ABS MITSUBISHI ECLIPSE 1991 Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 644 of 1216

17-34REAR SUSPENSION

12A0049CUP assemblv

Dud cover

Bracket assembly

1Shock absorber lower bushing

12R0140I

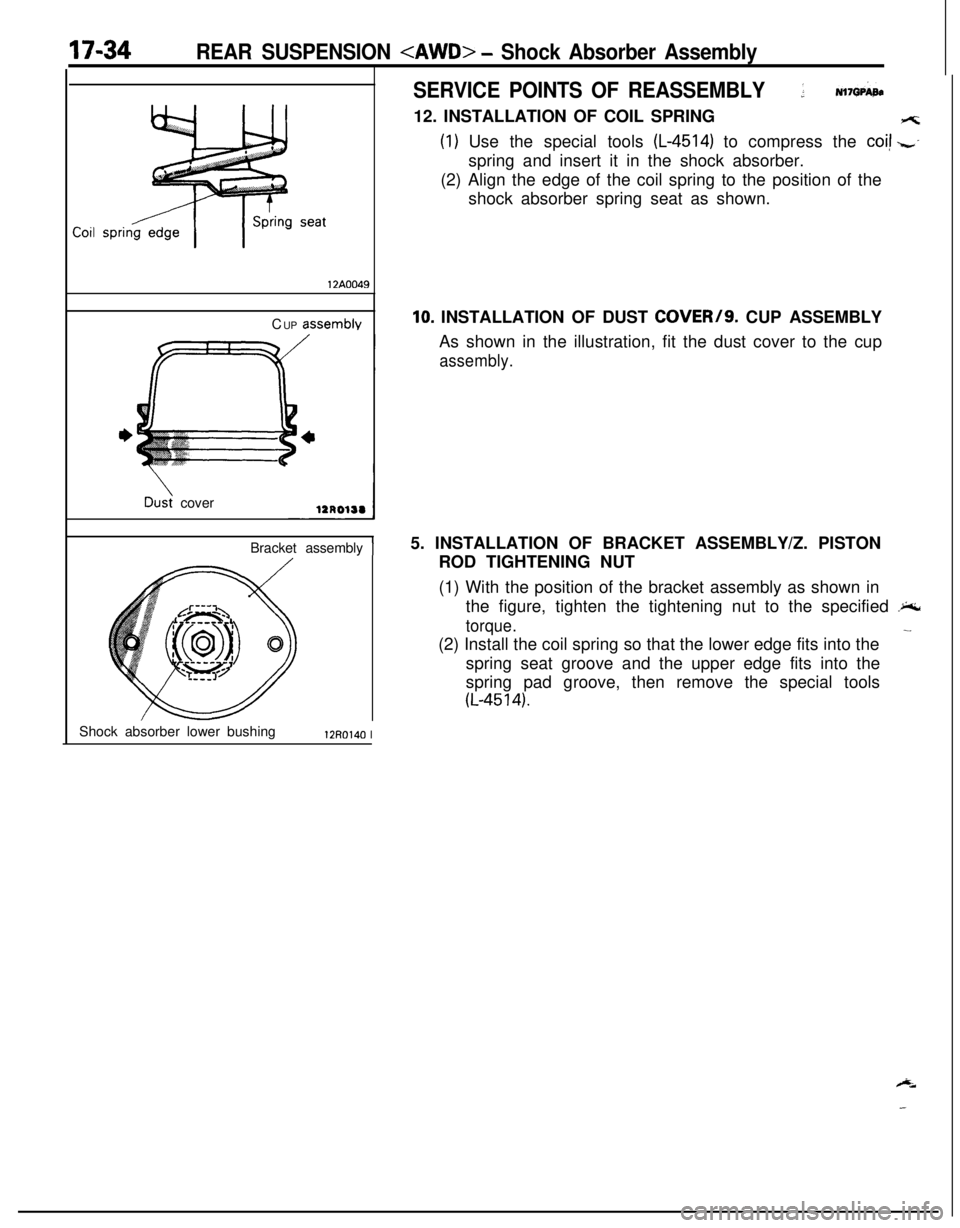

SERVICE POINTS OF REASSEMBLY; N17GPi4te12. INSTALLATION OF COIL SPRING

(1) Use the special tools (L-4514) to compress the coi! zspring and insert it in the shock absorber.

(2) Align the edge of the coil spring to the position of the

shock absorber spring seat as shown.

10. INSTALLATION OF DUST COVER/S. CUP ASSEMBLY

As shown in the illustration, fit the dust cover to the cup

assembly.5. INSTALLATION OF BRACKET ASSEMBLY/Z. PISTON

ROD TIGHTENING NUT

(1) With the position of the bracket assembly as shown in

the figure, tighten the tightening nut to the specified

.%

torque.

-(2) Install the coil spring so that the lower edge fits into the

spring seat groove and the upper edge fits into the

spring pad groove, then remove the special tools

(L-4514).

Page 661 of 1216

STEERING - Service -Adjustment Procedures < Power Steering >IgJf~

4.Disconnect the high-tension cable, and then while operating

the starting motor intermittently, turn the steering wheel all;

the way to the left and right several times to drain all of the

fluid.

Caution, 35

Be careful not to position thq high-tension able ye&r the

carburetor or the delivery pipe.5. Connect the return hoses securely, and then

secur& it ,with

the clip.6. Fill the oil reservoir with the specified fluid up

td the Ibwerposition of the filter, and then bleed the air.

.’

