power steering MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 272 of 1216

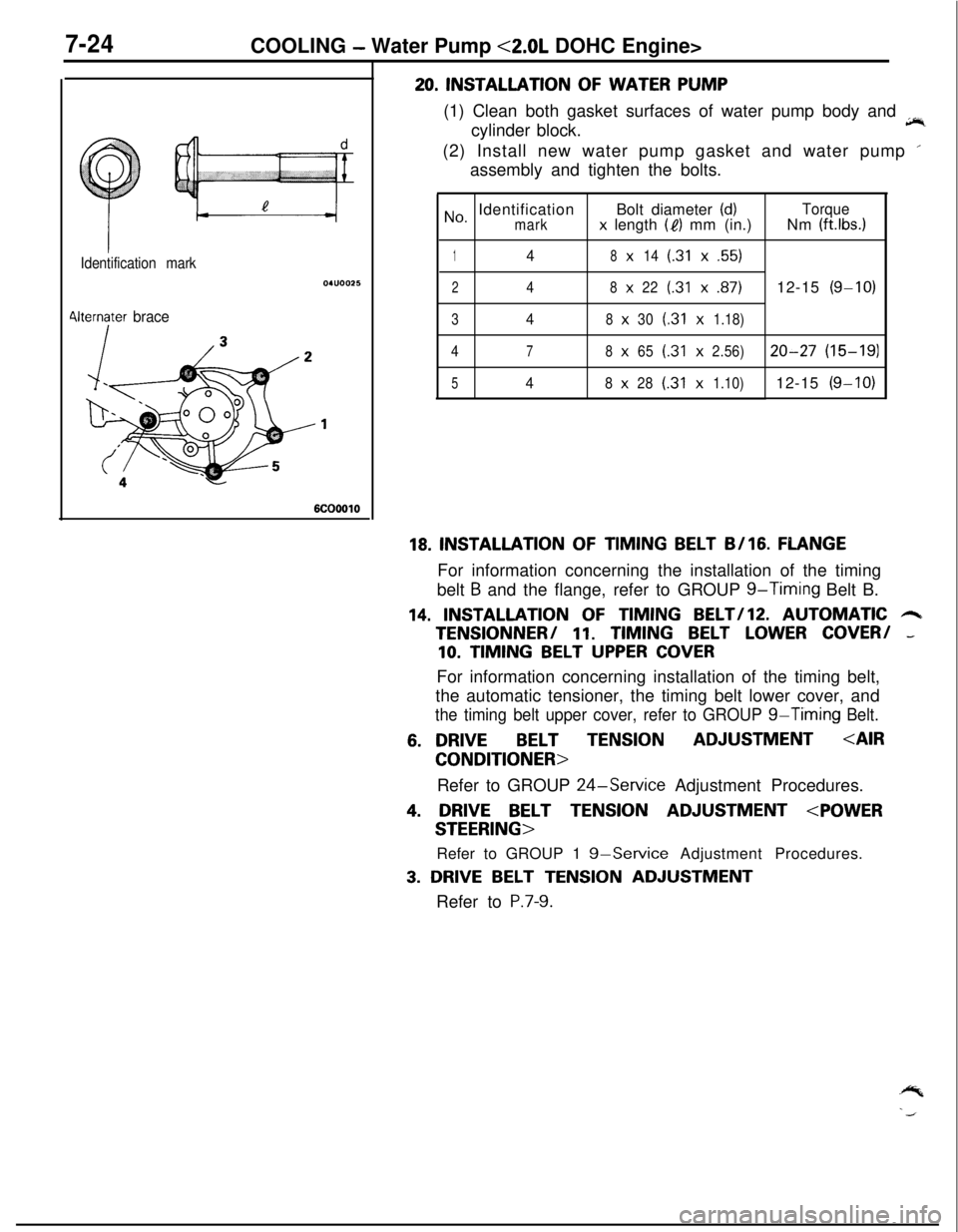

7-24COOLING - Water Pump <2.0L DOHC Engine>

Identification mark

4lternater brace

6COOOlO

20. INSTALLATION OF WATER PUMP

(1) Clean both gasket surfaces of water pump body and

jir,cylinder block.

(2) Install new water pump gasket and water pump ’

assembly and tighten the bolts.

No, IdentificationBolt diameter (d)Torquemarkx length (I?) mm (in.)Nm (ft.lbs.1

148x14(.31x.55)

248x22(.31x.87)12-15(g-10)

348x30(.31x1.18)

4

78x65(.31x2.56)20-27(15-191

548x28(.31x1.10)12-15(g-10)

18. INSTALLATION OF TIMING BELT B/16. FLANGEFor information concerning the installation of the timing

belt

B and the flange, refer to GROUP g-Timing Belt B.

14. INSTALLATION OF TIMING BELT/lZ. AUTOMATIC 6TENSlONNER/

11. TIMING BELT LOWER COVER/ -

10. TIMING BELT UPPER COVERFor information concerning installation of the timing belt,

the automatic tensioner, the timing belt lower cover, and

the timing belt upper cover, refer to GROUP g-Timing Belt.

6. DRIVEBELT TENSIONADJUSTMENT

Refer to GROUP

24-Service Adjustment Procedures.

4. DRIVE BELT TENSION ADJUSTMENT

Refer to GROUP 1

g-Service Adjustment Procedures.

3. DRIVE BELT TENSION ADJUSTMENT

Refer to

P.7-9.

