heater MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 374 of 1216

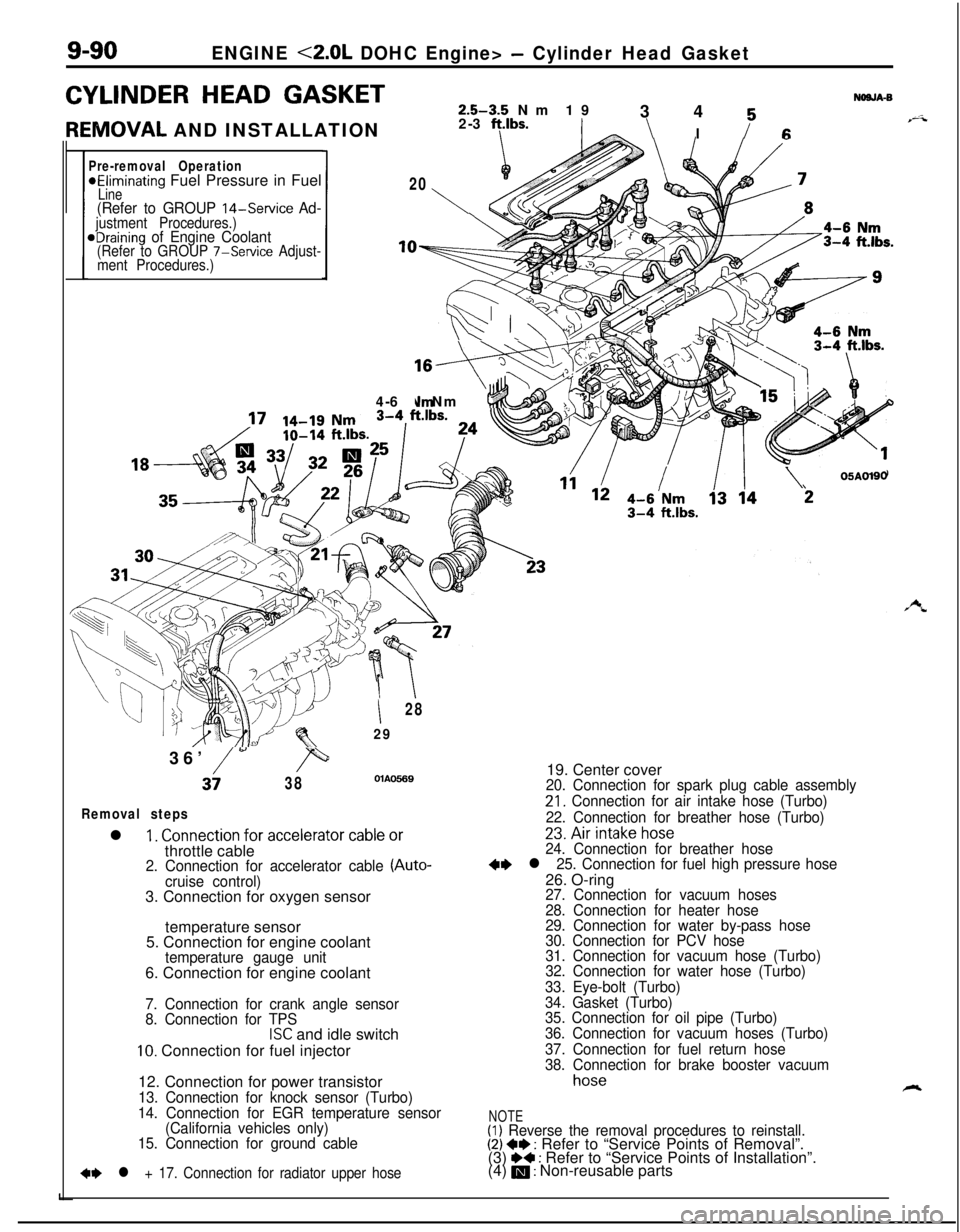

9-90ENGINE <2.0L DOHC Engine> - Cylinder Head Gasket

CYLINDER HEAD GASKETNOSJA-S2.5-3.5 Nm 19

3 4 K

REIVIOVAL AND INSTALLATION2-3 ft.lbs.\ I i-6

Pre-removal Operation*Eliminating Fuel Pressure in Fuel20Line1\(Refer to GROUP 14-Service Ad-justment Procedures.)eDraining of Engine Coolant(Refer to GROUP 7-Service Adjust-

ment Procedures.)

,,vs4-6 Nm

’

II28

2936’

/w,=

3i38OlAO5.69

Removal stepsl

1. Connection for accelerator cable orthrottle cable

2. Connection for accelerator cable (Auto-

cruise control)3. Connection for oxygen sensor

temperature sensor

5. Connection for engine coolant

temperature gauge unit6. Connection for engine coolant

7. Connection for crank angle sensor

8. Connection for TPS

ISC and idle switch

10. Connection for fuel injector

12. Connection for power transistor

13. Connection for knock sensor (Turbo)

14. Connection for EGR temperature sensor

(California vehicles only)

15. Connection for ground cable

+e l + 17. Connection for radiator upper hose

/\05ADl9019. Center cover

20. Connection for spark plug cable assembly

21. Connection for air intake hose (Turbo)

22. Connection for breather hose (Turbo)

23.Airintakehose24. Connection for breather hose+e l 25. Connection for fuel high pressure hose26. O-ring

27. Connection for vacuum hoses

28. Connection for heater hose

29. Connection for water by-pass hose

30. Connection for PCV hose

31. Connection for vacuum hose (Turbo)

32. Connection for water hose (Turbo)

33. Eye-bolt (Turbo)

34. Gasket (Turbo)

35. Connection for oil pipe (Turbo)

36. Connection for vacuum hoses (Turbo)

37. Connection for fuel return hose

38. Connection for brake booster vacuum

hoseA

NOTE(1) Reverse the removal procedures to reinstall.(2) +I) : Refer to “Service Points of Removal”.

