engine oil MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 688 of 1216

1 S-40STEERING - Power Steering Oil Pump

SERVICE POINTS OF REMOVAL

Nl8RW2. DISCONNECTION OF RETURN HOSE

(1) Removal the reservoir cap and disconnect the return

hose from the reservoir to drain the fluid.

(2) Jack up the front wheels.

(3) Disconnect the high tension cable and turn the engine

over several times to drain the fluid from the gear box.

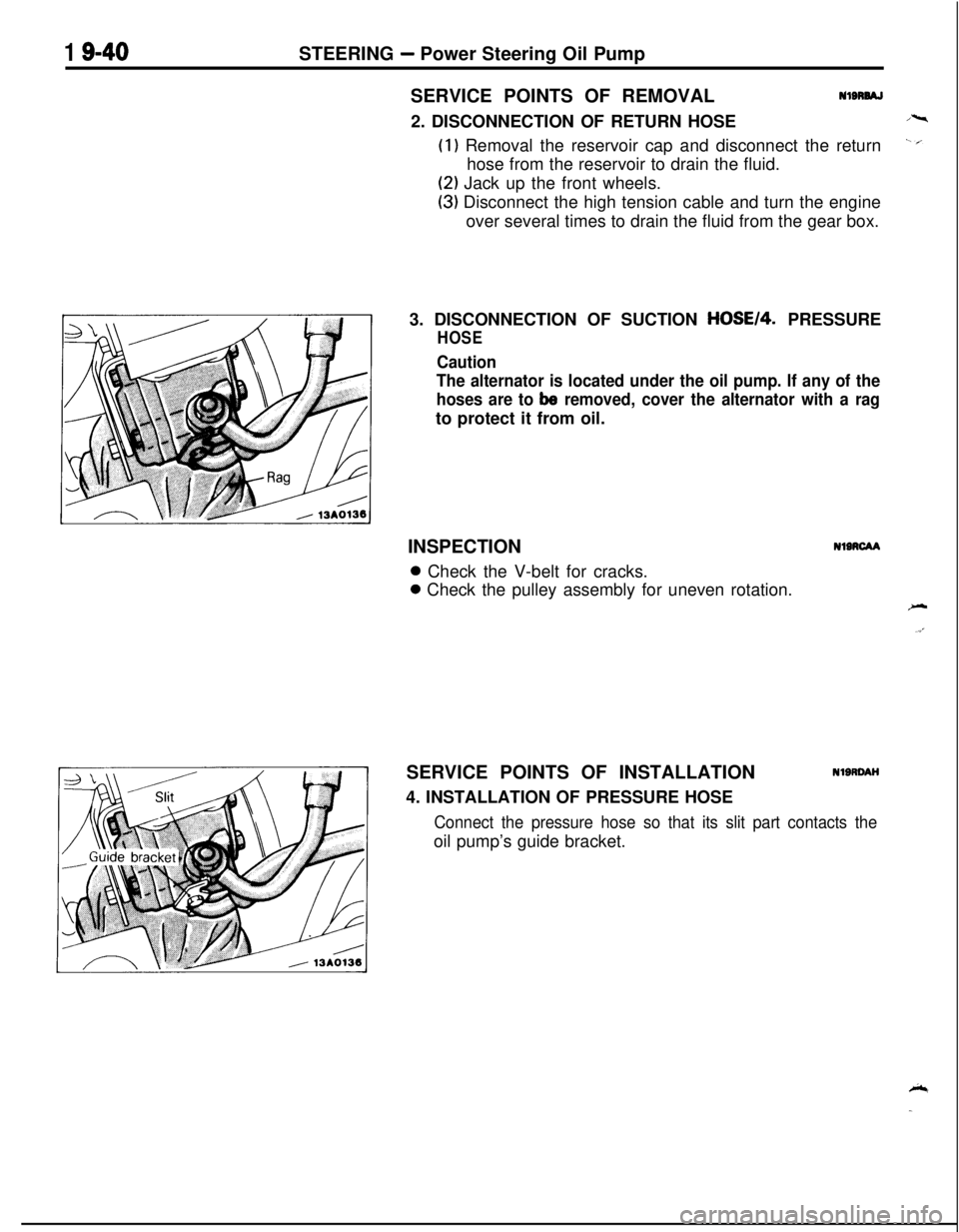

3. DISCONNECTION OF SUCTION

HOSE14. PRESSURE

HOSE

Caution

The alternator is located under the oil pump. If any of the

hoses are to

be removed, cover the alternator with a ragto protect it from oil.

INSPECTION

NIRCAA0 Check the V-belt for cracks.0 Check the pulley assembly for uneven rotation.

SERVICE POINTS OF INSTALLATION

4. INSTALLATION OF PRESSURE HOSE

NlSRDAH

Connect the pressure hose so that its slit part contacts theoil pump’s guide bracket.

