air condition MITSUBISHI ECLIPSE 1990 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 154 of 391

14-42

FUEL SYSTEM- Fuel Injection Control

4

Fz.or.c

4:0/

E

{!*760 (301Barometric pressure

mmHg (in.Hg) 6Fuo9z

c

Timet

6FUO279Drivecurrent

0: bri

F2JJ’ ipe; II

I+-JValve opening timi16240:

E‘C

F

.-

is

3

3:\Battery voltage

V162406

80 (176)Coolant temperature

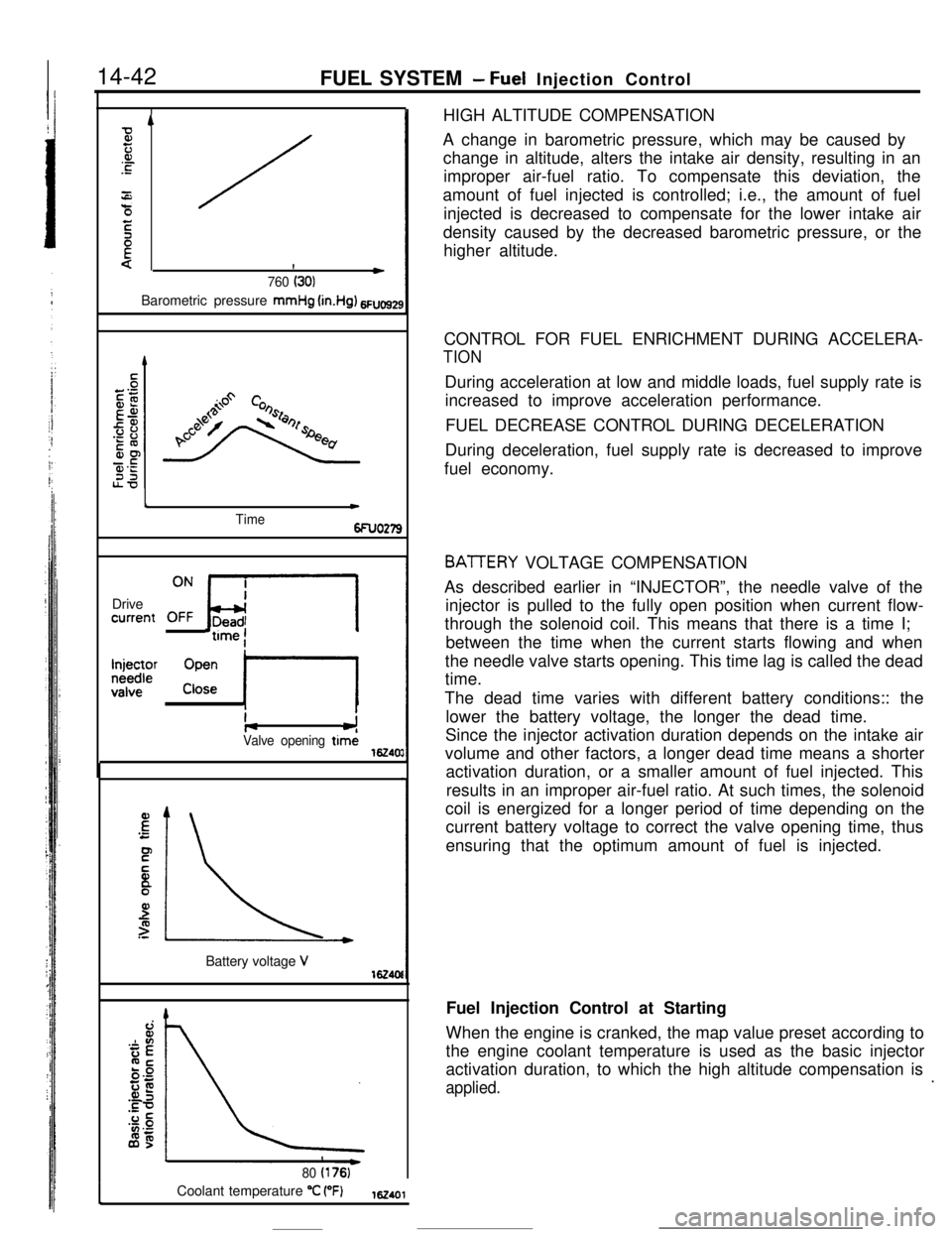

“C (“F)162401HIGH ALTITUDE COMPENSATION

A change in barometric pressure, which may be caused by

change in altitude, alters the intake air density, resulting in an

improper air-fuel ratio. To compensate this deviation, the

amount of fuel injected is controlled; i.e., the amount of fuel

injected is decreased to compensate for the lower intake air

density caused by the decreased barometric pressure, or the

higher altitude.

CONTROL FOR FUEL ENRICHMENT DURING ACCELERA-

TIONDuring acceleration at low and middle loads, fuel supply rate is

increased to improve acceleration performance.

FUEL DECREASE CONTROL DURING DECELERATION

During deceleration, fuel supply rate is decreased to improve

fuel economy.

BATTERY VOLTAGE COMPENSATION

As described earlier in “INJECTOR”, the needle valve of the

injector is pulled to the fully open position when current flow-

through the solenoid coil. This means that there is a time I;

between the time when the current starts flowing and when

the needle valve starts opening. This time lag is called the dead

time.

The dead time varies with different battery conditions:: the

lower the battery voltage, the longer the dead time.

Since the injector activation duration depends on the intake air

volume and other factors, a longer dead time means a shorter

activation duration, or a smaller amount of fuel injected. This

results in an improper air-fuel ratio. At such times, the solenoid

coil is energized for a longer period of time depending on the

current battery voltage to correct the valve opening time, thus

ensuring that the optimum amount of fuel is injected.

Fuel Injection Control at Starting

When the engine is cranked, the map value preset according to

the engine coolant temperature is used as the basic injector

activation duration, to which the high altitude compensation is

applied..