(3) ~~ : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts

Page 435 of 1216

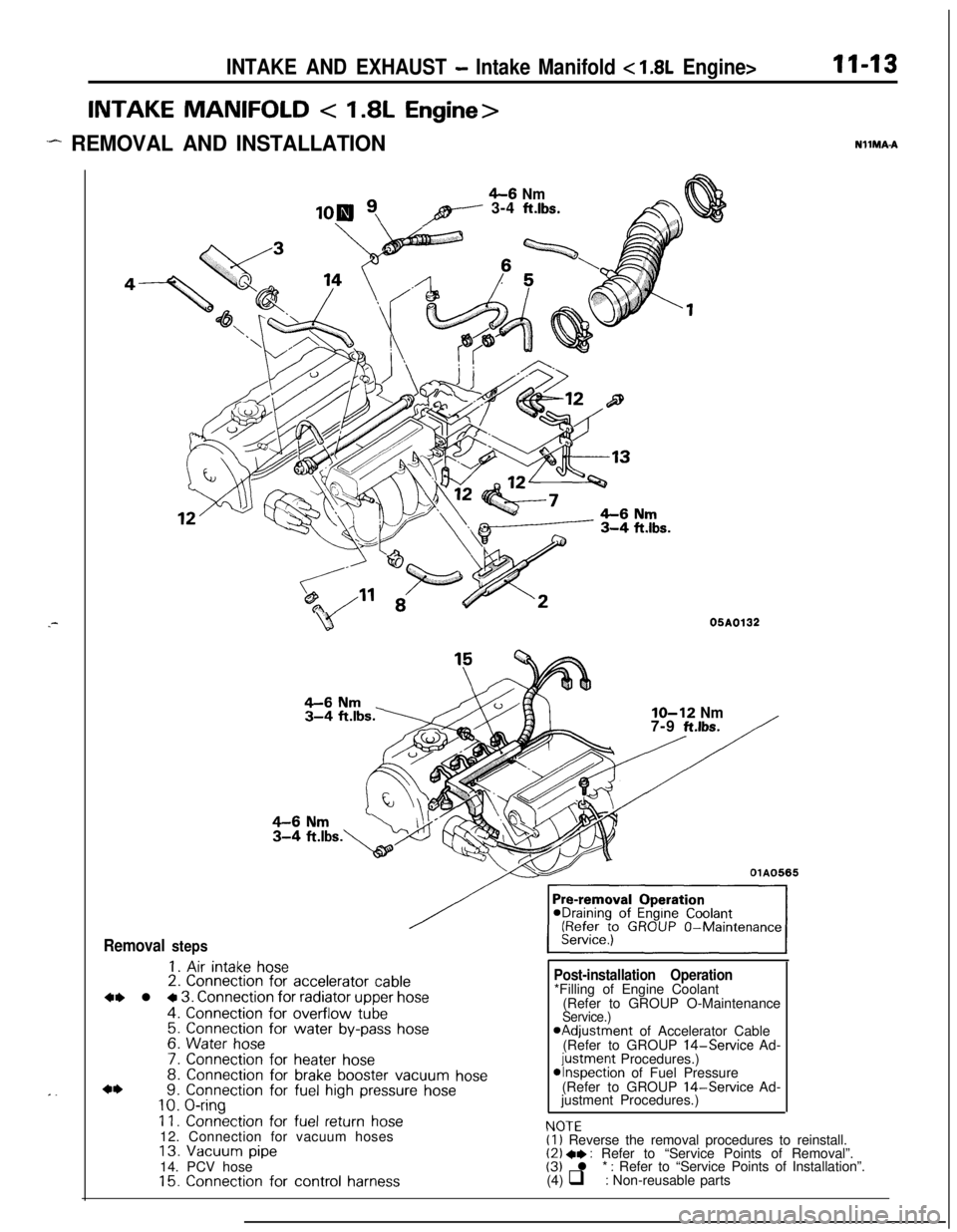

INTAKE AND EXHAUST - Intake Manifold < 1.8L Engine>

INTAKE MANIFOLD < 1.8L Engine>

.- REMOVAL AND INSTALLATION

11-13NllMA-A.-

. .

4-6 Nmpy---- 3-4 ft.lbs.

B05A0132

Removal steps

1. Air intake hose2. Connection for accelerator cable

4, l + 3. Connection for radiator upper hose

4. Connection for overflow tube5. Connection for water by-pass hose6. Water hose

7. Connection for heater hose8. Connection for brake booster vacuum hose9. Connection for fuel high pressure hose10. O-ring

11. Connection for fuel return hose12. Connection for vacuum hoses

13. Vacuum pipe14. PCV hose

15. Connection for control harness

IO-12 Nm7-9 ft.lbs.

OlA0565

Post-installation Operation

NfJTF*Filling of Engine Coolant

(Refer to GROUP O-Maintenance

Service.)aAdjustment of Accelerator Cable

(Refer to GROUP 14-Service Ad-

justment Procedures.)*Inspection of Fuel Pressure

(Refer to GROUP 14-Service Ad-

justment Procedures.)

I.” IL(1) Reverse the removal procedures to reinstall.(2) +* : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”.

