engine MITSUBISHI ECLIPSE 1990 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 144 of 391

__.-~-..- -

FUEL SYSTEM- Ermine Control Unit

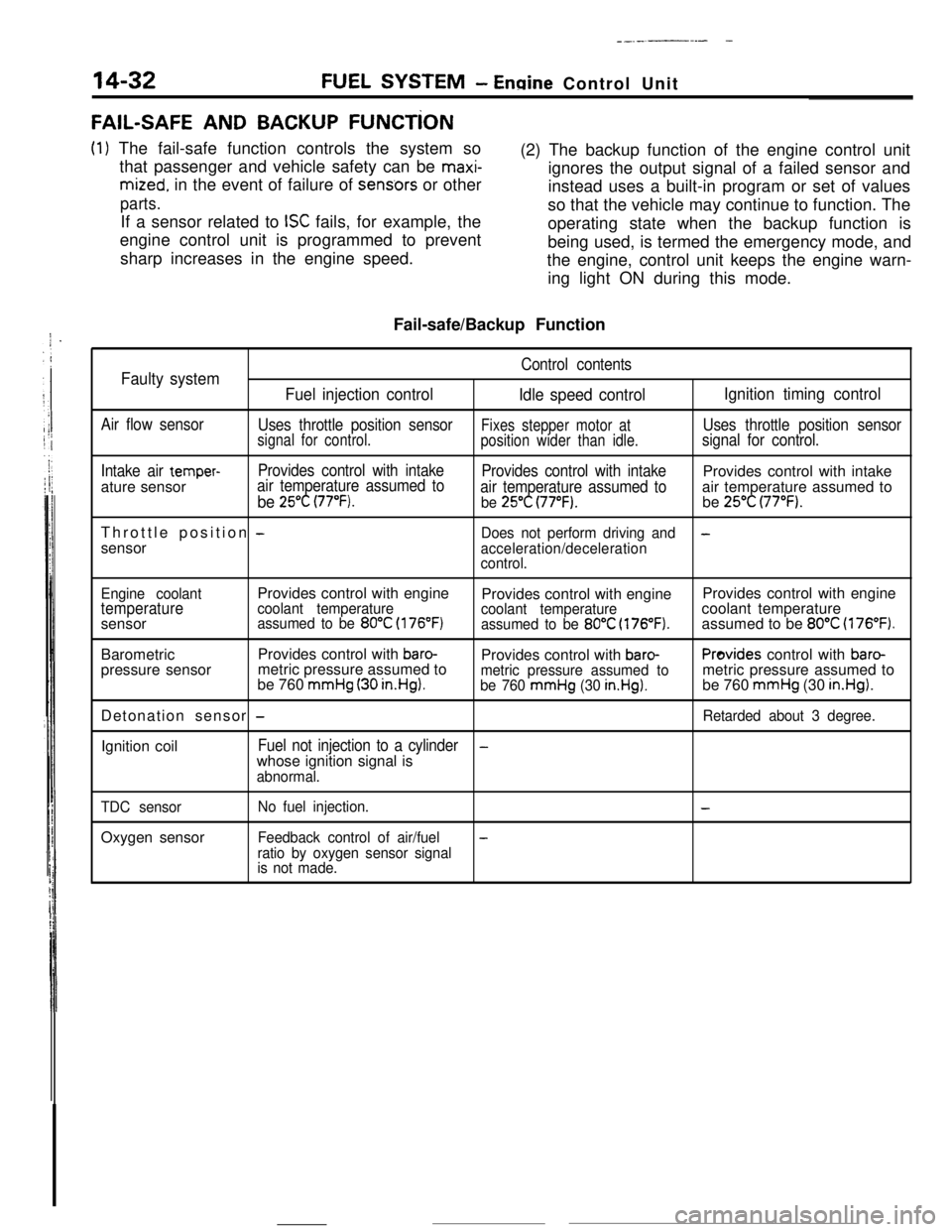

FAIL-SAFE AND BACKUP FUNCTiON

(1) The fail-safe function controls the system so

that passenger and vehicle safety can be

maxi-

mized. in the event of failure of sens.ors or other

parts.If a sensor related to

ISC fails, for example, the

engine control unit is programmed to prevent

sharp increases in the engine speed.(2) The backup function of the engine control unit

ignores the output signal of a failed sensor and

instead uses a built-in program or set of values

so that the vehicle may continue to function. The

operating state when the backup function is

being used, is termed the emergency mode, and

the engine, control unit keeps the engine warn-

ing light ON during this mode.

Fail-safe/Backup Function

Control contentsFaulty system

Fuel injection control

Idle speed controlIgnition timing control

Air flow sensor

Uses throttle position sensorFixes stepper motor atUses throttle position sensorsignal for control.

position wider than idle.signal for control.

Intake air

temper-Provides control with intake

Provides control with intakeProvides control with intake

ature sensorair temperature assumed to

be 25°C (77°F).air temperature assumed toair temperature assumed tobe 25°C (77°F).be 25°C (77°F).Throttle position

-Does not perform driving and-sensor

acceleration/deceleration

control.

Engine coolantProvides control with engine

Provides control with engineProvides control with engine

temperaturecoolant temperature

coolant temperaturecoolant temperature

sensorassumed to be 80°C (176°F)assumed to be 80°C (176°F).assumed to be 80°C (176°F).BarometricProvides control with

baro-Provides control with baro-Provides control with baro-pressure sensormetric pressure assumed to

be 760

mmHg (30 in.HgI.metric pressure assumed tometric pressure assumed tobe 760 mmHg (30 in.Hg).be 760 mmHg (30 in.Hg).Detonation sensor

-Retarded about 3 degree.Ignition coil

Fuel not injection to a cylinder-whose ignition signal is

abnormal.

TDC sensorOxygen sensor

No fuel injection.-

Feedback control of air/fuel-

ratio by oxygen sensor signal

is not made.

