wiring MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 315 of 1216

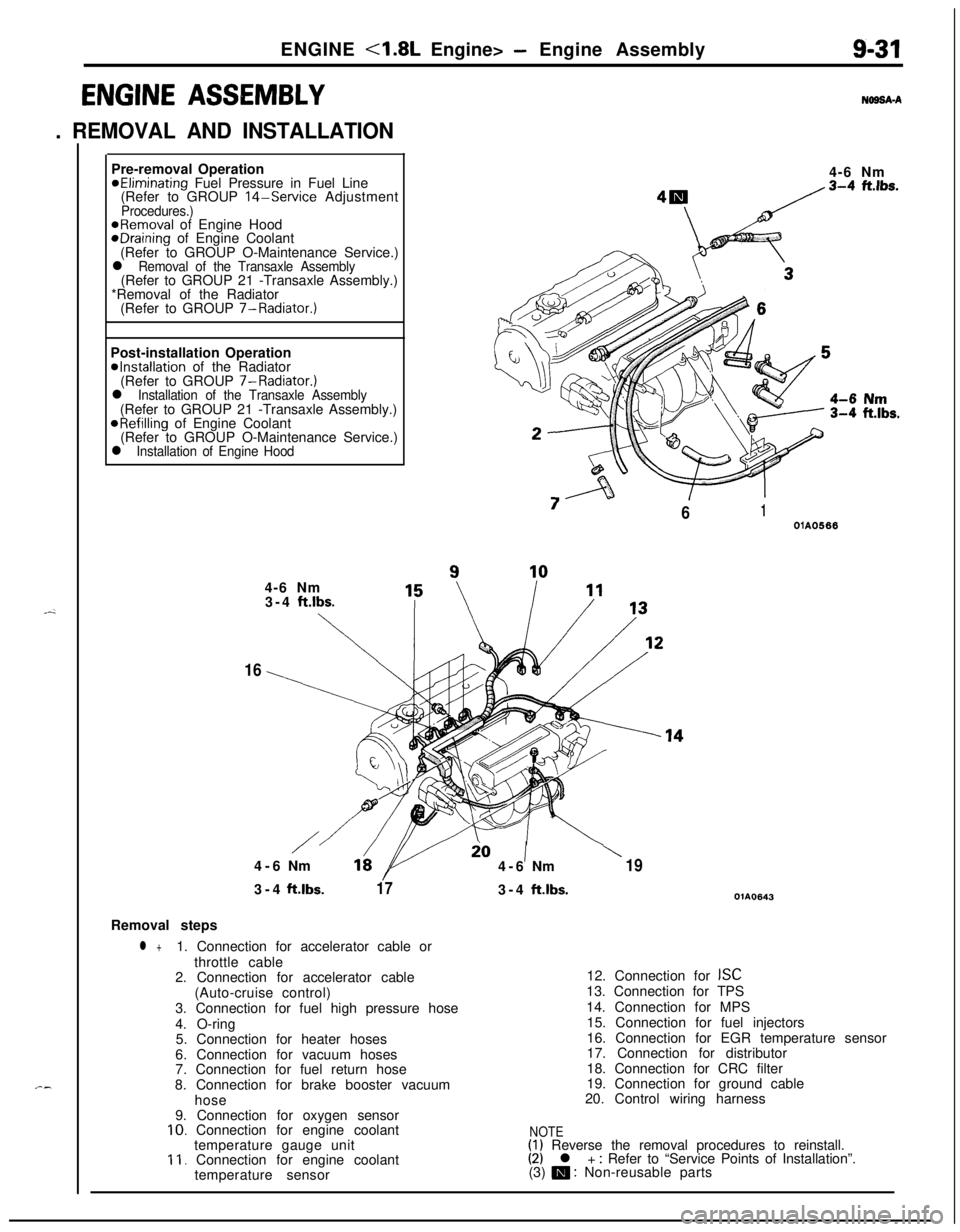

ENGINE <1.8L Engine> - Engine Assembly9-31

ENGINE ASSEMBLY

. REMOVAL AND INSTALLATION

N69SA-APre-removal Operation

@Eliminating Fuel Pressure in Fuel Line

(Refer to GROUP 14-Service AdjustmentProcedures.)@Removal of Engine HoodeDraining of Engine Coolant

(Refer to GROUP O-Maintenance Service.)

l Removal of the Transaxle Assembly(Refer to GROUP 21 -Transaxle Assembly.)

*Removal of the Radiator

(Refer to GROUP 7-Radiator.)

Post-installation Operation

@Installation of the Radiator

(Refer to GROUP 7-Radiator.)

l Installation of the Transaxle Assembly(Refer to GROUP 21 -Transaxle Assembly.)

@Refilling of Engine Coolant

(Refer to GROUP O-Maintenance Service.)

l Installation of Engine Hood4-6 Nm

“7

/61OlA05664-6 Nm

3-4

ft.lbs.

\

16

/io1\4-6Nm164-6Nm193-4ft.lbs.