(4) q : Non-reusable parts

Page 1124 of 1216

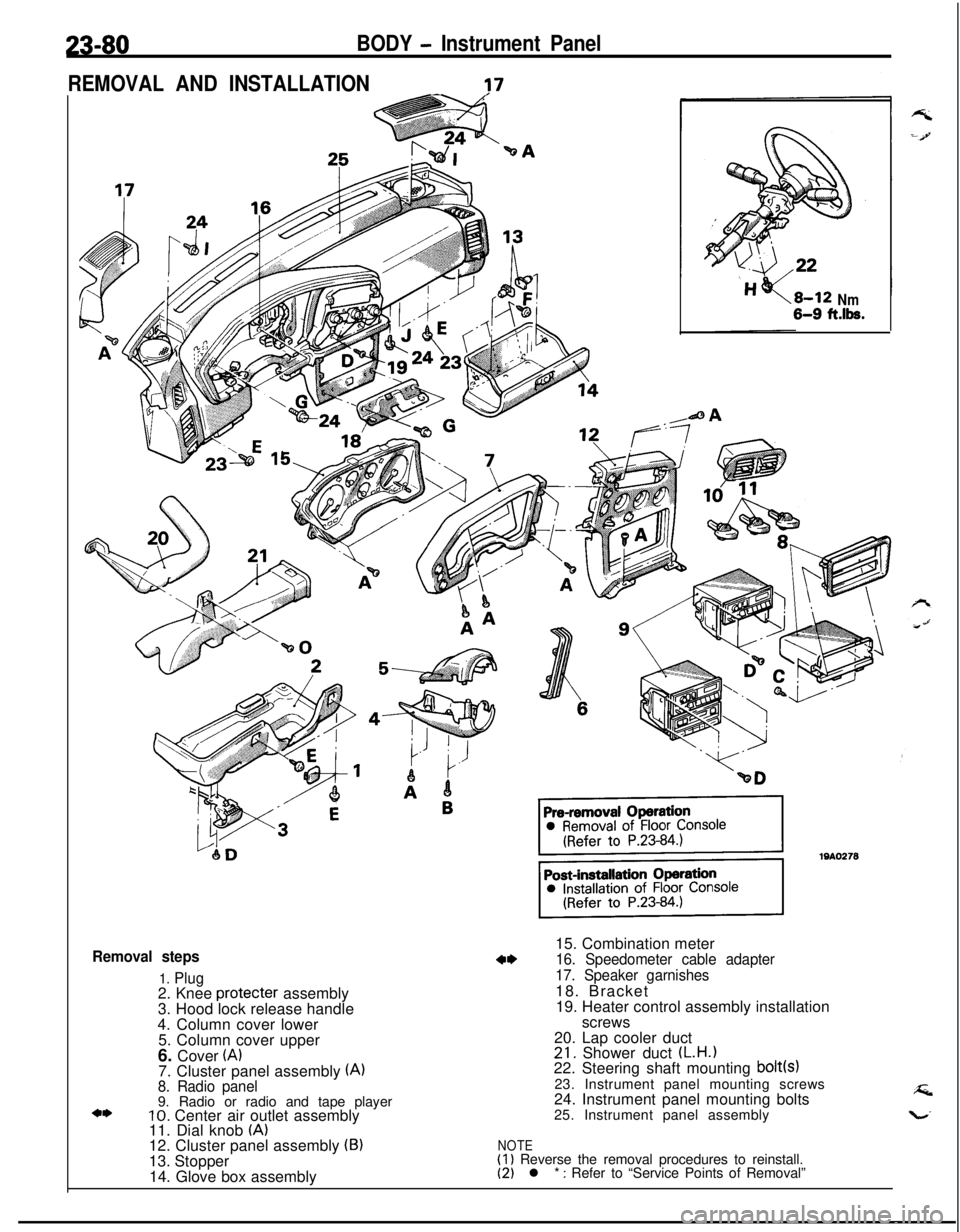

23-80BODY - Instrument Panel

REMOVAL AND INSTALLATION

-?7

Removal steps

1. Plug2. Knee protecter assembly

3. Hood lock release handle

4. Column cover lower

5. Column cover upper

6. Cover

(A)7. Cluster panel assembly (A)8. Radio panel9. Radio or radio and tape player

10. Center air outlet assembly

11. Dial knob (A)12. Cluster panel assembly (B)13. Stopper

14. Glove box assembly

Nm6-9 ft.lk.15. Combination meter

16. Speedometer cable adapter

17. Speaker garnishes18. Bracket

19. Heater control assembly installation

screws

20. Lap cooler duct

21. Shower duct (L.H.122. Steering shaft mounting bolt(s)23. Instrument panel mounting screws

24. Instrument panel mounting bolts

25. Instrument panel assembly

NOTE(1) Reverse the removal procedures to reinstall.(2) l * : Refer to “Service Points of Removal”

Page 1126 of 1216

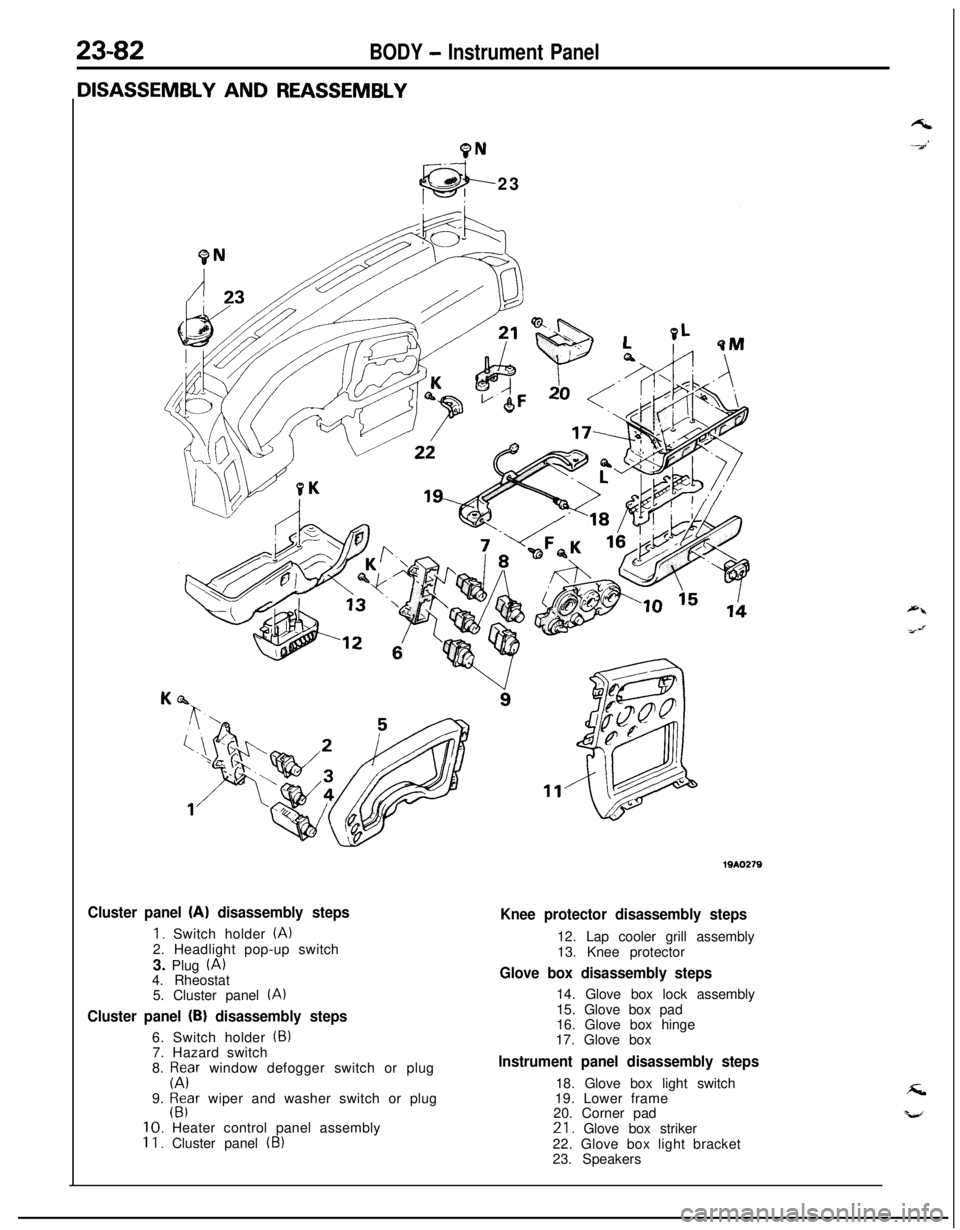

23-82BODY - Instrument Panel

9N23

Cluster panel (A) disassembly steps

1. Switch holder (A)2. Headlight pop-up switch

3. Plug

(A)4. Rheostat

5. Cluster panel

(A)

Cluster panel (B) disassembly steps6. Switch holder

(5)7. Hazard switch

8.

p;Fr window defogger switch or plug

9.