Specified fluid:MOPAR ATF PLUS (Automatic Transmis-sion Fluid Type 7176)/Automatic trans-

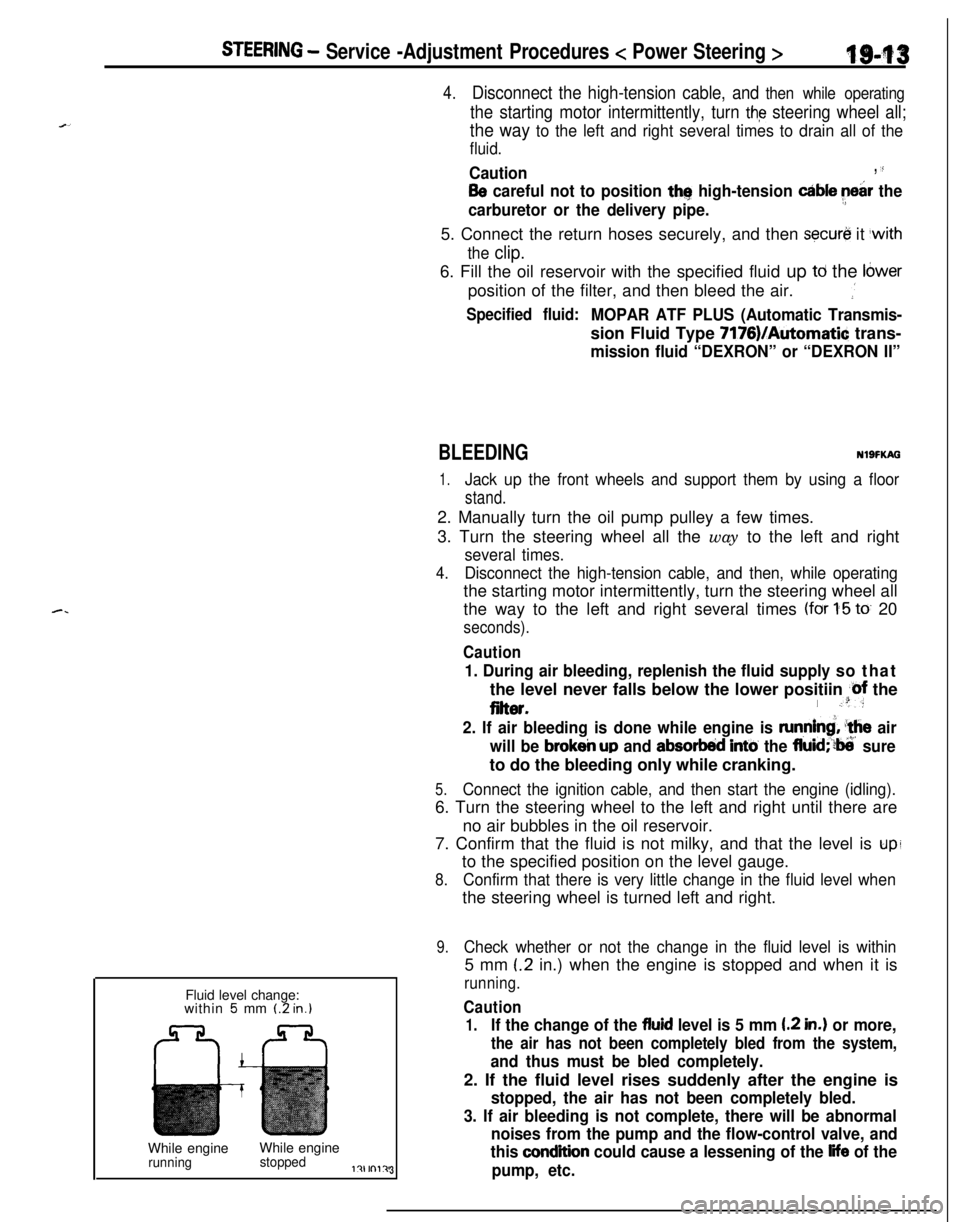

mission fluid “DEXRON” or “DEXRON II”Fluid level change:

within

5 mm (2 in.)While engineWhile engine

runningstoppedl?lrnl?J3

BLEEDINGNlSFKAG

1.Jack up the front wheels and support them by using a floor

stand.2. Manually turn the oil pump pulley a few times.

3. Turn the steering wheel all the way to the left and right

several times.

4.Disconnect the high-tension cable, and then, while operatingthe starting motor intermittently, turn the steering wheel all

the way to the left and right several times

(for 1-5 to 20

seconds).

Caution

1. During air bleeding, replenish the fluid supply so thatthe level never falls below the lower positiin

@f the

eiter.I .“:

2. If air bleeding is done while engine is runnind, ‘the air

will be

brokeir up and absorbed intti the fluid;‘?ti’ sureto do the bleeding only while cranking.

5.Connect the ignition cable, and then start the engine (idling).6. Turn the steering wheel to the left and right until there are

no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the level is

upito the specified position on the level gauge.

8.Confirm that there is very little change in the fluid level whenthe steering wheel is turned left and right.

9.Check whether or not the change in the fluid level is within5 mm

(.2 in.) when the engine is stopped and when it is

running.

Caution

1.If the change of the fluid level is 5 mm I.2 in.) or more,

the air has not been completely bled from the system,

and thus must be bled completely.2. If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled.

3. If air bleeding is not complete, there will be abnormal

noises from the pump and the flow-control valve, and

this

condition could cause a lessening of the life of the

pump, etc.

