engine MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 167 of 391

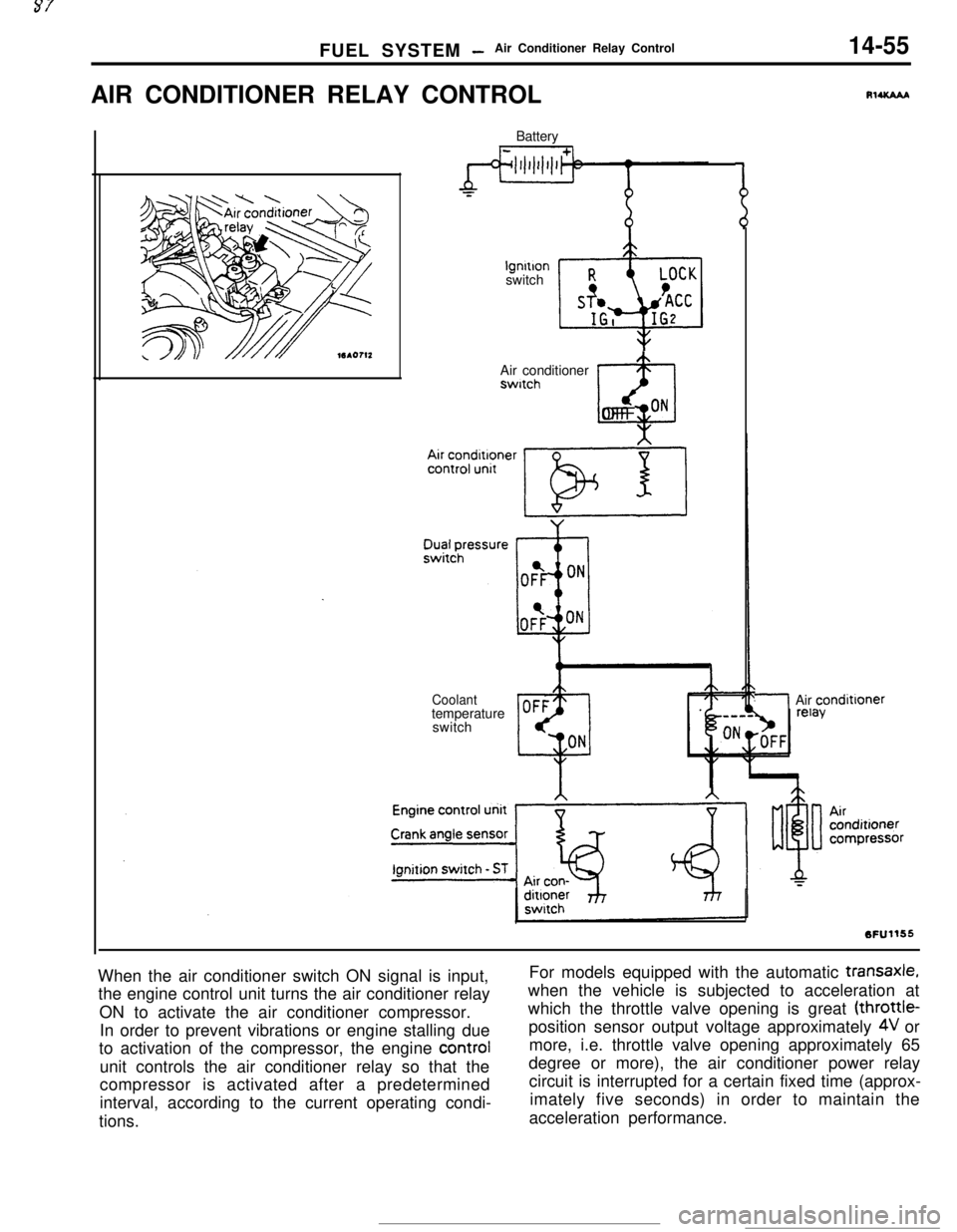

FUEL SYSTEM -Air Conditioner Relay Control14-55AIR CONDITIONER RELAY CONTROL

Batterylgnltlon

switch

Air conditionerswitch

@OFF ON

Coolanttemperature

switch

RlUCAAA

/Air condittoner

When the air conditioner switch ON signal is input,

the engine control unit turns the air conditioner relay

ON to activate the air conditioner compressor.

In order to prevent vibrations or engine stalling due

to activation of the compressor, the engine control

unit controls the air conditioner relay so that the

compressor is activated after a predetermined

interval, according to the current operating condi-

tions.For models equipped with the automatic

transaxle,when the vehicle is subjected to acceleration at

which the throttle valve opening is great (throttle-

position sensor output voltage approximately

4V or

more, i.e. throttle valve opening approximately 65

degree or more), the air conditioner power relay

circuit is interrupted for a certain fixed time (approx-

imately five seconds) in order to maintain the

acceleration performance.