Page 279 of 1216

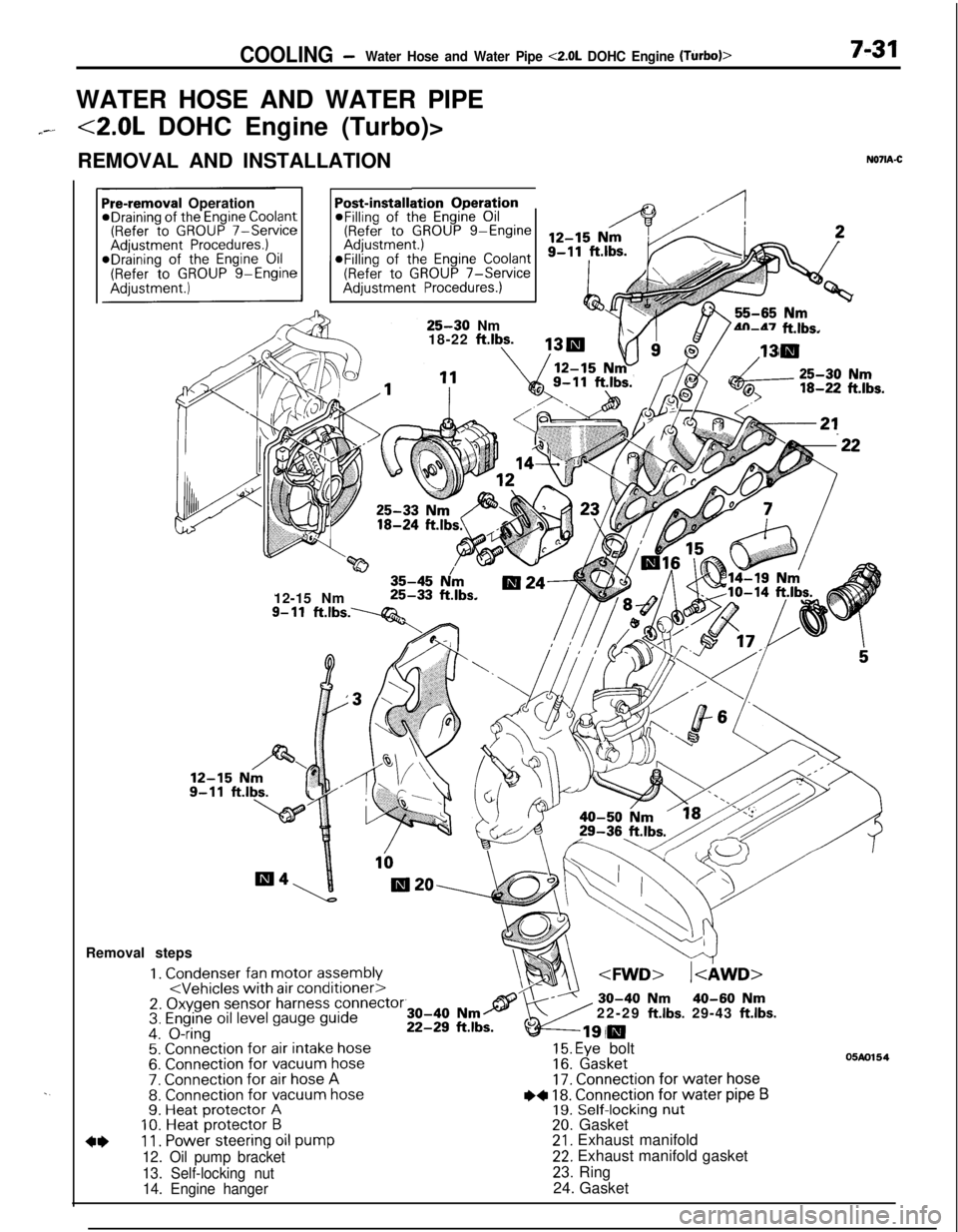

COOLING -Water Hose and Water Pipe <2.0L DOHC Engine (Turbo)>7-31WATER HOSE AND WATER PIPE

7--<2.0L DOHC Engine (Turbo)>

REMOVAL AND INSTALLATION

N071A-C

. .

ation OperationPost-installi@Filling of the Engine Oil(Refer to GROUP g-EngineaFilling of the

Engine Coolant(Refer to GROUP 7-ServiceAdjustment Procedures.)

Pre-removal OperationeDraining of the Engine Coolant(Refer to GROUP 7-ServiceAdjustment Procedures.)*Draining of the Engine Oil(Refer to GROUP g-Engine

25-30 Nm

18-22 ftlbs.4n-47 ft.lbs.

w35-45 N/m12-15 Nm25-33 ft.lbs.

9- 11ft.lbs.----Q&Removal steps

1. Condenser fan motor assembly

4*11. Power steering oil pump

12. Oil pump bracket

13. Self-locking nut

14. Engine hanger22-29

ft.lbs. 29-43 ft.lbs.

15. Eye bolt16. Gasket17. Connection for water hose

I)+ 18. Connection for water pipe B19. Self-locking nut20. Gasket21. Exhaust manifold22. Exhaust manifold gasket