173-4ft.lbs.OlA0643Removal steps

l +1. Connection for accelerator cable or

throttle cable

2. Connection for accelerator cable

(Auto-cruise control)

3. Connection for fuel high pressure hose

4. O-ring

5. Connection for heater hoses

6. Connection for vacuum hoses

7. Connection for fuel return hose

8. Connection for brake booster vacuum

hose

9. Connection for oxygen sensor

10. Connection for engine coolant

temperature gauge unit

11. Connection for engine coolant

temperature sensor12. Connection for

ISC13. Connection for TPS

14. Connection for MPS

15. Connection for fuel injectors

16. Connection for EGR temperature sensor

17. Connection for distributor

18. Connection for CRC filter

19. Connection for ground cable

20. Control wiring harness

NOTE(1) Reverse the removal procedures to reinstall.(2) l + : Refer to “Service Points of Installation”.

(3) m : Non-reusable parts

Page 320 of 1216

9-36ENGINE

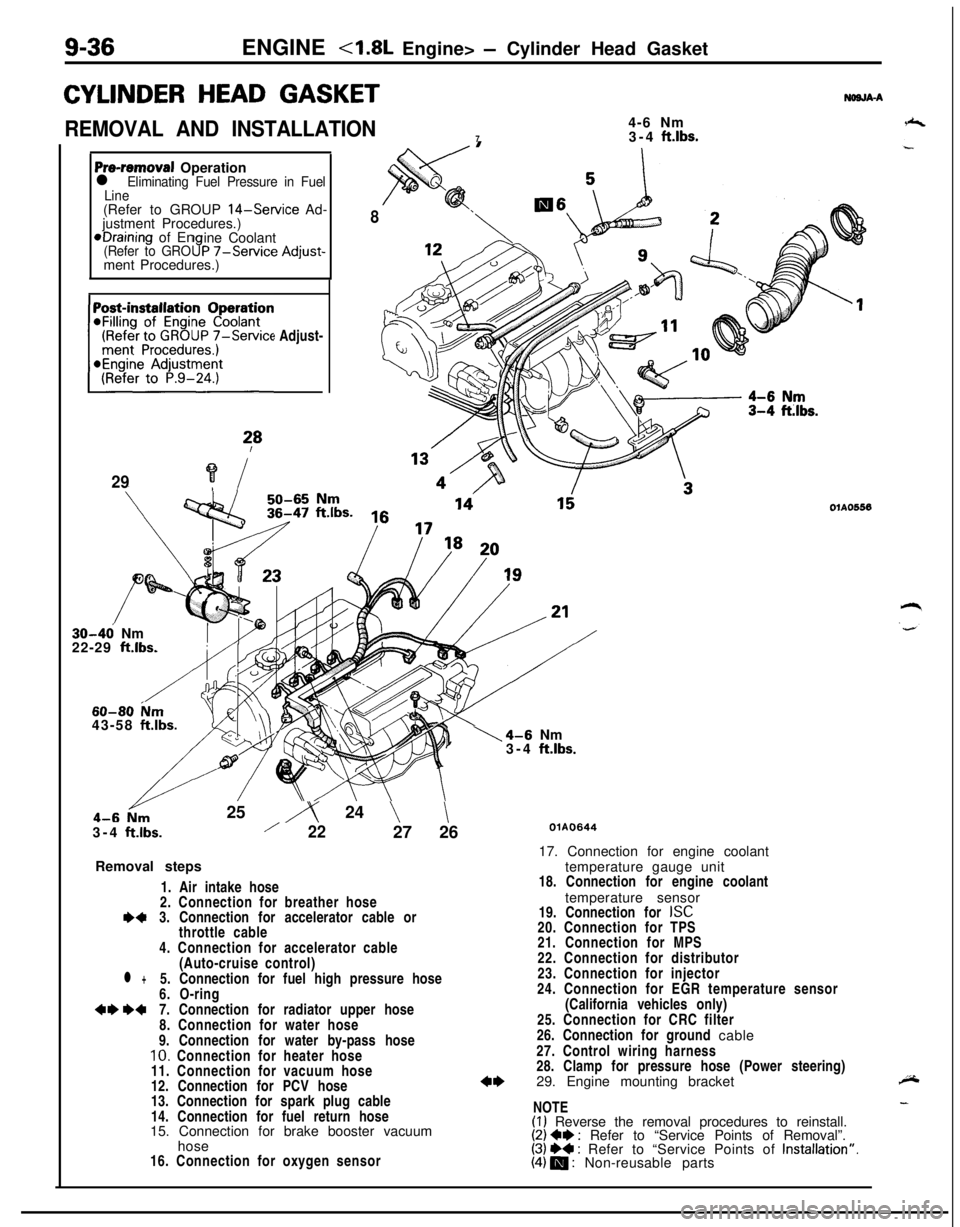

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION4-6 Nm

73-4 ft.lbs.

NWJA-A

Pre-removal Operationl Eliminating Fuel Pressure in Fuel

Line(Refer to GROUP

14-Service Ad-

justment Procedures.)*Draining of En

ine Coolant

(Refer to GRO9P -/-Service Adjust-ment Procedures.)

(Refer to GROUP

7-Service Adjust-~~~~~~~n

?*

29?i

8

30-46 Nm

22-29 ft.lbs.