Page 699 of 1216

MANUAL TRANSAXLE

SPECIFICATIQNS

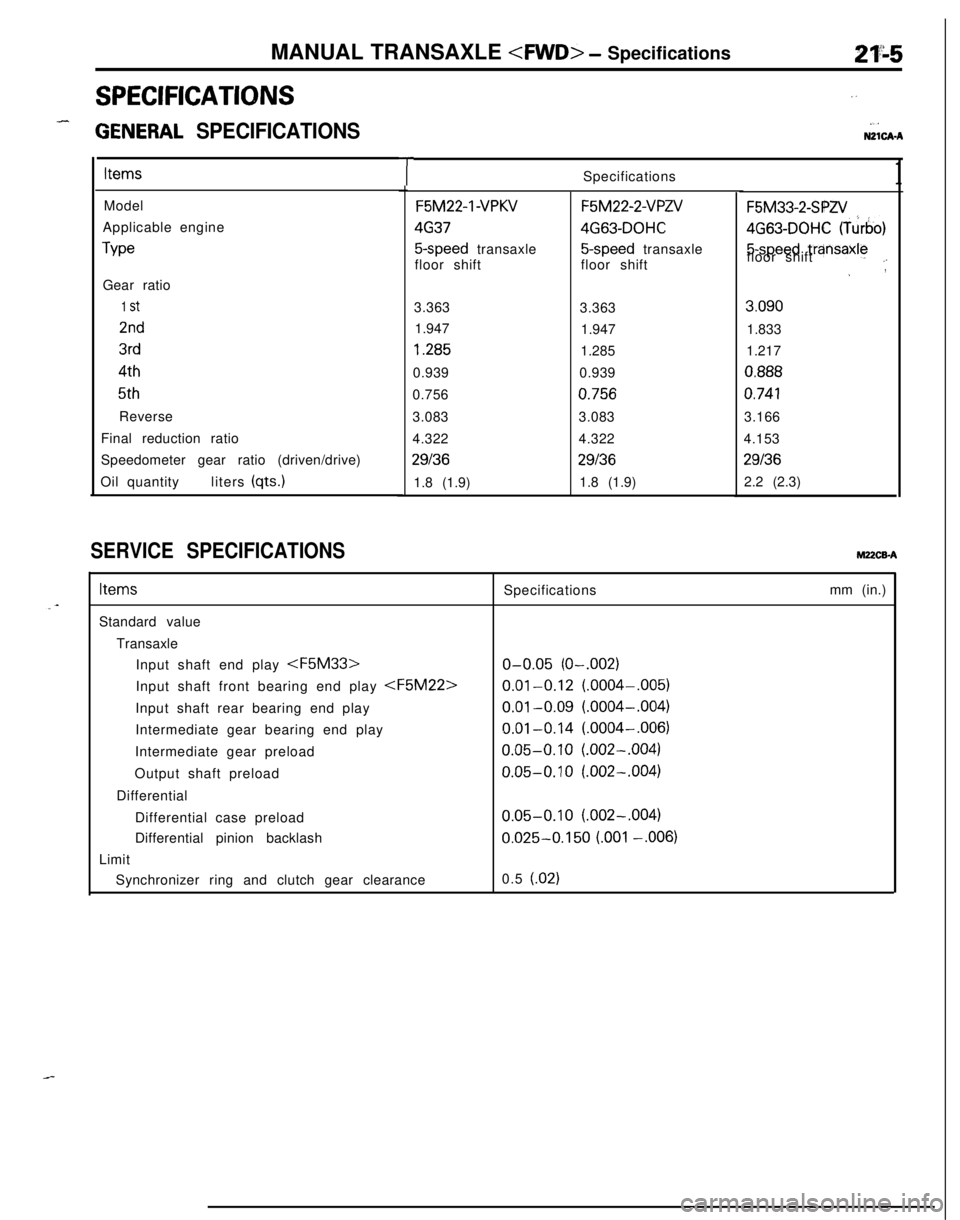

3ENERAL SPECIFICATIONS

ItemsModel

Applicable engine

TypeGear ratio

1 st2nd3rd

4th5th

Reverse

Final reduction ratio

Speedometer gear ratio (driven/drive)

Oil quantityliters (qts.)

SERVICE SPECIFICATIONShl22CBA

”

.,NZlCA-ASpecifications

1TF5M22-1

-VFWF5M22-2-VPZV

46374G63-DOHC

5-speed transaxle5-speed transaxle

floor shiftfloor shift

3.363

3.363

1.947

1.9471.285

1.285

0.9390.939

0.756

0.7563.0833.083

4.3224.322

29136291361.8 (1.9)1.8 (1.9)

F5M33-2-SPA!4G63-DOHC (Turbo)5-speed

trzinsaxlefloor shift.-~,3.090

1.833

1.217

0.888

0.7413.166

4.153

291362.2 (2.3)

ItemsStandard value

Transaxle

Input shaft end play

Intermediate gear bearing end play

Intermediate gear preload

Output shaft preload

Differential

Differential case preload

Differential pinion backlash

LimitSpecifications

o-0.05 (O-.002)

0.01-0.12 (.0004-.005)

0.01-0.09 (.0004-.004)

0.01-0.14 (.0004-,006)

0.05-0.10 (.002-.004)

0.05-0.10 (.002-.004)

0.05-0.10 (.002-.004)

0.025-0.150 LOO1 -.006)mm (in.)

Synchronizer ring and clutch gear clearance0.5 (.02)