Page 168 of 391

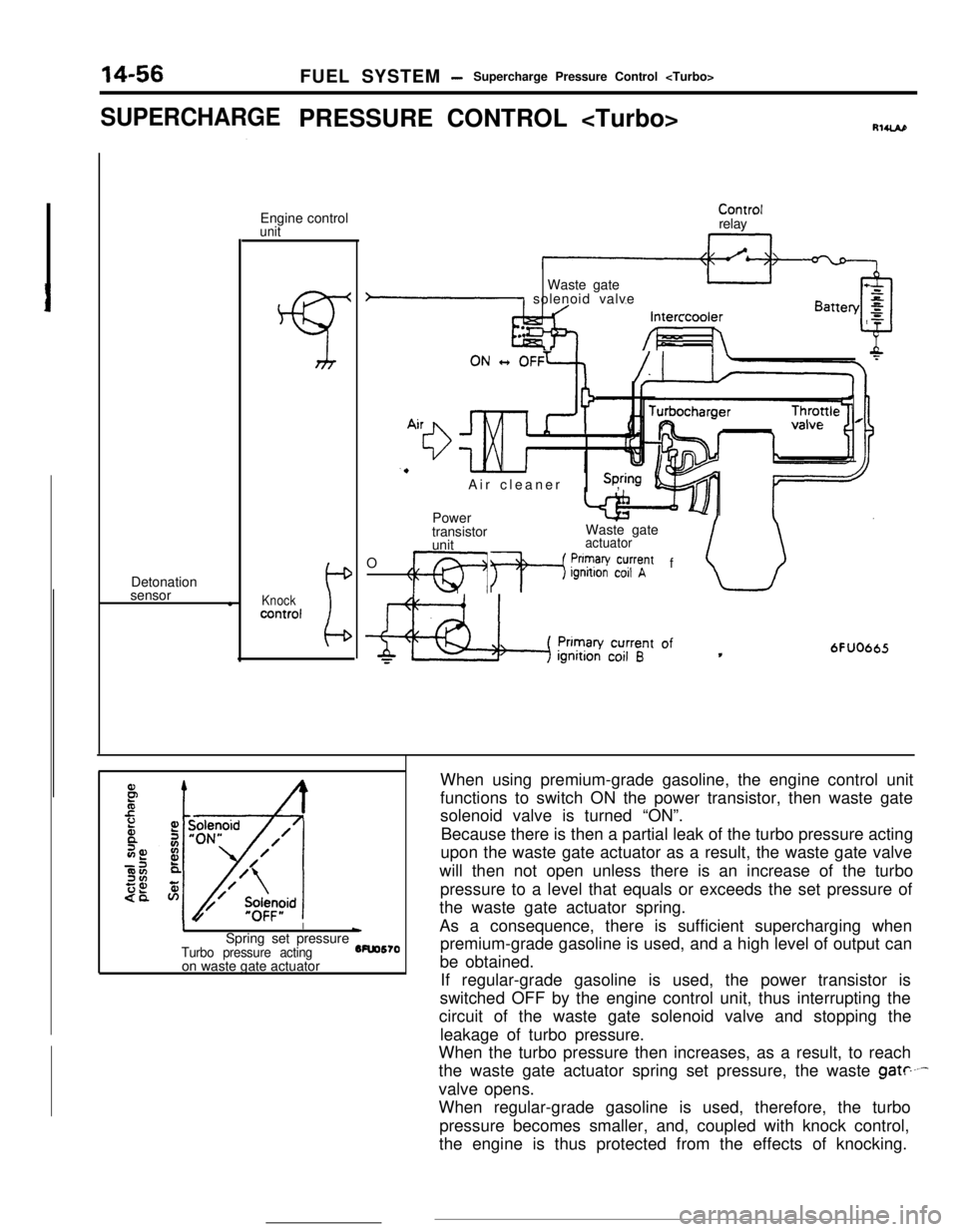

14-56FUEL SYSTEM -Supercharge Pressure Control

SUPERCHARGEPRESSURE CONTROL

sensor

lEngine control

unit

Knockcontrol

ControlrelayIntercooler

h&l --/I- h

.. .Waste gate

P solenoid valve

Air cleaner,

Power

transistorWaste gate

unit

actuatorOf

CT1 +p$?V~~~t

6FUO665

II\Spring set pressure

Turbo pressure acting5Fuo570

on waste gate actuatorWhen using premium-grade gasoline, the engine control unit

functions to switch ON the power transistor, then waste gate

solenoid valve is turned “ON”.

Because there is then a partial leak of the turbo pressure acting

upon the waste gate actuator as a result, the waste gate valve

will then not open unless there is an increase of the turbo

pressure to a level that equals or exceeds the set pressure of

the waste gate actuator spring.

As a consequence, there is sufficient supercharging when

premium-grade gasoline is used, and a high level of output can

be obtained.

If regular-grade gasoline is used, the power transistor is

switched OFF by the engine control unit, thus interrupting the

circuit of the waste gate solenoid valve and stopping the

leakage of turbo pressure.

When the turbo pressure then increases, as a result, to reach

the waste gate actuator spring set pressure, the waste

gate----valve opens.

When regular-grade gasoline is used, therefore, the turbo

pressure becomes smaller, and, coupled with knock control,

the engine is thus protected from the effects of knocking.

