height MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 232 of 1216

6-2CLUTCH - SDecifications

SPECIFICATIONS

GENERAL SPECIFICATIONS

Items1.8L Engine2.0L DOHC Engine

Clutch operating method

Hydraulic type

Hydraulic type

Hydraulic type

Clutch disc*

TypeSingle dry disc type

Single dry disc type

Single dry disc type

Facing diameter

O.D.

x I.D.

mm (in.) 200 x 130215 x 140225 x 150(7.9 x 5.1)

(8.5 x 5.5)

(8.9 x 5.9)

Clutch cover assembly

TypeDiaphragm spring strap Diaphragm spring strap Diaphragm spring strap

drive type

drive type

drive type

Clutch release cylinder

I.D.mm (in.) 20.64 (13/16)20.64 (13/6)19.05 (3h)Clutch master cylinder

I.D.mm (in.) 15.87 (%)15.87 (%)15.87 (543)

NOTE*: Non-asbestos discs on vehicles with 2.0L DOHC Engine.

SERVICE SPECIFICATIONS

Items

Standard valueClutch pedal heightmm (in.)

Clutch pedal

clevis pin playmm (in.)

Clutch pedal free playmm (in.)

Distance between the clutch pedal and the firewall

when the clutch is disengagedmm (in.)

Limit

Facing rivet sinkmm (in.)

Diaphragm spring end height differencemm (in.)

NO6lX- .H,

Specifications

176.0-I 81 .O (6.93-7.13)

l-3 (.04-.12)6-13 (.24-.51)

55 (2.2) or more

0.3 (012)

0.5

(.02)L-

Page 234 of 1216

6-4CLUTCH - Troubleshooting

TROUBLESHOOTINGNO6hi.J

SymptomProbable causeRemedy

Clutch slipsInsufficient clutch pedal playAdjust

Excessive wear of clutch disc facingReplace

Hardening of clutch disc facing, or adhesion of oilReplace

Clutch release fork catchingRepair or replace parts

Weak or damaged diaphragm spring

Replace

Clogging of hydraulic systemRepair or replace parts

Gear shift malfunctionExcessive clutch pedal playAdjust

Distorted clutch disc, excessive oscillation

Replace

Clutch cover assembly wornReplace

Clutch disc spline worn or corrodedReplace

Clutch disc facing peelingReplace

Clutch release bearing wornReplace

Damaged pressure plate or flywheelReplace

Leakage, air introduction or clogging of hydraulic systemRepair or replace parts

Clutch noiseInsufficient clutch pedal playAdjust

Improper installation of clutch cover assemblyRepair or replace parts

Excessive wear of clutch disc facing

Replace

Clutch release fork catchingRepair or replace parts

Clutch release bearing worn

Replace

Weak or damaged torsion springReplace

Damaged pilot bushingReplace

Insufficient lubrication of bearing sleeve sliding surfaceRepairClutch pedal feels “heavy”

Insufficient lubrication of clutch pedalRepairInsufficient lubrication of clutch disc spline