Page 156 of 391

- __..--

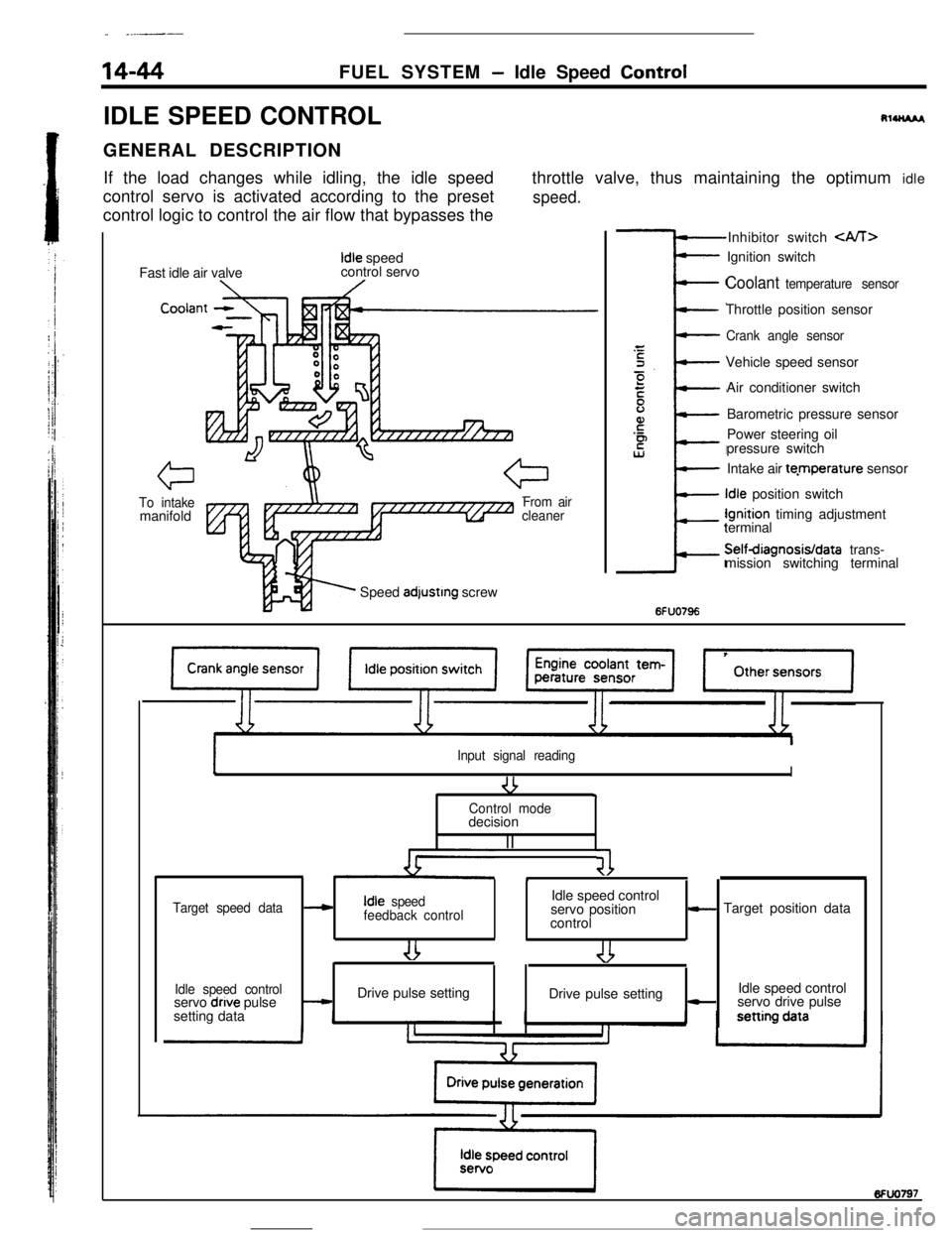

14-44FUEL SYSTEM- Idle Speed Control

IDLE SPEED CONTROL

RlUU*I,GENERAL DESCRIPTION

If the load changes while idling, the idle speed

control servo is activated according to the preset

control logic to control the air flow that bypasses thethrottle valve, thus maintaining the optimum idle

speed.Fast idle air valve

Idle speed

control servo

Cooiar

To intakemanifoldFrom air

cleanerSpeed

adjustrng screwInhibitor switch

Coolant temperature sensorThrottle position sensor

Crank angle sensorVehicle speed sensor

Air conditioner switch

Barometric pressure sensor

Power steering oil

pressure switch

Intake air te.mperature sensorIdle position switchIgnition timing adjustment

terminalSelfdiagnosisIdata trans-

mission switching terminal

6FUO796

Input signal reading

-3I9Control modedecision

II

41*

Target speed dataIdle speed control---cIdle speed

feedback controlservo position- Target position data

control

Idle speed controlIdle speed control

servo dnve pulse-Drive pulse setting

Drive pulse setting-servo drive pulse

setting data

Page 160 of 391

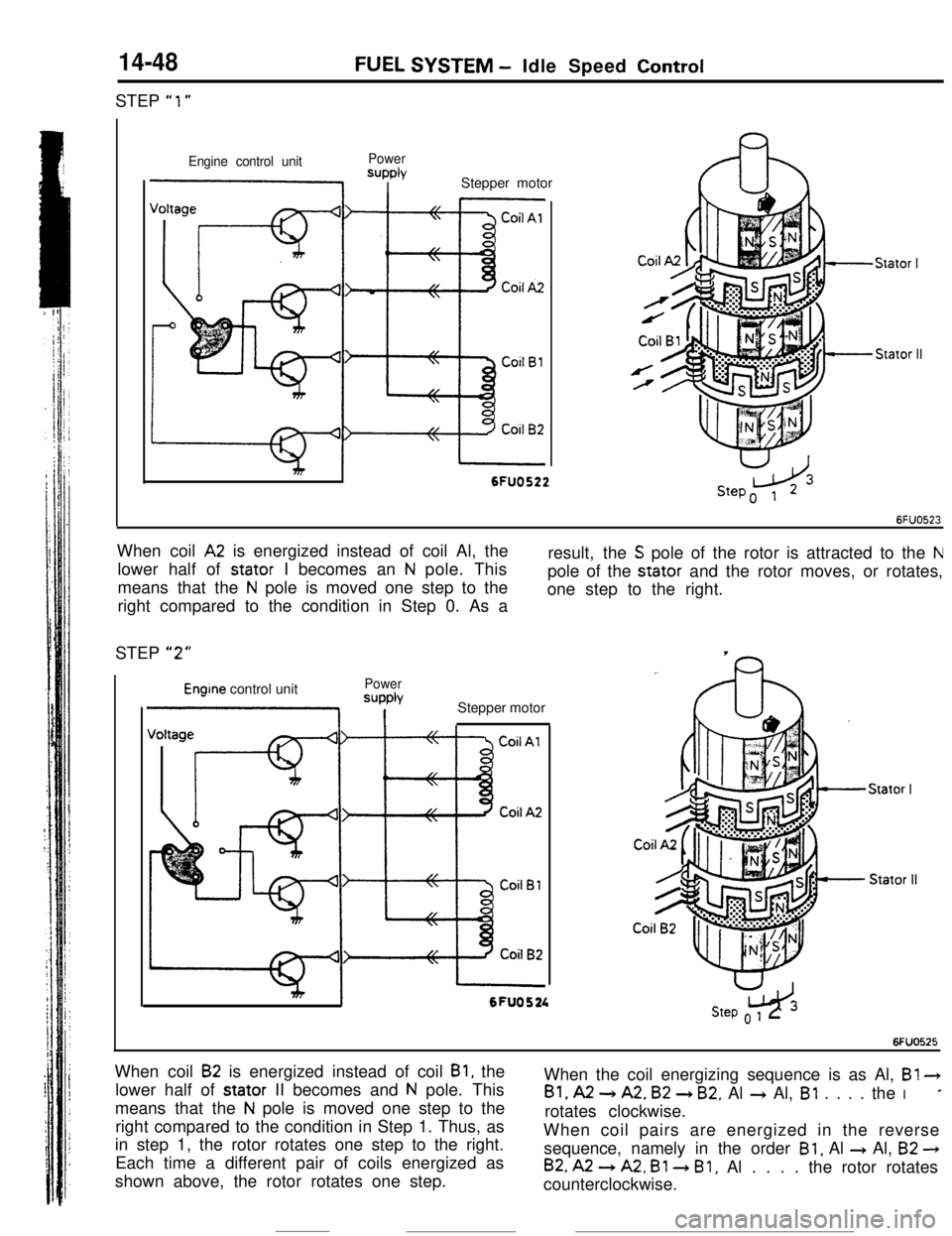

14-48STEP

“1”

