engine oil MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 477 of 1216

FUEL SYSTEM - Troubleshootinn

-.

_-

AIR FLOW SENSORr

INTAKK AlN AlNTENPERAIURE PLOUEENBOR BENBORA-36

q_-____-____--_ -----------5

T

14

c

----.19

Ic

21

lfl

2ON3OFF

Y

IDLESWITCH=4 EGR TEMPERATURE ENGINETHROTTLE

fi %i%kES FORPOSITION

CALIFORNIA)

B-08 mB-30 I

Ia

{mc

B-05

mPOWER

STEERING OIL

Pl?l?f;#RE

KX35-AC-UOBlBA-NC

Page 515 of 1216

FUEL SYSTEM - MPI System Inspection <1.8L Engine>

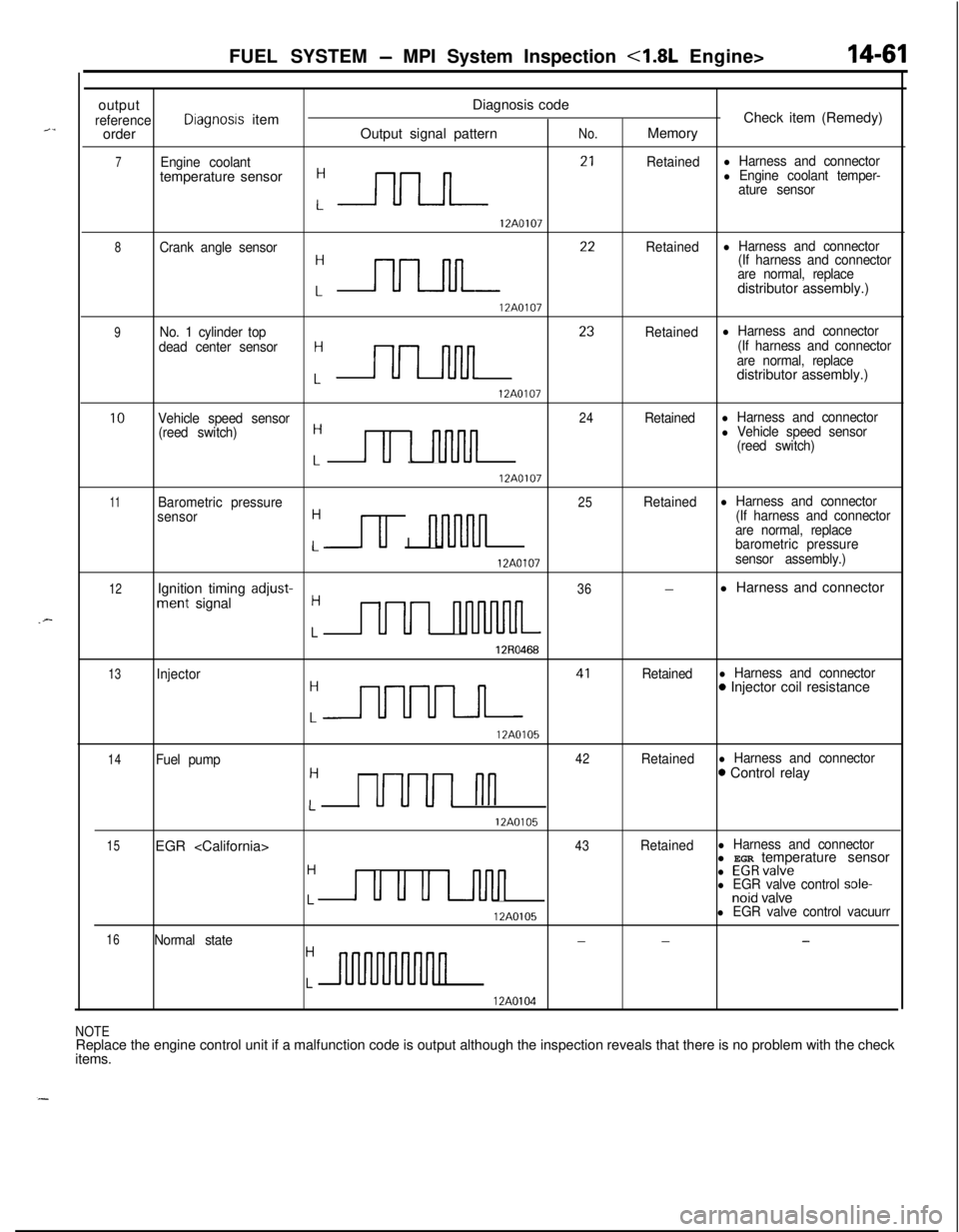

outputDiagnosis code

referenceDiagnosis itemCheck item (Remedy)

orderOutput signal patternNo.Memory

7Engine coolantRetainedl Harness and connectortemperature sensor

:-rlrLn- 2’

l Engine coolant temper-

ature sensor

12A0107

8Crank angle sensor

:nn 22

Retainedl Harness and connector

(If harness and connector

are normal, replacedistributor assembly.)

