air condition MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 3 of 391

TALON

BACKUP

README.N or for additional information

PreViOUSlVmanufactured.a *-a- .I._..-1-L,.* _____ #Q ^_^__ l L.-Orintul in U.S.A.

GROUP INDEXROSA. - -

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . .

Front Suspensio n................................

.

Brakes - Eir$rii. . . . . . . . . . . . . . . . . . . . . . . . . . ..s...

Clutch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling. . . . . . :. . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . ..-..................

Engine....................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Propeller Shaft and Universal. . . . . . . .

ml

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power steeringCD

ManualTransaxl e - Automatic....................

m

Bodym

Heaters and Air ConditioningRI

A

Emission Control Systems

Page 50 of 391

----------------l-~)..

(qt.I/min.

Thermostat

We

Valve opening temperature “C (“F)

Therm0switch

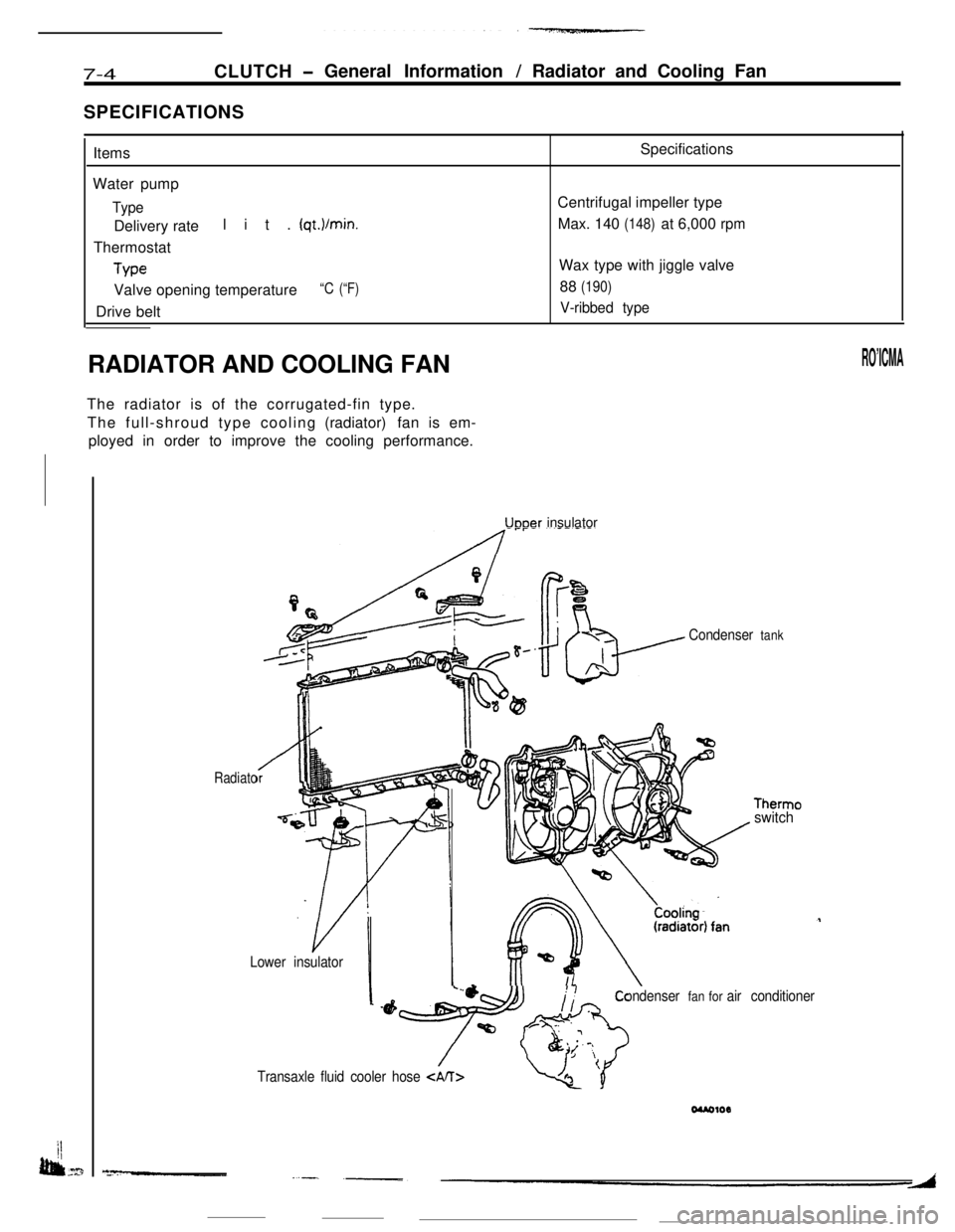

Uooer insulator

Condenser fan for air conditioner

--fyi$f&

/Transaxle fluid cooler hose

Page 55 of 391

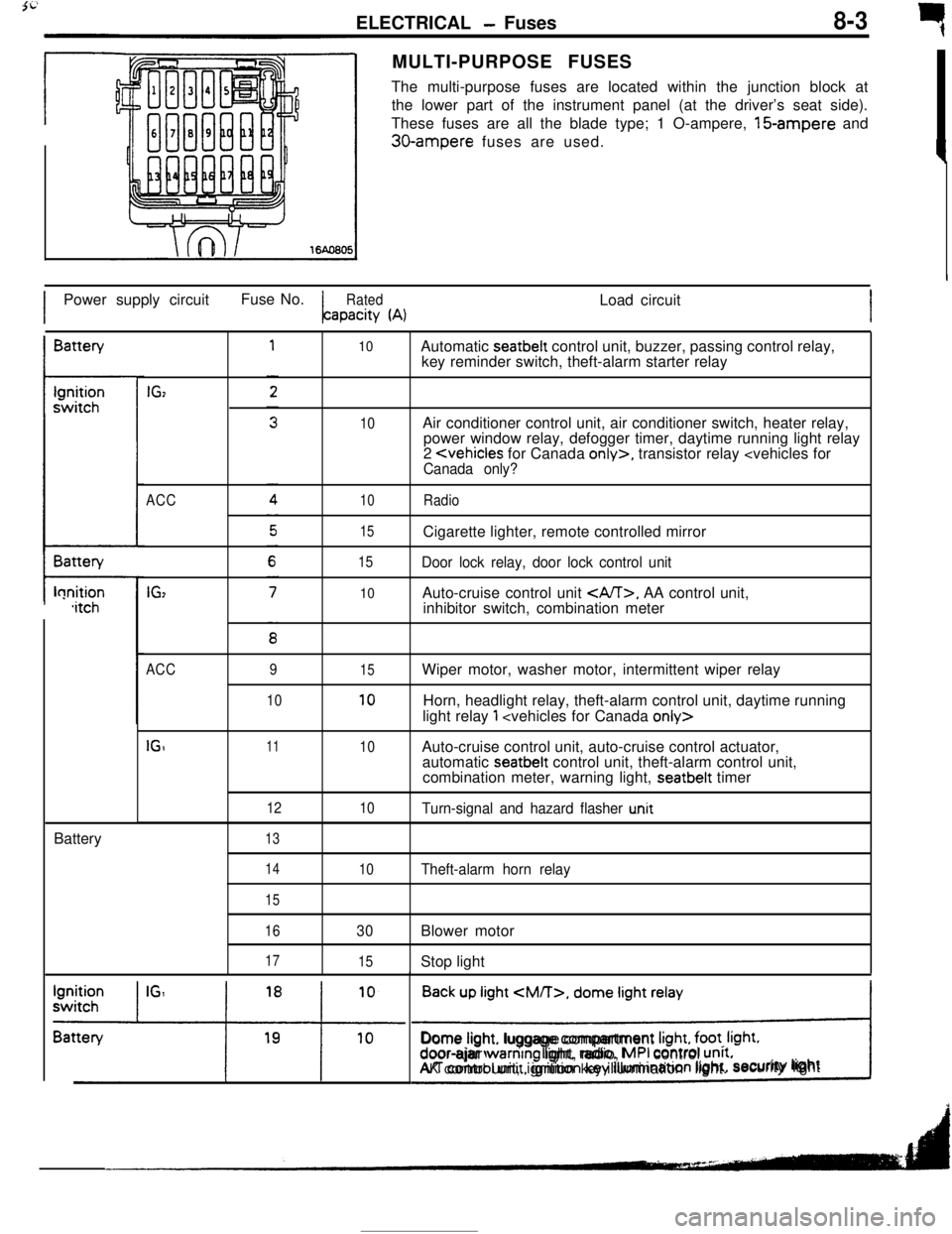

ELECTRICAL - Fuses8-3q

rMULTI-PURPOSE FUSES

The multi-purpose fuses are located within the junction block at