Page 706 of 1216

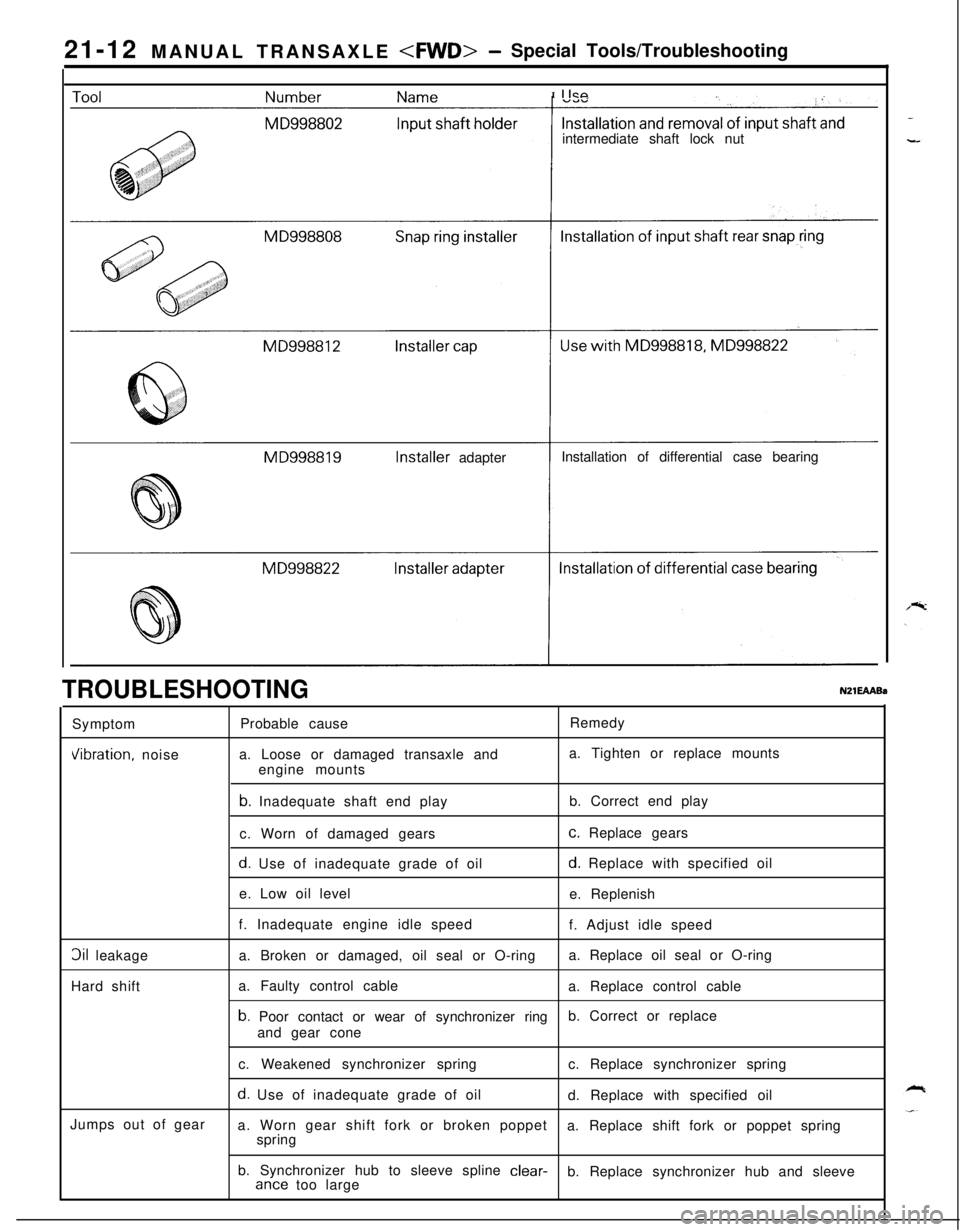

21-12 MANUAL TRANSAXLE

I

IICPintermediate shaft lock nut

MD998819Installer adapterInstallation of differential case bearing

TROUBLESHOOTINGNZlEAABsSymptomVibration, noise

3il leakage

Hard shift

Jumps out of gearProbable causeRemedy

a. Loose or damaged transaxle anda. Tighten or replace mounts

engine mounts

b. Inadequate shaft end playb. Correct end play

c. Worn of damaged gears

c. Replace gears

d. Use of inadequate grade of oild. Replace with specified oil

e. Low oil level

e. Replenish

f. Inadequate engine idle speed

f. Adjust idle speed

a. Broken or damaged, oil seal or O-ringa. Replace oil seal or O-ring

a. Faulty control cable

a. Replace control cable

b. Poor contact or wear of synchronizer ring

and gear coneb. Correct or replace

c. Weakened synchronizer springc. Replace synchronizer spring

d. Use of inadequate grade of oil

d. Replace with specified oil

a. Worn gear shift fork or broken poppet

springa. Replace shift fork or poppet spring

b. Synchronizer hub to sleeve spline

clear-ante too largeb. Replace synchronizer hub and sleeve

Page 1040 of 1216

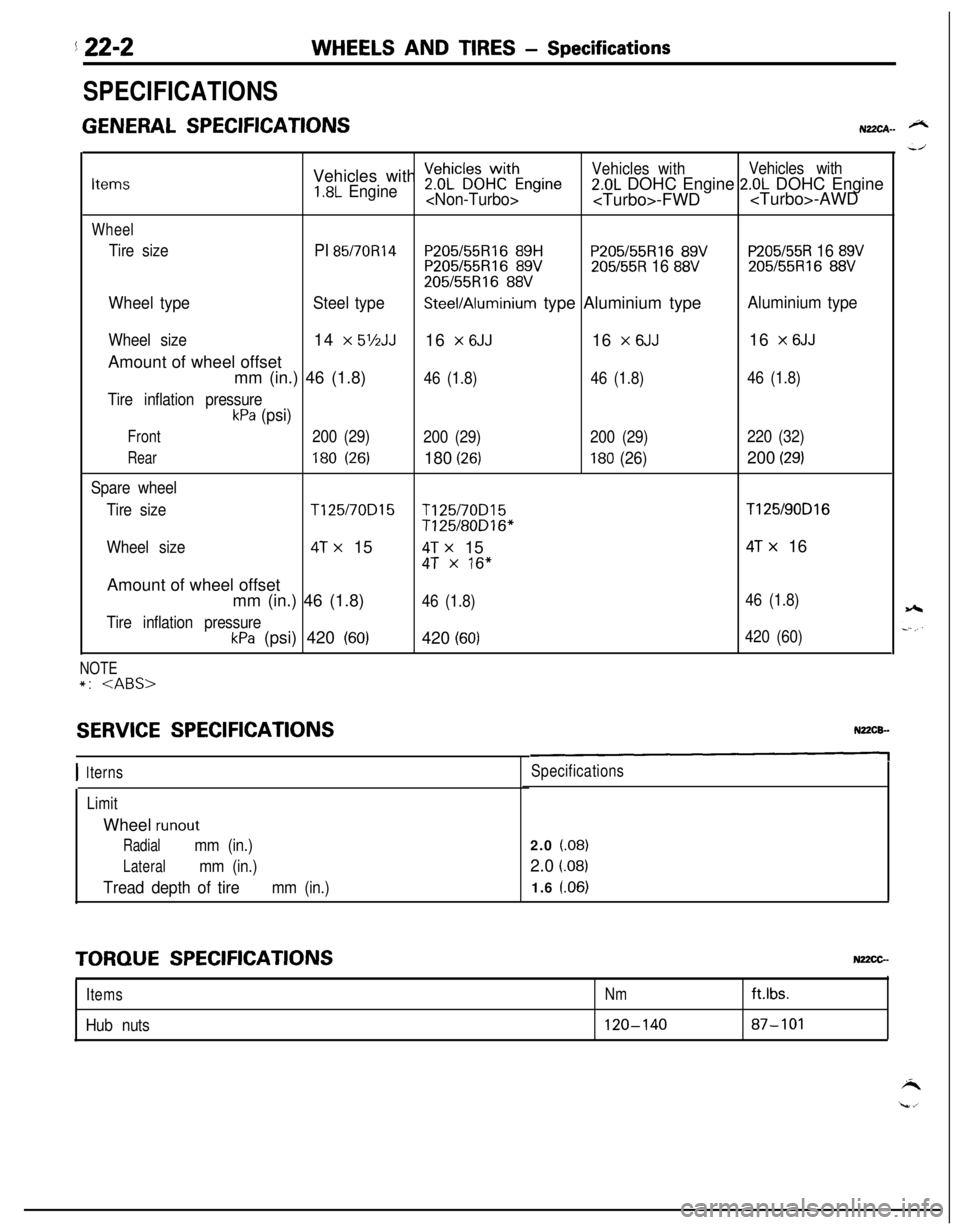