12A0107

9No. 1 cylinder top

dead center sensorH

Lnn 23

Retainedl Harness and connector

(If harness and connector

are normal, replacedistributor assembly.)

12A0107

10Vehicle speed sensor24Retainedl Harness and connector

(reed switch)H

Lu 1 nnJln

l Vehicle speed sensor

(reed switch)

12A0107

11Barometric pressure25Retainedl Harness and connector

sensorH

u I nl-uvln

(If harness and connector

are normal, replace

Lbarometric pressure

12A0107sensor assembly.)

12Ignition timing adjust-36-l Harness and connectorment signalH

LUUI nluvuuL

12R0468

13Injector

:m 41

Retainedl Harness and connector0 Injector coil resistance

12A0105

14Fuel pump42Retainedl Harness and connectorH0 Control relay

LUUUI nn

12A0105

15EGR

H

u u u u-inn

l EGRvalvel EGR valve control sole-Lnoid valve

12A0105l EGR valve control vacuurr

16Normal state---H

Ln

12A0104

NOTEReplace the engine control unit if a malfunction code is output although the inspection reveals that there is no problem with the check

items.

Page 519 of 1216

FUEL SYSTEM - MPI Svstem InsDection <1.8L Engine>14-65

3FUO349

/--

’ 3FU03991

Idle speed controlservo connector(motor side, front view)

3FUO393

INHIBITOR SWITCHN14QRACsRefer to GROUP 21

- Service Adjustment Procedures.

POWER STEERING OIL PRESSURE SWITCH

N14flCJBRefer to GROUP 19 for power steering system inspection.

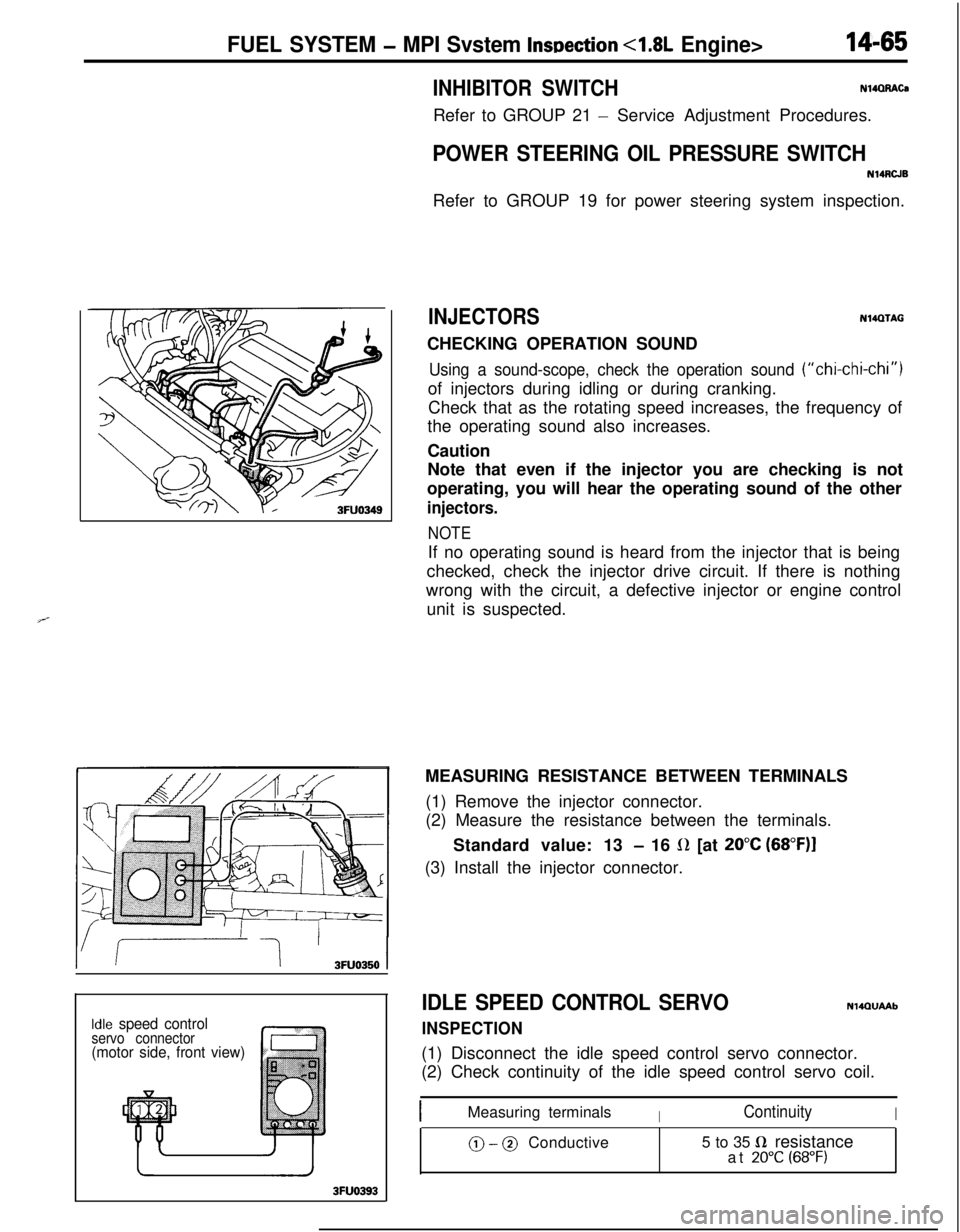

INJECTORSN14QTAGCHECKING OPERATION SOUND

Using a sound-scope, check the operation sound (“chi-chi-chi”)of injectors during idling or during cranking.

