (24 Nm).

15. Install the A/C pulley and pulley bracket,

16. Install the timing belts. Refer to the timing

belt procedure in this section.

17. Install the engine drive belts.

18. Install the engine mount bracket.

19. Install the engine undercover,

20. Fill the system with coolant.

21. Connect the negative battery cable, run the

vehicle until the thermostat opens and fill the radiator

completely.

22. Once the vehicle has cooled, recheck the

coolant level.

3.OL and 3.5L Engines

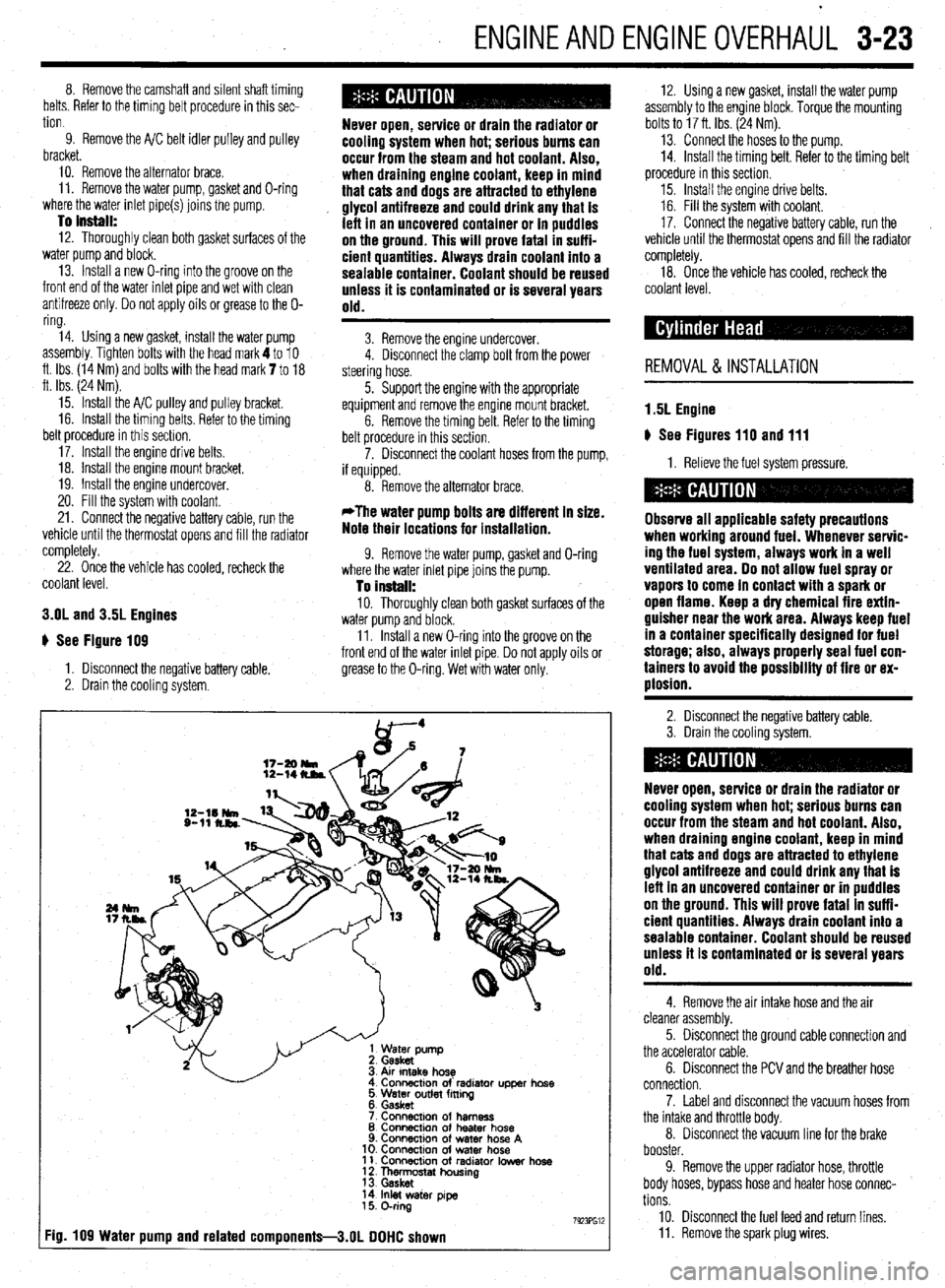

# See Figure 109

1. Disconnect the negative battery cable,

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the engine undercover.

4. Disconnect the clamp bolt from the power

steering hose.

5. Support the engine with the appropriate

equipment and remove the engine mount bracket.

6. Remove the timing belt. Refer to the timing

belt procedure in this section.

7. Disconnect the coolant hoses from the pump,

if equipped.

8. Remove the alternator brace.

*The water pump bolts are different in size.

Note their locations for installation.

9. Remove the water pump, gasket and O-ring

where the water inlet pipe joins the pump.

To install: 10. Thoroughly clean both gasket surfaces of the

water pump and block.

11. Install a new O-ring into the groove on the

front end of the water inlet pipe. Do not apply oils or

grease to the O-ring. Wet with water only.

Atr Intake hose

Connactlon of’ radlator upper hose

5 Water outlet fming

6. Gasket

7 Connacmn of harness

8 Connection of heater hose

9. Connection of water hose A

10. ConnectIon of water hose

11. Connection of radiator Iowar hose

1 f Thn&ostat housing

14 Inlet water pye

15 O-ring

7923Fw :ig. 109 Water pump and related components-3.01 DOHC shown

12. Using a new gasket, install the water pump

assembly to the engine block. Torque the mounting

bolts to 17 ft. Ibs. (24 Nm).

13. Connect the hoses to the pump.

14. Install the timing belt. Refer to the timing belt

procedure in this section.

15. Install the engine drive belts.

16. Fill the system with coolant.

17. Connect the negative battery cable, run the

vehicle until the thermostat opens and fill the radiator

completely.

18. Once the vehicle has cooled, recheck the

coolant level.

REMOVAL & INSTALLATION

1.5L Engine

u See Figures 110 and 111

1. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect the negative battery cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4. Remove the air intake hose and the air

cleaner assembly.

5. Disconnect the ground cable connection and

the accelerator cable.

6. Disconnect the PCV and the breather hose

connection.

7. Label and disconnect the vacuum hoses from

the intake and throttle body.

8. Disconnect the vacuum line for the brake

booster.

9. Remove the upper radiator hose, throttle

body hoses, bypass hose and heater hose connec-

tions

10. Disconnect the fuel feed and return lines.

11. Remove the spark plug wires.

Page 85 of 408

3-24 ENGINEANDENGINEOVERHAUL

Intake side Front of engine

e

Exhaust side

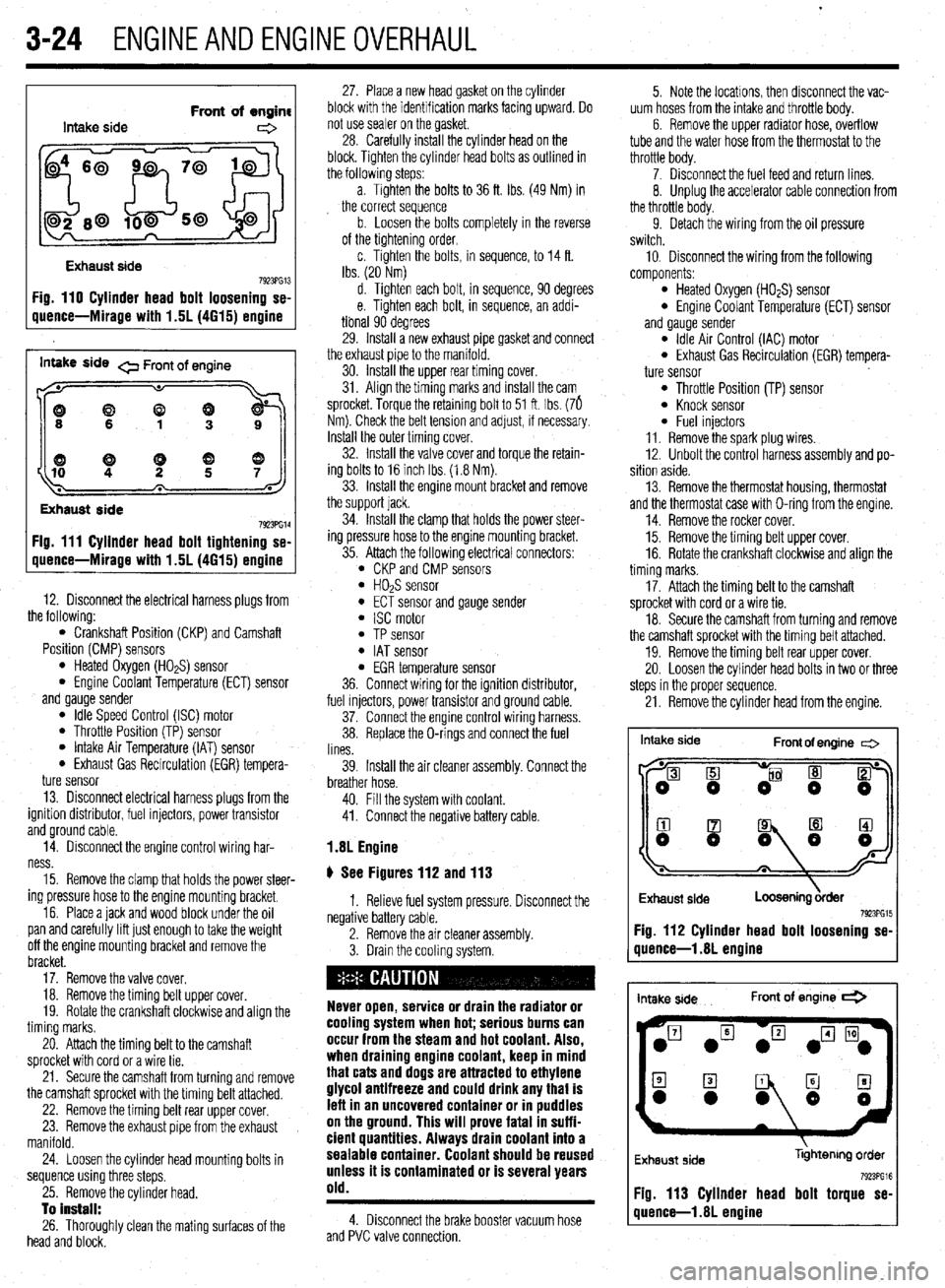

7923PG13 Fig. 110 Cylinder head bolt loosening se-

uuence-Mirage with 1.5L (4615) ermine

inwe side 0 Front of engine

((9

Exhaust side

7923PG14 Fig. 111 Cyllnder head bolt tightening se-

quence-Mirage with 1.5L (4615) engine

12. Disconnect the electrical harness plugs from

the following:

l Crankshaft Position (CKP) and Camshaft

Position (CMP) sensors

l Heated Oxygen (HO*S) sensor l Engine Coolant Temperature (ECT) sensor

and gauge sender

l Idle Speed Control (ISC) motor l Throttle Position (TP) sensor l Intake Air Temperature (IAT) sensor l Exhaust Gas Recirculation (EGR) tempera-

ture sensor

13. Disconnect electrical harness plugs from the

ignition distributor, fuel injectors, power transistor

and ground cable.

14. Disconnect the engine control wiring har-

ness.

15. Remove the clamp that holds the power steer-

ing pressure hose to the engine mounting bracket.

16. Place a jack and wood block under the oil

pan and carefully lift just enough to take the weight

off the engine mounting bracket and remove the

bracket.

17. Remove the valve cover.

18. Remove the timing belt upper cover.

19. Rotate the crankshaft clockwise and align the

timing marks.

20. Attach the timing belt to the camshaft

sprocket with cord or a wire tie.

21. Secure the camshaft from turning and remove

the camshaft sprocket with the timing belt attached.

22. Remove the timing belt rear upper cover.

23. Remove the exhaust pipe from the exhaust

manifold.

24. Loosen the cylinder head mounting bolts in

sequence using three steps.

25. Remove the cylinder head.

To install:

26. Thoroughly clean the mating surfaces of the

head and block. 27. Place a new head gasket on the cylinder

block with the identification marks facing upward. Do

not use sealer on the gasket.

28. Carefully install the cylinder head on the

block. Tighten the cylinder head bolts as outlined in

the followlng steps:

a. Tighten the bolts to 36 ft. Ibs. (49 Nm) in

the correct sequence

b. Loosen the bolts completely in the reverse

of the tightening order,

c. Tighten the bolts, in sequence, to 14 ft.

Ibs. (20 Nm)

d. Tighten each bolt, in sequence, 90 degrees

e. Tighten each bolt, in sequence, an addi-

tional 90 degrees

29. Install a new exhaust pipe gasket and connect

the exhaust pipe to the manifold.

30. Install the upper rear timing cover.

31. Align the timing marks and install the cam

sprocket. Torque the retaining bolt to 51 ft. Ibs. (76

Nm). Check the belt tension and adjust, if necessary.

Install the outer timing cover.

32. Install the valve cover and torque the retain-

ing bolts to 16 inch Ibs. (1.8 Nm).

33. Install the engine mount bracket and remove

the support jack.

34. Install the clamp that holds the power steer-

ing pressure hose to the engine mounting bracket.

35. Attach the following electrical connectors:

l CKP and CMP sensors l HOPS sensor l ECT sensor and gauge sender l ISC motor l TP sensor l IAT sensor l EGR temperature sensor

36. Connect wiring for the ignition distributor,

fuel injectors, power transistor and ground cable.

37. Connect the engine control wiring harness.

38. Replace the O-rings and connect the fuel

lines.

39. Install the air cleaner assembly. Connect the

breather hose.

40. Fill the system with coolant.

41. Connect the negative battery cable.

1.8L Engine

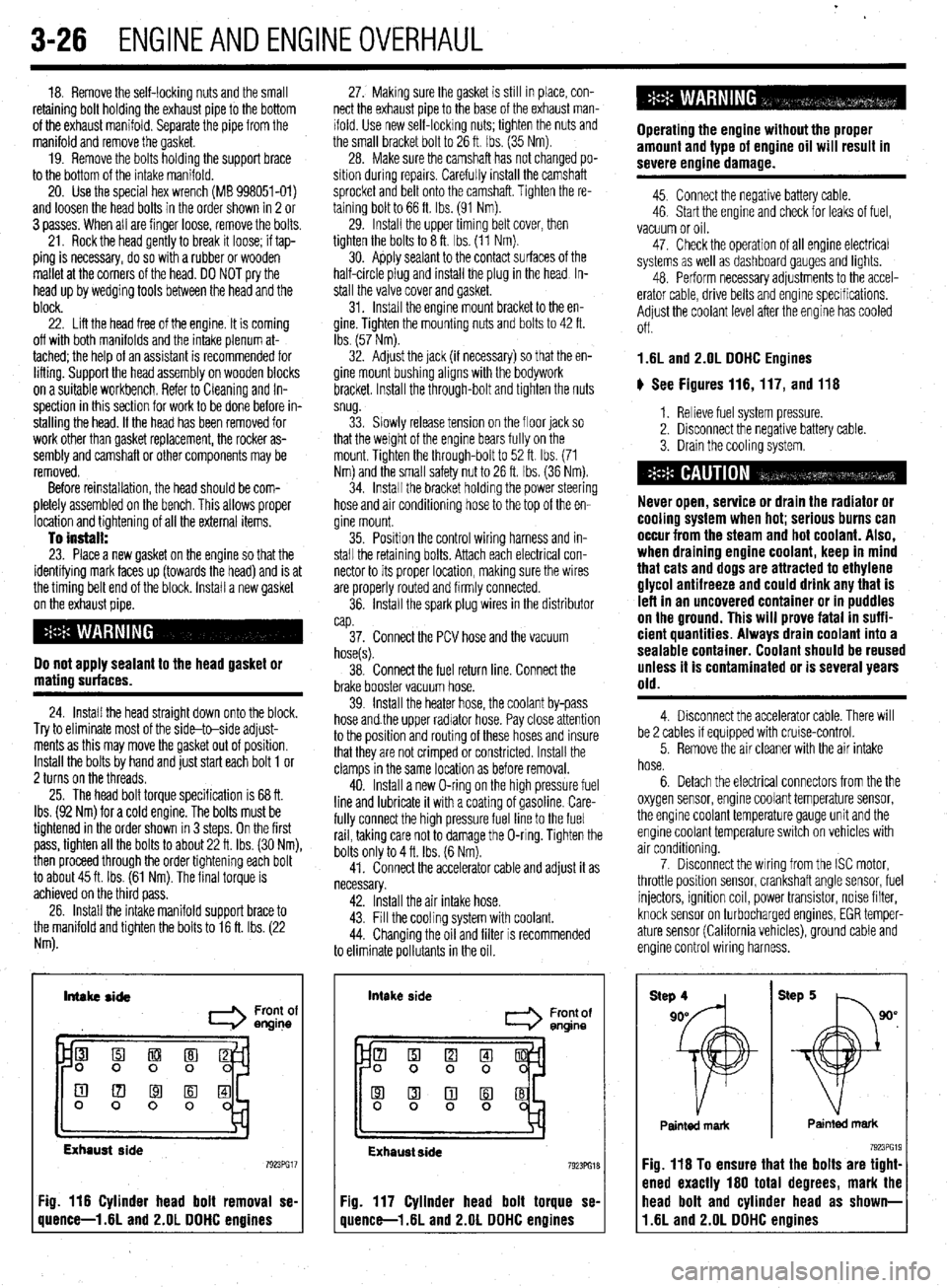

# See Figures 112 and 113

1. Relieve fuel system pressure. Disconnect the

negative battery cable.

2. Remove the air cleaner assembly.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

lefl in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4. Disconnect the brake booster vacuum hose

and PVC valve connection. 5. Note the locations, then disconnect the vac-

uum hoses from the intake and throttle body.

6. Remove the upper radiator hose, overflow

tube and the water hose from the thermostat to the

throttle body.

7. Disconnect the fuel feed and return lines.

8. Unplug the accelerator cable connection from

the throttle body.

9. Detach the wiring from the oil pressure

switch.

10, Disconnect the wiring from the following

components:

l Heated Oxygen (HO*S) sensor l Engine Coolant Temperature (ECT) sensor

and gauge sender

l Idle Air Control (IAC) motor l Exhaust Gas Recirculation (EGR) tempera-

ture sensor

l Throttle Position (TP) sensor l Knock sensor l Fuel injectors

11. Remove the spark plug wires.

12. Unbolt the control harness assembly and po-

sition aside.

13. Remove the thermostat housing, thermostat

and the thermostat case with O-ring from the engine.

14. Remove the rocker cover.

15. Remove the timing belt upper cover.

16. Rotate the crankshaft clockwise and align the

timing marks.

17. Attach the timing belt to the camshaft

sprocket with cord or a wire tie.

18. Secure the camshaft from turning and remove

the camshaft sprocket with the timing belt attached.

19. Remove the timing belt rear upper cover.

20. Loosen the cylinder head bolts in two or three

steps in the proper sequence.

21. Remove the cylinder head from the engine.

Intake side

Front of engine c=>

I

Exhaust side

Loosening &der 7923PG15 Fig. 112 Cylinder head bolt loosening se-

quence-l .8L engine

intake side Front of engine *

Exhaust side libhtenng order

Fig. 113 Cylinder head bolt torque se-

quence-l .8L engine

Page 87 of 408

3-26 ENGINEANDENGINEOVERHAUL

18. Remove the self-locking nuts and the small

retaining bolt holding the exhaust pipe to the bottom

of the exhaust manifold. Separate the pipe from the

manifold and remove the gasket.