FUEL SYSTEM - Idle Speed Control

Engine control unitPowerSUPPlYI IStepper motor

Stator I

Stator II

I6FUO522When coil

A2 is energized instead of coil Al, the

lower half of stator I becomes an

N pole. This

means that the

N pole is moved one step to the

right compared to the condition in Step 0. As aresult, the

S pole of the rotor is attracted to the Npole of the stator and the rotor moves, or rotates,

one step to the right.

STEP

“2”

Engine control unitPower

=JPPb

1 IStepper motor

Stator IStator II

mI6FU0524w3Step o 1 2

6FUO525When coil

B2 is energized instead of coil Bl, the

lower half of stator II becomes and

N pole. This

means that the

N pole is moved one step to the

right compared to the condition in Step 1. Thus, as

in step 1, the rotor rotates one step to the right.

Each time a different pair of coils energized as

shown above, the rotor rotates one step.When the coil energizing sequence is as Al, B!

3

Bl, A2 -) A2. B2 + B2. Al + Al, Bl . . . . the I*rotates clockwise.

When coil pairs are energized in the reverse

sequence, namely in the order

Bl, Al + Al, B2 -)

B2, A2 --) A2, Bl 3 Bl, Al . . . . the rotor rotates

counterclockwise.

Page 161 of 391

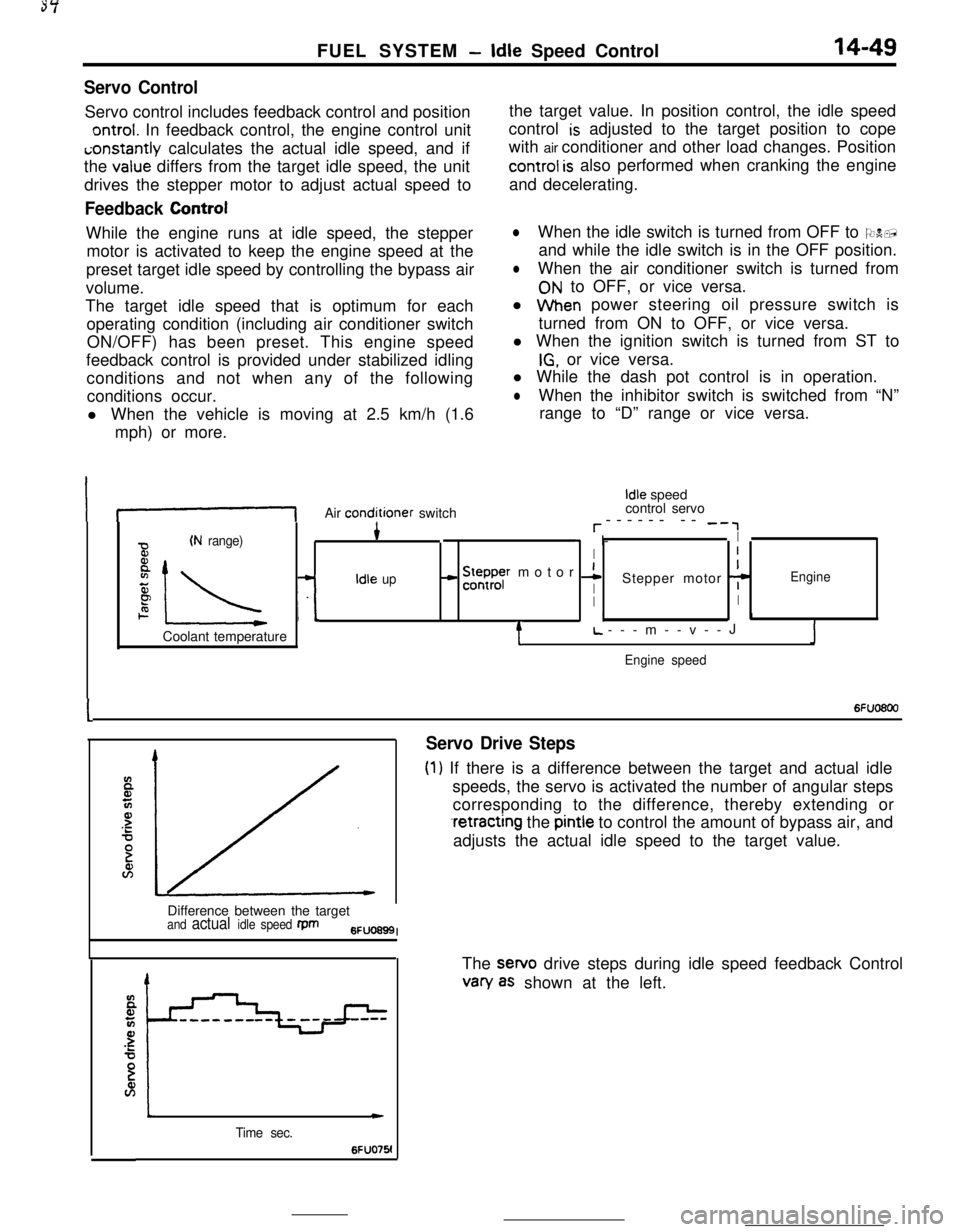

FUEL SYSTEM -Idle Speed Control14-49

Servo ControlServo control includes feedback control and position

ontrol. In feedback control, the engine control uniti;onstantly calculates the actual idle speed, and if

the

value differs from the target idle speed, the unit

drives the stepper motor to adjust actual speed to

Feedback ControlWhile the engine runs at idle speed, the stepper

motor is activated to keep the engine speed at the

preset target idle speed by controlling the bypass air

volume.

