height MITSUBISHI DIAMANTE 1900 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 140 of 408

Description

Cylinder Block (cont’d)

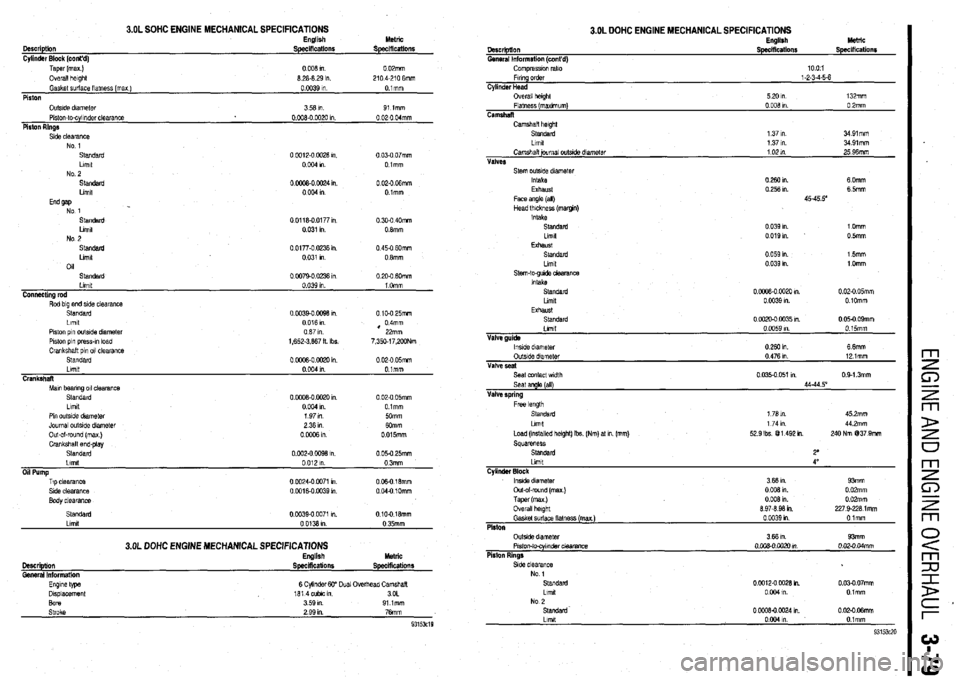

3.OL SOHC ENGINE MECHANICAL SPEClFlCATlONS English

Specifications Metric

Specifications

Taper (max.)

Overall klght

Gasket sudace flatness (max )

Piston

Oufslde diameter

Piston-to-cylinder clearanca

Piston Rinas 0008ln 0 OZmm

8 28.8 29 I”. 2104-210 6mm

0 ofI39 In Olmm

358ln. 91 lmm

0.008-o 0020 I” 0 020 04mm

.,

Side clearance

Standard

Llrw

No 2 0 COIZ-0 W28 I”. 0 03-O 07mm

0004 I” Olmm

Standard

0 0008-0 0024 I”. 0 020 06mm

Ltmlt

00041” Olmm

End gap

No 1

Standard 00118-00177,”

0.30-O 40mm

Llmlt

0 031 I” 0 8mm

No 2

Standard

0 0177-O 0236 I”. 0 45-O 60mm

Llmlt

0.031 I” 0 8mm

011

Standard

0 0079-o 02% I” 0 200 fiOmm

Llmlt

0 039 I” 1 Omm

C0nnactlng rod

Rod big end side clearance

Standard

Llmlt

Piston pin outslde diameter

Piston pin prawn load

Crankshaft pm 011 clearance

Standard

Llmlt

Crankshat

Mm bearing 011 clearance

Standard

Llmlt 0 00390 0098 I”.

0 016 m

087al

1,652.3.867 It Ibs.

0 ow3-0 mm I”.

0004m

o.rYm-0 oao I”.

0 Oil4 1” 0 10.0 25mm

, 04mm

22mm

7.350.17,ZOONm

0 02-O 05mm

O.lmm

0 02.0 05mm

Olmm

Pm outs& dfameter

Journal outs& diameter

Out-al-round hnax 1 197n

50mm

236111

0 OW8 in

FT~p clearance

St& clearance 0 0024.0 0071 I”. OC6016mm

0 0016-O 0039 I”. 004-O 10mm

Body clearance

Standard

Llmlt o.cn340 0071 I”.

0 0138 I”

3.OL DOHC ENGINE MECHANICAL SPECIFICATIONS English 010-018mm

0 35mm

M&lC

Description

Spscificalions SpecHicatiOllS Gemal lrlformtlon

Eqne type

Displacement

Bore

Slfoke 6 CylmderW Dual Overhead Camshaft

1814cubicm. 3OL

359m 91 lmm

2 99 I”. 76mm

9315x19

3.OL DOHC ENGINE MECHANICAL SPECIFICATIONS English Metric

Dsscription

General lnformstlon (cont’d) Specifications

Compraswm ratio

Fmng order

l-2-3-45-6

Cylinder Head

Overall helghl

5 20 I”. 132mm

Flatness (manmum)

0 008 I” 0 2mm

Camshall

Camhalt height

Standard

1 37 m 3491mm

Llmll

1 37 I”. 3491mm

Camshalt journal out&e

diameter 1 02 m. 25 96mm

VdVRS

Stem outsrde diameter

Intake

0 260 I”. 60mm

Exhaust

0 256 I”. 6 5mm

Face angle (all) 45-45 5”

Head thickness (mamn)

Intake

Standard

0 039 I” 1 Omm

Llmlt

0019,” 0 5mm

Exhaust

Standard

0 059 I”. 15mm

Llmlt

0 039 m. l.Omm

Stem-to-gude clearam

intake

Standard

0 oo#l-0 002il I”. 0 02-O 05mm

Limit

0 0039 I”. 0 IOmm

Exhaust

Standard

0 0020-0 0035 I”. 0 05-O 09mm

Lllllll

0 0059 m. 0 15mm

Valve guida

lwde dtameter

0 280 In. 6 6mm

Outs& diameter

0.476 I” 12 lmm

Vahre seal

Seat contact wtdlh

0 035-o 051 ,“. 0413mm

Seat angle (all)

44.44 5’

Valve spring

Llmlt

4”

Cvlindsf Block

tnslde dlametar

Out-&round (max )

Taper (max)

Overall hslght

Gasket surface llatnezs (max.)

Platen

Outs& diameter

Plslon-t@cylmn&r Clearance

Piston Rings 3.66 I”. 93mm

0 008 I”. 0 02mm

0 006 I”. 0 OPmm

8 97-8 98 in. 227 9.228 1 mm

0 CO39 I” Olmm

3 66 I”. 93mm

o.oQB-0 0020 M. 0 020.04mm

Page 141 of 408

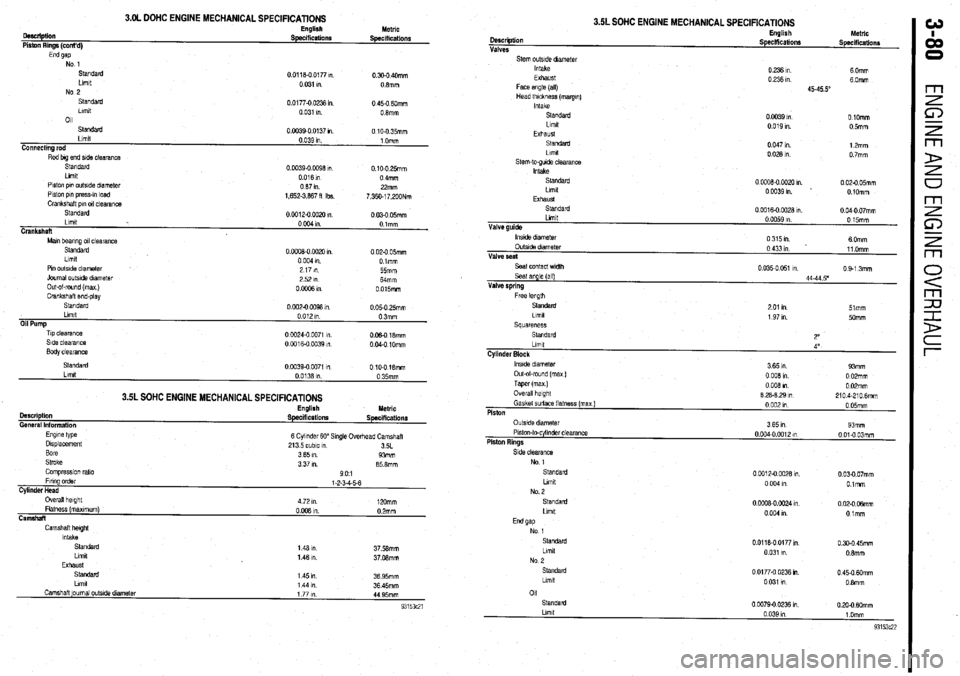

3.OL DOHC ENGINE MECHANICAL SPECIFICATIONS

oescliptiin

Piston Rings (cont’d) English Metric SpeclfiCatiOllS Specifications

End gap No 1

standard

Llmlt

No 2

Standard

Llmlt

011 0 0118-O 0177 ,“.

0.300 40mm

0 031 I” 08mm

0.01770 0236 I” 0 450 6Omm

0 031 I”. 08mm

Standard

Llmlt

Connecting rod

Rod big end side clearance 0.0039-0 0137 I” 0 10-O 35mm

0.039 1” 1 Omm

Slandard

Llmlt

Piston pm outside dnmeter

Piston pi” press-,” load

Crankshaft pm 011 clearance 0.0039-O 0098 m. 0.100 25mm

0016m 0 4mm

087111 22mm

1,652.3,887 fl Ibs.

