tow MITSUBISHI ECLIPSE 1990 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 299 of 391

![MITSUBISHI ECLIPSE 1990 Owners Manual ir yAUTOMATIC TRANSAXLE

- Trahsaxle Control21-774th Gear

3rd GearRear clutchKickdown

1servo

release sideFront clutch

-

Rear clutch3rd1-2 shiftKickdown

Front clutch

q]b Ture,‘r z&eside

7

1750107

1F MITSUBISHI ECLIPSE 1990 Owners Manual ir yAUTOMATIC TRANSAXLE

- Trahsaxle Control21-774th Gear

3rd GearRear clutchKickdown

1servo

release sideFront clutch

-

Rear clutch3rd1-2 shiftKickdown

Front clutch

q]b Ture,‘r z&eside

7

1750107

1F](/img/19/57103/w960_57103-298.png)

ir yAUTOMATIC TRANSAXLE

- Trahsaxle Control21-774th Gear

3rd GearRear clutchKickdown

1servo

release sideFront clutch

-

Rear clutch3rd1-2 shiftKickdown

Front clutch

q]b Ture,‘r z&eside

7

1750107

1Fromk-D3rd 14th pressure

control valve1 ;l;hiftpressure1750108

Upshift from

3rd to 4th Gear

.When the 4th pressure (line pressure) from the shift

control valve is directed to the rear clutch exhaust

valve through the No.8 line. the valve is pushed to

the right, closing the No.5c port. This cuts off the

pressure to the rear clutch and also releases the

pressure acting on the rear clutch through NO.

15port, No.20a port and No. 20

port.On the other hand, the rear clutch exhaust

valvewhich is pushed to the right opens the NO. 19

POnand directs the 4th pressure (line pressure) to the

right end of the

2-3/4-3 shift valve. The 3rdpressure (or the No.7 line pressure) is acting on theleft

end of the 2-3/4-3 shift valve. As this Pressure

..is equal to the No. 19 line pressure and acts on the

Mme area, the spring at the right end of the valveWhen the 4th pressure is released by the move-

ment of the shift control valve, the rear clutchDownshift from 4th to

3rd Gear

exhaust valve moves to the left, creating a

3rd gearstate, and the pressure is directed to the rear clutch.

At the same time as this happens, the 4th pressure

in No. 19 line which has been acting on the 2-3/4-3shift valve is released. This causes the

3rd pressure

established in the

No.7 line to push the 2-3/4-3shift valve to the right, and creates a 3rd gear state

where the line pressure from the

l-2 shift valve is

directed to the front clutch and the release side

chamber of kickdown servo cylinder through the

No. 12 line.shes the valve toward the

left. closing the No. 11me pressure port. This

btocks the pressure to the

front clutch and the release side chamber ofkickdown servo cylinder, and the pressure is re-

leased through the No. 12. and then the

No.9~ Pofi.