Page 706 of 1216

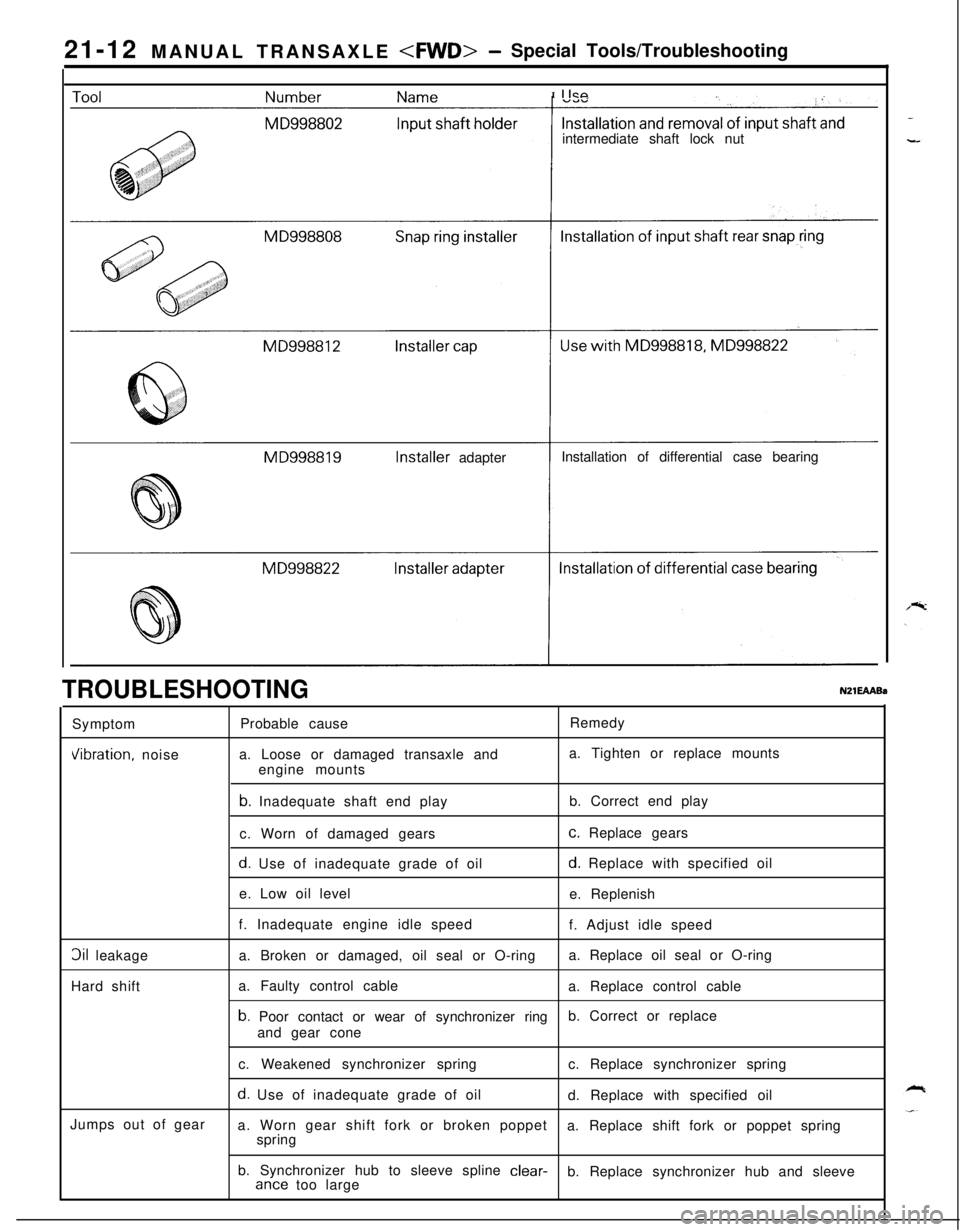

21-12 MANUAL TRANSAXLE

I

IICPintermediate shaft lock nut

MD998819Installer adapterInstallation of differential case bearing

TROUBLESHOOTINGNZlEAABsSymptomVibration, noise

3il leakage

Hard shift

Jumps out of gearProbable causeRemedy

a. Loose or damaged transaxle anda. Tighten or replace mounts

engine mounts

b. Inadequate shaft end playb. Correct end play

c. Worn of damaged gears

c. Replace gears

d. Use of inadequate grade of oild. Replace with specified oil

e. Low oil level

e. Replenish

f. Inadequate engine idle speed

f. Adjust idle speed

a. Broken or damaged, oil seal or O-ringa. Replace oil seal or O-ring

a. Faulty control cable

a. Replace control cable

b. Poor contact or wear of synchronizer ring

and gear coneb. Correct or replace

c. Weakened synchronizer springc. Replace synchronizer spring

d. Use of inadequate grade of oil

d. Replace with specified oil

a. Worn gear shift fork or broken poppet

springa. Replace shift fork or poppet spring

b. Synchronizer hub to sleeve spline

clear-ante too largeb. Replace synchronizer hub and sleeve

Page 713 of 1216

MANUAL TRANSAXLE

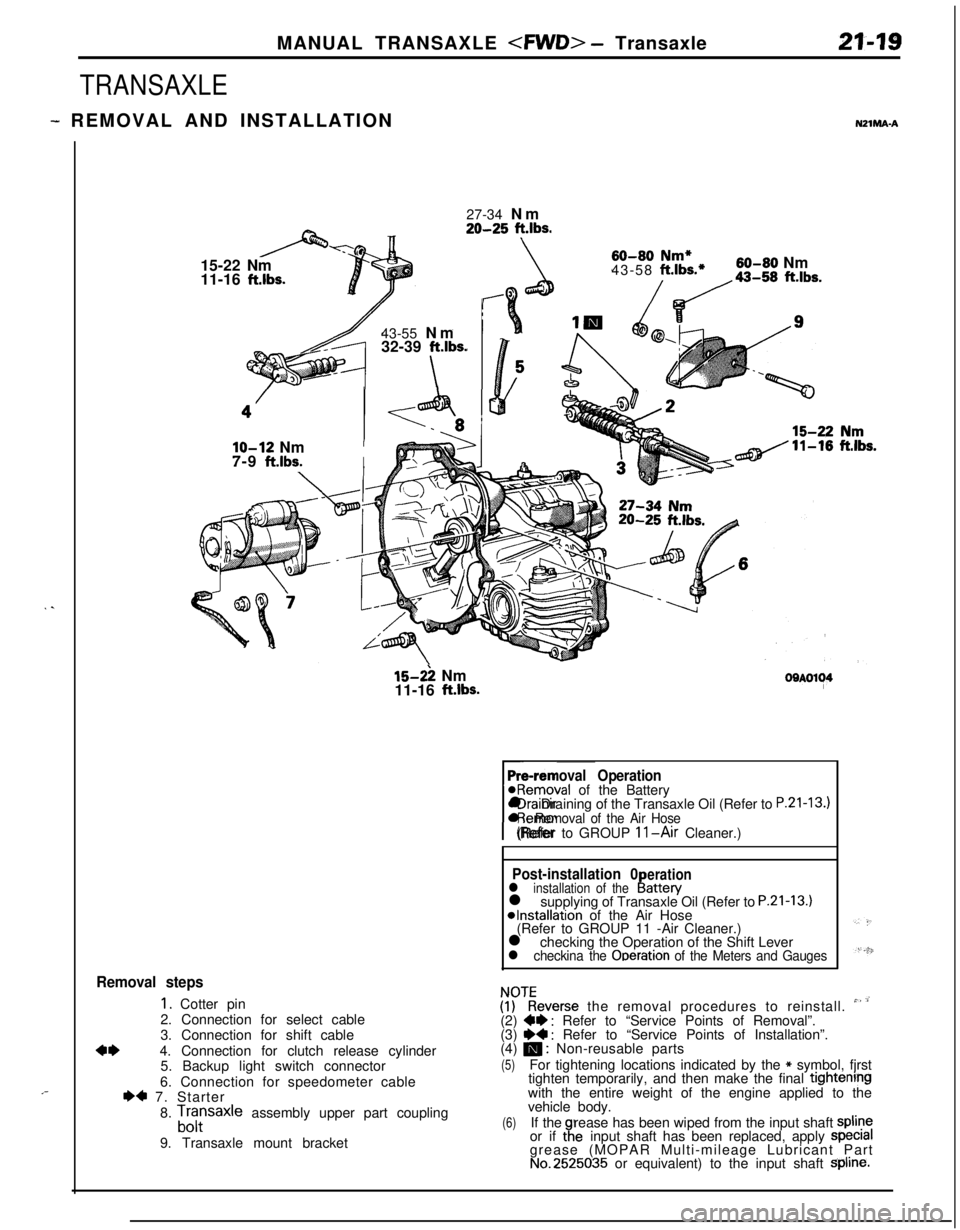

TRANSAXLE

- REMOVAL AND INSTALLATIONNZlMA-A

. .

,-27-34 Nm

20-25 ft.lbs.15-22 Nm

11-16

ft.lbs.43-55 Nm

32-39

ft.lbs.

\

60-80 Nm*43-58 ft.lbs.*60-80 Nm

/da-,, ft.lbs.

lo-12 NmI7-9

ft.lbs.I

15-2: Nm

11-16 ft.lbs.OOAOl~4

Pre-removal Operation@Removal of the Battery

rl Draining of the Transaxle Oil (Refer to

P.21-13.)l Removal of the Air Hose(Refer to GROUP 11-Air Cleaner.)

Post-installation 0erationl installation of theI!attery

l supplying of Transaxle Oil (Refer to P.21-13.)*Installation of the Air Hose

(Refer to GROUP 11 -Air Cleaner.)

l checking the Operation of the Shift Lever

l checkina the Ooeration of the Meters and Gauges

Removal steps

1. Cotter pin

2. Connection for select cable

3. Connection for shift cable

4*4. Connection for clutch release cylinder

5. Backup light switch connector

6. Connection for speedometer cable

I)* 7. Starter

8.

Lfrsaxle assembly upper part coupling

9. Transaxle mount bracket

ZKeverse the removal procedures to reinstall. ” ’(2) W : Refer to “Service Points of Removal”.

(3) ~~ : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts

(5)For tightening locations indicated by the * symbol, fjrst

tighten temporarily, and then make the final tightenrngwith the entire weight of the engine applied to the

vehicle body.

(6)If therease has been wiped from the input shaft spline

or if taeinput shaft has been replaced, apply specralgrease (MOPAR Multi-mileage Lubricant Part

No.2525035 or equivalent) to the input shaft Spline.