The target idle speed that is optimum for each

operating condition (including air conditioner switch

ON/OFF) has been preset. This engine speed

feedback control is provided under stabilized idling

conditions and not when any of the following

conditions occur.

l When the vehicle is moving at 2.5 km/h (1.6

mph) or more.the target value. In position control, the idle speed

control

is adjusted to the target position to cope

with air conditioner and other load changes. Position

control is also performed when cranking the engine

and decelerating.

lWhen the idle switch is turned from OFF to ON,

and while the idle switch is in the OFF position.

lWhen the air conditioner switch is turned from

ON to OFF, or vice versa.

l When power steering oil pressure switch is

turned from ON to OFF, or vice versa.

l When the ignition switch is turned from ST to

IG, or vice versa.

l While the dash pot control is in operation.

lWhen the inhibitor switch is switched from “N”

range to “D” range or vice versa.

If-1Air conditioner switch

Idle speed

control servo

r------ -- -‘,

(N range)4* I-I

BI

8

IL -L

- !5ysr motor 1I

zIdle upIStepper motor 7Engine

PII2. I.1Coolant temperature

tL.---m--v--JJ

Engine speed

I6Fuo6oo

Servo Drive Steps

(1) If there is a difference between the target and actual idle

speeds, the servo is activated the number of angular steps

corresponding to the difference, thereby extending or

.retracting the pintle to control the amount of bypass air, and

adjusts the actual idle speed to the target value.

Difference between the target

and actual idle speed fpm6FUO699I

Time sec.

c

6FUO76!The sewo drive steps during idle speed feedback Control

van/ as shown at the left.

Page 162 of 391

14-50FUEL SYSTEM- Idle Speed Control

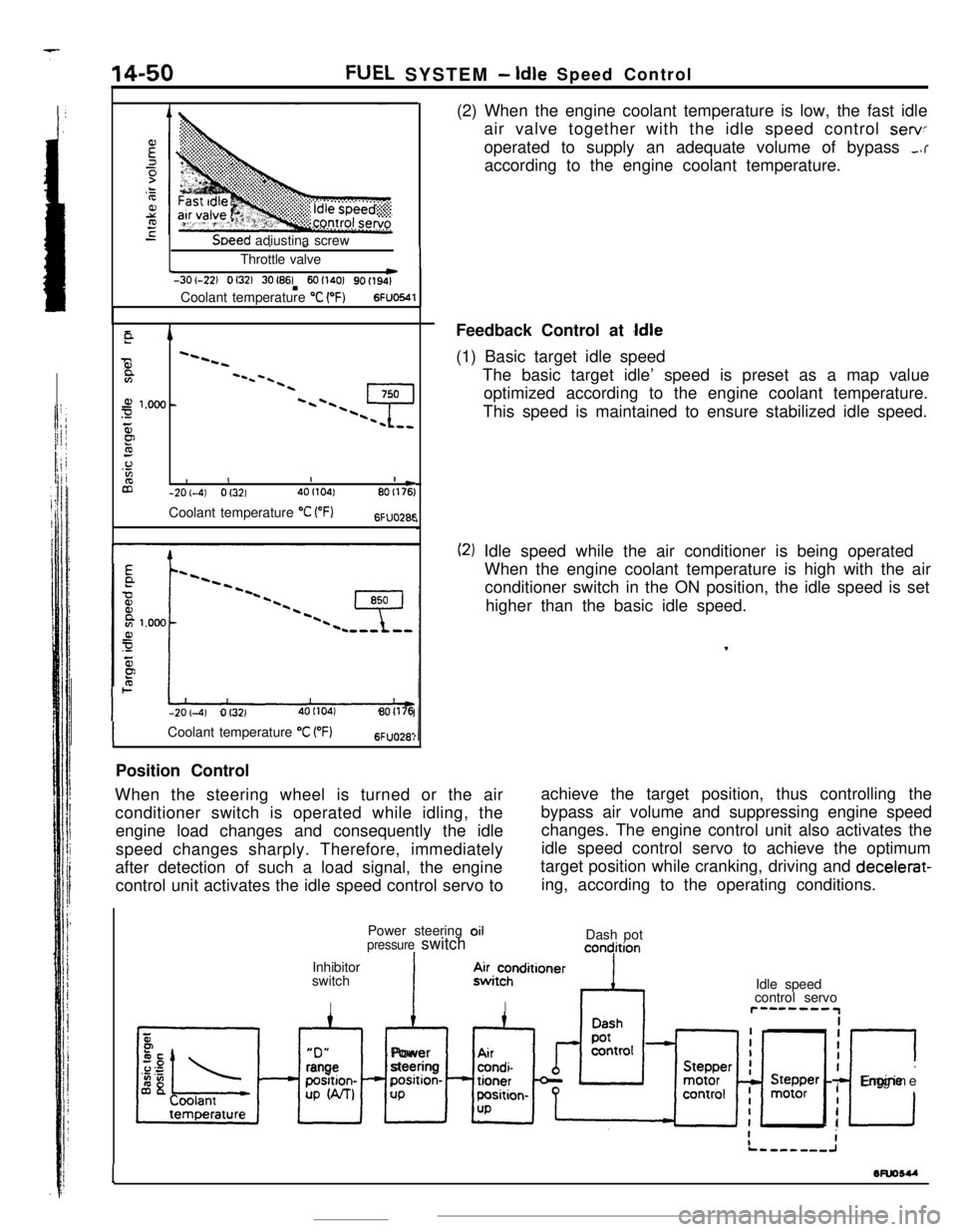

SDeed adiustina screwI -Throttle valve

Lw-3O(-22) 0132) 30(86! 601140) 9ofl94)Coolant temperature

“C (OF)6FUO641

E94

72--2--I

Q--.-.-z

3201.000 --4-\-\

5P9.o%IIIaI L-2O(-41 Of3214Of104)801176)Coolant temperature

“C VF)6FU028E

-201-4) Of3214OI104180(176(2) When the engine coolant temperature is low, the fast idle

air valve together with the idle speed control

servoperated to supply an adequate volume of bypass

,.raccording to the engine coolant temperature.

Feedback Control at

Idle(1) Basic target idle speed

The basic target idle’ speed is preset as a map value

optimized according to the engine coolant temperature.

This speed is maintained to ensure stabilized idle speed.

(2) Idle speed while the air conditioner is being operated

When the engine coolant temperature is high with the air

conditioner switch in the ON position, the idle speed is set

higher than the basic idle speed.

,

ICoolant temperature “C VF)6FUO28:Position Control

When the steering wheel is turned or the air

conditioner switch is operated while idling, theachieve the target position, thus controlling the

engine load changes and consequently the idlebypass air volume and suppressing engine speed

changes. The engine control unit also activates the

speed changes sharply. Therefore, immediately

after detection of such a load signal, the engine

control unit activates the idle speed control servo toidle speed control servo to achieve the optimum

target position while cranking, driving and decelerat-

ing, according to the operating conditions.