Page 145 of 391

FUEL SYSTEM- Fuel Injection Control14-33

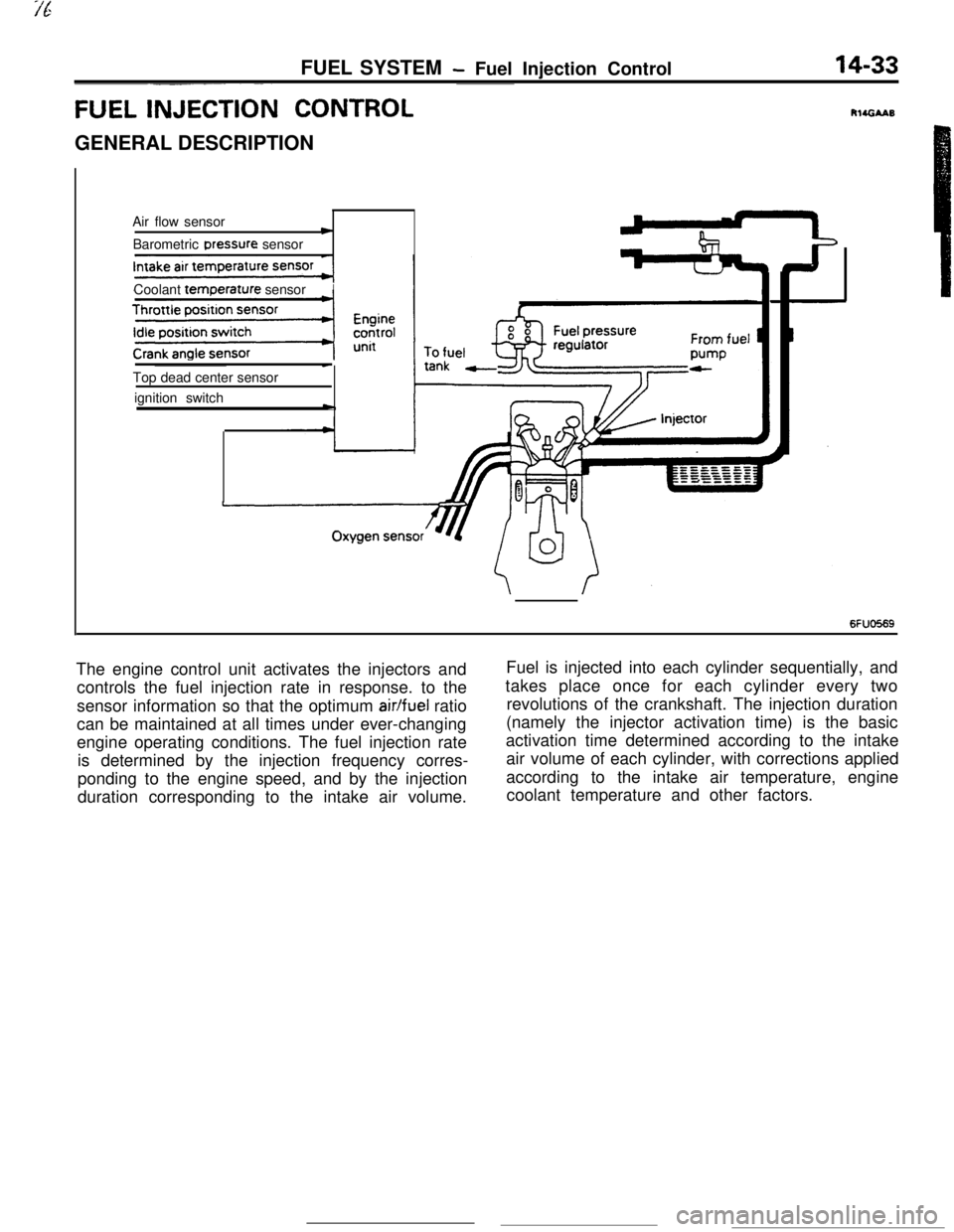

FUEL INJECTI& CONTROLGENERAL DESCRIPTION

Air flow sensor

cBarometric Dressure sensor

Coolant

temr3erature sensorITop dead center sensor

ignition switch

-

c

6FUO569The engine control unit activates the injectors andFuel is injected into each cylinder sequentially, and

controls the fuel injection rate in response. to thetakes place once for each cylinder every two

sensor information so that the optimum

air/fuel ratiorevolutions of the crankshaft. The injection duration

can be maintained at all times under ever-changing(namely the injector activation time) is the basic

engine operating conditions. The fuel injection rateactivation time determined according to the intake

is determined by the injection frequency corres-air volume of each cylinder, with corrections applied

ponding to the engine speed, and by the injectionaccording to the intake air temperature, engine

duration corresponding to the intake air volume.coolant temperature and other factors.