5 22-2WHEELS AND TIRES - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSN22CA- @NVehicles with

~eDhL”~~HWCthEngineVehicles withVehicles withItems1.8L Engine2.0L DOHC Engine 2.0L DOHC Engine

Wheel

Tire sizePI 85/70R14P205155Rl6 89HP205/55R16 89VP205/55R 16 89VP205155R16 89V205/55R 16 88V205/55R16 88V

205/55R16 88V

Wheel typeSteel typeSteel/Aluminium type Aluminium typeAluminium type

Wheel size14 x 5’/2JJ16 x 6JJ16 x 6JJ16 x 6JJAmount of wheel offset

mm (in.) 46 (1.8)

46 (1.8)46 (1.8)46 (1.8)

Tire inflation pressure

kPa (psi)

Front200 (29)

200 (29)200 (29)220 (32)

Rear180 (26)180 (26)180 (26)200 (29)

Spare wheel

Tire size

T125/70D15T125/70D15T125/90D16

T125/80D16*

Wheel size

4T x 154T x 154T x 16

4T x 16”Amount of wheel offset

mm (in.) 46 (1.8)

46 (1.8)46 (1.8)

Tire inflation pressure

kPa (psi) 420 (60)420 (60)420 (60)

NOTE*:

SERVICE SPECIFICATIONS

I 1terns

LimitWheel

runout

Radialmm (in.)

Lateralmm (in.)

Tread depth of tiremm (in.)

Specifications2.0

(.08)2.0

i.08)1.6 l.06)

TORQUE SPECIFICATIONSNz2cG-

ItemsNm

Hub nuts120-140ftlbs.87-101

Page 1048 of 1216

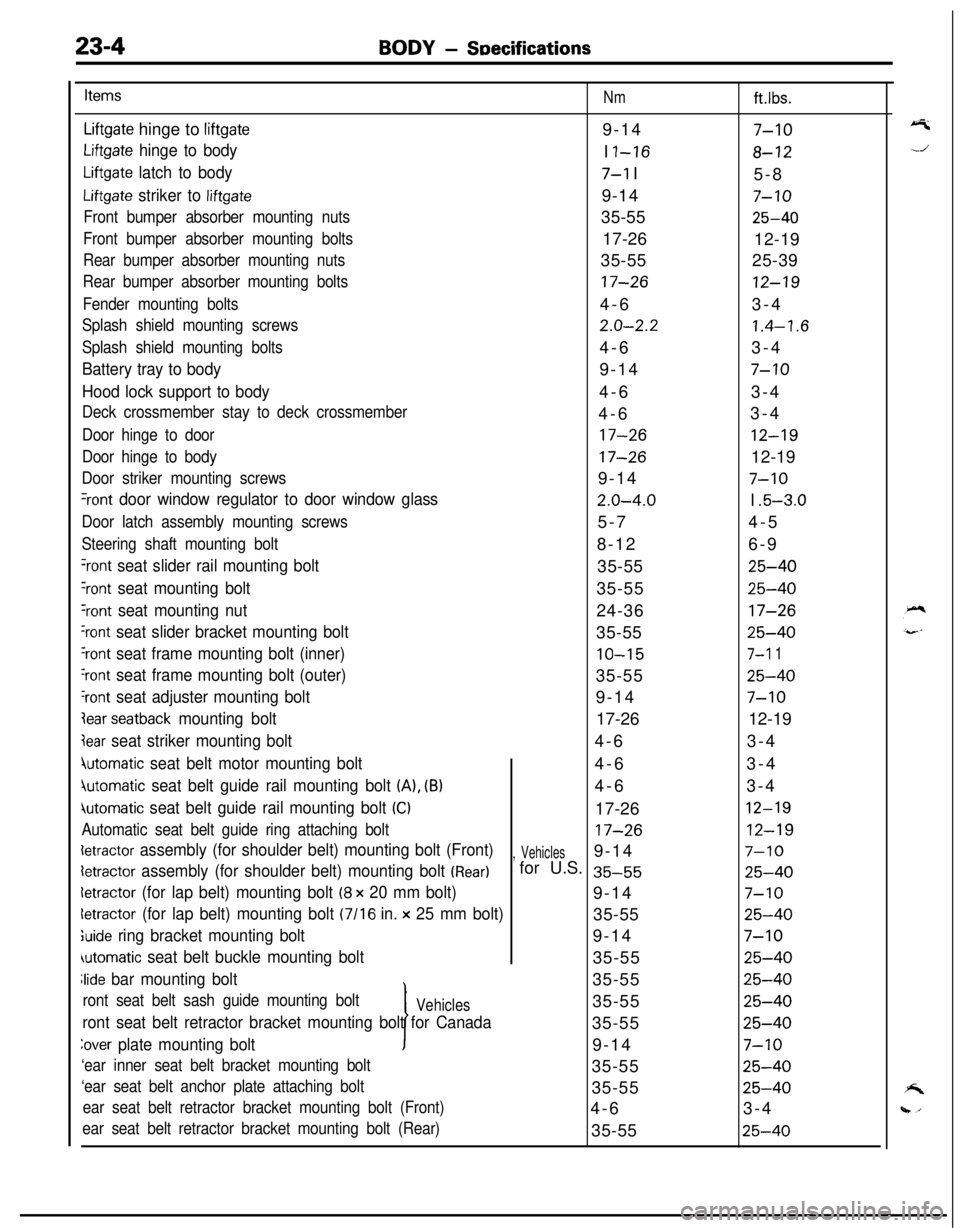

23-4BODY - SDecifications

Items

Nmft.lbs.