Page 763 of 1216

MANUAL TRANSAXLE

2f.46g

\ ,...,

,,, .,

SPECIFICATIONS

1 L,‘S. / ,‘; ,< ’,f. : ,: ; .>r

“. . ..&

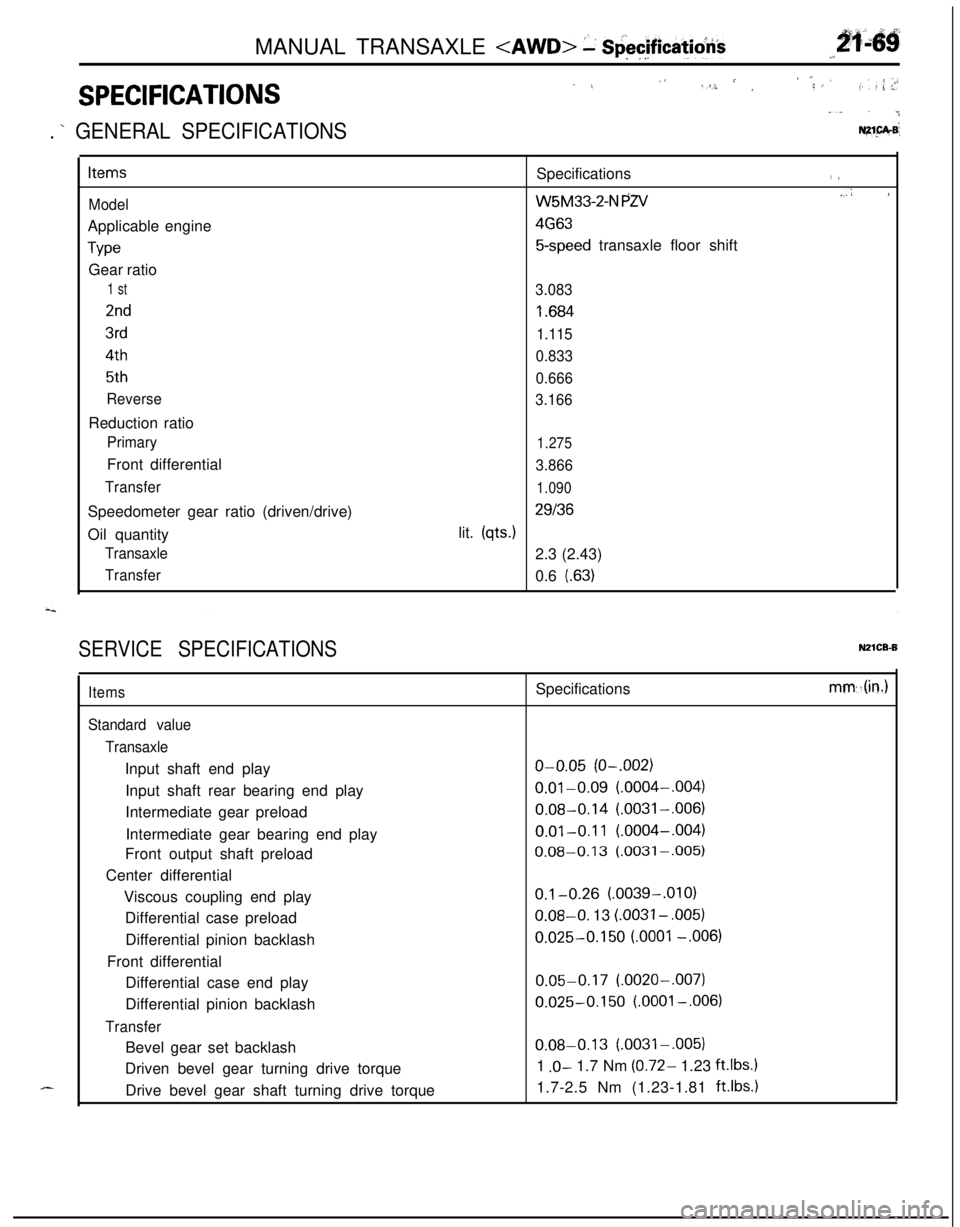

. ’ GENERAL SPECIFICATIONSNZ1.pA.B’

Items

ModelApplicable engine

TypeGear ratio

1 st

2nd

3rd

4th

5th

ReverseReduction ratio

PrimaryFront differential

TransferSpeedometer gear ratio (driven/drive)

Oil quantity

Transaxle

TransferSpecifications

(I

W5M33-2-N PZV.,A I

4G63

5-speed transaxle floor shift

3.083

I .684

1.115

0.833

0.666

3.166

1.275

3.866

1.090

29136lit.

(qts.)2.3 (2.43)

0.6

l.63)

SERVICE SPECIFICATIONSN21CB-B

d-...

Items

Standard value

TransaxleInput shaft end play

Input shaft rear bearing end play

Intermediate gear preload

Intermediate gear bearing end play

Front output shaft preload

Center differential

Viscous coupling end play

Differential case preload

Differential pinion backlash

Front differential

Differential case end play

Differential pinion backlash

TransferBevel gear set backlash

Driven bevel gear turning drive torque

Drive bevel gear shaft turning drive torqueSpecifications

o-0.05 (O-.002)

0.01-0.09 (.0004-,004)

0.08-0.14 (.0031-,006)

0.01-0.11 (.0004-,004)

0.08-0.13 (.0031-,005)

0.1-0.26 (.0039-.OlO)0.08-O. 13

LOO31 - ,005)

0.025-0.150 LOO01 -.006)

0.05-0.17 (.0020-,007)

0.025-0.150 (.OOOl-,006)

0.08-0.13 (.0031-.005)

1

.O- 1.7 Nm (0.72- 1.23 ft.lbs.11.7-2.5 Nm (1.23-1.81

ft.lbs.1

mm,.(in.)