Page 146 of 391

-

14-34FUEL SYSTEM - Fuel Injection Control

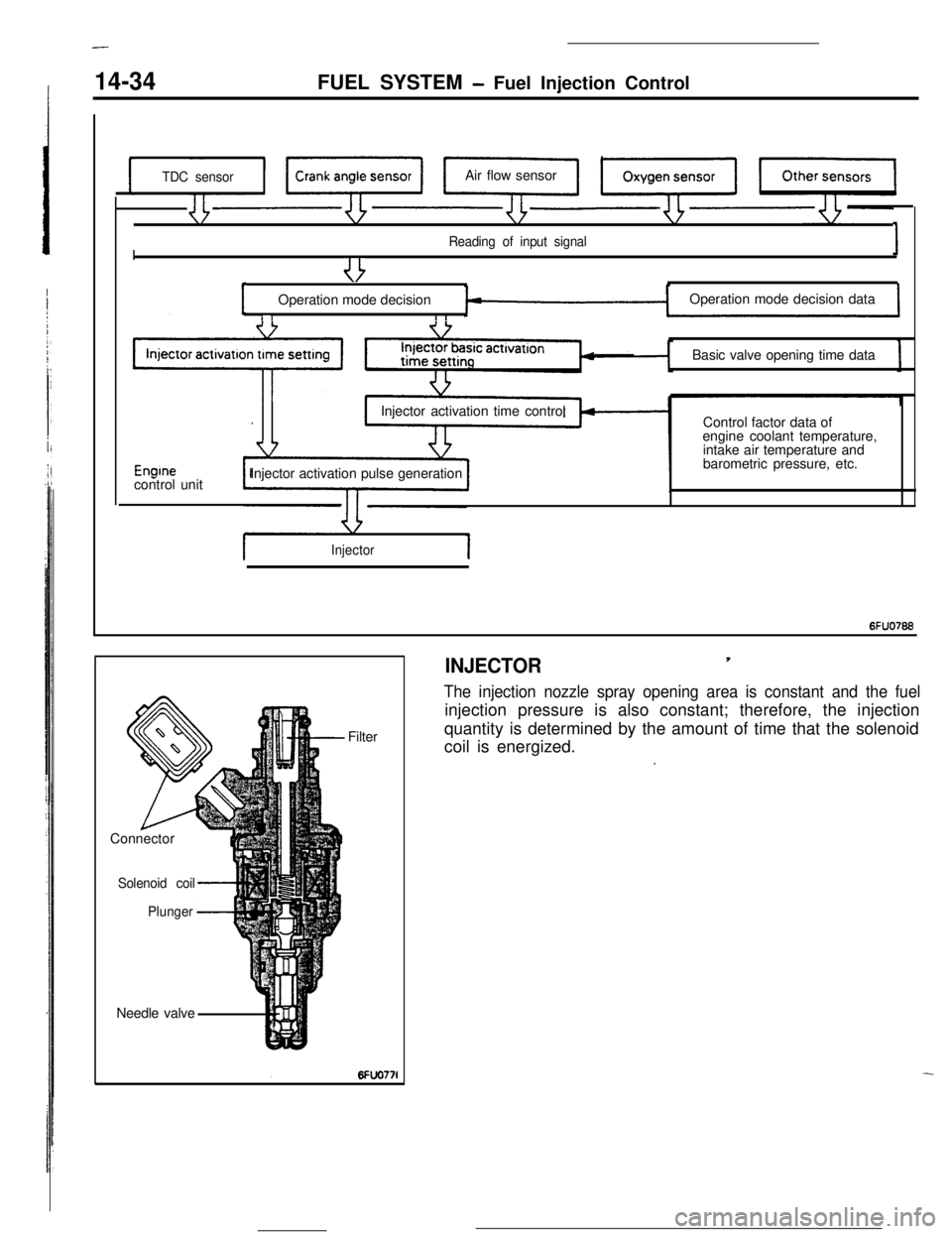

TDC sensorAir flow sensor

I

Reading of input signal1

I ,,

uOperation mode decisionOperation mode decision data

I rBasic valve opening time data

Enginecontrol unitInjector activation time control

Injector activation pulse generationControl factor data of

engine coolant temperature,

intake air temperature and

barometric pressure, etc.

Injector1

6FUO766Needle valveFilter

Connector

Solenoid coil

Plunger

-4

INJECTOR,

The injection nozzle spray opening area is constant and the fuelinjection pressure is also constant; therefore, the injection

quantity is determined by the amount of time that the solenoid

coil is energized.

.

Page 147 of 391

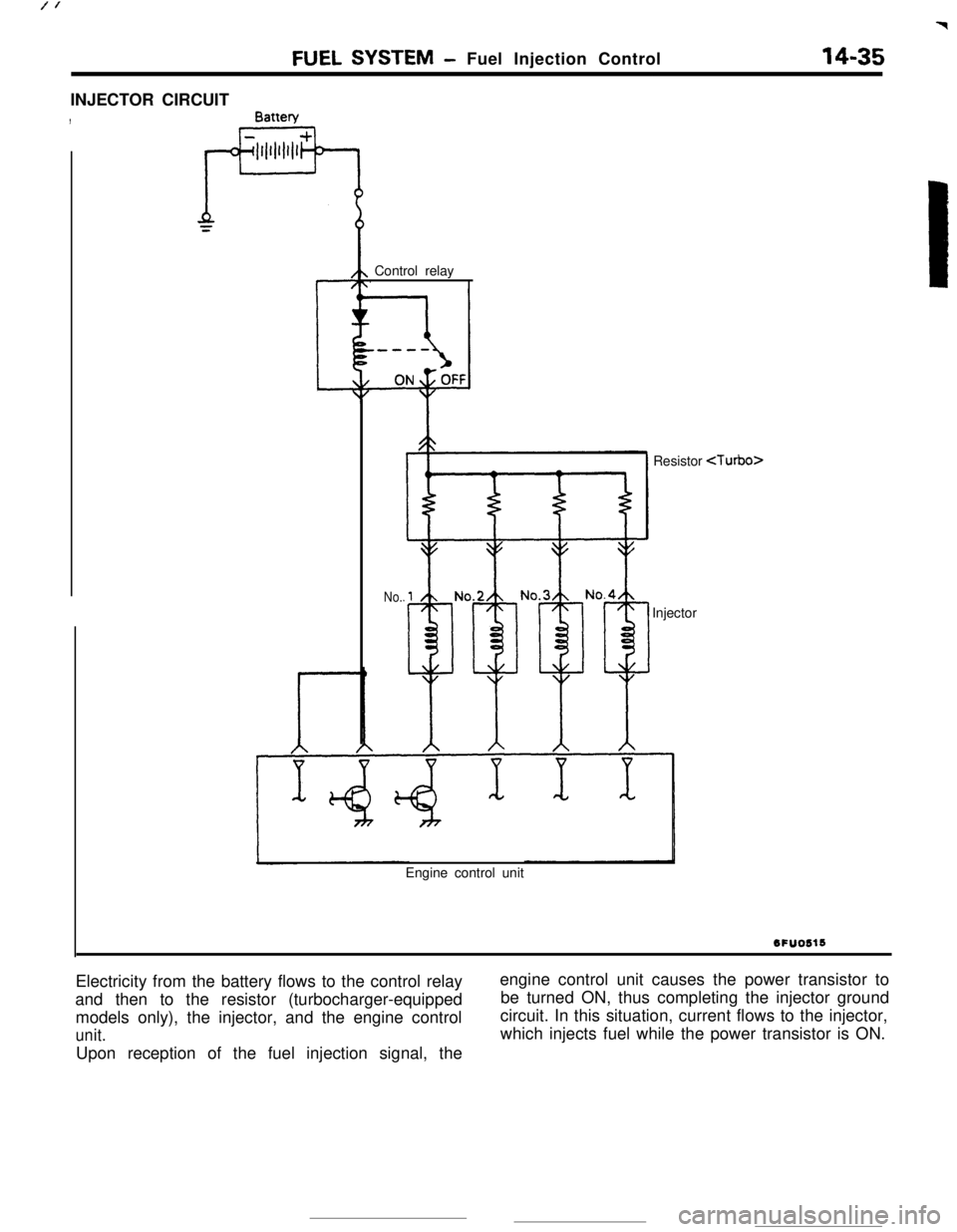

FUEL SYSTEM- Fuel Injection Control14-35INJECTOR CIRCUIT

,Battew

Control relay

Resistor

No.Injector

Engine control unit

6FU0516Electricity from the battery flows to the control relay

and then to the resistor (turbocharger-equipped

models only), the injector, and the engine control

unit.Upon reception of the fuel injection signal, theengine control unit causes the power transistor to

be turned ON, thus completing the injector ground

circuit. In this situation, current flows to the injector,

which injects fuel while the power transistor is ON.