Page 300 of 391

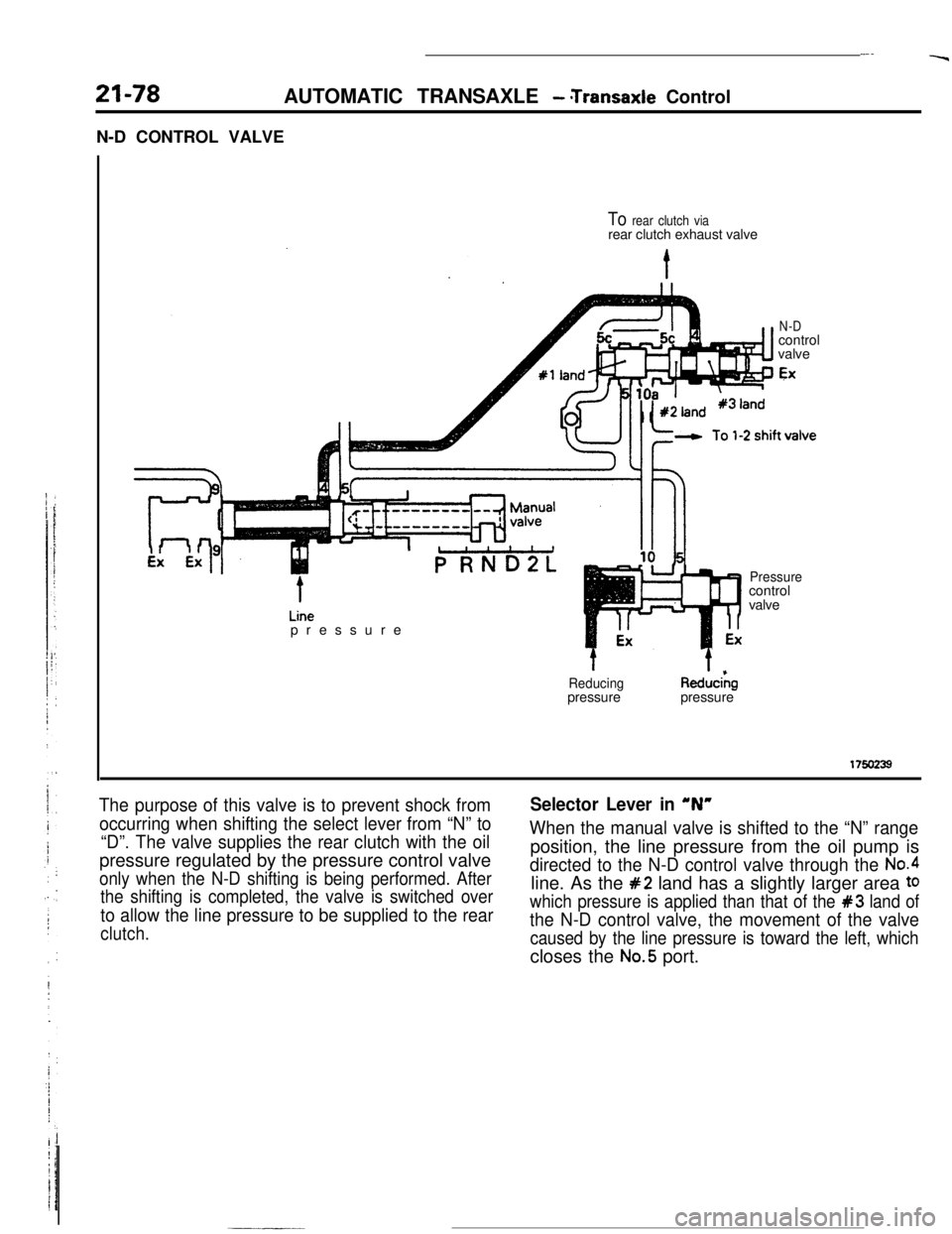

21-78AUTOMATIC TRANSAXLE - Transaxle Control

N-D CONTROL VALVE

.-.‘r

To rear clutch viarear clutch exhaust valve

N-Dcontrol

valve

EXpressure

Pressurecontrol

valve

t

Reducingpressure

t

Red”&pressure

175oz39

The purpose of this valve is to prevent shock from

occurring when shifting the select lever from “N” to

“D”. The valve supplies the rear clutch with the oilpressure regulated by the pressure control valve

only when the N-D shifting is being performed. After

the shifting is completed, the valve is switched over

to allow the line pressure to be supplied to the rear

clutch.

Selector Lever in ‘N”

When the manual valve is shifted to the “N” rangeposition, the line pressure from the oil pump is

directed to the N-D control valve through the No.4line. As the

#2 land has a slightly larger area to

which pressure is applied than that of the #3 land of

the N-D control valve, the movement of the valve

caused by the line pressure is toward the left, whichcloses the

No.5 port.

Page 301 of 391

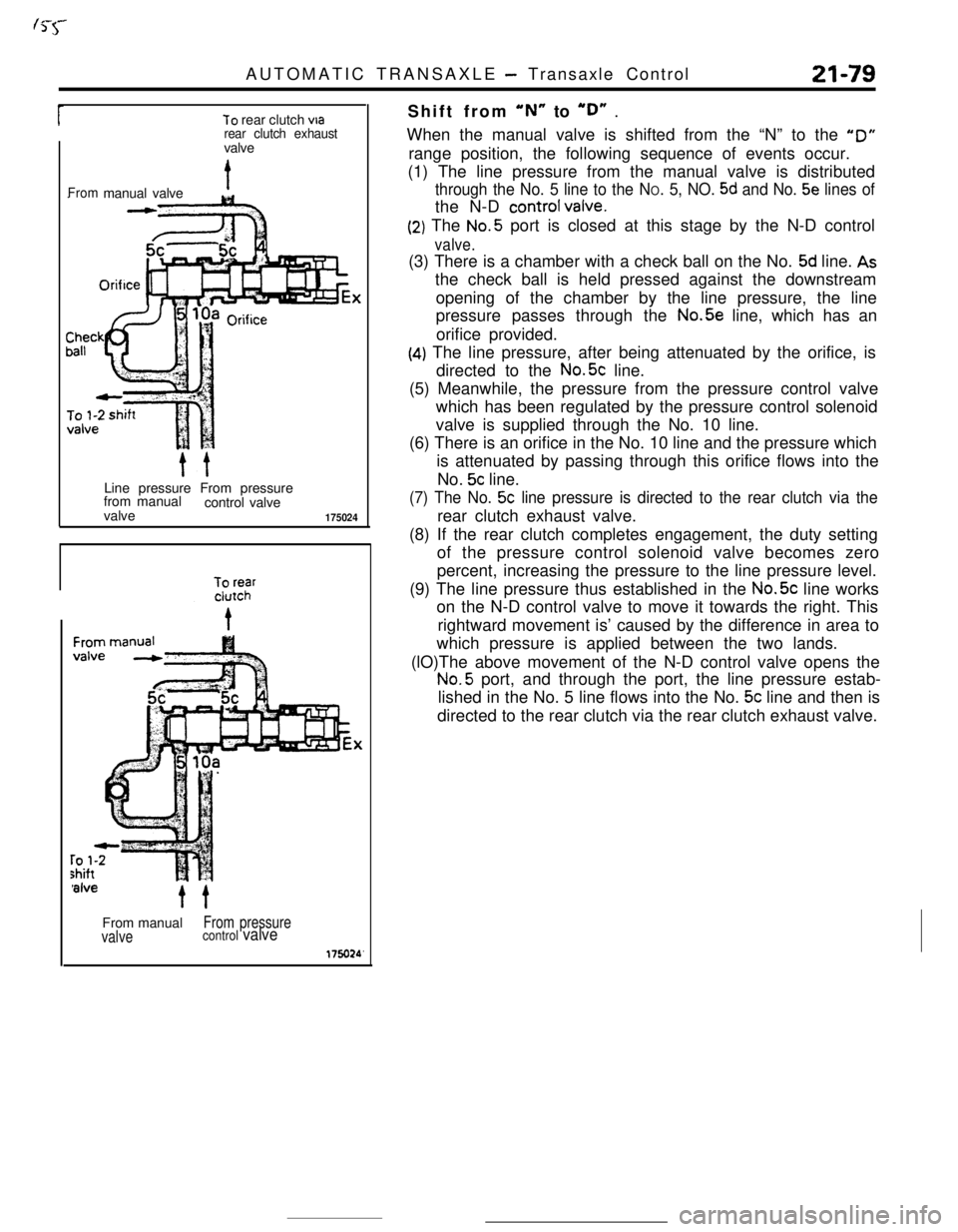

AUTOMATIC TRANSAXLE - Transaxle Control21-79

70 rear clutch via

rear clutch exhaustvalve

Frommanual valveOrifice

Line pressure From pressure

from manual

control valve

valve

175024

valveFrom manual

From pressure

valvecontrol valve175024Shift from “N” to

“D” .

When the manual valve is shifted from the “N” to the

“D”range position, the following sequence of events occur.