60-80 ium43-58 ftlbs.25

iy 24 \\3-4

ftlbs./2227 26

Removal steps

1. Air intake hose

2. Connection for breather hose

I)43. Connection for accelerator cable or

throttle cable

4. Connection for accelerator cable

(Auto-cruise control)

l +5. Connection for fuel high pressure hose

6. O-ring

+e W7. Connection for radiator upper hose

8. Connection for water hose

9. Connection for water by-pass hose

10. Connection for heater hose

11. Connection for vacuum hose

12. Connection for PCV hose

13. Connection for spark plug cable

14. Connection for fuel return hose

15. Connection for brake booster vacuum

hose

16. Connection for oxygen sensor

1\4-6 Nm

3-4 ftlbs.

OlAO556

QlAO64417. Connection for engine coolant

temperature gauge unit

18. Connection for engine coolant

temperature sensor

19. Connection for

ISC20. Connection for TPS

21. Connection for MPS

22. Connection for distributor

23. Connection for injector

24. Connection for EGR temperature sensor

(California vehicles only)

25. Connection for CRC filter

26. Connection for ground cable

27. Control wiring harness

28. Clamp for pressure hose (Power steering)

29. Engine mounting bracket

NOTE

(I) Reverse the removal procedures to reinstall.(2) Ce : Refer to “Service Points of Removal”.(3) ++ : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

Page 365 of 1216

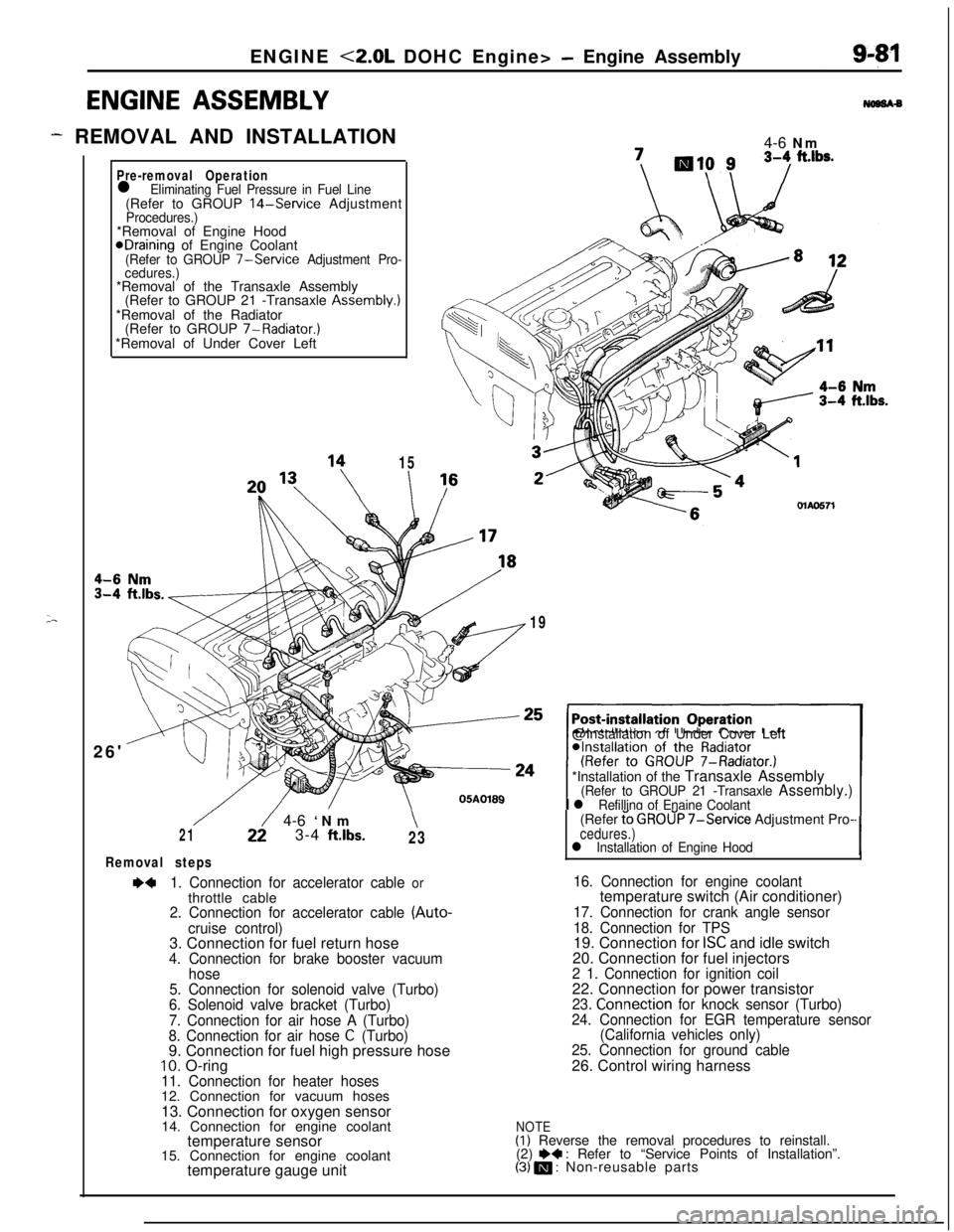

ENGINE <2.0L DOHC Engine> - Engine Assembly

ENGINE ASSEMBLY

- REMOVAL AND INSTALLATION

;-

Pre-removal Operationl Eliminating Fuel Pressure in Fuel Line(Refer to GROUP 14-Service AdjustmentProcedures.)*Removal of Engine Hood

@Draining of Engine Coolant(Refer to GROUP 7-Service Adjustment Pro-

cedures.)*Removal of the Transaxle Assembly

(Refer to GROUP 21 -Transaxle Assembly.)