Page 149 of 391

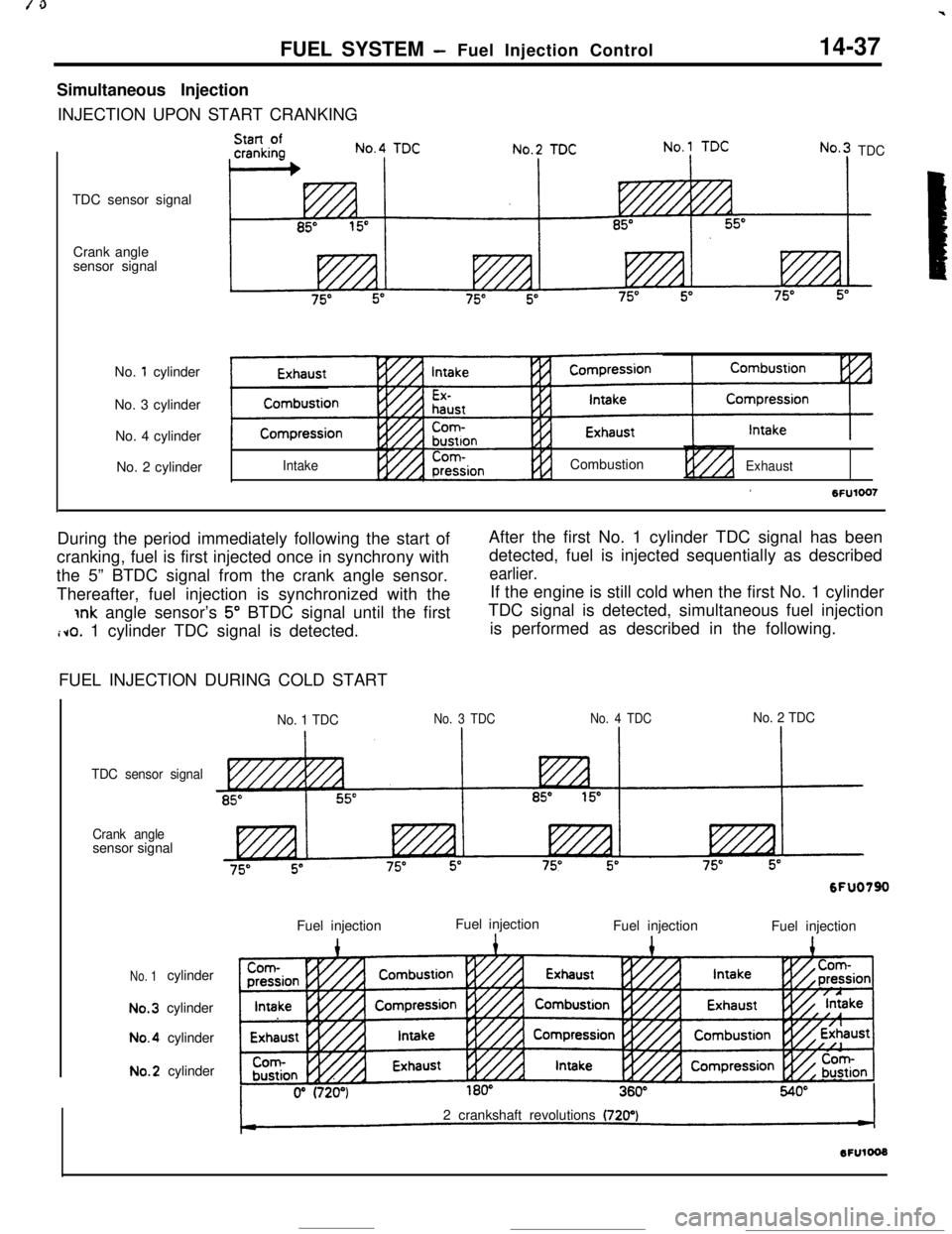

FUEL SYSTEM -Fuel Injection Control14-37Simultaneous Injection

INJECTION UPON START CRANKING

TDC sensor signal

Crank angle

sensor signal

No.

1 cylinder

No. 3 cylinder

No. 4 cylinder

No. 2 cylinder

TDC

IntakeCombustion

ExhaustDuring the period immediately following the start ofAfter the first No. 1 cylinder TDC signal has been

cranking, fuel is first injected once in synchrony withdetected, fuel is injected sequentially as described

the 5” BTDC signal from the crank angle sensor.

earlier.Thereafter, fuel injection is synchronized with theIf the engine is still cold when the first No. 1 cylinder

jnk angle sensor’s 5” BTDC signal until the firstTDC signal is detected, simultaneous fuel injection

i~o. 1 cylinder TDC signal is detected.is performed as described in the following.

FUEL INJECTION DURING COLD START

No. 1 TDCNo. 3 TDCNo. 4 TDCNo. 2 TDC

TDC sensor signal

Crank anglesensor signal

No. 1cylinderNo.3cylinderNo.4cylinderNo.2cylinder

6FUO790Fuel injection

1Fuel injection

Fuel injection1Fuel injection12 crankshaft revolutions

(720’)