(1) The line pressure from the manual valve is distributed

through the No. 5 line to the NO. 5, NO. 5d and No. 5e lines ofthe N-D control

VdVe.

(2) The No.5 port is closed at this stage by the N-D control

valve.(3) There is a chamber with a check ball on the No.

5d line. Asthe check ball is held pressed against the downstream

opening of the chamber by the line pressure, the line

pressure passes through the

No.Se line, which has an

orifice provided.

(4 The line pressure, after being attenuated by the orifice, is

directed to the No.5c line.

(5) Meanwhile, the pressure from the pressure control valve

which has been regulated by the pressure control solenoid

valve is supplied through the No. 10 line.

(6) There is an orifice in the No. 10 line and the pressure which

is attenuated by passing through this orifice flows into the

No.

5c line.

(7) The No. 5c line pressure is directed to the rear clutch via therear clutch exhaust valve.

(8) If the rear clutch completes engagement, the duty setting

of the pressure control solenoid valve becomes zero

percent, increasing the pressure to the line pressure level.

(9) The line pressure thus established in the No.5c line works

on the N-D control valve to move it towards the right. This

rightward movement is’ caused by the difference in area to

which pressure is applied between the two lands.

(lO)The above movement of the N-D control valve opens theNo.5 port, and through the port, the line pressure estab-

lished in the No. 5 line flows into the No.

5c line and then is

directed to the rear clutch via the rear clutch exhaust valve.

Page 303 of 391

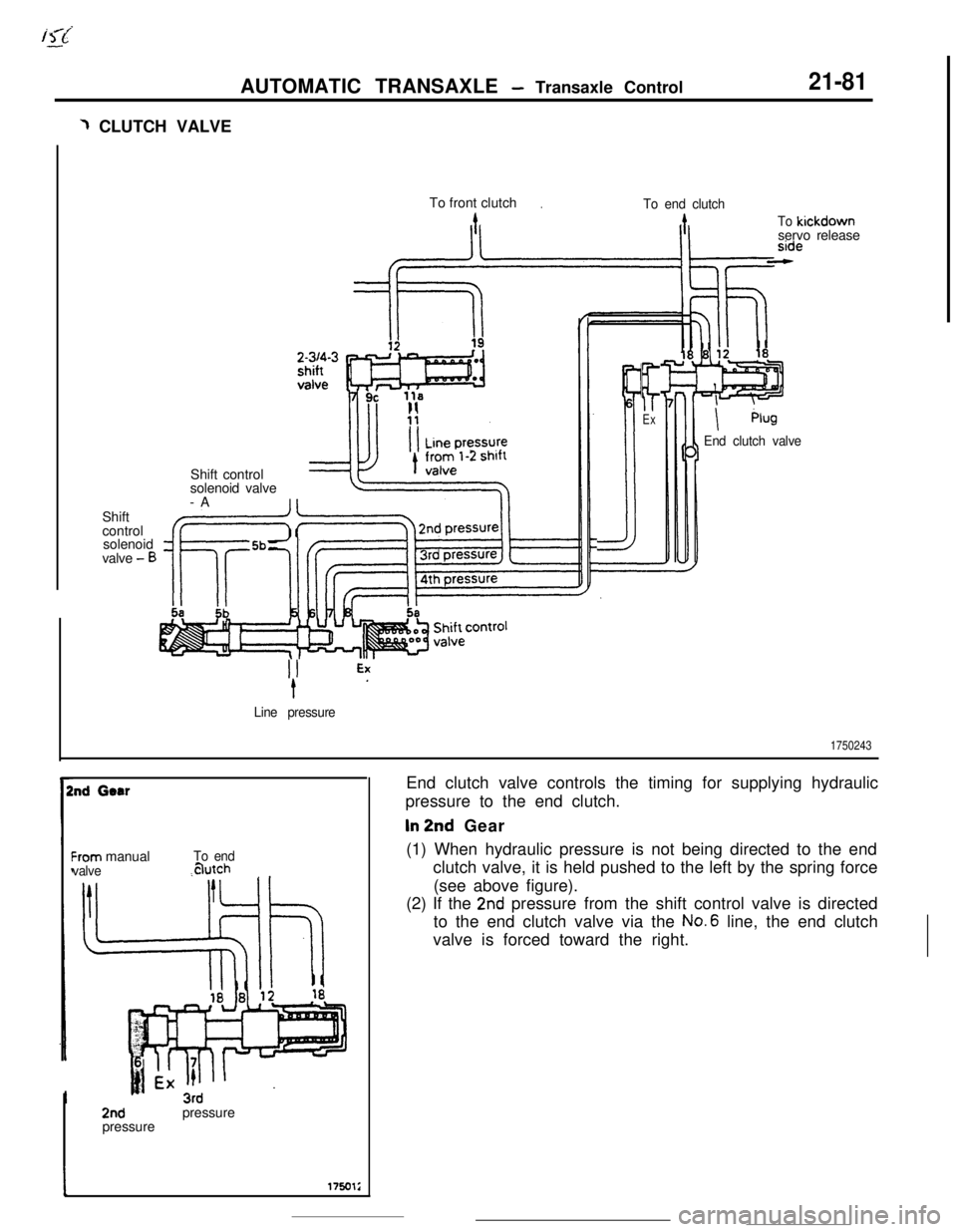

AUTOMATIC TRANSAXLE - Transaxle Control21-81

3 CLUTCH VALVE

To front clutch

.To end clutch

To kickdown

servo release

Shift

control

solenoid

valve

- BShift control

solenoid valve

-A

II

J

ExIPlug

End clutch valve

‘11 E”

Line pressure

1750243End clutch valve controls the timing for supplying hydraulic

pressure to the end clutch.In 2nd Gear

(1) When hydraulic pressure is not being directed to the end

clutch valve, it is held pushed to the left by the spring force

(see above figure).

(2) If the

2nd pressure from the shift control valve is directed

to the end clutch valve via the No.6 line, the end clutch

valve is forced toward the right.