the lower part of the instrument panel (at the driver’s seat side).

These fuses are all the blade type; 1 O-ampere, 15-ampere and

30-ampere fuses are used.

IPower supply circuitFuse No.

RatedLoad circuitapacity

(A)IBattery

t-lonition,itchBattery

IGz

ACC

IG,

10

10

10

15

15

10Automatic seatbelt control unit, buzzer, passing control relay,

key reminder switch, theft-alarm starter relay

Air conditioner control unit, air conditioner switch, heater relay,

power window relay, defogger timer, daytime running light relay

2

Door lock relay, door lock control unitAuto-cruise control unit

, AA control unit,

inhibitor switch, combination meter

ACC

IGI9

1011

12

1315

10

10

10Wiper motor, washer motor, intermittent wiper relay

Horn, headlight relay, theft-alarm control unit, daytime running

light relay

1

automatic seatbelt control unit, theft-alarm control unit,

combination meter, warning light, seatbelt timer

Turn-signal and hazard flasher u.nit

14

15

16

17

10Theft-alarm horn relay

30Blower motor

15Stop light

Back up light

CM/T>, dome light relay

!Dome light. luggage compartment

Irght, foot. Irght.door-ajar warntng light, radio, MPI control unrt.AK control unit, ignition key illumination light.security lightI