Page 150 of 391

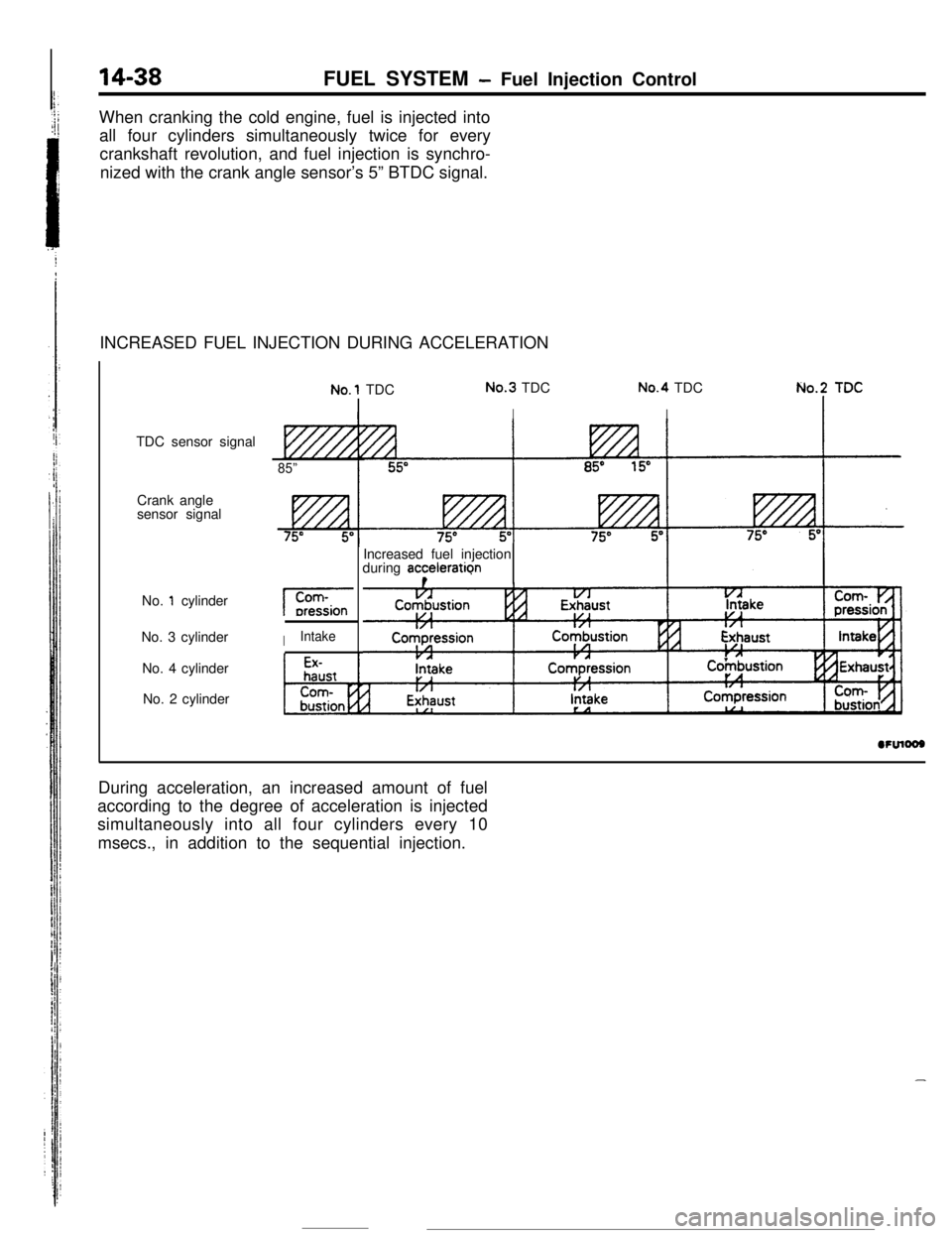

FUEL SYSTEM - Fuel Injection Control

When cranking the cold engine, fuel is injected into

all four cylinders simultaneously twice for every

crankshaft revolution, and fuel injection is synchro-

nized with the crank angle sensor’s 5” BTDC signal.

INCREASED FUEL INJECTION DURING ACCELERATION

No.1 TDC

TDC sensor signal

85”Crank angle

sensor signal

No.

1 cylinderINo. 3 cylinder

IIntakeNo.3 TDC

INo.4 TDCIIncreased fuel injection

during acceleratiqn

8

bxhaustNo. 4 cylinder

No. 2 cylinder

During acceleration, an increased amount of fuel

according to the degree of acceleration is injected

simultaneously into all four cylinders every 10

msecs., in addition to the sequential injection.

-

Page 151 of 391

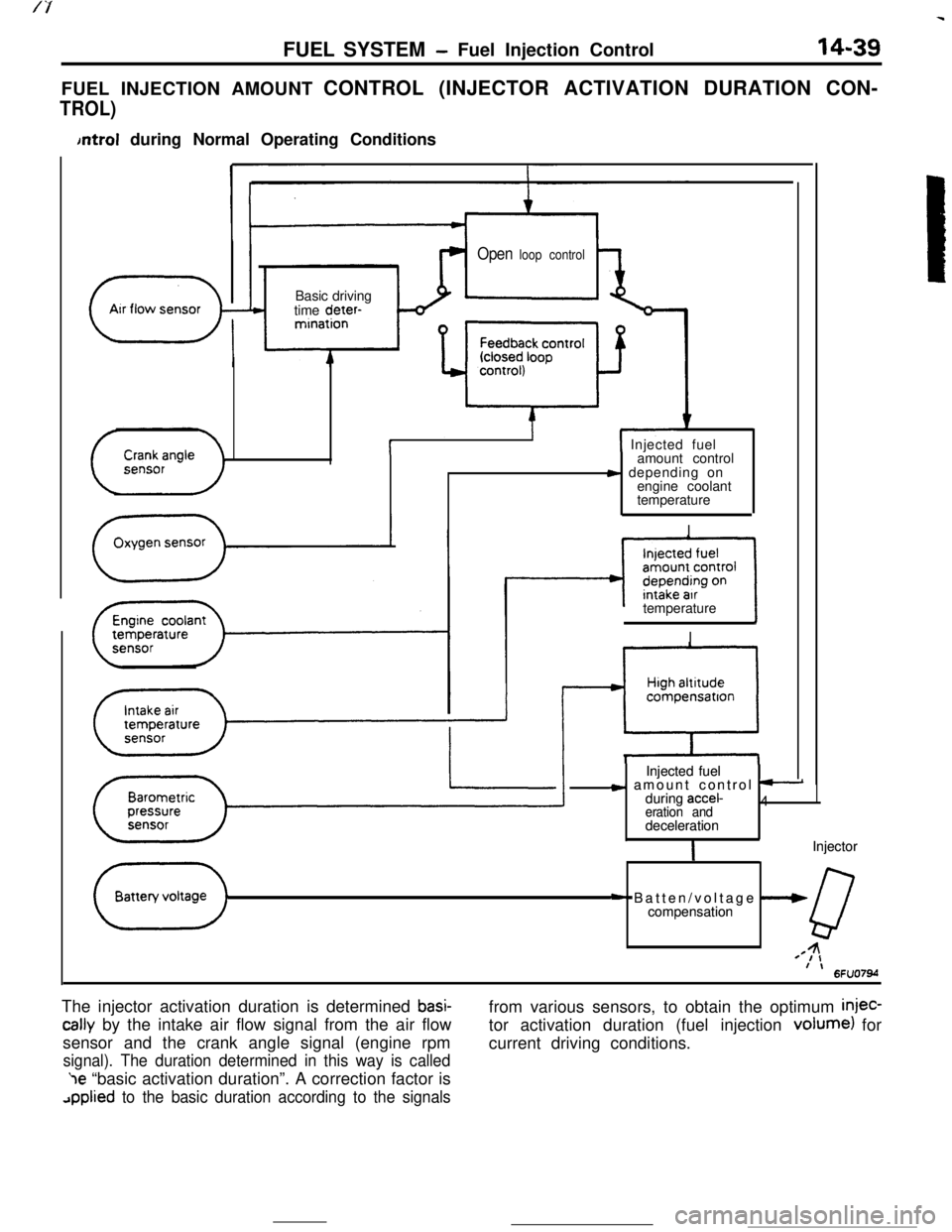

FUEL SYSTEM- Fuel Injection Control14-39FUEL INJECTION AMOUNT CONTROL (INJECTOR ACTIVATION DURATION CON-