Power steering oil

pressure switchIInhibitor

switch

IDash pot

concjition“D”

xl

rangeposition-

UP W-U

IAlPower

steeringposition-

UP.4~i~hnditioner

IIdle speed

control servor”--““IiiI

I

c

IEngine

I

I

1wuosu

-

Page 163 of 391

FUEL SYSTEM -Idle Speed Control14-51

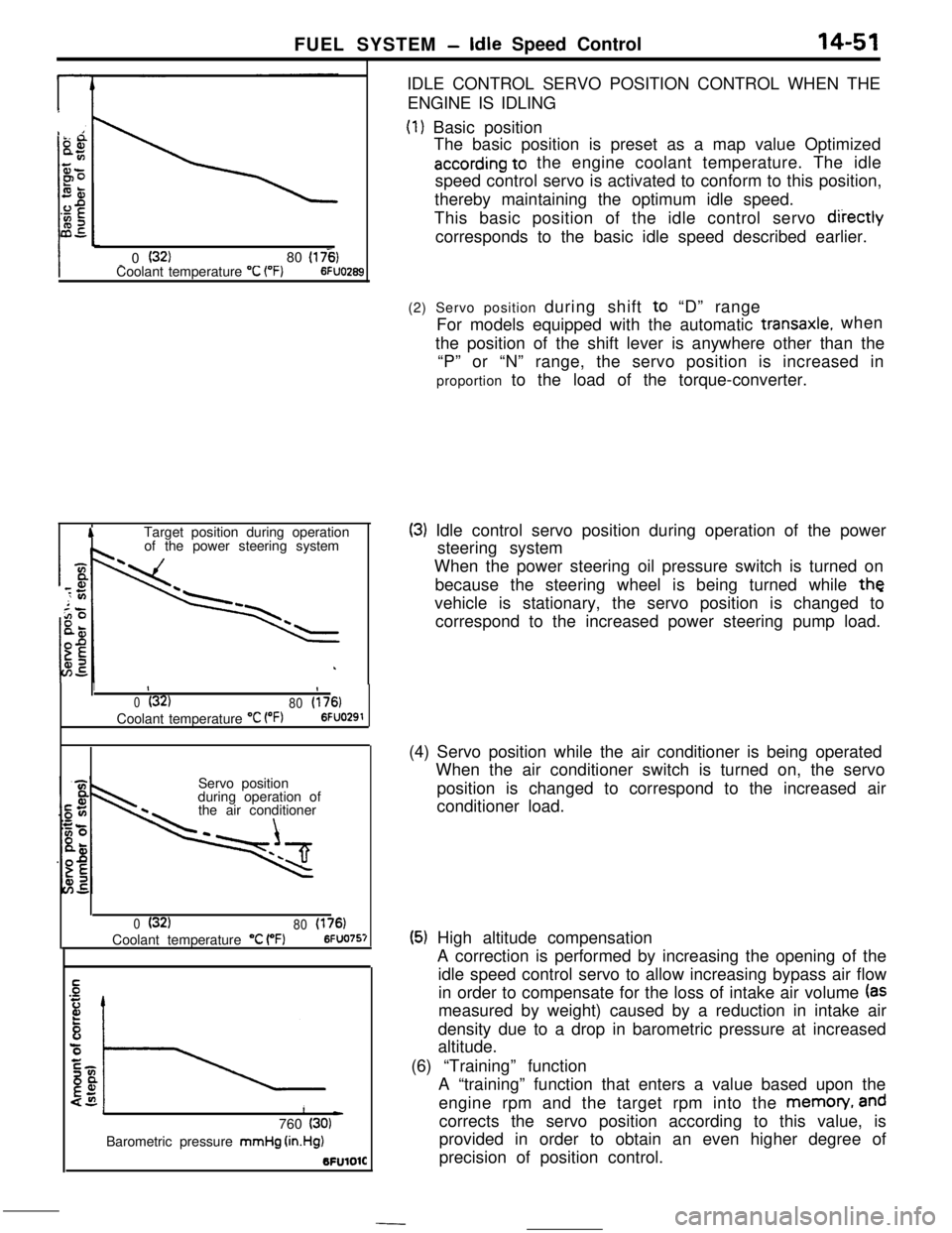

_ 0 (32)80 (175)Coolant temperature “C (“F)6FUO2653

ATarget position during operation

of the power steering systemIDLE CONTROL SERVO POSITION CONTROL WHEN THE

ENGINE IS IDLING

(1) Basic position

The basic position is preset as a map value Optimized

according to the engine coolant temperature. The idle

speed control servo is activated to conform to this position,

thereby maintaining the optimum idle speed.

This basic position of the idle control servo

diiectlycorresponds to the basic idle speed described earlier.

1II

0(32)

80(176)Coolant temperature

“C VW6FUO291Servo position

during operation of

the air conditioner

0(32)

80(176)Coolant temperature “C (“F)6FUO757

1L)760 (30)Barometric pressure mmHg

(in.Hg)BFUlOlC(2) Servo position during shift to “D” range

For models equipped with the automatic

transaxle.when

the position of the shift lever is anywhere other than the

“P” or “N” range, the servo position is increased in

proportion to the load of the torque-converter.

(3) Idle control servo position during operation of the power

steering system

When the power steering oil pressure switch is turned on

because the steering wheel is being turned while

thevehicle is stationary, the servo position is changed to

correspond to the increased power steering pump load.

(4) Servo position while the air conditioner is being operated

When the air conditioner switch is turned on, the servo

position is changed to correspond to the increased air

conditioner load.

(5) High altitude compensation

A correction is performed by increasing the opening of the

idle speed control servo to allow increasing bypass air flow

in order to compensate for the loss of intake air volume

(asmeasured by weight) caused by a reduction in intake air

density due to a drop in barometric pressure at increased

altitude.

(6) “Training” function

A “training” function that enters a value based upon the

engine rpm and the target rpm into the memon/,

andcorrects the servo position according to this value, is

provided in order to obtain an even higher degree of

precision of position control.