$far wiper and washer switch or plug10. Heater control panel assembly

II. Cluster panel (B)

Knee protector disassembly steps12. Lap cooler grill assembly

13. Knee protector

Glove box disassembly steps14. Glove box lock assembly

15. Glove box pad

16. Glove box hinge

17. Glove box

Instrument panel disassembly steps18. Glove box light switch

19. Lower frame

20. Corner pad21. Glove box striker

22. Glove box light bracket

23. Speakers

Page 1145 of 1216

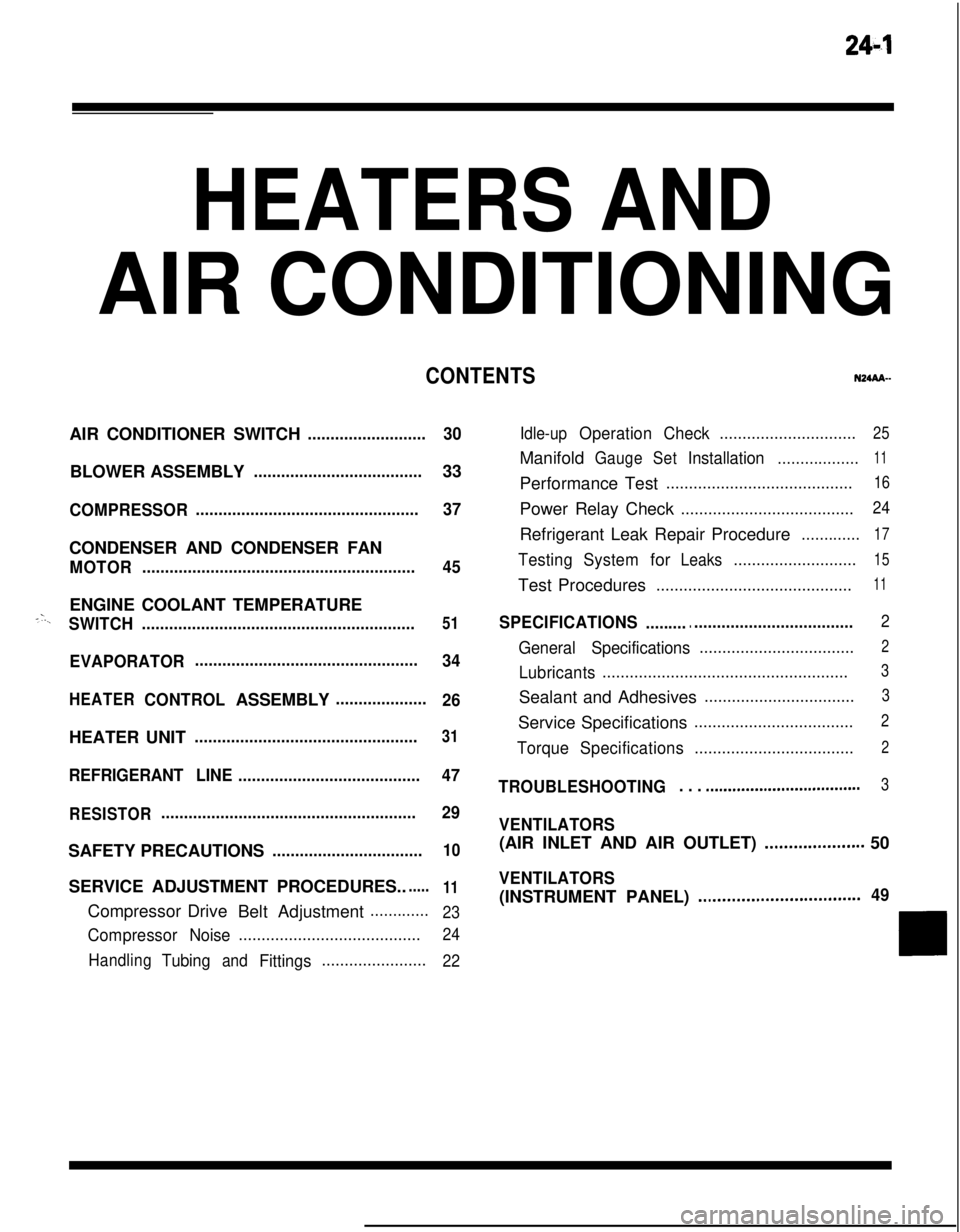

24-l

HEATERS ANDAIR CONDITIONING

CONTENTSN24M--AIR CONDITIONER SWITCH

..........................30BLOWER ASSEMBLY

.....................................33

COMPRESSOR.................................................37CONDENSER AND CONDENSER FAN

MOTOR............................................................45ENGINE COOLANT TEMPERATURE

-‘-.,SWITCH............................................................51

EVAPORATOR.................................................

34

HEATERCONTROLASSEMBLY....................

26HEATER UNIT

.................................................31

REFRIGERANTLINE........................................47

RESISTOR........................................................29SAFETY PRECAUTIONS

.................................10SERVICE ADJUSTMENT PROCEDURES..

.....11Compressor Drive

Belt Adjustment

.............

23

CompressorNoise........................................24

Handling

TubingandFittings.......................22Idle-up

OperationCheck..............................25Manifold

GaugeSetInstallation..................11Performance Test

.........................................16Power Relay Check

......................................24Refrigerant Leak Repair Procedure

.............17

TestingSystemforLeaks...........................15Test Procedures

...........................................11

SPECIFICATIONS.............................................2

General Specifications..................................2

Lubricants......................................................3Sealant and Adhesives

.................................3Service Specifications

...................................2

TorqueSpecifications...................................2

TROUBLESHOOTING. . . ..a................................3

VENTILATORS(AIR INLET AND AIR OUTLET)

..,....s............. 50

VENTILATORS(INSTRUMENT PANEL)