TROL)

bntrol during Normal Operating Conditions

Open loop control

( ArrflowsensorBasic driving

time deter-

-”mination

i( Injected fuel

amount control

s depending on

engine coolant

temperature

I

II

””compensatron

Injected fuel Injected fuel

c amount control t-c amount control t-during accel-during accel-4 4eration and eration anddeceleration decelerationIIInjector Injector

+ Batten/voltage --W+ Batten/voltage --Wcompensation compensation

QQ44=I,=I,f \f \6FU07M6FU07Mtemperature

II

The injector activation duration is determined

basi-

tally by the intake air flow signal from the air flow

sensor and the crank angle signal (engine rpm

signal). The duration determined in this way is called‘le “basic activation duration”. A correction factor is

applied to the basic duration according to the signalsfrom various sensors, to obtain the optimum

injec-tor activation duration (fuel injection volume) for

current driving conditions.

Page 152 of 391

14-40FUEL SYSTEM - Fuel Injection Control

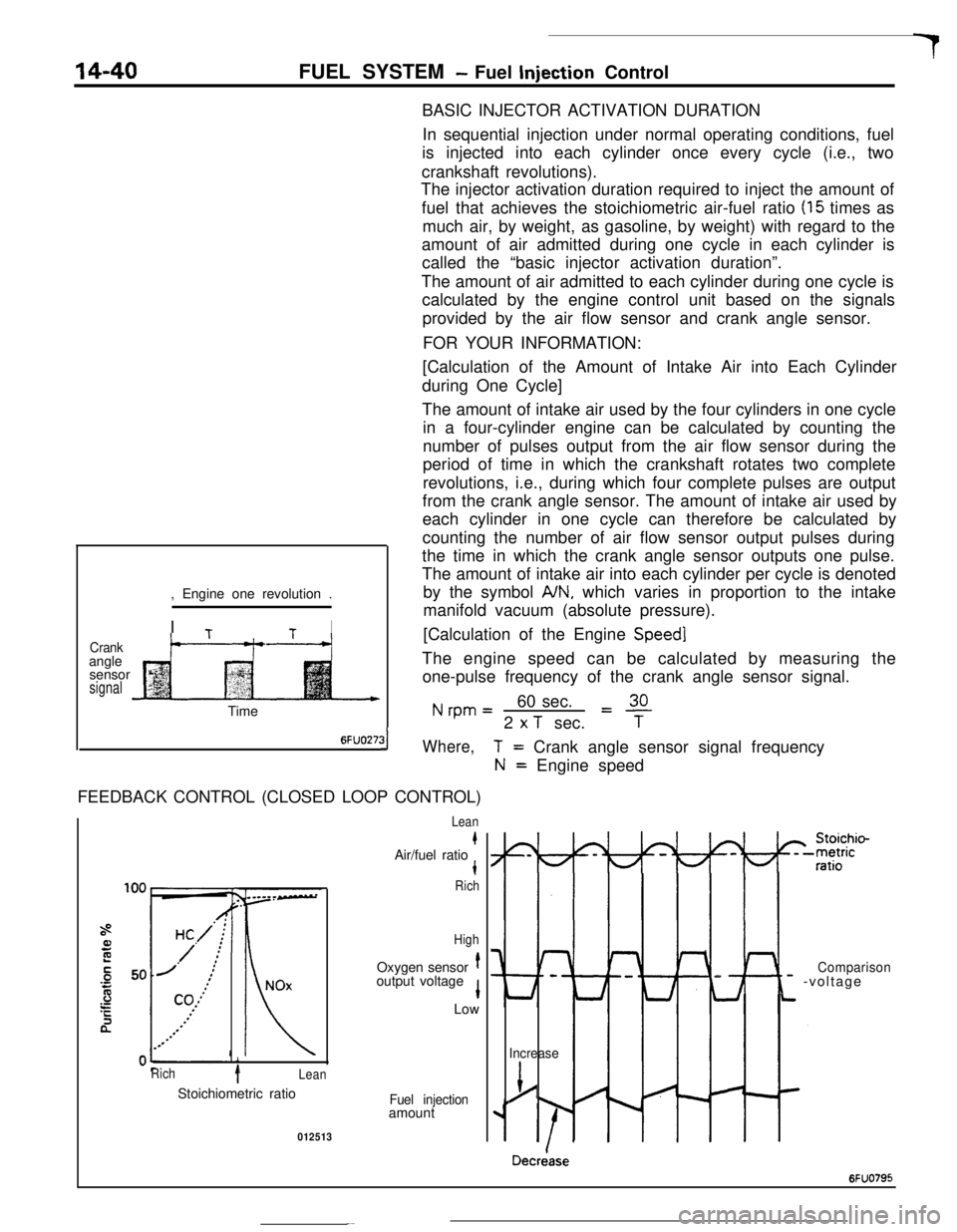

BASIC INJECTOR ACTIVATION DURATION

In sequential injection under normal operating conditions, fuel

is injected into each cylinder once every cycle (i.e., two

crankshaft revolutions).

The injector activation duration required to inject the amount of

fuel that achieves the stoichiometric air-fuel ratio

(15 times as

much air, by weight, as gasoline, by weight) with regard to the

amount of air admitted during one cycle in each cylinder is

called the “basic injector activation duration”.

The amount of air admitted to each cylinder during one cycle is

calculated by the engine control unit based on the signals

provided by the air flow sensor and crank angle sensor.

FOR YOUR INFORMATION:

Crankangle

sensor

signal, Engine one revolution .

I

TtI

t--“---t-+[Calculation of the Amount of Intake Air into Each Cylinder

during One Cycle]

The amount of intake air used by the four cylinders in one cycle

in a four-cylinder engine can be calculated by counting the

number of pulses output from the air flow sensor during the

period of time in which the crankshaft rotates two complete

revolutions, i.e., during which four complete pulses are output

from the crank angle sensor. The amount of intake air used by

each cylinder in one cycle can therefore be calculated by

counting the number of air flow sensor output pulses during

the time in which the crank angle sensor outputs one pulse.

