check oil MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 71 of 1216

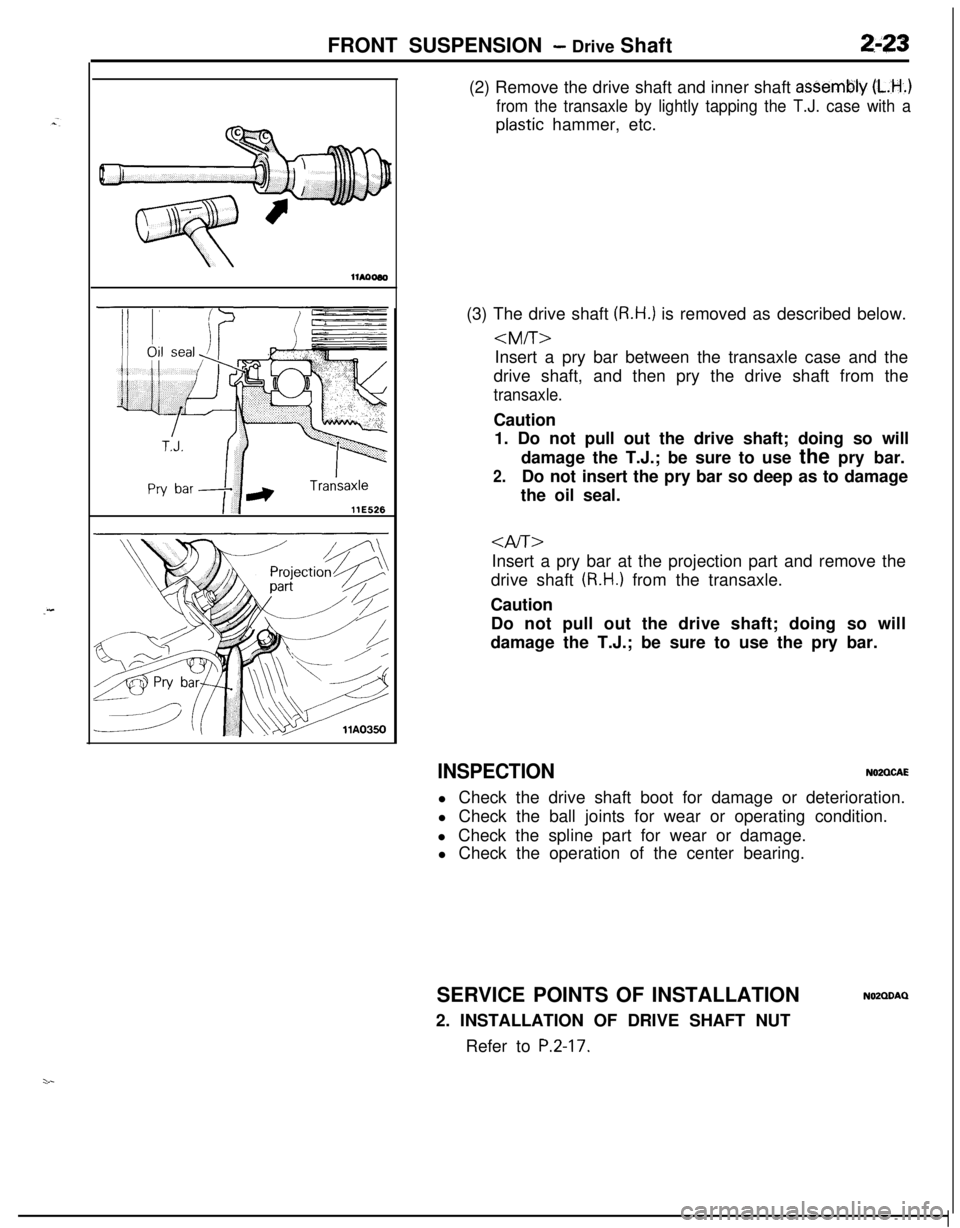

FRONT SUSPENSION - Drive Shaft2-23

llE526(2) Remove the drive shaft and inner shaft

asSembly (L.H..)

from the transaxle by lightly tapping the T.J. case with a

plastic hammer, etc.

(3) The drive shaft

(R.H.) is removed as described below.

drive shaft, and then pry the drive shaft from the

transaxle.Caution

1. Do not pull out the drive shaft; doing so will

damage the T.J.; be sure to use the pry bar.

2.Do not insert the pry bar so deep as to damage

the oil seal.

Insert a pry bar at the projection part and remove the

drive shaft

(R.H.) from the transaxle.

Caution

Do not pull out the drive shaft; doing so will

damage the T.J.; be sure to use the pry bar.

INSPECTIONN02QCAEl Check the drive shaft boot for damage or deterioration.

l Check the ball joints for wear or operating condition.

l Check the spline part for wear or damage.

l Check the operation of the center bearing.

SERVICE POINTS OF INSTALLATION

2. INSTALLATION OF DRIVE SHAFT NUT

Refer to

P.2-17.