Liftgate hinge to liftgate9-147-10

Liftgate hinge to bodyI I-168-12

Liftgate latch to body7-l I

5-8

Liftgate striker to liftgate9-147-10

Front bumper absorber mounting nuts35-5525-40

Front bumper absorber mounting bolts17-26

12-19

Rear bumper absorber mounting nuts35-5525-39

Rear bumper absorber mounting bolts17-2612-19

Fender mounting bolts4-63-4

Splash shield mounting screws2.0-2.21.4-1.6

Splash shield mounting bolts4-63-4

Battery tray to body9-147-10

Hood lock support to body4-63-4

Deck crossmember stay to deck crossmember4-63-4

Door hinge to door17-2612-19

Door hinge to body17-2612-19

Door striker mounting screws9-147-10

%ont door window regulator to door window glass2.0-4.0I .5-3.0

Door latch assembly mounting screws5-74-5

Steering shaft mounting bolt8-126-9

‘rant seat slider rail mounting bolt35-5525-40

Yont seat mounting bolt35-5525-40

‘rant seat mounting nut24-3617-26

‘rant seat slider bracket mounting bolt35-5525-40

‘rant seat frame mounting bolt (inner)10-157-l 1

‘rant seat frame mounting bolt (outer)35-5525-40

‘rant seat adjuster mounting bolt9-147-10

lear seatback mounting bolt17-2612-19

jear seat striker mounting bolt4-63-4

4utomatic seat belt motor mounting bolt4-63-4

jutomatic seat belt guide rail mounting bolt (A), (B)4-63-4

iutomatic seat belt guide rail mounting bolt (Cl17-2612-19

Automatic seat belt guide ring attaching bolt17-2612-19

detractor assembly (for shoulder belt) mounting bolt (Front), Vehicles9-147-10

detractor assembly (for shoulder belt) mounting bolt (Rear)for U.S. 35-5525-40

detractor (for lap belt) mounting bolt (8 x 20 mm bolt)9-147-10

letractor (for lap belt) mounting bolt (7116 in. x 25 mm bolt)35-5525-40

;uide ring bracket mounting bolt9-147-10

automatic seat belt buckle mounting bolt35-5525-40