Page 169 of 391

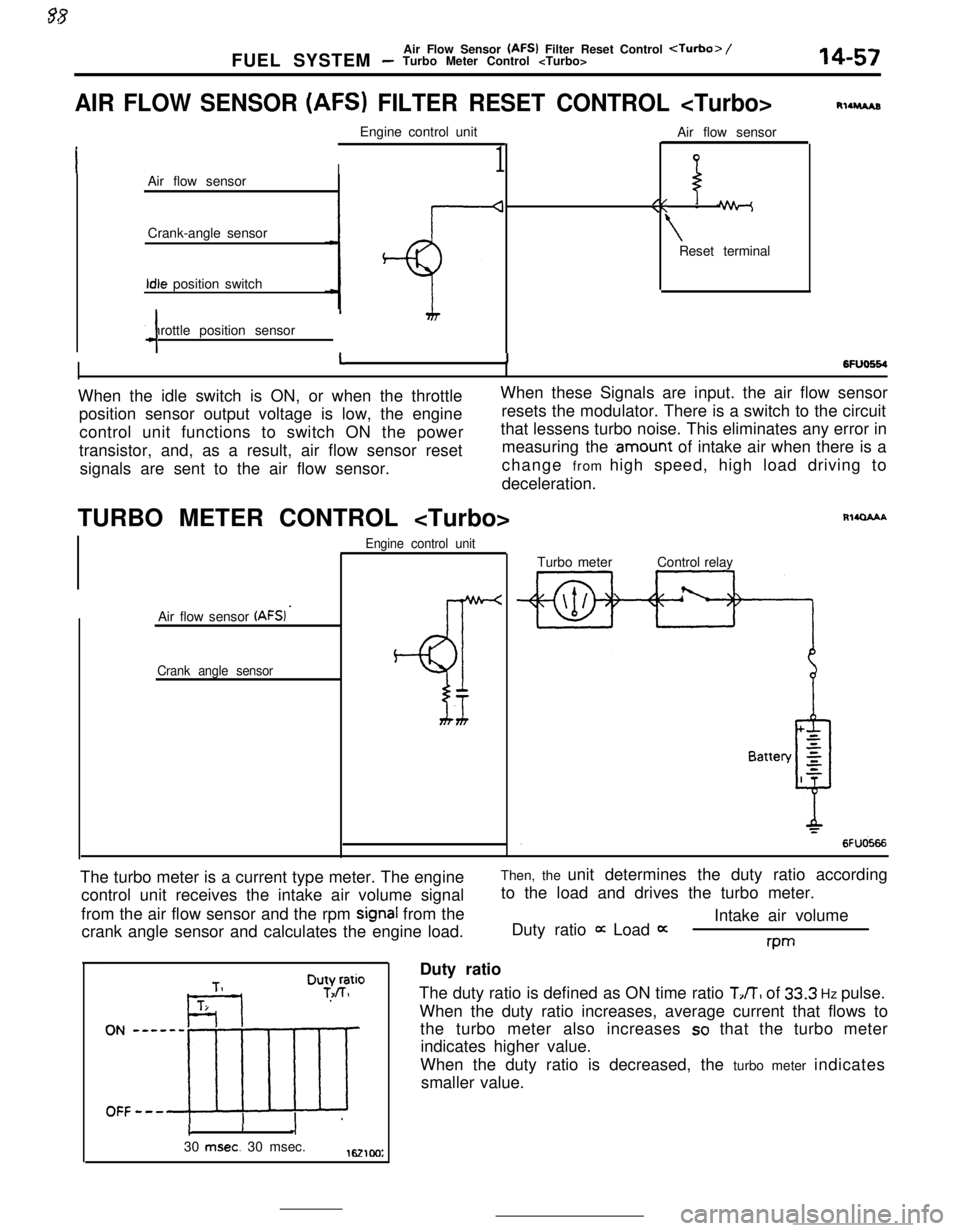

FUEL SYSTEMAir Flow Sensor (AFSI Filter Reset Control

AIR FLOW SENSOR (AFS) FILTER RESET CONTROL

I1Air flow sensor

Crank-angle sensorIdle position switch

Throttle position sensor

4Air flow sensor

//\\ -

\Reset terminal

RllruAs

6FlJo664I11When the idle switch is ON, or when the throttleWhen these Signals are input. the air flow sensor

position sensor output voltage is low, the engineresets the modulator. There is a switch to the circuit

control unit functions to switch ON the powerthat lessens turbo noise. This eliminates any error in

transistor, and, as a result, air flow sensor resetmeasuring the

.amount of intake air when there is a

signals are sent to the air flow sensor.change from high speed, high load driving to

deceleration.

TURBO METER CONTROL

Air flow sensor

(AFSI ’

Crank angle sensorEngine control unit

BT

Rl4QAAATurbo meterControl relay

The turbo meter is a current type meter. The engine

control unit receives the intake air volume signal

from the air flow sensor and the rpm

signal from the

crank angle sensor and calculates the engine load.Then, the unit determines the duty ratio according

to the load and drives the turbo meter.

Intake air volume

Duty ratio

it Load 0:rwDuty ratio

The duty ratio is defined as ON time ratio

TJT, of 33.3 Hz pulse.

When the duty ratio increases, average current that flows to

the turbo meter also increases

so that the turbo meter

indicates higher value.

When the duty ratio is decreased, the turbo meter indicates

smaller value.

cI30

msec. 30 msec.1621cm:

Page 223 of 391

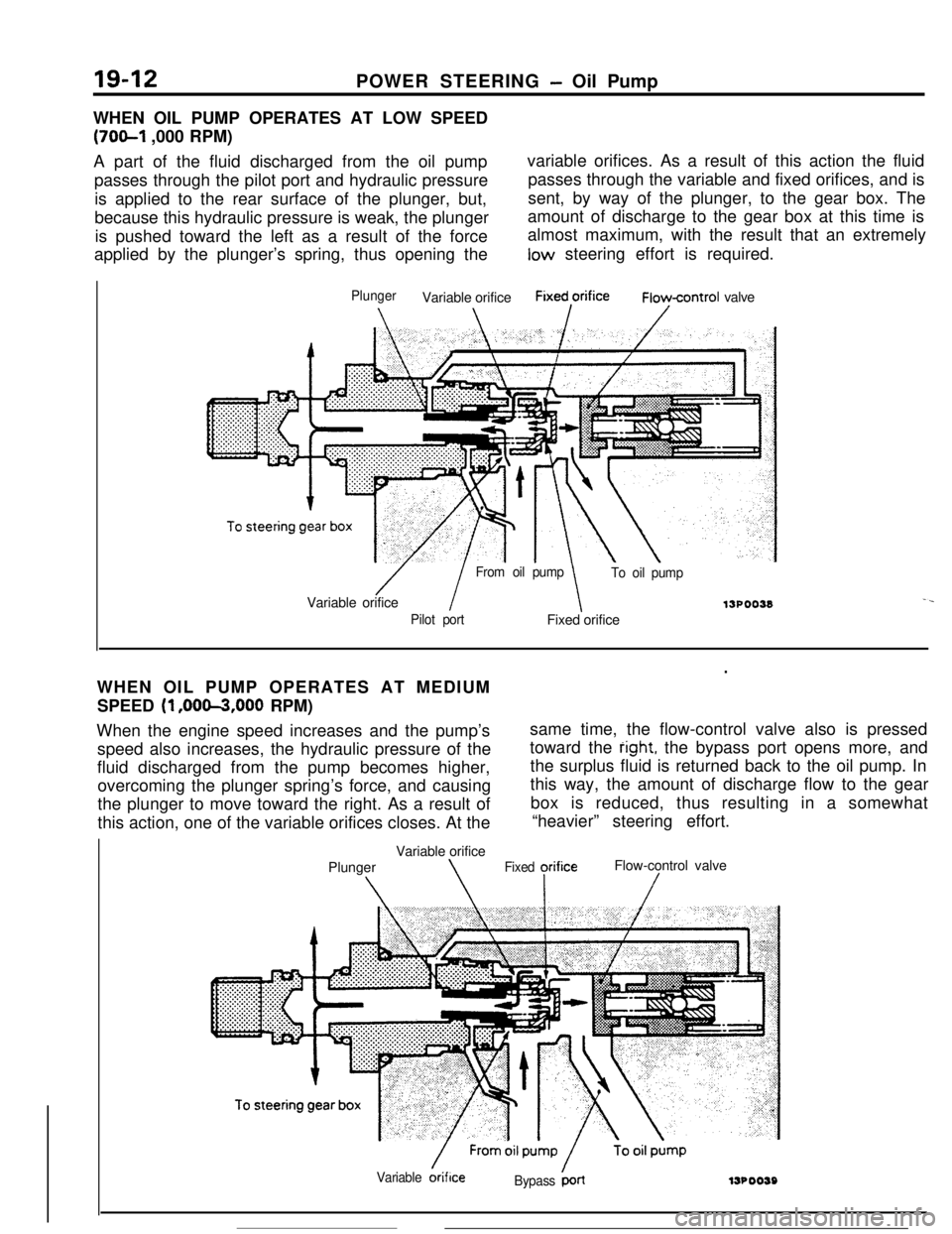

19-12POWER STEERING - Oil Pump

WHEN OIL PUMP OPERATES AT LOW SPEED

(70&l ,000 RPM)

A part of the fluid discharged from the oil pumpvariable orifices. As a result of this action the fluid

passes through the pilot port and hydraulic pressurepasses through the variable and fixed orifices, and is

is applied to the rear surface of the plunger, but,sent, by way of the plunger, to the gear box. The

because this hydraulic pressure is weak, the plungeramount of discharge to the gear box at this time is

is pushed toward the left as a result of the forcealmost maximum, with the result that an extremely

applied by the plunger’s spring, thus opening thelow steering effort is required.