Repair

Clutch release fork catchingRepair or replace parts

Insufficient lubrication of bearing sleeve sliding surface

Repair

Clutch chattersWorn or damaged clutch disc facingReplace

Oil adhered to clutch disc facingReplace

Uneven height of diaphragm springRepair or replace parts

Weak or damaged torsion spring

Replace

Damaged pressure plate or flywheelReplace

Loose or damaged mountingReplace or tighten

mounting

Page 235 of 1216

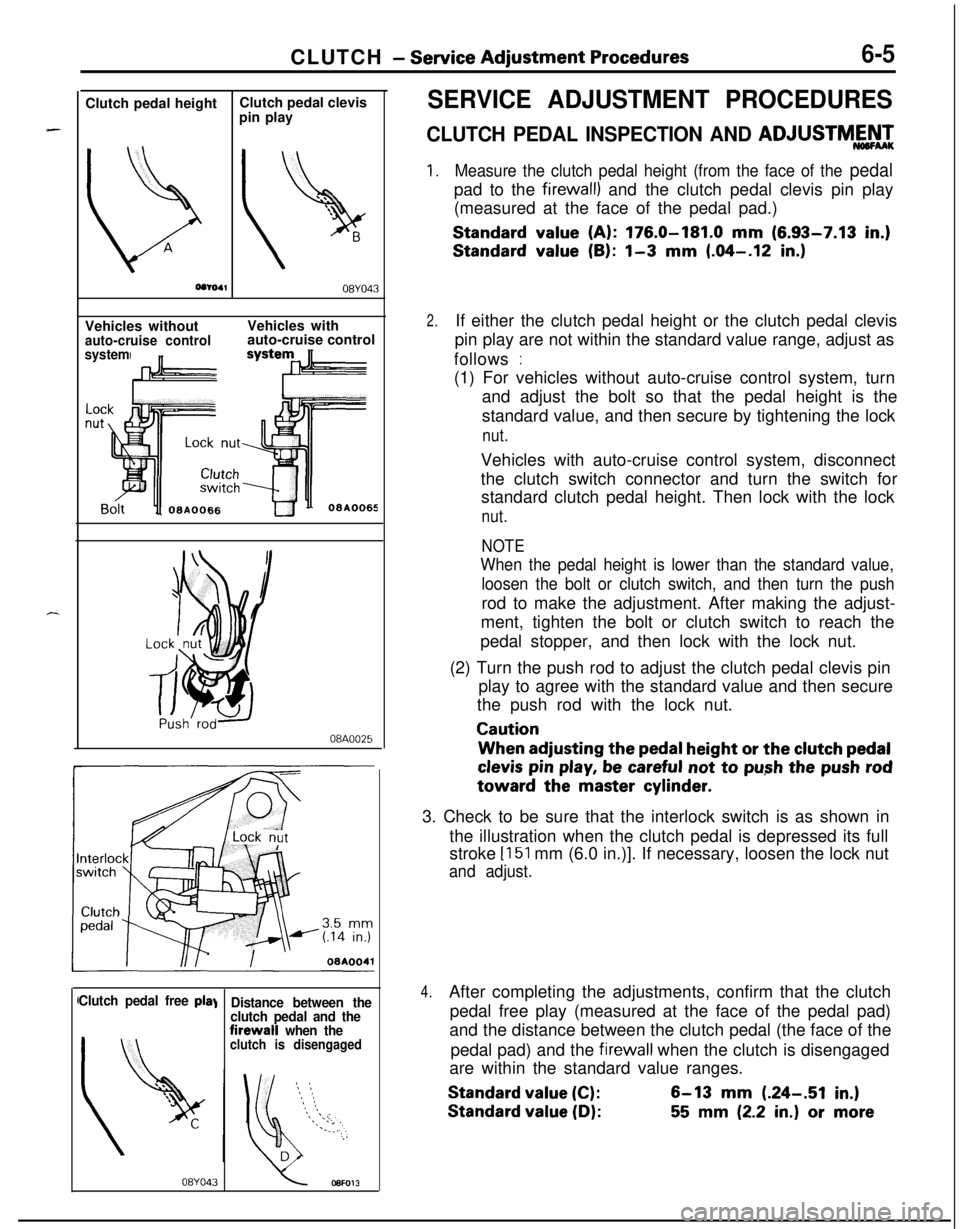

CLUTCH - Service Adjustment Procedures6-5Clutch pedal height

b

AClutch pedal clevis

pin play

08YO43Vehicles without

auto-cruise control

systemVehicles with

auto-cruise control

08A0025I

Clutch pedal free pIa\

08YO43

Distance between the

clutch pedal and thefirewall

when theclutch is disengaged

SERVICE ADJUSTMENT PROCEDURES

CLUTCH PEDAL INSPECTION AND ADJUSTMY’,

1.Measure the clutch pedal height (from the face of the pedalpad to the

firewall) and the clutch pedal clevis pin play

(measured at the face of the pedal pad.)

Standard value (A): 176.0-181.0 mm (6.93-7.13 in.)

Standard value (B): l-3 mm (.04-.12 in.)

2.If either the clutch pedal height or the clutch pedal clevis

pin play are not within the standard value range, adjust as

follows

:(1) For vehicles without auto-cruise control system, turn

and adjust the bolt so that the pedal height is the

standard value, and then secure by tightening the lock

nut.Vehicles with auto-cruise control system, disconnect

the clutch switch connector and turn the switch for

standard clutch pedal height. Then lock with the lock

nut.

NOTE

When the pedal height is lower than the standard value,

loosen the bolt or clutch switch, and then turn the pushrod to make the adjustment. After making the adjust-

ment, tighten the bolt or clutch switch to reach the

pedal stopper, and then lock with the lock nut.

(2) Turn the push rod to adjust the clutch pedal clevis pin

play to agree with the standard value and then secure

the push rod with the lock nut.

CautionWhen adjusting the

pedal height or the clutch pedal

clevis pin play, be careful not to push the push rodtoward the master

cylinder.3. Check to be sure that the interlock switch is as shown in

the illustration when the clutch pedal is depressed its full

stroke

[151 mm (6.0 in.)]. If necessary, loosen the lock nut

and adjust.

4.After completing the adjustments, confirm that the clutch

pedal free play (measured at the face of the pedal pad)

and the distance between the clutch pedal (the face of the

pedal pad) and the

firewall when the clutch is disengaged

are within the standard value ranges.

Standard value (C):6-13 mm (.24-.51 in.)