..,...................*...........49

Page 1146 of 1216

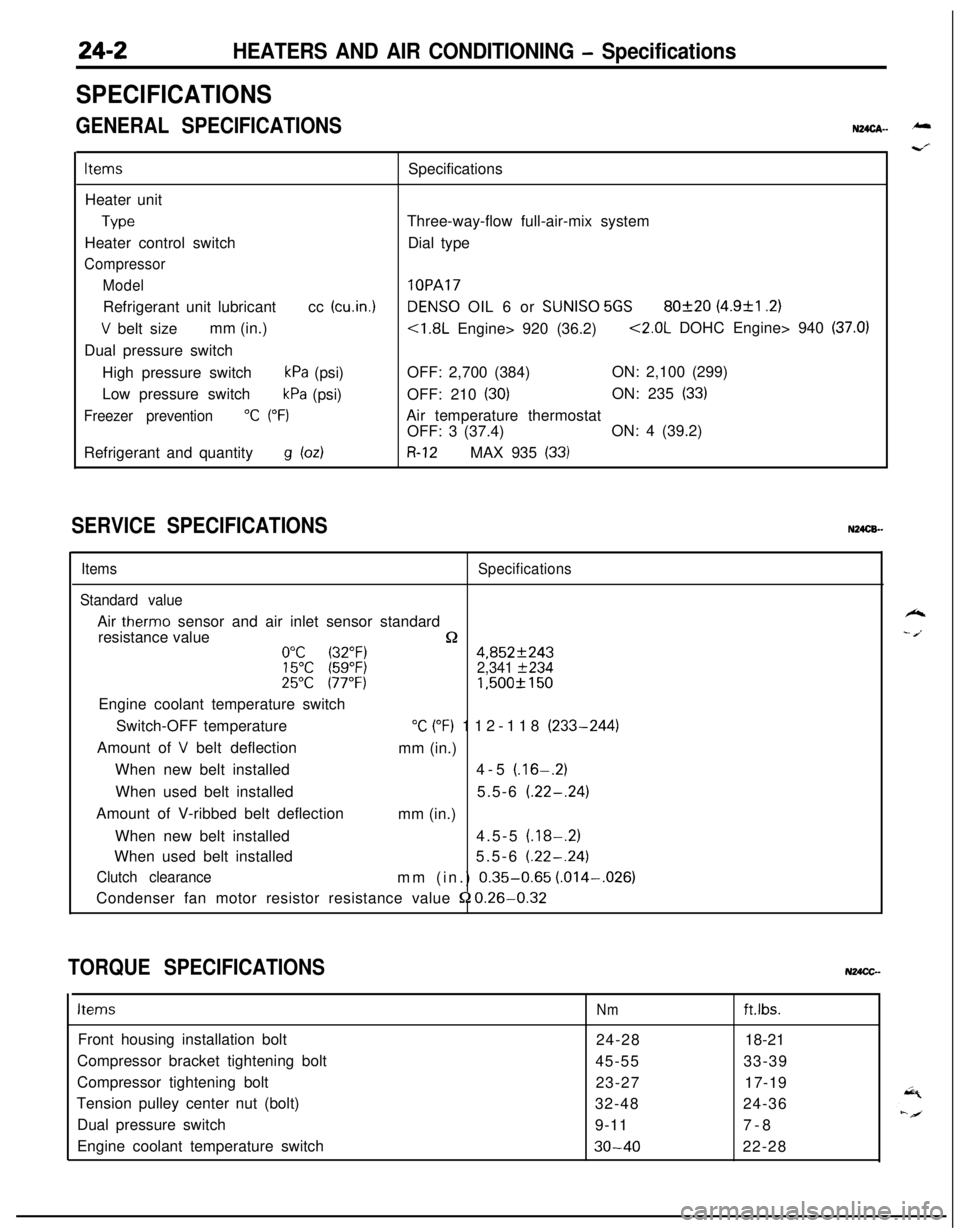

24-2HEATERS AND AIR CONDITIONING - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSN24cA- -

ItemsSpecifications

Heater unit

TypeThree-way-flow full-air-mix system

Heater control switchDial type

Compressor

Model

lOPARefrigerant unit lubricantcc

(cu.in.1DENS0 OIL 6 or SUNISO 5GS80f20 (4.9&l .2)

V belt sizemm (in.)<1.8L Engine> 920 (36.2)<2.0L DOHC Engine> 940 (37.0)Dual pressure switch

High pressure switch

kPa (psi)OFF: 2,700 (384)ON: 2,100 (299)

Low pressure switch

kPa (psi)OFF: 210 (30)ON: 235 (33)

Freezer prevention“C (“F)Air temperature thermostat

OFF: 3 (37.4)ON: 4 (39.2)

Refrigerant and quantity

g bdR-12MAX 935 (33)

SERVICE SPECIFICATIONSN24CB.-

ItemsSpecifications

Standard valueAir

therm0 sensor and air inlet sensor standard

resistance value

n0°C (32°F)4,852f24315°C (59°F)2,341 f23425°C 177°F)1,500f 150Engine coolant temperature switch

Switch-OFF temperature

“C (“F) 112-118 (233-244)

Amount of

V belt deflection

mm (in.)

When new belt installed4-5

(.16-.2)When used belt installed5.5-6

(.22-.24)Amount of V-ribbed belt deflection

mm (in.)

When new belt installed4.5-5

(.18-.2)When used belt installed5.5-6

(.22-.24)

Clutch clearancemm (in.) 0.35-0.65 (.014-,026)

Condenser fan motor resistor resistance value

52 0.26-0.32

TORQUE SPECIFICATIONSN24CC-

ItemsNmft.lbs.Front housing installation bolt

24-2818-21

Compressor bracket tightening bolt

45-5533-39

Compressor tightening bolt

23-2717-19

Tension pulley center nut (bolt)

32-4824-36

Dual pressure switch

9-117-8

Engine coolant temperature switch

30-4022-28

k

- /.