,nd Gear

Lrom manualvalveTo end,&tch.

2ndpressurepressure

I17501i

Page 304 of 391

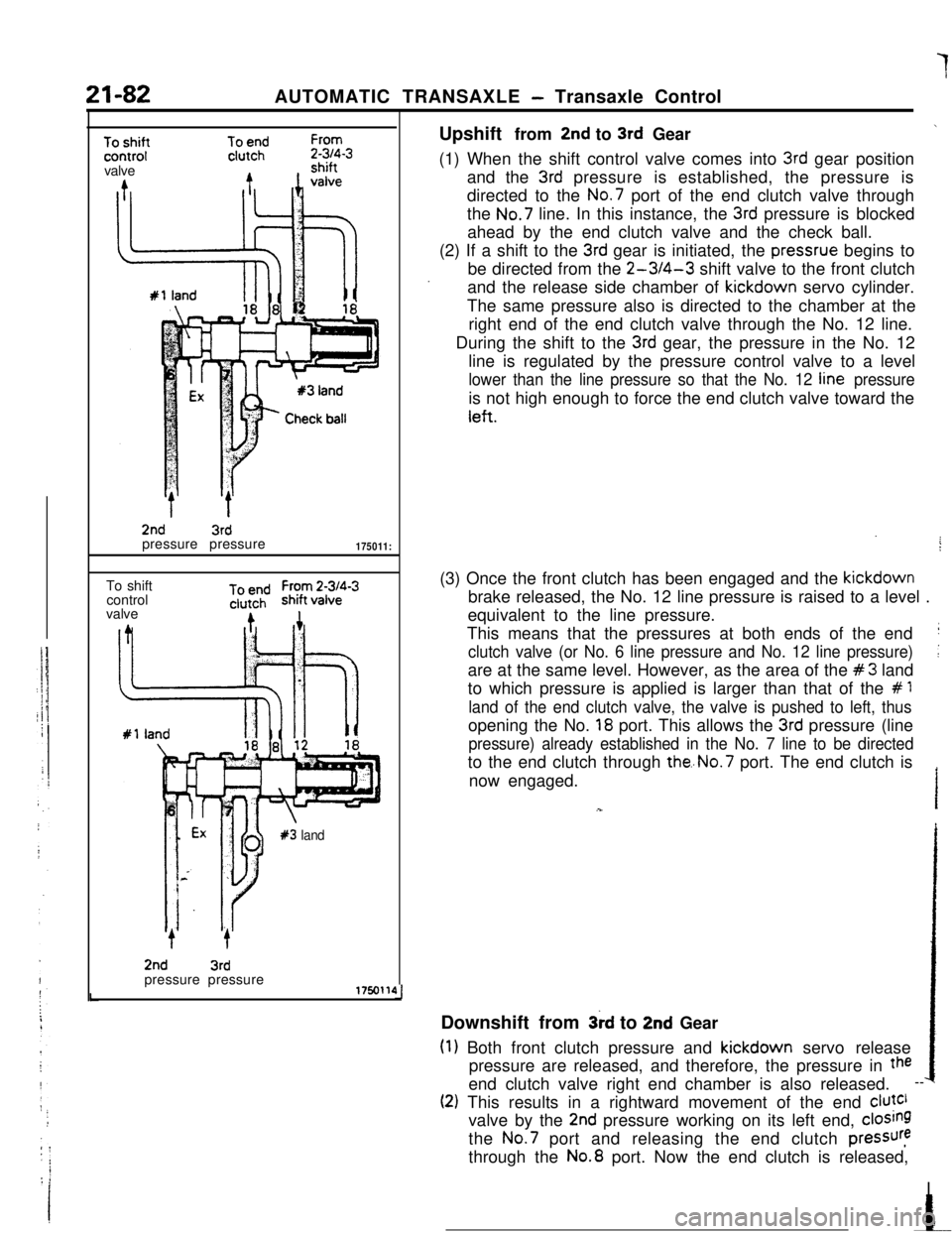

21-82AUTOMATIC TRANSAXLE - Transaxle Control

valve

A

2nd3rdpressure pressure175011:To shift

control

valve#3

land

2nd3rdpressure pressure

175011~LlUpshift from

2nd to 3rd Gear\(1) When the shift control valve comes into

3rd gear position

and the

3rd pressure is established, the pressure is

directed to the No.7 port of the end clutch valve through

the No.7 line. In this instance, the

3rd pressure is blocked

ahead by the end clutch valve and the check ball.

(2) If a shift to the

3rd gear is initiated, the pressrue begins to

be directed from the

2-3/4-3 shift valve to the front clutch

and the release side chamber of kickdown servo cylinder.

The same pressure also is directed to the chamber at the

right end of the end clutch valve through the No. 12 line.

During the shift to the

3rd gear, the pressure in the No. 12

line is regulated by the pressure control valve to a level

lower than the line pressure so that the No. 12 line pressureis not high enough to force the end clutch valve toward the

left.(3) Once the front clutch has been engaged and the kickdown

brake released, the No. 12 line pressure is raised to a level .

equivalent to the line pressure.

This means that the pressures at both ends of the end

j

clutch valve (or No. 6 line pressure and No. 12 line pressure)[are at the same level. However, as the area of the

#3 land

to which pressure is applied is larger than that of the

# 1

land of the end clutch valve, the valve is pushed to left, thusopening the No.

18 port. This allows the 3rd pressure (line

pressure) already established in the No. 7 line to be directedto the end clutch through

the..No.7 port. The end clutch is

now engaged.

Downshift from

3rd to 2nd Gear

(1) Both front clutch pressure and kickdown servo release

pressure are released, and therefore, the pressure in

theend clutch valve right end chamber is also released.