NOZQDAQ

Page 77 of 1216

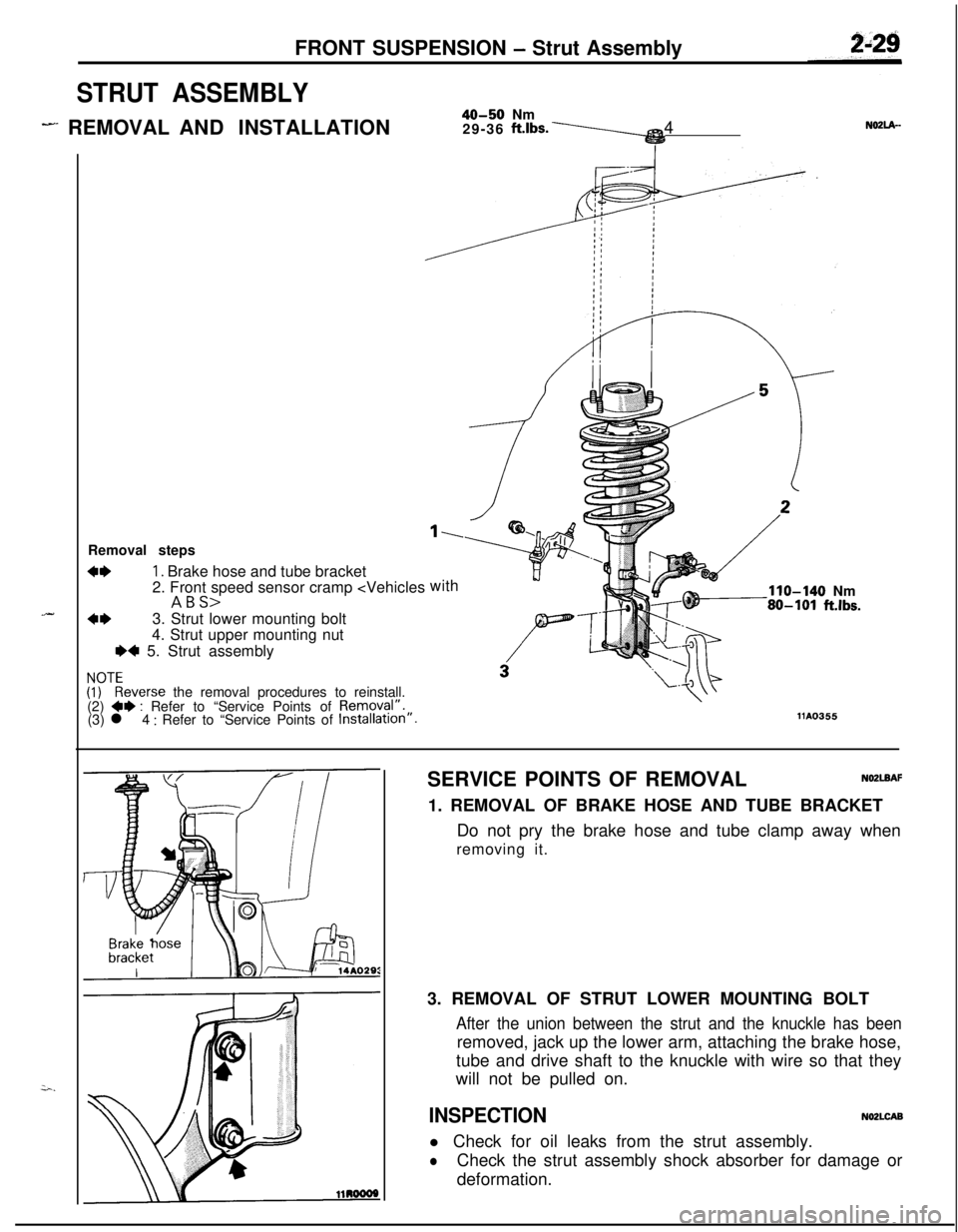

FRONT SUSPENSION - Strut Assembly

STRUT ASSEMBLY

- REMOVAL AND INSTALLATION40-50 Nm

29-36 ft.lbs.\4N02lA-

.-Removal steps

4*1. Brake hose and tube bracket

2. Front speed sensor cramp

4*3. Strut lower mounting bolt

4. Strut upper mounting nut

e+ 5. Strut assembly

!rEeverse the removal procedures to reinstall.

(2) **: Refer to “Service Points of Removal”.

(3) l 4 : Refer to “Service Points of Installation”.

1.with

110-140 Nm80-101 ft.lbs.

1110355SERVICE POINTS OF REMOVAL

NO2LBAF1. REMOVAL OF BRAKE HOSE AND TUBE BRACKET

Do not pry the brake hose and tube clamp away when

removing it.

3. REMOVAL OF STRUT LOWER MOUNTING BOLT

After the union between the strut and the knuckle has beenremoved, jack up the lower arm, attaching the brake hose,

tube and drive shaft to the knuckle with wire so that they

will not be pulled on.

INSPECTIONNO2LCABl Check for oil leaks from the strut assembly.

lCheck the strut assembly shock absorber for damage or

deformation.