19. Remove the bolts holding the support brace

to the bottom of the intake manifold.

20. Use the special hex wrench (MB 998051-01)

and loosen the head bolts in the order shown in 2 or

3 passes. When all are finger loose, remove the bolts.

21. Rock the head gently to break it loose; if tap-

ping is necessary, do so with a rubber or wooden

mallet at the corners of the head. DO NOT pry the

head up by wedging tools between the head and the

block.

22. Lift the head free of the engine. It is coming

off with both manifolds and the intake plenum at-

tached; the help of an assistant is recommended for

lifting. Support the head assembly on wooden blocks

on a suitable workbench. Refer to Cleaning and In-

spection in this section for work to be done before in-

stalling the head. If the head has been removed for

work other than gasket replacement, the rocker as-

sembly and camshaft or other components may be

removed.

Before reinstallation, the head should be com-

pletely assembled on the bench. This allows proper

location and tightening of all the external items.

To install: 23. Place a new gasket on the engine so that the

identifying mark faces up (towards the head) and is at

the timing belt end of the block. Install a new gasket

on the exhaust pipe.

Do not apply sealant to the head gasket or

mating surfaces.

24. Install the head straight down onto the block.

Try to eliminate most of the side-to-side adjust-

ments as this may move the gasket out of position.

Install the bolts by hand and just start each bolt 1 or

2 turns on the threads.

25. The head bolt torque specification is 68 ft.

Ibs. (92 Nm) for a cold engine. The bolts must be

tightened in the order shown in 3 steps. On the first

pass, tighten all the bolts to about 22 ft. Ibs. (30 Nm),

then proceed through the order tightening each bolt

to about 45 ft. Ibs. (61 Nm). The final torque is

achieved on the third pass.

26. Install the intake manifold support brace to

the manifold and tighten the bolts to 16 ft. Ibs. (22

Nm). 27. Making sure the gasket is still in place, con-

nect the exhaust pipe to the base of the exhaust man-

ifold. Use new self-locking nuts; tighten the nuts and

the small bracket bolt to 26 ft. Ibs. (35 Nm).

28. Make sure the camshaft has not changed po-

sition during repalrs. Carefully install the camshaft

sprocket and belt onto the camshaft. Tighten the re-

taining bolt to 66 ft. Ibs. (91 Nm).

29. Install the upper timing belt cover, then

tighten the bolts to 8 ft. Ibs. (11 Nm).

30. Apply sealant to the contact surfaces of the

half-circle plug and install the plug in the head In-

stall the valve cover and gasket.

31. Install the engine mount bracket to the en-

gine. Tighten the mounting nuts and bolts to 42 ft.

Ibs. (57 Nm).

32. Adjust the jack (if necessary) so that the en-

gine mount bushing aligns with the bodywork

bracket. Install the through-bolt and tighten the nuts

snug.

33. Slowly release tension on the floor jack so

that the weight of the engine bears fully on the

mount. Tighten the through-bolt to 52 ft. Ibs. (71

Nm) and the small safety nut to 26 ft. tbs. (36 Nm).

34. Install the bracket holding the power steering

hose and air conditioning hose to the top of the en-

gine mount.

35. Position the control wiring harness and in-

stall the retaining bolts. Attach each electrical con-

nector to its proper location, making sure the wires

are properly routed and firmly connected.

36. Install the spark plug wires in the distributor

cap.

37. Connect the PCV hose and the vacuum

hose(s).

38. Connect the fuel return line. Connect the

brake booster vacuum hose.

39. Install the heater hose, the coolant by-pass

hose and.the upper radiator hose. Pay close attention

to the position and routing of these hoses and insure

that they are not crimped or constricted. Install the

clamps in the same location as before removal.

40. Install a new O-ring on the high pressure fuel

line and lubricate it with a coating of gasoline. Care-

fully connect the high pressure fuel line to the fuel

rail, taking care not to damage the O-ring. Tighten the

bolts only to 4 ft. Ibs. (6 Nm).

41. Connect the accelerator cable and adjust it as

necessary.

42. Install the air intake hose.

43. Fill the cooling system with coolant.

44. Changing the oil and filter is recommended

to eliminate pollutants in the oil.

Intake side

I Front of

engine

Exhaust side

Fig. 116 Cylinder head bolt removal se-

quence-l .6L and 2.OL DDHC engines intake

side

Front of

entine

Exhaust side 7923PG18

Fig. 117 Cylinder head bolt torque se-

quence-l .6L and 2.OL DDHC engines Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

45. Connect the negative battery cable.

46. Start the engine and check for leaks of fuel,

vacuum or oil.

47. Check the operation of all engine electrical

systems as well as dashboard gauges and lights.

48. Perform necessary adjustments to the accel-

erator cable, drive belts and engine specifications.

Adjust the coolant level after the engine has cooled

Off.

1.6L and 2.OL DDHC Engines

ti See Figures 116,117, and 116

1. Relieve fuel system pressure.

2. Disconnect the negative battery cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4. Disconnect the accelerator cable. There will

be 2 cables if equipped with cruise-control.

5. Remove the air cleaner with the air intake

hose.

6. Detach the electrical connectors from the the

oxygen sensor, engine coolant temperature sensor,

the engine coolant temperature gauge unit and the

engine coolant temperature switch on vehicles with

air conditioning.

7. Disconnect the wiring from the ISC motor,

throttle position sensor, crankshaft angle sensor, fuel

injectors, ignition coil, power transistor, noise filter,

knock sensor on turbocharged engines, EGR temper-

ature sensor (California vehicles), ground cable and

engine control wiring harness.

Painted mark Painted mark

Fig. 116 To ensure that the bolts are tight-

ened exactly 160 total degrees, mark the

11.6L and 2.OL DDHC engines head bolt and cylinder head as shown-

Page 88 of 408

ENGlNEANDENGlNEOVERHALiL 3-27

8. Remove the upper radiator hose and the

sages thoroughly. Check the head for flatness. End to 31. Install the air cleaner and intake hose. Con-

overflow tube. end, the head should be within 0.002 in. (0.05mm) nect the breather hose.

9. Remove the spark plug cable center cover,

normally, with 0.008 in. (0.2mm) the maximum al- 32. Change the engine oil and oil filter,

then remove the spark plug cables.

lowed out of true. The total thickness allowed to be 33. Fill the system with coolant.

10. Disconnect and plug the high pressure fuel

removed from the head and block is 0.008 in.

line. 34. Connect the negative battery cable.

(0.2mm) maximum. 35. Run the vehicle until the thermostat opens,

11. Disconnect the small vacuum hoses.

23. Place a new head gasket on the cylinder and fill the radiator completely.

12. Remove the heater hose and water bypass

block with the identification marks at the front top 36. Check and adjust the idle speed and ignition

hose.

(upward) position. Make sure the gasket has the timing.

13. Remove the PCV hose.

proper identification mark for the engine. Do not use 37. Once the vehicle has cooled, recheck the

14. If turbocharged, remove the vacuum hoses,

sealer on the gasket. Replace the turbo gasket and coolant level.

water line and eyebolt connection for the oil line for

ring, if equipped.

the turbo.