Check that as the rotating speed increases, the frequency of

the operating sound also increases.

Caution

Note that even if the injector you are checking is not

operating, you will hear the operating sound of the other

injectors.

NOTEIf no operating sound is heard from the injector that is being

checked, check the injector drive circuit. If there is nothing

wrong with the circuit, a defective injector or engine control

unit is suspected.

MEASURING RESISTANCE BETWEEN TERMINALS

(1) Remove the injector connector.

(2) Measure the resistance between the terminals.

Standard value: 13

- 16 L(Z [at 20°C (68”F)I(3) Install the injector connector.

IDLE SPEED CONTROL SERVO

INSPECTION

NlQQUAAb(1) Disconnect the idle speed control servo connector.

(2) Check continuity of the idle speed control servo coil.

IMeasuring terminalsIContinuityI

@ - @ Conductive5 to 35 fi resistance

at 20°C (68°F)

Page 523 of 1216

![MITSUBISHI ECLIPSE 1991 Service Manual FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>

EGR control solenoid valve

[Calif. only]

Purge control solenoid valve

1

/AF--Y:rIgnition coil, Power transistor

Oxygen sensorPower

steering flu MITSUBISHI ECLIPSE 1991 Service Manual FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>

EGR control solenoid valve

[Calif. only]

Purge control solenoid valve

1

/AF--Y:rIgnition coil, Power transistor

Oxygen sensorPower

steering flu](/img/19/57104/w960_57104-522.png)

FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>

EGR control solenoid valve

[Calif. only]

Purge control solenoid valve

1

/AF--Y:rIgnition coil, Power transistor

Oxygen sensorPower

steering fluid Dressure switch

Coolant temDerature sensor

Page 525 of 1216

FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>

InjectorII

01A0499

/

Purge control

Fuel pressureII solenoid valve

control valve

solenoid valve

0110503Ignition coil, Power transistor

IOxvnen sensorEGR control solenoid valve

[Calif. only]

Purge control solenoid valve

Fuel pressure control valve [Turbo only]

\’