PlungerVariable orificeFixed,orificeFioycontrol valve

/ I

From oil pump

To oil pumpVariable orifice

13POO38-.

Pilot portFixed orifice

.WHEN OIL PUMP OPERATES AT MEDIUM

SPEED

(1 ,OOm,OOO RPM)

When the engine speed increases and the pump’ssame time, the flow-control valve also is pressed

speed also increases, the hydraulic pressure of thetoward the

right, the bypass port opens more, and

fluid discharged from the pump becomes higher,the surplus fluid is returned back to the oil pump. In

overcoming the plunger spring’s force, and causingthis way, the amount of discharge flow to the gear

the plunger to move toward the right. As a result ofbox is reduced, thus resulting in a somewhat

this action, one of the variable orifices closes. At the“heavier” steering effort.

Variable orifice

PlungerFlow-control valve

\\Fixed yrifice/

Variable &iflceBypass ‘LrllJPOO59

Page 227 of 391

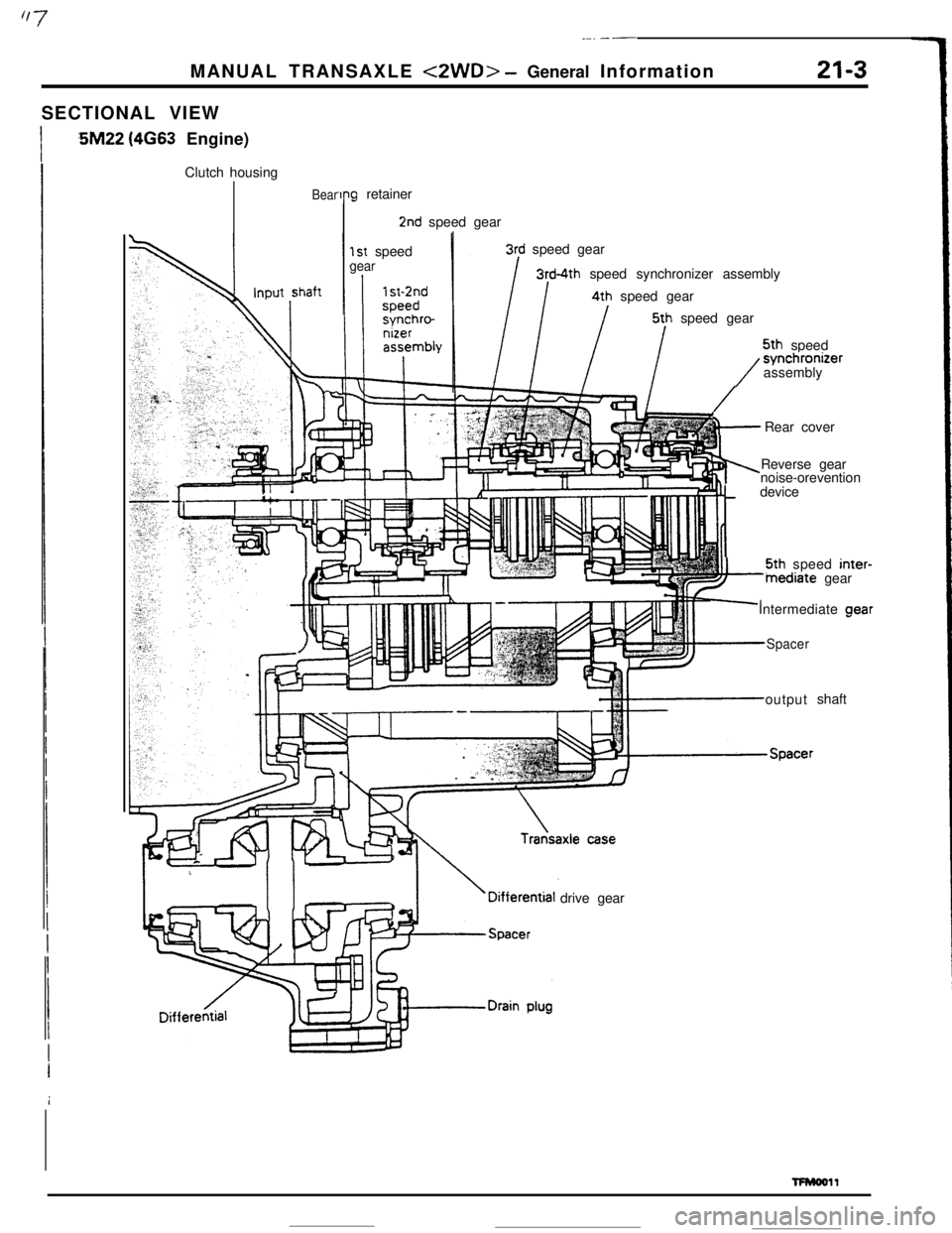

_-. ---MANUAL TRANSAXLE

<2WD> - General Information21-3SECTIONAL VIEW

:5M22 (4663 Engine)

Clutch housing

Bear‘Ing retainer

2nd speed gear

1st speedgear

3rd speed gear

3rd-4th speed synchronizer assembly4th speed gear5th speed gear5th speed

/synchronizer

assembly

ii+-Rear cover

Reverse gear

noise-orevention

tdevice5th speed inter-

inediate gear

Intermediate aear

Spaceroutputshaft

drive gear

TFMooll

Page 232 of 391

_.c.