Page 776 of 1216

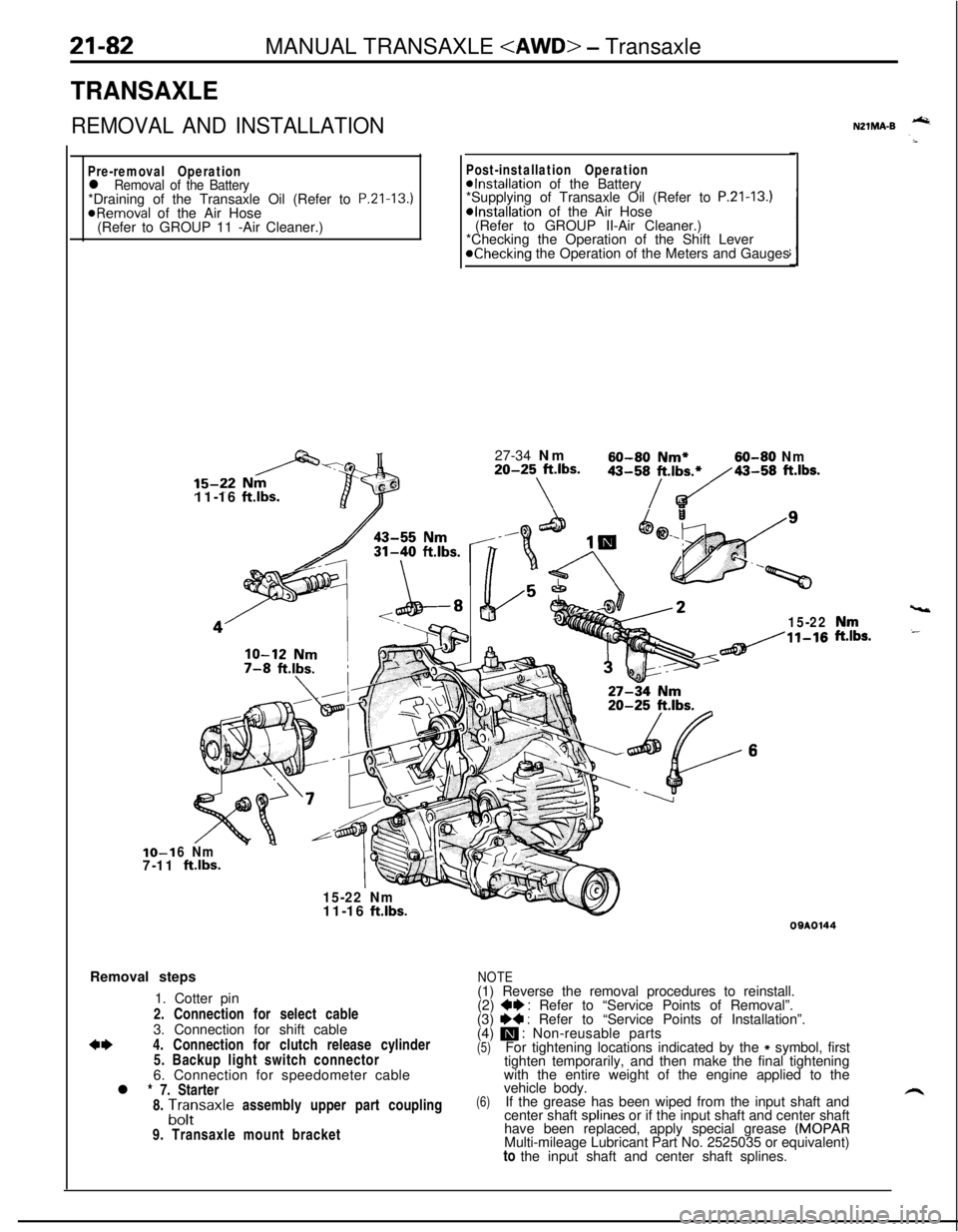

21-82MANUAL TRANSAXLE

TRANSAXLE

REMOVAL AND INSTALLATION

Pre-removal Operationl Removal of the Battery*Draining of the Transaxle Oil (Refer to P.Zl-13.)

@Removal of the Air Hose

(Refer to GROUP 11 -Air Cleaner.)IO-1

7-1111-16

ftlbs.

Post-installation Operation@Installation of the Battery

*Supplying of Transaxle Oil (Refer to P.21-13.)*Installation of the Air Hose

(Refer to GROUP II-Air Cleaner.)

*Checking the Operation of the Shift Lever

@Checking the Operation of the Meters and Gauges

27-34 Nm

60-60 Nm*60-80 Nm20-25 ft.lbs.

\

43-58/t.,b~43-58 ft.lbs.

15-22

6 Nm

ftlbs.

15-22 Nm

vt11-16

ft.lbs.Removal steps

1. Cotter pin

2. Connection for select cable

3. Connection for shift cable

*I)4. Connection for clutch release cylinder

5. Backup light switch connector

6. Connection for speedometer cable

l * 7. Starter

8.

A;;saxle assembly upper part coupling

9. Transaxle mount bracket

NZlMA-B -

,“rr,s.

09AOl44

NOTE(1) Reverse the removal procedures to reinstall.

(2)

+e : Refer to “Service Points of Removal”.

(3) I)+ : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts(5)For tightening locations indicated by the * symbol, first

tighten temporarily, and then make the final tightening

with the entire weight of the engine applied to the

(6)vehicle body.

If the grease has been wiped from the input shaft and

center shaft splines or if the input shaft and center shaft

have been replaced, apply special grease

(MOPARMulti-mileage Lubricant Part No. 2525035 or equivalent)

to the input shaft and center shaft splines.