*Removal of the Radiator

(Refer to GROUP 7-Radiator.)

*Removal of Under Cover Left

26'

15

I4-6 Nm\I /MAO571

19@Installation of Under Cover Left

*Installation of the Transaxle Assembly

(Refer to GROUP 21 -Transaxle Assembly.)

I l Refilling of Enaine Coolant

/22/ 4-6 ‘Nm\213-4 ftlbs.23

Removal steps

~~1. Connection for accelerator cable orthrottle cable

2. Connection for accelerator cable (Auto-

cruise control)3. Connection for fuel return hose

4. Connection for brake booster vacuum

hose

5. Connection for solenoid valve (Turbo)

6. Solenoid valve bracket (Turbo)

7. Connection for air hose A (Turbo)

8. Connection for air hose

C (Turbo)9. Connection for fuel high pressure hose

10. O-ring11. Connection for heater hoses12. Connection for vacuum hoses

13. Connection for oxygen sensor

14. Connection for engine coolant

temperature sensor

15. Connection for engine coolant

temperature gauge unit(Refer

t’o GROUP 7-Service Adjustment Pro-cedures.)l Installation of Engine Hood‘I

16. Connection for engine coolanttemperature switch (Air conditioner)

17. Connection for crank angle sensor

18. Connection for TPS19. Connection for

ISC and idle switch

20. Connection for fuel injectors

2 1. Connection for ignition coil22. Connection for power transistor

23. Connection for knock sensor (Turbo)

24. Connection for EGR temperature sensor

(California vehicles only)

25. Connection for ground cable26. Control wiring harness

NOTE(I) Reverse the removal procedures to reinstall.

(2) e+ : Refer to “Service Points of Installation”.(3) m : Non-reusable parts

Page 366 of 1216

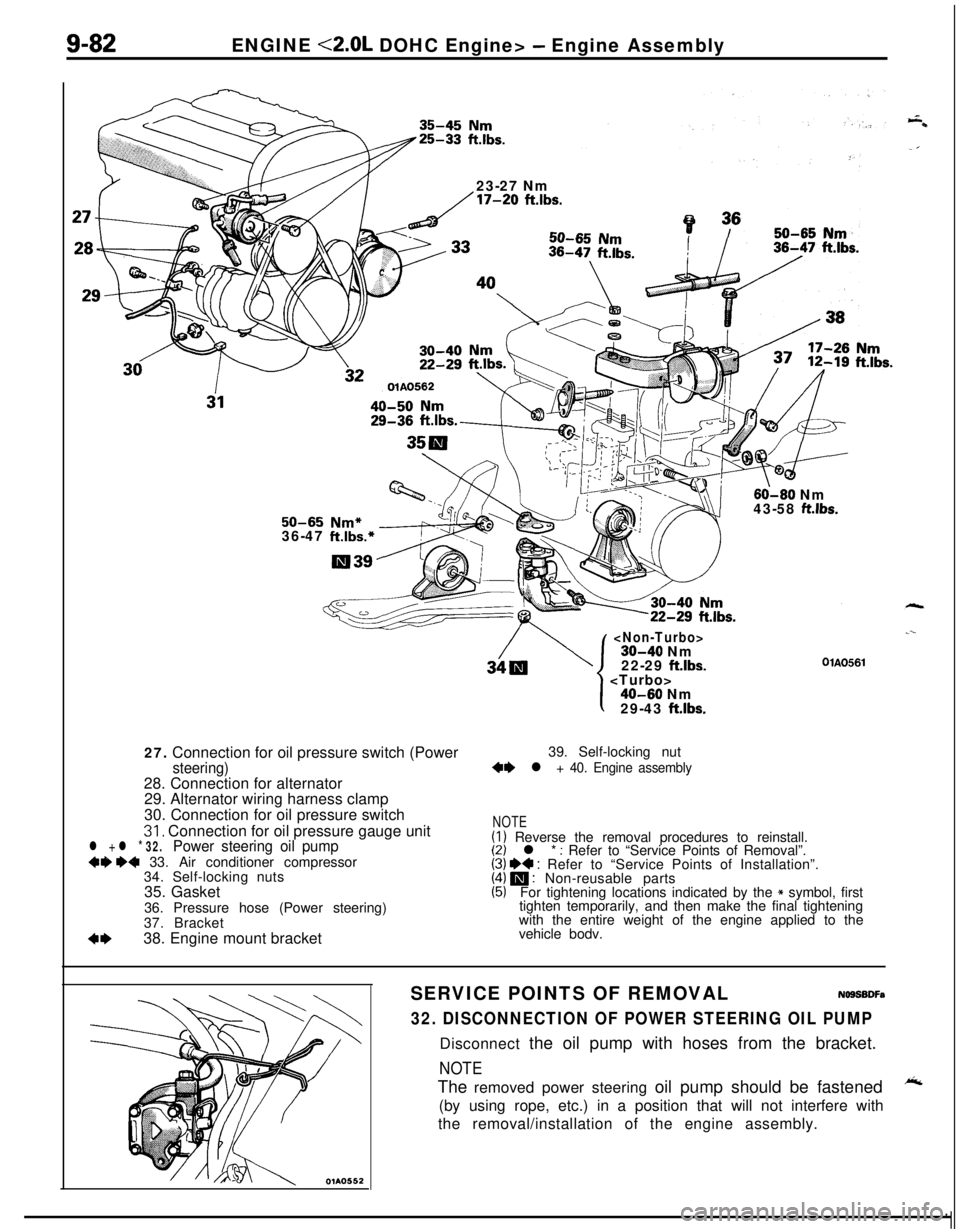

9-82ENGINE <2.0L DOHC Engine> - Engine Assembly

23-27 Nm

/17-20 ftlbs.