Page 56 of 391

_--

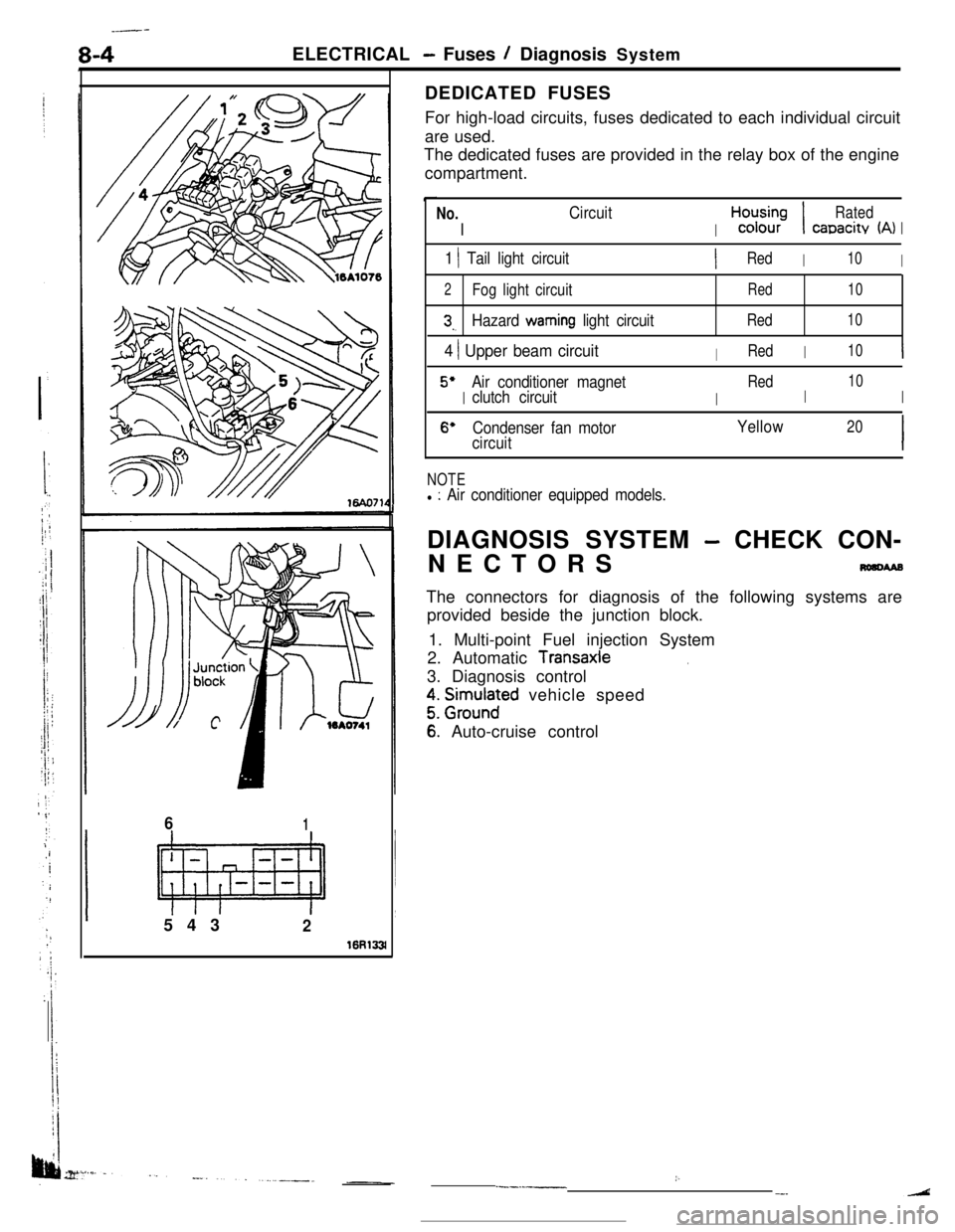

8-4ELECTRICAL - Fuses / Diagnosis System

61543

2

16R133lDEDICATED FUSES

For high-load circuits, fuses dedicated to each individual circuit

are used.

The dedicated fuses are provided in the relay box of the engine

compartment.

No.

I

Circuit

I

H,“d;;-;I

Rated

canacitv (A)I

1 1 Tail light circuitIRedI10I

2Fog light circuitRed10

3,.Hazard warning light circuitRed10

4 ) Upper beam circuitIRedI10I

5’

I

Air conditioner magnet

I

Red

I

10

clutch circuitI

6’Condenser fan motorYellow20

circuitI

NOTEl : Air conditioner equipped models.DIAGNOSIS SYSTEM

- CHECK CON-

NECTORS

nmcwaBThe connectors for diagnosis of the following systems are

provided beside the junction block.

1. Multi-point Fuel injection System

2. Automatic

Transaxle.3. Diagnosis control

z. grm.rlnaFd vehicle speed

6: Auto-cruise control

:..--.-__-.