Page 79 of 1216

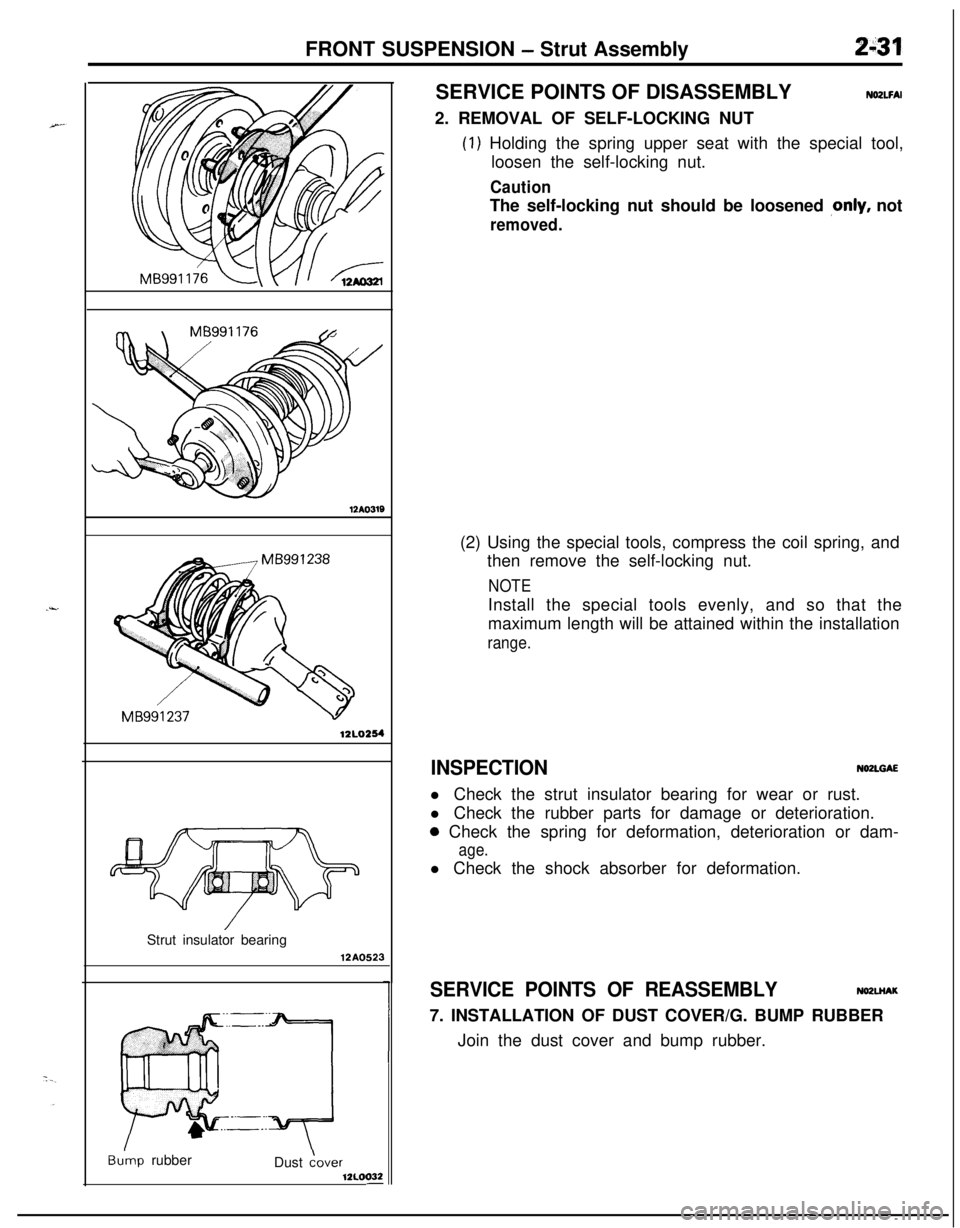

FRONT SUSPENSION - Strut Assembly

MB991237 -12l.0254

Strut insulator bearing12A0523

Bu’mp rubber

Dust Gover12LOO32-SERVICE POINTS OF DISASSEMBLY

NO2LFAI2. REMOVAL OF SELF-LOCKING NUT

(1) Holding the spring upper seat with the special tool,

loosen the self-locking nut.

CautionThe self-locking nut should be loosened

,only, not

removed.(2) Using the special tools, compress the coil spring, and

then remove the self-locking nut.

NOTEInstall the special tools evenly, and so that the

maximum length will be attained within the installation

range.

INSPECTIONNOZLGAEl Check the strut insulator bearing for wear or rust.

l Check the rubber parts for damage or deterioration.

0 Check the spring for deformation, deterioration or dam-

age.l Check the shock absorber for deformation.

SERVICE POINTS OF REASSEMBLYNO2LHAK7. INSTALLATION OF DUST COVER/G. BUMP RUBBER

Join the dust cover and bump rubber.

Page 103 of 1216

3-1

REAR AXLE

CONTENTSAXLE SHAFT

...................................................10

DIFFERENTIAL CARRIER................................19DRIVE SHAFT

..................................................13SERVICE ADJUSTMENT PROCEDURES..

.....8

GearOilLevelCheck...................................8

LimitedSlipDifferentialCheck....................9

..Rear Axle Total Backlash Check.................8Rear Wheel Bearing End Play Check

.........

8Rear Wheel Bearing Rotation Sliding

ResistanceCheck.........................................9

SPECIALTOOLS.............................................4

SPECIFICATIONS.............................................

2

GeneralSpecifications..................................2

Lubricants......................................................3Sealants and Adhesives...............................

3Service

Specifications...................................2TorqueSpecifications...................................

3

TROUBLESHOOTING......................................6Axle Shaft

Grease leakageNoise while wheels are rotatingDifferential (Conventional Differential)

Bearing noise while driving or coasting

Constant noise

Gear noise while coasting

Gear noise while driving

HeatNoise while turning

Oil leakage

Differential (Limited Slip Differential)