Page 164 of 391

--

14-52FUEL SYSTEM - Idle Speed Control

4

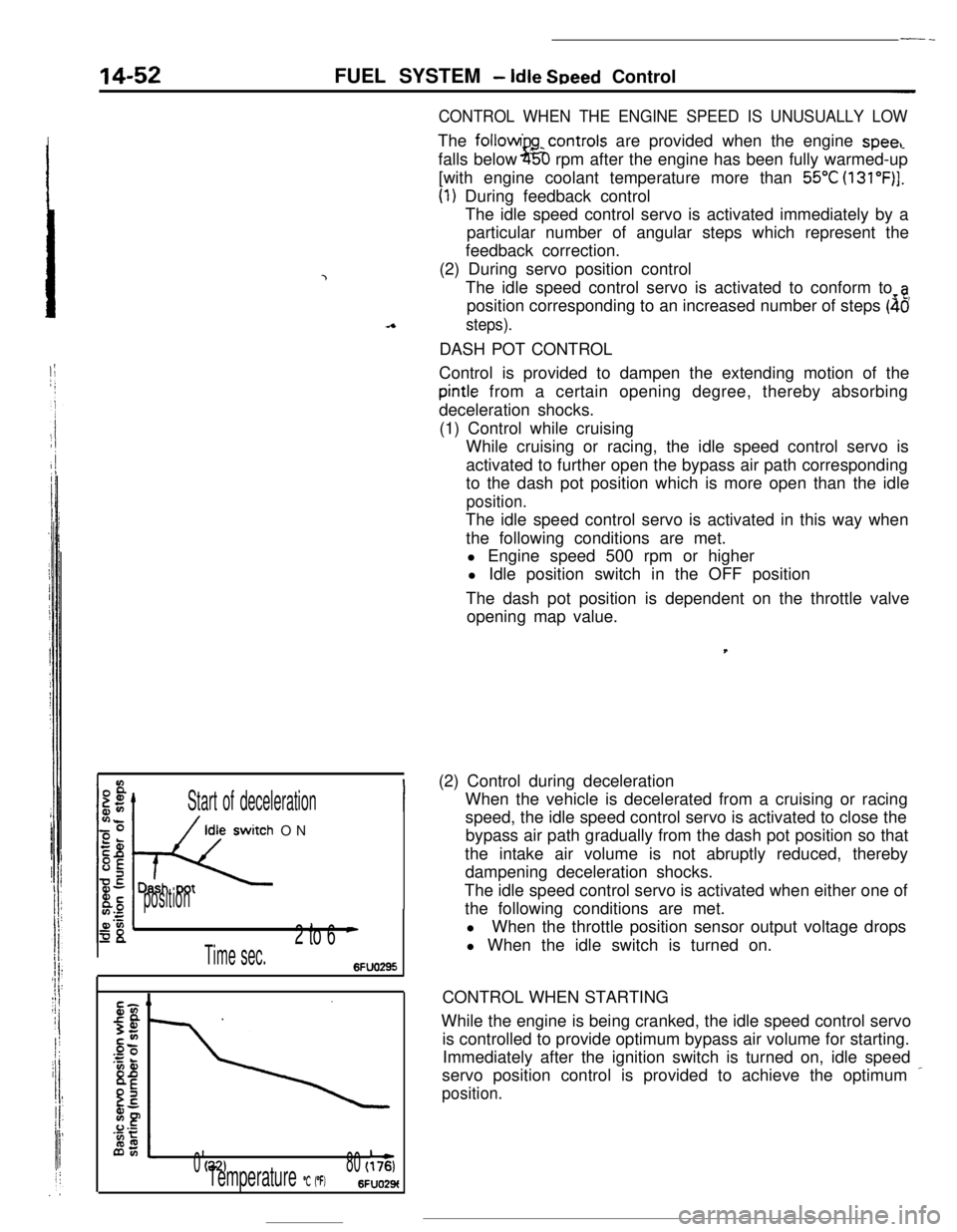

Start of deceleration

DLhq ON

position

I*2 to 6

Time sec.6FUO295

II)

0(32180(176)Temperature “C 1°F)6FUO29t

CONTROL WHEN THE ENGINE SPEED IS UNUSUALLY LOWThe followi

gcontrols are provided when the engine speecfalls below

i5;D rpm after the engine has been fully warmed-up

[with engine coolant temperature more than

55°C (131”F)].

(1) During feedback control

The idle speed control servo is activated immediately by a

particular number of angular steps which represent the

feedback correction.

(2) During servo position control

The idle speed control servo is activated to conform to

aposition corresponding to an increased number of steps

(46

steps).DASH POT CONTROL

Control is provided to dampen the extending motion of the

pintle from a certain opening degree, thereby absorbing

deceleration shocks.

(1) Control while cruising

While cruising or racing, the idle speed control servo is

activated to further open the bypass air path corresponding

to the dash pot position which is more open than the idle

position.The idle speed control servo is activated in this way when

the following conditions are met.

l Engine speed 500 rpm or higher

l Idle position switch in the OFF position

The dash pot position is dependent on the throttle valve

opening map value.,

(2) Control during deceleration

When the vehicle is decelerated from a cruising or racing

speed, the idle speed control servo is activated to close the

bypass air path gradually from the dash pot position so that

the intake air volume is not abruptly reduced, thereby

dampening deceleration shocks.

The idle speed control servo is activated when either one of

the following conditions are met.

lWhen the throttle position sensor output voltage drops

l When the idle switch is turned on.

CONTROL WHEN STARTING

While the engine is being cranked, the idle speed control servo

is controlled to provide optimum bypass air volume for starting.

Immediately after the ignition switch is turned on, idle speed

servo position control is provided to achieve the optimum

_

position.