7,350.17,200Nm

Standard

00012-oOOx)m

0 030 05mm

Llmlt

0 004 I” Olmm

Crankshaft

Mm bearing 011 clearanca

Standard

Llmlt 0 ooO8-0 0020 I” 0 020 05mm

0 004 9”. Dimm

Pm outslde diameter

Journal outs& dlametar

Out-ol-round (max )

Crankshaft end-play

standard

Llmlt

Oil Pump

Tip clearance

Side clearance

Body clearance 2171n

55mm

2521n

Mmm

OoOffiRl 0 015mm

0 002-O 0098 I” 0 05-O 25mm

0 012 I” 03mm

0 CO24.0 0071 m

006018mm

0 0016-O 0039 in. 0 040 1Omm

3.5L SOHC ENGINE MECHANICAL SPECIFICATIONS

Description

General Information

Engme type

Displacement

Bore

Stroke

Comprasslon ratio English Metric

Specifications Specifications

6 Cylinder 60” Single Ovedvzad Camshaft

213 5 cubic I”

3SL

3 65 I”. 93mm

3 37 m. 85 8mm

901

Llmlt

Camshaft ]oumal outs& dtameter 1 44 I”. 36 45mm

1771n

44 95mm

3.5L SOHC ENGINE MECHANICAL SPECIFICATIONS

Llmlt Description

Valve guide Valves

Stem outstde dmmetar

Intake

Exhaust

Face angle (all)

Head thickness (margm)

Intake

Standard

Llmlt

Exhaust

Sl.SldZld

Llmd

stem-to-gude clearance

Intake

standard

Llmlt

EXhaUsl

standarc

0 0059 I” English

0 15mm hletrlc

Speciffcationr

Specificationr

0 236 I”. 6 Omm

0 236 I”. 60mm

4545.5”

0 0039 I” OlOmm

0 019 I”. 05mlll

0 047 I” 12mm

00281n 0 7mm

0

0008-O 0020 I” 0 020 05mm

OW391n 0 lOmm

0

0016-O 0028 I”. 0 040 07mm

lnstde dram&t

OutsIde diameter

Valve seat

Seat contact width

Seal angle (all)

Valve spring

Free knoth 0315m

6 Omm

0 433 I” 11 Omm

0 035-O 051 I” 0 9-l 3mm

44-44 5’

Standard

2 01 I” 51mm

Llmlt

1 97 I”. 5omm

Squareness

Standard

2”

Llmlt

4”

Cylinder Block

lnslde diameter

3 65 I”. 93mm

Out-ol-round (max )

0 008 in 0 02mm

Taper (max ) 0 008 I” 0 02mm

Overall height

8 28-8 29 I” 2104.2106mm

Gasket surface flatness (max)

0 002 I” 0 05mm

Piston

Side clearance

No 1

standard

Llmlt

No. 2

Standard

Llmlt 0 0012-O CO28 1”.

0 03-O 07mm

0 004 In O.lmm

0 CCQ8-0 0024 I” 0 02-O 06mm

0 004 I” Otmm

01

Standard

0 0079-O 0236 I” 0 20-O MXnm

Page 287 of 408

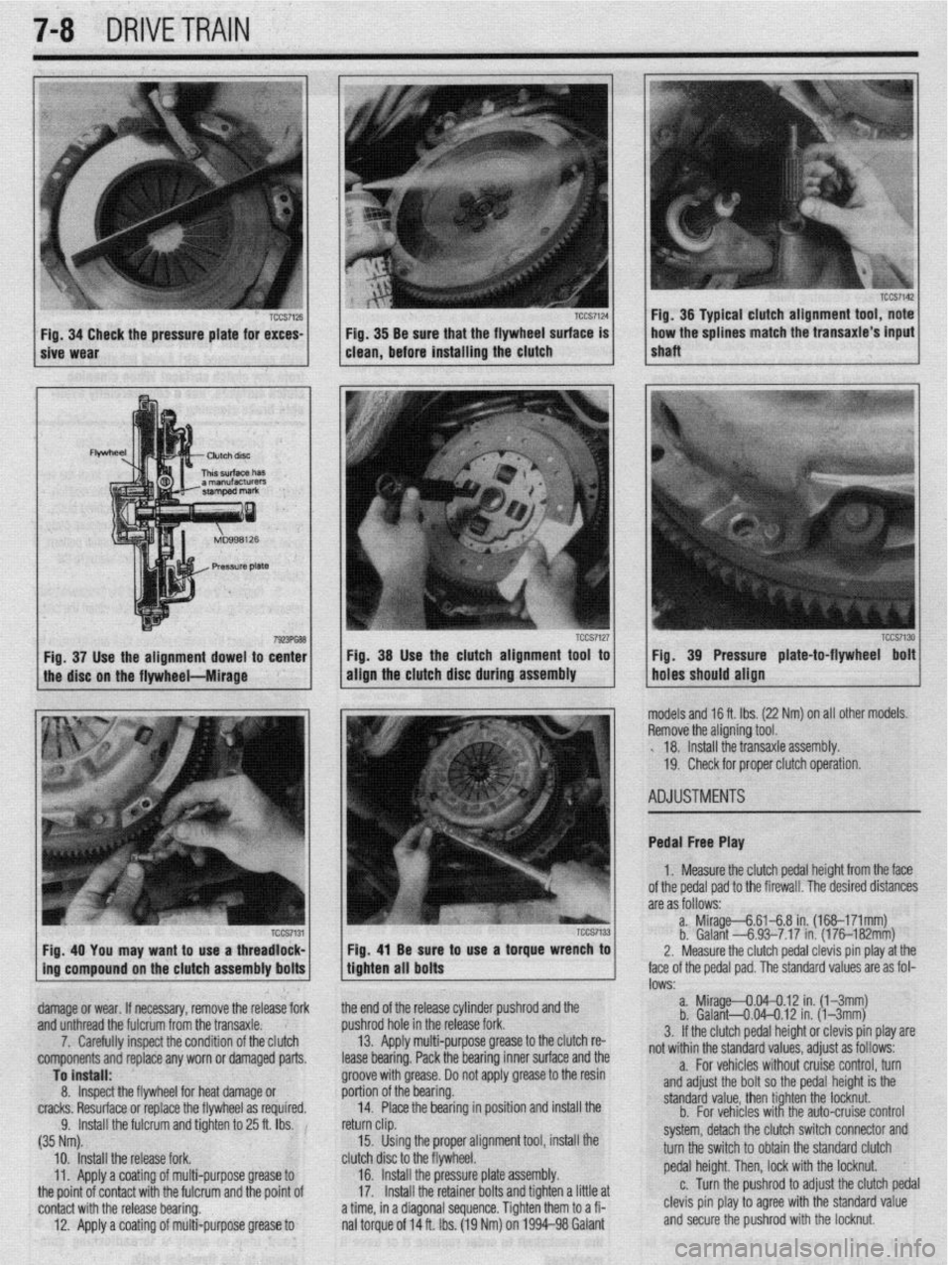

7-8 DRIVETRAIN

/ sive Wear TCCS7124 1 Fig 34 Check the pressure plate for exces- TCCS7126 j / . Fig 38 Be sure that the flywheel surface is

clean, before installing the clutch

Fig. 38 Use the clutch alignment tool to

align the

clutch disc during assembly

Fig. 40 You may want to use a threadlock- Fig, 41 Be sure to use a torque wrench to

ing compound on the clutch assembly bolts

tighten all bolts

damage or wear. If necessary, remove the release fork the end of the release cylinder pushrod and the

and unthread the fulcrum from the transaxle. pushrod hole in the release fork.

7. Carefully inspect the condition of the clutch 13. Apply multi-purpose grease to the clutch re-

components and replace any worn or damaged parts.

lease bearing. Pack the bearing inner surface and the r Fig. 36 Typical clutch alignment tool, note

shaft ,,, 1 how the splines match the transaxle’s input

TCCS7130 Fig. 39 Pressure plate-to-flywheel bolt

holes should align

nodels and 16 ft. Ibs. (22 Nm) on all other models.

3emove the aligning tool.

. 18. Install the transaxle assembly.

19. Check for proper clutch operation.

4DJUSTMENTS

Pedal Free Play

1. Measure the clutch pedal height from the face

of the pedal pad to the firewall. The desired distances

are as follows:

a. Mirage--&6148 in. (168-171mm)

b. Galant -6.93-7.17 in. (176182mm)

2. Measure the clutch pedal clevis pin play at the

ace of the pedal pad. The standard values are as fol-

DWS: a. Mirage--0.04--0.12 in. (l-3mm)

b. Galant4.04-0.12 in. (l-3mm)

3. If the clutch pedal height or clevis pin play are

rot within the standard values, adjust as follows:

Page 288 of 408

DRIVETRAIN 7-9

*When adjusting the clutch pedal height or

the clutch pedal clevis pin play, be careful

not to push the pushrod toward the master

cylinder.

d. Check that when the clutch pedal is de-

pressed all the way, the interlock switch switches

over from ON to OFF.