Abnormal noise during driving or

gear changing

Abnormal noise when cornering

Break down

Gear noise

Gear oil leakage

SeizureThe limited slip differential does

not function

Drive Shaft

Noise

Page 108 of 1216

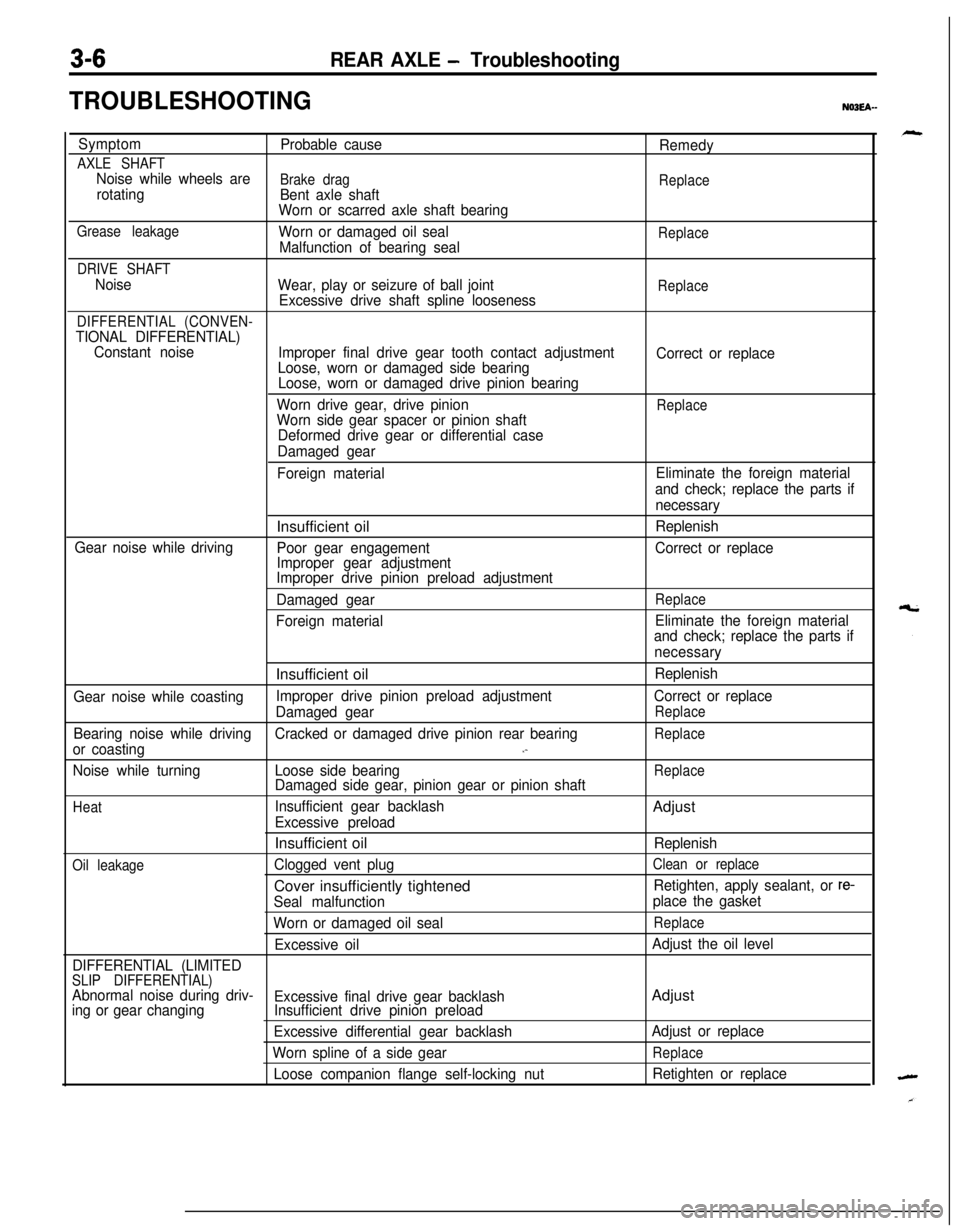

3-6REAR AXLE - Troubleshooting

TROUBLESHOOTINGNO3EA-

Symptom

Probable cause

Remedy

AXLE SHAFTNoise while wheels areBrake drag

Replacerotating

Bent axle shaft

Worn or scarred axle shaft bearing

Grease leakageWorn or damaged oil sealReplaceMalfunction of bearing seal

DRIVE SHAFT

Noise

Wear, play or seizure of ball jointReplaceExcessive drive shaft spline looseness

DIFFERENTIAL (CONVEN-TIONAL DIFFERENTIAL)

Constant noise

Improper final drive gear tooth contact adjustment

Correct or replace

Loose, worn or damaged side bearing

Loose, worn or damaged drive pinion bearing

Worn drive gear, drive pinion

ReplaceWorn side gear spacer or pinion shaft

Deformed drive gear or differential case

Damaged gear

Foreign materialEliminate the foreign material

and check; replace the parts if

necessaryInsufficient oil

Replenish

Gear noise while driving

Poor gear engagementCorrect or replace

Improper gear adjustment

Improper drive pinion preload adjustment

Damaged gear

Replace

Foreign materialEliminate the foreign material

and check; replace the parts if

necessaryInsufficient oil

Replenish

Gear noise while coastingImproper drive pinion preload adjustmentCorrect or replace

Damaged gear

Replace

Bearing noise while drivingCracked or damaged drive pinion rear bearingReplace

or coasting.-

Noise while turningLoose side bearingReplaceDamaged side gear, pinion gear or pinion shaft

HeatInsufficient gear backlashAdjust

Excessive preloadInsufficient oil

Replenish

Oil leakageClogged vent plugClean or replaceCover insufficiently tightened

Retighten, apply sealant, or re-

Seal malfunctionplace the gasket

Worn or damaged oil seal

Replace

Excessive oilAdjust the oil level

DIFFERENTIAL (LIMITED

SLIP DIFFERENTIAL)Abnormal noise during driv-

Excessive final drive gear backlashAdjusting or gear changingInsufficient drive pinion preload