Page 1147 of 1216

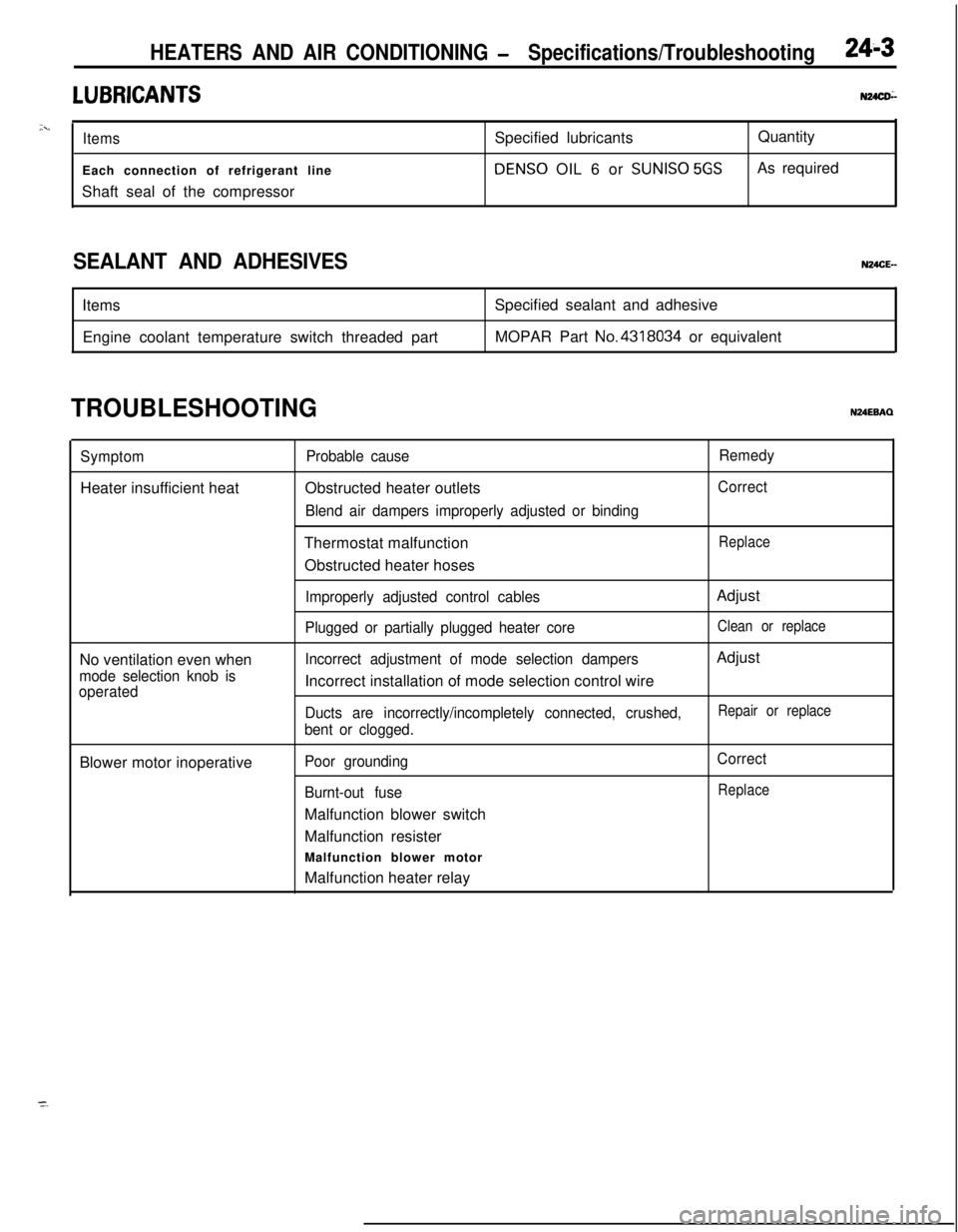

HEATERS AND AIR CONDITIONING - Specifications/Troubleshooting24-3LUBRICANTS

u24as-

;xiItemsSpecified lubricantsQuantity

Each connection of refrigerant lineDENS0 OIL 6 or

SUNISO 5GSAs required

Shaft seal of the compressor

SEALANT AND ADHESIVES, Items

Engine coolant temperature switch threaded partSpecified sealant and adhesive

MOPAR Part No.4318034 or equivalentN24CE-

TROUBLESHOOTINGN24EBAQ

SymptomHeater insufficient heat

No ventilation even when

mode selection knob is

operatedBlower motor inoperative

Probable causeObstructed heater outlets

Blend air dampers improperly adjusted or bindingThermostat malfunction

Obstructed heater hoses

Improperly adjusted control cables

Plugged or partially plugged heater core

Incorrect adjustment of mode selection dampersIncorrect installation of mode selection control wire

Ducts are incorrectly/incompletely connected, crushed,

bent or clogged.