ADJUSTMENT

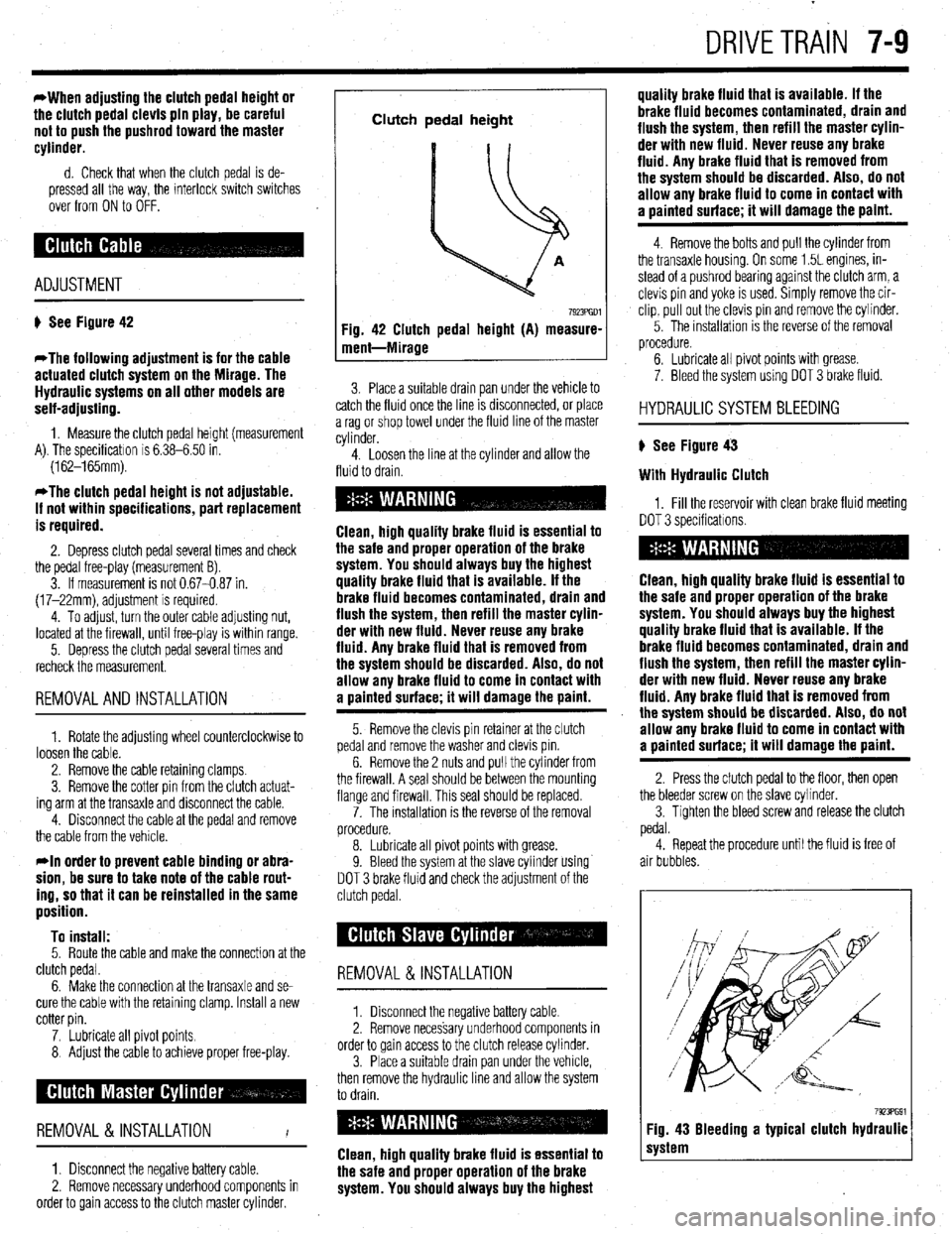

# See Figure 42

*The following adjustment is for the cable

actuated clutch system on the Mirage. The

Hydraulic systems on all other models are

self-adjusting.

1. Measure the clutch pedal height (measurement

A). The specificatron is 6.38-6.50 in.

(162-165mm).

*The clutch pedal height is not adjustable.

If not within specifications, part replacement

is required.

2. Depress clutch pedal several times and check

the pedal free-play (measurement B).

3. If measurement is not 0.67-0.87 in.

(17-22mm), adjustment is required.

4. To adjust, turn the outer cable adjusting nut,

located at the firewall, until free-play is within range.

5. Depress the clutch pedal several times and

recheck the measurement.

REMOVALANDINSTALLATION

1. Rotate the adjusting wheel counterclockwise to

loosen the cable.

2. Remove the cable retaining clamps.

3. Remove the cotter pin from the clutch actuat-

ing arm at the transaxle and disconnect the cable.

4. Disconnect the cable at the pedal and remove

the cable from the vehicle.

rln order to prevent cable binding or abra-

sion, be sure to take note of the cable rout-

ing, so that it can be reinstalled in the same

position.

To install:

5. Route the cable and make the connection at the

clutch pedal.

6. Make the connection at the transaxle and se-

cure the cable with the retaining clamp. Install a new

cotter pin.

7. Lubricate all pivot points.

8 Adjust the cable to achieve proper free-play.

REMOVAL &INSTALLATION

I

1. Disconnect the negative battery cable.

2. Remove necessary underhood components in

order to gain access to the clutch master cylinder.

Clutch pedal height

Fig. 42 Clutch pedal height (A) measure-

ment-Mirage

7923PGDl

3. Place a suitable drain pan under the vehicle to

catch the fluid once the line IS drsconnected, or place

a rag or shop towel under the fluid line of the master

cylinder.

4. Loosen the line at the cylinder and allow the

fluid to drain.

Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest

quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake

fluid. Any brake fluid that is removed from

the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a oainted surface; it will damage the paint.

5. Remove the clevis pin retainer at the clutch

pedal and remove the washer and clevis pm.

6. Remove the 2 nuts and pull the cylinder from

the firewall. A seal should be between the mounting

flange and firewall. This seal should be replaced.

7. The installation is the reverse of the removal

procedure.

8. Lubricate all pivot points with grease.

9. Bleed the system at the slave cylinder using

DOT 3 brake fluid and check the adjustment of the

clutch pedal.

REMOVAL &INSTALLATION

1. Disconnect the negative battery cable

2. Remove necessary underhood components in

order to gain access to the clutch release cylinder.

3. Place a suitable drain pan under the vehicle,

then remove the hydraulic line and allow the system

to drain.

Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake

fluid. Any brake fluid that is removed from

the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a uainted surface; it will damage the paint.

4. Remove the bolts and pull the cylinder from

the transaxle housing. On some 1.5L engines, in-

stead of a pushrod bearing against the clutch arm, a

clevis pin and yoke is used. Simply remove the cir-

clip, pull out the clevis pin and remove the cylinder.

5. The installation IS the reverse of the removal

procedure.

6. Lubricate all pivot points with grease.

7. Bleed the system using DOT 3 brake fluid.

HYDRAULIC SYSTEM BLEEDING

) See Figure 43

With Hydraulic Clutch

1, Fill the reservoir with clean brake fluid meeting

DOT 3 specificatrons.

Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest

quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake

fluid. Any brake fluid that is removed from

the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a painted surface; it will damage the paint.

2. Press the clutch pedal to the floor, then open

the bleeder screw on the slave cvlinder.

3. Tighten the bleed screw and release the clutch

pedal.

4. Repeat the procedure until the fluid is free of

air bubbles.