Standard value (D):55 mm (2.2 in.) or more

Page 247 of 1216

CLUTCH - Clutch Cover and Disc647

08A0038

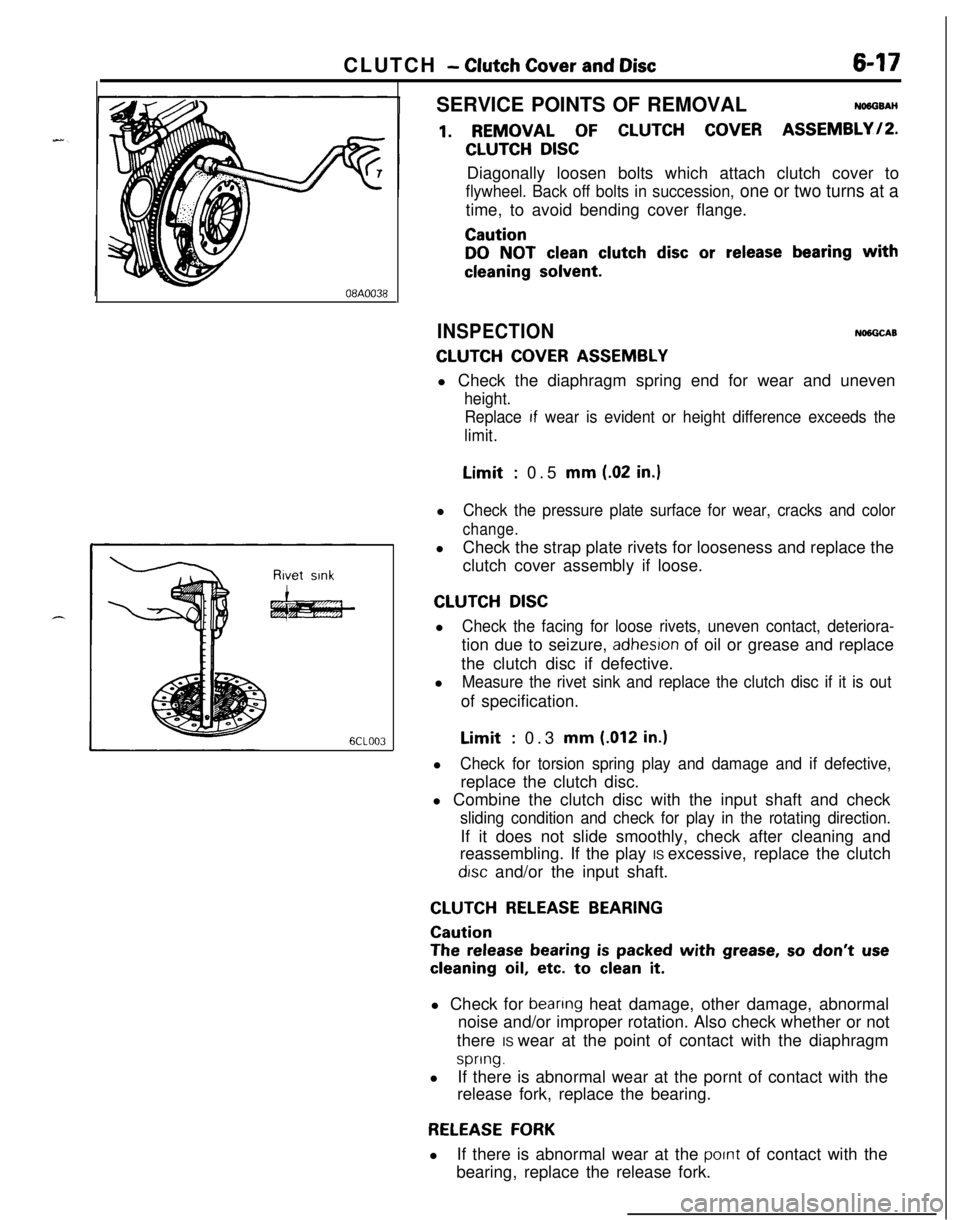

6CLOO3SERVICE POINTS OF REMOVAL

NO6OSAH

1. REMOVAL OF CLUTCH COVER ASSEMBLY/P.

CLUTCH DISCDiagonally loosen bolts which attach clutch cover to

flywheel. Back off bolts in succession, one or two turns at atime, to avoid bending cover flange.

Caution

DO NOT clean clutch disc or release bearing with

cleaning solvent.

INSPECTIONNlNGCAB

CLUTCH COVER ASSEMBLYl Check the diaphragm spring end for wear and uneven

height.

Replace

If wear is evident or height difference exceeds the

limit.Limit

: 0.5 mm (.02 in.)l

Check the pressure plate surface for wear, cracks and color

change.lCheck the strap plate rivets for looseness and replace the

clutch cover assembly if loose.

CLUTCH DISCl

Check the facing for loose rivets, uneven contact, deteriora-tion due to seizure,

adhesron of oil or grease and replace

the clutch disc if defective.

l

Measure the rivet sink and replace the clutch disc if it is outof specification.Limit

: 0.3 mm (.012 in.)l

Check for torsion spring play and damage and if defective,replace the clutch disc.

l Combine the clutch disc with the input shaft and check

sliding condition and check for play in the rotating direction.If it does not slide smoothly, check after cleaning and

reassembling. If the play IS excessive, replace the clutch

drsc and/or the input shaft.

CLUTCH RELEASE BEARING

Caution

The release bearing is packed with grease, so don’t use

cleaning oil, etc. to clean it.l Check for

beanng heat damage, other damage, abnormal

noise and/or improper rotation. Also check whether or not

there IS wear at the point of contact with the diaphragm

spring.lIf there is abnormal wear at the pornt of contact with the

release fork, replace the bearing.

RELEASE FORKlIf there is abnormal wear at the

pornt of contact with the

bearing, replace the release fork.

Page 264 of 1216

7-16COOLING - Thermostat

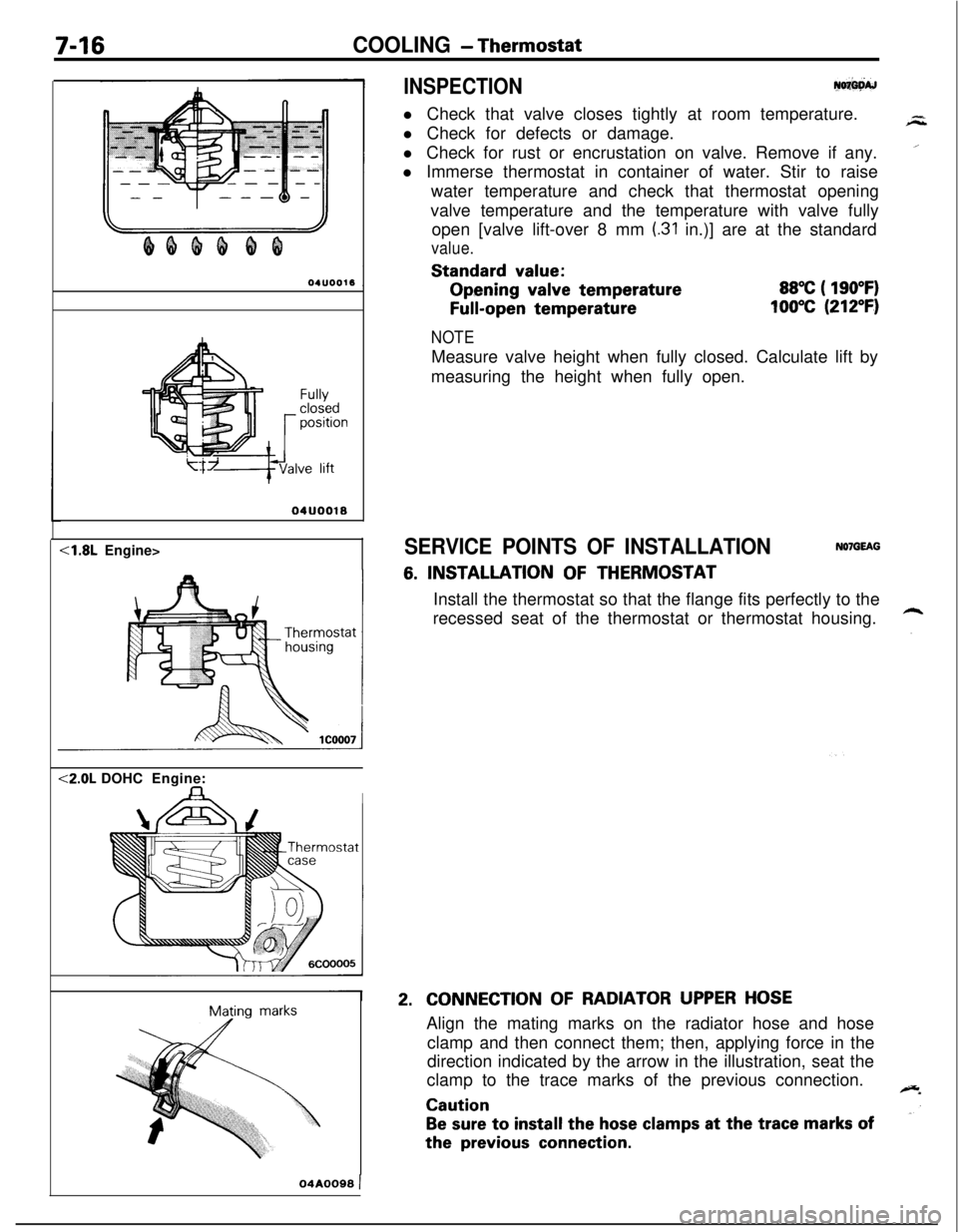

INSPECTIONy+w

l Check that valve closes tightly at room temperature.