60-60 Nm

43-58 ft.lbs.50-65 Nm*36-47 ft.lbs.*27. Connection for oil pressure switch (Power

steering)28. Connection for alternator

29. Alternator wiring harness clamp

30. Connection for oil pressure switch

31, Connection for oil pressure gauge unitl + l * 32.Power steering oil pump+9 ~~ 33. Air conditioner compressor

34. Self-locking nuts

35. Gasket

36. Pressure hose (Power steering)

37. Bracket

4*38. Engine mount bracket

22-29 ftlbs.

.--

OlAO561

1

I40-60 Nm

29-43 ft.lbs.39. Self-locking nut

+e l + 40. Engine assembly

NOTE(I) Reverse the removal procedures to reinstall.(2) l * : Refer to “Service Points of Removal”.(3) I)+ : Refer to “Service Points of Installation”.(4) m : Non-reusable parts(5)For tightening locations indicated by the * symbol, first

tighten temporarily, and then make the final tightening

with the entire weight of the engine applied to the

vehicle bodv.

SERVICE POINTS OF REMOVALNOSSBDFa

32. DISCONNECTION OF POWER STEERING OIL PUMPDisconnect the oil pump with hoses from the bracket.

NOTEThe removed power steering oil pump should be fastened

A(by using rope, etc.) in a position that will not interfere with

the removal/installation of the engine assembly.