\

16A0803Detonation sensor

\Power steering fluid oressure switch

Page 529 of 1216

FUEL SYSTEM - MPI Svstem InsDection <2.0L DOHC Engine>

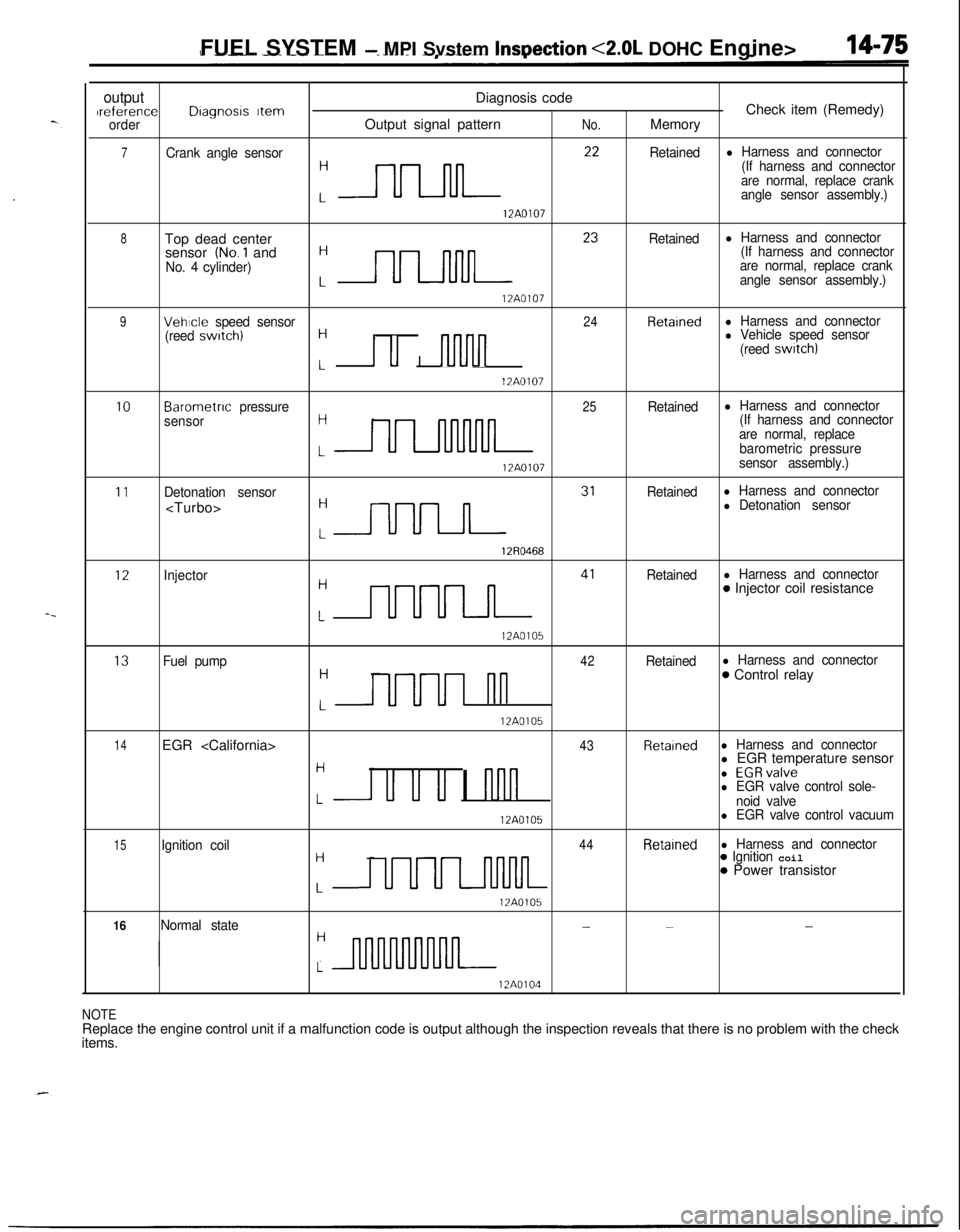

outputDiagnosis codeIreferenceDragnosrs ItemCheck item (Remedy)orderOutput signal patternNo.Memory

7Crank angle sensor

:nn **

Retainedl Harness and connector

(If harness and connector

are normal, replace crank

angle sensor assembly.)

12A0107

8Top dead center

:- 23

Retainedl Harness and connectorsensor (No.1 and(If harness and connector

No. 4 cylinder)are normal, replace crank

angle sensor assembly.)

12A0107

9Vehicle speed sensor24Retainedl Harness and connector

(reed swatch)H

I u I nlvln

l Vehicle speed sensor

(reed switch)

L12A0107

10Barometnc pressure25Retainedl Harness and connector

sensorH(If harness and connector

are normal, replace

LULllnMllbarometric pressure

12A0107sensor assembly.)

11Detonation sensorRetainedl Harness and connector

:m 31

l Detonation sensor

12R0468

12Injector

:m 41

Retainedl Harness and connector0 Injector coil resistance

12A0105

13Fuel pump42Retainedl Harness and connectorH

UUUI nn

0 Control relay

L12A0105

14EGR

Hl EGR temperature sensor

u u u I nnn

l EGRvalvel EGR valve control sole-Lnoid valve

12A0105l EGR valve control vacuum

15Ignition coil44Retainedl Harness and connectorH

UUUL-llMlL

0 Ignition coil0 Power transistor

L12A0105

16Normal state---H

L

12A0104

NOTEReplace the engine control unit if a malfunction code is output although the inspection reveals that there is no problem with the check

items.

Page 533 of 1216

FUEL SYSTEM - MPI System Inspection <2.0L QOHC Engine>14-79EGR TEMPERATURE SENSOR

N14RCHAaRefer to GROUP 25

- Exhaust Gas Recirculation System.

VEHICLE SPEED SENSOR

Refer to GROUP 8

- Meters and Gauges.

N140EBBaAIR CONDITIONER SWITCH

Nl4QQAEaRefer to GROUP 8

- Column Switch.

POWER STEERING OIL PRESSURE SWITCH

N14RCJBRefer to GROUP 19 for power steering system inspection.