l Check for defects or damage.

l Check for rust or encrustation on valve. Remove if any.

l Immerse thermostat in container of water. Stir to raise

water temperature and check that thermostat opening

valve temperature and the temperature with valve fully

open [valve lift-over 8 mm

(.31 in.)] are at the standard

value.Standard

value:Opening

valve temperature

Full-open temperature

88°C ( 190°F)

100°C (212°F)

Fullyclosedpositionve lift

04UOO18<1.8L Engine><2.0L DOHCEngine:

IMating

marks

NOTEMeasure valve height when fully closed. Calculate lift by

measuring the height when fully open.

SERVICE POINTS OF INSTALLATIONNOlGEAG

6. INSTALLATION OF THERMOSTAT

Install the thermostat so that the flange fits perfectly to the

recessed seat of the thermostat or thermostat housing.

2.CONNECTION OF RADIATOR UPPER HOSEAlign the mating marks on the radiator hose and hose

clamp and then connect them; then, applying force in the

direction indicated by the arrow in the illustration, seat the

clamp to the trace marks of the previous connection.

Caution

Be sure to install the hose clamps at the trace marks ofthe

previous connection.

04A0099 )

Page 292 of 1216

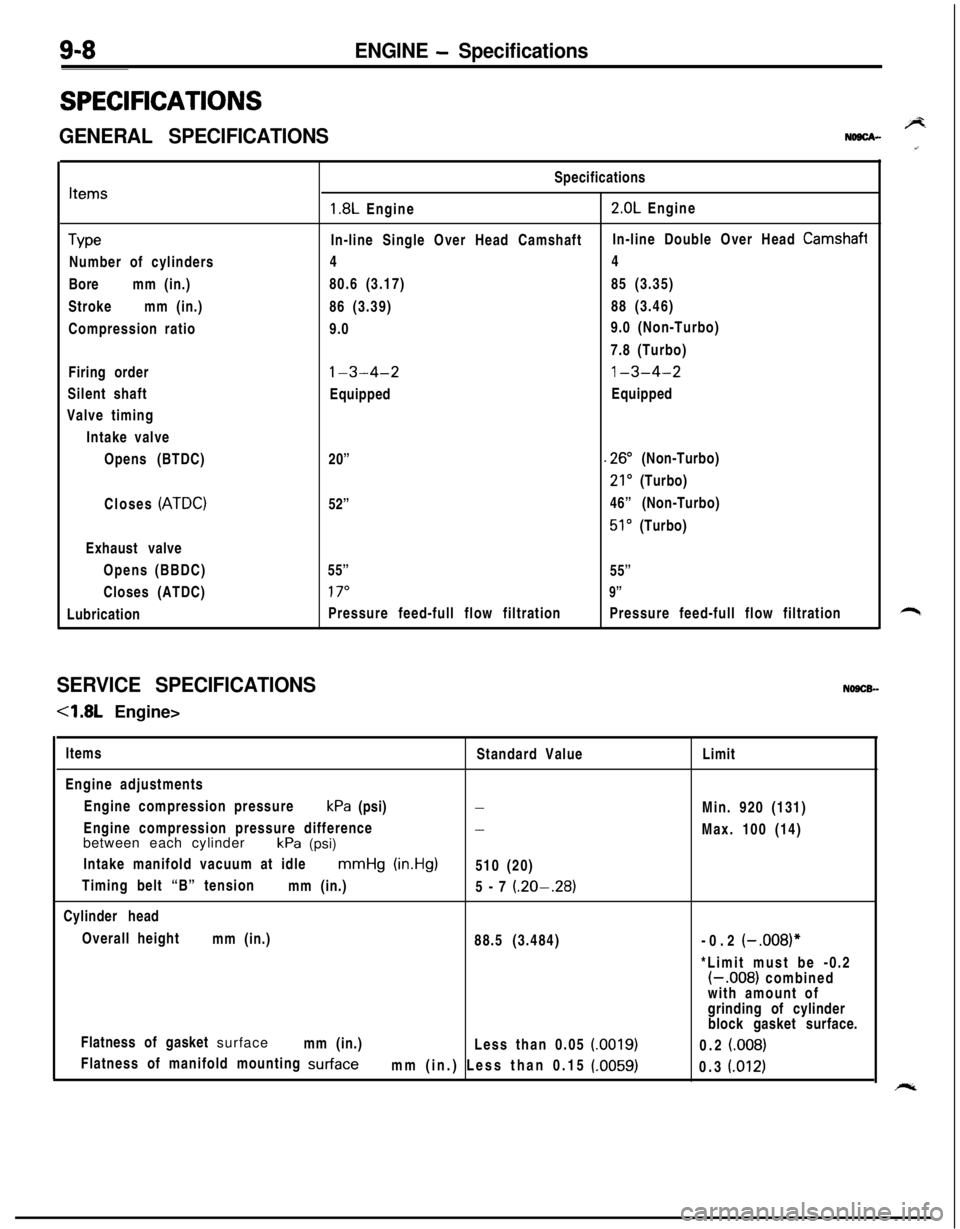

9-8ENGINE - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSBNDBCA-

Items

TypeNumber of cylinders

Boremm (in.)

Strokemm (in.)