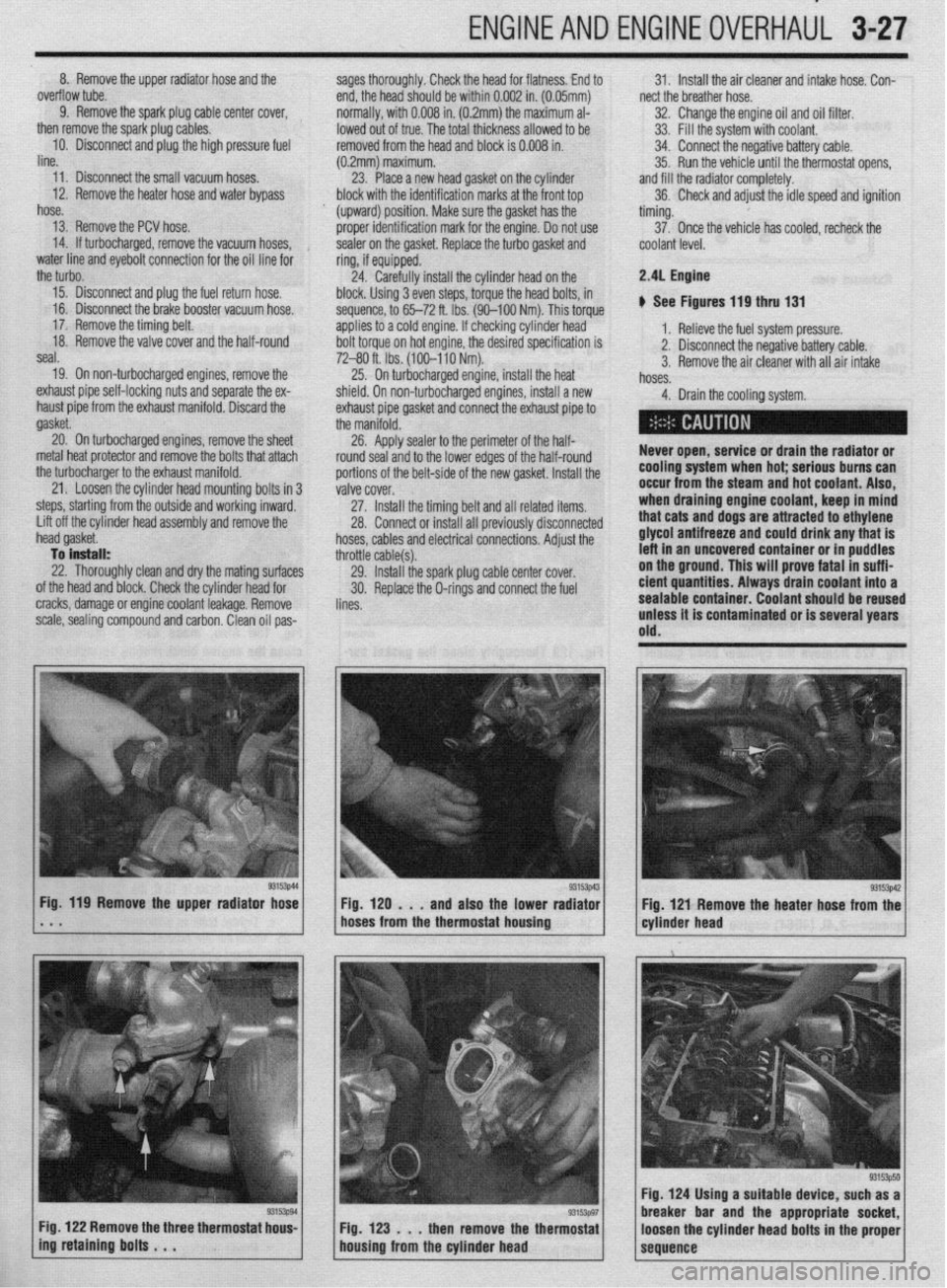

24. Carefully install the cylinder head on the 2.41 Engine

15. Disconnect and plug the fuel return hose. block. Using 3 even steps, torque the head bolts, in

16. Disconnect the brake booster vacuum hose.

sequence, to 65-72 ft. Ibs. (90-100 Nm). This torque b See Figures 119 thru 131

17. Remove the timing belt. applies to a cold engine. If checking cylinder head

18. Remove the valve cover and the half-round

bolt torque on hot engine, the desired specification is 1. Relieve the fuel system pressure.

seal.

7240 ft. Ibs. (100-110 Nm). 2. Disconnect the negative battery cable.

19. On non-turbocharged engines, remove the 3. Remove the air cleaner with all air intake

25. On turbocharged engine, install the heat

hoses.

exhaust pipe self-locking nuts and separate the ex-

shield. On non-turbocharged engines, install a new

haust pipe from the exhaust manifold. Discard the

exhaust pipe gasket and connect the exhaust pipe to 4. Drain the cooling system.

gasket.

the manifold.

20. On turbocharged engines, remove the sheet

26. Apply sealer to the perimeter of the half-

metal heat protector and remove the bolts that attach

round seal and to the lower edges of the half-round Never open, service or drain the radiator or

the turbocharger to the exhaust manifold.

portions of the belt-side of the new gasket. Install the cooling system when hot; serious burns can

21. Loosen the cylinder head mounting bolts in 3

valve cover. occur from the steam and hot coolant. Also,

steps, starting from the outside and working inward,

27. Install the timing belt and all related items. when draining engine coolant, keep in mind

Lift off the cylinder head assembly and remove the

28. Connect or install all previously disconnected that cats and dogs are attracted to ethylene

n head gasket.

hoses, cables and electrical connections. Adjust the glycol antifreeze and could drink any that is

To install:

throttle cable(s). left in an uncovered container or in puddles

22. Thoroughly clean and dry the mating surfaces

29. Install the spark plug cable center cover. on the ground. This will prove fatal in suffi-

of the head and block. Check the cylinder head for

30. Replace the O-rings and connect the fuel eient quantities. Always drain coolant into a

cracks, damage or engine coolant leakage. Remove

lines. sealable container. Coolant should be reused

scale, sealing compound and carbon. Clean oil pas- unless it is contaminated or is several years

old.

g3153p44 Fig. 119 Remove the upper radiator hose

* . . 1 Fig. 129 . . . and also the lower rad:gzi / cyl.der head g3153W

Fig 121 Remove the heater hose from the

hoses from the thermostat housing

Fig. 122 Remove the three thermostat hous-

Fig. 123 . . . then remove the thermostat

ing retaining bolts . . .

housing from the cylinder head

93153p50 Fig. 124 Using a suitable device, such as a

breaker bar and the appropriate socket,

loosen the cylinder head bolts in the proper

sequence

Page 90 of 408

ENGINEANDENGINEOVERHAUL 3-29

l HOzS sensor l ECT gauge sender l ECT sensor l MAP sensor l IAT sensor l TP sensor l IAC motor l injector harness l ignition coil l CMP sensor l EGR solenoid valve

33. Install the spark plug wires and cover,

34. Replace the O-rings and connect the fuel

lines.

35. Install the air cleaner and intake hose. Con-

nect the breather hose.

36. Fill the cooling system.

37. Connect the negative battery cable

3.01 DDHC Engine

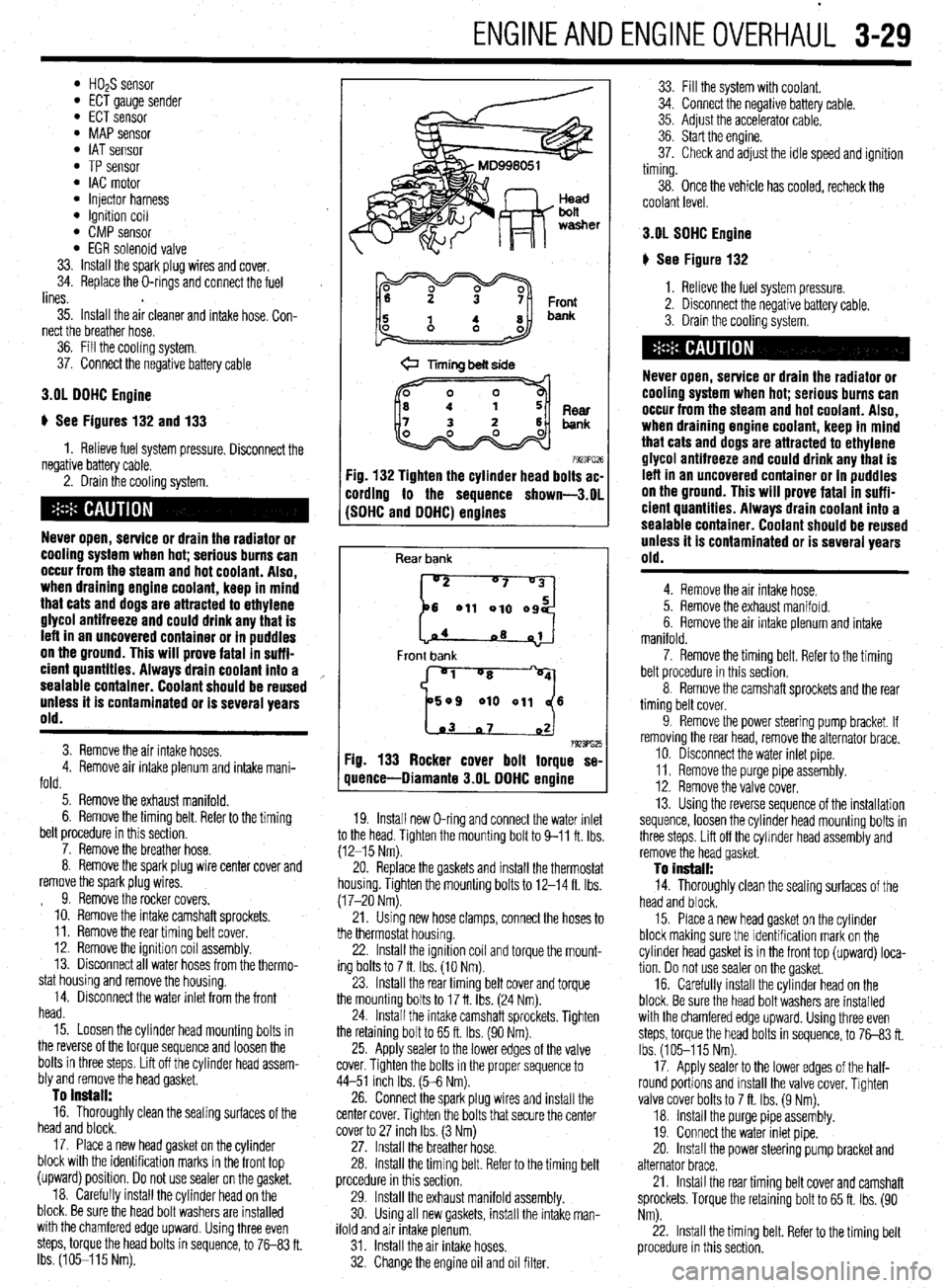

ti See Figures 132 and 133

1. Relieve fuel system pressure. Disconnect the

negative battery cable.

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantltles. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the air intake hoses.

4. Remove air intake plenum and intake mani-

fold.

5. Remove the exhaust manifold.

6. Remove the timing belt. Refer to the timing

belt procedure in this section.

7. Remove the breather hose.

8. Remove the spark plug wire center cover and

remove the spark plug wires.

9. Remove the rocker covers.

10. Remove the intake camshaft sprockets.

11. Remove the rear timing belt cover.

12. Remove the ignition coil assembly.

13. Disconnect all water hoses from the thermo-

stat housing and remove the housing.

14. Disconnect the water inlet from the front

head.

15. Loosen the cylinder head mounting bolts in

the reverse of the torque sequence and loosen the

bolts in three steps. Lift off the cylinder head assem-

bly and remove the head gasket.

To install: 16. Thoroughly clean the sealing surfaces of the

head and block.

17. Place a new head gasket on the cylinder

block with the identification marks in the front top

(upward) position. Do not use sealer on the gasket,

18. Carefully install the cylinder head on the

block. Be sure the head bolt washers are installed

with the chamfered edge upward. Using three even

steps, torque the head bolts in sequence, to 76-83 ft.

