engine oil capacity MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 5 of 408

1-6 GENERALINFORMATIONAND MAINTENANCE

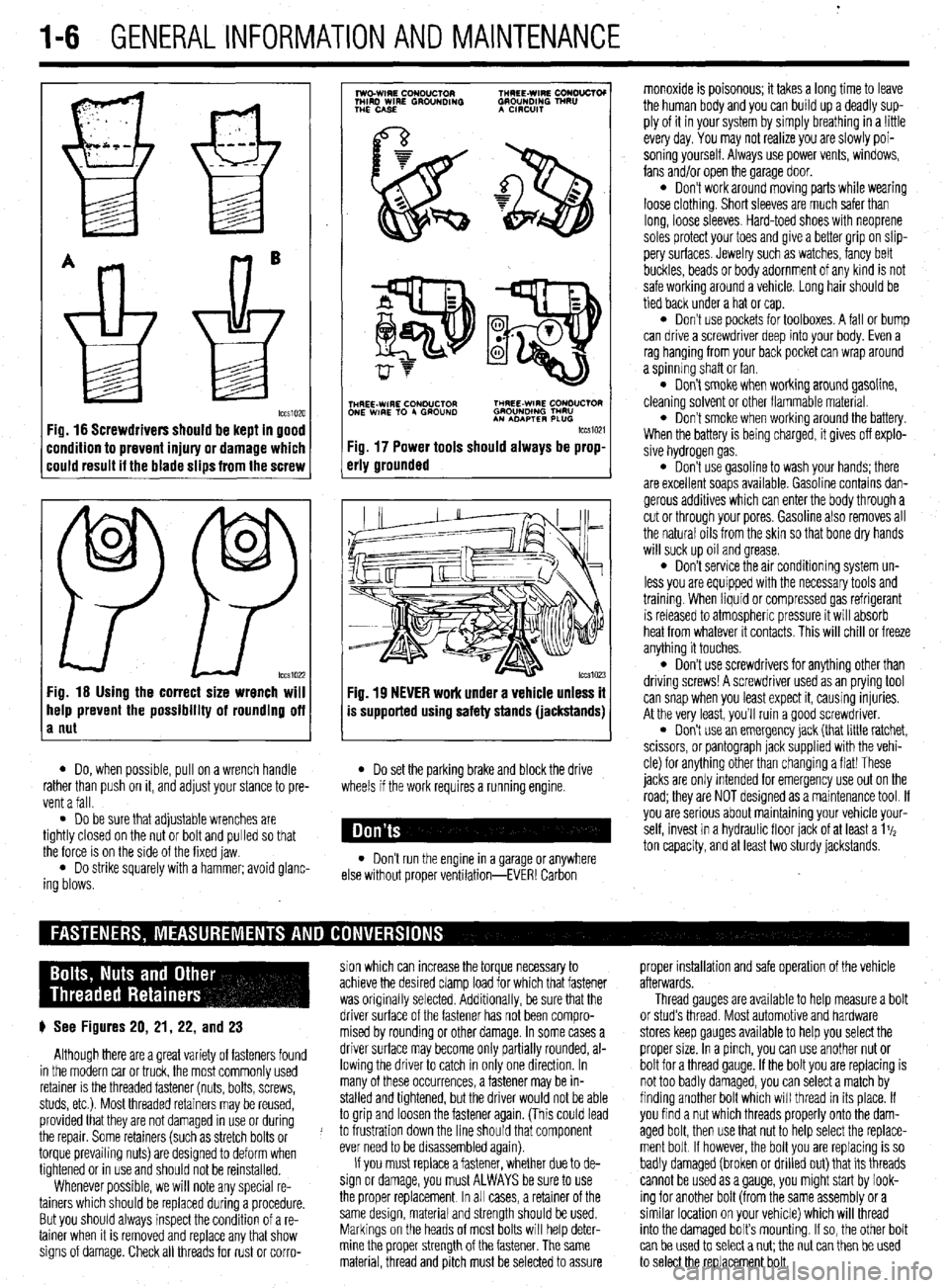

Fig. 16 Screwdrivers should be kept in good

:ondition to prevent injury or damage which

:ould result it the blade slips from the screw

0

0

PP tccs1022 Fig. 16 Using the correct size wrench will

help prevent the possibility of rounding off

a nut

7

lwo.WIRE CouDuClOR TMREE-WIRE CONO”CTOI

MIRD WIRE GROUNDING GROUNDING TNRU

THE CASE A CmxlIT

.

i$Y$$pQ

p-+

TNHREE-WIRE CONDUCTOR THREE-WIRE CONDUCTOR

ONE WIRE TO 4 GROUND GROUNOlNG TMRU

AN ADAPTER PLUG

tccm21

Fig. 17 Power tools should always be prop-

erly grounded

Fig. 19 NEVER work under a vehicle unless it

is supported using safety stands (jackstands)

l Do, when possible, pull on a wrench handle l Do set the parking brake and block the drive

rather than push on it, and adjust your stance to pre-

vent a fall. wheels if the work requires a running engine.

l Do be sure that adjustable wrenches are

tightly closed on the nut or bolt and pulled so that

the force is on the side of the fixed jaw.

l Do strike squarely with a hammer; avoid glanc-

ing blows. l Don’t run the engine in a garage or anywhere

else without proper ventilation-EVER! Carbon monoxide is poisonous; it takes a long time to leave

the human body and you can build up a deadly sup-

ply of it in your system by simply breathing in a !ittle

every day. You may not realize you are slowly poi-

soning yourself. Always use power vents, windows,

fans and/or open the garage door.

l Don’t work around moving parts while wearing

loose clothing. Short sleeves are much safer than

long, loose sleeves. Hard-toed shoes with neoprene

soles protect your toes and give a better grip on slip-

pery surfaces. Jewelry such as watches, fancy belt

buckles, beads or body adornment of any kind is not

safe working around a vehicle. Long hair should be

tied back under a hat or cap.

l Don’t use pockets for toolboxes. A fall or bump

can drive a screwdriver deep into your body. Even a

rag hanging from your back pocket can wrap around

a spinning shaft or fan.

l Don’t smoke when working around gasoline,

cleaning solvent or other flammable material.

l Don’t smoke when workrng around the battery.

When the battery is being charged, it gives off explo-

sive hydrogen gas.

l Don’t use gasoline to wash your hands; there

are excellent soaps available. Gasoline contains dan-

gerous additives which can enter the body through a

cut or through your pores. Gasoline also removes all

the natural oils from the skin so that bone dry hands

will suck up oil and grease.

l Don’t service the air conditioning system un-

less you are equipped with the necessary tools and

trainmg. When liquid or compressed gas refrigerant

is released to atmospheric pressure it will absorb

heat from whatever it contacts. This will chill or freeze

anything it touches.

l Don’t use screwdrivers for anything other than

driving screws! A screwdriver used as an prying tool

can snap when you least expect it, causing injuries.