Compression ratio

Firing order

Silent shaft

Valve timing

Intake valve

Opens (BTDC)

Closes

(ATDC)Exhaust valve

Opens (BBDC)

Closes (ATDC)

LubricationSpecifications

1.8L Engine2.0L Engine

In-line Single Over Head CamshaftIn-line Double Over Head

Camshafi44

80.6 (3.17)85 (3.35)

86 (3.39)88 (3.46)

9.09.0 (Non-Turbo)

7.8 (Turbo)

l-3-4-21-3-4-2EquippedEquipped

20”

.26” (Non-Turbo)

21’ (Turbo)

52”46” (Non-Turbo)

51’ (Turbo)

55”

55”

17”9”Pressure feed-full flow filtrationPressure feed-full flow filtration

SERVICE SPECIFICATIONSNOSCB-

-4.8L Engine>

Items

Standard Value

Engine adjustments

Engine compression pressurekPa (psi)

-Engine compression pressure difference

-between each cylinder

kPa (psi)

Intake manifold vacuum at idle

mmHg (in.Hg)510 (20)

Timing belt “B” tension

mm (in.)

5-7

(.20-.28)Cylinder head

Overall height

mm (in.)

88.5 (3.484)

Flatness of gasket surface

mm (in.)

Less than 0.05

(0019)Flatness of manifold mounting

surfacemm (in.) Less than 0.15 (.0059)Limit

Min. 920 (131)

Max. 100 (14)

-0.2

(-.008)**Limit must be -0.2

(-.008) combined

with amount of

grinding of cylinder

block gasket surface.

0.2

(008)0.3

(.012)

Page 293 of 1216

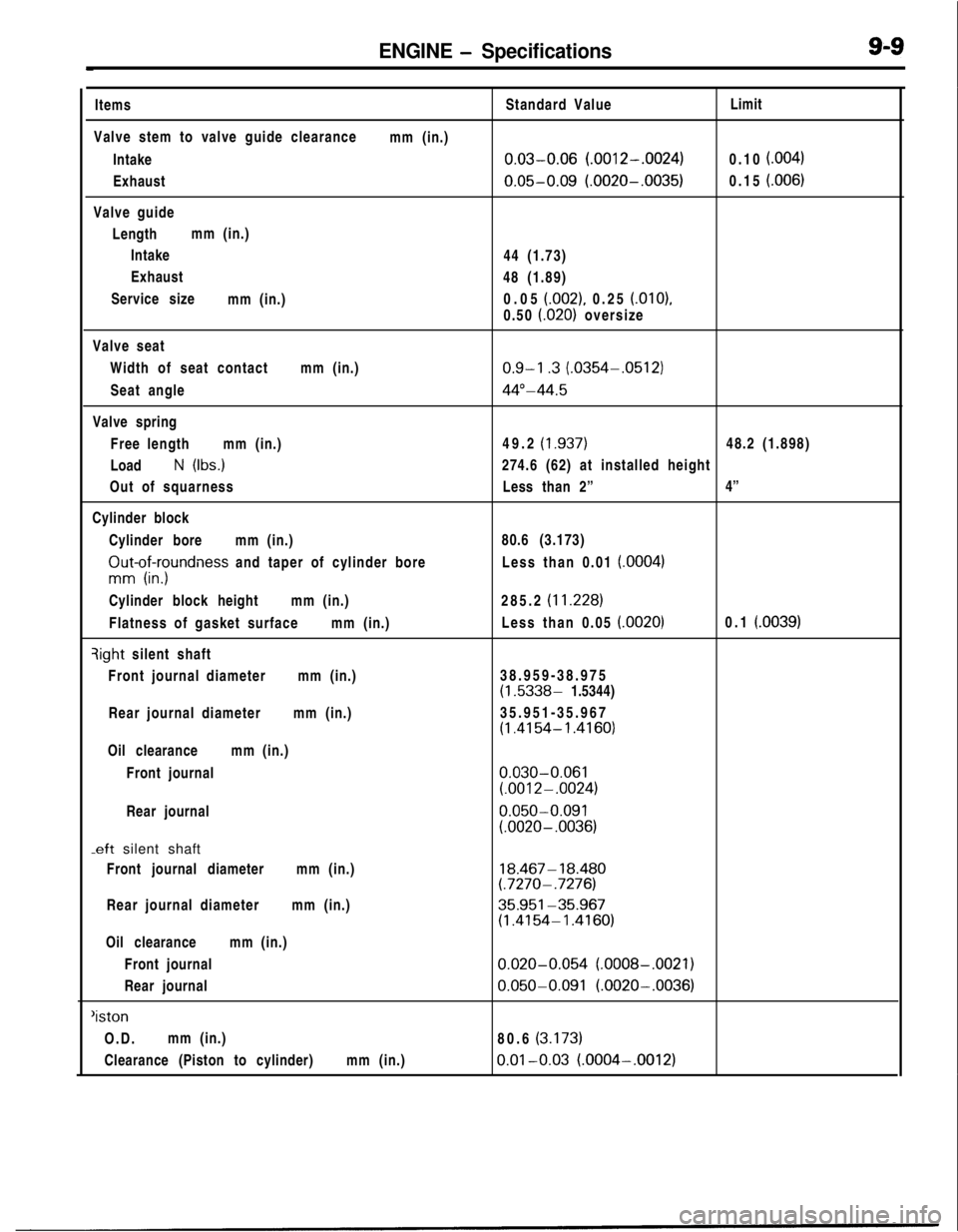

ENGINE - SpecificationsItems

Valve stem to valve guide clearance

Intake

Exhaust

Valve guide

Lengthmm (in.)

Intake

Exhaust

Service size

mm (in.)mm (in.)Standard Value

0.03-0.06 (.0012-.0024)

0.05-0.09 (.0020-.0035)44 (1.73)

48 (1.89)

0.05

(.002), 0.25 (.OlO),

0.50

i.020) oversizeLimit

0.10

f.004)0.15

i.006)Valve seat

Width of seat contactmm (in.)

Seat angle

Valve spring

Free lengthmm (in.)

Load

N (Ibs.)

Out of squarness

Cylinder block

Cylinder boremm (in.)