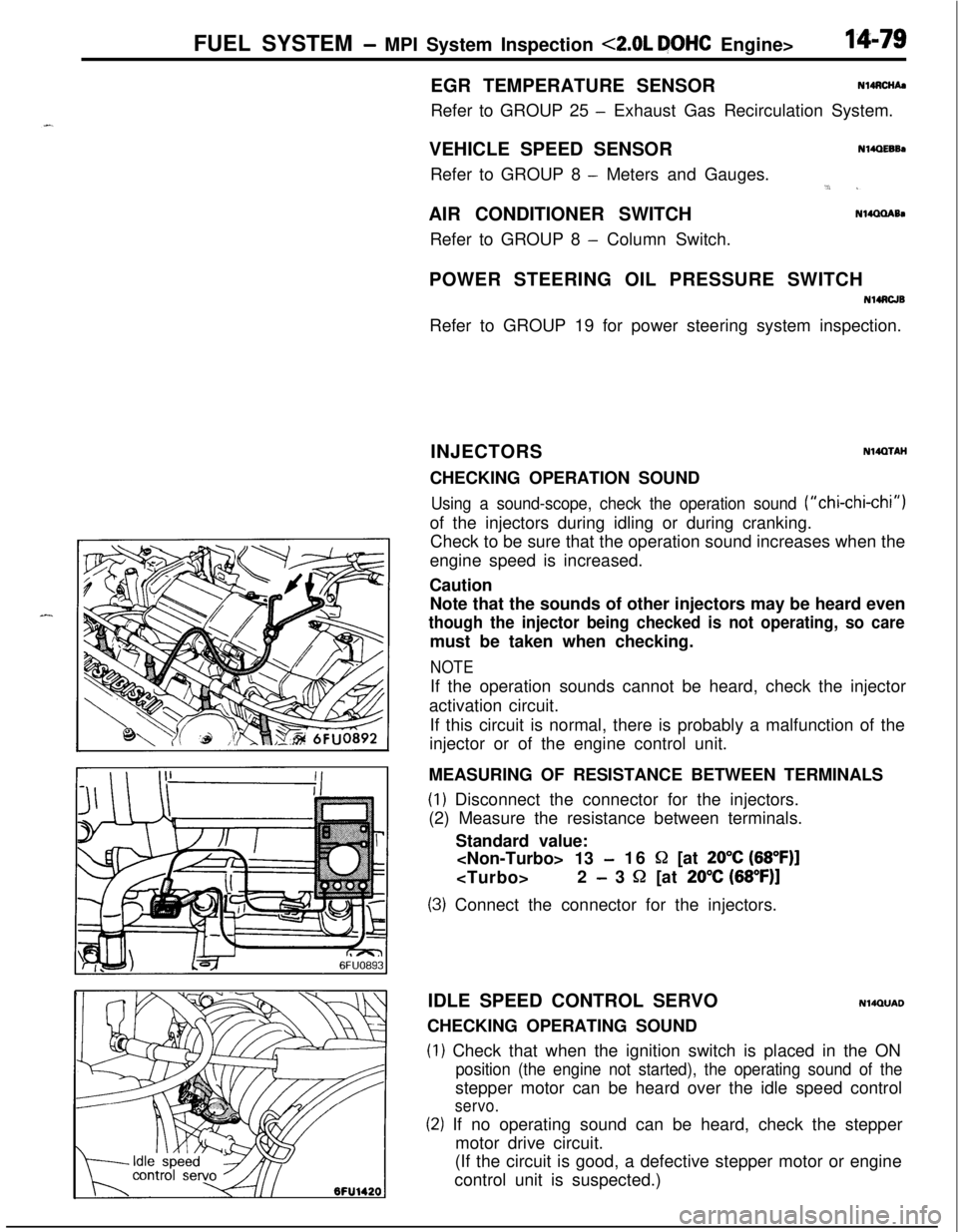

INJECTORS

NWXAHCHECKING OPERATION SOUND

Using a sound-scope, check the operation sound (“chi-chi-chi”)of the injectors during idling or during cranking.

Check to be sure that the operation sound increases when the

engine speed is increased.

Caution

Note that the sounds of other injectors may be heard even

though the injector being checked is not operating, so caremust be taken when checking.

NOTEIf the operation sounds cannot be heard, check the injector

activation circuit.

If this circuit is normal, there is probably a malfunction of the

injector or of the engine control unit.

MEASURING OF RESISTANCE BETWEEN TERMINALS

(1) Disconnect the connector for the injectors.

(2) Measure the resistance between terminals.

Standard value:

-16 S2 [at 20°C (68”F)]

- 3 52 [at 20% (68”F)]

(3) Connect the connector for the injectors.

IDLE SPEED CONTROL SERVO

N14QUADCHECKING OPERATING SOUND

(1) Check that when the ignition switch is placed in the ON

position (the engine not started), the operating sound of thestepper motor can be heard over the idle speed control

servo.

(2) If no operating sound can be heard, check the stepper

motor drive circuit.

(If the circuit is good, a defective stepper motor or engine

control unit is suspected.)

Page 536 of 1216

14-82FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>

\ \\I \3FUO352

,\ \

\I \3FUO353

,\ ‘\R/

\ \\I \3FUo354

POWER TRANSISTORRefer to GROUP 8

- Ignition System

NlIAcQAl

a-4

AIR CONDITIONER POWER RELAYN14NCl.a -Refer to GROUP 24

- Air Conditioner.

PURGE CONTROL SOLENOID VALVEN14RCKARefer to GROUP 25

- Evaporative Emission Control System.

EGR CONTROL SOLENOID VALVE

N14NCURefer to GROUP 25

- Exhaust Gas Recirculation System.