Poor grounding

Burnt-out fuseMalfunction blower switch

Malfunction resister

Malfunction blower motor

Malfunction heater relay

Remedy

Correct

ReplaceAdjust

Clean or replaceAdjust

Repair or replace

Correct

Replace

Page 1148 of 1216

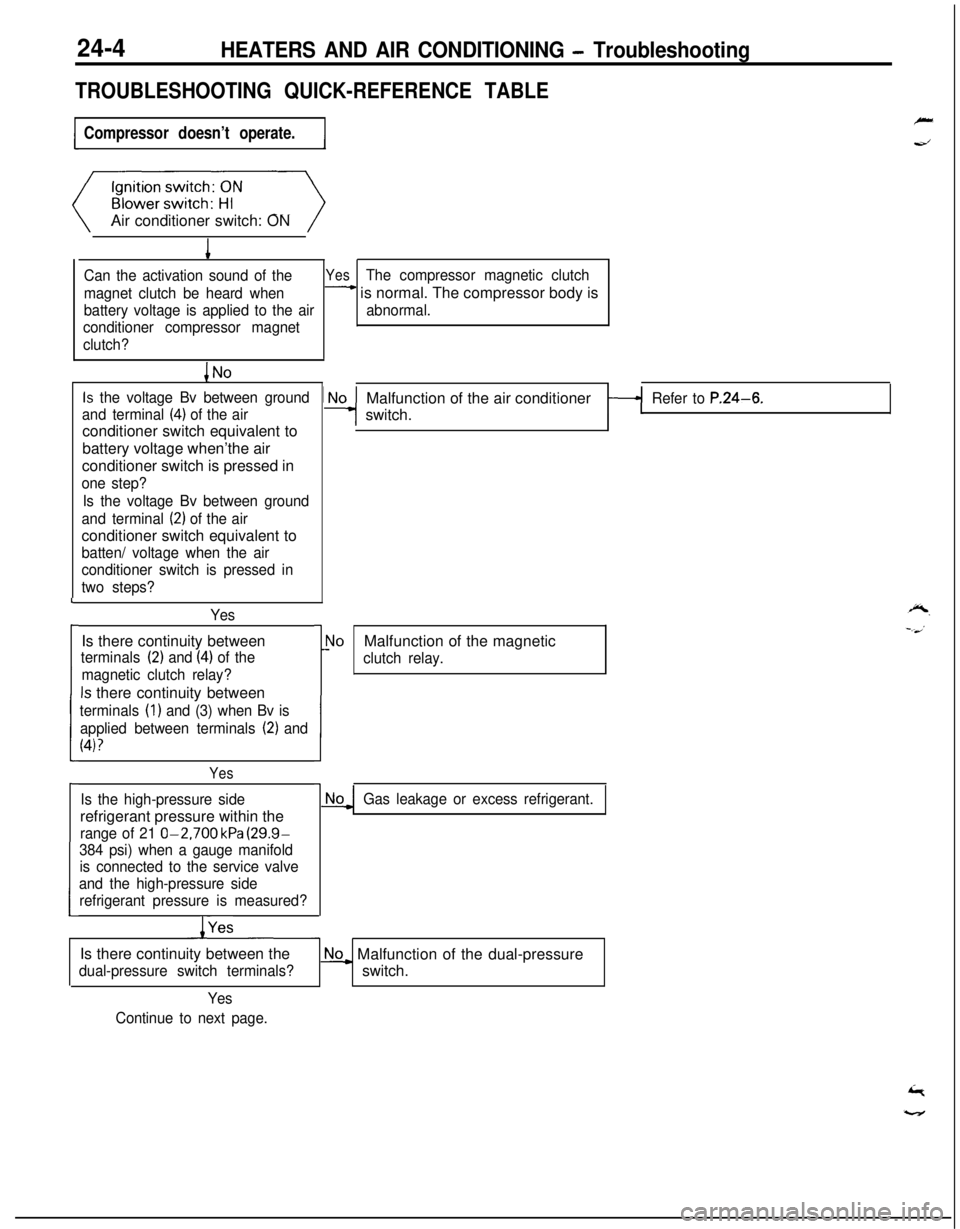

24-4HEATERS AND AIR CONDITIONING - Troubleshooting

TROUBLESHOOTING QUICK-REFERENCE TABLE

Compressor doesn’t operate.Air conditioner switch: ON

1

Can the activation sound of theYesThe compressor magnetic clutch

magnet clutch be heard when

- is normal. The compressor body is

battery voltage is applied to the airabnormal.

conditioner compressor magnet

clutch?

Is the voltage Bv between ground

and terminal

(4) of the airconditioner switch equivalent to

battery voltage when’the air

conditioner switch is pressed in

one step?

Is the voltage Bv between ground

and terminal

(2) of the airconditioner switch equivalent to

batten/ voltage when the air

conditioner switch is pressed in

two steps?

YesIs there continuity between

terminals (2) and (4) of the

magnetic clutch relay?

Is there continuity between

terminals (1) and (3) when Bv is

applied between terminals

(2) and

(4)?

L

i

I

Yes

Is the high-pressure siderefrigerant pressure within the

range of 21 O-2,700 kPa (29.9-

384 psi) when a gauge manifold

is connected to the service valve

and the high-pressure side

refrigerant pressure is measured?

/YesMalfunction of the air conditioner

switch.

Refer to P.24-6.

r

1!

\loMalfunction of the magnetic

clutch relay.

Gas leakage or excess refrigerant.Is there continuity between the

dual-pressure switch terminals?

No_ Malfunction of the dual-pressure

switch.

Yes

Continue to next page.

Page 1149 of 1216

HEATERS AND AIR CONDITIONING - Troubleshooting24-5

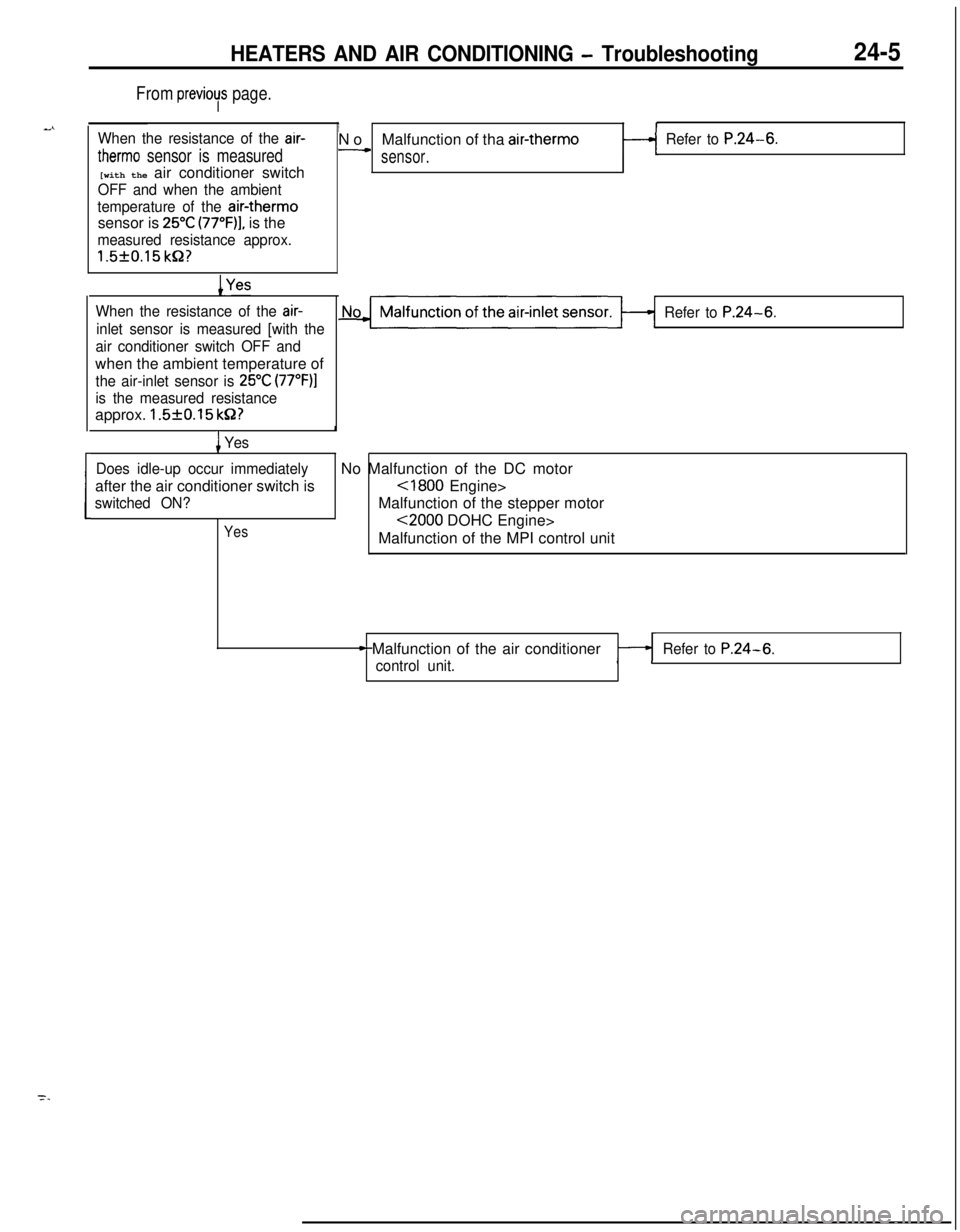

From previoys page.