Page 565 of 1216

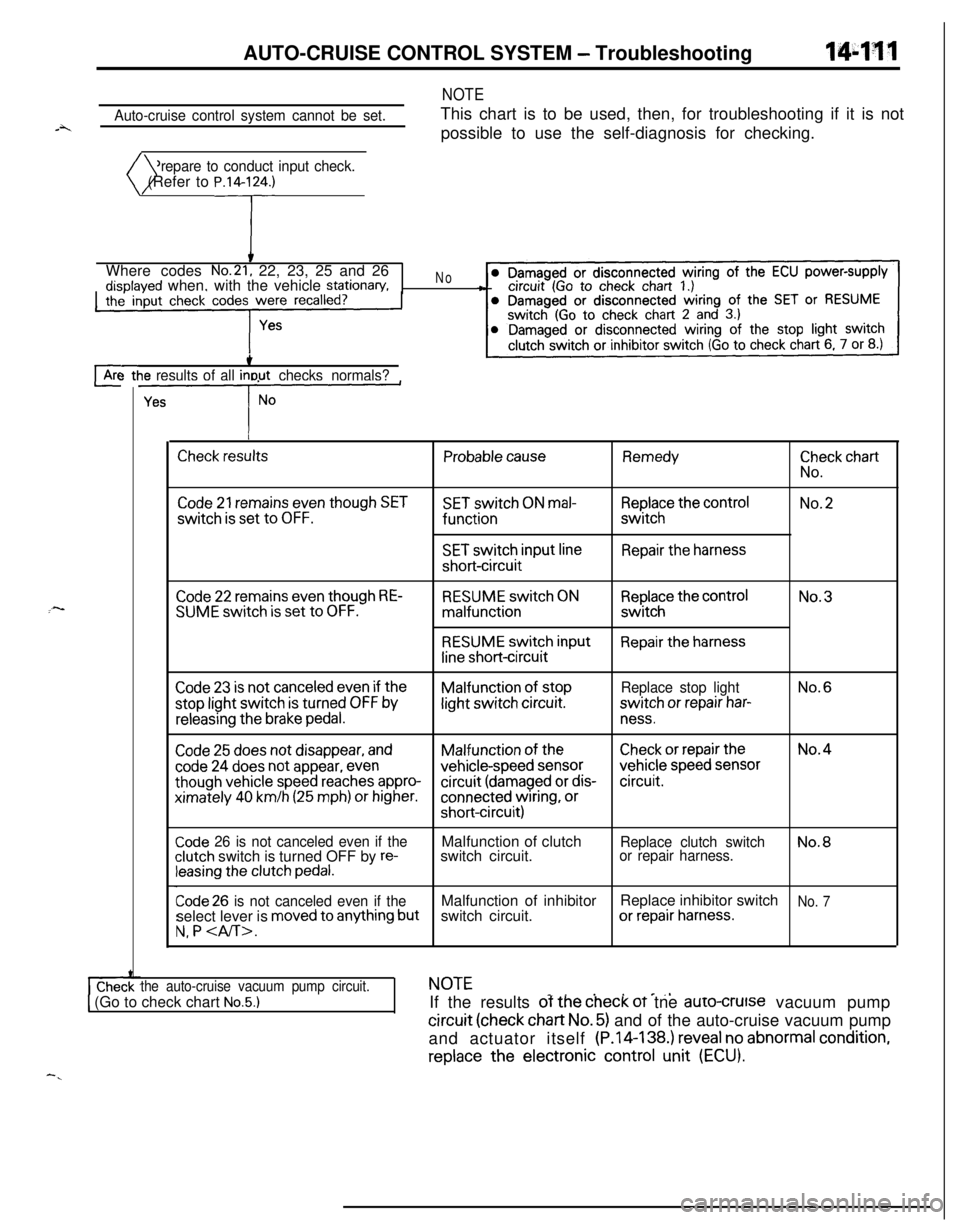

AUTO-CRUISE CONTROL SYSTEM - Troubleshooting144w

Auto-cruise control system cannot be set.

NOTEThis chart is to be used, then, for troubleshooting if it is not

possible to use the self-diagnosis for checking.

Prepare to conduct input check.

)( (Refer to P.14lrWhere codes

No.21, 22, 23, 25 and 26disolaved when, with the vehicle stationary,the’ input check codes were recalled?

‘#

No-8

cArc-3 ttie results of all inout checks normals?

L--y--

I

Check resultsProbable causeRemedy

ii”,:” chart

Code 21 remains even though SETSET switch ON mal-Replace the controlNo.2switch

is set to OFF.functionswitch

SET switch input lineRepair the harnessshort-circuit

:-Code 22 remains even though RE-SUME switch is set to OFF.RESUME switch ONmalfunction

RESUME switch input

line short-circuit

Replace the controlswitch

Repair the harnessNo.3

Code 23 is not canceled even if theMalfunction of stopReplace stop lightNo.6stop light switch

is turned OFF bylight switch circuit.switch or repair har-

releasing the brake pedal.ness.

Code 25 does not disappear, andMalfunction of theCheck or repair theNo.4

code 24 does not appear, evenvehicle-speed sensorvehicle speed sensor

though vehicle speed reaches appro-circuit (damaged or dis-circuit.ximately

40 km/h (25 mph) or higher.connected wiring, orshort-circuit)

Code 26 is not canceled even if theclutch switch is turned OFF by re-leasing the clutch pedal.Malfunction of clutch

switch circuit.

Replace clutch switchNo.8or repair harness.

Code 26 is not canceled even if theMalfunction of inhibitorReplace inhibitor switchNo. 7select lever is moved to anything butswitch circuit.or repair harness.

N, P

the auto-cruise vacuum pump circuit.NOTE_. . . e_,1 (Go to check chart No.5.)IIf the results of the check oT tne auro-crutse vacuum pump

circuit (check chart No. 5) and of the auto-cruise vacuum pump

and actuator itself (P.14-138.) reveal no abnormal

condition,replace

the electronic control unit (ECU).

-.

Page 566 of 1216

14-112AUTO-CRUISE CONTROL SYSTEM - Troubleshootina

Trouble symptomProbable causeCheck chart No.Remedy

l The set vehicle speed variesMalfunction of the vehi-No.4Repair the vehicle speec

greatly upward or downward.cle speed sensor circuitsensor system, or re-l “Hunching”

(repeated alternatingplace the part.

acceleration and deceleration)Malfunction of the

occurs after setting is made.speedometer cable orspeedometer drive gearAuto-cruise

vacuumNo.5Repair the auto-cruise

pump circuit poor con-vacuum pump, ortactreplace the part.Malfunction of the

auto-

cruise vacuum pumpMalfunction of the

ECU-Replace the ECU.

The auto-cruise control system is notDamaged or discon-If the input check codeRepair the harness or

canceled when the brake pedal isnetted wiring of theNo. 23 indicates a mal-replace the stop light

depressed.stop light switch inputfunction. No. 6switch.circuit; brake switch (forauto-cruise control) mal-function (short-circuit)Auto-cruise

vacuumNo. 5Repair the harness or

pump drive circuit short-replace the auto-cruisecircuitvacuum pump.Malfunction of the

ECU-Replace the ECU.

The auto-cruise control system is notDamaged or discon-If the input check codeRepair the harness, or

canceled when the clutch pedal isnetted wiring of clutchNo. 26 indicates a mal-repair or replace the

depressed. (vehicles with a manualswitch input circuitfunction. No. 8clutch switch.

transaxle)(It is canceled, however, when theClutch switch improper

brake pedal is depressed.)installation (won’tswitch ON)Malfunction of the

ECU-Replace the ECU.

The auto-cruise control system is notDamaged or discon-If the input check codeRepair the harness, orcanceled when the shift lever isnetted wiring of inhibi-No. 26 indicates a mal-repair or replace the in-

moved to the “N” position. (vehiclestor switch input circuitfunction. No.7hibitor switch.llvith an automatic transaxle)

[It is canceled, however, when theImproper adjustment of

Drake pedal is depressed.)inhibitor switchMalfunction of the

ECU-Replace the ECU.

Cannot decelerate by using the SETTemporary damaged orNo. 2Repair the harness orswitchdisconnected wiring ofreplace the SET switch.SET switch input circuitAuto-cruise

vacuumNo.5Repair the harness orpump circuit poor con-replace the auto-cruisetactvacuum pump andactuator.Malfunction of the auto-cruise vacuum pump

and actuator (includingclogging of negativepressure passage)Malfunction of the

ECU-Replace the ECU.