ZIut-of;yundness and taper of cylinder bore

Cylinder block heightmm (in.)

Flatness of gasket surfacemm (in.)qight silent shaft

Front journal diametermm (in.)

Rear journal diametermm (in.)

Oil clearancemm (in.)

Front journal

Rear journal

-eft silent shaft

Front journal diametermm (in.)

Rear journal diametermm (in.)

Oil clearancemm (in.)

Front journal

Rear journal

‘istonO.D.mm (in.)

Clearance (Piston to cylinder)mm (in.)

0.9-l .3 (.0354-.0512)

44”-44.549.2

(1.937)48.2 (1.898)

274.6 (62) at installed height

Less than 2”4”

80.6 (3.173)

Less than 0.01

(.0004)285.2

(11.228)Less than 0.05

(.0020)0.1 (.0039)38.959-38.975

(1.5338- 1.5344)

35.951-35.967

(1.4154- 1.4160)

0.030-0.061(.0012-.0024)

0.050-0.091(.0020- .0036)

18.467- 18.480(.7270- .7276)

35.951-35.967(1.4154-1.4160)

0.020-0.054 (.0008-.0021)

0.050-0.091 (.0020-.0036)80.6

(3.173)

0.01-0.03 (.0004-.0012)

Page 294 of 1216

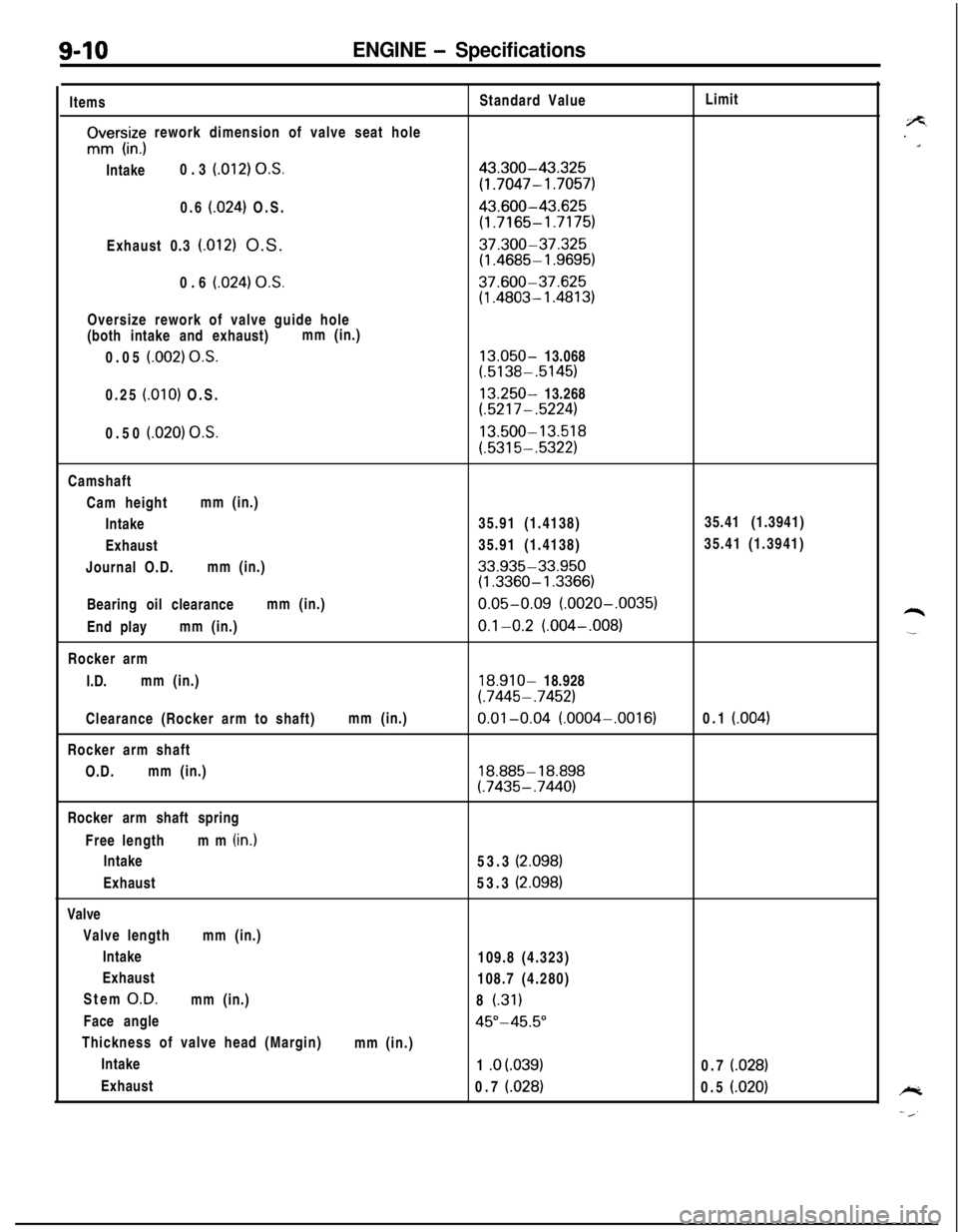

9-10ENGINE - SpecificationsItems

rIvrs,iz; rework dimension of valve seat hole

Intake0.3

(012) O.S.0.6

(024) O.S.

Exhaust 0.3

(.012) O.S.

0.6

(024) OS.Oversize rework of valve guide hole

(both intake and exhaust)mm (in.)

0.05

(.002) O.S.0.25

(.OlO) O.S.

0.50

(.020) O.S.Standard Value

43.300-43.325

(1.7047- 1.7057)

43.600-43.625

(1.7165-1.7175)

37.300-37.325(1.4685- 1.9695)

37.600-37.625(1.4803- 1.4813)

13.050- 13.068(.5138-.5145)

13.250- 13.268(.5217-.5224)

13.500-13.518

(.5315-.5322)Limit

Camshaft

Cam heightmm (in.)

Intake35.91 (1.4138)35.41 (1.3941)

Exhaust35.91 (1.4138)35.41 (1.3941)

Journal O.D.mm (in.)