Jide bar mounting bolt

I35-55

25-40

ront seat belt sash guide mounting boltVehicles35-5525-40

ront seat belt retractor bracket mounting bolt for Canada35-5525-40

Zover plate mounting bolt9-147-10

‘ear inner seat belt bracket mounting bolt35-5525-40

‘ear seat belt anchor plate attaching bolt35-5525-40

ear seat belt retractor bracket mounting bolt (Front)4-63-4

ear seat belt retractor bracket mounting bolt (Rear)35-5525-40

Page 1062 of 1216

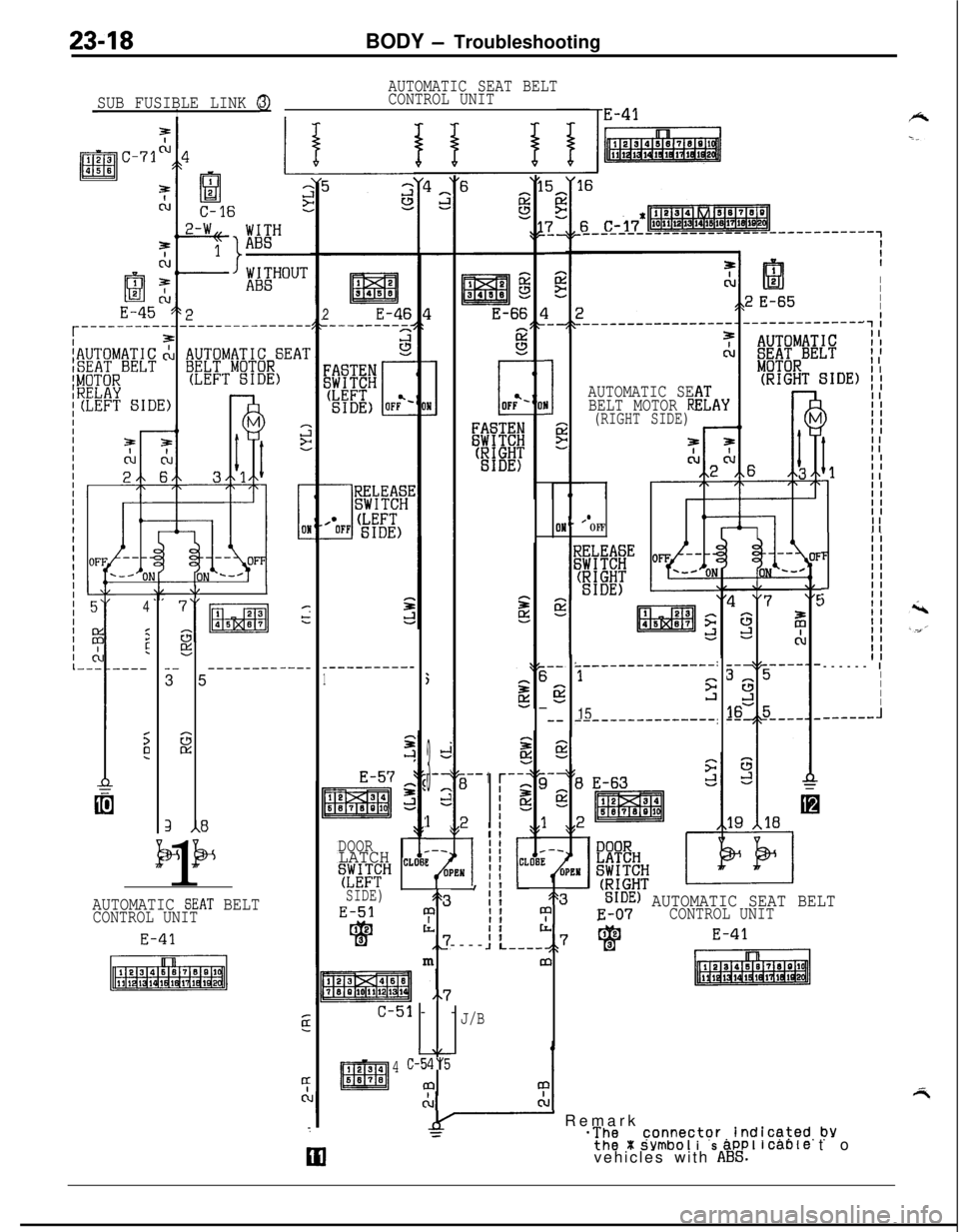

23-18BODY - Troubleshooting

AUTOMATIC SEAT BELT

SUB FUSIBLE LINK QCONTROL UNITIE-41

-------____---__-----~-~--~~~-----I1

2E-46

I

I

I

I

‘1 II I

I II II I

I II I

I I

I II I

I I

I II I

I I

I II I

I I

_----------

1

sL

E-57

t

--A37t

1 :

1

I

I

I

IDOORLATCH 7-I

TF;W;H cLo8'I

SIDE), IE-51

9+3 I

125!?‘pIcr.3,,7 f----

m

I

AUTOMATIC SEIBELT MOTOR R

!3

(RIGHT SIDE)

ON$ .aOFF

I I

1 ..

I I

I I

jI I

I I

I I

i I------ I

I

I

I

I

__----J

\/I

‘,“piaq

E!G__ --------3 5

slx

3 A0

++1

4

:

c_---

2.

L----------------:1--1

2

15_---_---_____---~--

II

ISk3m

11

ICL-,,7L---- ,,

m

.h7

c-51 --J/B

LL

, 2 3 4 C-54 “5

56678m

SIDE) AUTOMATIC SEAT BELTE-07CONTROL UNIT

E-41

AUTOMATIC SEAT BELTCONTROL UNITE-41

&- Remark=*The connectqr,indicated,QYthe x SYmbOl is aPPIicat)le to

vehicles with ABS.

Page 1077 of 1216

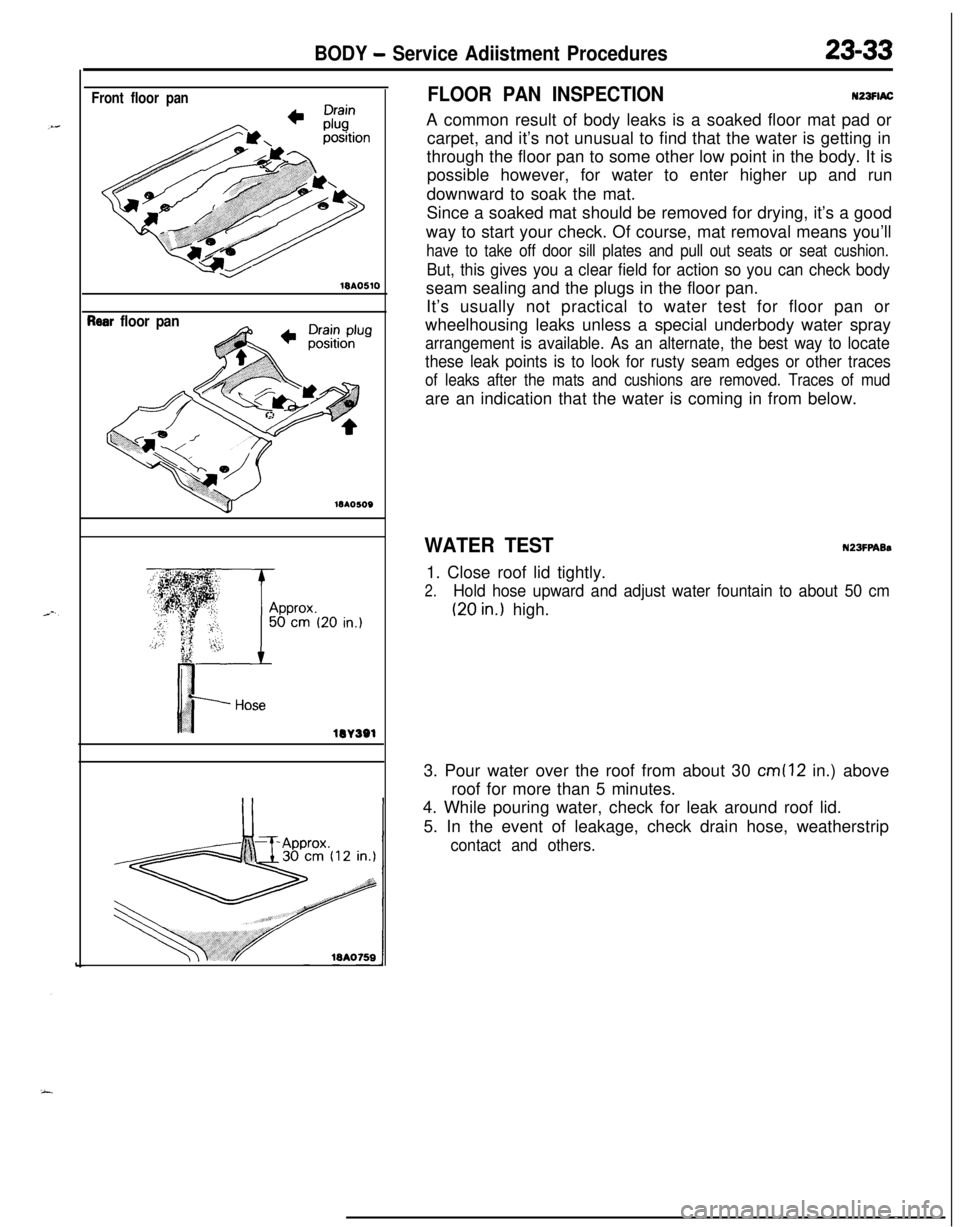

BODY - Service Adiistment Procedures23-33

Front floor pan18AO510

?ear floor pan

lOA

lW391

FLOOR PAN INSPECTIONN23FlACA common result of body leaks is a soaked floor mat pad or

carpet, and it’s not unusual to find that the water is getting in

through the floor pan to some other low point in the body. It is

possible however, for water to enter higher up and run

downward to soak the mat.