7923PG91 Fig. 43 Bleeding a typical clutch hydraulic

system

Page 290 of 408

DRIVETRAIN 7-11

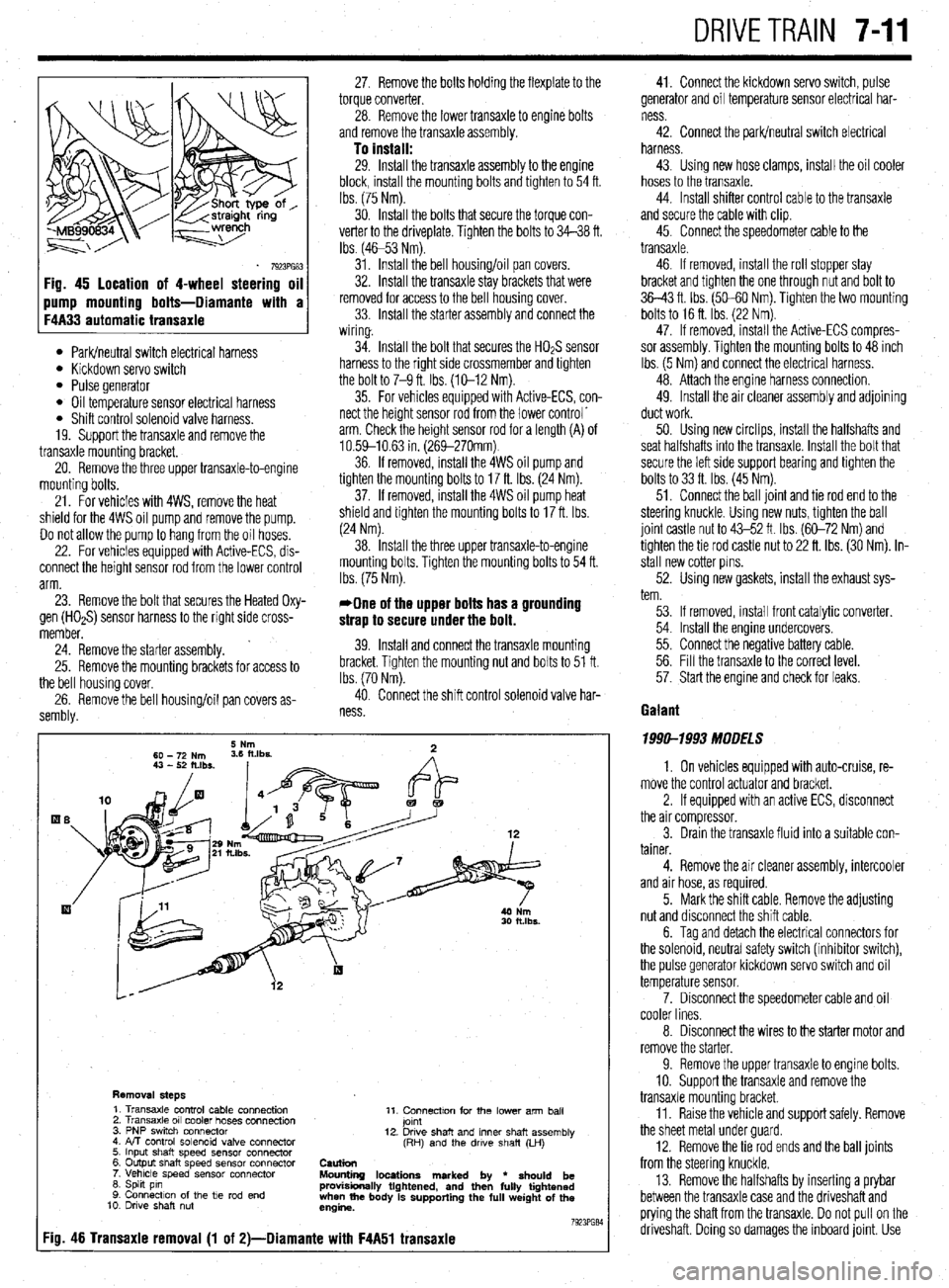

Fig. 45 location of 4-wheel steering oil

l Park/neutral switch electrical harness l Kickdown servo switch l Pulse generator l Oil temperature sensor electrical harness l Shift control solenoid valve harness.

19. Support the transaxle and remove the

transaxle mounting bracket.

20. Remove the three upper transaxle-to-engine

mounting bolts.

21. For vehicles with 4WS, remove the heat

shield for the 4WS oil pump and remove the pump.

Do not allow the pump to hang from the oil hoses.

22. For vehicles equipped with Active-ECS, dis-

connect the height sensor rod from the lower control

arm.

23. Remove the bolt that secures the Heated Oxy-

gen (HOaS) sensor harness to the right side cross-

member.

’ 24. Remove the starter assembly.

25. Remove the mounting brackets for access to

the bell housing cover,

26. Remove the bell housing/oil pan covers as-

sembly. 27. Remove the bolts holding the flexplate to the

torque converter.

28. Remove the lower transaxle to engine bolts

and remove the transaxle assembly.

To install: 29. Install the transaxle assembly to the engine

block, install the mounting bolts and tighten to 54 ft.

tbs. (75 Nm).

30. Install the bolts that secure the torque con-

verter to the driveplate. Tighten the bolts to 34-38 ft.

Ibs (4653 Nm).

31. Install the bell housing/oil pan covers.

32. Install the transaxle stay brackets that were

removed for access to the bell housing cover.

33. Install the starter assembly and connect the

wiring.

34. Install the bolt that secures the HO& sensor

harness to the right side crossmember and tighten

the bolt to 7-9 ft. Ibs. (X-12 Nm).

35. For vehicles equipped with Active-ECS, con-

nect the height sensor rod from the lower control’

arm. Check the height sensor rod for a length (A) of

10.59-10.63 in. (269-270mm)

36. If removed, install the 4WS oil pump and

tighten the mounting bolts to 17 ft. Ibs. (24 Nm).

37. If removed, install the 4WS oil pump heat

shield and tighten the mounting bolts to 17 ft. Ibs.

(24 Nm).

38. Install the three upper transaxle-to-engine

mounting bolts. Tighten the mounting bolts to 54 ft.

Ibs. (75 Nm).

*One of the upper bolts has a grounding

strap to secure under the bolt.

39. Install and connect the transaxle mounting

bracket. Tighten the mounting nut and bolts to 51 ft.

Ibs. (70 Nm).

40. Connect the shift control solenoid valve har-

ness

Removal steps 1. Transaxle control cable connection

2. Transaxle 011 cooler hoses connection

3. PNP swrtch connector

4. FvT control solenoid valve connector

5. Input shaft speed sensor connector

6. Output shaft speed sensor connector

7. Vehicle speed sensor connector

6. Spht pin

9. Connection of the tie rod end

10. Drwe shaft nut 11. Connectton for the lower arm ball

jomt

12. Drwe shaft and inner shaft assembly

(RH) and the drwe shaft (LH)

Caution

Mounting locations marked by

l should be

provisionally tightened, and then fully tightened

when the body is supporting the full weight of the

engine.

7923PG84

:io. 46 Transaxie removal (1 of 2)-Diamante with F4A51 transaxie

41. Connect the kickdown servo switch, pulse

generator and oil temperature sensor electrical har-

ness

42. Connect the park/neutral switch electrical

harness.

43. Using new hose clamps, install the oil cooler

hoses to the transaxle.

44. Install shifter control cable to the transaxle

and secure the cable with clip.

45. Connect the speedometer cable to the

transaxle.

46. If removed, install the roll stopper stay

bracket and tighten the one through nut and bolt to

36-43 ft. Ibs. (50-60 Nm). Tighten the two mounting

bolts to 16 ft. Ibs. (22 Nm).

47. If removed, install the Active-ECS compres-

sor assembly. Tighten the mounting bolts to 48 inch

Ibs. (5 Nm) and connect the electrical harness.

48. Attach the engine harness connection.

49. Install the air cleaner assembly and adjoining

duct work.

50. Using new circlips, install the halfshafts and

seat halfshafts into the transaxle. Install the bolt that

secure the left side support bearing and tighten the

bolts to 33 ft. Ibs. (45 Nm).

51. Connect the ball joint and tie rod end to the

steering knuckle. Using new nuts, tighten the ball

joint castle nut to 43-52 ft. Ibs. (60-72 Nm) and

tighten the tie rod castle nut to 22 ft. ibs. (30 Nm). in-

stall new cotter pins.

52. Using new gaskets, install the exhaust sys-

tem.

53. If removed, install front catalytic converter.

54. Install the engine undercovers.

55. Connect the negative battery cable.

56. Fill the transaxle to the correct level.

57. Start the engine and check for leaks.

Gaiant

1999-1993 MODELS

1. On vehicles equipped with auto-cruise, re-

move the control actuator and bracket.

2. If equipped with an active ECS, disconnect

the air compressor.

3. Drain the transaxle fluid into a suitable con-

tainer.

4. Remove the air cleaner assembly, intercooler

and air hose, as required.

5. Mark the shift cable. Remove the adjusting

nut and disconnect the shift cable.

6. Tag and detach the electrical connectors for

the solenoid, neutral safety switch (inhibitor switch),

the pulse generator kickdown servo switch and oil

temperature sensor.

7. Disconnect the speedometer cable and oil

cooler lines.

8. Disconnect the wires to the starter motor and

remove the starter.

9. Remove the upper transaxle to engine bolts.

10. Support the transaxle and remove the

transaxle mounting bracket.

11. Raise the vehicle and support safely. Remove

the sheet metal under guard

12. Remove the tie rod ends and the bail joints

from the steering knuckle.