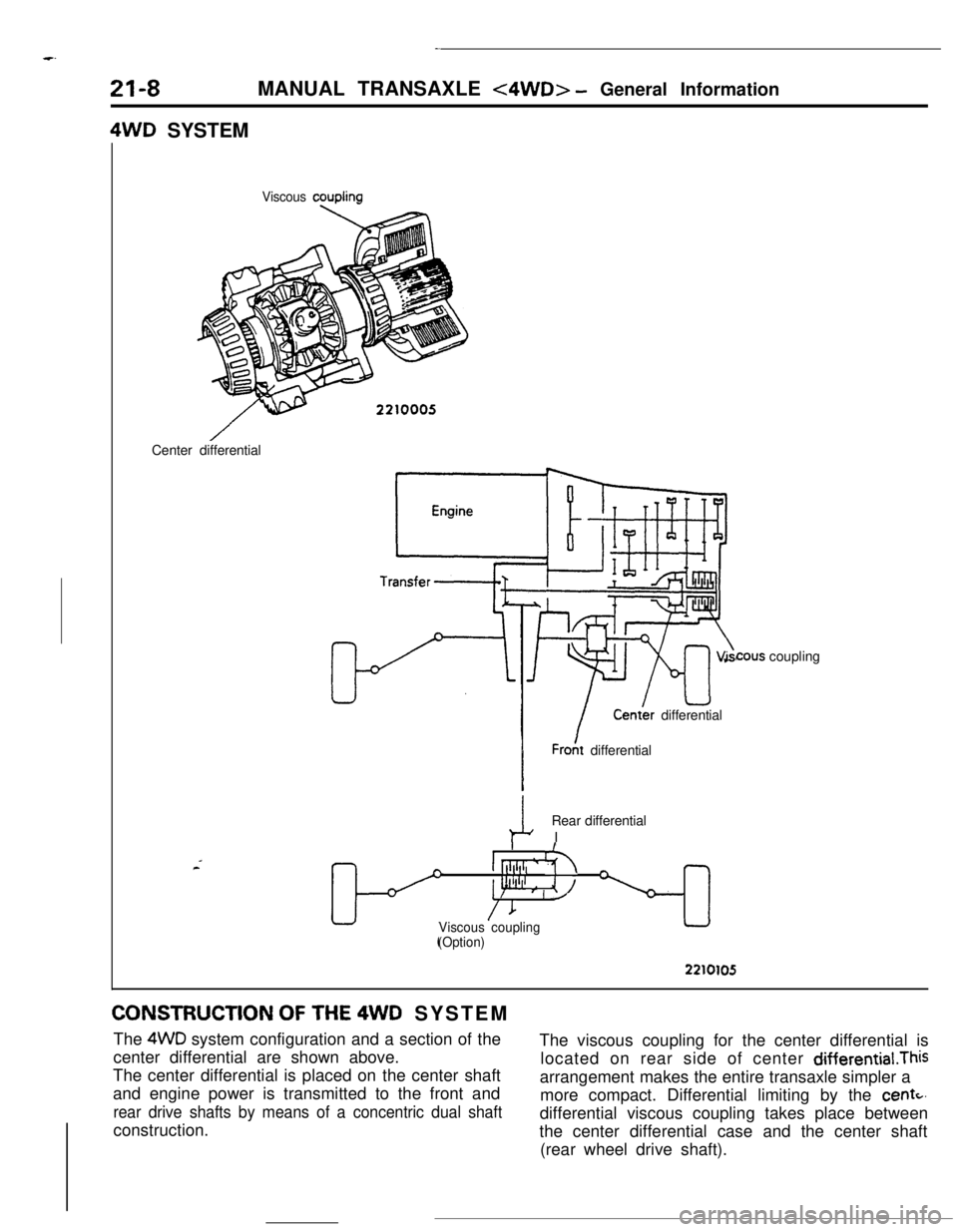

21-8MANUAL TRANSAXLE <4WD> - General Information4WD SYSTEM

Viscous couplingCenter differential

cous coupling

kCenth differential

I

IFro& differential

Rear differential

I

I

I [[lll,i, ‘- h-

1 p’f’ ,* , l/i\

/IViscous couplingL

(Option)

3

2210105CONSTRUCTION

OF THE 4WD SYSTEM

The 4WD system configuration and a section of the

center differential are shown above.The viscous coupling for the center differential is

The center differential is placed on the center shaftlocated on rear side of center differential.This

and engine power is transmitted to the front andarrangement makes the entire transaxle simpler a

rear drive shafts by means of a concentric dual shaftmore compact. Differential limiting by the

centc,construction.differential viscous coupling takes place between

the center differential case and the center shaft

(rear wheel drive shaft).