Page 63 of 391

1ELECTRICAL

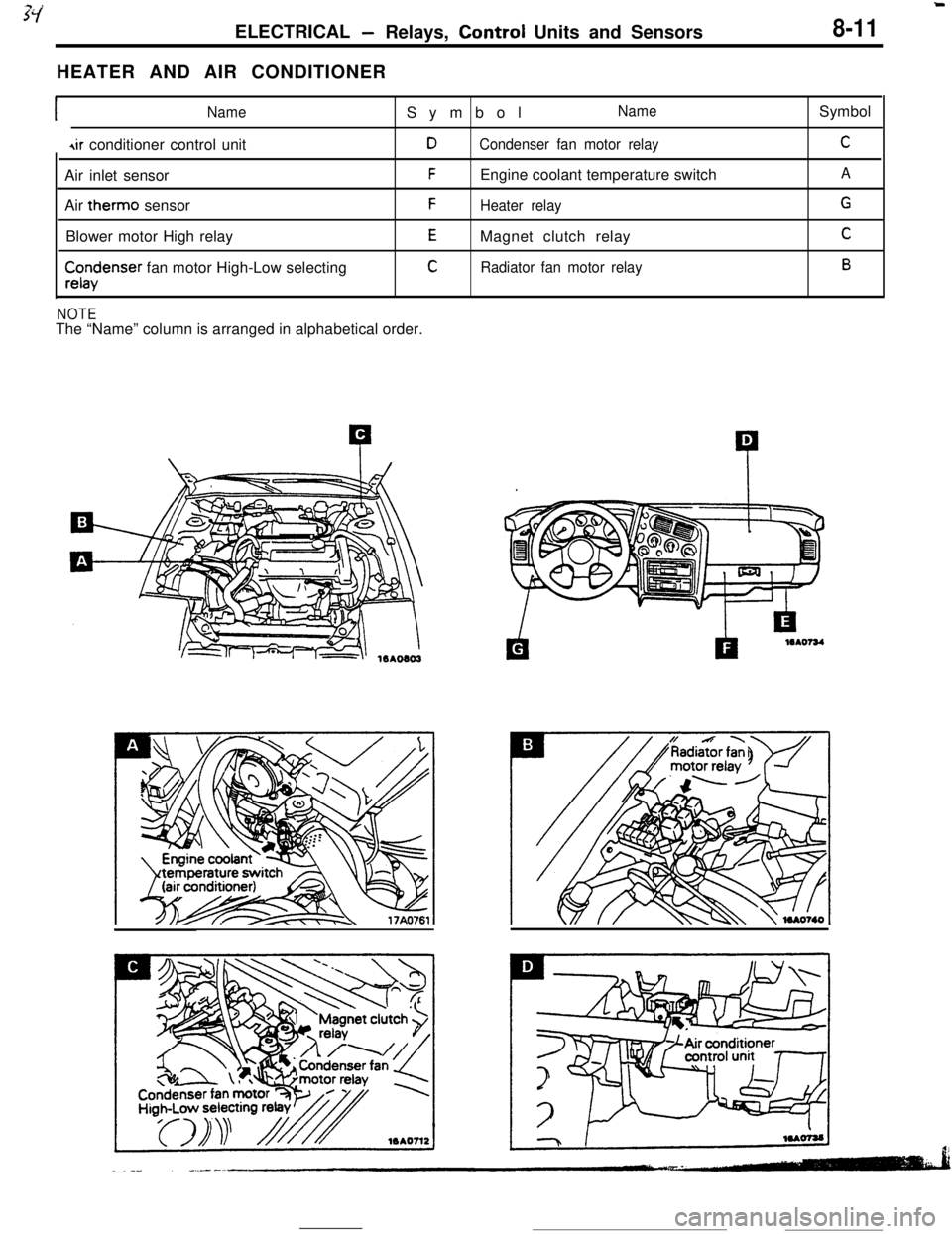

-Relays, Control Units and Sensors8-11HEATER AND AIR CONDITIONER

INameSymbolName

4ir conditioner control unitDCondenser fan motor relayAir inlet sensor

FEngine coolant temperature switch

Air therm0 sensor

FHeater relayBlower motor High relay

EMagnet clutch relay

$x$enser fan motor High-Low selectingCRadiator fan motor relay

NOTEThe “Name” column is arranged in alphabetical order.Symbol

C

A

G

C

B

Page 79 of 391

-----. _-- ___ELECTRICAL

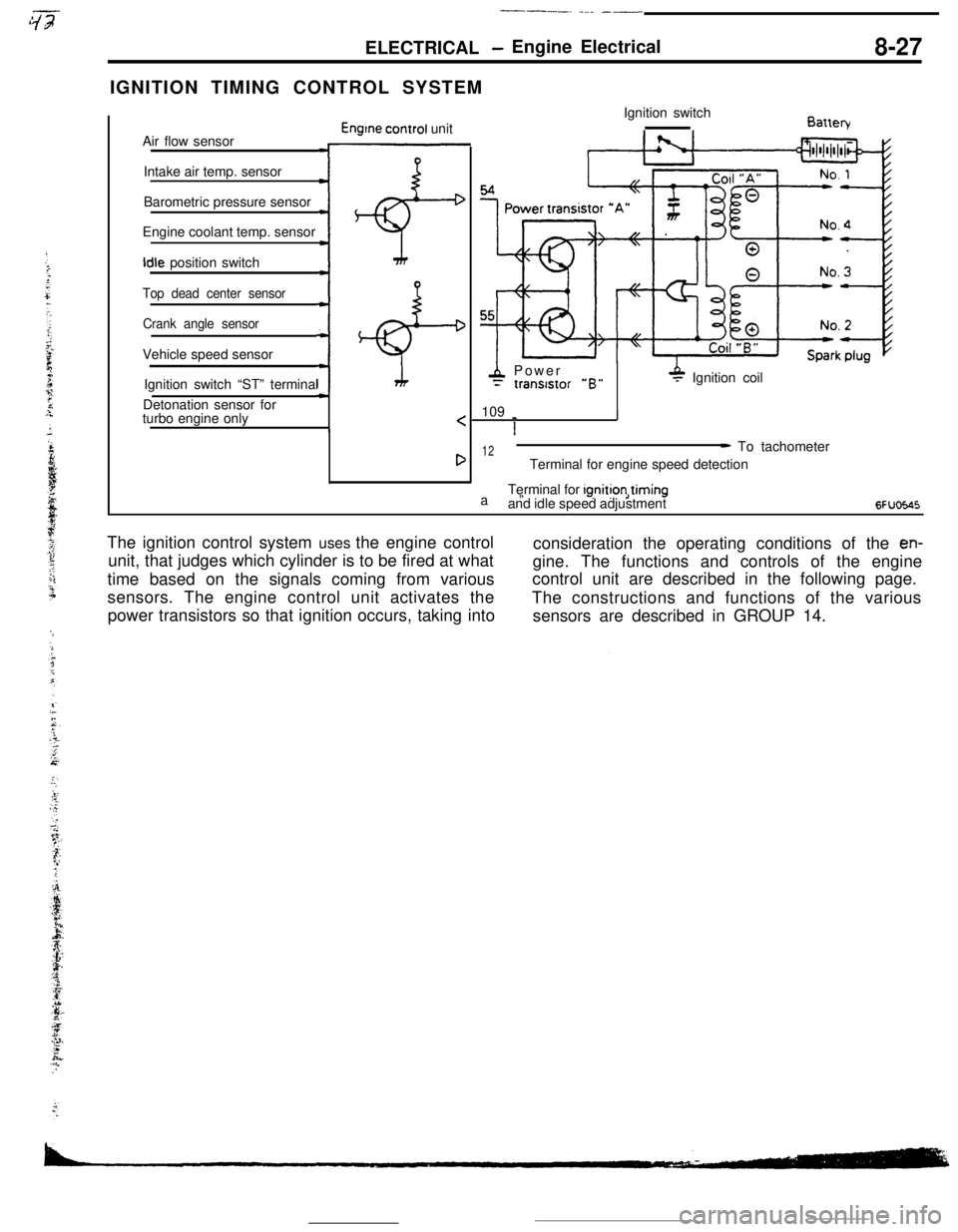

- Engine Electrical8-27IGNITION TIMING CONTROL SYSTEM

Air flow sensor

Engtne control unit

Intake air temp. sensor

Barometric pressure sensor

Engine coolant temp. sensorIdle position switch

:+

Top dead center sensor

Crank angle sensorVehicle speed sensor

;+Ignition switch “ST” terminal

Detonation sensor for

turbo engine only

4 Power= tranststor “B”P Ignition coil

109

_

I

1

12a”- To tachometer

Terminal for engine speed detection

Terminal for ignition,timing

and idle speed adjustment

6FUoE.45The ignition control system uses the engine control

consideration the operating conditions of the

en-unit, that judges which cylinder is to be fired at what