The amount of intake air into each cylinder per cycle is denoted

by the symbol

A/N, which varies in proportion to the intake

manifold vacuum (absolute pressure).

[Calculation of the Engine

Speed]The engine speed can be calculated by measuring the

one-pulse frequency of the crank angle sensor signal.

Nrpm=60 sec.L!!L2

x T sec.TTime

6FUO27:31Where,FEEDBACK CONTROL (CLOSED LOOP CONTROL)

i

Rich1Lean

T= Crank angle sensor signal frequency

N= Engine speed

Lean

kAir/fuel ratiot

Rich

HighOxygen sensor

toutput voltage

1Low

Stoichiometric ratio

Fuel injectionamount

012513

I-

Lt

Comparison- -voltage

Increase

j/

Decriase

6FUO795

Page 153 of 391

FUEL SYSTEM -Fuel Injection Control

14-41

During normal operation (including idling), the en-

gine control unit controls the injector activation time

tcThieve the stoichiometric air/fuel ratio, which

e.;res maximum efficiency of the catalytic conver-

ter, on the basis of the oxygen sensor signal.

When the air/fuel mixture is richer than the

stoichiometric ratio, there is less oxygen in the

exhaust gas and thus the oxygen sensor output

voltage is higher; hence a “mixture rich” signal is

input to the engine control unit. Then, the engine

control unit decreases the amount of fuel injected. If

the air/fuel ratio decreases to the point that and the

mixture becomes leaner than the stoichiometric

ratio, the oxygen concentration in the exhaust gas

increases and the oxygen sensor output voltage

becomes lower. Then, a “mixture lean” signal isinput to the engine control unit.

Upon input of this signal, the engine control unit

increases the feedback correction factor, thus caus-

ing more fuel to be injected.

By means of the above-mentioned controls (collec-

tively called “feedback control”), the air-fuel mixture

is maintained at the stoichiometric ratio.

Under the following specific conditions, this feed-

back control is not performed, in order to improve

driveability.

(11

(2)

::I

(5)While cranking the engine

During engine warm-up when engine coolant

temperature is less than

45°C (113°F)During acceleration/deceleration

During high load operation

When oxygen sensor is not functioning

IOPEN LOOP CONTROL

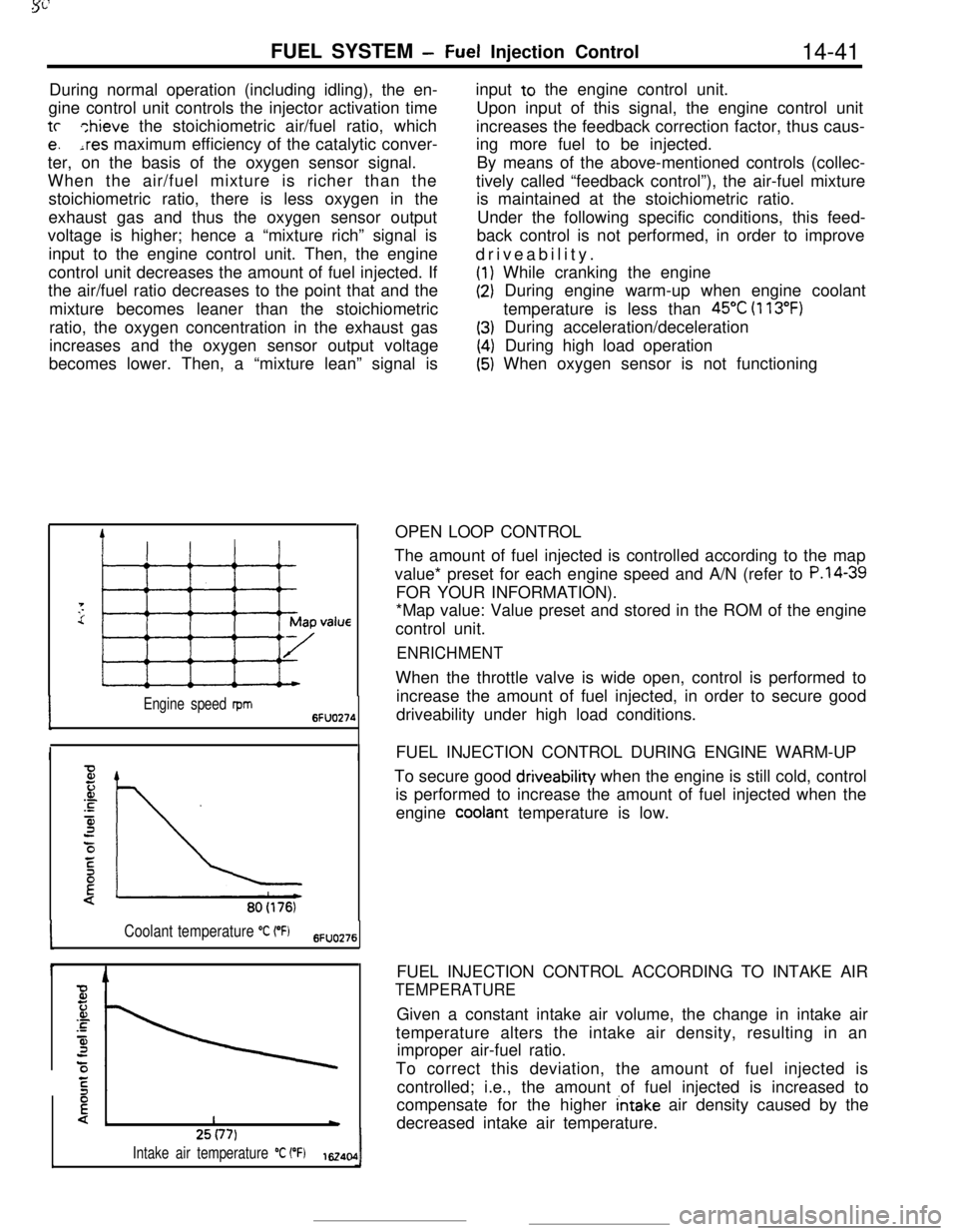

Engine speed rpm6FUO274

II

80(176)

Coolant temperature “C (“Fj6FlJO276

I425(77)

Intake air temperature “C (“F)1~40,0IThe amount of fuel injected is controlled according to the map

value* preset for each engine speed and A/N (refer to

P.l4-39FOR YOUR INFORMATION).

*Map value: Value preset and stored in the ROM of the engine

control unit.