At the very least, you’ll ruin a good screwdriver.

. Don’t use an emergency jack (that little ratchet,

scissors, or pantograph jack supplied with the vehi-

cle) for anything other than changing a flat! These

jacks are only Intended for emergency use out on the

road; they are NOT designed as a maintenance tool. If

you are serious about mamtaining your vehicle your-

self, invest in a hydraulic floor jack of at least a 1%

ton capacity, and at least two sturdy jackstands.

sion which can increase the torque necessary to proper installation and safe operation of the vehicle

achieve the desired clamp load for which that fastener afterwards.

was originally selected. Additionally, be sure that the Thread gauges are available to help measure a bolt

p See Figures 20, 21, 22, and 23 driver surface of the fastener has not been compro- or stud’s thread. Most automotive and hardware

mised by rounding or other damage. In some cases a stores keep gauges available to help you select the

Although there are a great variety of fasteners found driver surface may become only partially rounded, al- proper size. In a pinch, you can use another nut or

in the modern car or truck, the most commonly used lowing the driver to catch in only one direction. In bolt for a thread gauge. If the bolt you are replacing is

retainer is the threaded fastener (nuts, bolts, screws, many of these occurrences, a fastener may be in- not too badly damaged, you can select a match by

studs, etc.). Most threaded retainers may be reused, stalled and tightened, but the driver would not be able finding another bolt which will thread in its place. If

provided that they are not damaged in use or during to grip and loosen the fastener again. (This could lead you find a nut which threads properly onto the dam-

the repair. Some retainers (such as stretch bolts or J to frustration down the line should that component aged bolt, then use that nut to help select the replace-

torque prevailing nuts) are designed to deform when ever need to be disassembled again). ment bolt If however, the bolt you are replacing is so

tightened or in use and should not be reinstalled. If you must replace a fastener, whether due to de- badly damaged (broken or drilled out) that its threads

Whenever possible, we will note any special re- sign or damage, you must ALWAYS be sure to use cannot be used as a gauge, you might start by look-

tainers which should be replaced during a procedure. the proper replacement In all cases, a retainer of the ing for another bolt (from the same assembly or a

But you should always inspect the condition of a re- same design, material and strength should be used. similar location on your vehicle) which will thread

tainer when It is removed and replace any that show Markings on the heads of most bolts will help deter- into the damaged bolt’s mounting. If so, the other bolt

signs of damage. Check all threads for rust or corro- mine the proper strength of the fastener. The same

can be used to select a nut; the nut can then be used

material, thread and pitch must be selected to assure

to select the replacement bolt.

Page 34 of 408

GENERALINFORMATIONAND MAINTENANCE l-35

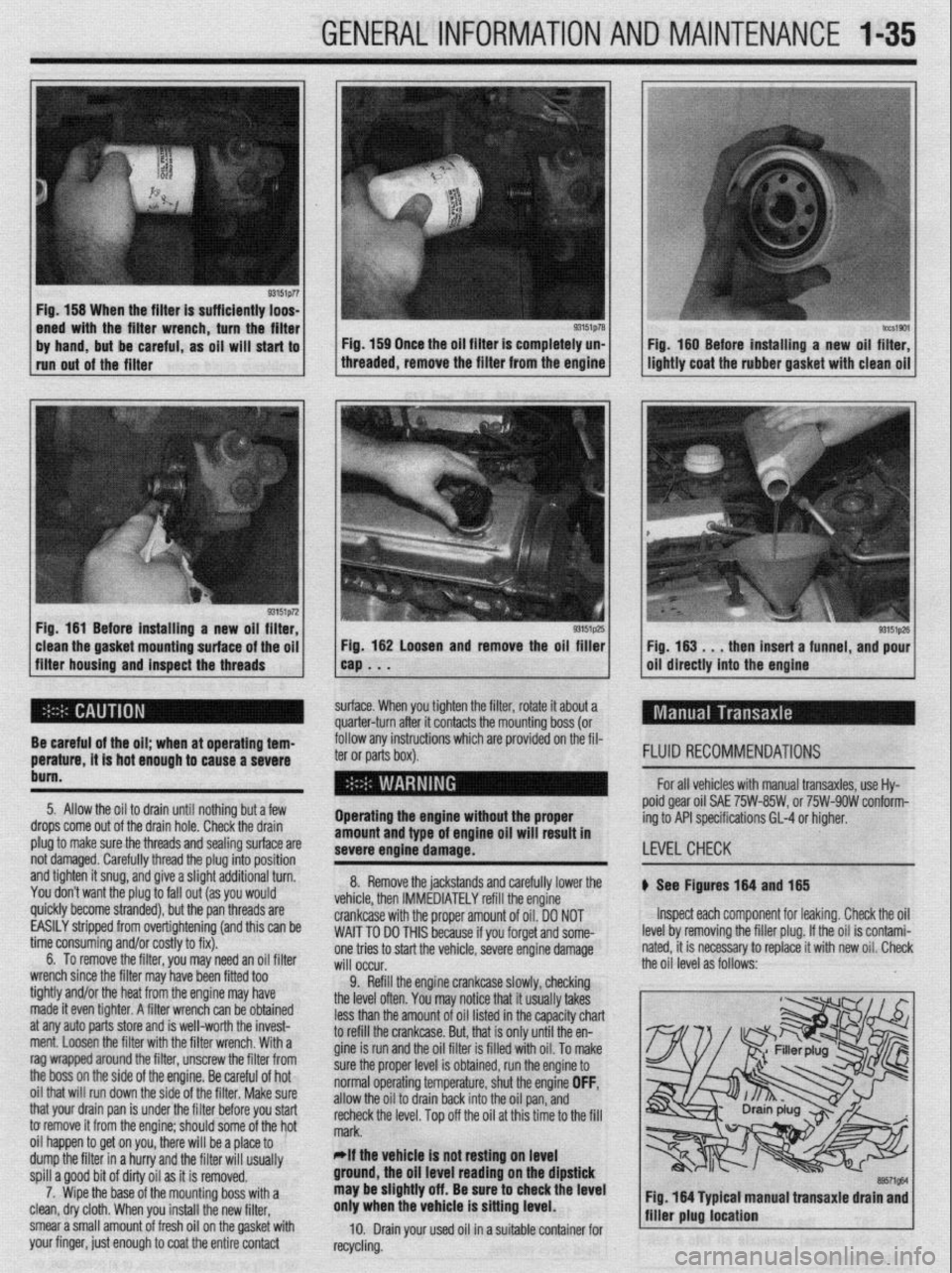

Fig. 158 When the filter is sufficiently loos-

Fig. 181 Before installing a new oil filter,

clean the gasket mounting surface of the oil

filter housing and inspect the threads Fig. 182 Loosen and remove the oil filler

cap . . .

surface. When you tighten the filter, rotate it about a

quarter-turn after it contacts the mounting boss (or Fig. 183 . , , then insert a funnel, and pour

oil directly into the engine

follow any instructions

which are provided on the fil-

ter or parts box).