Ibs. (105-115 Nm).

@ Timing belt side

7923PG26 :ig. 132 Tighten the cylinder head bolts ac-

:ording to the sequence shown-3.01

SDHC and DDHC) engines

Rear bank

[::od

04

~8 01

Front bank

'1 "8

509 010 011 6

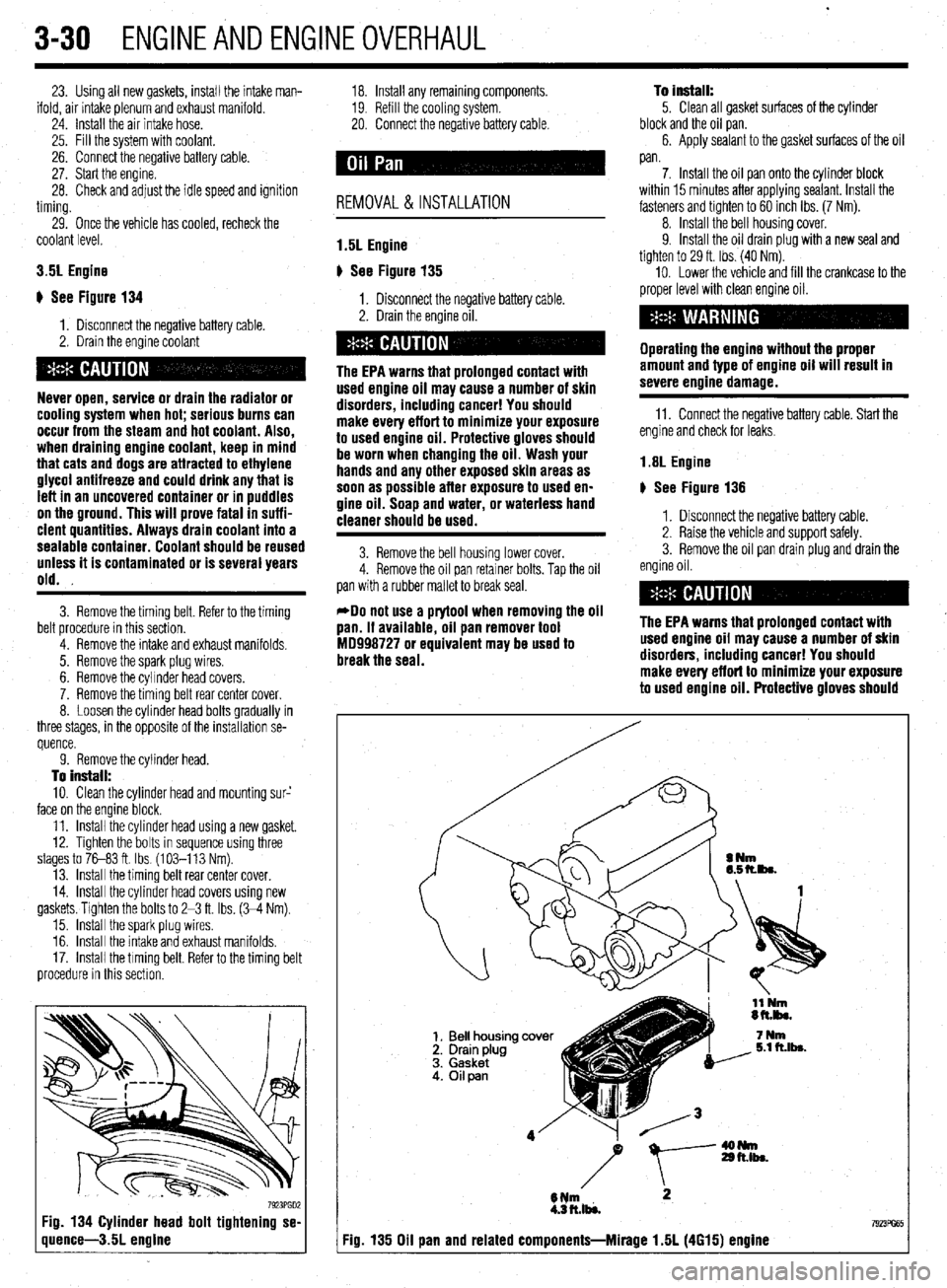

1.03 07 02 7923ffi25 Fig. 133 Rocker cover bolt torque se-

quence-Diamante 3.OL DDHC engine

19. Install new O-ring and connect the water inlet

to the head. Tighten the mounting bolt to 9-11 ft. Ibs

(12-15 Nm).

20. Replace the gaskets and install the thermostat

housing. Tighten the mounting bolts to 12-14 ft. Ibs.

(17-20 Nm).

21. Using new hose clamps, connect the hoses to

the thermostat housing.

22. Install the Ignition coil and torque the mount-

ing bolts to 7 ft. Ibs. (10 Nm).

23. Install the rear timing belt cover and torque

the mounting bolts to 17 ft. Ibs. (24 Nm).

24. Install the intake camshaft sprockets. Tighten

the retaining bolt to 65 ft. Ibs. (90 Nm).

25. Apply sealer to the lower edges of the valve

cover. Tighten the bolts in the proper sequence to

44-51 inch Ibs. (5-6 Nm).

26. Connect the spark plug wires and install the

center cover. Tighten the bolts that secure the center

cover to 27 inch Ibs. (3 Nm)

27. Install the breather hose.

28. Install the timing belt. Refer to the timing belt

procedure in this section,

29. Install the exhaust manifold assembly.

30. Using all new gaskets, install the intake man-

ifold and air intake plenum.

31. Install the air intake hoses.

32. Change the engine oil and oil filter. 33. Fill the system wrth coolant.

34. Connect the negabve battery cable.

35. Adjust the accelerator cable.

36. Start the engine.

37. Check and adjust the idle speed and ignition

timing.

38. Once the vehicle has cooled, recheck the

coolant level.

3.OL SDHC Engine

# See Figure 132

1. Relieve the fuel system pressure.

2. Disconnect the negative battery cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

alvcol antifreeze and could drink any that is

Left in an uncovered container or in puddles

on the ground. This will Drove fatal in suff i-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

Unless it is Contaminated or is several years

old.

4. Remove the air intake hose.

5. Remove the exhaust manifold.

6. Remove the air intake plenum and intake

manifold.

7. Remove the timing belt. Refer to the timing

belt procedure in this section.

8. Remove the camshaft sprockets and the rear

timing belt cover.

9. Remove the power steering pump bracket. If

removing the rear head, remove the alternator brace.

10. Disconnect the water inlet pipe.

11. Remove the purge pipe assembly.

12. Remove the valve cover,

13. Using the reverse sequence of the installation

sequence, loosen the cylinder head mounting bolts in

three steps. Lift off the cylmder head assembly and

remove the head gasket.

To install: 14. Thoroughly clean the sealing surfaces of the

head and block.

15. Place a new head gasket on the cylinder

block making sure the identification mark on the

cylrnder head gasket is in the front top (upward) loca-

tion. Do not use sealer on the gasket,

16. Carefully install the cylinder head on the

block. Be sure the head bolt washers are installed

with the chamfered edge upward. Using three even

steps, torque the head bolts in sequence, to 7683 ft.

Ibs. (105-115 Nm).

17. Apply sealer to the lower edges of the half-

round portions and install the valve cover. Tighten

valve cover bolts to 7 ft. Ibs. (9 Nm).

18. Install the purge pipe assembly.

19. Connect the water inlet pipe.

20. Install the power steering pump bracket and

alternator brace.

21. Install the rear timing belt cover and camshaft

sprockets. Torque the retaining bolt to 65 ft. Ibs. (90

Nm).

22. Install the timing belt. Refer to the timing belt

procedure in this section.

Page 91 of 408

.

3-30 ENGINEANDENGINEOVERHAUL

23. Using all new gaskets, install the intake man-

ifold, air intake plenum and exhaust manifold.

24. Install the air intake hose.

25. Fill the system with coolant.

26. Connect the negative battery cable.

27. Start the engine.

28. Check and adjust the idle speed and ignition

timing.

29. Once the vehicle has cooled, recheck the

coolant level.