gine. The functions and controls of the engine

time based on the signals coming from variouscontrol unit are described in the following page.

sensors. The engine control unit activates the

The constructions and functions of the various

power transistors so that ignition occurs, taking into

sensors are described in GROUP 14.

Page 80 of 391

8-28ELECTRICAL- Engine Electrical

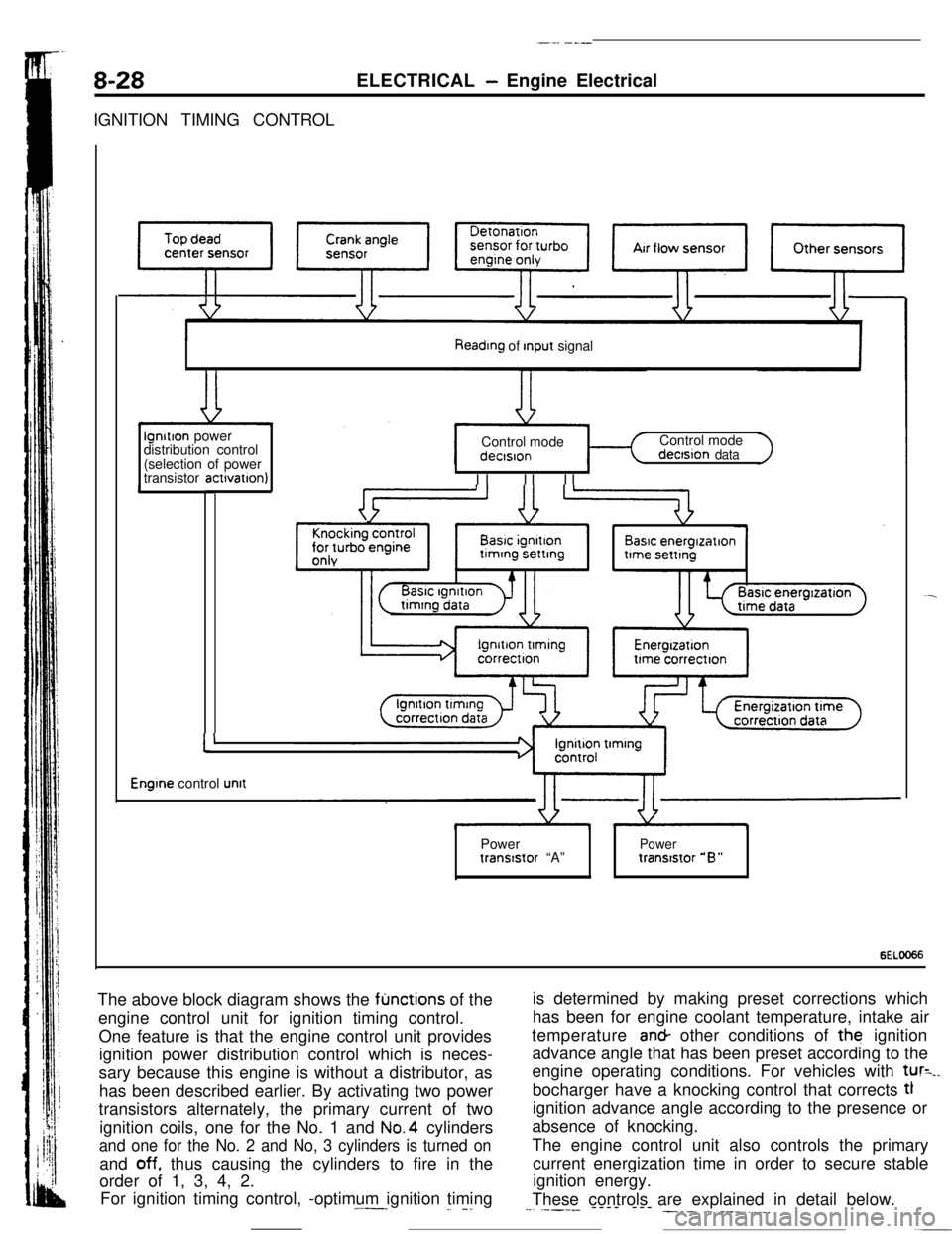

IGNITION TIMING CONTROL

Reading of Input signallgnitlon power

distribution control

(selection of power

transistor actlvatlon)Control mode

I II II IControl mode

dectsion data

Basic energlzatlon

I’

Engine control unitPower

Powertranststor “A”tranststor “B”

6ELOO66The above block diagram shows the

fljnctions of the

engine control unit for ignition timing control.

One feature is that the engine control unit provides

ignition power distribution control which is neces-

sary because this engine is without a distributor, as

has been described earlier. By activating two power

transistors alternately, the primary current of two

ignition coils, one for the No. 1 and No.4 cylinders

and one for the No. 2 and No, 3 cylinders is turned onand

off. thus causing the cylinders to fire in the

order of 1, 3, 4, 2.