Operating the engine without the proper

amount and type of engine oil will result In

severe engtne damage. FLUID RECOMMENDATIONS

For all vehicles with manual transaxles, use Hy-

poid gear oil SAE 75W-85W, or 75W-9OW conform-

ing to API specifications GL-4 or higher.

LEVELCHECK Be careful of the oil; when at operating tem-

perature, it is hot enough to cause a severe

bum.

5. Allow the oil to drain until nothing but a few

drops come out of the drain hole. Check the drain

plug to make sure the threads and sealing surface are

not damaged. Carefully thread the plug into position

and tighten it snug, and give a slight additional turn.

You don’t want the plug to fall out (as you would

quickly become stranded), but the pan threads are

EASILY stripped from overtightening (and this can be

time consuming and/or costly to fix).

6. To remove the filter, you may need an oil filter

wrench since the filter may have been fitted too

tightly and/or the heat from the engine may have

made it even tighter. A filter wrench can be obtained

at any auto parts store and is well-worth the invest-

ment. Loosen the filter with the filter wrench. With a

rag wrapped around the filter, unscrew the filter from

the boss on the side of the engine. Be careful of hot

oil that will run down the side of the filter. Make sure

that your drain pan is under the filter before you start

to remove it from the engine; should some of the hot

oil happen to get on you, there will be a place to

dump the filter in a hurry and the filter will usually

spill a good bit of dirty oil as it is removed.

7. Wipe the base of the mounting boss with a

clean, dry cloth. When you install the new filter,

smear a small amount of fresh oil on the gasket with

your finger, just enough to coat the entire contact 8. Remove the jackstands and carefully lower the

vehicle, then IMMEDIATELY refill the engine

crankcase with the proper amount of oil. DO NOT

WAIT TO DO THIS because if you forget and some-

one tries to start the vehicle, severe engine damage

will occur.

9. Refill the engine crankcase slowly, checking

the level oflen, you may r..‘:-- U.-1 :L ..-..” II.. .-L-e

lVL,VY II,UL II UUUU,,J ,“,\U.J

less than the amount of oil listed in the capacity chart

to refill the crankcase. But, that is only until the en-

gine is run and the oil filter is filled with oil. To make

sure the proper level is obtained, run the engine to

normal operating temperature, shut the engine OFF,

allow the oil to drain back into the oil pan, and

recheck the level. Top off the oil at this time to the fill

mark.

*If the vehicle Is not resting on level

ground, the oil level reading on the dipstick

may be slightly off. Be sure to check the level

only when the vehicle is sitting level.

10. Drain your used oil in a suitable container for

recycling. b See Flgures 184 and 185

Inspect each component for leaking. Check the oil

level by removing the filler plug. If the oil is contami-

nated, it is necessary to replace it with new oil. Check

the oil level as follows:

89571gM Fig. 164 Typtcal manual transaxle drain and

filler plug location

Page 37 of 408

t

1-38 GENERALINFORMATIONAND MAINTENANCE

11 I Add the recommended automatic transaxle

fluid to the transaxle through the dipstick tube. You

will need a long necked funnel, or a funnel and tube

to do this. A quick check of the capacities chart later

in this Section will reveal the capacity of the transaxle

in your vehicle. On a first fill after removing the pan

and filter, this number should be cut into a ‘hand

checked on the dipstick before refilling.

12. With the transaxle in P, put on the parking

brake, block the front wheels, start the engine and let

it idle. DO NOT RACE THE ENGINE. DO NOT MOVE

THE LEVER THROUGH ITS RANGES.