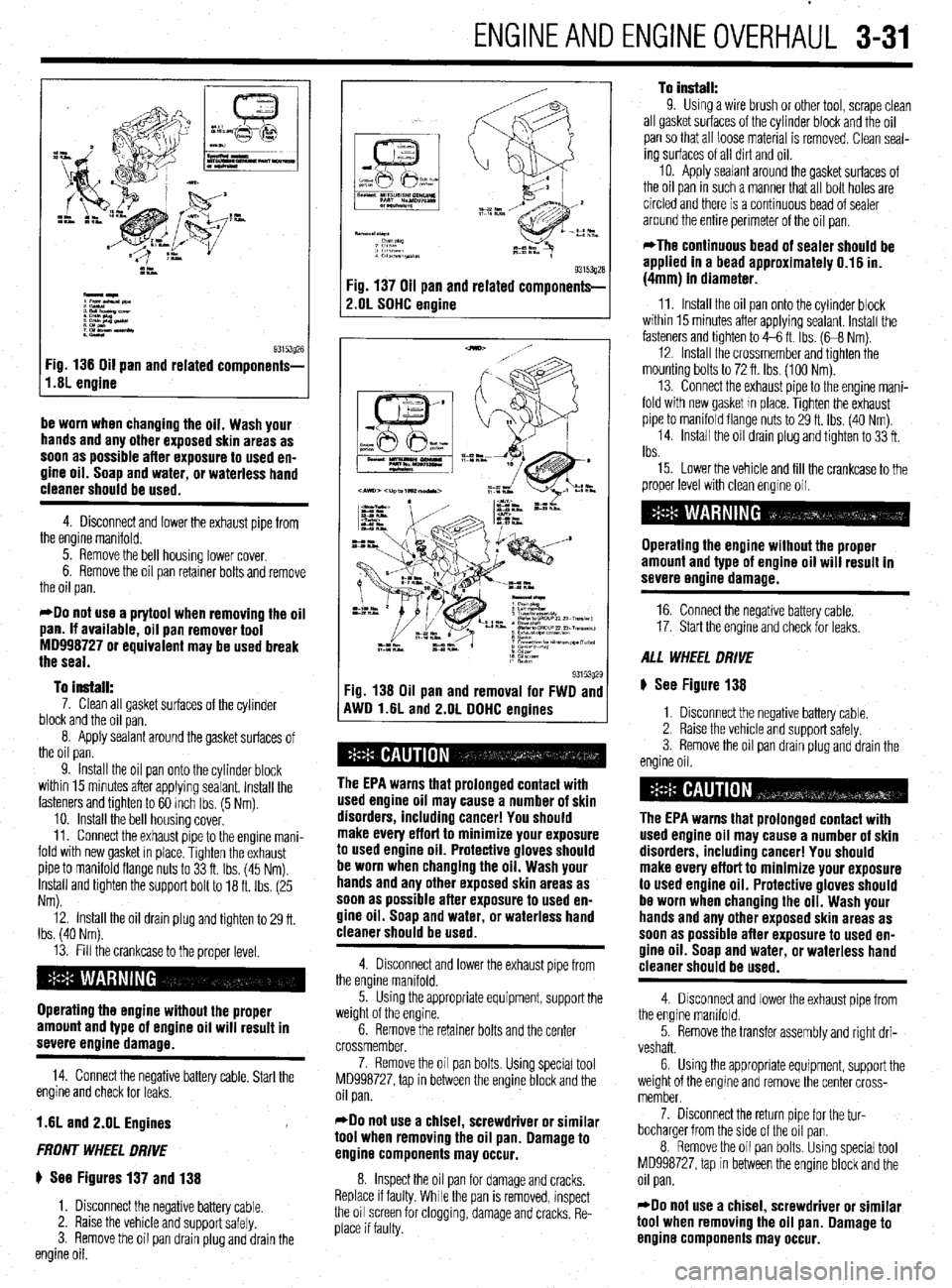

3.51 Engine

ti See Figure 134

1. Disconnect the negative battery cable.

2. Drain the engine coolant

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the timing belt. Refer to the timing

belt procedure in this section.

4. Remove the intake and exhaust manifolds.

5. Remove the spark plug wires.

6. Remove the cylrnder head covers.

7. Remove the timing belt rear center cover.

8. Loosen the cylinder head bolts gradually in

three stages, in the opposite of the installation se-

quence.

9. Remove the cylinder head.

To install: 10. Clean the cylinder head and mounting sur-’

face on the engine block.

11. Install the cylinder head using a new gasket.

12. Tighten the bolts in sequence using three

stages to 76-83 ft. Ibs. (103-113 Nm).

13. Install the timing belt rear center cover.

14. Install the cylinder head covers using new

gaskets. Tighten the bolts to 2-3 ft. Ibs. (334 Nm).

15. Install the spark plug wires,

16. Install the intake and exhaust manifolds,

17. Install the timing belt. Refer to the timing belt

procedure in this section.

7923PGD2 Fig. 134 Cylinder head bolt tightening se-

quence-3.5L engine

18. Install any remaining components.

19. Refill the cooling system.

20. Connect the negative battery cable.

REMOVAL &INSTALLATION

1.5L Engine

p See Figure 135

1. Disconnect the negative battery cable.

2. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the bell housing lower cover.

4. Remove the oil pan retainer bolts. Tap the oil

pan with a rubber mallet to break seal.

*Do not use a prytool when removing the oil

pan. If available, oil pan remover tool

MD998727 or equivalent may be used to

break the seal. To install:

5. Clean all gasket surfaces of the cylinder

block and the oil pan.

6. Apply sealant to the gasket surfaces of the oil

pan.

7. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 60 inch Ibs. (7 Nm).

8. Install the bell housing cover.

9. Install the oil drain plug with a new seal and

tighten to 29 ft. Ibs. (40 Nm).

10. Lower the vehicle and fill the crankcase to the

proper level with clean engine oil.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

11. Connect the negative battery cable. Start the

engine and check for leaks.

1.8L Engine

# See Figure 136

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Remove the oil pan drain plug and drain the

engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

I Fig. 135 Oil pan and related components-Mirage 1.5L (4615) engine

Page 92 of 408

ENGINEANDENGINEOVERHAUL 3-31

I,.s; engine g3i53g26

Fig 136 Oil pan and related components-

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

4. Disconnect and lower the exhaust pipe from

the engine manifold.

5. Remove the bell housing lower cover.

6. Remove the oil pan retainer bolts and remove

the oil pan.

*Do not use a prytool when removing the oil

pan. If available, oil pan remover tool

MD998727 or equivalent may be used break

the seal.

To install:

7. Clean all gasket surfaces of the cylinder

block and the oil pan.

8. Apply sealant around the gasket surfaces of

the oil pan.

9. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 60 inch Ibs. (5 Nm).

10. install the bell housing cover.

11. Connect the exhaust pipe to the engine mani-

fold with new gasket in place. Tighten the exhaust

pipe to manifold flange nuts to 33 ft. Ibs. (45 Nm).

Install and tighten the support bolt to 18 ft. Ibs. (25

Nm).

12. Install the oil drain plug and tighten to 29 ft.

Ibs. (40 Nm).

13. Fill the crankcase to the proper level.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

14. Connect the negative battery cable. Start the

engine and check for leaks.

1.6L and 2.OL Engines

FRONT WHEEL DRIVE

ti See Figures 137 and 138

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Remove the oil pan drain plug and drain the

engine oil.

93153gza Fig. 137 Oil pan and related components-

2.OL SOHC engine

93153g29 Fig. 138 Oil pan and removal for FWD and

AWD l.liL and 2.OL DDHC enoines

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

4. Disconnect and lower the exhaust pipe from

the engine manifold.

5. Using the appropriate equipment, support the

weight of the engine.

6. Remove the retainer bolts and the center

crossmember,

7. Remove the oil pan bolts. Using special tool

MD998727, tap in between the engine block and the

oil pan.

*Do not use a chisel, screwdriver or similar

tool when removing the oil pan. Damage to

engine components may occur.

8. Inspect the oil pan for damage and cracks.

Replace if faulty. While the pan is removed, inspect

the oil screen for clogging, damage and cracks. Re-

place if faulty.

To install: 9. Using a wire brush or other tool, scrape clean

all gasket surfaces of the cylinder block and the oil

pan so that all loose material is removed. Clean seal-

ing surfaces of all dirt and oil.

10. Apply sealant around the gasket surfaces of

the oil pan in such a manner that all bolt holes are

circled and there is a continuous bead of sealer

around the entire perimeter of the oil pan.

*The continuous bead of sealer should be

applied in a bead approximately 0.16 in.

(4mm) in diameter.

11. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 4-6 ft. Ibs. (G8 Nm).

12. Install the crossmember and tighten the

mounting bolts to 72 ft. Ibs. (100 Nm).

13. Connect the exhaust pipe to the engine mani-

fold with new gasket In place. Tighten the exhaust

pipe to manifold flange nuts to 29 ft. Ibs. (40 Nm)

14. Install the oil drain plug and tighten to 33 ft.

Ibs.

15. Lower the vehicle and fill the crankcase to the

proper level with clean engine oil.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

16. Connect the negative battery cable.

17. Start the engine and check for leaks.

ALL WHEEL DRIVE

ti See Figure 138

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Remove the oil pan drain plug and drain the

engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

4. Disconnect and lower the exhaust pipe from

the engine manifold.

5. Remove the transfer assembly and right dri-

veshaft.

6. Using the appropriate equipment, support the

weight of the engine and remove the center cross-

member.

7. Disconnect the return pipe for the tur-

bocharger from the side of the oil pan.

8. Remove the oil pan bolts. Using special tool

MD998727, tap In between the engine block and the

oil pan.

*Do not use a chisel, screwdriver or similar

tool when removing the oil pan. Damage to

engine components may occur.

Page 93 of 408

.

3-32 ENGINEANDENGINEOVERHAUL

9. Inspect the oil pan for damage and cracks.

Replace if faulty, While the pan is removed, inspect

the oil screen for clogging, damage and cracks, Re-

place if faulty.

To install: 10. Using a wire brush or other tool, scrape clean

all gasket surfaces of the cylinder block and the oil

pan so that all loose material is removed. Clean seal-

ing surfaces of all dirt and oil.

11, Apply sealant around the gasket surfaces of

the oil pan in such a manner that all bolt holes are

circled and there is a continuous bead of sealer

around the entire perimeter of the oil pan.

*The continuous bead of sealer should be

applied in a bead approximately 0.16 in.

(4mm) in diameter.

12. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 4-6 ft. Ibs. (68 Nm).

13. Install the oil return pipe using a new gasket,

if removed. Tighten retainers to 5-7 ft. Ibs. (7-10

Nm).

14. Install the left member and tighten the forward

retainer bolts to 72 ft. Ibs. (100 Nm). Tighten the

rearward left member bolts to 58 ft. Ibs. (80 Nm).

15. Install the transfer assembly and right drive-

shaft.

16. Connect the exhaust pipe from the engine

manifold with new gasket in place. Tighten the ex-

haust pipe to manifold flange nuts to 29 ft. Ibs. (40

Nm).

17. Install the oil drain plug and tighten to 33 ft.

Ibs.

18. Lower the vehicle and fill the crankcase to the

proper level with clean engine oil.

Operating the engine without the proper

amount and type of engine oil will result in

severe enaine damage.

19. Connect the negative battery cable. Start the

engine and check for leaks.