Page 233 of 391

-MANUAL TRANSAXLE

<4WD> - General information

21-9

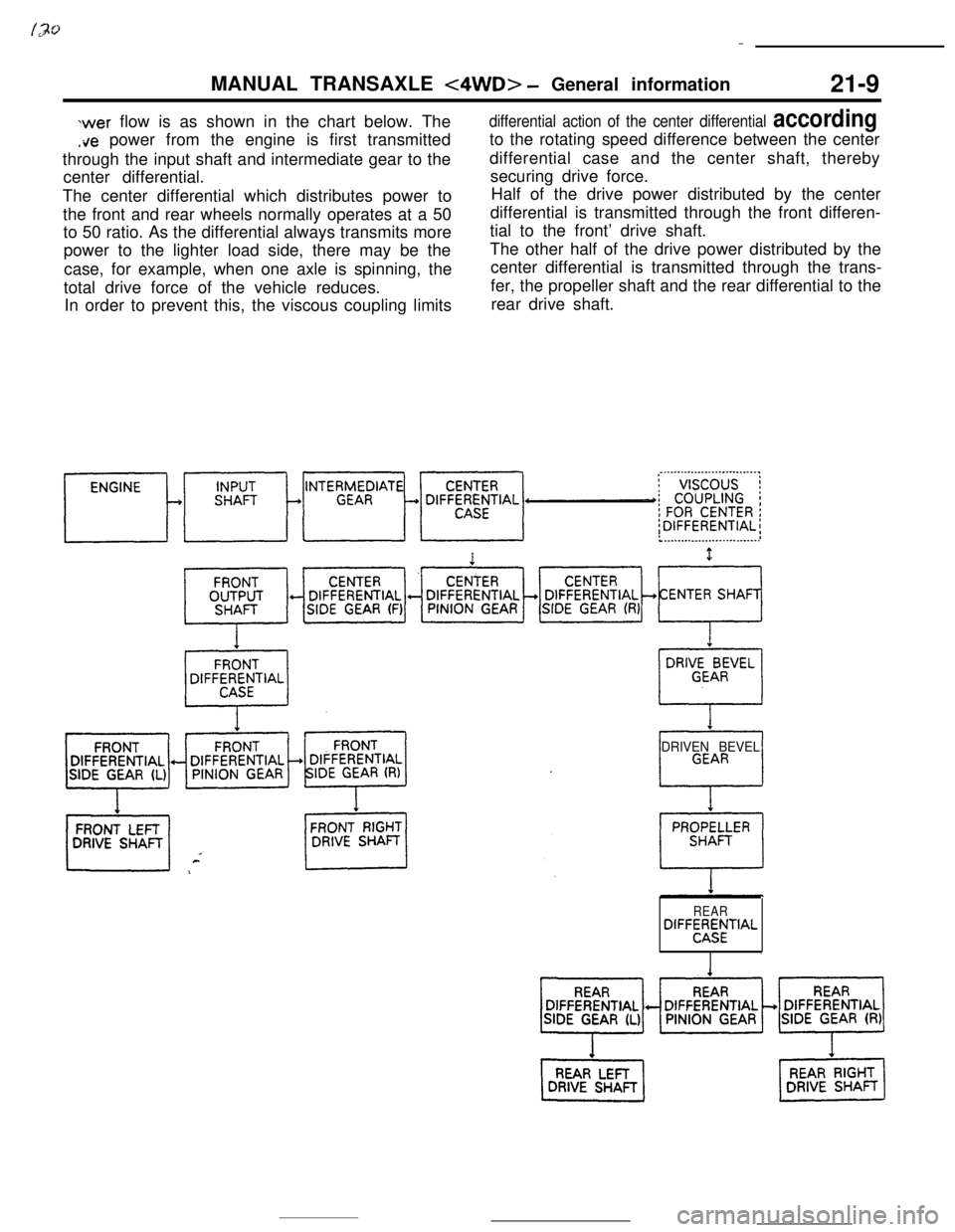

wer flow is as shown in the chart below. The

.ire power from the engine is first transmitted

through the input shaft and intermediate gear to the

center differential.

The center differential which distributes power to

the front and rear wheels normally operates at a 50

to 50 ratio. As the differential always transmits more

power to the lighter load side, there may be the

case, for example, when one axle is spinning, the

total drive force of the vehicle reduces.

In order to prevent this, the viscous coupling limits

differential action of the center differential accordingto the rotating speed difference between the center

differential case and the center shaft, thereby

securing drive force.

Half of the drive power distributed by the center

differential is transmitted through the front differen-

tial to the front’ drive shaft.

The other half of the drive power distributed by the

center differential is transmitted through the trans-

fer, the propeller shaft and the rear differential to the

rear drive shaft.

DRIVEN BEVEL

REARDIFF~;MfTIAL

,

Page 240 of 391

_-

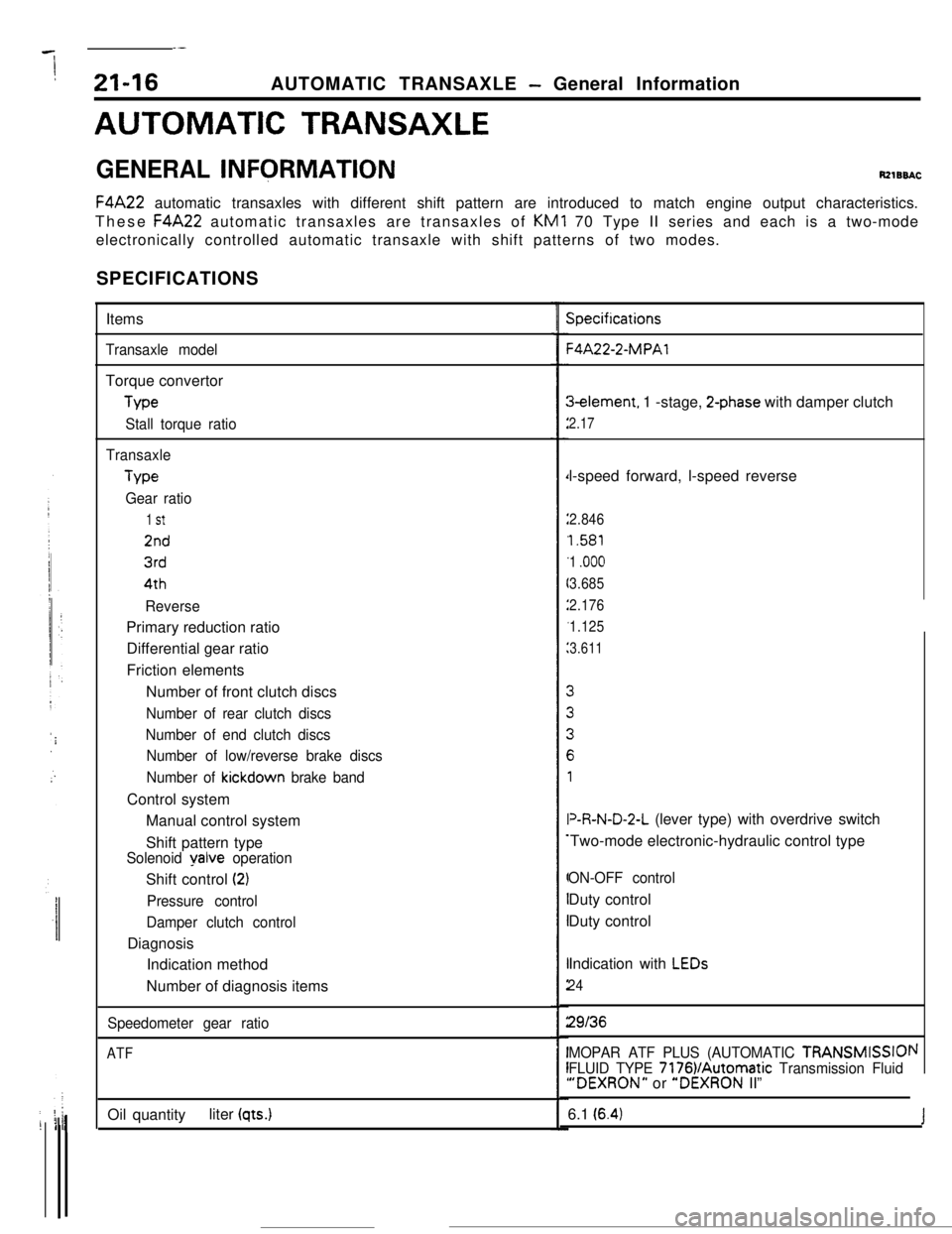

21-16AUTOMATIC TRANSAXLE - General InformationAUTOMATIC

TRANSAXLE

GENERAL INFQRMATIONRzlBBACF4A22 automatic transaxles with different shift pattern are introduced to match engine output characteristics.

These F4A22 automatic transaxles are transaxles of KM1 70 Type II series and each is a two-mode

electronically controlled automatic transaxle with shift patterns of two modes.