When the resistance of the air-

therm0 sensor is measured[with the air conditioner switch

OFF and when the ambient

temperature of the

air-therm0sensor is

25°C (77“F)], is the

measured resistance approx.

1.5f0.15 kP?

INoMalfunction of tha air-therm0Refer to P.24-6.-sensor.

Refer to P.24-6.

1Yes

When the resistance of the air-

inlet sensor is measured [with the

air conditioner switch OFF andwhen the ambient temperature of

the air-inlet sensor is 25°C (77”F)l

is the measured resistanceapprox.

1.5f0.15 k&2?I

1 Yes

Does idle-up occur immediatelyNo Malfunction of the DC motor

after the air conditioner switch is

cl800 Engine>

switched ON?Malfunction of the stepper motor

Yes~2000 DOHC Engine>

Malfunction of the MPI control unit

* Malfunction of the air conditioner

control unit.Refer to P.24-6.

Page 1150 of 1216

24-6HEATERS AND AIR CONDITIONING - TroubleshootingAIR CONDITIONER CONTROL

UNIT CIRCUIT

1 Battery IBlower switch

litalAir conditioner

IAir inlet Air outlet1-isensorsensor

temperature

Corn- L Tpressor

relayI IMagnetic

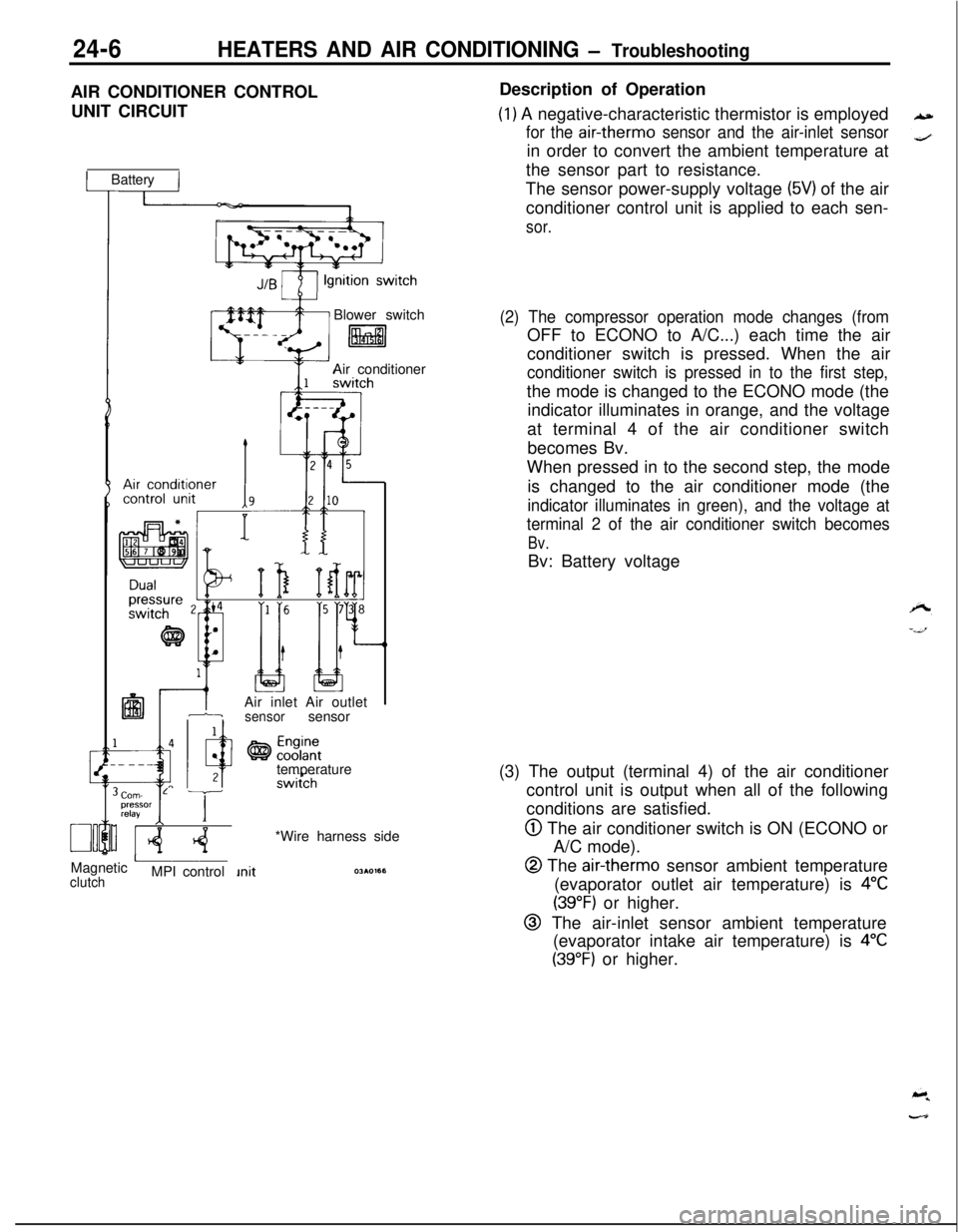

AclutchMPI control*Wire harness sideDescription of Operation

(1) A negative-characteristic thermistor is employed

for the air-therm0 sensor and the air-inlet sensorin order to convert the ambient temperature at

the sensor part to resistance.

The sensor power-supply voltage

(5V) of the air

conditioner control unit is applied to each sen-

sor.

(2) The compressor operation mode changes (fromOFF to ECONO to A/C...) each time the air

conditioner switch is pressed. When the air

conditioner switch is pressed in to the first step,the mode is changed to the ECONO mode (the

indicator illuminates in orange, and the voltage

at terminal 4 of the air conditioner switch

becomes Bv.

When pressed in to the second step, the mode

is changed to the air conditioner mode (the

indicator illuminates in green), and the voltage at

terminal 2 of the air conditioner switch becomes

Bv.Bv: Battery voltage

(3) The output (terminal 4) of the air conditioner

control unit is output when all of the following

conditions are satisfied.

@ The air conditioner switch is ON (ECONO or

A/C mode).

@ The air-therm0 sensor ambient temperature

(evaporator outlet air temperature) is

4°C

(39°F) or higher.

@ The air-inlet sensor ambient temperature

(evaporator intake air temperature) is

4°C

(39°F) or higher.