Page 567 of 1216

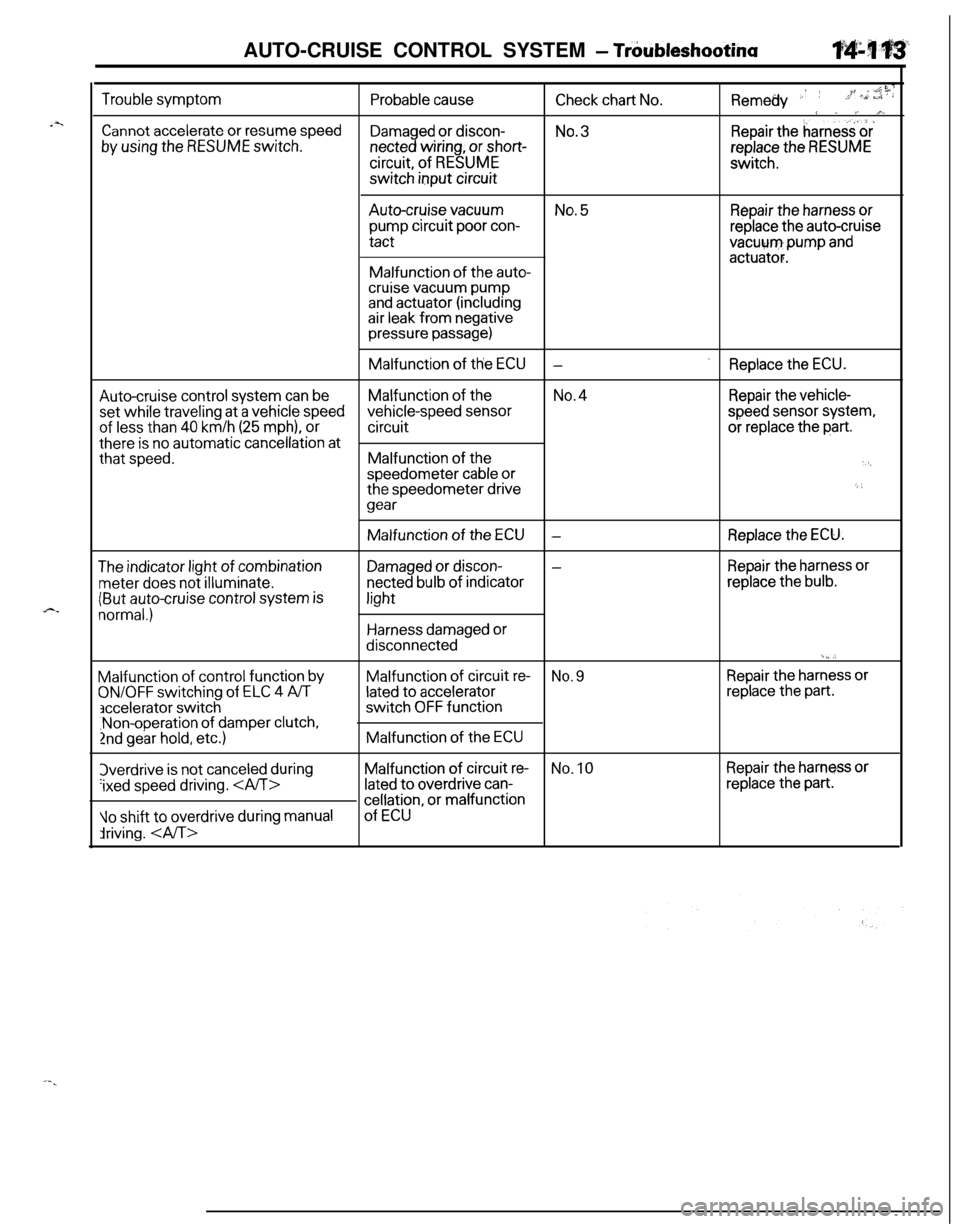

.z

c-AUTO-CRUISE CONTROL SYSTEM

- Tr6ubleshootina

Trouble symptom

Cannot accelerate or resume speed

by using the RESUME switch.

Probable cause

Damaged or discon-netted wiring, or short-circuit, of

RESUMEswitch input circuit

Remedy .’ ’-c liiCheck chart No.,;+ >,, a”:; : :

9 . /~ A%No.3.Repair theharness‘&

replace the RESUMEswitch.Auto-cruise

vacuumNo. 5Repair the harness orpump circuit poor con-replace the auto-cruisetact

vacuum,pump andactuator.Malfunction of the auto-cruise vacuum pumpand actuator (includingair leak from negativepressure passage)Malfunction of the

ECU.-Replace the ECU.

Auto-cruise control system can beMalfunction of theNo.4Repair the vehicle-set while

traveling at a vehicle speedvehicle-speed sensorspeed sensor system,

of less than 40 km/h (25 mph), orcircuitor replace the part.there

is no automatic cancellation atthat

speed.Malfunction of the‘I,speedometer cable orthe speedometer drive6 i

gear

The indicator light of combination

meter does not illuminate.