Excessive differential gear backlashAdjust or replace

Worn spline of a side gear

Replace

Loose companion flange self-locking nutRetighten or replace

Page 109 of 1216

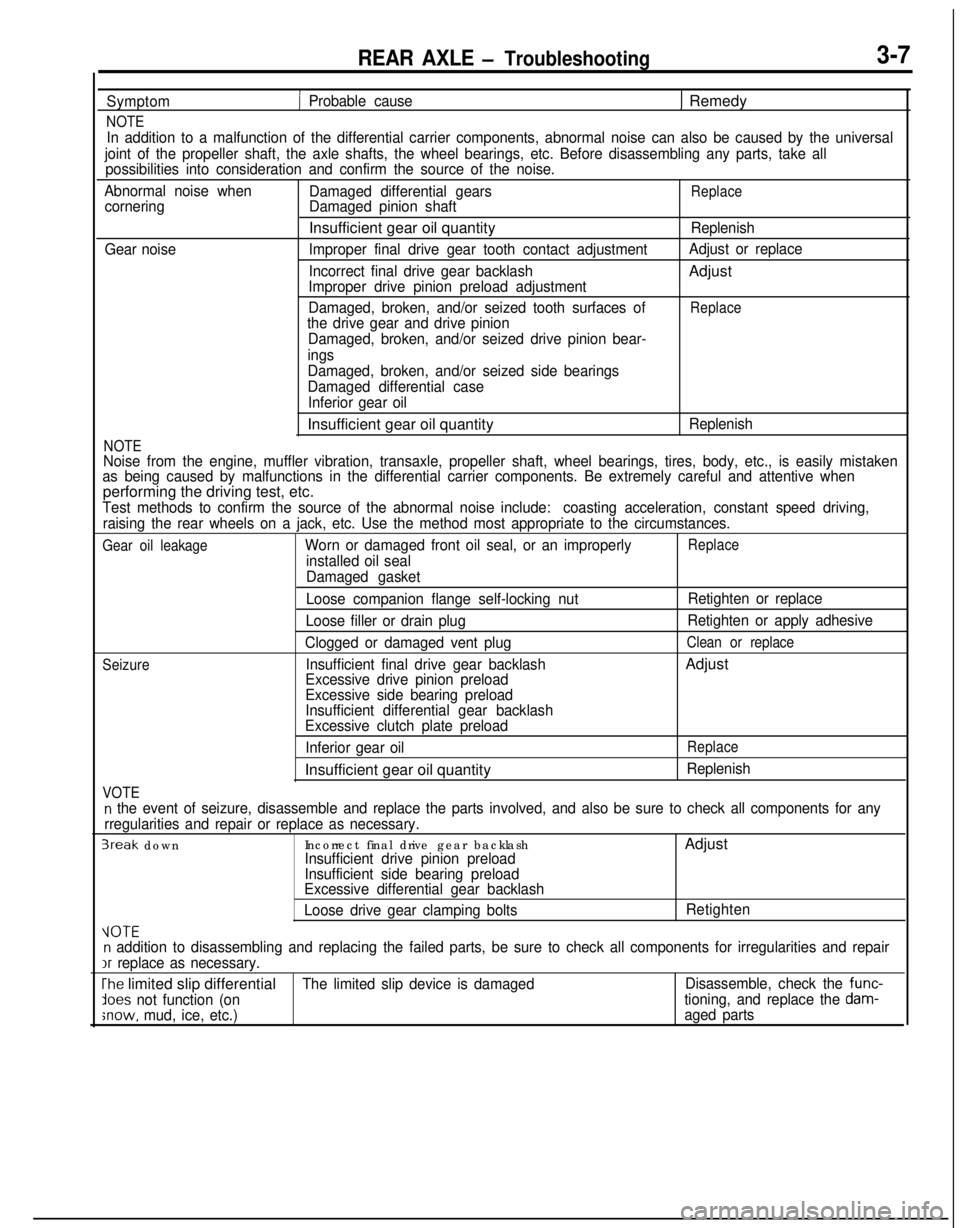

REAR AXLE - Troubleshooting3-7

Symptom

NOTE

1 Probable cause1 Remedy

In addition to a malfunction of the differential carrier components, abnormal noise can also be caused by the universal

joint of the propeller shaft, the axle shafts, the wheel bearings, etc. Before disassembling any parts, take all

possibilities into consideration and confirm the source of the noise.

Abnormal noise when

Damaged differential gears

ReplacecorneringDamaged pinion shaftInsufficient gear oil quantity

Replenish

Gear noiseImproper final drive gear tooth contact adjustmentAdjust or replace

Incorrect final drive gear backlashAdjust

Improper drive pinion preload adjustment

Damaged, broken, and/or seized tooth surfaces of

Replacethe drive gear and drive pinion

Damaged, broken, and/or seized drive pinion bear-

ings

NOTE

Damaged, broken, and/or seized side bearings

Damaged differential case

Inferior gear oilInsufficient gear oil quantity

Replenish

Noise from the engine, muffler vibration, transaxle, propeller shaft, wheel bearings, tires, body, etc., is easily mistaken

as being caused by malfunctions in the differential carrier components. Be extremely careful and attentive whenperforming the driving test, etc.

Test methods to confirm the source of the abnormal noise include:coasting acceleration, constant speed driving,

raising the rear wheels on a jack, etc. Use the method most appropriate to the circumstances.

Gear oil leakageWorn or damaged front oil seal, or an improperlyReplace

installed oil seal

Damaged gasket

Seizure

VOTE

Loose companion flange self-locking nut

Loose filler or drain plug

Clogged or damaged vent plug

Insufficient final drive gear backlash

Excessive drive pinion preload

Excessive side bearing preload

Insufficient differential gear backlash

Excessive clutch plate preload

Inferior gear oilInsufficient gear oil quantityRetighten or replace

Retighten or apply adhesive

Clean or replaceAdjust

Replace

Replenish

n the event of seizure, disassemble and replace the parts involved, and also be sure to check all components for any

rregularities and repair or replace as necessary.

3reak downIncorrect final drive gear backlashAdjustInsufficient drive pinion preload

Insufficient side bearing preload

Excessive differential gear backlash

Loose drive gear clamping boltsRetighten

VOTEn addition to disassembling and replacing the failed parts, be sure to check all components for irregularities and repairIr

replace as necessary.

The limited slip differentialThe limited slip device is damagedDisassemble, check the func-