13. Remove the halfshafts by inserting a prybar

between the transaxle case and the driveshaft and

prying the shaft from the transaxle. Do not pull on the

driveshaft. Doing so damages the inboard joint. Use

Page 302 of 408

SUSPENSION AND STEERING 8-7

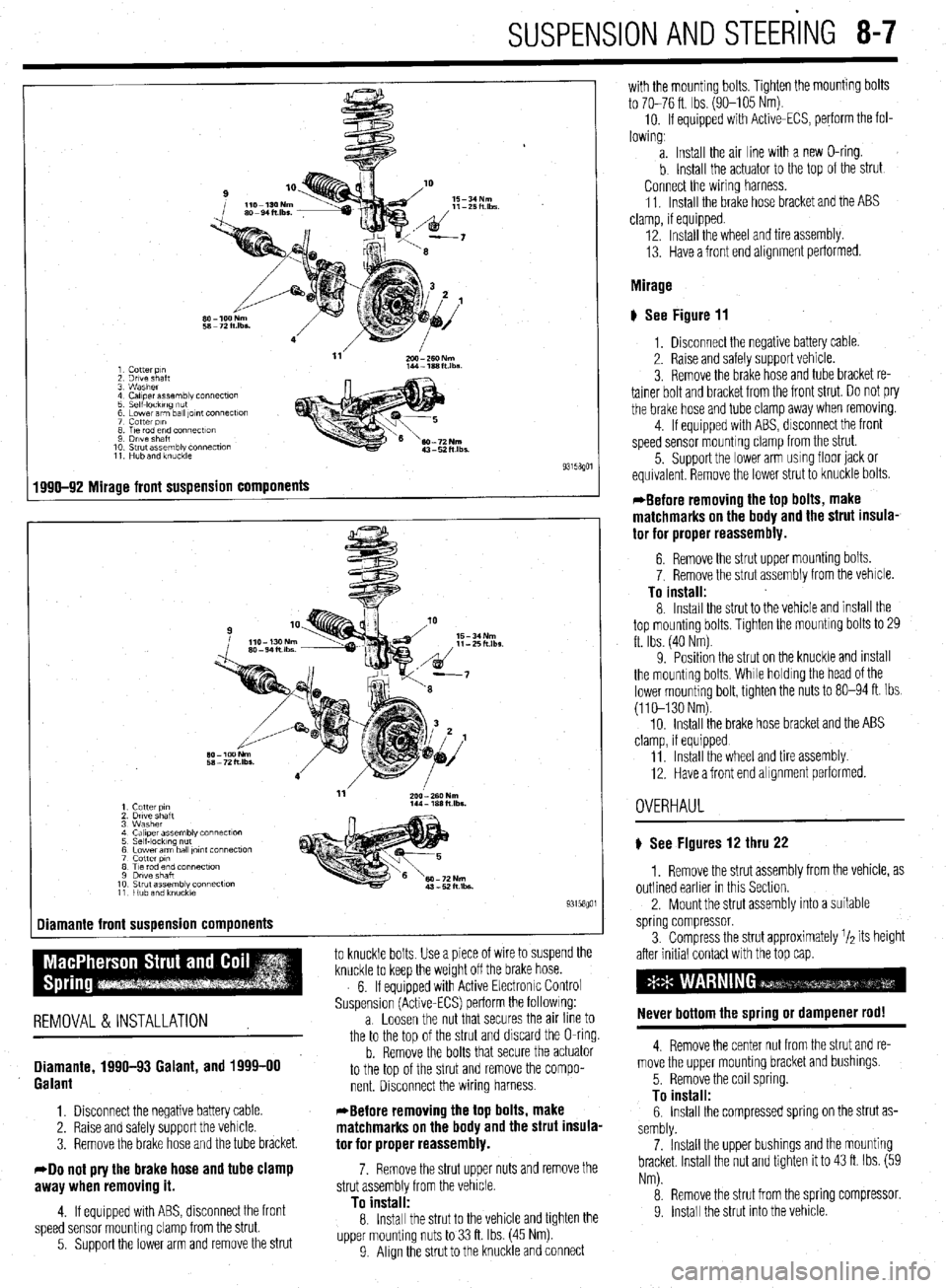

1 Cotter p,n

2 Drive shaft

3 Washer

4 Caliper assembly connecf~on

5 Self-IockIng ““f

6 Lower arm ball ,Ol”f Connectlo”

7 cotter PI”

8 T,e rod end connectton

9 Drive Shaft

10 Strut assembly connection

11 Hub and knuckle

1990-92 Mirage front suspension components

-

1 Cutter PI”

2 Drtve shaft

3 Washer

4 Ca,,perassembly connect~o”

5 Self-locking nut

6 Lower arm ball ,o,nt connection

7 cotter PI”

8 Tie rod end connection

9 Dwe shaft

10 Strut assembly connection

11 Hub and knuckie

Diamante front suspension components

1

to knuckle bolts Use a piece of wire to suspend the

knuckle to keep the weight off the brake hose.

6. If equipped with Active Electronrc Control

Suspension (Active-ECS) perform the followrng:

REMOVAL &INSTALLATION a. Loosen the nut that secures the an line to

the to the too of the strut and discard the O-ring.

Diamante, 1990-93 Galant, and 1999-00

Galant

1. Disconnect the negative battery cable.

2. Raise and safely support the vehicle.

3. Remove the brake hose and the tube bracket.

40 not pry the brake hose and tube clamp

awav when removino it.

b. Remove the bolts that secure the actuator

to the top of the strut and remove the compo-

nent. Disconnect the wiring harness.

*Before removing the top bolts, make

matchmarks on the body and the strut insula-

tor for proper reassembly.

7. Remove the strut upper nuts and remove the

strut assemblv from the vehicle.

4. If equipped with ABS, disconnect the front

speed sensor mounting clamp from the strut.

5. Support the lower arm and remove the strut

To instalf: 8. Install the strut to the vehicle and tighten the

upper mounting nuts to 33 ft. Ibs. (45 Nm)

9 Align the strut to the knuckle and connect with the mounting bolts. Tighten the mounting bolts

to 70-76 ft. Ibs. (90-105 Nm).

10. If equipped with Active-ECS, perform the fol-

lowing,

a. Install the air line with a new O-ring.

b Install the actuator to the top of the strut

Connect the wiring harness.

11. Install the brake hose bracket and the ABS

clamp, if equipped.

12. Install the wheel and tire assembly.

13. Have a front end alignment performed.

Mirage

# See Figure 11

1, Disconnect the negative battery cable.

2. Raise and safely support vehicle.

3. Remove the brake hose and tube bracket re-

tainer bolt and bracket from the front strut. Do not pry

the brake hose and tube clamp away when removrng.

4. If equipped with ABS, disconnect the front

speed sensor mounting clamp from the strut.

5. Support the lower arm usmg floor jack or

equivalent Remove the lower strut to knuckle bolts.

*Before removing the top bolts, make

matchmarks on the body and the strut insula-

tor for proper reassembly.

6. Remove the strut upper mounting bolts.

7. Remove the strut assembly from the vehicle.

To install: 8. Install the strut to the vehicle and install the

top mounting bolts, Tighten the mountrng bolts to 29

ft. Ibs. (40 Nm)

9. Position the strut on the knuckle and mstall

the mounting bolts, While holdrng the head of the

lower mounting bolt, tighten the nuts to 80-94 ft. Ibs.

(110-130 Nm).

10. Install the brake hose bracket and the ABS

clamp, if equipped

11 Install the wheel and tire assembly

12. Have a front end alignment performed.

OVERHAUL

) See Figures 12 thru 22

1. Remove the strut assembly from the vehicle, as

outlined earlier in this Section.

2. Mount the strut assembly into a suitable

spring compressor.

3. Compress the strut approximately r/a its height

after initial contact with the top cap.

Never bottom the spring or dampener rod!

4. Remove the center nut from the strut and re-

move the upper mounting bracket and bushings.

5. Remove the coil spring.

To install: 6. Install the compressed spring on the strut as-

sembly.

7. Install the upper bushings and the mounting

bracket Install the nut and tighten it to 43 ft. Ibs. (59

Nm).

8. Remove the strut from the spring compressor.

9. Install the strut into the vehrcle

Page 308 of 408

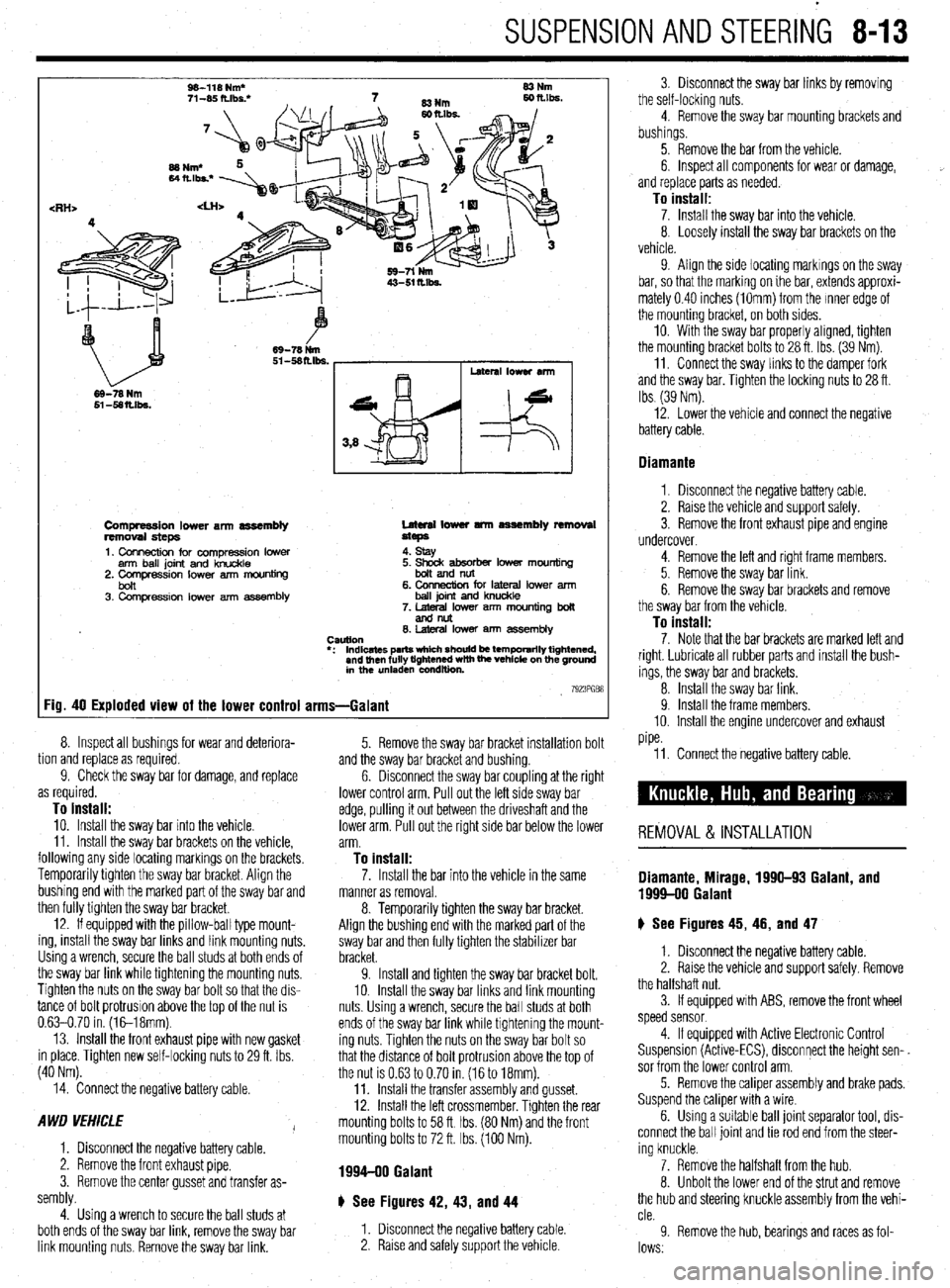

SUSPENSION AND STEERING 8-13

W-118 Nm*

71-W ft.lbs: 83Nm

69-78 Nm

Compression lower arm assembly

removal steps

1. Connection for compression lower

arm ball joint and knuckle

2. Comoression lower arm mouniina Lateral lower tmn assembly removal

steps

4. stay

bon ’ 3. Compression lower arm assembly 6. CMlnection for lateral lower arm

ball joint and knuckle

7. lateral lower arm mounting boll

andnllt

0. hleral lower am7 assembly

CWtlOtl

l : Indicates parts which should be temporarily tightened,

and then fully tightened with the vehicle on the ground

in the unladen condition

7923PGB8 Fig. 40 Exploded view of the lower control arms-Galant

tion and replace as required. 8.