For ignition timing control, -optimum ignition timing.^--_

_. -.is determined by making preset corrections which

has been for engine coolant temperature, intake air

temperature an& other conditions of the ignition

advance angle that has been preset according to the

engine operating conditions. For vehicles with

tur=_.bocharger have a knocking control that corrects tl

ignition advance angle according to the presence or

absence of knocking.

The engine control unit also controls the primary

current energization time in order to secure stable

ignition energy.

These controls are explained in detail below.

--. .----- ---- --- ___. .-. ___.,.__

Page 82 of 391

8-30ELECTRICAL - Engine Electrical

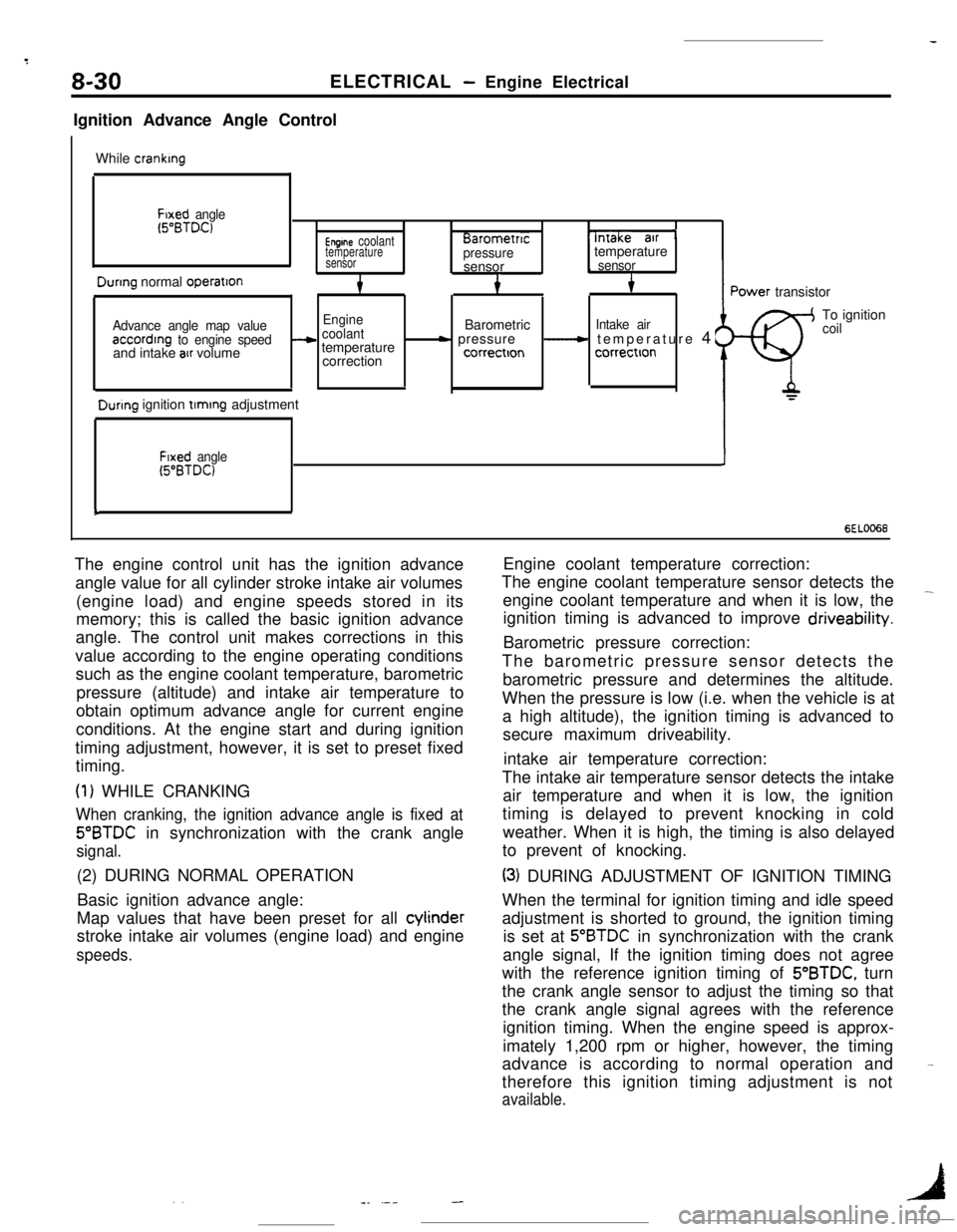

Ignition Advance Angle Control

While

cranking

Fixed angle(5”BTD.C)Engme coolantBarometnc‘-Intake air 1temperaturepressuretemperaturesensorsensor, sensor

Dunng normal operatlon4i+

Advance angle map valueEngine

coolantBarometricIntake airaccording to engine speed4and intake air volumetemperature- pressure__c temperature 4

correctioncorrectloncorrectton

Durtng ignition tlmmg adjustment

Fixed angle(5”BTDC)

c

=ower transistor

-$To ignition

coil

s

6EL0066The engine control unit has the ignition advance

angle value for all cylinder stroke intake air volumes

(engine load) and engine speeds stored in its

memory; this is called the basic ignition advance

angle. The control unit makes corrections in this

value according to the engine operating conditions

such as the engine coolant temperature, barometric

pressure (altitude) and intake air temperature to

obtain optimum advance angle for current engine

conditions. At the engine start and during ignition

timing adjustment, however, it is set to preset fixed

timing.