lees not function (ontioning, and replace the dam-

;now, mud, ice, etc.)aged parts

Page 110 of 1216

3-8REAR AXLE - Service Adjustment Procedures

09D031

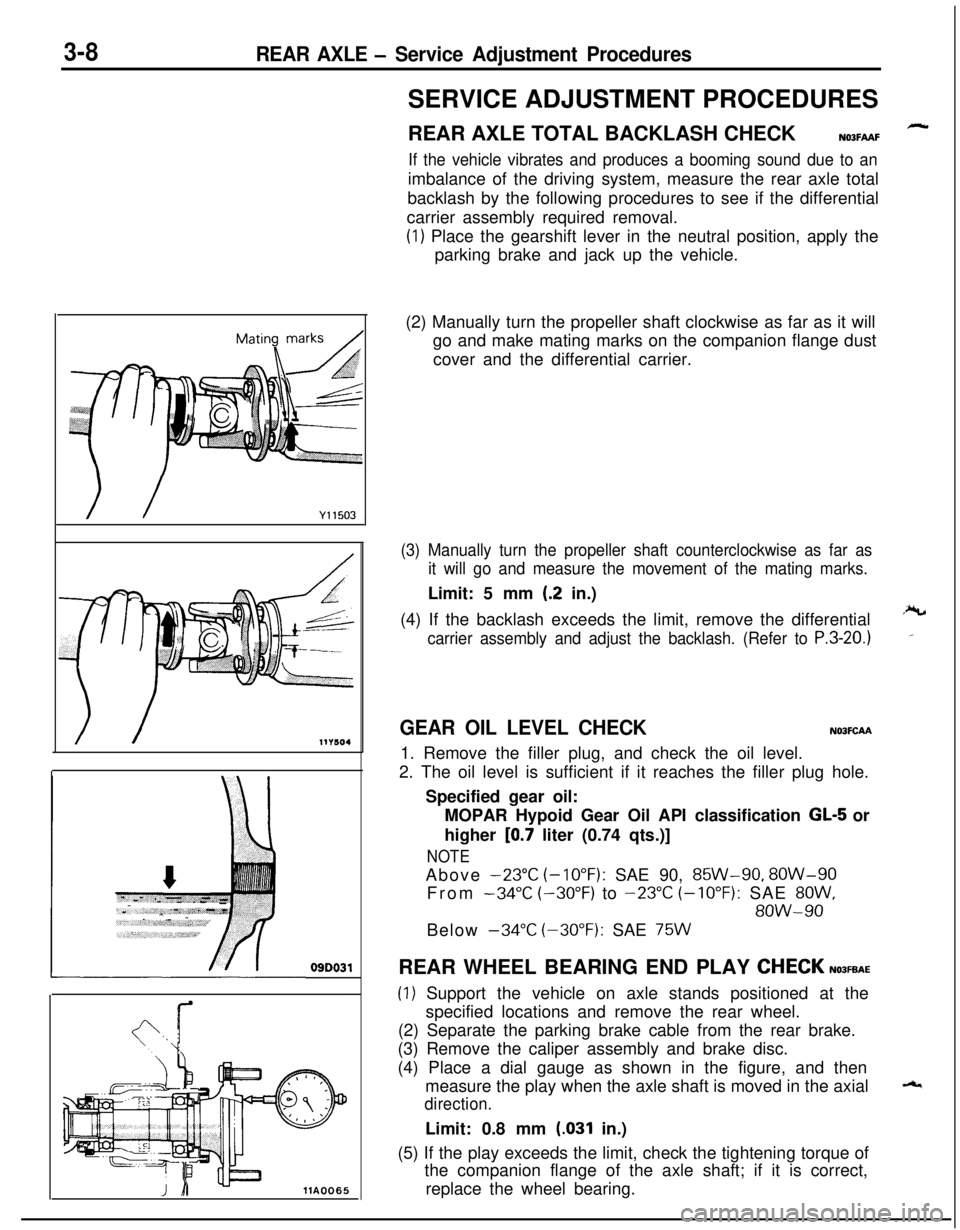

llA0065SERVICE ADJUSTMENT PROCEDURES

REAR AXLE TOTAL BACKLASH CHECK

N03FAAF

If the vehicle vibrates and produces a booming sound due to animbalance of the driving system, measure the rear axle total

backlash by the following procedures to see if the differential

carrier assembly required removal.

(1) Place the gearshift lever in the neutral position, apply the

parking brake and jack up the vehicle.

(2) Manually turn the propeller shaft clockwise as far as it will

go and make mating marks on the companion flange dust

cover and the differential carrier.

(3) Manually turn the propeller shaft counterclockwise as far as

it will go and measure the movement of the mating marks.Limit: 5 mm

(.2 in.)

(4) If the backlash exceeds the limit, remove the differential

carrier assembly and adjust the backlash. (Refer to P.3-20.)

GEAR OIL LEVEL CHECKN03FCAA1. Remove the filler plug, and check the oil level.

2. The oil level is sufficient if it reaches the filler plug hole.

Specified gear oil:

MOPAR Hypoid Gear Oil API classification

GL-5 or

higher

[0.7 liter (0.74 qts.)]

NOTEAbove

-23°C (-10°F): SAE 90, 85W-90, 8OW-90

From

-34°C (-30°F) to -23°C (-10°F): SAE 8OW,

8OW-90Below

-34°C (-30°F): SAE 75WREAR WHEEL BEARING END PLAY

CHECKN03FEAE

(1) Support the vehicle on axle stands positioned at the

specified locations and remove the rear wheel.

(2) Separate the parking brake cable from the rear brake.

(3) Remove the caliper assembly and brake disc.

(4) Place a dial gauge as shown in the figure, and then

measure the play when the axle shaft is moved in the axial

direction.Limit: 0.8 mm

(.031 in.)

(5) If the play exceeds the limit, check the tightening torque of

the companion flange of the axle shaft; if it is correct,

replace the wheel bearing.