Page 853 of 1216

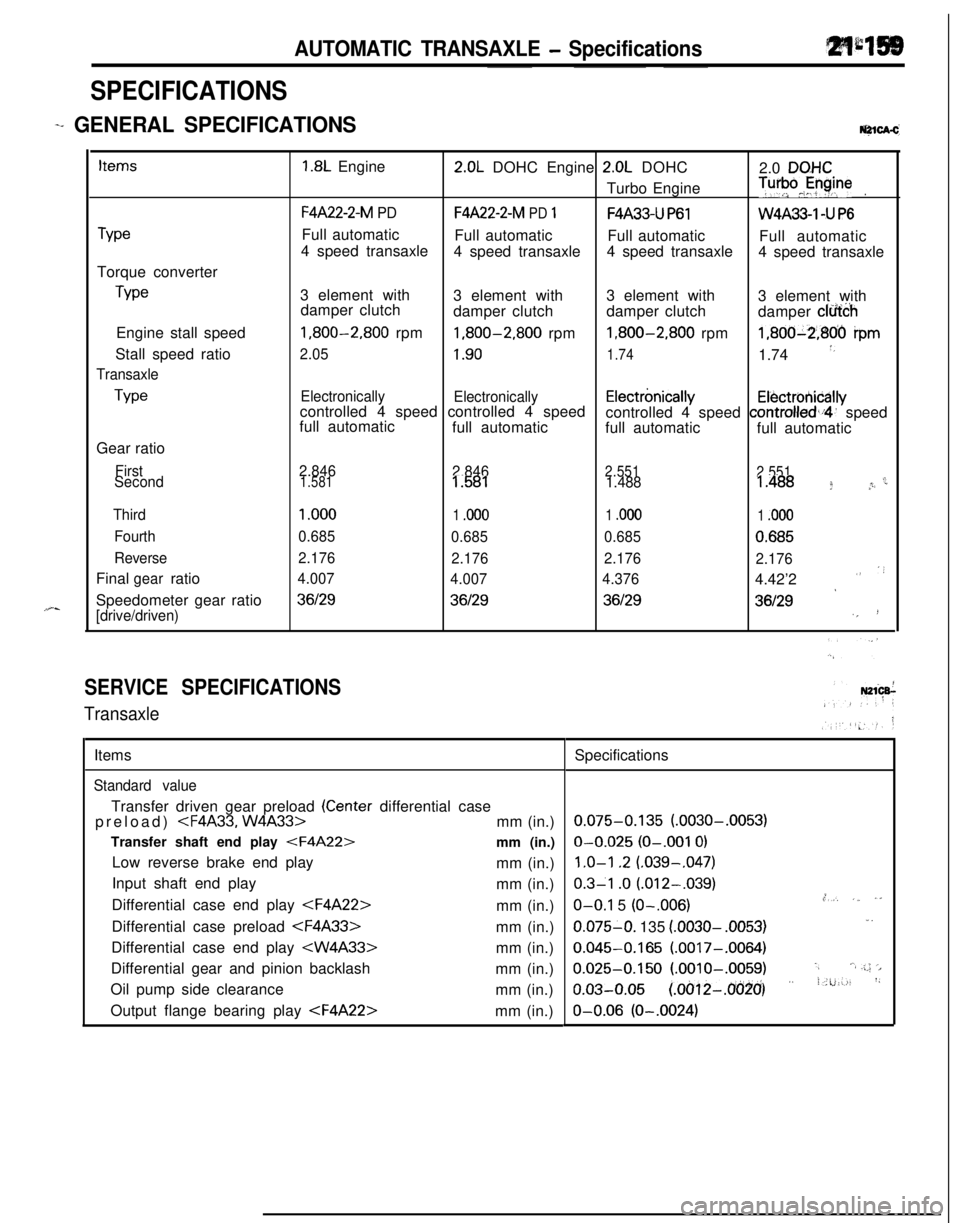

AUTOMATIC TRANSAXLE - Specifications

SPECIFICATIONS

-+ GENERAL [email protected]

TypeTorque converter

TypeEngine stall speed

Stall speed ratio

Transaxle

TypeGear ratio

First

Second

Third

Fourth

ReverseFinal ratio

gearSpeedometer gear ratio

[drive/driven)

1.8L Engine2.0L DOHC Engine 2.0L DOHC

2.0 DQHCTurbo Engine

T”‘pJyine.

F4A22-2-M PDF4A22-2-M PD 1F4A33-U P61W4A33-1 -U P6Full automatic

Full automatic

Full automatic

Full automatic

4 speed transaxle

4 speed transaxle4 speed transaxle

4 speed transaxle

3 element with

3 element with3 element with

3 element with

damper clutch

damper clutchdamper clutch

damper clfi&h

1,800-2,800 rpm1,800-2,800 rpm1,800-2,800 rpm1,800-2,806 ipm

2.051.901.741.74 *,

Electronically

Electronicallycontrolled 4 speed controlled 4 speedElectrbnicallyElectrotiicallyfull automaticcontrolled 4 speed controlled,i4’ speed

full automatic

full automatic

full automatic

2.846

2.8462.551

2.551c1.5811.5811.4881.488 f *r

1 .ooo

1 .ooo1 .ooo1 .ooo

0.685

0.6850.6850.685

2.176

2.1762.176

2.176

4.007

4.0074.3764.42’2

””

*36129361293612936129‘,!

SERVICE SPECIFICATIONS

TransaxleItems

Standard valueTransfer driven gear preload

(Center differential case

preload)

Transfer shaft end play

Low reverse brake end play

mm (in.)

Input shaft end play

mm (in.)

Differential case end play

Differential case preload

Differential case end play

Differential gear and pinion backlash

mm (in.)

Oil pump side clearance

mm (in.)

Output flange bearing play

0.075-0.135 (.0030-.0053)O-0.025

(O-.001 0)

1.0-l .2 (.039-,047)

0.3-l .o (.012-.039).,O-O.1 5 (O-.006),*, ,_ ,”0.075-O. 135

(.0030- .0053)1.

0.045-0.165 (.0017-.0064)

0.025-0.150 (.OOlO-.0059).,‘.a .;.; ‘>

o.03-o.05 (~oo12-~o(j~o’) ” i.u:-., ‘~O-0.06

(O-.0024)