33.935-33.950(1.3360- 1.3366)Bearing oil clearancemm (in.)

0.05-0.09 (.0020-.0035)End playmm (in.)

0.1-0.2 (.004-,008)Rocker arm

I.D.mm (in.)

18.910- 18.928

(.7445- .7452)Clearance (Rocker arm to shaft)mm (in.)

0.01-0.04 (.0004-.0016)0.1 (004)Rocker arm shaft

O.D.mm (in.)

18.885- 18.898(.7435-.7440)Rocker arm shaft spring

Free lengthmm (in.)

Intake

Exhaust

Valve

Valve lengthmm (in.)

Intake

Exhaust

Stem

O.D.mm (in.)

Face angle

Thickness of valve head (Margin)

Intake

Exhaust53.3

(2.098)53.3

(2.098)109.8 (4.323)

108.7 (4.280)

8

(.31)

45”-45.5”mm (in.)

1 .o

(.039)0.7 (028)0.7

(.028)0.5 (.020)

Page 297 of 1216

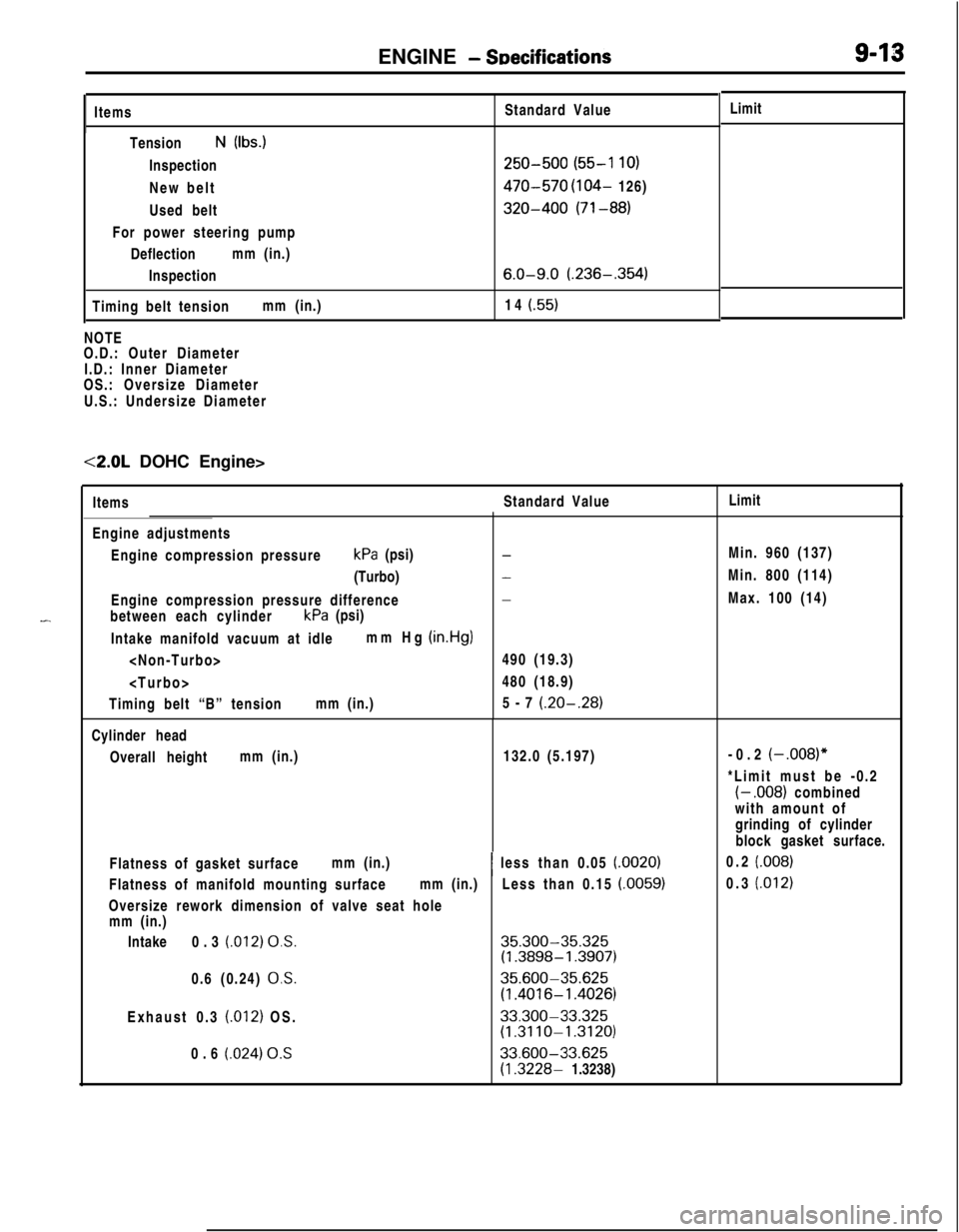

ENGINE - SDecificationsItems

TensionN (Ibs.)

Inspection

New belt

Used belt

For power steering pump

Deflectionmm (in.)

Inspection

Timing belt tensionmm (in.)Standard Value

250-500 (55-l 10)

470-570 (104- 126)

320-400 (71-88)

6.0-9.0 (.236-.354)14

(.55)NOTE

O.D.: Outer Diameter

I.D.: Inner Diameter

OS.: Oversize Diameter

U.S.: Undersize Diameter<2.0L DOHC Engine>

-ItemsStandard ValueLimit

Engine adjustments

Engine compression pressurekPa (psi)

(Turbo)

Engine compression pressure difference

between each cylinderkPa (psi)

Intake manifold vacuum at idlemm Hg

(in.Hg)

Timing belt “B” tensionmm (in.)

-

-

-490 (19.3)

480 (18.9)

5-7

(.20-.28)Cylinder head

Overall heightmm (in.)132.0 (5.197)

Flatness of gasket surfacemm (in.)

Flatness of manifold mounting surfacemm (in.)

Oversize rework dimension of valve seat hole

mm (in.)

Intake0.3

(.012) 0,s.0.6 (0.24)

0,s.Exhaust 0.3

(.012) OS.