9. Inspect all bushings for wear and deteriora-

Check the sway bar for damage, and replace

as required.

To install: 10. Install the sway bar into the vehicle.

11. Install the sway bar brackets on the vehicle,

following any side locating markings on the brackets.

Temporarily tighten the sway bar bracket. Align the

bushing end with the marked part of the sway bar and

then fully tighten the sway bar bracket.

12. If equipped with the pillow-ball type mount-

ing, install the sway bar links and link mounting nuts.

Using a wrench, secure the ball studs at both ends of

the sway bar link while tightening the mounting nuts.

Tighten the nuts on the sway bar bolt so that the dis-

tance of bolt protrusion above the top of the nut is

0.63-0.70 in. (1&18mm).

13. Install the front exhaust pipe with new gasket

in place. Tighten new self-locking nuts to 29 ft. Ibs.

(40 Nm). and the sway bar bracket and bushing.

6. 5. Remove the sway bar bracket installation bolt

Disconnect the sway bar coupling at the right

lower control arm. Pull out the left side sway bar

edge, pulling it out between the driveshaft and the

lower arm. Pull out the right side bar below the lower

arm.

To install:

14. Connect the negative battery cable.

A WD VEHICLE

I

1. Disconnect the negative battery cable.

2. Remove the front exhaust pipe.

3. Remove the center gusset and transfer as-

sembly.

4. Using a wrench to secure the ball studs at

both ends of the sway bar link, remove the sway bar

link mounting nuts. Remove the sway bar link. 11. Connect the negative battery cable.

REMOVAL & INSTALLATION

7. Install the bar into the vehicle in the same Diamante, Mirage, 1996-93 Galant, and manner as removal. 1999-00 Galant 8. Temporarily tighten the sway bar bracket.

Align the bushing end with the marked part of the

sway bar and then fully tighten the stabilizer bar

bracket.

9. Install and tighten the sway bar bracket bolt.

10. Install the sway bar links and link mounting

nuts Using a wrench, secure the ball studs at both

ends of the sway bar link while tightening the mount-

ing nuts. Tighten the nuts on the sway bar bolt so

that the distance of bolt protrusion above the top of

the nut is 0.63 to 0.70 in. (16 to 18mm).

11. Install the transfer assembly and gusset.

12. Install the left crossmember. Tighten the rear

mounting bolts to 58 ft Ibs. (80 Nm) and the front

mounting bolts to 72 ft. Ibs. (100 Nm). ) See Figures 45, 46, and 47

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely. Remove

the halfshaft nut.

3. If equipped with ABS, remove the front wheel

speed sensor

1994-90 Galant

4. If equipped with Active Electronic Control

Suspension (Active-ECS), disconnect the height sen-.

sor from the lower control arm.

5. Remove the caliper assembly and brake pads.

Suspend the caliper with a wire

6. Using a suitable ball joint separator tool, dis-

connect the ball joint and tie rod end from the steer-

ing knuckle.

7. Remove the halfshaft from the hub.

8. Unbolt the lower end of the strut and remove

the hub and steering knuckle assembly from the vehi-

cle.

9 Remove the hub, bearings and races as fol-

lows.

# See Figures 42, 43, and 44

1. Disconnect the negative battery cable.

2. Raise and safely support the vehicle 3. Disconnect the sway bar links by removing

the self-locking nuts.

4. Remove the sway bar mounting brackets and

bushings.

5. Remove the bar from the vehicle.

6. Inspect all components for wear or damage,

and replace parts as needed.

To install: 7. Install the sway bar into the vehicle.

8. Loosely install the sway bar brackets on the

vehicle.

9. Align the side locating markings on the sway

bar, so that the marking on ihe bar, extends approxi-

mately 0.40 inches (1Omm) from the Inner edge of

the mounting bracket, on both sides.

10. With the sway bar properly aligned, tighten

the mounting bracket bolts to 28 ft. Ibs. (39 Nm).

11. Connect the sway links to the damper fork

and the sway bar. Tighten the locking nuts to 28 ft.

Ibs (39 Nm).

12. Lower the vehicle and connect the negative

battery cable.

Diamante

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Remove the front exhaust pipe and engine

undercover.

4. Remove the left and right frame members.

5. Remove the sway bar link.

6. Remove the sway bar brackets and remove

the sway bar from the vehicle.

To install: 7. Note that the bar brackets are marked left and

right. Lubricate all rubber parts and install the bush-

ings, the sway bar and brackets.

8. Install the sway bar link.

9. Install the frame members.

10. Install the engine undercover and exhaust

pipe.

Page 310 of 408

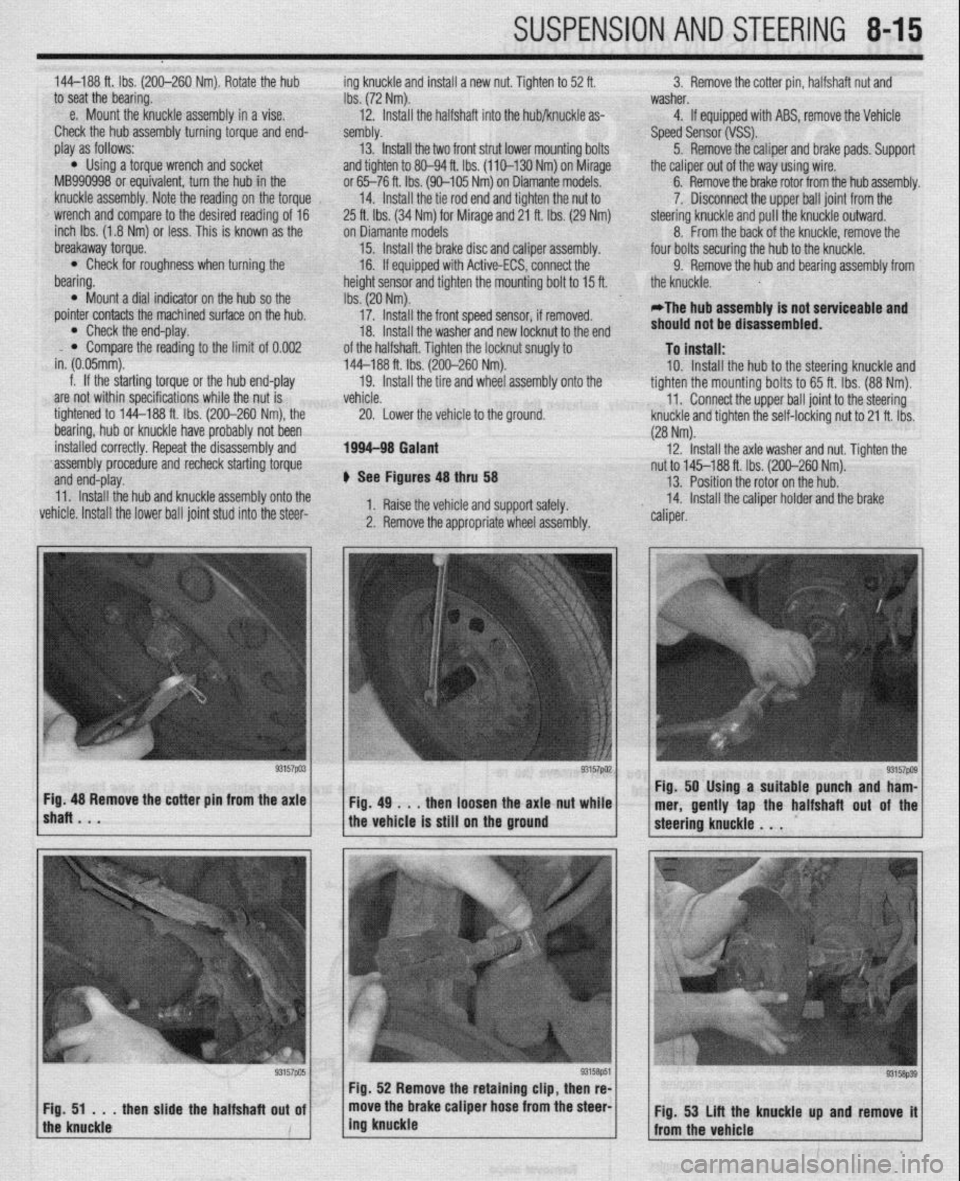

SUSPENSION AND STEERING 845

144-188 ft. Ibs. (200-260 Nm). Rotate the hub ing knuckle and install a new nut. Tighten to 52 ft. 3. Remove the cotter pin, halfshaft nut and

to seat the bearing.

Ibs. (72 Nm). washer.

e. Mount the knuckle assembly in a vise.

12. Install the halfshaft into the hub/knuckle as- 4. If equipped with ABS, remove the Vehicle

Check the hub assembly turning torque and end- sembly.

Speed Sensor (VSS).

play as follows: 13. Install the two front strut lower mounting bolts

5. Remove the caliper and brake pads. Support

l Using a torque wrench and socket

and tighten to 80-94 ft. Ibs. (110-130 Nm) on Mirage

the caliper out of the way using wire.