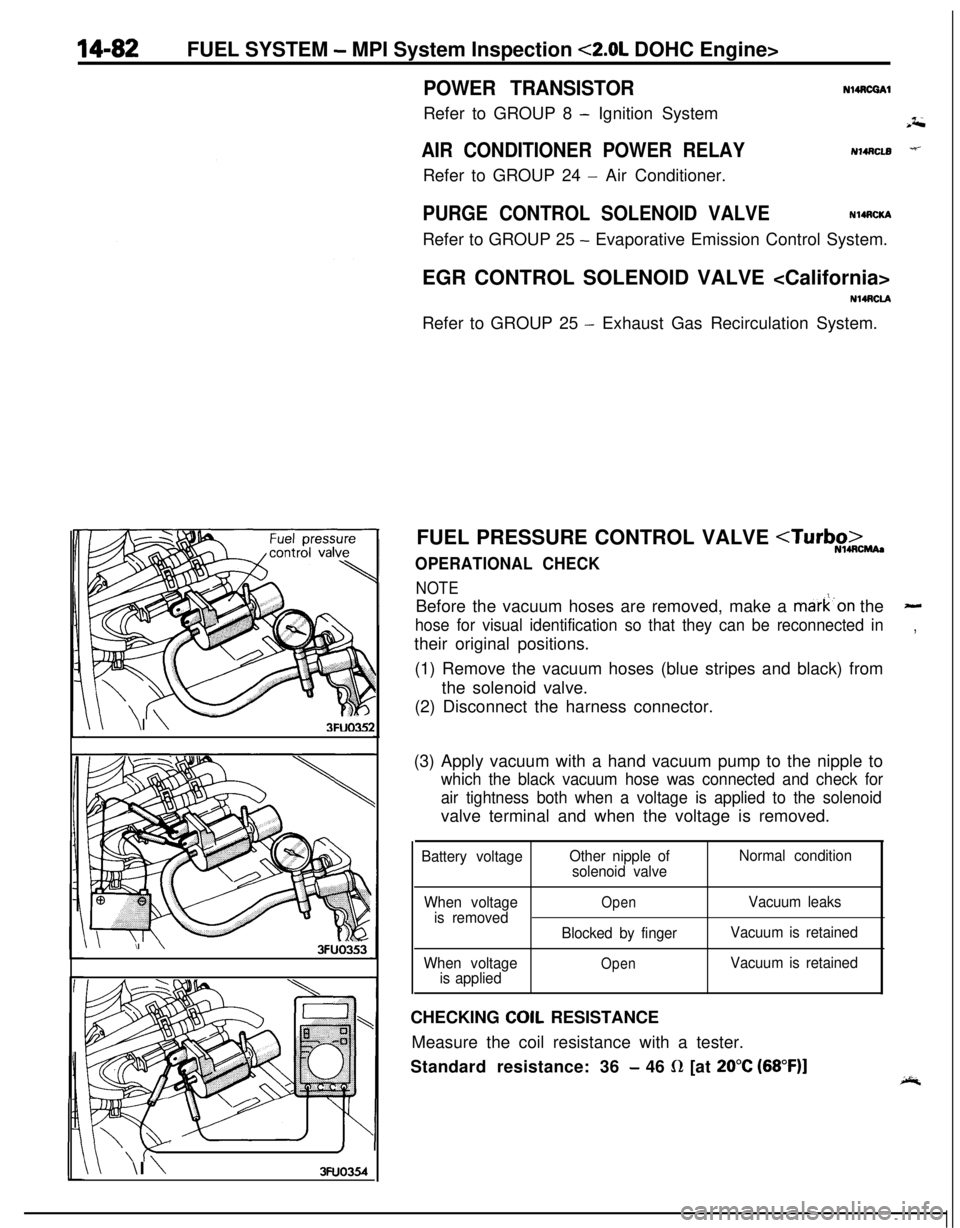

FUEL PRESSURE CONTROL VALVE

NOTEBefore the vacuum hoses are removed, make a mark’on the

-

hose for visual identification so that they can be reconnected in,their original positions.

(1) Remove the vacuum hoses (blue stripes and black) from

the solenoid valve.

(2) Disconnect the harness connector.

(3) Apply vacuum with a hand vacuum pump to the nipple to

which the black vacuum hose was connected and check for

air tightness both when a voltage is applied to the solenoidvalve terminal and when the voltage is removed.

Battery voltageOther nipple of

solenoid valveNormal condition

When voltage

is removed

When voltage

is applied

OpenVacuum leaks

Blocked by fingerVacuum is retained

OpenVacuum is retainedCHECKING

COIL RESISTANCE

Measure the coil resistance with a tester.

Standard resistance: 36

- 46 R [at 20°C (68”F)]

Page 538 of 1216

14-84FUEL SYSTEM - Injector

03*0095

Delivery pipe03A0095-SERVICE POINTS OF REMOVAL

H4s0m1‘~

3.DISCONNECTION OF THE HIGH PRESSURE FlJFL HOSE /;;

Bleed the residual pressure within the fuel pipe line’& as to~prevent the flow of fuel.

For information concerning the method to be folfowed for

bleeding the residual pressure, refer to

P.14-44.Caution

Cover the hose connection with rags to prevent splash,

of fuel that could be caused by some residual pressure

in the fuel pipe line.

12. REMOVAL OF DELIVERY PIPE/ 15. INJECTOR

Remove the deliver-y pipe (with the injectors attached to it).Caution

Care must be taken, when removing the delivery pipe,

not to drop the injector.