13. With the lever in Park, check the fluid level. If

it’s OK, take the car out for a short drive, park on a

level surface, and check the level again, as outlined

earlier in this section. Add more fluid if necessary. Be

careful not to overfill, which will cause foaming and

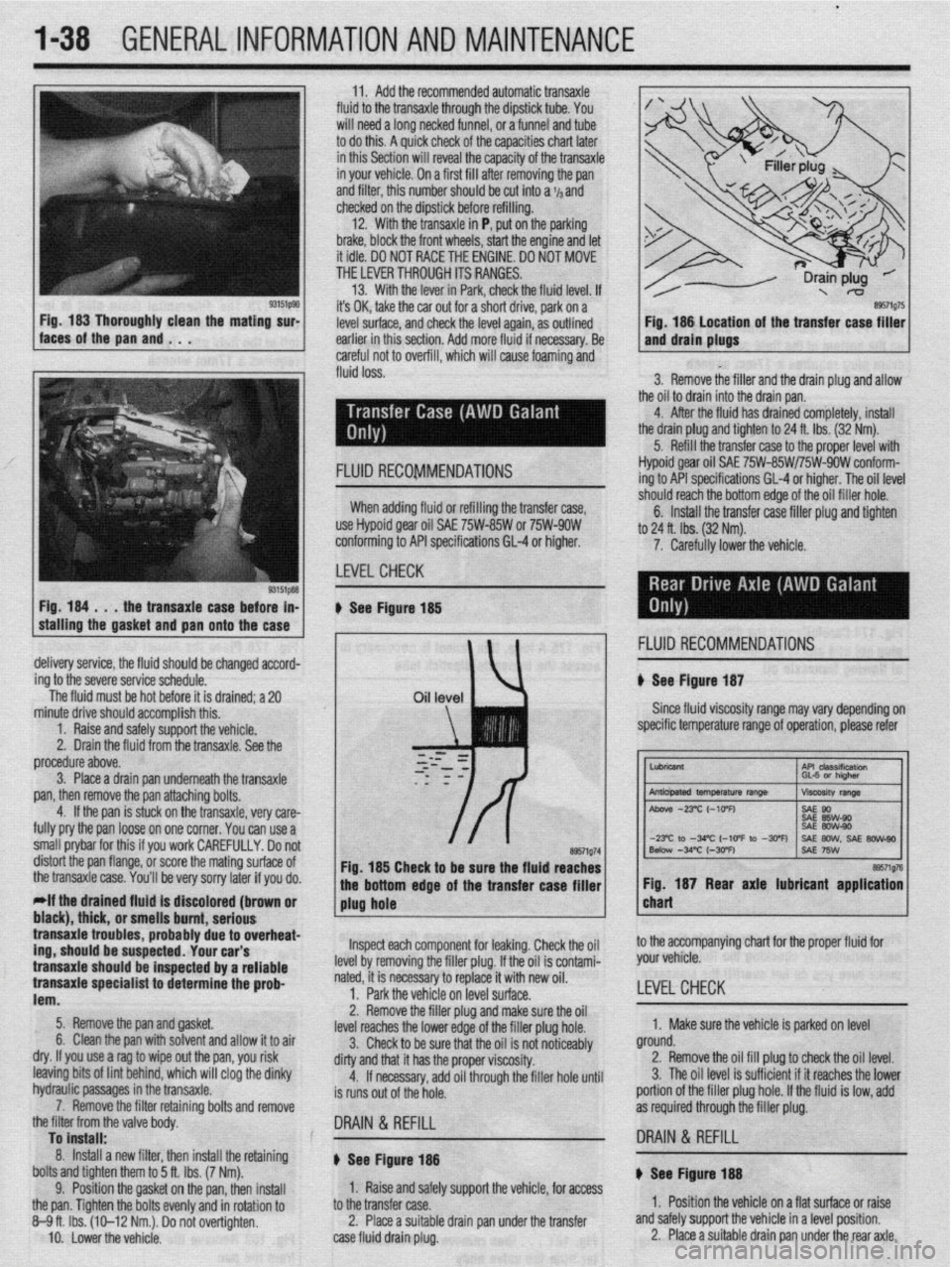

w fluid loss. n of the transfer case filler

3. Remove the filler and the drain plug and allow

the oil to drain into the drain pan.

4. After the fluid has drained completely, install

the drain plug and tighten to 24 ft. Ibs. (32 Nm).

5. Refill the transfer case to the proper level with

Fig. 184 . . .

the transaxle case before in-

stalling the gasket

and pan onto the case FLUID RECOMMENDATIONS Hypoid gear oil SAE 75W-85W/75W-9OW conform-

ing to API specifications GL-4 or higher. The oil level

-‘-,*I’ -nnnh +‘* “%om edge of the oil filler hole.

nxfer raw filler nlm and tinhtm When adding fluid or refilling the transfer case,

use Hypoid gear oil SAE 75W-85W or 75W-9OW

conforming to API specifications 61-4 or higher.

LEVELCHECK 6. Install the tra .._._. ____ .._. T.-J _.._ .lJ . .._..

to 24 ft. lbs. (32 Nm).

7. Carefully lower the vehicle.

u See Figure 185

, 1 FLUID RECOMMENDATIONS

delivery service, the fluid should be changed accord-

ing to the severe service schedule.

The fluid must be hot before it is drained; a 20 u See Figure 187

Since fluid viscosity range may

vary depending on

specific temperature range of operation, please refer

~~

tne transaxle case.

You’ll be very sorry later if you do. bottom edge of the transfer case filler 1 1 Fig. 187 Rear axle lubricant application I

*If the drained fluld is discolored (brown or

1 plug hole chart black), thick, or pmmll~ hmmt nnrinmm I transaxle trouble .llln3llU ““III., url,““P s, probably due to overheat-

,r..rr,rA “#.a.- rrdr

trig, should be susp~~lr;u. lvUl vLlr J

transaxle should be inspected by a reliable

transaxle specialist to determine the prob-

lem.

5. Remove the pan and gasket.

6. Clean the pan with solvent and allow it to air

dry. If you use a rag to wipe out the pan, you risk

leaving bits of lint behind, which will clog the dinky

hydraulic passages in the bansaxle.

7. Remove the filter retaining bolts and remove

the filter from the valve bodv. lnsoect each component for leaking. Check the oil

he filler plug. If the oil is contami-

ry to replace it with new oil.

if% nn IPVPI z11rf2r~

level by removing t

nated, it is necessa

1. Park the vehi,., -.. ,-.“, __. ,“-_.

2. Remove the filler plug and make sure the oil

level reaches the lower edge of the filler plug hole.

3. Check to be sure that the oil is not noticeably

dirty and that it has the proper viscosity.

4. If necessary, add oil through the filler hole until

is runs out of the hole. to the accompanying chart for the proper fluid for

your vehicle.

LEVEL CHECK

1. Make sure the vehicle is parked on level

ground.

2. Remove the oil fill plug to check the oil level.

3. The oil level is sufficient if it reaches the lower

portion of the filler plug hole. If the fluid is low, add

as required through the filler plug.

To install: .

8. Install a new filter, then install the retaining

bolts and tighten them to 5 ft. Ibs. (7 Nm).

9. Position the gasket on the pan, then install

the pan. Tighten the bolts evenly and in rotation to

8-9ft. Ibs. (10-12 Nm.). Do not overtighten.

IO. Lower the vehicle. DRAIN & REFILL

I8 DRAIN & REFILL

u See Figure 188 ) See Figure- 14

1. Raise and safely support the vehicle, for access

to the transfer case.

2. Place a suitable drain pan under the transfer

case fluid drain plug. 1. Position the vehicle on a flat surface or raise

and safely support the vehicle in a level position.

2. Place a suitable drain pan under the rear axle.

Page 40 of 408

.