SPECIFICATIONS

Items

Transaxle modelTorque convertor

Me

Stall torque ratio

TransaxleType

Gear ratio

1 St

2nd

3rd4th

ReversePrimary reduction ratio

Differential gear ratio

Friction elements

Number of front clutch discs

Number of rear clutch discs

Number of end clutch discs

Number of low/reverse brake discs

Number of

kickdown brake bandControl system

Manual control system

Shift pattern type

Solenoid yalve operationShift control

(2)

Pressure control

Damper clutch controlDiagnosis

Indication method

Number of diagnosis items

Speedometer gear ratio

ATFOil quantityliter

(qts.)

Specifications-4A22-2-MPAl3element, 1 -stage,

2-phase with damper clutch

2.17l-speed forward, l-speed reverse

2.846

1.581

1

.ooo

3.685

2.176

1.125

3.611V&N-D-2-L (lever type) with overdrive switch

Two-mode electronic-hydraulic control type

ON-OFF controlDuty control

Duty control

Indication with

LEDs

24

29136

MOPAR ATF PLUS (AUTOMATIC TRANSMISSIOI

FLUID TYPE 7176VAutomatic Transmission Fluid“DEXRON” or “DEXRON II”

\I6.1

(6.4)J

Page 246 of 391

AUTOMATIC TRANSAXLE - Torque Converter

TORQUE CONVERTER

Lock

ring

I

Damper

F

clutch-

B-.Turbine

.AA

/:ront cover

h,Impeller

AStartorWhen damper clutch is

I\When damper

aInput shaftactivated

clutch isactivated

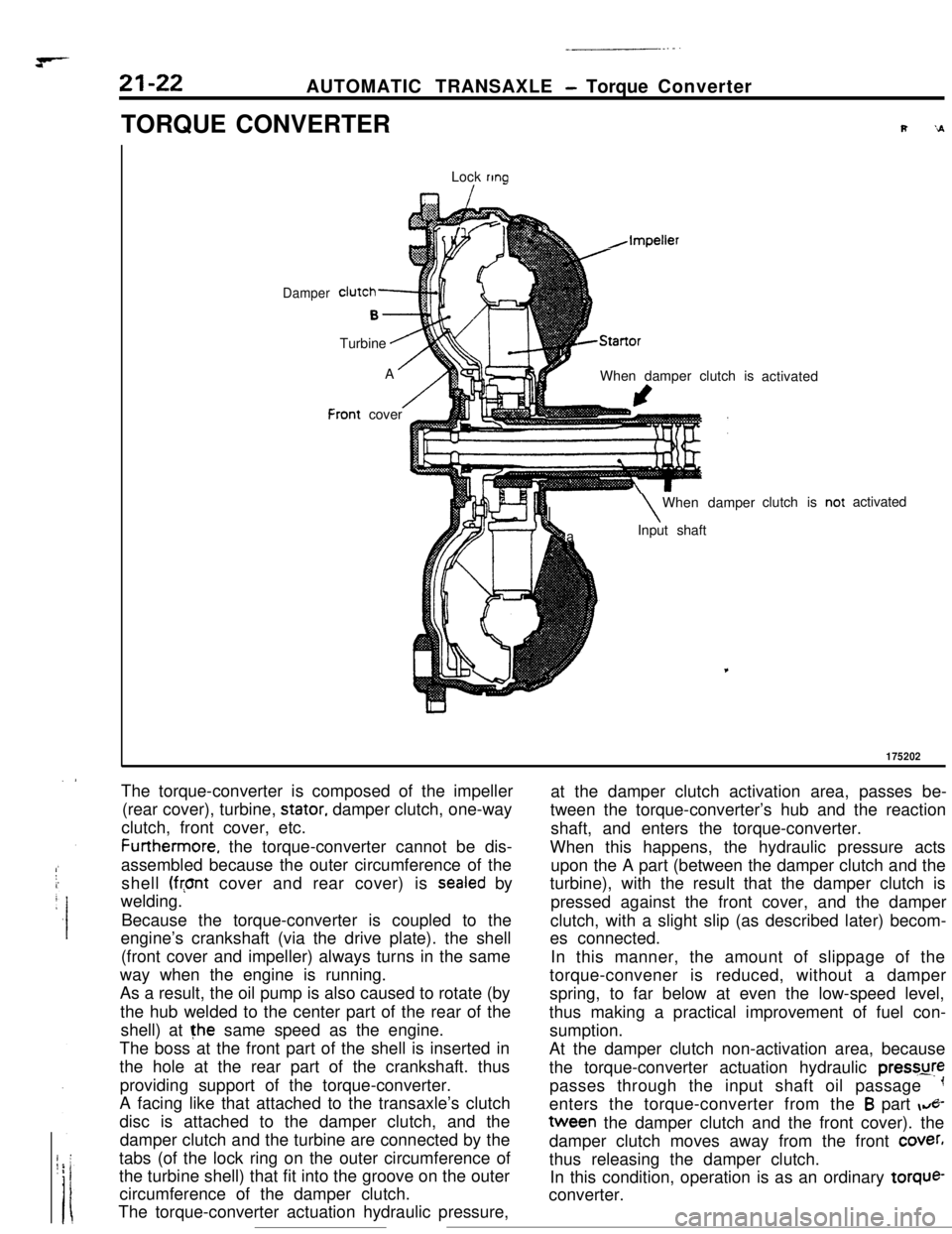

175202The torque-converter is composed of the impeller

(rear cover), turbine,

stator, damper clutch, one-way

clutch, front cover, etc.Furthermore. the torque-converter cannot be dis-

assembled because the outer circumference of the

shell

(front cover and rear cover) is sealed by

welding.

Because the torque-converter is coupled to the

engine’s crankshaft (via the drive plate). the shell

(front cover and impeller) always turns in the same

way when the engine is running.

As a result, the oil pump is also caused to rotate (by

the hub welded to the center part of the rear of the

shell) at the same speed as the engine.

The boss at the front part of the shell is inserted in

the hole at the rear part of the crankshaft. thus

providing support of the torque-converter.

A facing like that attached to the transaxle’s clutch

disc is attached to the damper clutch, and the

damper clutch and the turbine are connected by the

tabs (of the lock ring on the outer circumference of

the turbine shell) that fit into the groove on the outer

circumference of the damper clutch.

The torque-converter actuation hydraulic pressure,at the damper clutch activation area, passes be-

tween the torque-converter’s hub and the reaction

shaft, and enters the torque-converter.

When this happens, the hydraulic pressure acts

upon the A part (between the damper clutch and the

turbine), with the result that the damper clutch is

pressed against the front cover, and the damper

clutch, with a slight slip (as described later) becom-

es connected.