23. Ring

24. Gasket

05m154

Page 281 of 1216

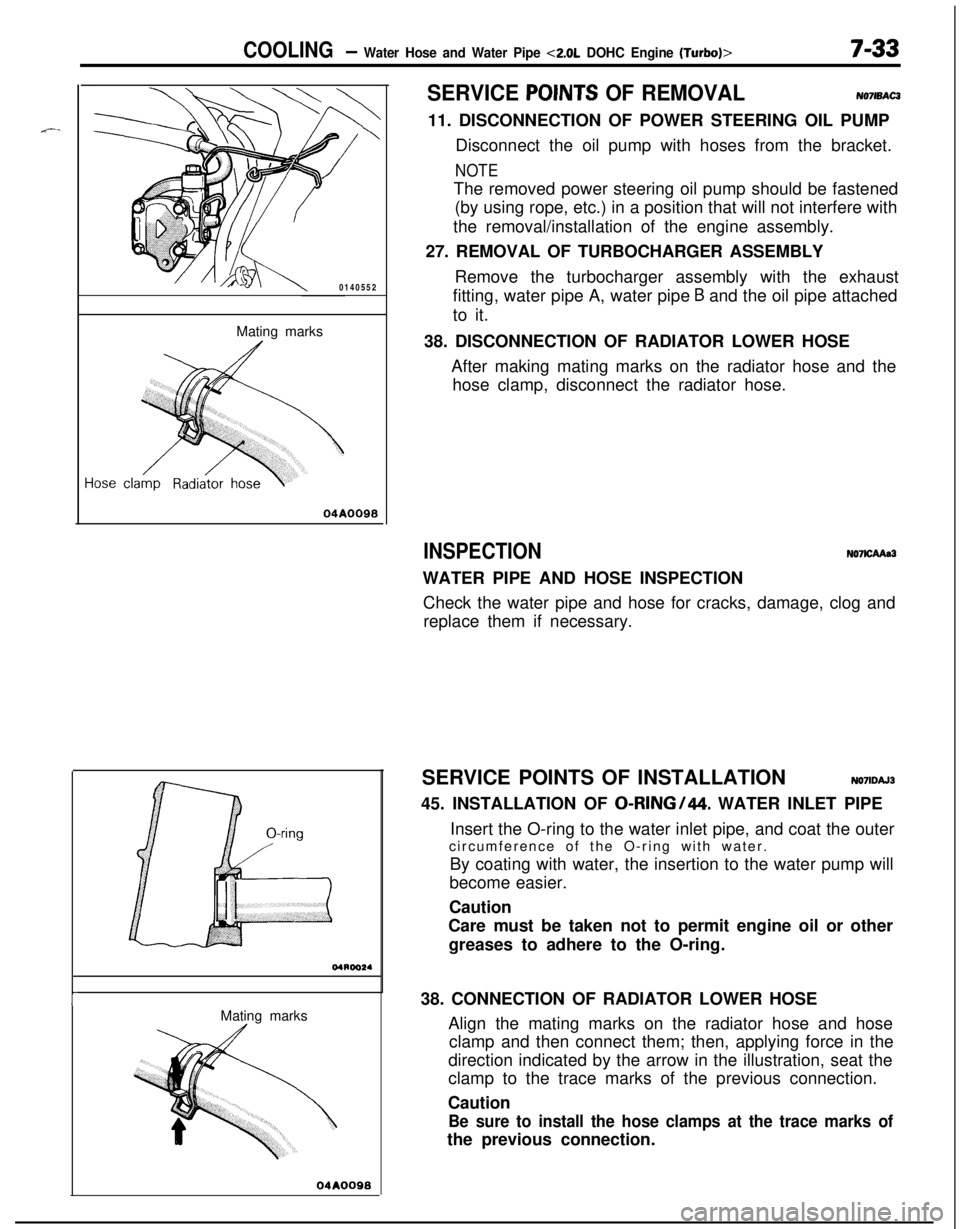

COOLING- Water Hose and Water Pipe <2.0L DOHC Engine (Turbo)>7-330140552

Mating marks

04A0090

rMating marks

04A0090

SERVICE POINTS OF REMOVALNO7lBAC311. DISCONNECTION OF POWER STEERING OIL PUMP

Disconnect the oil pump with hoses from the bracket.

NOTEThe removed power steering oil pump should be fastened

(by using rope, etc.) in a position that will not interfere with

the removal/installation of the engine assembly.

27. REMOVAL OF TURBOCHARGER ASSEMBLY

Remove the turbocharger assembly with the exhaust

fitting, water pipe A, water pipe

B and the oil pipe attached

to it.

38. DISCONNECTION OF RADIATOR LOWER HOSE

After making mating marks on the radiator hose and the

hose clamp, disconnect the radiator hose.

INSPECTIONN07lCAAa3WATER PIPE AND HOSE INSPECTION

Check the water pipe and hose for cracks, damage, clog and

replace them if necessary.

SERVICE POINTS OF INSTALLATION

N071DAJ345. INSTALLATION OF

0-RING/44. WATER INLET PIPE

Insert the O-ring to the water inlet pipe, and coat the outer

circumference of the O-ring with water.

By coating with water, the insertion to the water pump will

become easier.

Caution

Care must be taken not to permit engine oil or other

greases to adhere to the O-ring.

38. CONNECTION OF RADIATOR LOWER HOSE

Align the mating marks on the radiator hose and hose

clamp and then connect them; then, applying force in the

direction indicated by the arrow in the illustration, seat the

clamp to the trace marks of the previous connection.

Caution

Be sure to install the hose clamps at the trace marks ofthe previous connection.

Page 297 of 1216

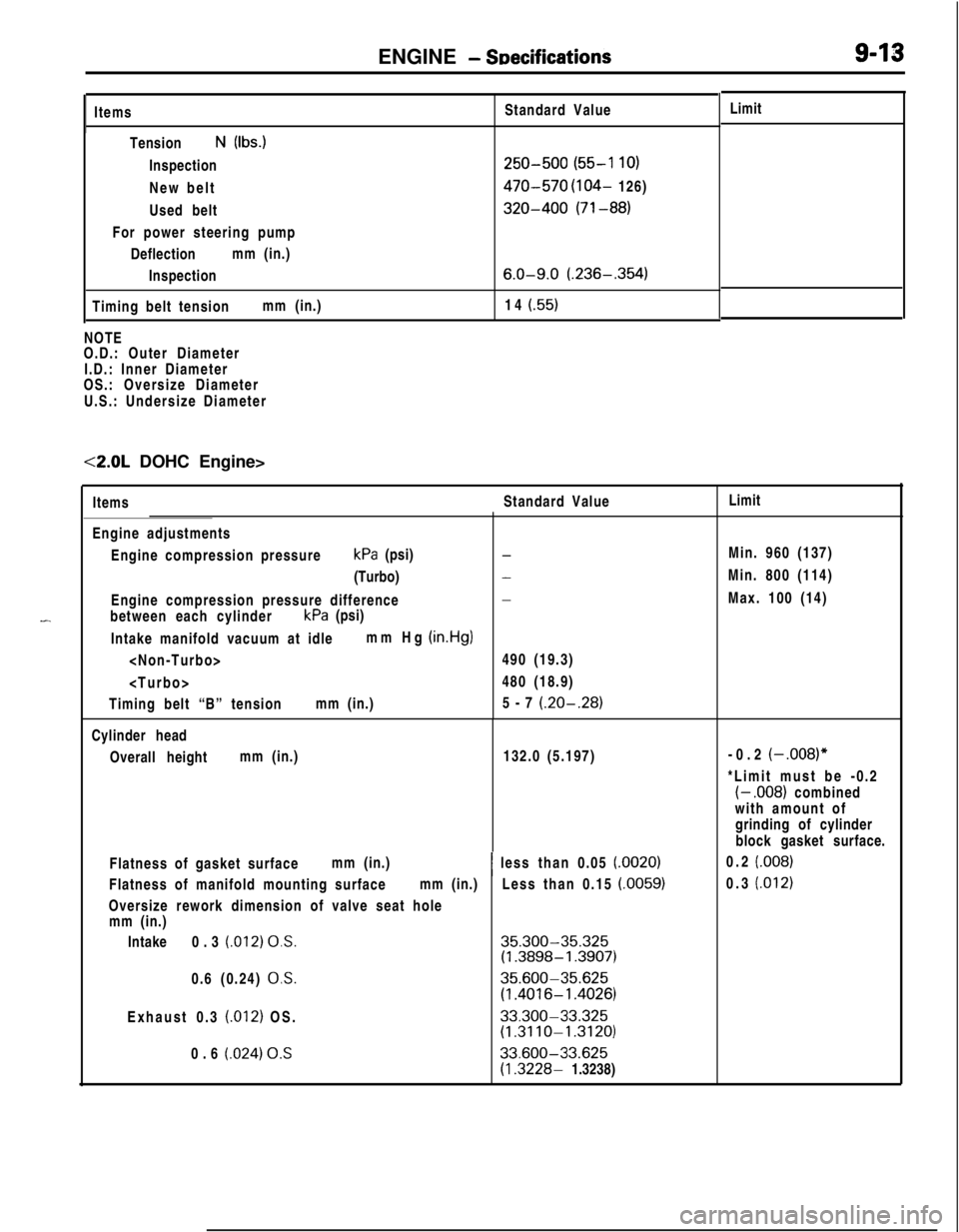

ENGINE - SDecificationsItems

TensionN (Ibs.)

Inspection

New belt

Used belt

For power steering pump

Deflectionmm (in.)