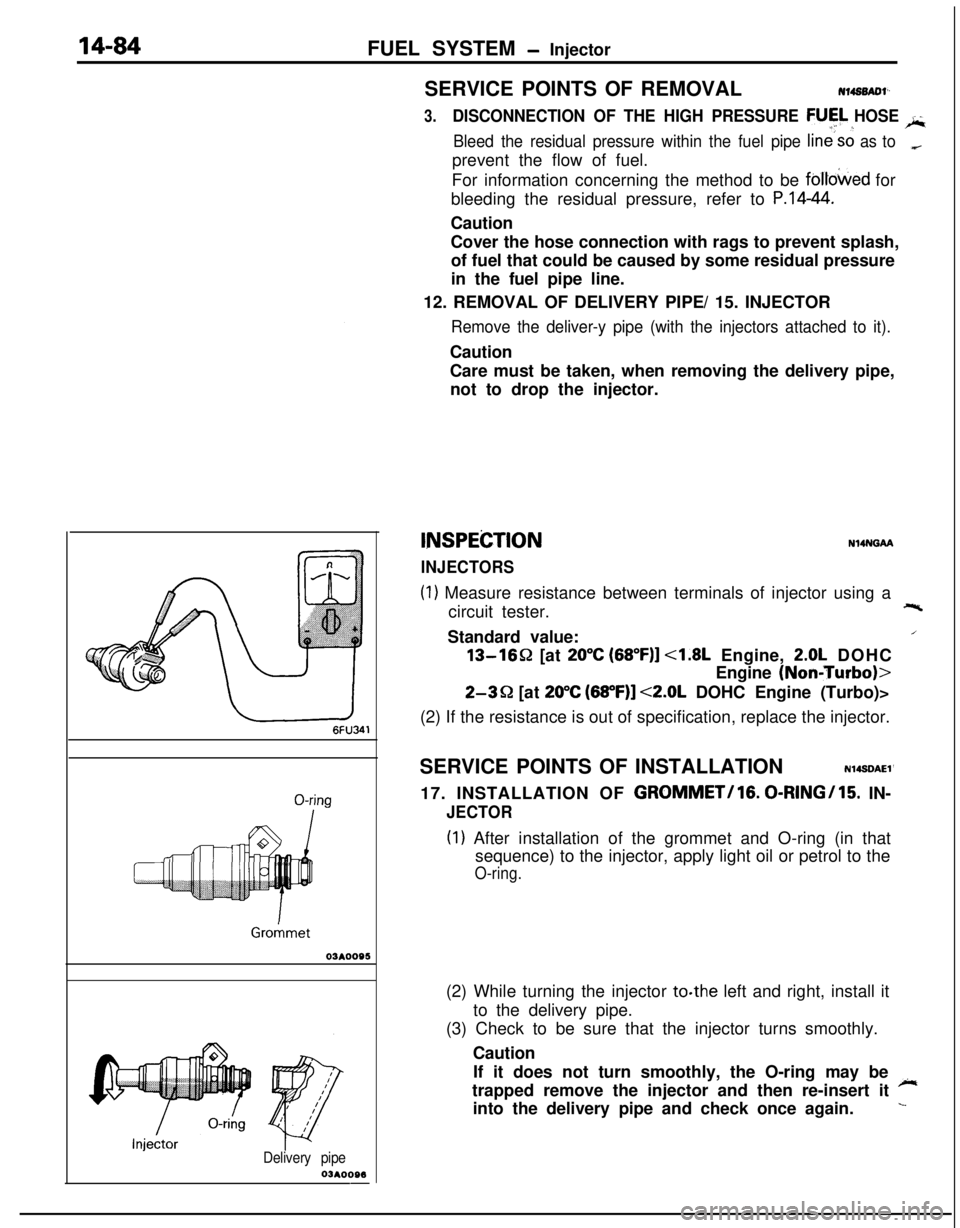

INSPEiZTION

INJECTORS

N14NGAA

(1) Measure resistance between terminals of injector using a

circuit tester.+-%Standard value:

/13-1652 [at

20°C (68”F)] <1.8L Engine, 2.0L DOHC

Engine

(NoniTurbo)>

2-3Q [at 20°C (68”F)] <2.0L DOHC Engine (Turbo)>

(2) If the resistance is out of specification, replace the injector.

SERVICE POINTS OF INSTALLATION

N14SDAEl’17. INSTALLATION OF

GROMMET/lG. 0-RINGI15. IN-

JECTOR

(I) After installation of the grommet and O-ring (in that

sequence) to the injector, apply light oil or petrol to the

O-ring.(2) While turning the injector to.the left and right, install it

to the delivery pipe.

(3) Check to be sure that the injector turns smoothly.

Caution

If it does not turn smoothly, the O-ring may be

~trapped remove the injector and then re-insert it

into the delivery pipe and check once again.