GENERALINFORMATIONAND MAINTENANCE l-41

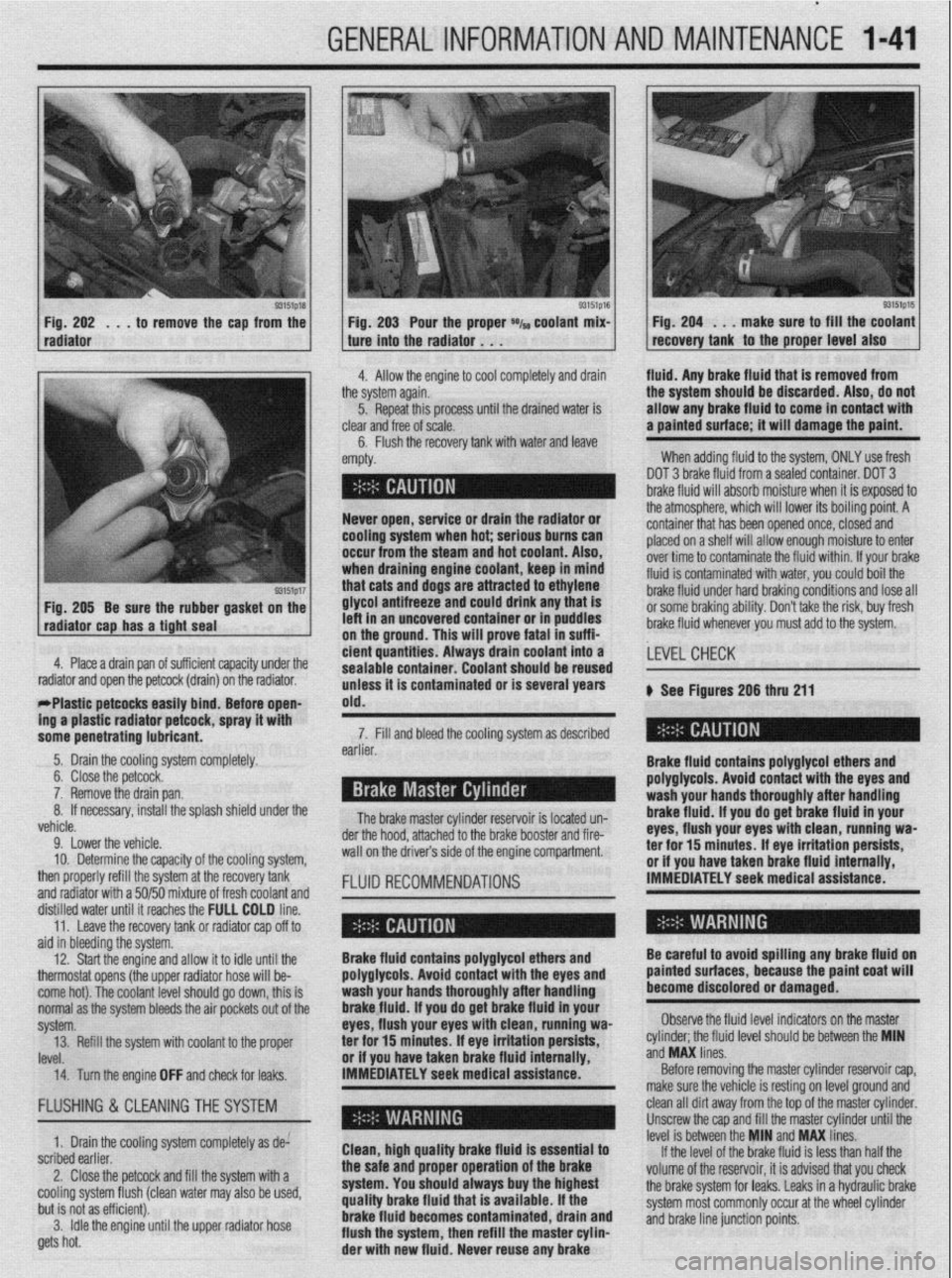

93151p18 Fig. 202 . , . to remove the cap from the

radiator

93151p17 Fig. 205 Be sure the rubber gasket on the

radiator cap has a tight seal e Fig. 203 Pour the proper *I~ coolant mix- 1 Fig. 204 . . . make sure to fill the coolant

recovery tank to the proper level also ture into the radiator . . .

.I

4. Allow the engine to cool completely and drain fluid. Any brake fluid that is removed from

ie system again.

5. Repeat this processuntil the drained water is

lear

and free of scale.

6. Flush the recovery tank with water and leave ’

mpty. the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a painted surface; it will damage the paint.

When adding fluid to the system, ONLY use fresh

DOT 3 brake fluid from a sealed container. DOT 3

brake fluid will absorb moisture when it is exposed to

.a . . . , .*a. . . * .*. . .

- Never open, service or drain the radiator or

cooling system when hot; serious bums can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep In mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

4. Place a drain pan of suff i ’ 1 . . . ..I .I. 1,~ cient quantities. Always tne atmospnere, wnrcn wnr rower 1r.s oourng pomr. A

container that has been opened once, closed and

placed on a shelf will allow enough moisture to enter

over time to contaminate the fluid within. If your brake

fluid is contaminated with water, you could boil the

brake fluid under hard braking conditions and lose all

or some braking ability. Don’t take the risk, buy fresh

brake fluid whenever you must add to the system.

crenr capacrry unaer me

drain) on the radiator.

rrrasuc perwcss easuy bind; Before open-

ing a plastic radiator petcock, spray it with

some penetrating lubricant. drain coolant into a

earner. sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

The brake master cylinder ~a~~~~r,~~ :A I~nnL.4 n-n 7. Fill and bleed the cooling system as described

Brake fluid contains polyglycol ethers and

polyglycols. Avoid contact with the eyes and ,LEVEL CHECK

wash your hands thoroughly after handling

brake fluid. If vou do oet brake fluid in vour

eyes, flush your eyeswith clean, runniug wa-

a-.. ‘Y-- ar -l-..n-- II -.._ I____ k See Figures 206 thru 211

.a-11-- - __-PA._ radiator and open the petcock (

- w&1--x3_ --mm.._..- . . ..-I...

5. Drain the cooling system completely.

6. Close the petcock.

7. Remove the drain pan.

If necessary, install the splash shield under the 8.

L.-l

venicie.

9. Lower the vehicle.

10. Determine the capacity of the cooling system,

then properly refill the system at the recovery tank

and radiator with a 50/50 mixture of fresh coolant and

fKm”“ll 15 IUMLC” “II- brake booster and fire- der the hood, attached to the

wall on the drivers side of the engine compartment.

FLUID RECOMMENDATIONS rer mr 13 mmures. IT eye irriIauon persim, or if you have taken brake fluid internally,

IMMEDIATELY seek medical assistance.

ala in oreerring me sysrem.

12. Start the engine and allow it to idle until the

thermostat opens (the upper radiator hose will be-

come hot). The coolant level should go down, this is

normal as the system bleeds the air pockets out of the

svstem.

IRVf!l ._._. 14. Turn the engine OFF and check for leaks. IMMEDIATELY seek medical assistance.” Brake fluid contains polyglycol ethers and

polyglycols. Avoid contact with the eyes and

wash your hands thoroughly after handling

brakefluid. If you do get brake fluid in your

eyes, flush your eyes with clean, running wa-

or if vou have taken brake fluid internallv.

Before removing the master cylinder reservoir cap,

make sure the vehicle is resting on level ground and Be careful to avoid spilling any brake fluid on

painted surfaces, because the paint coat will

become discolored or damaged.

Observe the fluid level indicators on the master

._ ._ __

‘eve1 should be between the MIN

ano

ivw unes. 13. Refill the system with coolant to the proper ter for 15 minutes; If eye irritation persists, cylinder; the tluld II

..J ..I” I....