Page 113 of 1216

12A0611

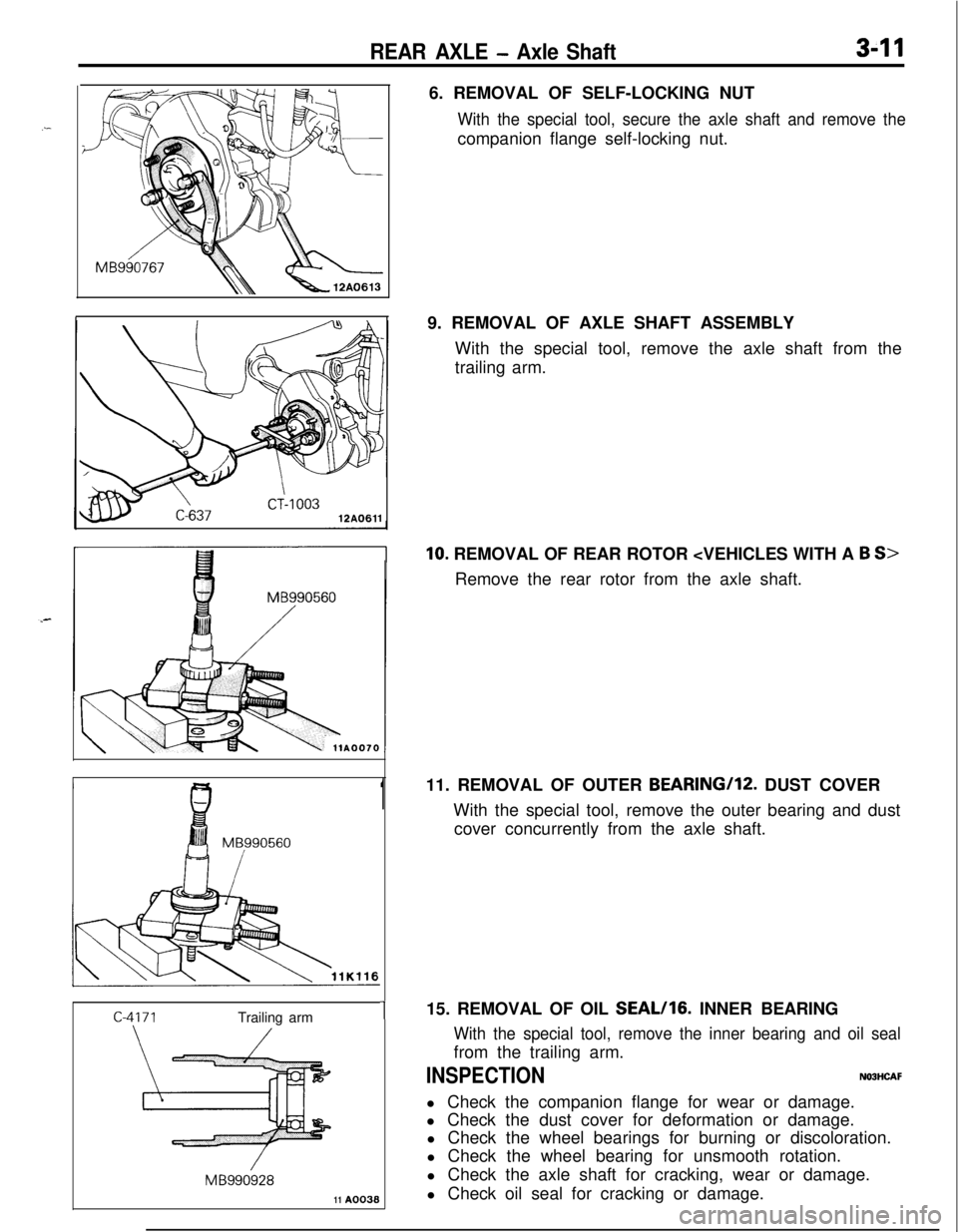

REAR AXLE - Axle Shaft3-116. REMOVAL OF SELF-LOCKING NUT

With the special tool, secure the axle shaft and remove thecompanion flange self-locking nut.

9. REMOVAL OF AXLE SHAFT ASSEMBLY

With the special tool, remove the axle shaft from the

trailing arm.

10. REMOVAL OF REAR ROTOR

111. REMOVAL OF OUTER BEARING/lZ. DUST COVER

With the special tool, remove the outer bearing and dust

cover concurrently from the axle shaft.

115. REMOVAL OF OIL SEAL/lG. INNER BEARING

MB990560

/Trailing arm

/

/MB99092811

A0038

With the special tool, remove the inner bearing and oil sealfrom the trailing arm.

INSPECTIONNOBHCAFl Check the companion flange for wear or damage.

l Check the dust cover for deformation or damage.

l Check the wheel bearings for burning or discoloration.

l Check the wheel bearing for unsmooth rotation.

l Check the axle shaft for cracking, wear or damage.

l Check oil seal for cracking or damage.

Page 116 of 1216

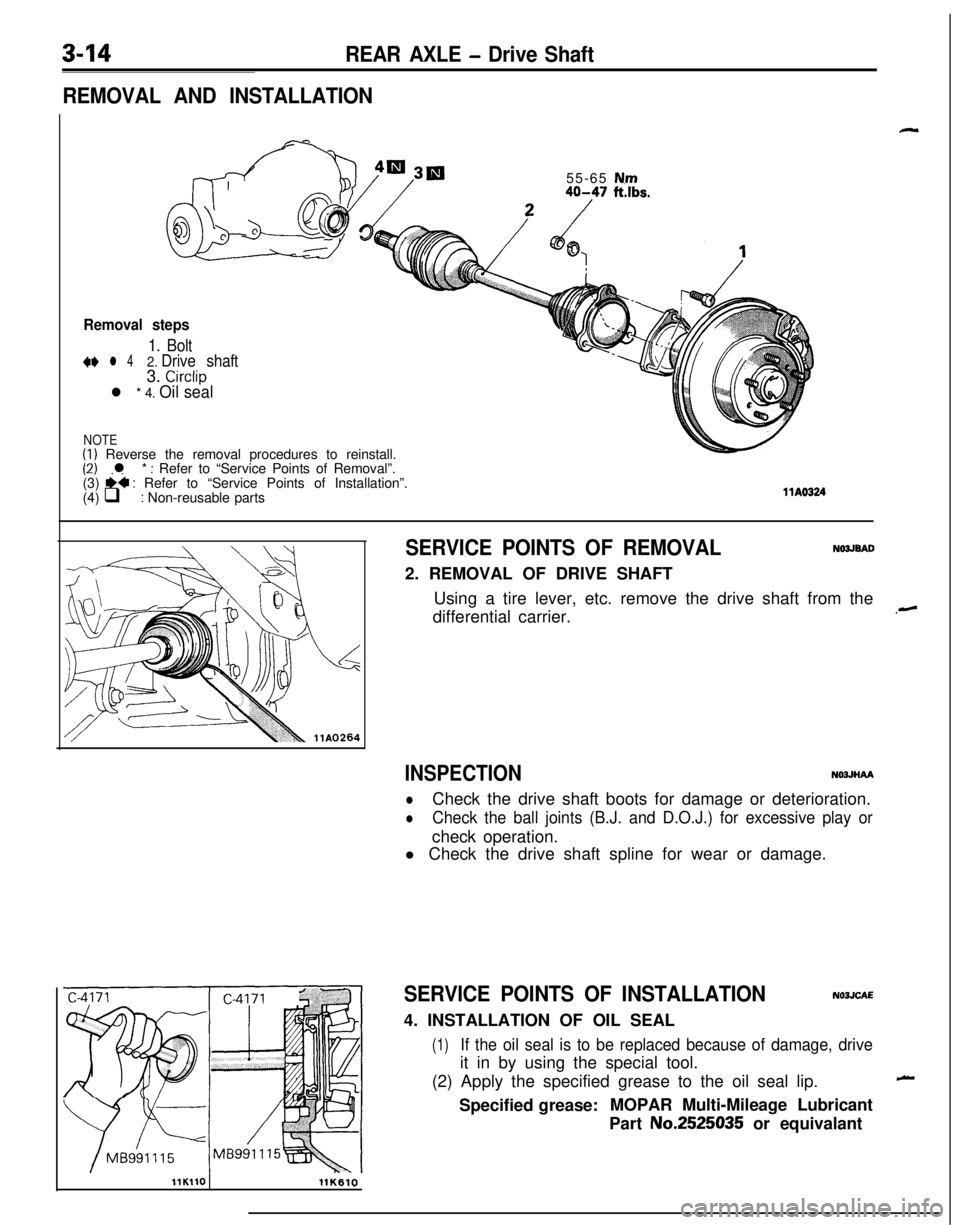

3-‘14REAR AXLE - Drive Shaft

REMOVAL AND INSTALLATION55-65

N.m40-47 ft.lbs.