Inspection

Timing belt tensionmm (in.)Standard Value

250-500 (55-l 10)

470-570 (104- 126)

320-400 (71-88)

6.0-9.0 (.236-.354)14

(.55)NOTE

O.D.: Outer Diameter

I.D.: Inner Diameter

OS.: Oversize Diameter

U.S.: Undersize Diameter<2.0L DOHC Engine>

-ItemsStandard ValueLimit

Engine adjustments

Engine compression pressurekPa (psi)

(Turbo)

Engine compression pressure difference

between each cylinderkPa (psi)

Intake manifold vacuum at idlemm Hg

(in.Hg)

Timing belt “B” tensionmm (in.)

-

-

-490 (19.3)

480 (18.9)

5-7

(.20-.28)Cylinder head

Overall heightmm (in.)132.0 (5.197)

Flatness of gasket surfacemm (in.)

Flatness of manifold mounting surfacemm (in.)

Oversize rework dimension of valve seat hole

mm (in.)

Intake0.3

(.012) 0,s.0.6 (0.24)

0,s.Exhaust 0.3

(.012) OS.

0.6

(.024) 0.S~ less than 0.05

(.0020)Less than 0.15

(.0059)

35.300-35.325(1.3898-1.3907)

35.600-35.625

(1.4016-l .4026)

33.300-33.325(1.3110-1.3120)

33.600-33.625

(1.3228- 1.3238)Limit

Min. 960 (137)

Min. 800 (114)

Max. 100 (14)

-0.2

(-,008)”*Limit must be -0.2

(- .008) combined

with amount of

grinding of cylinder

block gasket surface.

0.2

(.008)0.3

(.012)

Page 301 of 1216

ENGINE - Specifications

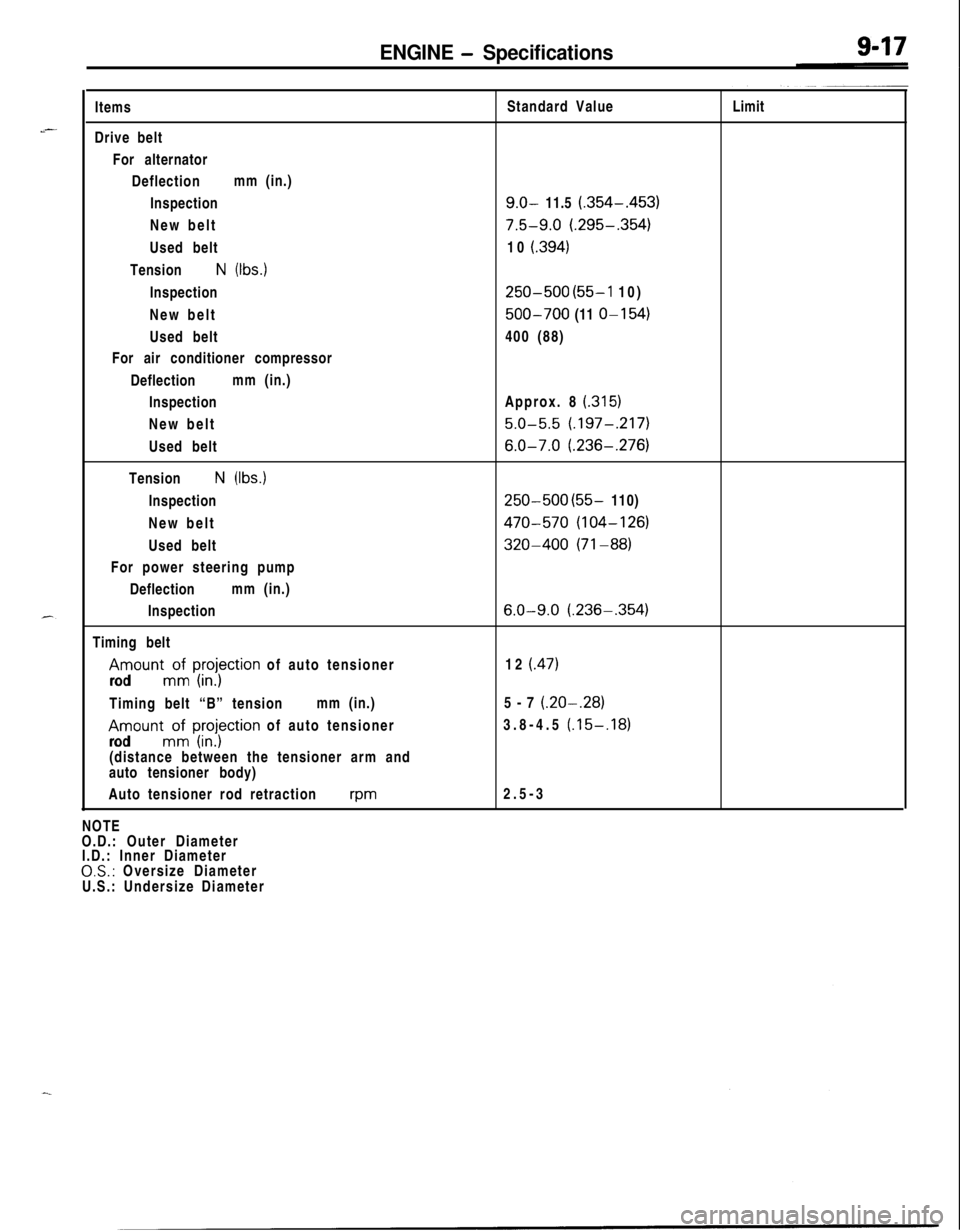

..--Items

Drive belt

For alternator

Deflectionmm (in.)

Inspection

New belt

Used belt

Tension

N (Ibs.)

Inspection

New belt

Used belt

For air conditioner compressor

Deflectionmm (in.)

Inspection

New belt

Used belt

Tension

N (Ibs.)

Inspection

New belt

Used belt

For power steering pump

Deflectionmm (in.)

Inspection

Timing belt

Amount;; I;;;j;ction of auto tensioner

rodTiming belt “B” tensionmm (in.)

Amount;: I;;;jytion of auto tensioner

rod(distance between the tensioner arm and

auto tensioner body)

Auto tensioner rod retraction

wmNOTE

O.D.: Outer Diameter

I.D.: Inner Diameter

0,s.: Oversize Diameter

U.S.: Undersize DiameterStandard Value

9.0- 11.5 (.354-.453)

7.5-9.0 (.295-.354)10

i.394)

250-500 (55-l 10)

500-700 (11 o-1 54)400 (88)

Approx. 8

(.315)

5.0-5.5 (.197-.217)

6.0-7.0 (.236-,276)

250-500 (55- 110)

470-570 (104-126)

320-400 (71-88)