FLUSHING & CLEANINGTHE SYSTEM

1. Drain the cooling system completely as de:

scribed earlier.

2. Close the petcock and fill the system with a

cooling system flush (clean water may also be used,

but is not as efficient).

3. Idle the engine until the upper radiator hose

gets hot. Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest

quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake clean all dirt away from the top of the master cylinder.

Unscrew the cap and fill the master cylinder until the

level is between the MIN and MAX lines.

If the level of the brake fluid is less than half the

volume of the reservoir, it is advised that you check

the brake system for leaks. Leaks in a hydraulic brake

system most commonly occur at the wheel cylinder

and brake line junction points.

Page 205 of 408

6-2 CHASSIS ELECTRICAL

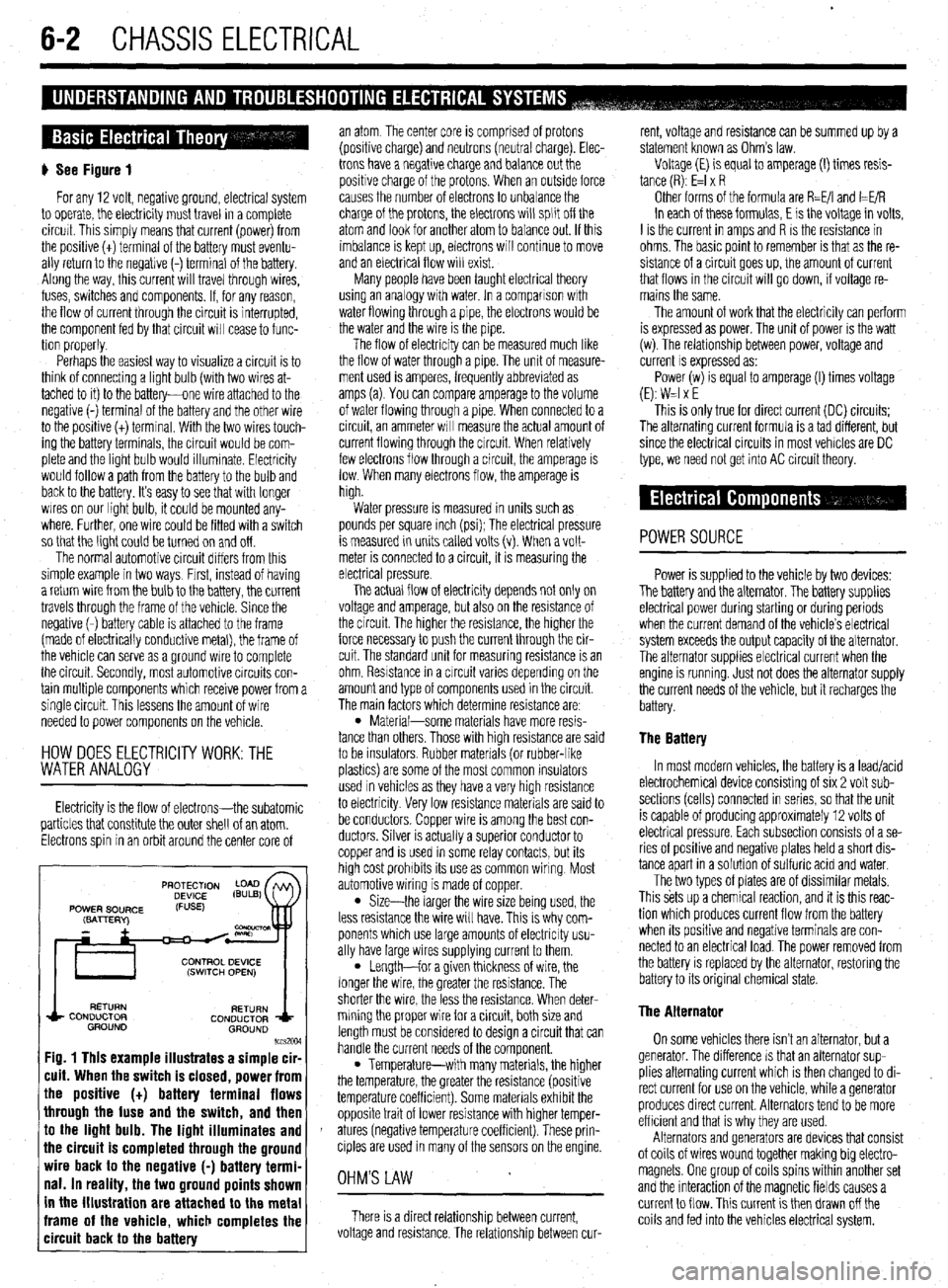

) See Figure 1

For any 12 volt, negative ground, electrical system

to operate, the electricity must travel in a complete

circurt. This simply means that current (power) from

the posibve (t) terminal of the battery must eventu-

ally return to the negative (-) terminal of the battery.

Along the way, this current will travel through wires,

fuses, switches and components. If, for any reason,

the flow of current through the circuit is interrupted,

the component fed by that circuit will cease to func-

tion properly.

Perhaps the easiest way to visualize a circuit is to

think of connecting a light bulb (with two wires at-

tached to it) to the battery-one wire attached to the

negative (-) terminal of the battery and the other wire

to the positive (t) terminal. With the two wires touch-

ing the battery terminals, the circuit would be com-

plete and the light bulb would illummate. Electricity

would follow a path from the battery to the bulb and

back to the battery. It’s easy to see that wrth longer

wires on our light bulb, it could be mounted any-

where. Further, one wire could be fitted with a switch

so that the light could be turned on and off.

The normal automotive circuit differs from this

simple example in two ways, Frrst, instead of having

a return wire from the bulb to the battery, the current

travels through the frame of the vehicle. Since the

negative (-) battery cable is attached to the frame

(made of electrically conductive metal), the frame of

the vehicle can serve as a ground wire to complete

the circuit. Secondly, most automotive circuits con-

tain multiple components which receive power from a

single circuit. This lessens the amount of wire

needed to power components on the vehicle.

HOW DOES ELECTRlClTYWORK:THE

WATER ANALOGY

Electricity is the flow of electrons-the subatomic

particles that constitute the outer shell of an atom.