Page 167 of 391

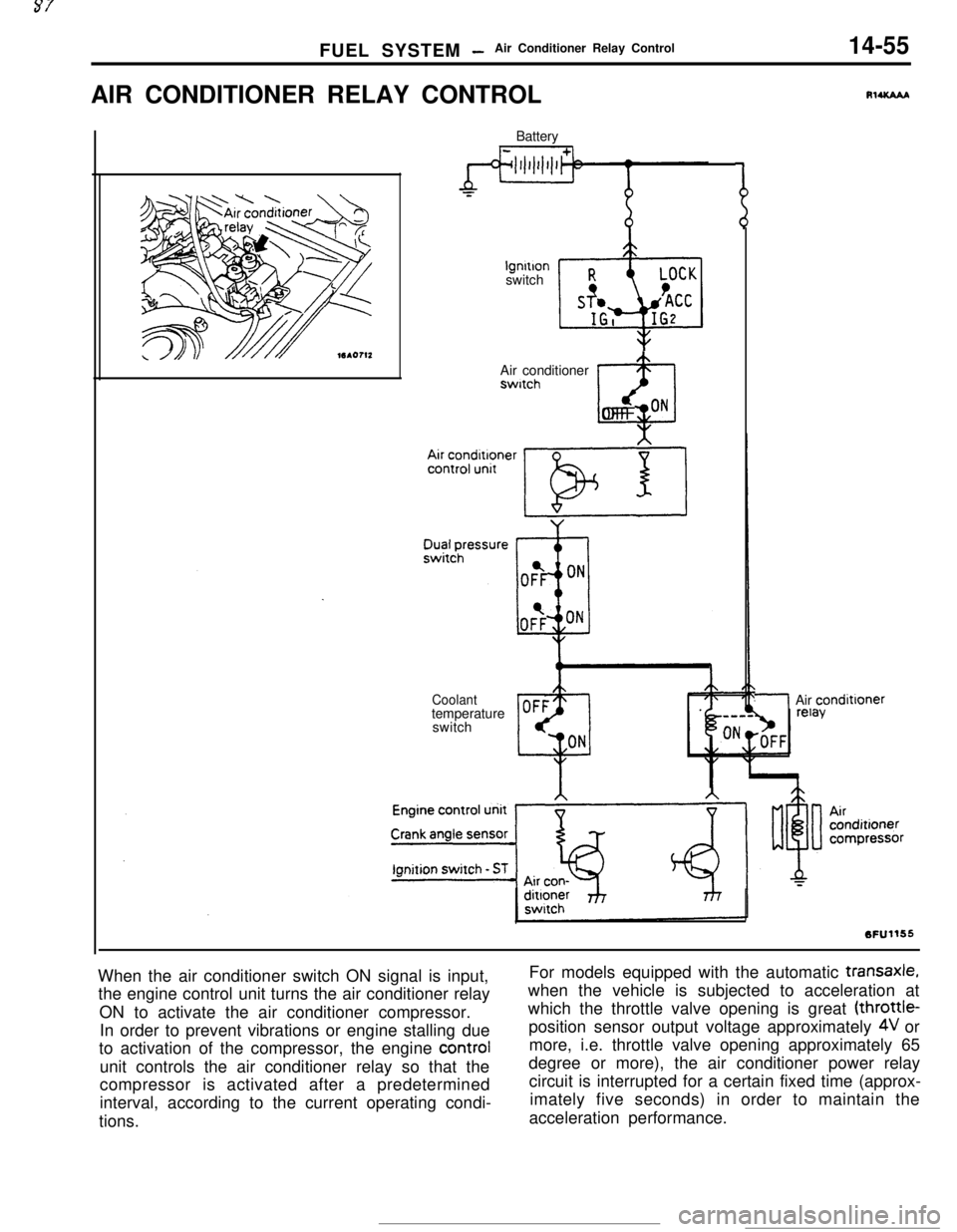

FUEL SYSTEM -Air Conditioner Relay Control14-55AIR CONDITIONER RELAY CONTROL

Batterylgnltlon

switch

Air conditionerswitch

@OFF ON

Coolanttemperature

switch

RlUCAAA

/Air condittoner

When the air conditioner switch ON signal is input,

the engine control unit turns the air conditioner relay

ON to activate the air conditioner compressor.

In order to prevent vibrations or engine stalling due

to activation of the compressor, the engine control

unit controls the air conditioner relay so that the

compressor is activated after a predetermined

interval, according to the current operating condi-

tions.For models equipped with the automatic

transaxle,when the vehicle is subjected to acceleration at

which the throttle valve opening is great (throttle-

position sensor output voltage approximately

4V or

more, i.e. throttle valve opening approximately 65

degree or more), the air conditioner power relay

circuit is interrupted for a certain fixed time (approx-

imately five seconds) in order to maintain the

acceleration performance.

Page 238 of 391

21-14MANUAL TRANSAXLE t4WD> - Viscous Coupling (VCU)

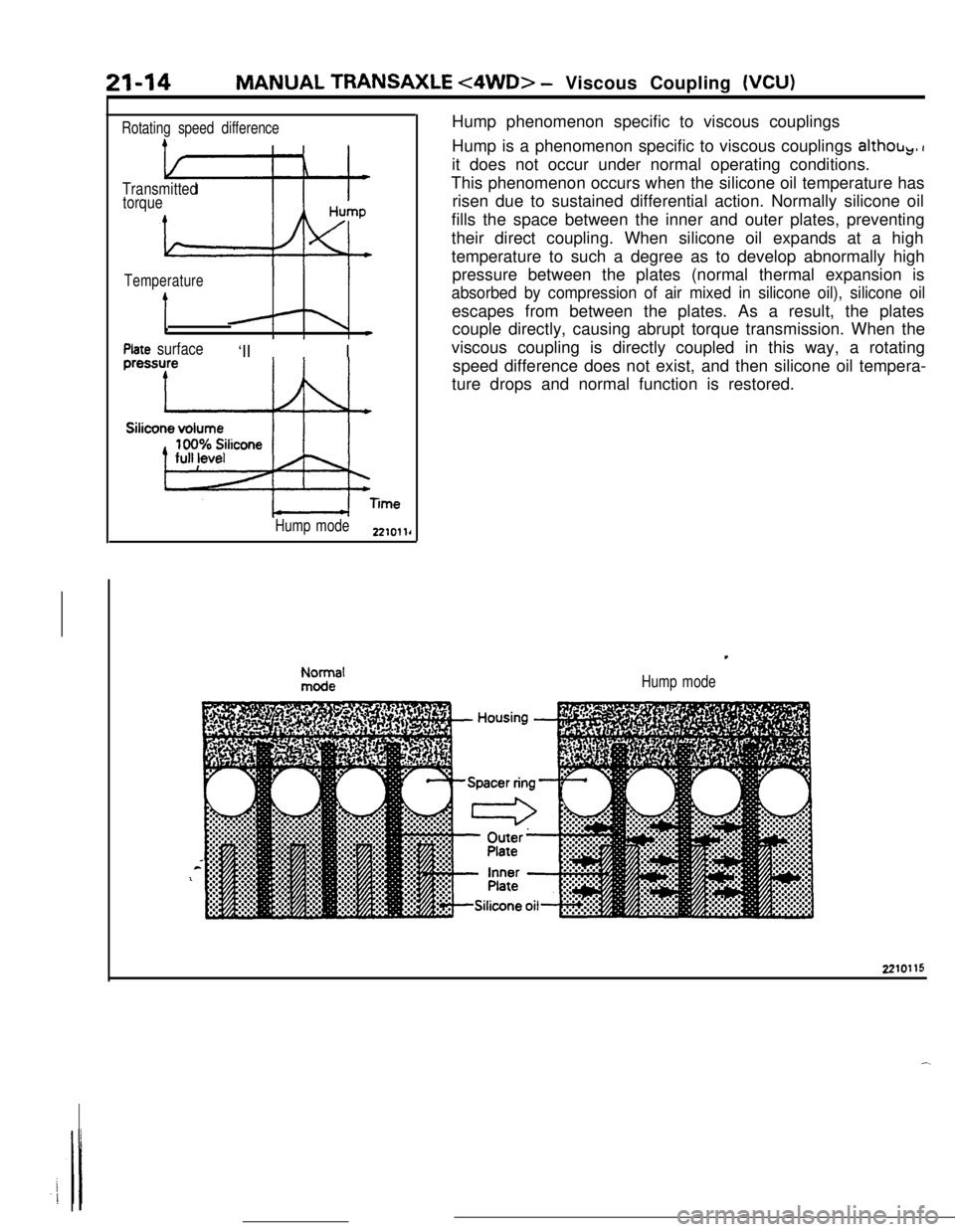

Rotating speed difference

Transmitted

torque

TemperatureII I

t

/

IIc

P&e surface‘II I

preTYl-LLL

Hump mode2210llrHump phenomenon specific to viscous couplings

Hump is a phenomenon specific to viscous couplings

althob,, Iit does not occur under normal operating conditions.