Since a soaked mat should be removed for drying, it’s a good

way to start your check. Of course, mat removal means you’ll

have to take off door sill plates and pull out seats or seat cushion.

But, this gives you a clear field for action so you can check bodyseam sealing and the plugs in the floor pan.

It’s usually not practical to water test for floor pan or

wheelhousing leaks unless a special underbody water spray

arrangement is available. As an alternate, the best way to locate

these leak points is to look for rusty seam edges or other traces

of leaks after the mats and cushions are removed. Traces of mudare an indication that the water is coming in from below.

WATER TESTN23FPABs1. Close roof lid tightly.

2.Hold hose upward and adjust water fountain to about 50 cm

(20 in.) high.

3. Pour water over the roof from about 30

cm (12 in.) above

roof for more than 5 minutes.

4. While pouring water, check for leak around roof lid.

5. In the event of leakage, check drain hose, weatherstrip

contact and others.

Page 1085 of 1216

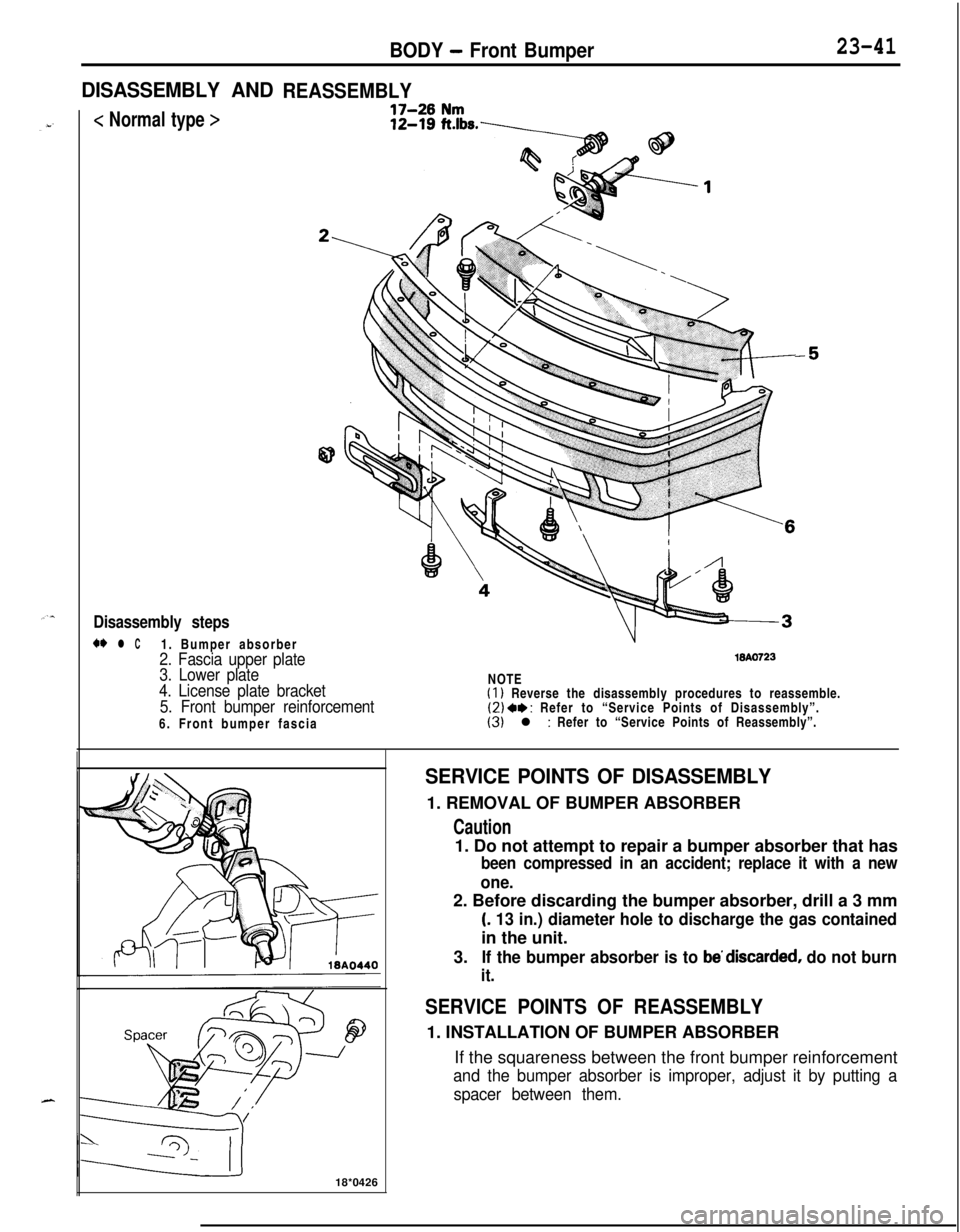

BODY - Front Bumper23-41

DISASSEMBLY ANDREASSEMBLY

< Normal type >

-

Disassembly steps

w l C1. Bumper absorber

2. Fascia upper plate

3. Lower plate18AO723

4. License plate bracket

5. Front bumper reinforcement6. Front bumper fasciaNOTE(1) Reverse the disassembly procedures to reassemble.(2) 4, : Refer to “Service Points of Disassembly”.(3) l : Refer to “Service Points of Reassembly”.

18*0426

SERVICE POINTS OF DISASSEMBLY1. REMOVAL OF BUMPER ABSORBER

Caution1. Do not attempt to repair a bumper absorber that has

been compressed in an accident; replace it with a new

one.2. Before discarding the bumper absorber, drill a 3 mm

(. 13 in.) diameter hole to discharge the gas containedin the unit.