Removal steps

1. Bolt+e l 42. Drive shaft3. Circlip

l * 4. Oil seal

NOTE(1) Reverse the removal procedures to reinstall.(2) l * : Refer to “Service Points of Removal”.<-,(3) ii : Refer to “Service Points of Installation”.

(4) q : Non-reusable partsllA0324

SERVICE POINTS OF REMOVALNO3JEAD2. REMOVAL OF DRIVE SHAFT

Using a tire lever, etc. remove the drive shaft from the

differential carrier.

INSPECTIONNOJJHAA

lCheck the drive shaft boots for damage or deterioration.

lCheck the ball joints (B.J. and D.O.J.) for excessive play orcheck operation.

l Check the drive shaft spline for wear or damage.

SERVICE POINTS OF INSTALLATIONN03JCAE4. INSTALLATION OF OIL SEAL

(1)If the oil seal is to be replaced because of damage, driveit in by using the special tool.

(2) Apply the specified grease to the oil seal lip.

Specified grease:MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalant

,-

-

llK110llK610

Page 127 of 1216

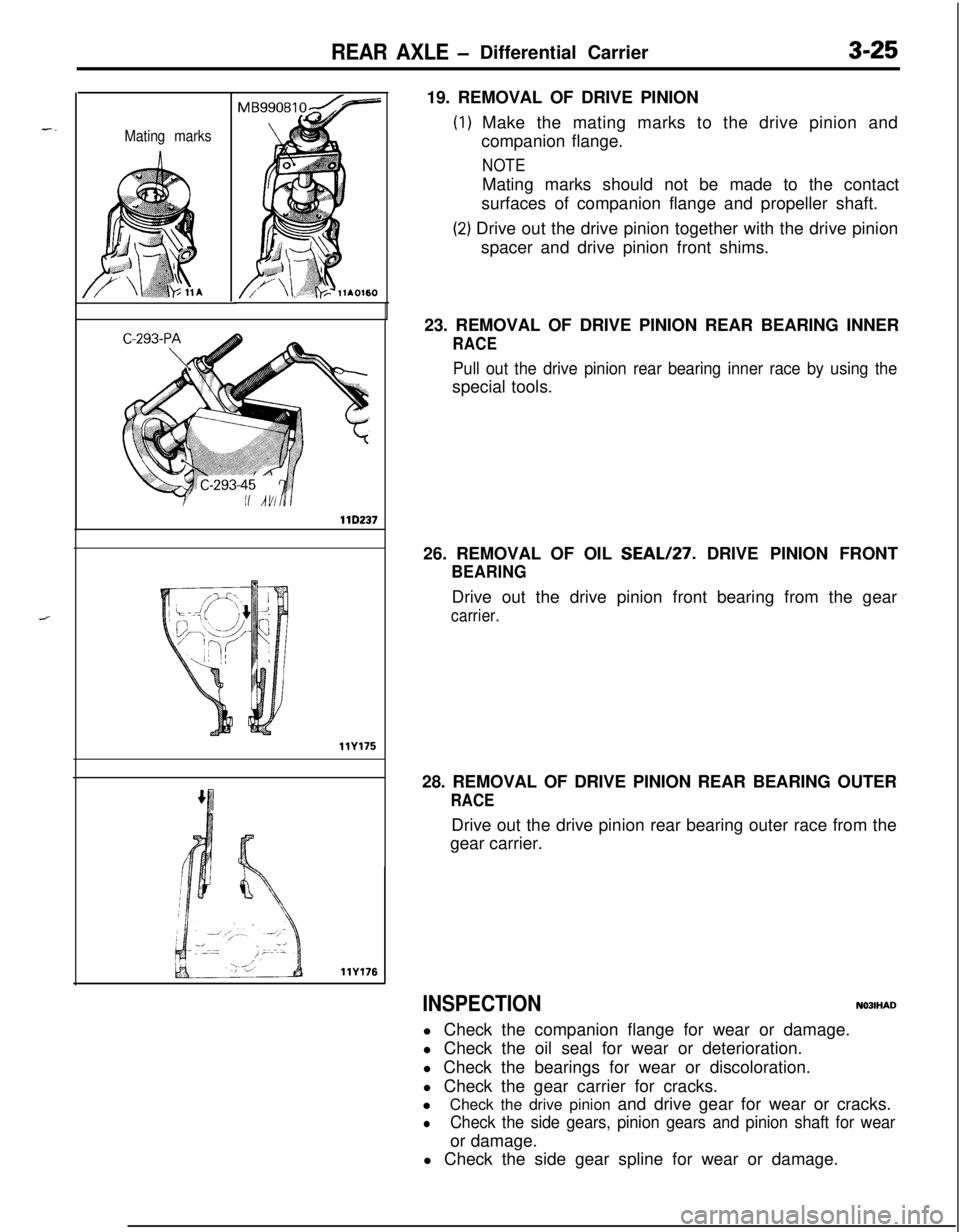

REAR AXLE -Differential Carrier3-25

Mating marks

llD237

llY175

llY17619. REMOVAL OF DRIVE PINION

) Make the mating marks to the drive pinion and

companion flange.

NOTEMating marks should not be made to the contact

surfaces of companion flange and propeller shaft.

!) Drive out the drive pinion together with the drive pinion

spacer and drive pinion front shims.

23. REMOVAL OF DRIVE PINION REAR BEARING INNER

RACE

Pull out the drive pinion rear bearing inner race by using thespecial tools.

26. REMOVAL OF OIL SEAL/27. DRIVE PINION FRONT

BEARINGDrive out the drive pinion front bearing from the gear

carrier.28. REMOVAL OF DRIVE PINION REAR BEARING OUTER

RACEDrive out the drive pinion rear bearing outer race from the

gear carrier.

INSPECTIONN03lHADl Check the companion flange for wear or damage.

l Check the oil seal for wear or deterioration.

l Check the bearings for wear or discoloration.

l Check the gear carrier for cracks.

lCheck the drive pinion and drive gear for wear or cracks.

lCheck the side gears, pinion gears and pinion shaft for wearor damage.

l Check the side gear spline for wear or damage.