MB990998 or equivalent, turn the hub in the or 65-76 ft. Ibs. (90-105 Nm) on Diamante models. 6. Remove the brake rotor from the hub assembly.

knuckle assembly. Note the reading on the torque

14. Install the tie rod end and tighten the nut to 7. Disconnect the upper ball joint from the

wrench and compare to the desired reading of 16

25 ft. lbs. (34 Nm) for Mirage and 21 ft. Ibs. (29 Nm) steering knuckle and pull the knuckle outward.

inch Ibs. (1.8 Nm) or less. This is known as the ‘on Diamante models

8. From the back of the knuckle, remove the

breakaway torque.

15. Install the brake disc and caliper assembly. ‘four bolts securing the hub to the knuckle.

l Check for roughness when turning the

16. If equipped with Active-ECS, connect the

9. Remove the hub and bearing assembly from

bearing.

height sensor and tighten the mounting bolt to 15 ft.

the knuckle.

0 Mount a dial indicator on the hub so the

Ibs. (20 Nm).

pointer contacts the machined surface on the hub.

17. Install the front speed sensor, if removed.

*The hub assembly is not serviceable and

l Check the end-play.

18. Install the washer and new locknut to the end should not be disassembled.

l Compare the reading to the limit of 0.002

in. (0.05mm). of the halfshaft. Tighten the locknut snugly to To install: 144-188 ft. Ibs. (200-260 Nm).

f. If the starting torque or the hub end-play

19. Install the tire and wheel assembly onto the 10. Install the hub to the steering knuckle and

are not within specifications while the nut is tighten the mounting bolts to 65 ft. Ibs. (88 Nm).

vehicle.

11.

tightened to 144-188 ft. Ibs. (200-260 Nm), the

Lower the vehicle to the ground. Connect the upper ball joint to the steering

20.

bearing, hub or knuckle have probably not been ‘knuckle and tighten the self-locking nut to 21 ft. Ibs.

(28 Nm).

installed correctly. Repeat the disassembly and 1994-98 Galant 12.

‘assembly procedure and recheck starting torque Install the axle washer and nut. Tighten the

and end-play. nut to 145-188 ft. Ibs. (200-260 Nm).

+ See Figures 48 thru 58 13. Position the rotor on the hub.

11. Install the hub and knuckle assembly onto the

vehicle. Install the lower ball joint stud into the steer- 1. Raise the vehicle and support safely. 14. Install the caliper holder and the brake

2. Remove the appropriate wheel assembly. ” caliper.

lshaRBmV * “57pa3~ ~Fig.4g~..thenloosehtheaxlattut~~;.~ Fig. 48 Remove the cotter pm from the axle Fig. 50 Using a suitable punch and ham-

mer, gently tap the halfshaft out of the

the vehicle is still on the ground

Page 319 of 408

8-24 SUSPENSION AND STEERING

9315t$M 93158p26 Fig. 68 Remove the through-bolt connecting Fig. 70 Disconnect the ball joint stud from

the knuckle assembly to the lower control the steering knuckle

1 arm

Fig. 71 Remove the mounting bolt connect-

Fig, 89 Remove the mounting bolt connect- /

1 ing the toe lower control arm to the SW

Dolt. 9; Connect the knuckle to the lower control arm 9. With the full weigh

ground, tighten the control

and lightly tighten the through-bolt.

10. Connect the stabilizer bar link to the control

arm and tighten the nut to 28 ft. Ibs. (39 Nm).

11. Install the wheels and lower the vehicle to the

floor.

12. Once the full weight of the vehicle is on the

suspension, tighten the lower arm mounting bolt nuts

to 71 ft. Ibs. (98 Nm).

13. Check rear wheel alignment and adjust if nec-

essary.

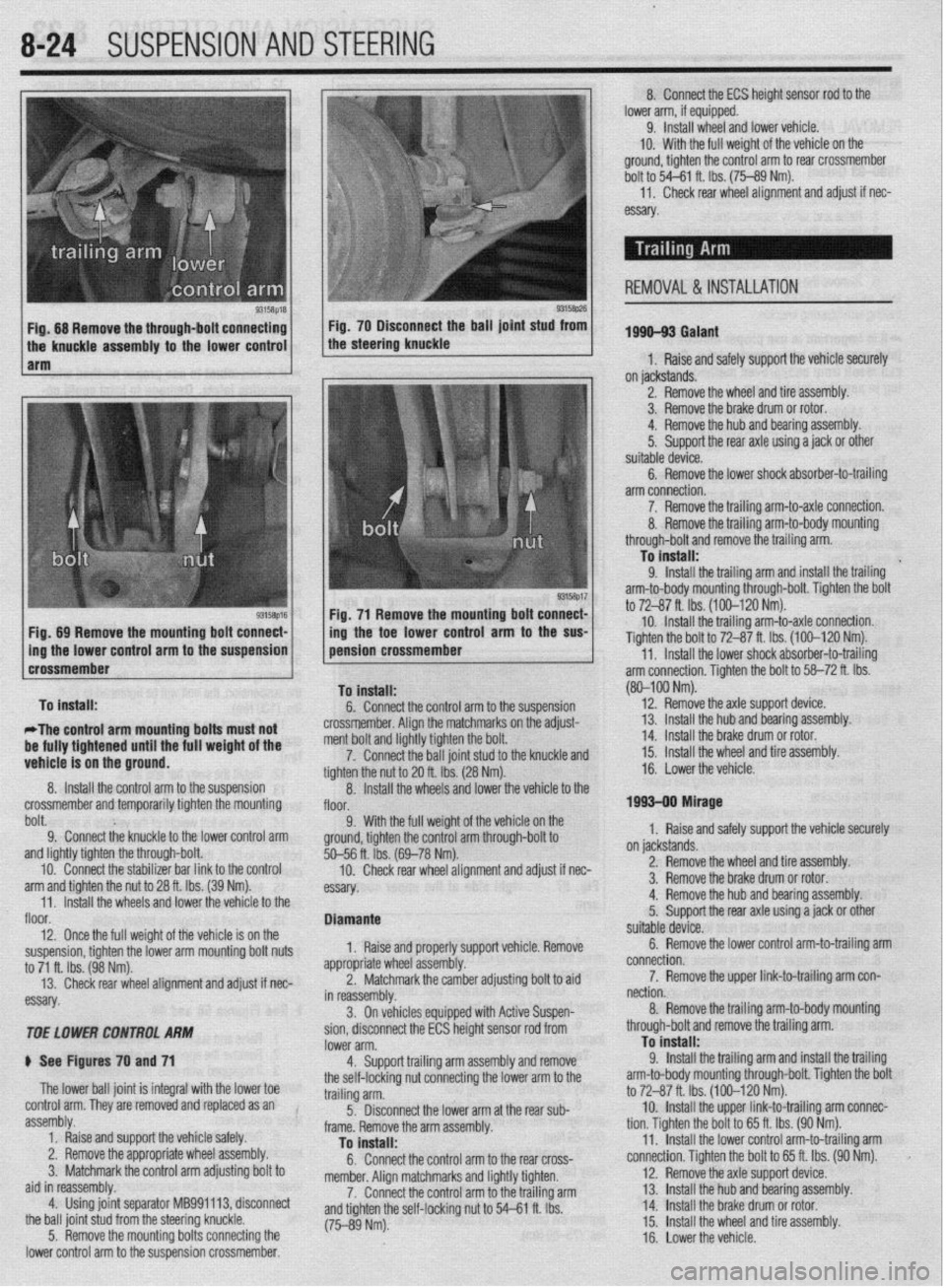

TOE LOWER CONTROL ARhl

ti See Figures 70 and 71

The lower ball joint is integral with the lower toe

control arm. They are removed and replaced as an

assembly.

1. Raise and support the vehicle safely.

2. Remove the appropriate wheel assembly.

3. Matchmark the control arm adjusting bolt to

aid in reassembly.

4. Using joint separator MB991113, disconnect

the ball joint stud from the steering knuckle.

5. Remove the mounting bolts connecting the

lower control arm to the suspension crossmember. %--56 ft. ibs. (

10. Check

essay. rem an0 aajusr

II nec-

orl vehicle Remove

ldiustina bolt to aid

soen- Diamante

1, Raise and properly supp

appropriate whl

eel assembly.

2. Matchn

narkthe camber a , _

in reassembly.

3. On vehicles equipped with Active Su r

sion, disconnect the ECS height sensor rod from

lower arm.

4. Support trailing arm assembly and remove

the self-locking nut connecting the lower arm to the

trailing arm.

5. Disconnect the lower arm at the rear sub-

frame. Remove the arm assembly.

To install:

6. Connect the control arm to the rear cross-

member. Alion matchmarks and liahtlv tiohten.

7. Connect the control arm tothe trailing arm

and tighten the self-locking nut to 54-P e rho I I IL IY.J.

(75-89 Nm). 8. Connect the ECS height sensor rod to the

lower arm, if equipped.

9. Install wheel and lower vehicle.

IO. With the full weight of the vehicle on the

ground, tighten the control arm to rear crossmember

bolt to 54-61 ft. Ibs. (75-89 Nm).

11,

Check rear wheel alignment and adjust if nec-

essary

1996-93 Galant

1, Raise and safely support the vehicle securely

on jackstands.

2. Remove the wheel and tire assembly.

3. Remove the brake drum or rotor.

4. Remove the hub and bearing assembly.

5.

Support the rear axle using a jack or other

suitable device.

6. Remove the lower shock absorber-to-trailing

arm connection.