--

(2) This results in a rightward movement of the end clutclvalve by the

2nd pressure working on its left end, closingthe

No.7 port and releasing the end clutch pressurethrough the No.8 port. Now the end clutch is released,

I

Page 307 of 391

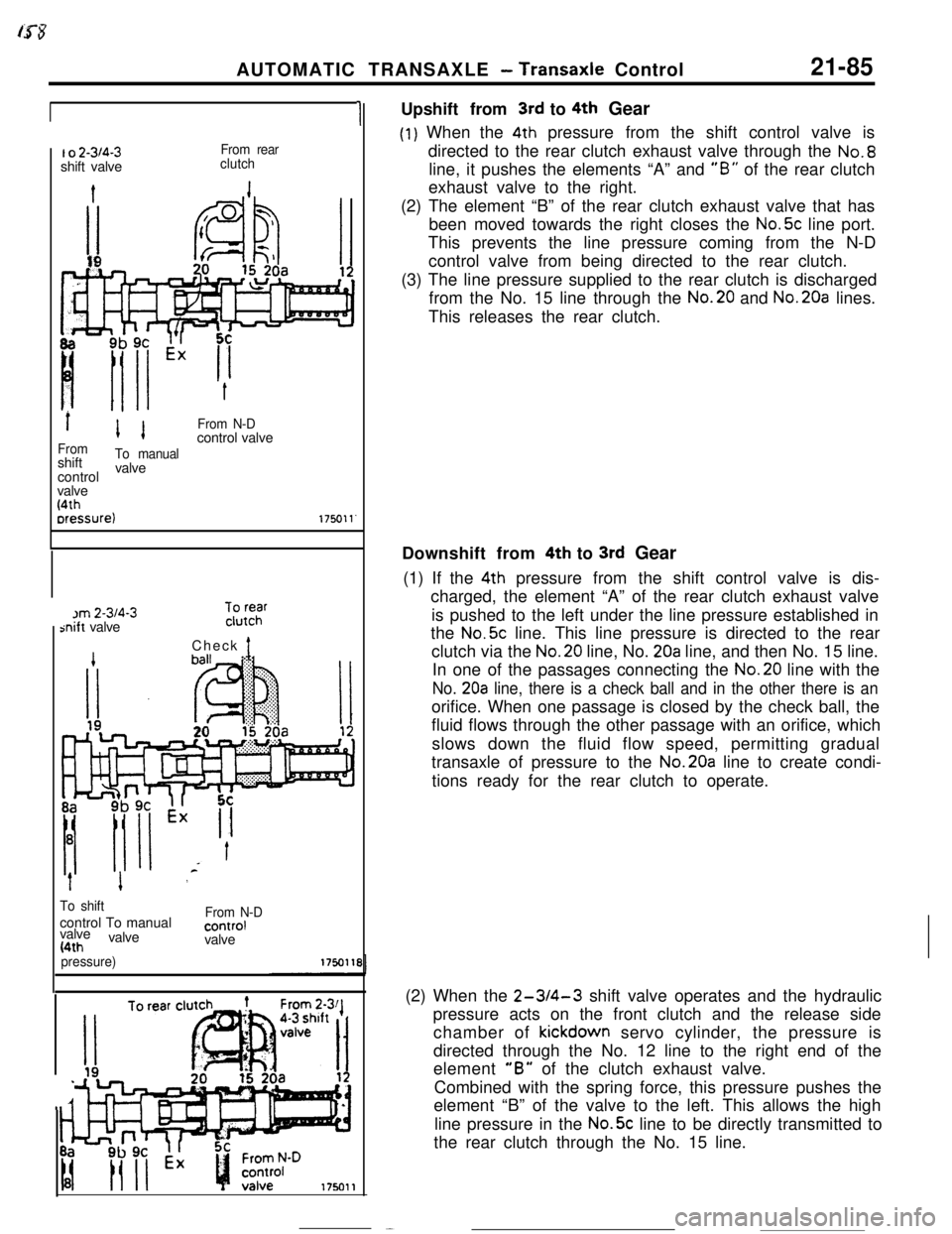

AUTOMATIC TRANSAXLE - Transaxle Control21-85

I o 2-314-3shift valveFrom rear

clutch

11 1From N-Dcontrol valve

FromshiftTo manualcontrolvalve

valve

(4thoressure)175011‘

1

>rn 2-314-3jnift valveTCPUE’Check t

I

To shiftcontrol To manualFrom N-Dmntmlvalve

”.,,l”l

(4thvalve

valvepressure)

--

II1111

”

E,Upshift from

3rd to 4th Gear

(1) When the 4th pressure from the shift control valve is

directed to the rear clutch exhaust valve through the No.8

line, it pushes the elements “A” and

“B” of the rear clutch

exhaust valve to the right.

(2) The element “B” of the rear clutch exhaust valve that has

been moved towards the right closes the

No.5~ line port.

This prevents the line pressure coming from the N-D

control valve from being directed to the rear clutch.

(3) The line pressure supplied to the rear clutch is discharged

from the No. 15 line through the No.20 and No.20a lines.

This releases the rear clutch.

Downshift from 4th to

3rd Gear

(1) If the

4th pressure from the shift control valve is dis-

charged, the element “A” of the rear clutch exhaust valve

is pushed to the left under the line pressure established in

the

No.5~ line. This line pressure is directed to the rear

clutch via the No.20 line, No.

20a line, and then No. 15 line.

In one of the passages connecting the No.20 line with the

No. 20a line, there is a check ball and in the other there is anorifice. When one passage is closed by the check ball, the

fluid flows through the other passage with an orifice, which

slows down the fluid flow speed, permitting gradual

transaxle of pressure to the No.20a line to create condi-

tions ready for the rear clutch to operate.

(2) When the

2-3/4-3 shift valve operates and the hydraulic

pressure acts on the front clutch and the release side

chamber of kickdown servo cylinder, the pressure is

directed through the No. 12 line to the right end of the

element

“8” of the clutch exhaust valve.

Combined with the spring force, this pressure pushes the

element “B” of the valve to the left. This allows the high

line pressure in the

No.5~ line to be directly transmitted to

the rear clutch through the No. 15 line.