Electrons spin in an orbit around the center core of

RETURN

RETURN

CONDUCTOR

CONDUCTOR

GROUND

GROUND

lccs2w

Fig. 1 This example illustrates a simple cir-

cuit. When the switch is closed, power from

the positive (t) battery terminal flows

through the fuse and the switch, and then

to the light bulb. The light illuminates and

the circuit is completed through the ground

wire back to the negative (-) battery termi-

nal. In reality, the two ground points shown

in the illustration are attached to the metal

frame of the vehicle, which completes the

circuit back to the battery

an atom The center core is comprised of protons

(positive charge) and neutrons (neutral charge). Elec-

trons have a negative charge and balance

out the

positive charge of the protons. When an outside force

causes the number of electrons to unbalance the

charge of the protons, the electrons will split off the

atom and look for another atom to balance out. If this

imbalance is kept up, electrons will continue to move

and an electrical flow will exist.

Many people have been taught electrical theory

using an analogy with water. In a comparison wrth

water flowing through a pipe, the electrons would be

the water and the wire is the pipe.

The flow of electricity can be measured much like

the flow of water through a pipe. The unit of measure-

ment used is amperes, frequently abbreviated as

amps (a). You can compare amperage to the volume

of water flowing through a pipe. When connected to a

circuit, an ammeter WIII measure the actual amount of

current flowing through the circuit. When relatively

few electrons flow through a circuit, the amperage is

low. When many electrons flow, the amperage is

high.

Water pressure is measured in units such as

pounds per square inch (psi); The electrical pressure

is measured in unrts called volts (v). When a volt-

meter is connected to a circuit, it is measuring the

electrical pressure.

The actual flow of electricity depends not only on

voltage and amperage, but also on the resistance of

the circuit The higher the resistance, the higher the

force necessary to push the current through the cir-

cuit. The standard unit for measuring resistance is an

ohm. Resistance in a crrcuit varies dependmg on the

amount and type of components used in the circuit.

The main factors which determine resistance are:

l Material-some materials have more resis-

tance than others Those with high resistance are said

to be insulators Rubber materials (or rubber-like

plashcs) are some of the most common insulators

used in vehicles as they have a very high resistance

to electricity Very low resistance materials are said to

be conductors. Copper wire is among the best con-

ductors. Silver is actually a superior conductor to

copper and is used in some relay contacts, but its

high cost prohibits its use as common wiring Most

automotive wiring is made of copper.

l Size-the larger the wire size being used, the

less resistance the wire will have. This IS why com-

ponents which use large amounts of electricity usu-

ally have large wires supplying current to them.

l Length-for a given thickness of wire, the

longer the wire, the greater the resistance. The

shorter the wire, the less the resistance. When deter-

mining the proper wire for a circuit, both size and

length must be considered to design a circuit that can

handle the current needs of the component.

l Temperature-with many materials, the higher

the temperature, the greater the resistance (positive

temperature coefficient). Some materials exhibit the

opposite trait of lower resistance with higher temper-

atures (negative temperature coefficient). These prin-

ciples are used in many of the sensors on the engine

OHM'S LAW

There is a direct relationship between current,

voltage and resistance. The relationship between cur- rent, voltage and resistance can be summed up by a

statement known as Ohm’s law.

Voltage (E) is equal to amperage (I) times resis-

tance (R): E=l x R

Other forms of the formula are R=E/I and I=E/R

In each of these formulas, E is the voltage in volts,

I is the current in amps and R IS the resistance in

ohms. The basic point to remember is that as the re-

sistance of a circuit goes up, the amount of current

that flows in the circuit will go down, if voltage re-

mains the same.

The amount of work that the electricity can perform

is expressed as power. The unit of power is the watt

(w). The relationship between power, voltage and

current

IS expressed as:

Power(w) is equal to amperage (I) times voltage

(E): W=l x E

This is only true for direct current (DC) circuits:

The alternating current formula is a tad different, but

since the electrical circuits in most vehicles are DC

type, we need not get into AC circuit theory.

POWERSOURCE

Power is supplied to the vehicle by two devices:

The battery and the alternator. The battery supplies

electrical power during starting or during periods

when the current demand of the vehicle’s electrical

system exceeds the output capacity of the alternator.

The alternator supplies electrical current when the

engine is running

Just not does the alternator supply

the current needs of the vehicle, but it recharges the

battery.

The Battery

In most modern vehicles, the battery is a lead/acid

electrochemical device consisting of six 2 volt sub-

sections (cells) connected in series, so that the unit

is capable of producing approximately 12 volts of

electrical pressure. Each subsection consists of a se-

ries of positive and negative plates held a short dis-

tance apart in a solutron of sulfuric acid and water.

The two types of plates are of dissimilar metals,

This sets up a chemrcal reaction, and it is this reac-

tion which produces current flow from the battery

when Its positive and negattve terminals are con-

nected to an electrical load. The power removed from

the battery is replaced by the alternator, restoring the

battery to its original chemical state.

The Alternator

On some vehicles there isn’t an alternator, but a

generator. The difference IS that an alternator sup-

plies alternating current which is then changed to di-

rect current for

use on the vehicle, while a generator

produces direct current. Alternators tend to be more

efficient and that is why they are used.

Alternators and generators are devices that consist

of coils of wires wound together making big electro-

magnets. One group of coils spins within another set

and the interaction of the magnetic fields causes a

current to flow. This current is then drawn off the

coils and fed into the vehicles electrical system.

Page 390 of 408

11-8 TROUBLESHOOTING

Ignition systems may be controlled by, or linked to, the engine fuel management sys-

tem. Similar to the fuel injection system, these ignition systems rely on electronic sen-

sors for information to determine the optimum ignition timing for a given engine speed

and load. Some ignition systems no longer allow the ignition timing to be adjusted.

Feedback from low voltage electrical sensors provide information to the control unit to

determine the amount of ignition advance. On these systems, if a failure occurs the failed

component must be replaced. Before replacing suspected failed electrical components,

carefully inspect the wiring and electrical connectors to the related components. Make

sure the electrical connectors are fully connected, clean and not physically damaged. If

necessary, clean the electrical contacts using electrical contact cleaner. The use of clean-

ing agents not specifically designed for electrical contacts should be avoided, as they

could leave a surface film or damage the insulation of the wiring.

1. Engine makes a knocking or pinging noise when accelerating

a. Check the octane rating of the fuel being used. Depending on the type of driving or

driving conditions, it may be necessary to use a higher octane fuel.

b. Verify the ignition system settings and operation. Improperly adjusted ignition timing

or a failed component, such as a knock sensor, may cause the ignition timing to ad-

vance excessively or prematurely. Check the ignition system operation and adjust, or

replace components as needed.

c. Check the spark plug gap, heat range and condition. If the vehicle is operated in se-

vere operating conditions or at continuous high speeds, use a colder heat range spark

plug. Adjust the spark plug gap to the manufacturer’s recommended specification and

replace worn or damaged spark plugs.