0.6

(.024) 0.S~ less than 0.05

(.0020)Less than 0.15

(.0059)

35.300-35.325(1.3898-1.3907)

35.600-35.625

(1.4016-l .4026)

33.300-33.325(1.3110-1.3120)

33.600-33.625

(1.3228- 1.3238)Limit

Min. 960 (137)

Min. 800 (114)

Max. 100 (14)

-0.2

(-,008)”*Limit must be -0.2

(- .008) combined

with amount of

grinding of cylinder

block gasket surface.

0.2

(.008)0.3

(.012)

Page 298 of 1216

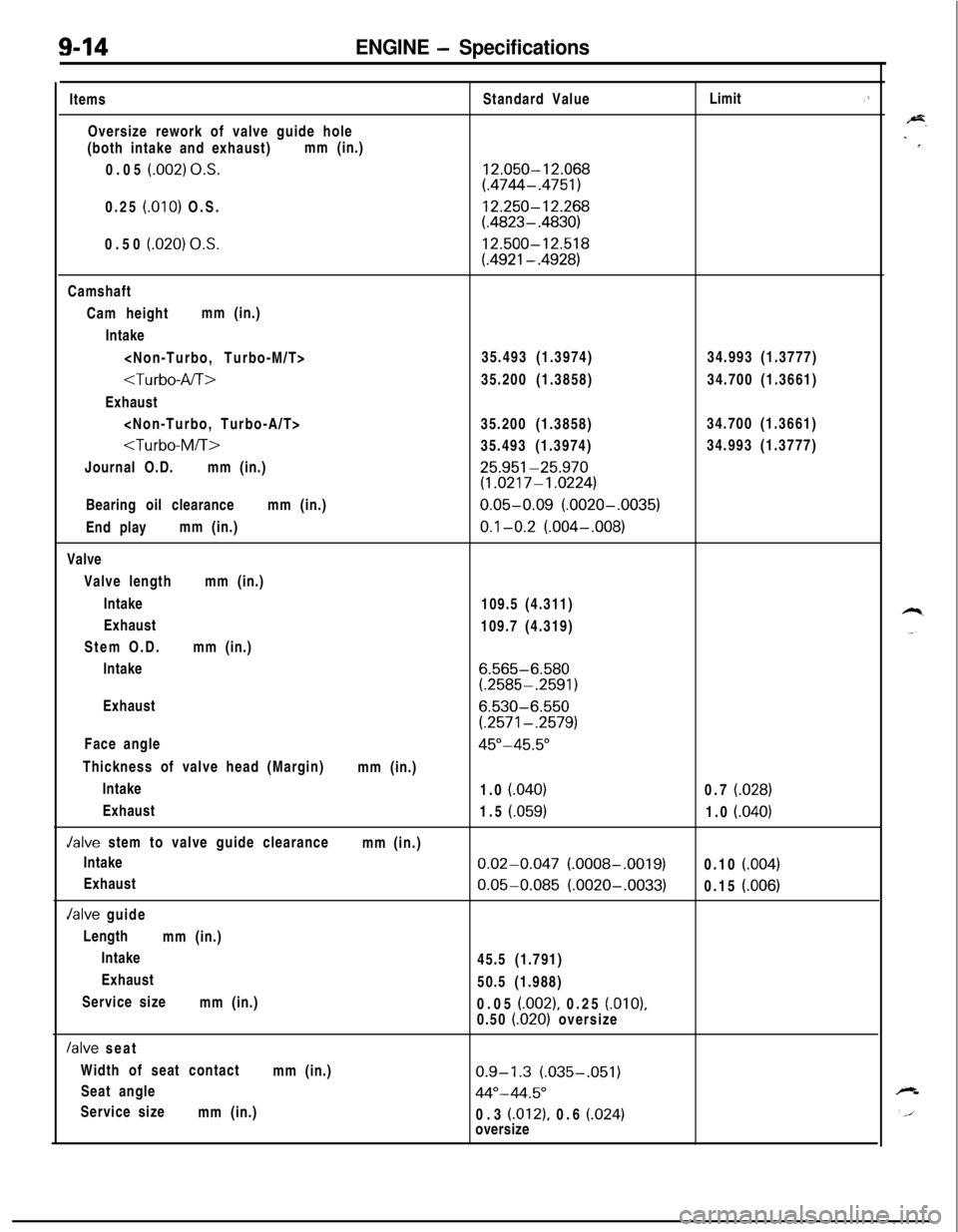

9-14ENGINE - SpecificationsItems

Oversize rework of valve guide hole

(both intake and exhaust)mm (in.)

0.05

(.002) O.S.0.25

(.OlO) O.S.

0.50

(.020) 0,s.Standard Value

12.050-12.068(.4744-.4751)

12.250-12.268(.4823-.4830)

12.500-12.518

(.4921-.4928)Limit

,’Camshaft

Cam heightmm (in.)

Intake

Exhaust

Journal O.D.mm (in.)

25.951-25.970(1.0217-1.0224)Bearing oil clearancemm (in.)

0.05-0.09 (.0020-.0035)End playmm (in.)

0.1-0.2 (.004-,008)Valve

Valve lengthmm (in.)

Intake

109.5 (4.311)

Exhaust

109.7 (4.319)

Stem O.D.mm (in.)

Intake

6.565-6.580(.2585-.2591)Exhaust

6.530-6.550

(.2571-.2579)Face angle

45"-45.5"Thickness of valve head (Margin)

mm (in.)

Intake

1.0

(.040)0.7 (.028)Exhaust

1.5

(.059)1.0 (.040)Jalve stem to valve guide clearance

mm (in.)

Intake

0.02-0.047 (.0008-.0019)0.10 (.004)Exhaust

0.05-0.085 (.0020-.0033)0.15 (.006)Jalve guide

Length

mm (in.)

Intake

45.5 (1.791)

Exhaust

50.5 (1.988)

Service size

mm (in.)

0.05

(.002), 0.25 (.OlO),0.50 (.020) oversize

/alve seat

Width of seat contact

mm (in.)

0.9-1.3 (.035-.051)Seat angle

44"-44.5"Service size

mm (in.)

0.3

(.012), 0.6 (.024)oversize