Page 860 of 1216

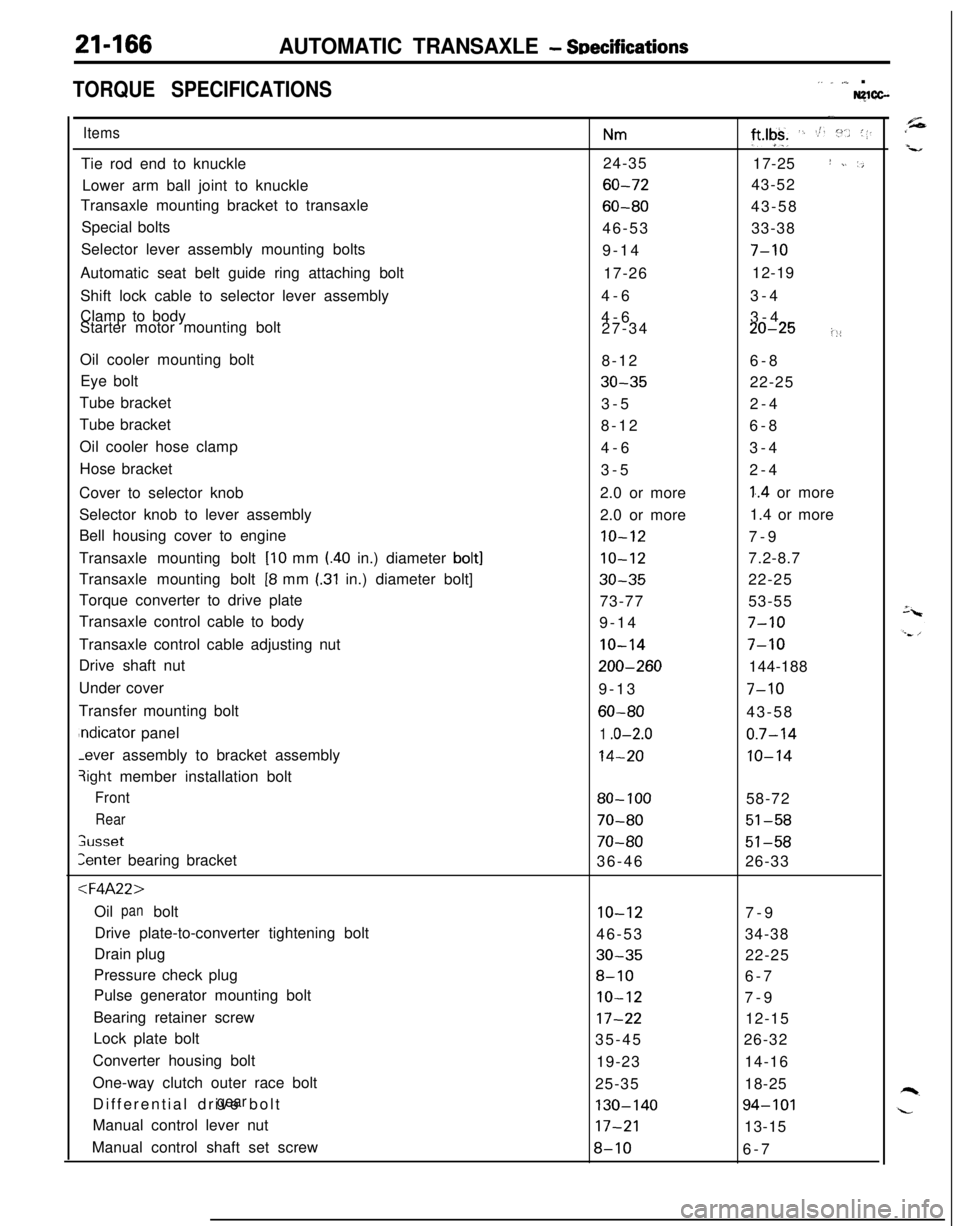

21-166AUTOMATIC TRANSAXLE - SDecifications

TORQUE SPECIFICATIONS,. _ ,,,_ .Nglcc-

ItemsTie rod end to knuckle

Lower arm ball joint to knuckle

Transaxle mounting bracket to transaxle

Special bolts

Selector lever assembly mounting bolts

Automatic seat belt guide ring attaching bolt

Shift lock cable to selector lever assembly

Clamp to body

Starter motor mounting bolt

Oil cooler mounting bolt

Eye bolt

Tube bracket

Tube bracket

Oil cooler hose clamp

Hose bracket

Cover to selector knob

Selector knob to lever assembly

Bell housing cover to engine

Transaxle mounting bolt

[lo mm l.40 in.) diameter bolt]Transaxle mounting bolt

[8 mm I.31 in.) diameter bolt]

Torque converter to drive plate

Transaxle control cable to body

Transaxle control cable adjusting nut

Drive shaft nut

Under cover

Transfer mounting boltndicator panel-ever assembly to bracket assembly

3ight member installation bolt

Front

Rear

;usset

Zenter bearing bracket

:l=4A22>Oil bolt

panDrive plate-to-converter tightening bolt

Drain plug

Pressure check plug

Pulse generator mounting bolt

Bearing retainer screw

Lock plate bolt

Converter housing bolt

One-way clutch outer race bolt

Differential drive bolt

gearManual control lever nut

Manual control shaft set screw

Nm24-35

60-72

60-8046-53

9-14

17-26

4-6

4-6

27-34

8-12

30-353-5

8-12

4-6

3-5

2.0 or more

2.0 or more

10-12

10-12

30-3573-77

9-14

IO-14

200-2609-13

60-80

1 .o-2.0

14-20

80- 100

70-80

70-8036-46

10-1246-53

30-35

8-10

IO-12

17-2235-45

19-23

25-35

130-14017-21

8-10

-.

ft*lgk+ ‘. St. :“.. (1.17-25

I ~. ‘,43-52

43-58

33-38

7-1012-19

3-4

3-4

20-25i::6-8

22-25

2-4

6-8

3-4

2-4

1..4 or more

1.4 or more

7-9

7.2-8.7

22-25

53-55

7-10

7-10144-188

7-1043-58

0.7-14

10-1458-72

51-58

51-5826-33

7-9

34-38

22-25

6-7

7-9

12-15

26-32

14-16

18-25

94-10113-15

6-7

Page 869 of 1216

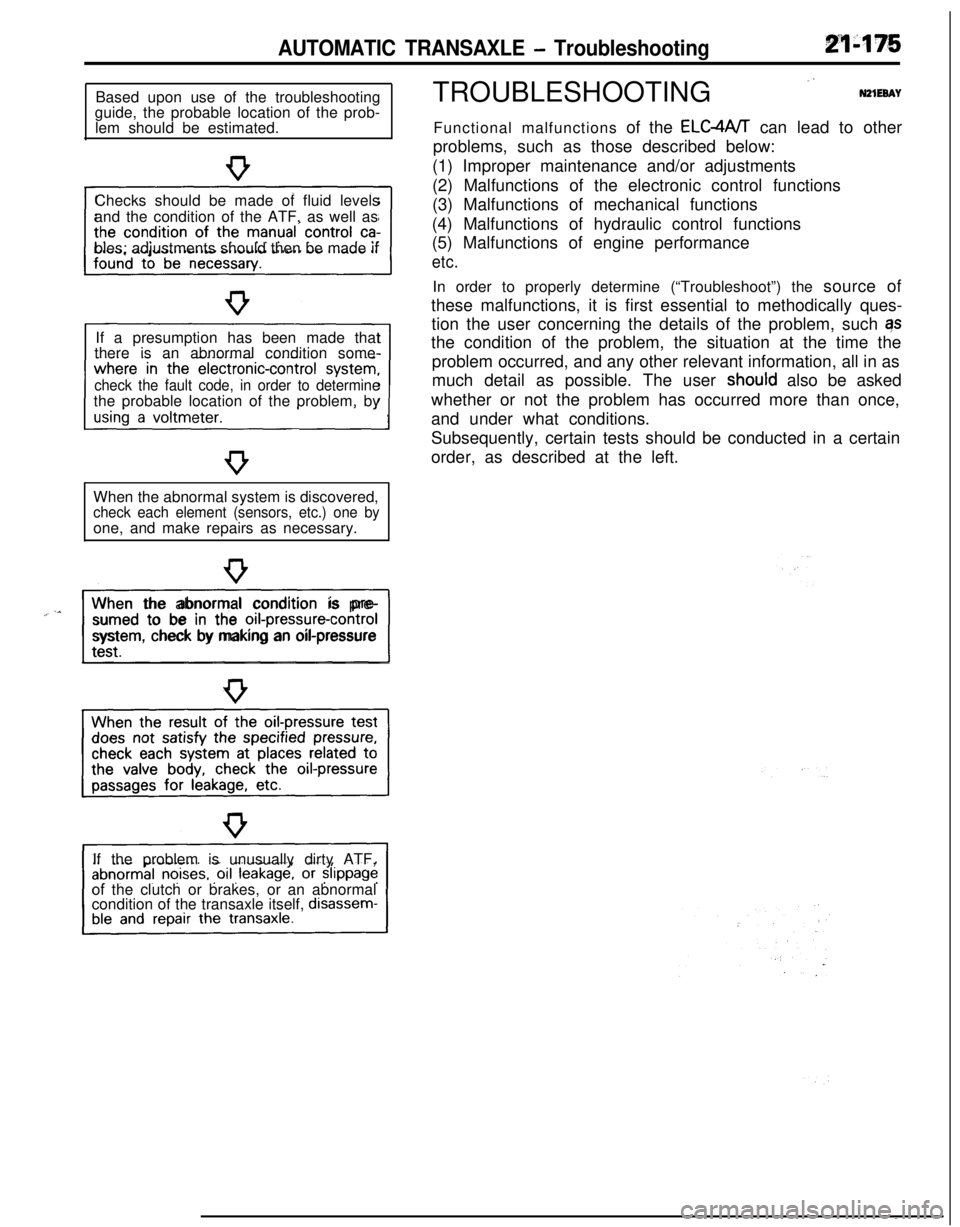

AUTOMATIC TRANSAXLE - TroubleshootingBased upon use of the troubleshooting

guide, the probable location of the prob-

lem should be estimated.