Page 313 of 391

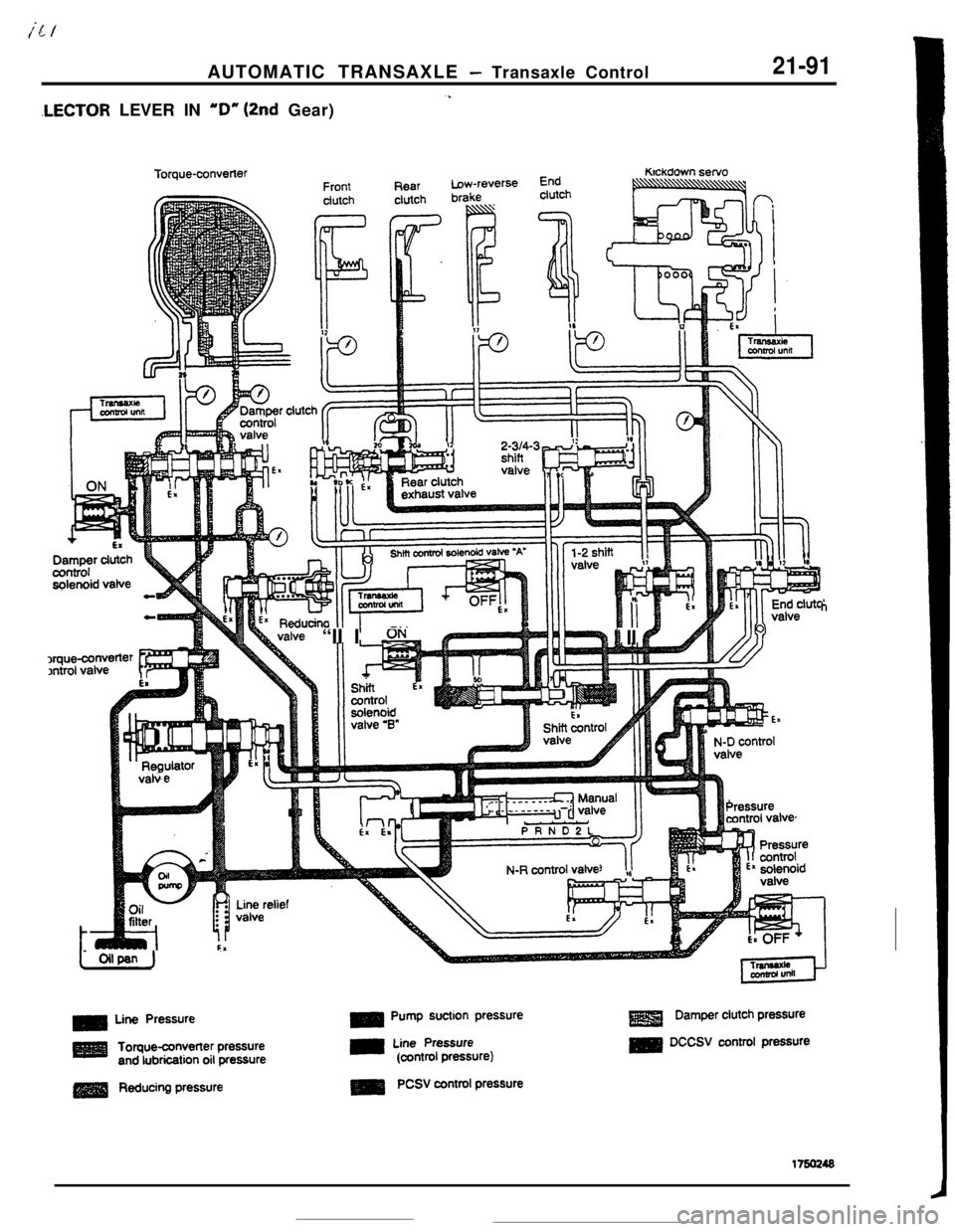

AUTOMATIC TRANSAXLE - Transaxle Control21-91

.LECTOR LEVER IN ‘D” (2nd Gear)Torque-converter

FrontdutchKEkctown servoRearLow-reverseEnd

clutchbrakeclutch

ri

t

valr

hvalve

“II I

ON-II II

LOUpan)-

N-D controlvalve

Pressurecontrol valve

N-R control valve

118 Line Pressure

Torqueconverter pressureand lubrication oil pressure

m Pump suction pressure

m Line Pressure(control pressure)Damper clutch pressurem DCCSV control pressureReducing pressure