(1) WHILE CRANKING

When cranking, the ignition advance angle is fixed at

5”BTDC in synchronization with the crank angle

signal.(2) DURING NORMAL OPERATION

Basic ignition advance angle:

Map values that have been preset for all cylinder

stroke intake air volumes (engine load) and engine

speeds.Engine coolant temperature correction:

The engine coolant temperature sensor detects the

engine coolant temperature and when it is low, the

-ignition timing is advanced to improve driveability.

Barometric pressure correction:

The barometric pressure sensor detects the

barometric pressure and determines the altitude.

When the pressure is low (i.e. when the vehicle is at

a high altitude), the ignition timing is advanced to

secure maximum driveability.

intake air temperature correction:

The intake air temperature sensor detects the intake

air temperature and when it is low, the ignition

timing is delayed to prevent knocking in cold

weather. When it is high, the timing is also delayed

to prevent of knocking.

(3) DURING ADJUSTMENT OF IGNITION TIMING

When the terminal for ignition timing and idle speed

adjustment is shorted to ground, the ignition timing

is set at

5”BTDC in synchronization with the crank

angle signal, If the ignition timing does not agree

with the reference ignition timing of 5’BTDC, turn

the crank angle sensor to adjust the timing so that

the crank angle signal agrees with the reference

ignition timing. When the engine speed is approx-

imately 1,200 rpm or higher, however, the timing

advance is according to normal operation and

therefore this ignition timing adjustment is not

available.

-

. .1-_ .---

Page 97 of 391

9-12

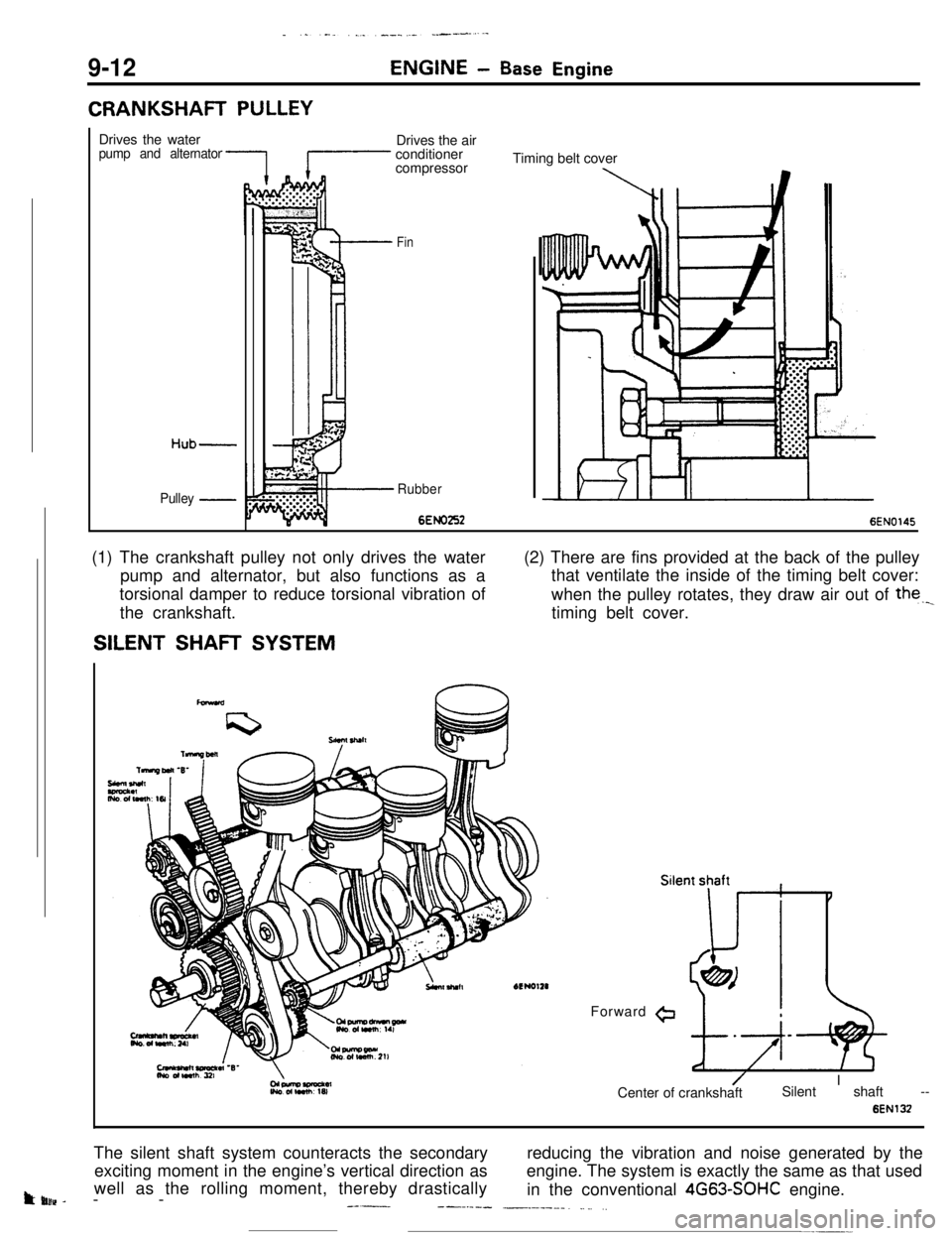

CRANKSHAFT PULLEY

ENGINE- Base EngineDrives the water

pump and alternator

Hub-

Pulley -Drives the air

conditioner

compressor

Fin

Rubber

6EMI2526EN0145 Timing belt cover

(1) The crankshaft pulley not only drives the water

pump and alternator, but also functions as a

torsional damper to reduce torsional vibration of

the crankshaft.

SILENT SHAFT SYSTEM(2) There are fins provided at the back of the pulley

that ventilate the inside of the timing belt cover:

when the pulley rotates, they draw air out of the._

timing belt cover.