Checks should be made of fluid levels

and the condition of the ATF, as well as

bles; adjustments should then be made if

If a presumption has been made that

there is an abnormal condition some-

check the fault code, in order to determinethe probable location of the problem, by

When the abnormal system is discovered,

check each element (sensors, etc.) one byone, and make repairs as necessary.

“~^II_When the abnormal condition is pre-

sumed to be in the

orI-pressure-controlsystem, check by making an oil-pressure

If the problem is unusually dirty ATF,

of the clutch or brakes, or an abnormal

condition of the transaxle itself,

disassem-TROUBLESHOOTING

”N21EeAYFunctional malfunctions of the ELC4A/T can lead to other

problems, such as those described below:

(1) Improper maintenance and/or adjustments

(2) Malfunctions of the electronic control functions

(3) Malfunctions of mechanical functions

(4) Malfunctions of hydraulic control functions

(5) Malfunctions of engine performance

etc.In order to properly determine (“Troubleshoot”) the source of

these malfunctions, it is first essential to methodically ques-

tion the user concerning the details of the problem, such qs

the condition of the problem, the situation at the time the

problem occurred, and any other relevant information, all in as

much detail as possible. The user

shoutd also be asked

whether or not the problem has occurred more than once,

and under what conditions.

Subsequently, certain tests should be conducted in a certain

order, as described at the left.

Page 882 of 1216

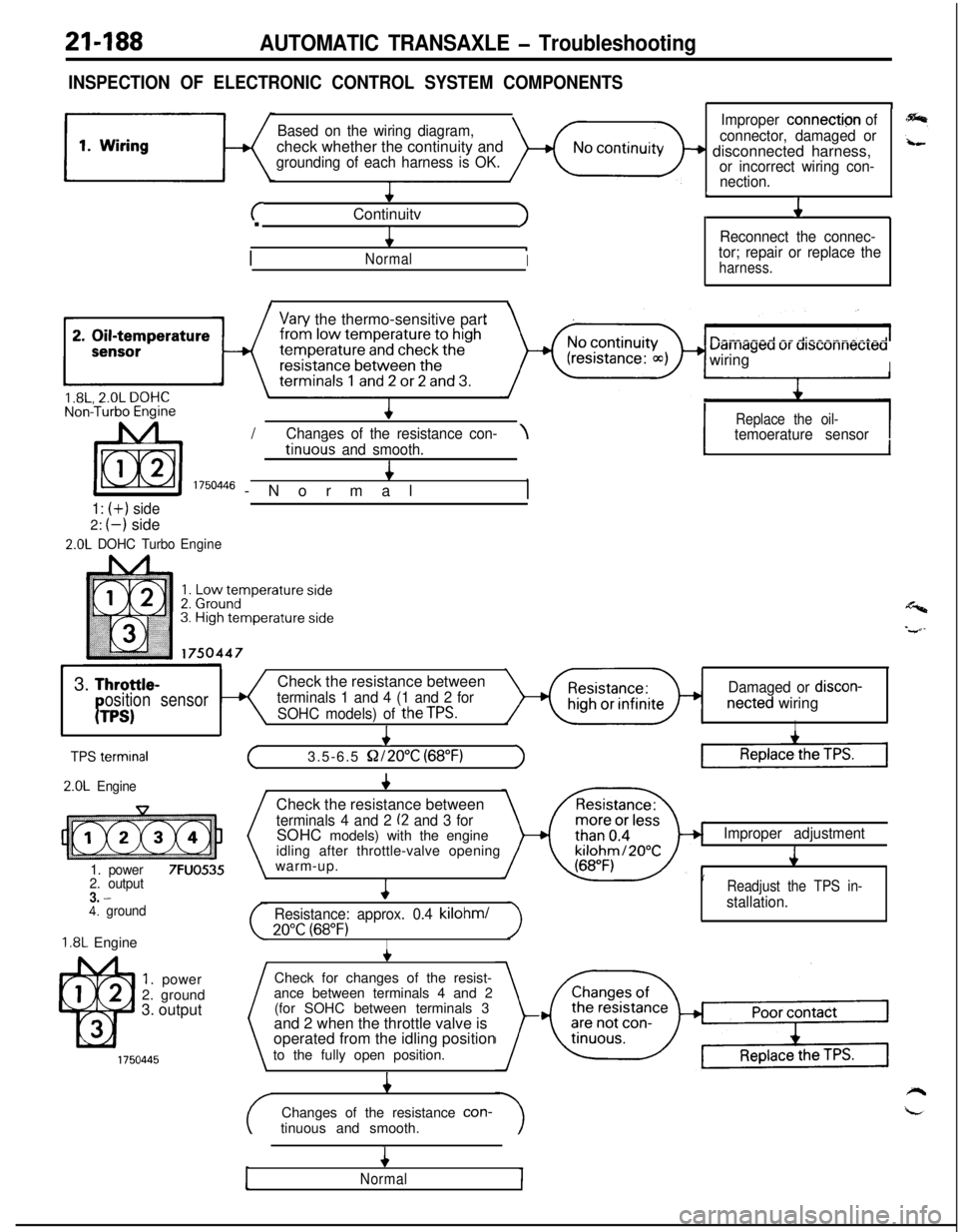

21-188AUTOMATIC TRANSAXLE - Troubleshooting

INSPECTION OF ELECTRONIC CONTROL SYSTEM COMPONENTS

Based on the wiring diagram,check whether the continuity and

grounding of each harness is OK.

+

cContinuitvJ.

4

/

.NormalI

1

Improper connection of

connector, damaged or

+ disconnected harness,or incorrect wiring con-

nection.

L

J1

Reconnect the connec-

tor; repair or replace the

harness.

I\

Vary the thermo-sensitive part

uarriageu ur ursconnecreawiring

I/

IReplace the oil-Chanaes of the resistance con-\temoerature sensortinuo& and smooth.4

I 1750446 -Normal,

1: (+) side2:

(-) side

2.0L DOHC TurboEngine

1I

Y3.

Throttle-Check the resistance betweenosition sensorterminals 1 and 4 (1 and 2 forDamaged or discon-

PTPS)SOHC models) of theTPS.netted wiringI

I

TPS termrnal

2.0L Engine

1. power

7FUO5352. output3. -4. ground

1.8L Engine

1. power

2. ground

3. output

+

(3.5-6.5 S2/2O”C (68°F)1Check the resistance between

terminals 4 and 2 (2 and 3 forSOHC models) with the engine

idling after throttle-valve opening

warm-up.

4

Resistance: approx. 0.4 kilohml

20°C (68°F)I

Improper adjustment

J

’Readjust the TPS in-

stallation.Check for changes of the resist-

ance between terminals 4 and 2

(for SOHC between terminals 3

and 2 when the throttle valve is

operated from the idling position

to the fully open position.

4Changes of the resistance con-

tinuous and smooth.

4

Normal