ENRICHMENTWhen the throttle valve is wide open, control is performed to

increase the amount of fuel injected, in order to secure good

driveability under high load conditions.

FUEL INJECTION CONTROL DURING ENGINE WARM-UP

To secure good driveability when the engine is still cold, control

is performed to increase the amount of fuel injected when the

engine

cooiant temperature is low.

FUEL INJECTION CONTROL ACCORDING TO INTAKE AIR

TEMPERATUREGiven a constant intake air volume, the change in intake air

temperature alters the intake air density, resulting in an

improper air-fuel ratio.

To correct this deviation, the amount of fuel injected is

controlled; i.e., the amount of fuel injected is increased to

compensate for the higher

intake air density caused by the

decreased intake air temperature.

Page 154 of 391

14-42

FUEL SYSTEM- Fuel Injection Control

4

Fz.or.c

4:0/

E

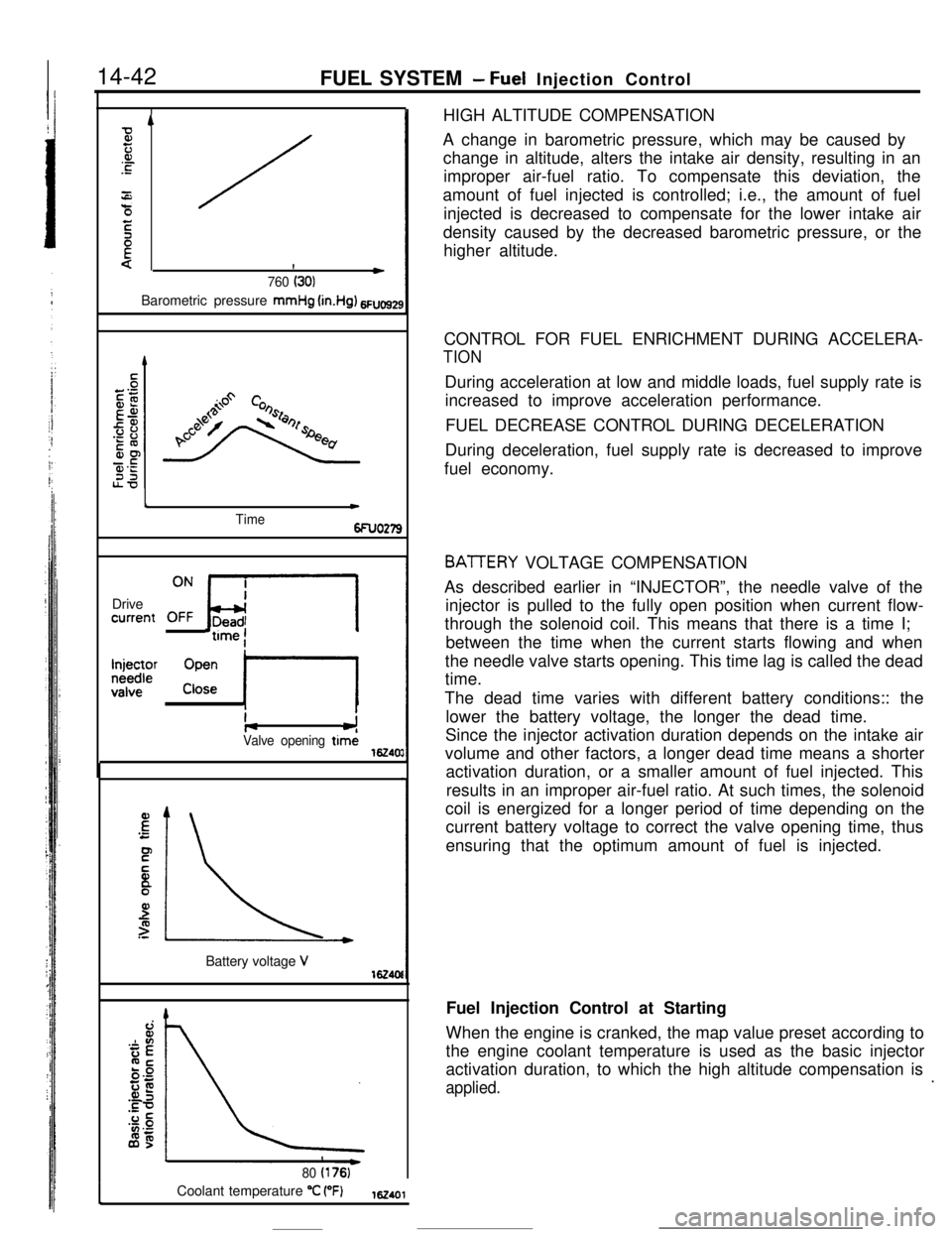

{!*760 (301Barometric pressure

mmHg (in.Hg) 6Fuo9z

c

Timet

6FUO279Drivecurrent

0: bri

F2JJ’ ipe; II

I+-JValve opening timi16240:

E‘C

F

.-

is

3

3:\Battery voltage

V162406

80 (176)Coolant temperature

“C (“F)162401HIGH ALTITUDE COMPENSATION

A change in barometric pressure, which may be caused by

change in altitude, alters the intake air density, resulting in an

improper air-fuel ratio. To compensate this deviation, the

amount of fuel injected is controlled; i.e., the amount of fuel

injected is decreased to compensate for the lower intake air

density caused by the decreased barometric pressure, or the

higher altitude.

CONTROL FOR FUEL ENRICHMENT DURING ACCELERA-

TIONDuring acceleration at low and middle loads, fuel supply rate is

increased to improve acceleration performance.

FUEL DECREASE CONTROL DURING DECELERATION

During deceleration, fuel supply rate is decreased to improve

fuel economy.

BATTERY VOLTAGE COMPENSATION

As described earlier in “INJECTOR”, the needle valve of the

injector is pulled to the fully open position when current flow-

through the solenoid coil. This means that there is a time I;

between the time when the current starts flowing and when

the needle valve starts opening. This time lag is called the dead

time.

The dead time varies with different battery conditions:: the

lower the battery voltage, the longer the dead time.

Since the injector activation duration depends on the intake air

volume and other factors, a longer dead time means a shorter

activation duration, or a smaller amount of fuel injected. This

results in an improper air-fuel ratio. At such times, the solenoid

coil is energized for a longer period of time depending on the

current battery voltage to correct the valve opening time, thus

ensuring that the optimum amount of fuel is injected.

Fuel Injection Control at Starting

When the engine is cranked, the map value preset according to

the engine coolant temperature is used as the basic injector

activation duration, to which the high altitude compensation is

applied..