6.0-9.0 (.236-,354)12

(.47)5-7

(.20-.28)3.8-4.5

(.15-,1812.5-3Limit

Page 302 of 1216

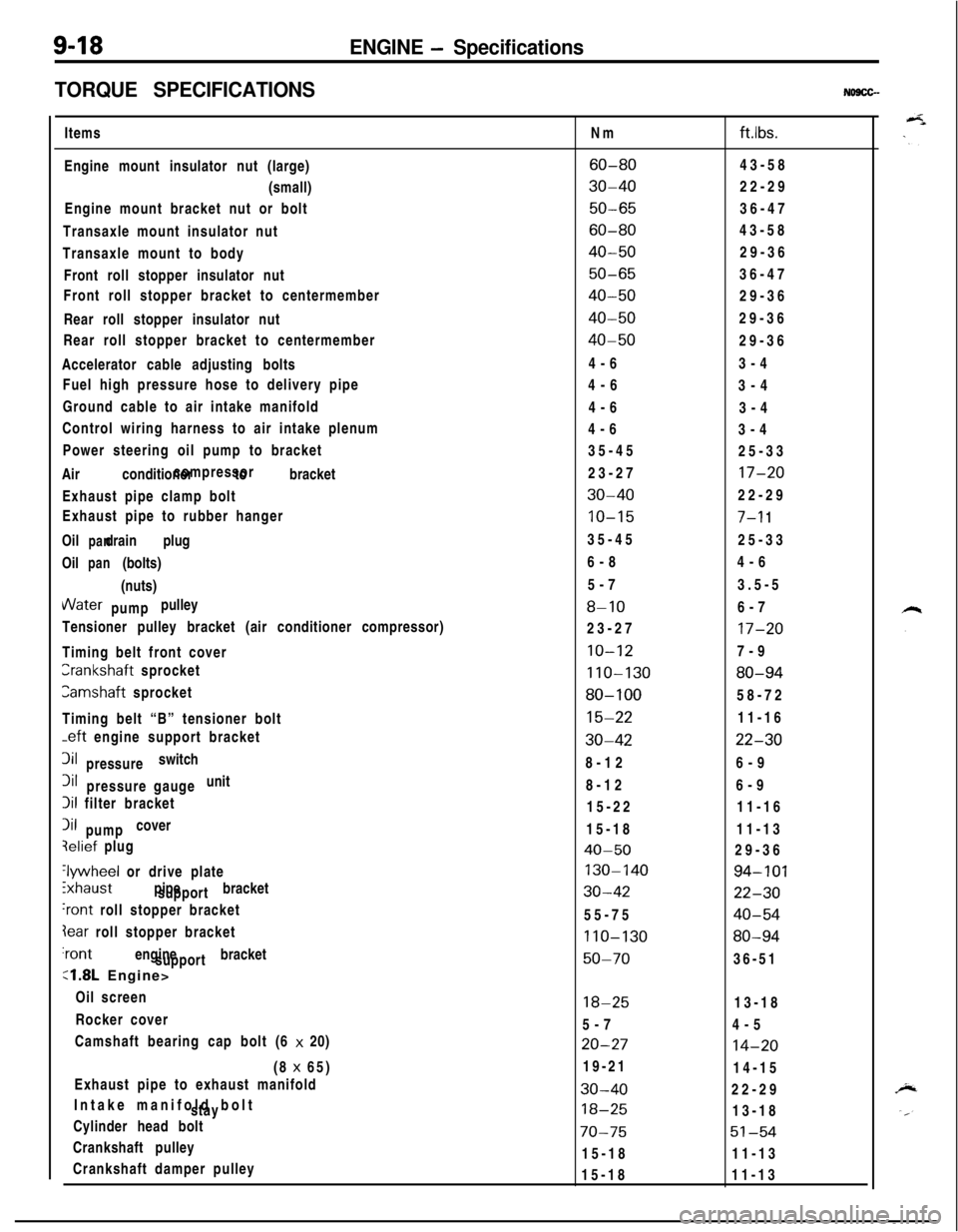

9-18ENGINE - Specifications

TORQUE SPECIFICATIONS

NO9CG-Items

Engine mount insulator nut (large)

(small)

Engine mount bracket nut or bolt

Transaxle mount insulator nut

Transaxle mount to body

Front roll stopper insulator nut

Front roll stopper bracket to centermember

Rear roll stopper insulator nut

Rear roll stopper bracket to centermember

Accelerator cable adjusting bolts

Fuel high pressure hose to delivery pipe

Ground cable to air intake manifold

Control wiring harness to air intake plenum

Power steering oil pump to bracket

Air conditioner to bracketcompressor

Exhaust pipe clamp bolt

Exhaust pipe to rubber hanger

Oil drain plug

panOil (bolts)

pan(nuts)VVater pulley

pump

Tensioner pulley bracket (air conditioner compressor)

Timing belt front coverCrankshaft sprocket

Camshaft sprocket

Timing belt “B” tensioner bolt

-eft engine support bracket3il switch

pressure3il unit

pressure gauge

Iii filter bracket

Iii cover

pumpqelief plug

‘lywheel or drive plate

ixhaust pipe bracket

support

‘rant roll stopper bracket

Iear roll stopper bracket‘rant engine bracket

support

:1.8L Engine>

Oil screen

Rocker cover

Camshaft bearing cap bolt (6 x 20)

(8 x 65)

Exhaust pipe to exhaust manifold

Intake manifold bolt

stay

Cylinder head bolt

Crankshaft pulley

Crankshaft damper pulleyNm

ftlbs.