2. Sfarter motor grinds when used

a. Examine the starter pinion gear and the engine ring gear for damage, and replace dam-

aged parts.

b. Check the starter mounting bolts and housing. If the housing is cracked or damaged

replace the starter motor and check the mounting bolts for tightness.

3. Engine makes a screeching noise

a. Check the accessory drive belts for looseness and adjust as necessary.

b. Check the accessory drive belt tensioners for seizing or excessive bearing noises and

replace if loose, binding, or excessively noisy.

c. Check for a seizing water pump. The pump may not be leaking; however, the bearing

may be faulty or the impeller loose and jammed. Replace the water pump.

4. Engine makes a growling noise

a. Check for a loose or failing water pump. Replace the pump and engine coolant.

b. Check the accessory drive belt tensioners for excessive bearing noises and replace if

loose or excessively noisy.

5. Engine makes a ticking or tapping noise

a. On vehicles with hydraulic lash adjusters, check for low or dirty engine oil and top off

or replace the engine oil and filter.

b. On vehicles with hydraulic lash adjusters, check for collapsed lifters and replace failed

components.

c. On vehicles with hydraulic lash adjusters, check for low oil pressure caused by a re-

stricted oil filter, worn engine oil pump, or oil pressure relief valve.

d. On vehicles with manually adjusted valves, check for excessive valve clearance or

worn valve train parts. Adjust the valves to specification or replace worn and defective

parts.

e. Check for a loose or improperly tensioned timing belt or timing chain and adjust or re-

place parts as necessary.

f. Check for a bent or sticking exhaust or intake valve. Remove the engine cylinder head

to access and replace.

6. Engine makes a heavy knocking noise

a. Check for a loose crankshaft pulley or flywheel; replace and torque the mounting

bolt(s) to specification.

b. Check for a bent connecting rod caused by a hydro-lock condition. Engine disassem-

bly is necessary to inspect for damaged and needed replacement parts.

c. Check for excessive engine rod bearing wear or damage. This condition is also asso-

ciated with low engine oil pressure and will require engine disassembly to inspect for

damaged and needed replacement parts,

7. Vehicle has a fuel odor when driven ’ a. Check the fuel gauge level. If the fuel gauge registers full, it is possible that the odor is

caused by being filled beyond capacity, or some spillage occurred during refueling.

The odor should clear after driving an hour, or twenty miles, allowing the vapor canis-

ter to purge.

b. Check the fuel filler cap for looseness or seepage. Check the cap tightness and, if

loose, properly secure. If seepage is noted, replace the filler cap.

c. Check for loose hose clamps, cracked or damaged fuel delivery and return lines, or

leaking components or seals, and replace or repair as necessary. d. Check the vehicle’s fuel economy. If fuel consumption has increased due to a failed

component, or if the fuel is not properly ignited due to an ignition related failure, the

catalytic converter may become contaminated. This condition may also trigger the

check engine warning light. Check the spark plugs for a dark, rich condition or verify

the condition by testing the vehicle’s emissions. Replace fuel fouled spark plugs, and

test and replace failed components as necessary.

5. Vehicle has a rotten egg odor when driven

a. Check for a leaking intake gasket or vacuum leak causing a lean running condition. A

lean mixture may result in increased exhaust temperatures, causing the catalytic con-

verter to run hotter than normal. This condition may also trigger the check engine

warning light. Check and repair the vacuum leaks as necessary.

b. Check the vehicle’s alternator and battery condition. If the alternator is overcharging,

the battery electrolyte can be boiled from the battery, and the battery casing may begin

to crack, swell or bulge, damaging or shorting the battery internally. If this has oc-

curred, neutralize the battery mounting area with a suitable baking soda and water

mixture or equivalent, and replace the alternator or voltage regulator. Inspect, service,

and load test the battery, and replace if necessary.

9. Vehicle has a sweet odor when driven

a. Check for an engine coolant leak caused by a seeping radiator cap, loose hose clamp,

weeping cooling system seal, gasket or cooling system hose and replace or repair as

needed.

b. Check for a coolant leak from the radiator, coolant reservoir, heater control valve or

under the dashboard from the heater core, and replace the failed part as necessary.

c. Check the engine’s exhaust for white smoke in addition to a sweet odor. The presence

of white, steamy smoke with a sweet odor indicates coolant leaking into the combus-

tion chamber. Possible causes include a failed head gasket, cracked engine block or

cylinder head. Other symptoms of this condition include a white paste build-up on the

inside of the oil filler cap, and softened, deformed or bulging radiator hoses.

19. Engine vibraies when idling

a. Check for loose, collapsed, or damaged engine or transmission mounts and repair or

replace as necessary.

b. Check for loose or damaged engine covers or shields and secure or replace as neces-

sary.

11. Engine vibrates during acceleration

a. Check for missing, loose or damaged exhaust system hangers and mounts; replace or

repair as necessary.

b. Check the exhaust system routing and fit for adequate clearance or potential rubbing;

repair or adjust as necessary.

7. Battery goes dead while driving

a. Check the battery condition. Replace the battery if the battery will not hold a charge or

fails a battery load test. If the battery loses fluid while driving, check for an overcharg-

ing condition. If the alternator is overcharging, replace the alternator or voltage regula-

tor. (A voltage regulator is typically built into the alternator, necessitating alternator re-

placement or overhaul.)

b. Check the battery cable condition. Clean or replace corroded cables and clean the bat-

tery terminals.

c. Check the alternator and voltage regulator operation. If the charging system is over or

undercharging, replace the alternator or voltage regulator, or both.

d. Inspect the wiring and wire connectors at the alternator for looseness, a missing .

ground or defective terminal, and repair as necessary.

e. Inspect the alternator drive belt tension, tensioners and condition. Properly tension the

drive belt, replace weak or broken tensioners, and replace the drive belt if worn or

cracked.

2. Battery goes dead overnight

a. Check the battery condition. Replace the battery if the battery will not hold a charge or

fails a battery load test.

b. Check for a voltage draw, such as a trunk light, interior light or glove box light staying

on. Check light switch position and operation, and replace if defective.

c. Check the alternator for an internally failed diode, and replace the alternator if defec-

tive.

1. Engine overheats

a. Check the coolant level. Set the heater temperature to full hot and check for internal air

pockets, bleed the cooling system and inspect for leakage. Top off the cooling system

with the correct coolant mixture.

b. Pressure test the cooling system and radiator cap for leaks. Check for seepage caused

by loose hose clamps, failed coolant hoses, and cooling system components such as

the heater control valve, heater core, radiator, radiator cap, and water pump. Replace

defective parts and fill the cooling system with the recommended coolant mixture.