L

Page 539 of 1216

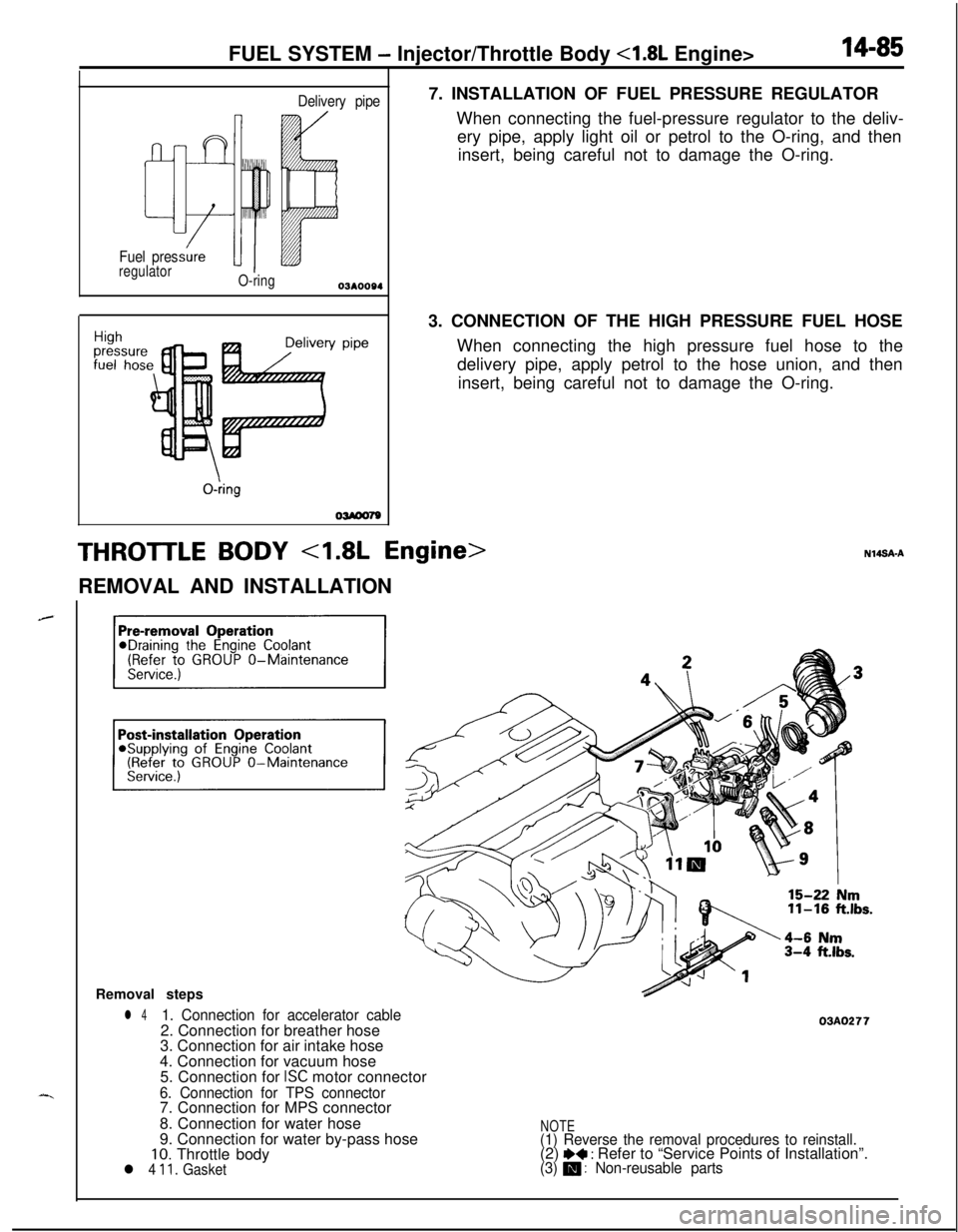

FUEL SYSTEM - Injector/Throttle Body <1.8L Engine>14-85

Delivery pipe

Fuel pres

regulator

O-ringY pipe

O-kg

OWOO797. INSTALLATION OF FUEL PRESSURE REGULATOR

When connecting the fuel-pressure regulator to the deliv-

ery pipe, apply light oil or petrol to the O-ring, and then

insert, being careful not to damage the O-ring.

3. CONNECTION OF THE HIGH PRESSURE FUEL HOSE

When connecting the high pressure fuel hose to the

delivery pipe, apply petrol to the hose union, and then

insert, being careful not to damage the O-ring.

THROTTLE BODY 4.8L Engine>REMOVAL AND INSTALLATION

Removal steps

l 41. Connection for accelerator cable2. Connection for breather hose

3. Connection for air intake hose

4. Connection for vacuum hose

5. Connection for

ISC motor connector

6. Connection for TPS connector7. Connection for MPS connector

8. Connection for water hose

9. Connection for water by-pass hose

10. Throttle bodyl 4 11. Gasket

03AO277

NOTE(1) Reverse the removal procedures to reinstall.(2) I)+ : Refer to “Service Points of Installation”.(3) m : Non-reusable parts