PCSV control pressure

Page 339 of 391

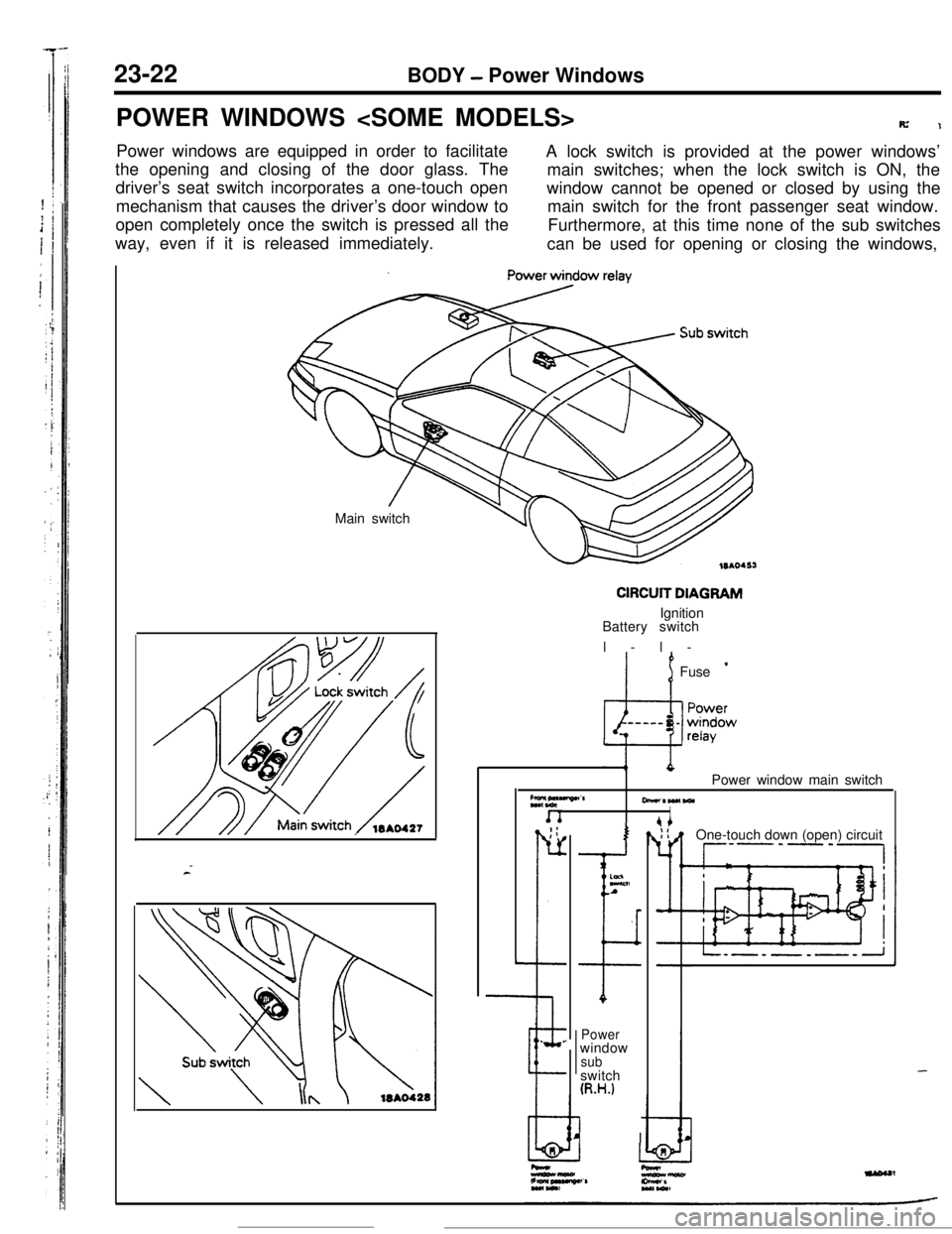

23-22BODY - Power Windows

POWER WINDOWS

R’1Power windows are equipped in order to facilitate

A lock switch is provided at the power windows’

the opening and closing of the door glass. The

main switches; when the lock switch is ON, the

driver’s seat switch incorporates a one-touch open

mechanism that causes the driver’s door window towindow cannot be opened or closed by using the

main switch for the front passenger seat window.

open completely once the switch is pressed all the

way, even if it is released immediately.Furthermore, at this time none of the sub switches

can be used for opening or closing the windows,

Main switch

CIRCUIT DIAGRAMIgnition

Battery switch

l-l-

’ 1Fuse ’

Z*,“““”CrPower window main switch

-*W(WlI. _;:

r-

L

--e.

.

I

ELnA

I

Powerwindow

subswitch

(R.H.)