3.

If the bumper absorber is to be’discarded, do not burn

it.

SERVICE POINTS OF REASSEMBLY1. INSTALLATION OF BUMPER ABSORBER

If the squareness between the front bumper reinforcement

and the bumper absorber is improper, adjust it by putting a

spacer between them.

Page 1086 of 1216

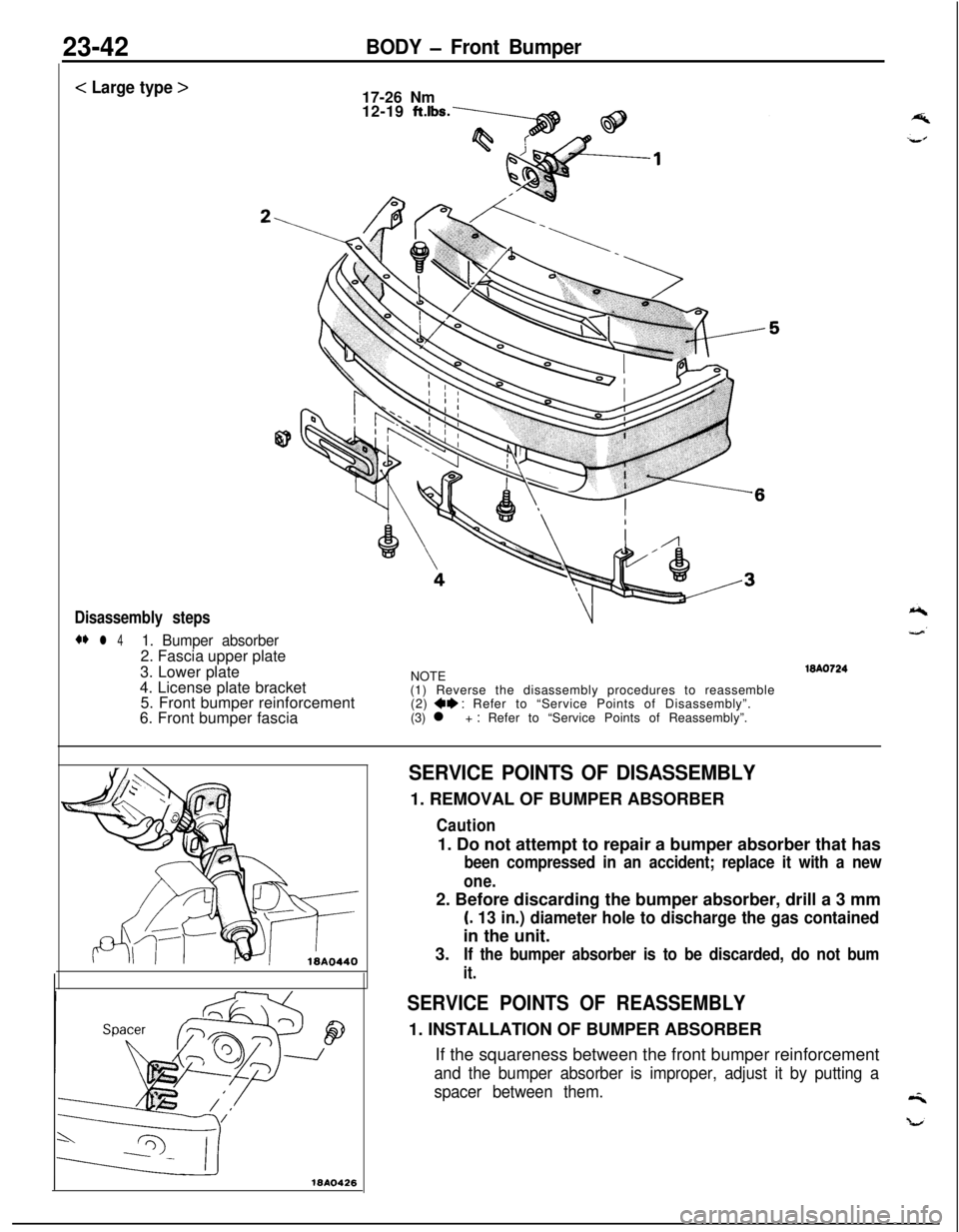

23-42BODY - Front Bumper

< Large type >

17-26 Nm

12-19

ftlbs.

Disassembly steps

** l 41. Bumper absorber2. Fascia upper plate

3. Lower plate

4. License plate bracket

5. Front bumper reinforcement

6. Front bumper fasciaNOTE

(1) Reverse the disassembly procedures to reassemble

(2)

+e : Refer to “Service Points of Disassembly”.

(3) l + : Refer to “Service Points of Reassembly”.WA0724

18410426

SERVICE POINTS OF DISASSEMBLY1. REMOVAL OF BUMPER ABSORBER

Caution1. Do not attempt to repair a bumper absorber that has

been compressed in an accident; replace it with a new

one.2. Before discarding the bumper absorber, drill a 3 mm

(. 13 in.) diameter hole to discharge the gas containedin the unit.

3.

If the bumper absorber is to be discarded, do not bum

it.

SERVICE POINTS OF REASSEMBLY1. INSTALLATION OF BUMPER ABSORBER

If the squareness between the front bumper reinforcement

and the bumper absorber is improper, adjust it by putting a

spacer between them.

Page 1089 of 1216

BODY - Rear Bummer23-45

DISASSEMBLY AND REASSEMBLY<

Normal type >

Disassembly steps1. License plate light

2. Back-up light

3. Rear side marker light

4. License plate light wiring harness

5. Bumper absorber

6. Rear bumper reinforcement

7. License plate bracket

8. Rear bumper fasciaNOTE

(1) Reverse the disassembly procedures to reassemble.(2) +* : Refer to “Service Points of Disassembly”.

SERVICE POINTS OF DISASSEMBLY5. REMOVAL OF BUMPER ABSORBER

Caution1. Do not attempt to repair a bumper absorber that has

been compressed in an accident; replace it with a new

one.2. Before discarding the bumper absorber, drill a 3 mm

(. 13 in.) diameter hole to discharge the gas containedin the unit.

3.

If the bumper absorber is to be discarded, do not burn

it.