2.4L Engine

) See Figure 139

1, Disconnect the negative battery cable. -

,(L.. K%

2 mM_

-Ip

t 8*t.almcwr

:y&pn

::Elm

93153g30 Fig. 139 Oil pan and related components-

2.4L engine

2. Remove the oil pan drain plug and drain the

engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the oil dipstick and tube assembly.

4. Detach the Heated Oxygen (HOaS) sensor

connector.

5. Remove the front exhaust pipe from the vehi-

cle.

6. Remove the bell housing cover.

7. Remove the oil pan retainer bolts. Using spe-

cial tool MD998727 or equivalent, tap in between the

engine block and the oil pan.

*Do not use a prytool when removing the oil

pan. Damage to engine components may oc-

cur.

To install:

8. Apply sealant around the gasket surfaces of

the oil pan.

9. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 6 ft. Ibs. (8 Nm).

10. Install the oil drain plug and tighten to 29 ft.

Ibs. (39 Nm).

11. Install the bell housing cover, and tighten the

mounting bolts to 7 ft. Ibs. (9 Nm).

12. Install the front exhaust pipe and tighten the

bolts at the catalytic converter to 36 ft. Ibs. (49 Nm).

Tighten the nuts at the exhaust manifold to 32 ft. Ibs.

(44 Nm).

13. Reconnect the HOPS sensor connector.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

15. Connect the negative battery cable. Start the

engine and check for leaks.

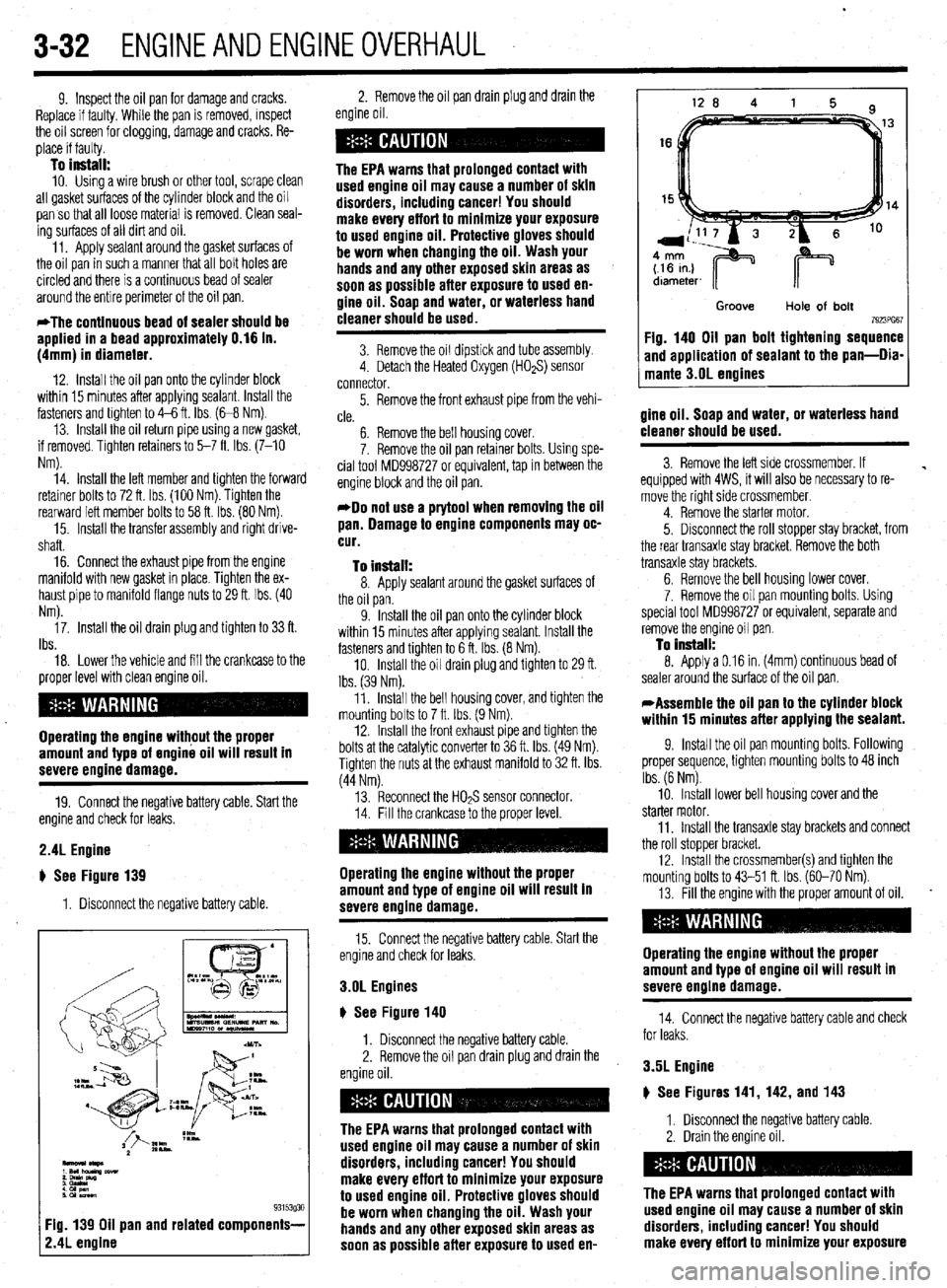

3.OL Engines

u See Figure 140

1. Disconnect the negative battery cable.

2. Remove the oil pan drain plug and drain the

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

Groove

Hole of bolt 7923PG67 Fig. 140 Oil pan bolt tightening sequence

and application of sealant to the pan-Dia-

mante 3.OL engines

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the left side crossmember. If

equipped with 4WS, it will also be necessary to re-

move the right side crossmember.

4. Remove the starter motor.

5. Disconnect the roll stopper stay bracket, from

the rear transaxle stay bracket. Remove the both

transaxle stay brackets.

6. Remove the bell housing lower cover.

7. Remove the oil pan mounting bolts. Using

special tool MD998727 or equivalent, separate and

remove the engine oil pan.

To install: 8. Apply a 0.16 in. (4mm) continuous bead of

sealer around the surface of the oil pan.

*Assemble the oil pan to the cylinder block

within 15 minutes after applying the sealant.

9. Install the oil pan mounting bolts. Following

proper sequence, tighten mounting bolts to 48 inch

Ibs. (6 Nm).

10. Install lower bell housing cover and the

starter motor.

11, Install the transaxle stay brackets and connect

the roll stopper bracket.

12. Install the crossmember and tighten the

mounting bolts to 43-51 ft. Ibs. (60-70 Nm).

13. Fill the engine with the proper amount of oil.

.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

14. Connect the negative battery cable and check

for leaks.

3.5L Engine

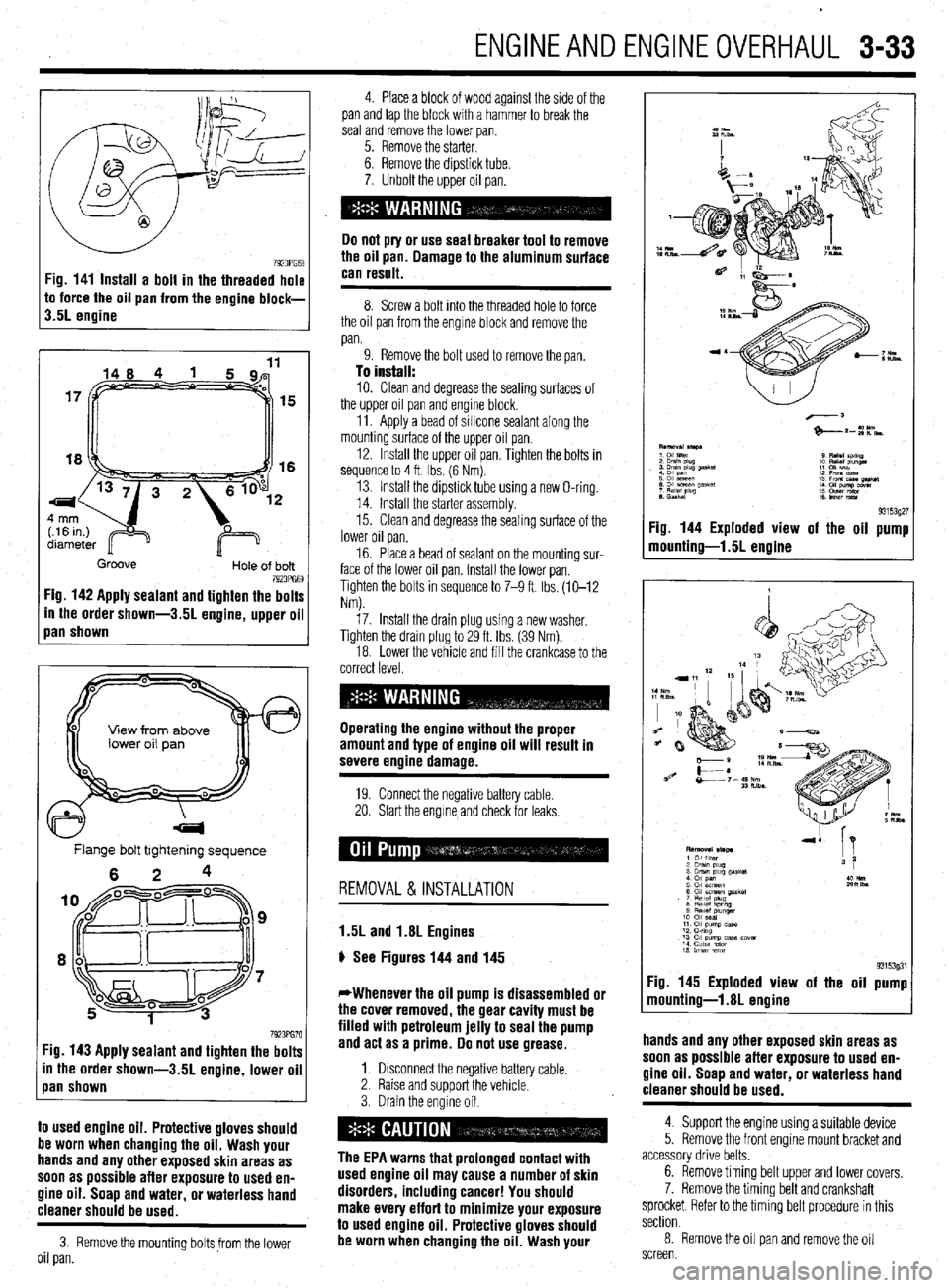

p See Figures 141, 142, and 143

1, Disconnect the negative battery cable.

2. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, includina cancer! You should

make eve’ry effort to minimize your exposure

Page 94 of 408

ENGINEANDENGINEOVERHAUL 3-33

7923PG68 Fig. 141 Install a bolt in the threaded hole

to force the oil pan from the engine block-

3.5L engine

15

16

Groove

Hole of bolt 7923PG69 Fig. 142 Apply sealant and tighten the bolts

In the order shown-3.51 engine, upper oil

Ian shown

View from above

Flange bolt tightening sequence

6 2 4

7923PG70 :ig. 143 Apply sealant and tighten the bolts

in the order shown-3.51 engine, lower oil

pan shown

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the mounting boltsfrom the lower

oil pan. 4. Place a block of wood against the side of the

pan and tap the block with a hammer to break the

seal and remove the lower pan.

5. Remove the starter.

6. Remove the dipstick tube.

7. Unbolt the upper oil pan.

Do not pry or use seal breaker tool to remove

the oil pan. Damage to the aluminum surface

can result.

8. Screw a bolt into the threaded hole to force

the oil pan from the engine block and remove the

pan.

9. Remove the bolt used to remove the pan.

To install:

10. Clean and degrease the sealing surfaces of

the upper oil pan and engine block.

11. Apply a bead of sillcone sealant along the

mounting surface of the upper oil pan.

12. Install the upper oil pan. Tighten the bolts in

sequence to 4 ft Ibs. (6 Nm).

13. Install the dipstick tube using a new O-ring.

14. Install the starter assembly.

15. Clean and degrease the sealing surface of the

lower oil pan.

16. Place a bead of sealant on the mounting sur-

face of the lower

oil pan. Install the lower pan.

Tighten the bolts in sequence to 7-9 ft. Ibs. (10-12

Nm).

17. Install the drain plug using a new washer,

Tighten the drain plug to 29 ft. Ibs (39 Nm).

18. Lower the vehicle and fill the crankcase to the

correct level.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

19 Connect the negative battery cable.

20. Start the engrne and check for leaks,

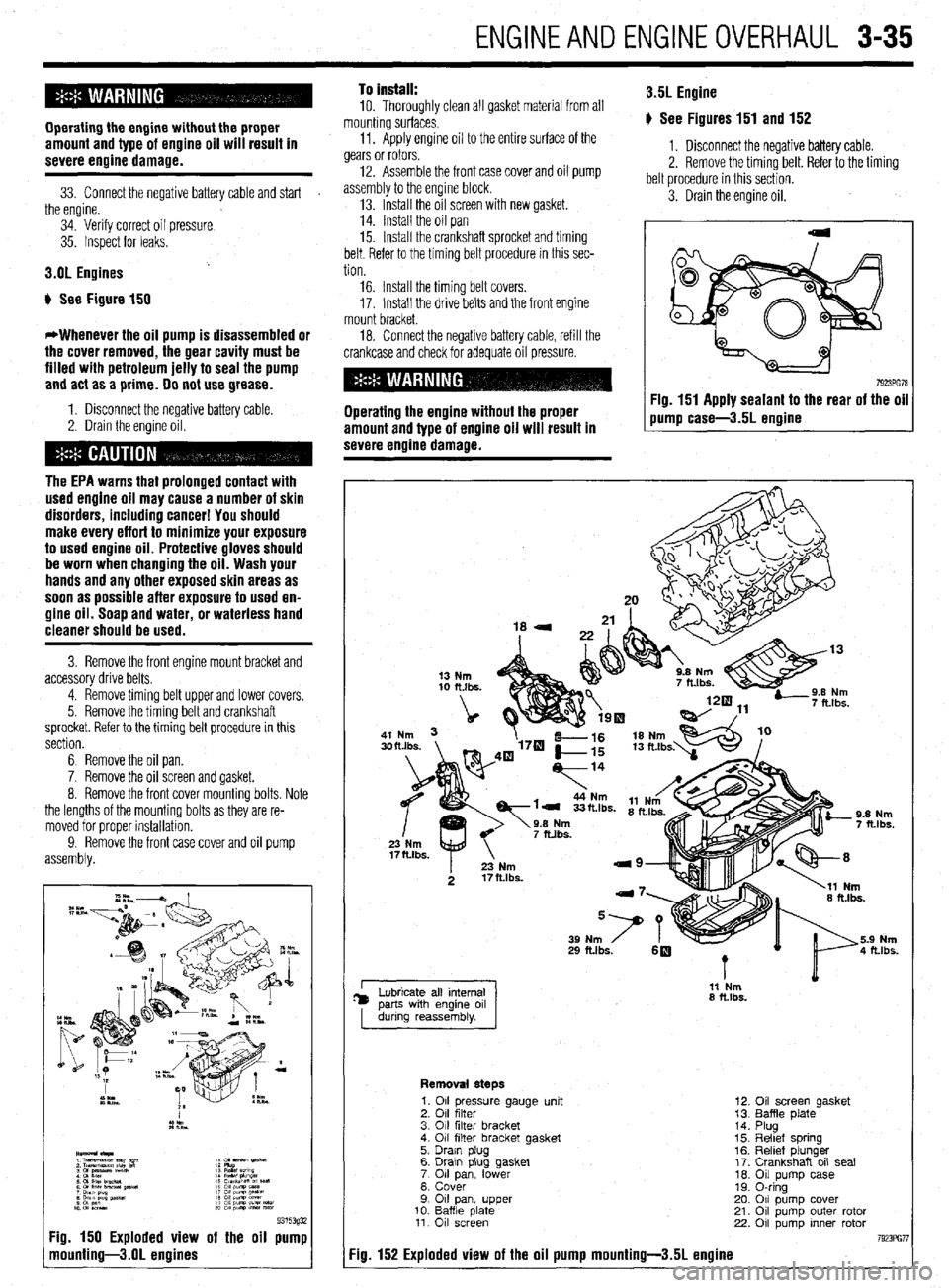

REMOVAL & INSTALLATION

1.5L and 1.8L Engines

p See Figures 144 and 145

*Whenever the oil pump is disassembled or

the cover removed, the gear cavity must be

filled with petroleum jelly to seal the pump

and act as a prime. Do not use grease.

1. Drsconnect the negative battery cable.

2. Raise and support the vehicle.

3. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

93153927 Fig. 144 Exploded view of the oil pump

mounting-l .5L engine

93153931 Fig. 145 Exploded view of the oil pump

mounting-l.81 engine

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

. . . .

cleaner snoutd be used.

4. Support the engine using a suitable device

5. Remove the front engme mount bracket and

accessory drive belts.

6. Remove timing belt upper and lower covers.

7. Remove the timing belt and crankshaft

sprocket. Refer to the timing belt procedure in this

section.

8. Remove the oil pan and remove the oil

screen.

Page 96 of 408

ENGINEANDENGINEOVERHAUL 3-35

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

33. Connect the negative battery cable and start

the engine.

34. Verify correct oil pressure

35. Inspect for leaks.

3.OL Engines

b See Figure 150

*Whenever the oil pump is disassembled or

the cover removed, the gear cavity must be

filled with petroleum jelly to seal the pump

and act as a prime. 00 not use grease.

1. Disconnect the negative battery cable.

2. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the front engine mount bracket and

accessory drive belts.

4. Remove timing belt upper and lower covers.

5. Remove the timing belt and crankshaft

sprocket. Refer to the timing belt procedure in this

section.

6 Remove the oil pan.

7. Remove the oil screen and gasket.

8. Remove the front cover mounting bolts. Note

the lengths of the mounting bolts as they are re-

moved for proper installation.

9. Remove the front

assembly. and oil pump

9315393i 7g. 150 Exploded view of the oil pump

nounting-3.01 engines

To install:

10. Thoroughly clean all gasket material from all

mounting surfaces.

11. Apply engine oil to the entire surface of the

gears or rotors.

12. Assemble the front case cover and oil pump

assembly to the engine block.

13. Install the oil screen with new gasket.

14. Install the oil pan

15. Install the crankshaft sprocket and timing

belt. Refer to the timing belt procedure in this sec-

tion 3.5L Engine

p See Figures 151 and 152

1. Disconnect the negative battery cable.

2. Remove the timing belt. Refer to the timing

belt procedure in this section.

3. Drain the engine oil.

16. Install the timing belt covers.

17. Install the drive belts and the front engine

mount bracket.

18. Connect the negative battery cable, refill the

crankcase and check for adequate oil pressure.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage. Fig. 151 Apply sealant to the rear of the oil

pump case-3.5L ermine

I 11 Nm

8 ft.lbs.

Removal steps

7g. 152 Exploded view of the oil pump mounting-3.51 engine

1. 011 pressure gauge unit

2. 011 filter

3. 011 filter bracket

4. 011 filter bracket gasket

5. Drain plug

6. Drawn plug gasket

7 011 lower pan,

8. Cover

9 011 pan, upper

10. Baffle date 11. 011 screen

12.

13.

14.

15.

16.

17.

10.

19.

20.

21.

22. Oil screen gasket

Baffle plate

Plug

Reltef spring

Relief plunger

Crankshaft oil seal

Oil pump case

0-ring

011 pump cover

011 pump outer rotor

011 pump inner rotor