I IOne-touch down (open) circuit

--P’-‘-,

-

Page 342 of 391

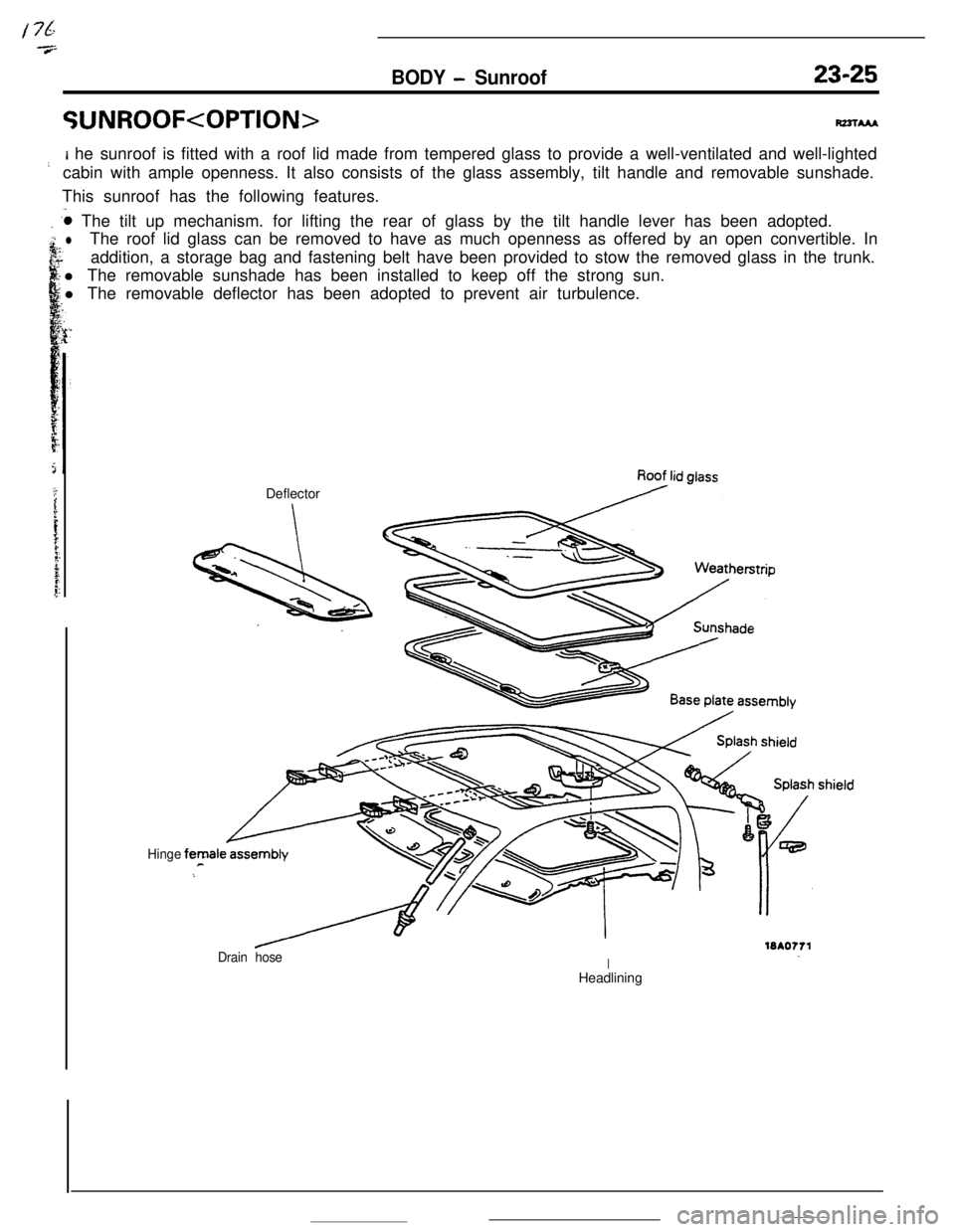

CUNROOF

Page 345 of 391

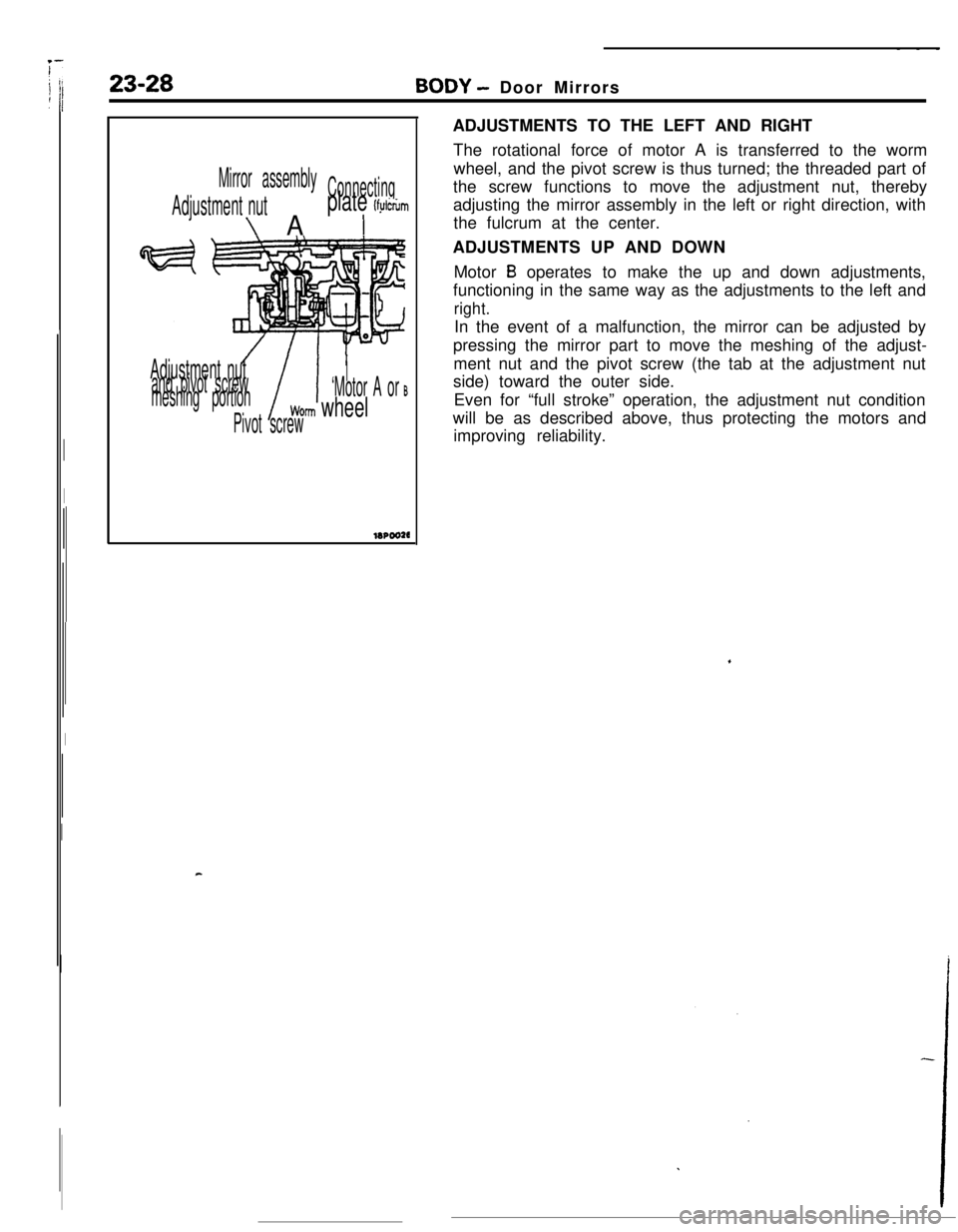

Mirror assemblywheel, and the pivot screw is thus turned; the threaded part of

Adjustment nut

\A

Connectingthe screw functions to move the adjustment nut, therebyplate (fylcrum

Iadjusting the mirror assembly in the left or right direction, with

the fulcrum at the center.

23-28---BODY - Door Mirrors

ADJUSTMENTS TO THE LEFT AND RIGHT

The rotational force of motor A is transferred to the worm

Adjustment nutand pivot screwI

meshing portionI ’‘Motor A or

B

Worm wheel

Pivot screwADJUSTMENTS UP AND DOWN

Motor

B operates to make the up and down adjustments,

functioning in the same way as the adjustments to the left and

right.In the event of a malfunction, the mirror can be adjusted by

pressing the mirror part to move the meshing of the adjust-

ment nut and the pivot screw (the tab at the adjustment nut

side) toward the outer side.

Even for “full stroke” operation, the adjustment nut condition

will be as described above, thus protecting the motors and

improving reliability.

c