60-8043-58

30-4022-29

50-6536-47

60-8043-58

40-5029-36

50-6536-47

40-5029-36

40-5029-36

40-5029-36

4-63-4

4-6

3-4

4-6

3-4

4-6

3-4

35-45

25-33

23-27

17-20

30-4022-29

10-157-l 135-45

25-33

6-84-6

5-73.5-5

8-106-7

23-27

17-20

10-127-9

110-13080-94

80-10058-72

15-2211-16

30-4222-308-126-9

8-126-9

15-2211-16

15-1811-13

40-5029-36

130-14094-101

30-4222-3055-75

40-54

110-13080-94

50-7036-51

18-2513-18

5-74-5

20-2714-2019-21

14-15

30-4022-29

18-2513-18

70-7551-5415-1811-13

15-1811-13

Page 312 of 1216

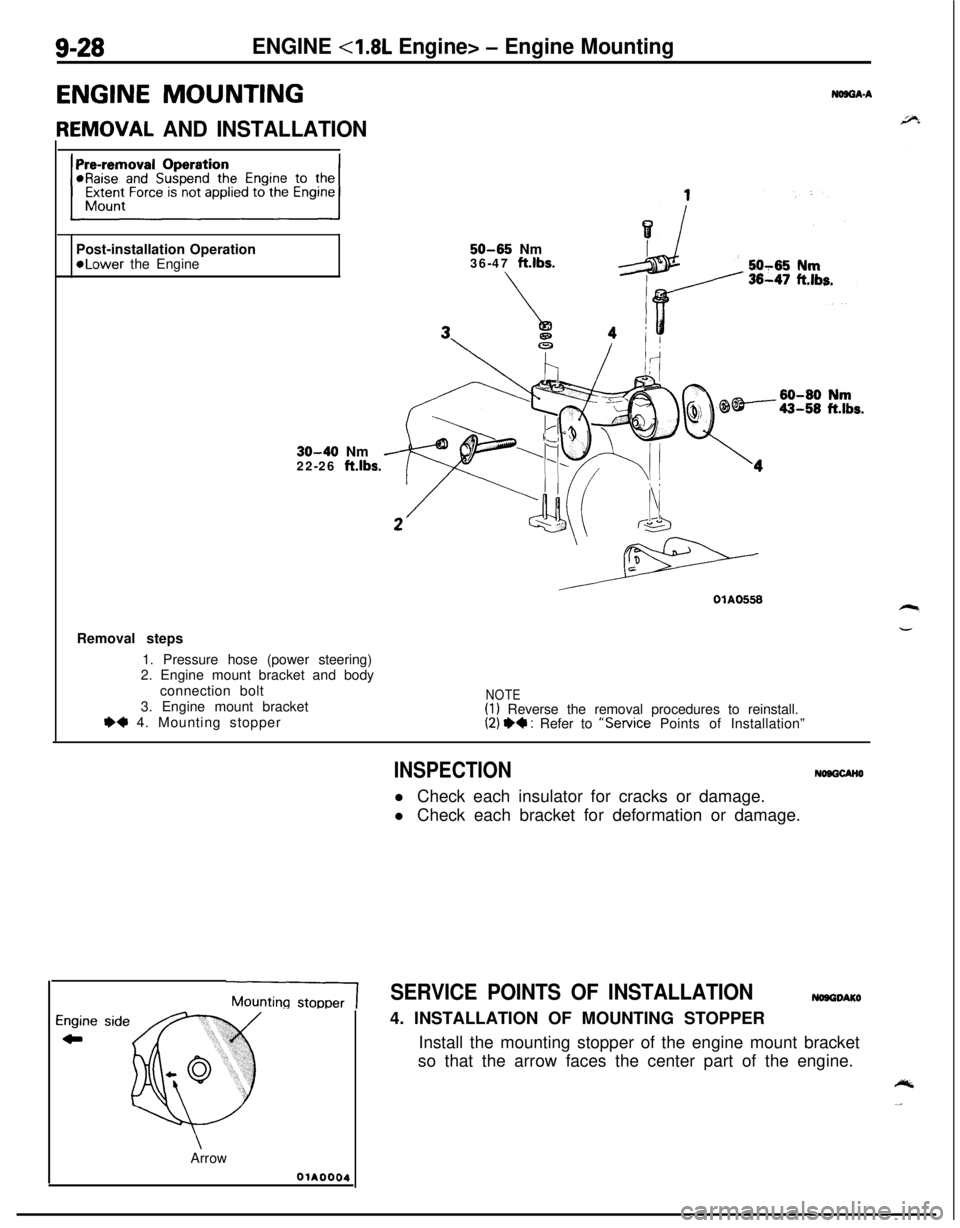

9-28ENGINE <1.8L Engine> - Engine Mounting

ENGINE MOUNTING

IEMOVAL AND INSTALLATION

NOB8A-APost-installation Operation

50-65 Nm*Lower the Engine36-47 ft.lbs.

30-40 Nm

22-26 ft.lbs.Removal steps

1. Pressure hose (power steering)

2. Engine mount bracket and body

connection bolt

3. Engine mount bracket

e+ 4. Mounting stopper

NOTE(1) Reverse the removal procedures to reinstall.(2) +* : Refer to “Service Points of Installation”

INSPECTIONNOOQCANOl Check each insulator for cracks or damage.

l Check each bracket for deformation or damage.

MountingSERVICE POINTS OF INSTALLATION4. INSTALLATION OF MOUNTING STOPPER

Install the mounting stopper of the engine mount bracket

so that the arrow faces the center part of the engine.