Forward

@

/I

Center of crankshaftSilent shaft --

6ENl32The silent shaft system counteracts the secondaryreducing the vibration and noise generated by the

exciting moment in the engine’s vertical direction asengine. The system is exactly the same as that used

t uluv -well as the rolling moment, thereby drastically

in the conventional 4G63-SOHC engine.

-------_---.--- __.----_. _... ,.

Page 114 of 391

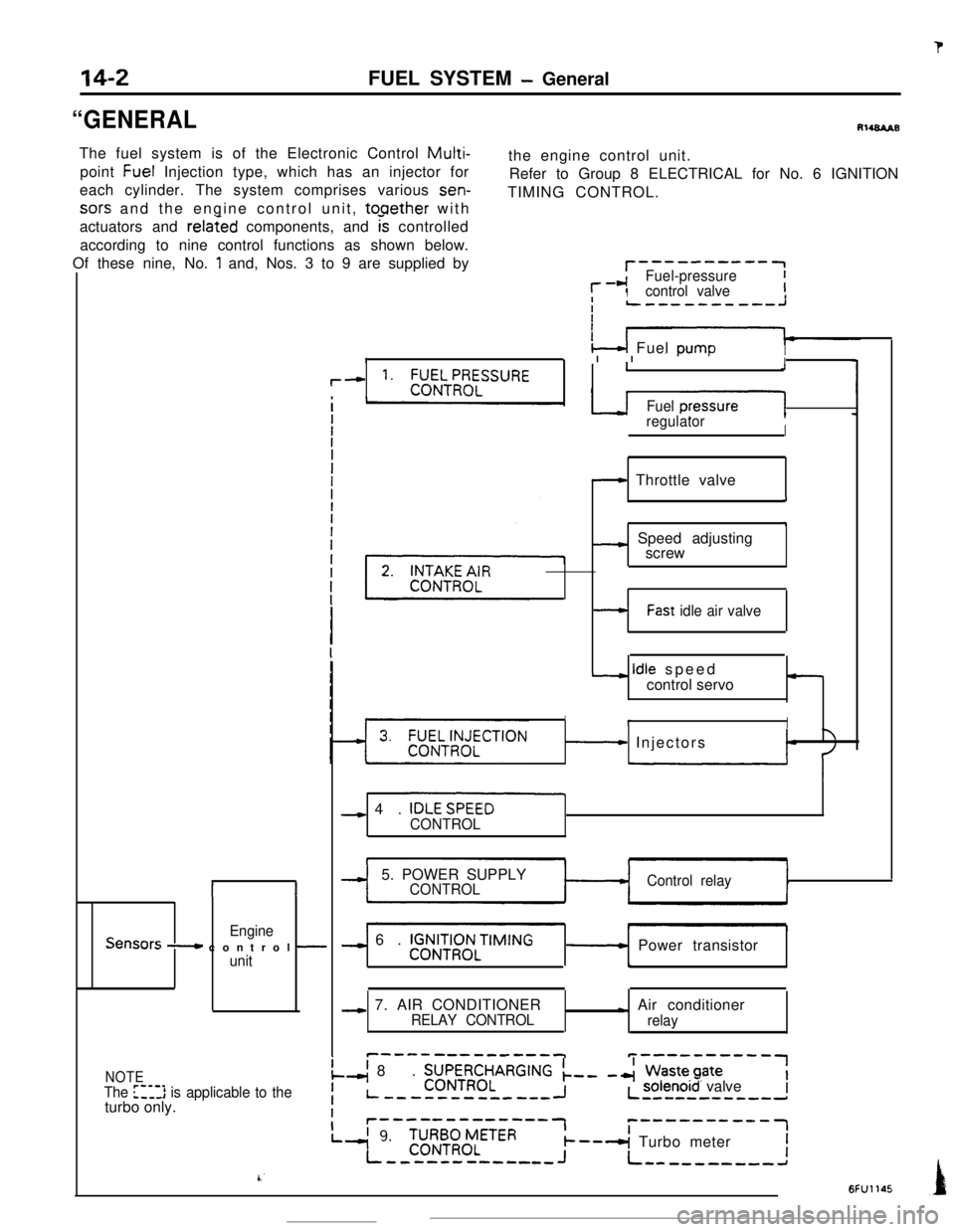

sors and the engine control unit, tooether with

actuators and

related components, and k controlled

according to nine control functions as shown below.

Of these nine, No.

1 and, Nos. 3 to 9 are supplied by

II

EngineSensors - control -unit

r--------‘-1

l--cIFuel-pressureIcontrol valveII

‘4 Fuel DumoI13 I I or-’I

,--c 1. ;;EILT!I;ELSSURE1J

Fuel presJ1regulatorI

- Throttle valve

i

7

_c Speed adjusting

screw

14-2

“GENERALFUEL SYSTEM

- GeneralRl484AB

The fuel system is of the Electronic Control

Multi-point Fuel Injection type, which has an injector forthe engine control unit.

each cylinder. The system comprises various sen-Refer to Group 8 ELECTRICAL for No. 6 IGNITION

TIMING CONTROL.

-Fast idle air valve

- idle speed

control servo-

IrI

- Injectors

- 4. IOLESPEEO

CONTROL

-I5. POWER SUPPLYCONTROLControl relay

-) 6. V$&iRq3NLTIMING- Power transistor

b

-c 7. AIR CONDITIONERRELAY CONTROL- Air conditioner

relay

c-------------Tp----------1

NOTEI

The [‘-,l> is applicable to theI

.-( 8. ZJJ\~RR~LARGING k-- -4 Wastepate

Liturbo only.-----w--------IL solenoid valve--B--------d

Ir-‘---‘---“‘-7c------v--w-1

L’ 9.

-I

‘C;RB;zLETER--A Turbo meterI--------c----J+ L----------a

k’6FU1145