7. Remove the trailing arm-to-axle connection.

REMOVAL & INSTALLATION

(80-100 Nm).

12.

Remove the axle suooort device.

on jackstands.

2. Remove the wheel and tire assembly.

3. Remove the brake drum or rotor.

4. Remove the hub and bearing assembly.

5.

Support the rear axle using a jack or other

suitable device.

6. Remove the lower control arm-to-trailing arm

connection.

7. Remove the upper link-to-trailing arm con-

nection.

8. Remove the trailing arm-to-body mounting

through-bolt and remove the trailing arm.

To install:

9.

Install the trailing arm and install the trailing

arm-to-body mounting through-bolt. Tighten the bolt

to 72-87 ft. Ibs. (100-120 Nm).

10. Install the upper link-to-trailing arm connec-

tion. Tighten the bolt to 65 ft. Ibs. (90 Nm).

11. Install the lower control arm-to-trailing arm

connection. Tighten the bolt to 65 ft. Ibs. (90 Nm).

12. Remove the axle support device.

13. Install 1 he hub and bearing assembly.

14 Install 1

. _ .he brake drum or rotor.

15.

Install the wheel and tire assembly.

16. Lower the vehicle.

Page 340 of 408

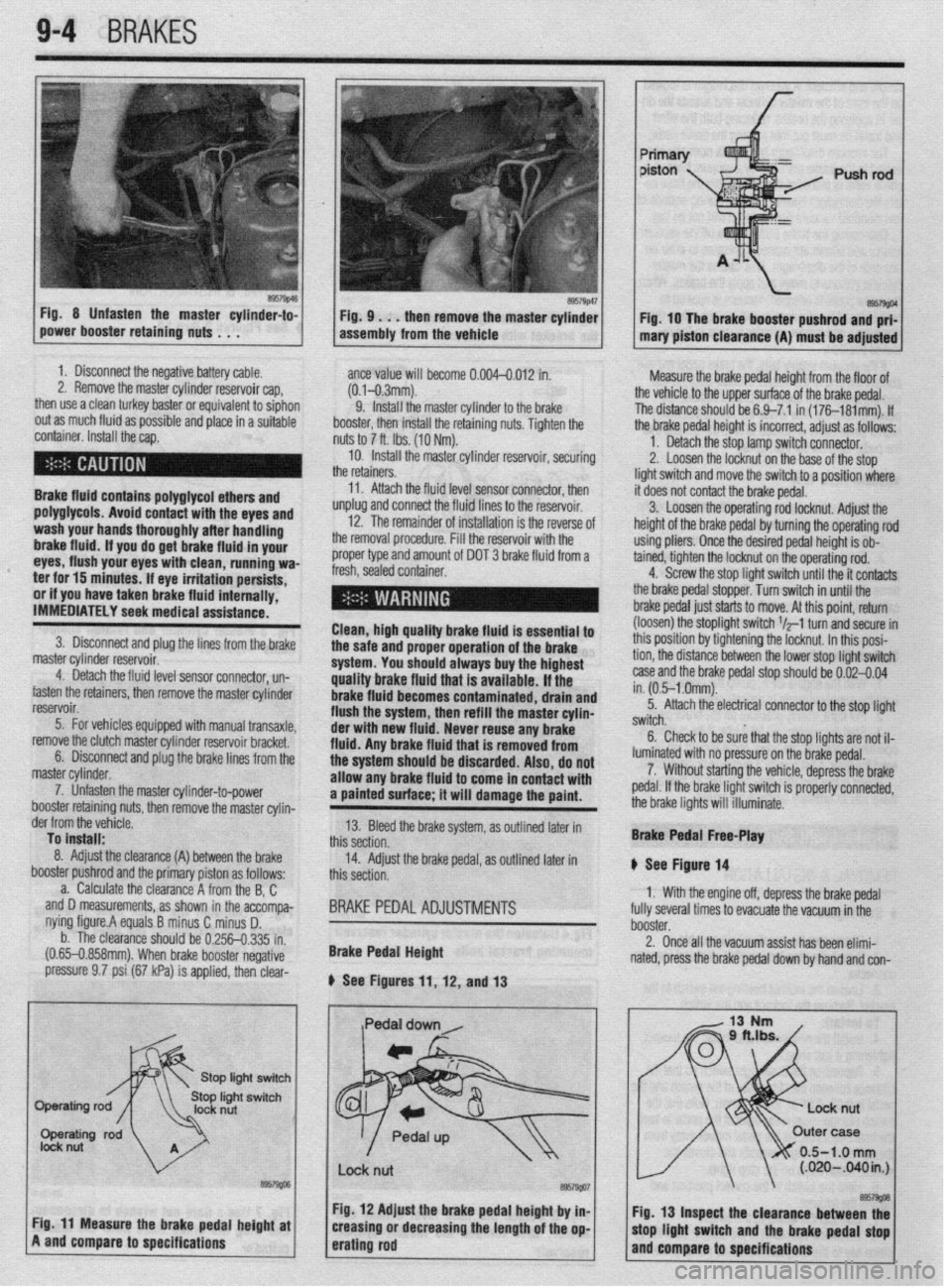

9-4 BRAKES

Fig 8 Unfasten the master cylinder-to-

power booster retaining nuts . . . F57g’6~ Fig. 9 . . . then remove the master cylinder

assembly from the vehicle Fig. 10 The brake booster pushrod and prf-

mary piston clearance (A) must be adjusted

1. Disconnect the negative battery cable.

2. Remove the master cylinder reservoir cap,

then use a clean turkey baster or equivalent to siphon

out as much fluid as possible and place in a suitable

container. Install the cap.

Brake fluid contains polyglycol ethers and

polyglycols. Avoid contact with the eyes and

wash your hands thoroughly after handling

brake fluid. If you do get brake fluid in your

eyes, flush your eyes with clean, running wa-

ter for 15 minutes. If eye irritation persists,

or if you have taken brake fluid internally,

IMMEDIATELY seek medical assistance.

3. Disconnect and plug the lines from the brake

master cylinder reservoir.

4. Detach the fluid level sensor connector, un-

fasten the retainers, then remove the master cylinder

reservoir.

5. For vehicles equipped with manual transaxle,

remove the clutch master cylinder reservoir bracket.

6. Disconnect and plug the brake lines from the

master cylinder.

7. Unfasten the master cylinder-to-power

booster retainino nuts, then remove the master cvlin- ante value will become 0.004-0.012 in.

(0.1-0.3mm).

9. install the master cylinder to the brake

booster, then install the retaining nuts. Tighten the

nuts to 7 ft. Ibs. (10 Nm).

10. Install the master cylinder reservoir, securing

the retainers.

11. Attach the fluid level sensor connector, then

unplug and connect the fluid lines to the reservoir.

12. The remainder of installation is the reverse of

the removal procedure. Fill the reservoir with the

proper type and amount of DOT 3 brake fluid from a

fresh, sealed container.

I l

Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest

quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake

fluid. Any brake fluid that is removed from

the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a painted surface; it will damage the paint. Measure the brake pedal height from the floor of

the vehicle to the upper surface of the brake pedal.

The distance should be 6.9-7.1 in (176181mm). If

the brake pedal height is incorrect, adjust as follows:

1. Detach the stop lamp switch connector.

2. Loosen the locknut on the base of the stop

light switch and move the switch to a position where

it does not contact the brake pedal.

3. Loosen the operating rod locknut. Adjust the

height of the brake pedal by turning the operating rod

using pliers. Once the desired pedal height is ob-

tained, tighten the locknut on the operating rod.

4. Screw the stop light switch until the it contacts

the brake pedal stopper. Turn switch in until the

brake pedal just starts to move. At this point, return

(loosen) the stoplight switch $-1 turn and secure in

this position by tightening the locknut. In this posi-

tion, the distance between the lower stop light switch

case and the brake pedal stop should be 0.02-0.04

in. (0.5-l .Omm).

5. Attach the electrical connector to the stop light

switch.

6. Check to be sure that the stop lights are not il-

luminated with no pressure on the brake pedal.

7. Without starting the vehicle, depress the brake

pedal. If the brake light switch is properly connected,

the brake lights will illuminate.

der from the vefiicle.

To install:

8. Adjust the clearance (A)

booster pushrod ant

a. Calculate tl -,

between the brake

I the primary piston as follows:

le clearance A from the B, C

accompa-

i D.

I.335 in.

negative and D measurements, as shown in the

nying figure.A equals B minus C minus

b. The clearance should be 0.256-t

(0.65-0.858mm). When brake booster I

pressure 9.7 psi (67 kPa) is applied, then clear- 13. Bleed the brake system, as outlined later in

this section.

14. Adjust the brake pedal, as outlined later in

this section.

BRAKE PEDAL ADJUSTMENTS

Brake Pedal Height

b See Figures 11, 12, and 13 Brake Pedal Free-Play

II See Figure 14

1. With the engine off, depress the brake pedal

fully several times to evacuate the vacuum in the

booster.

2. Once all the vacuum assist has been elimi-

nated, press the brake pedal down by hand and con-

/

0.5-1.0 mm (.020-B40in.J I

I

I I

Fig. 12 Adjust the brake pedal height by in- I I.

@57w

Cir 44 “a*., .._^ *I.- 9.--l,- ---I-* L-@-L. -I Fig. 13 Inspect the clearance between thf . . - _-.L -*.a- - . . * _ . . . . ._ . rly. I I rnca~urc we urime peoai nefgnr ar

A and compare to specifications creasmg or aecreasing the lengrn or me op-

erating rod mop llgnt WItCh arm the brake pedal stop

and compare to specifications