Arrow

OiA0004

Page 316 of 1216

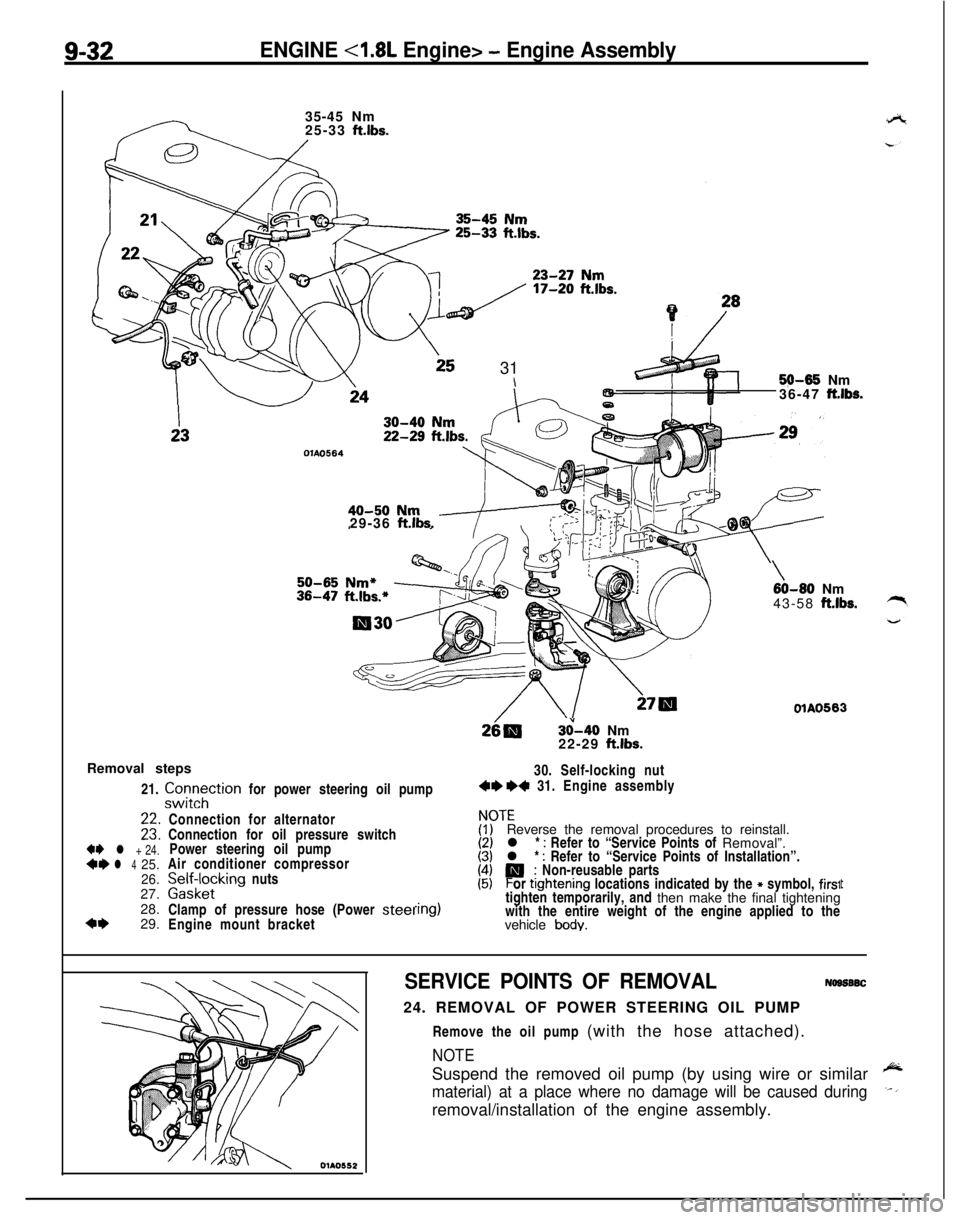

9-32ENGINE <1.8L Engine> - Engine Assembly35-45 Nm

25-33

ft.lbs.

25 31\5$M35 Nm

36-47 ft.lbs.

OlAO56429-36

ft.lbs.

3&40 Nm

22-29 ft.lbs.

Removal steps

21.

zztTtion for power steering oil pump30. Self-locking nut4e +4 31. Engine assembly

+e l + 24.*I)l 425.

26.27.

28.

4+29.

\60-80 Nm

43-58 ft.lbs.

OlAO563Connection for alternator

Connection for oil pressure switch

Power steering oil pump

Air conditioner compressor

palffz,cklng nuts

Clamp of pressure hose (Power

steelEngine mount bracket

ITEReverse the removal procedures to reinstall.

l *

: Refer to “Service Points of Removal”.

l * : Refer to “Service Points of Installation”.

P; Non-reusable parts

or ttghtening locations indicated by the * symbol, firs1tighten temporarily, and then make the final tightening

with the entire weight of the engine applied to the

vehicle

body.

t

SERVICE POINTS OF REMOVALNogs6SC24. REMOVAL OF POWER STEERING OIL PUMP

Remove the oil pump (with the hose attached).

NOTESuspend the removed oil pump (by using wire or similar

material) at a place where no damage will be caused duringremoval/installation of the engine assembly.

Page 317 of 1216

ENGINE <1.8L Engine> - Engine Assemblv9-33

c

!

OlAO582

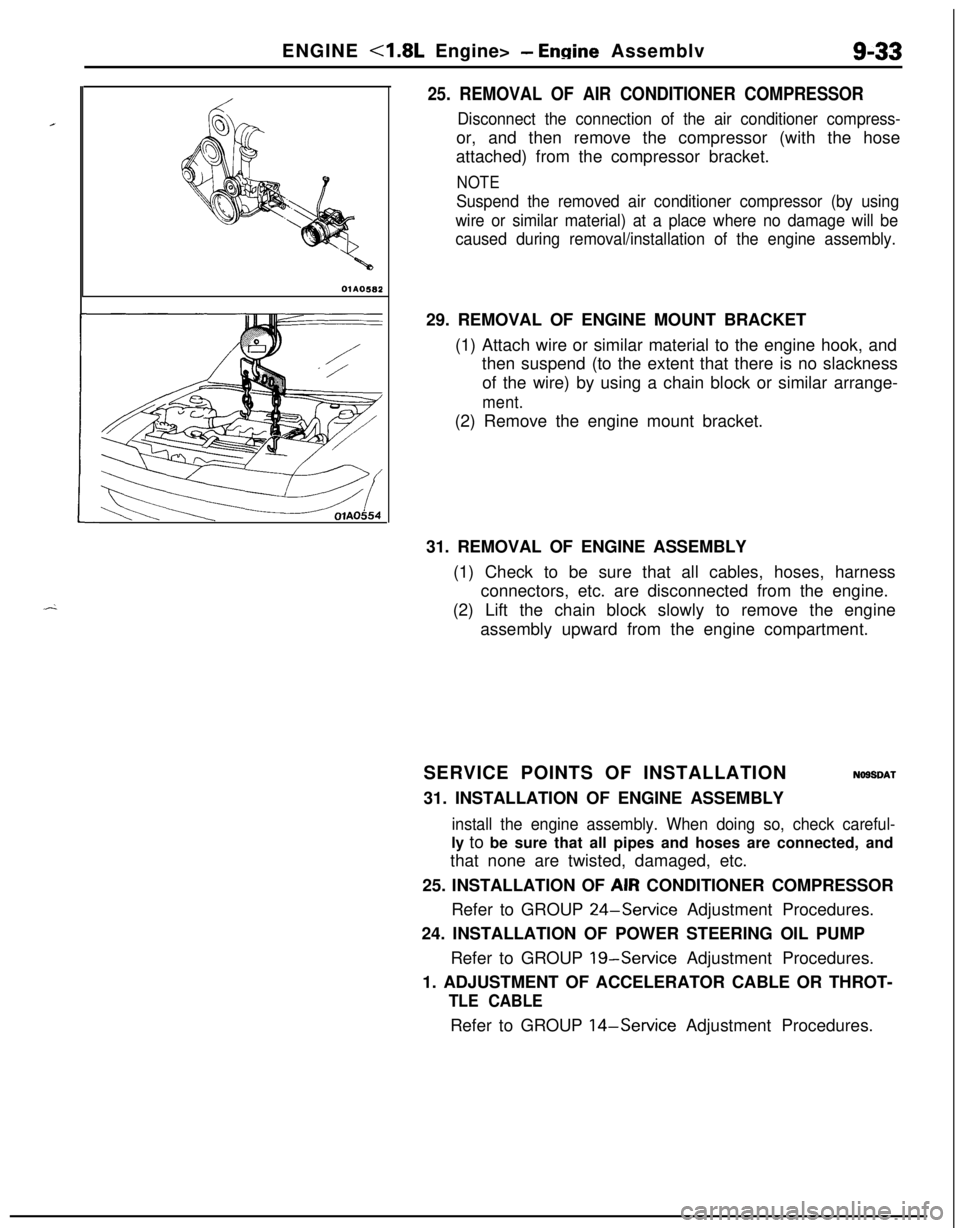

25. REMOVAL OF AIR CONDITIONER COMPRESSOR

Disconnect the connection of the air conditioner compress-or, and then remove the compressor (with the hose

attached) from the compressor bracket.

NOTE

Suspend the removed air conditioner compressor (by using

wire or similar material) at a place where no damage will be

caused during removal/installation of the engine assembly.29. REMOVAL OF ENGINE MOUNT BRACKET

(1) Attach wire or similar material to the engine hook, and

then suspend (to the extent that there is no slackness

of the wire) by using a chain block or similar arrange-

ment.(2) Remove the engine mount bracket.