This phenomenon occurs when the silicone oil temperature has

risen due to sustained differential action. Normally silicone oil

fills the space between the inner and outer plates, preventing

their direct coupling. When silicone oil expands at a high

temperature to such a degree as to develop abnormally high

pressure between the plates (normal thermal expansion is

absorbed by compression of air mixed in silicone oil), silicone oilescapes from between the plates. As a result, the plates

couple directly, causing abrupt torque transmission. When the

viscous coupling is directly coupled in this way, a rotating

speed difference does not exist, and then silicone oil tempera-

ture drops and normal function is restored.

Hump mode2210115

Page 271 of 391

AUTOMATIC TRANSAXLE - Transaxle Control21-47

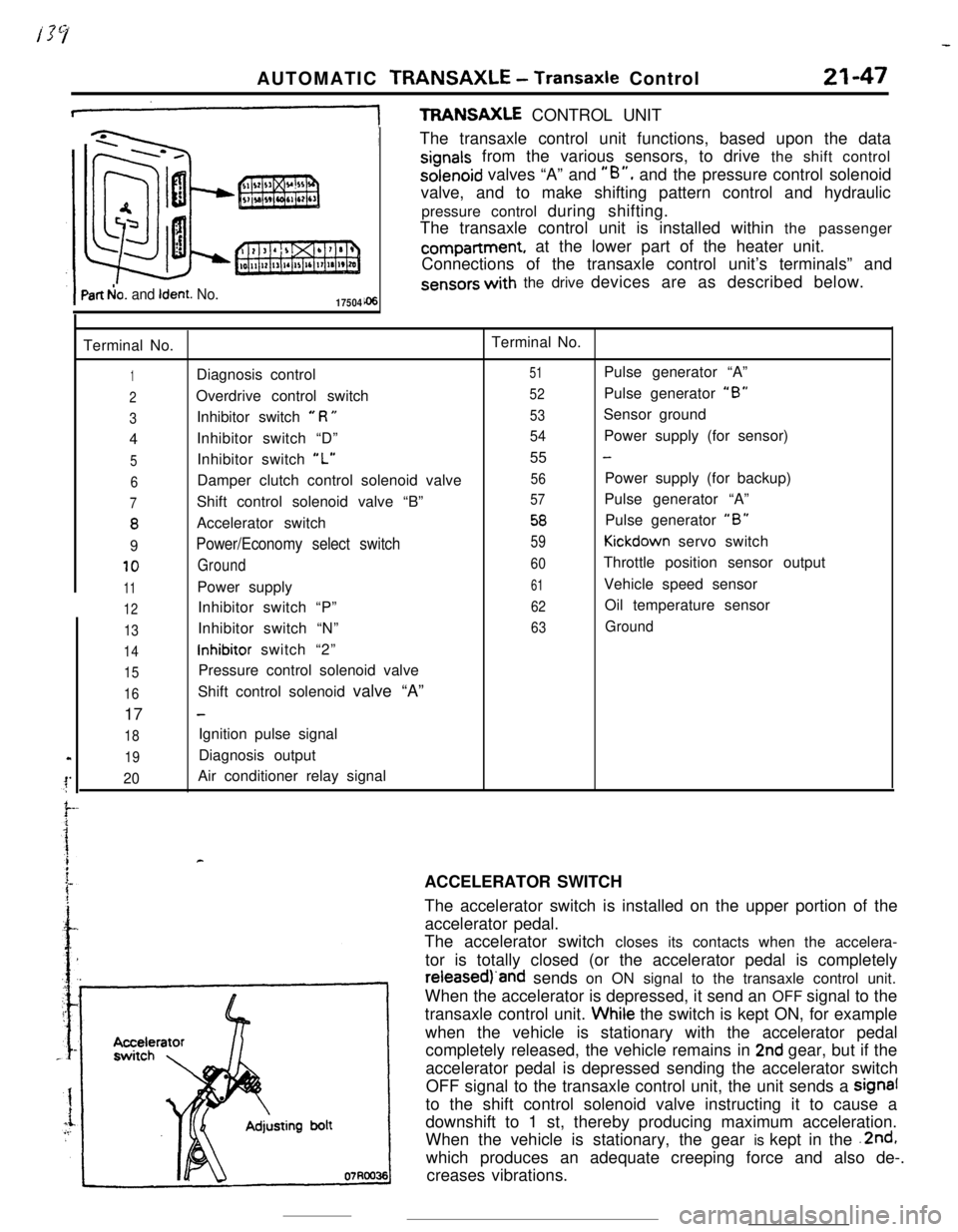

+TFWNSAXLE CONTROL UNIT

Part b!o. and Ident. No.17504The transaxle control unit functions, based upon the data

signals from the various sensors, to drive the shift controlsolenoid valves “A” and

“B”, and the pressure control solenoid

valve, and to make shifting pattern control and hydraulic

pressure control during shifting.

The transaxle control unit is installed within the passengercompartment, at the lower part of the heater unit.

Connections of the transaxle control unit’s terminals” and

sensors with the drive devices are as described below.

Terminal No.Terminal No.

1Diagnosis control51Pulse generator “A”

2Overdrive control switch52Pulse generator “B”

3Inhibitor switch e R U53Sensor ground

4Inhibitor switch “D”

54Power supply (for sensor)

5Inhibitor switch “L”55 -

6Damper clutch control solenoid valve56Power supply (for backup)

7Shift control solenoid valve “B”57Pulse generator “A”

8Accelerator switch58Pulse generator “B”

9Power/Economy select switch59Kickdown servo switch

10Ground60Throttle position sensor output

11Power supply61Vehicle speed sensor

12Inhibitor switch “P”62Oil temperature sensor

13Inhibitor switch “N”63Ground

14inhibitor switch “2”

15Pressure control solenoid valve

16Shift control solenoid valve “A”

17

-

18Ignition pulse signal

19Diagnosis output

20Air conditioner relay signal

rACCELERATOR SWITCH

The accelerator switch is installed on the upper portion of the

accelerator pedal.

The accelerator switch closes its contacts when the accelera-

tor is totally closed (or the accelerator pedal is completelyreieasedj‘and sends on ON signal to the transaxle control unit.

When the accelerator is depressed, it send an OFF signal to the

transaxle control unit. Whiie the switch is kept ON, for example

when the vehicle is stationary with the accelerator pedal

completely released, the vehicle remains in

2nd gear, but if the

accelerator pedal is depressed sending the accelerator switch

OFF signal to the transaxle control unit, the unit sends a signal

to the shift control solenoid valve instructing it to cause a

downshift to 1 st, thereby producing maximum acceleration.

When the vehicle is stationary, the gear is kept in the .2nd,

which produces an adequate creeping force and also de-.

creases vibrations.