In this manner, the amount of slippage of the

torque-convener is reduced, without a damper

spring, to far below at even the low-speed level,

thus making a practical improvement of fuel con-

sumption.

At the damper clutch non-activation area, because

the torque-converter actuation hydraulic pressure

passes through the input shaft oil passage

-1enters the torque-converter from the

B part &-tween the damper clutch and the front cover). the

damper clutch moves away from the front

cover,thus releasing the damper clutch.

In this condition, operation is as an ordinary torque-

converter.

Page 247 of 391

I,?+7_-AUTOMATIC TRANSAXLE

- Transaxle Mechanism21-23

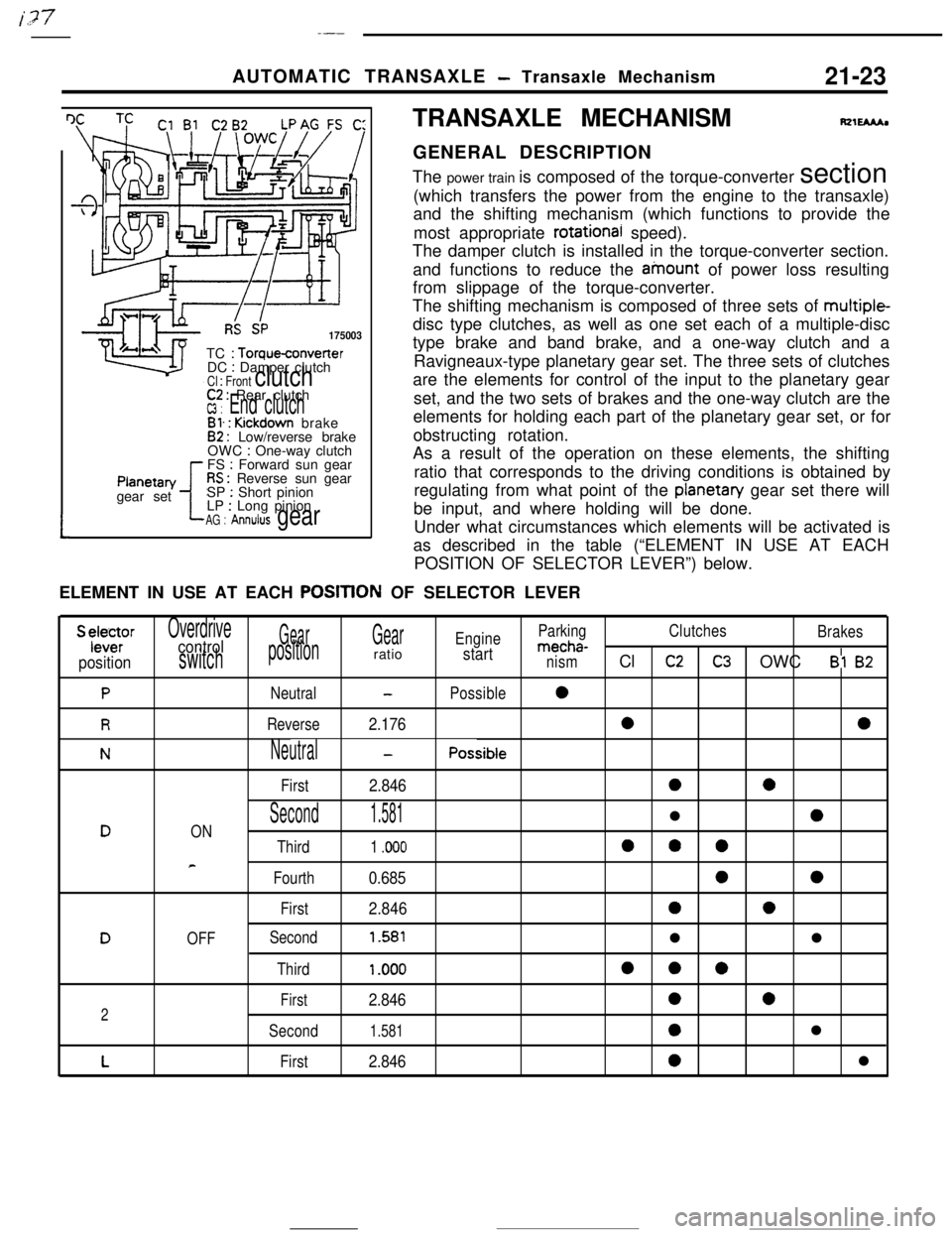

I IRS SP175003TC

: Torqueconverter

DC : Damper clutchCl : Front clutch

tPlanetan/

gear set

C2 : Rear clutchW : End clutchBl. : Kickdown brake82 : Low/reverse brake

OWC : One-way clutch

FS : Forward sun gearRS : Reverse sun gear

SP : Short pinion

LP : Long pinionAG : Annulus gearTRANSAXLE MECHANISM

fQlEMhGENERAL DESCRIPTION

The power train is composed of the torque-converter section

(which transfers the power from the engine to the transaxle)

and the shifting mechanism (which functions to provide the

most appropriate

rotational speed).

The damper clutch is installed in the torque-converter section.

and functions to reduce the ainount of power loss resulting

from slippage of the torque-converter.

The shifting mechanism is composed of three sets of multiple-

disc type clutches, as well as one set each of a multiple-disc

type brake and band brake, and a one-way clutch and a

Ravigneaux-type planetary gear set. The three sets of clutches

are the elements for control of the input to the planetary gear

set, and the two sets of brakes and the one-way clutch are the

elements for holding each part of the planetary gear set, or for

obstructing rotation.

As a result of the operation on these elements, the shifting

ratio that corresponds to the driving conditions is obtained by

regulating from what point of the

planetan/ gear set there will

be input, and where holding will be done.

Under what circumstances which elements will be activated is

as described in the table (“ELEMENT IN USE AT EACH

POSITION OF SELECTOR LEVER”) below.

ELEMENT IN USE AT EACH

POSITtON OF SELECTOR LEVER

S ylele~rOverdriveGearGearEngineParkingClutches

Brakescontrolmecha-

positionswitchpositionratiostartnismCl c2C3 OWC Bl 82

PNeutral-Possible0

RReverse2.17600

NNeutral-Possible

First

2.8460a

Second1.581l0DON

Third1 .ooo000

e

Fourth0.68500

First2.84600

DOFFSecond1.581ll

Third1 .ooo000

First2.846002

Second1.5810l

LFirst2.8460l