31. REMOVAL OF ENGINE ASSEMBLY

(1) Check to be sure that all cables, hoses, harness

connectors, etc. are disconnected from the engine.

(2) Lift the chain block slowly to remove the engine

assembly upward from the engine compartment.

SERVICE POINTS OF INSTALLATION

NOSSDAT31. INSTALLATION OF ENGINE ASSEMBLY

install the engine assembly. When doing so, check careful-ly to be sure that all pipes and hoses are connected, and

that none are twisted, damaged, etc.

25. INSTALLATION OF AIR CONDITIONER COMPRESSOR

Refer to GROUP

24-Service Adjustment Procedures.

24. INSTALLATION OF POWER STEERING OIL PUMP

Refer to GROUP

19-Service Adjustment Procedures.

1. ADJUSTMENT OF ACCELERATOR CABLE OR THROT-

TLE CABLERefer to GROUP

14-Service Adjustment Procedures.

Page 320 of 1216

9-36ENGINE

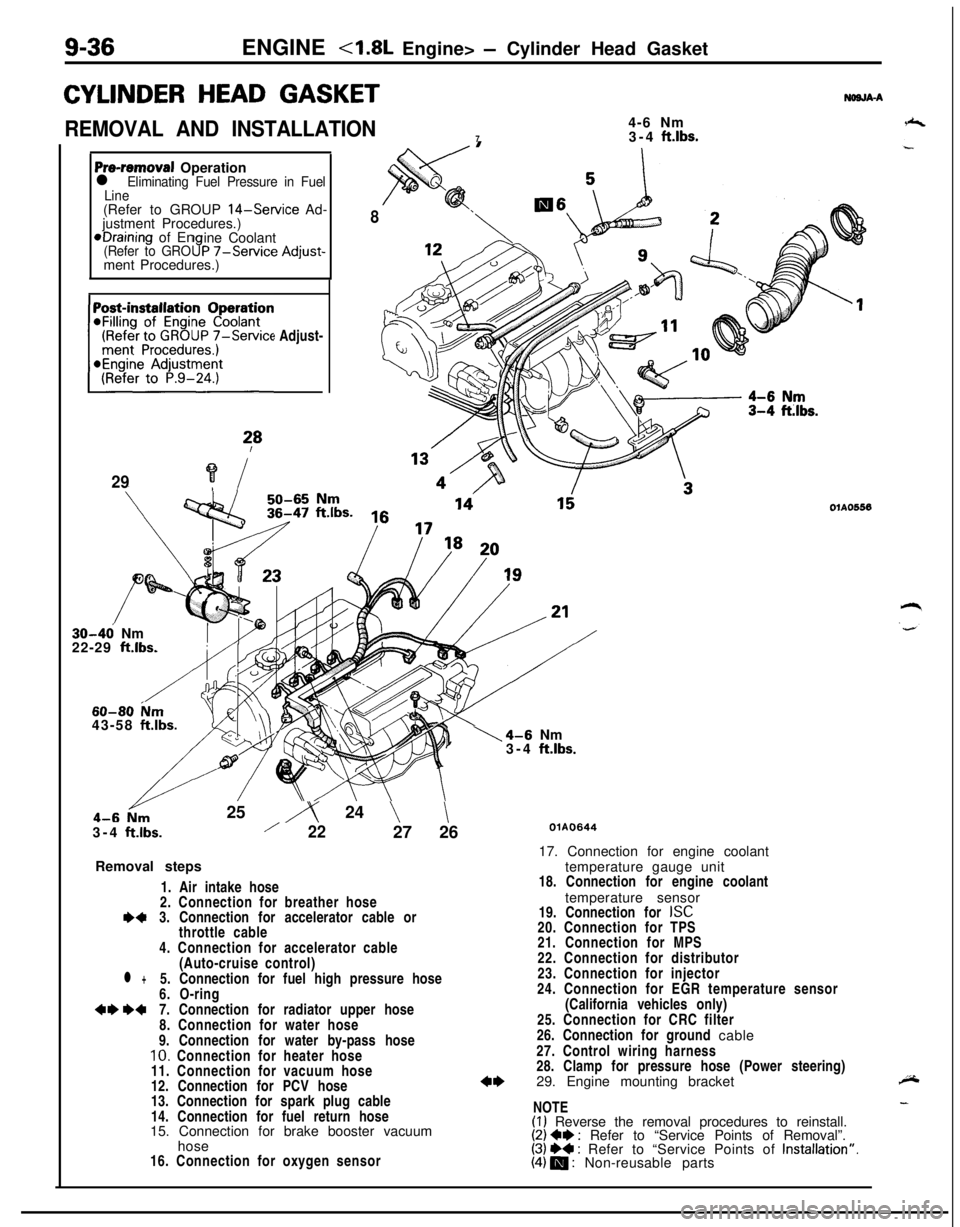

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION4-6 Nm

73-4 ft.lbs.

NWJA-A

Pre-removal Operationl Eliminating Fuel Pressure in Fuel

Line(Refer to GROUP

14-Service Ad-

justment Procedures.)*Draining of En

ine Coolant

(Refer to GRO9P -/-Service Adjust-ment Procedures.)

(Refer to GROUP

7-Service Adjust-~~~~~~~n

?*

29?i

8

30-46 Nm

22-29 ft.lbs.

60-80 ium43-58 ftlbs.25

iy 24 \\3-4

ftlbs./2227 26

Removal steps

1. Air intake hose

2. Connection for breather hose

I)43. Connection for accelerator cable or

throttle cable

4. Connection for accelerator cable

(Auto-cruise control)

l +5. Connection for fuel high pressure hose

6. O-ring

+e W7. Connection for radiator upper hose

8. Connection for water hose

9. Connection for water by-pass hose

10. Connection for heater hose

11. Connection for vacuum hose

12. Connection for PCV hose

13. Connection for spark plug cable

14. Connection for fuel return hose

15. Connection for brake booster vacuum

hose

16. Connection for oxygen sensor

1\4-6 Nm

3-4 ftlbs.

OlAO556

QlAO64417. Connection for engine coolant

temperature gauge unit

18. Connection for engine coolant

temperature sensor

19. Connection for

ISC20. Connection for TPS

21. Connection for MPS

22. Connection for distributor

23. Connection for injector

24. Connection for EGR temperature sensor

(California vehicles only)

25. Connection for CRC filter

26. Connection for ground cable

27. Control wiring harness

28. Clamp for pressure hose (Power steering)

29. Engine mounting bracket

NOTE

(I) Reverse the removal procedures to reinstall.(2) Ce : Refer to “Service Points of Removal”.(3) ++ : Refer to “Service Points of Installation”.(4) m : Non-reusable parts