(But auto-cruise control system is

normal.)Malfunction

of control function by

ON/OFF switching of ELC 4 A/T

accelerator switch,Non-operation of damper clutch,

2nd gear hold, etc.)3verdrive

is not canceled during

‘ixed speed driving.

10 shift to overdrive during manual

driving. Malfunction of the

ECU-Replace the ECU.

Damaged or discon--Repair the harness or

netted bulb of indicatorreplace the bulb.light

Harness damaged ordisconnected

‘._,.Malfunction of circuit

re-No. 9Repair the harness or

lated to acceleratorreplace the part.switch

OFF functionMalfunction of the

ECUMalfunction of circuit

re-No. 10Repair the harness or

lated to overdrive can-replace the part.

cellation, or malfunction

of ECU

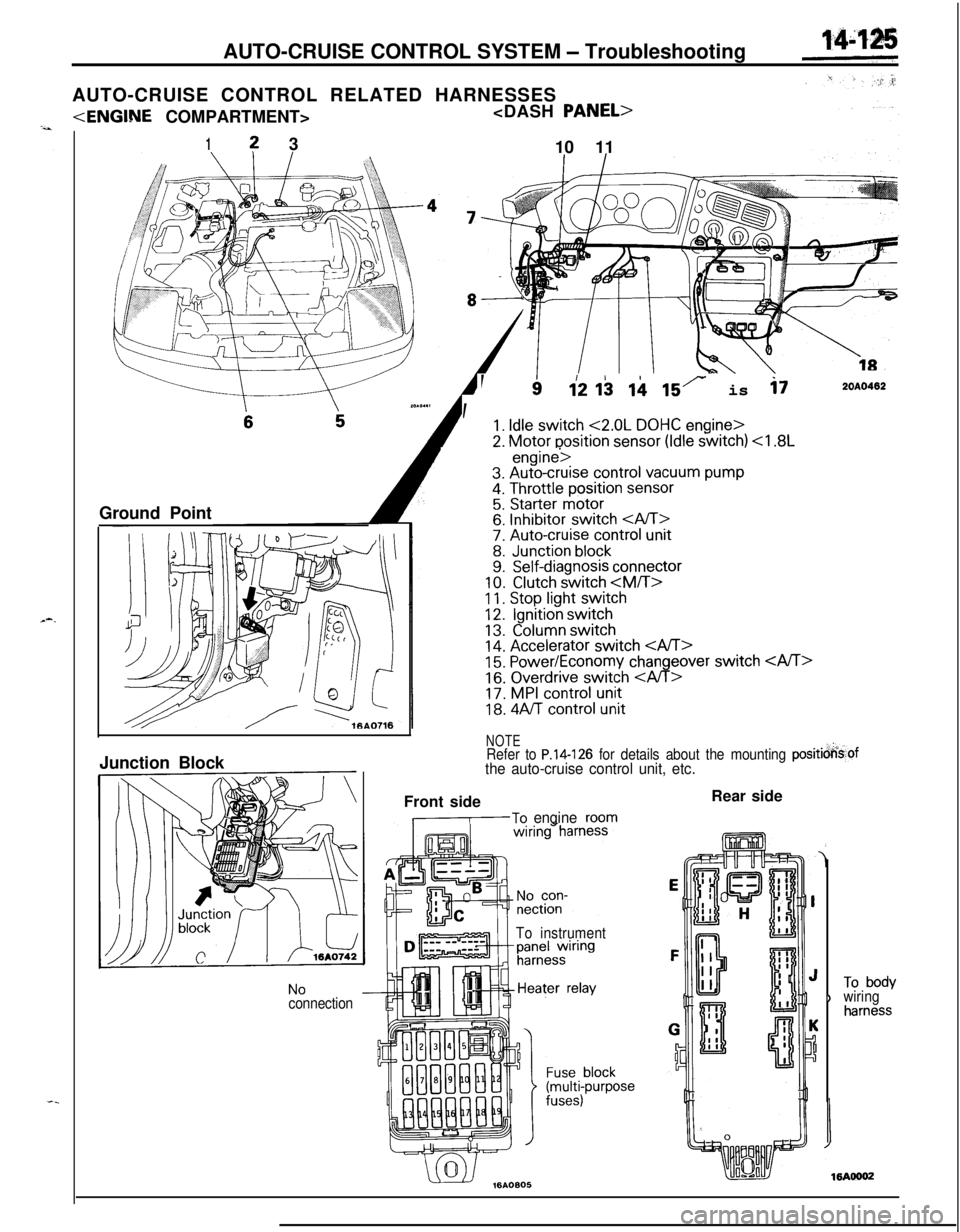

Page 579 of 1216

AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

AUTO-CRUISE CONTROL RELATED HARNESSES

1? 3

10 11

Ground Point

--

, ’

112 I$ ii 15r is i72OAO402

1. Idle switch <2.0L DOHC engine>

2. Motor position sensor (Idle switch)

11. Stop light switch12.Ignition switch

13.Column switch14. Accelerator switch 15. Power/Economy changeover switch

16. Overdrive switch

18. 4Aff control unit

NOTERefer to P.14-126 for details about the mounting positicjkof

the auto-cruise control unit, etc.Junction Block

NoconnectionFront side

,-To engineroom

To instrumentRear side

)To bodywiringharness

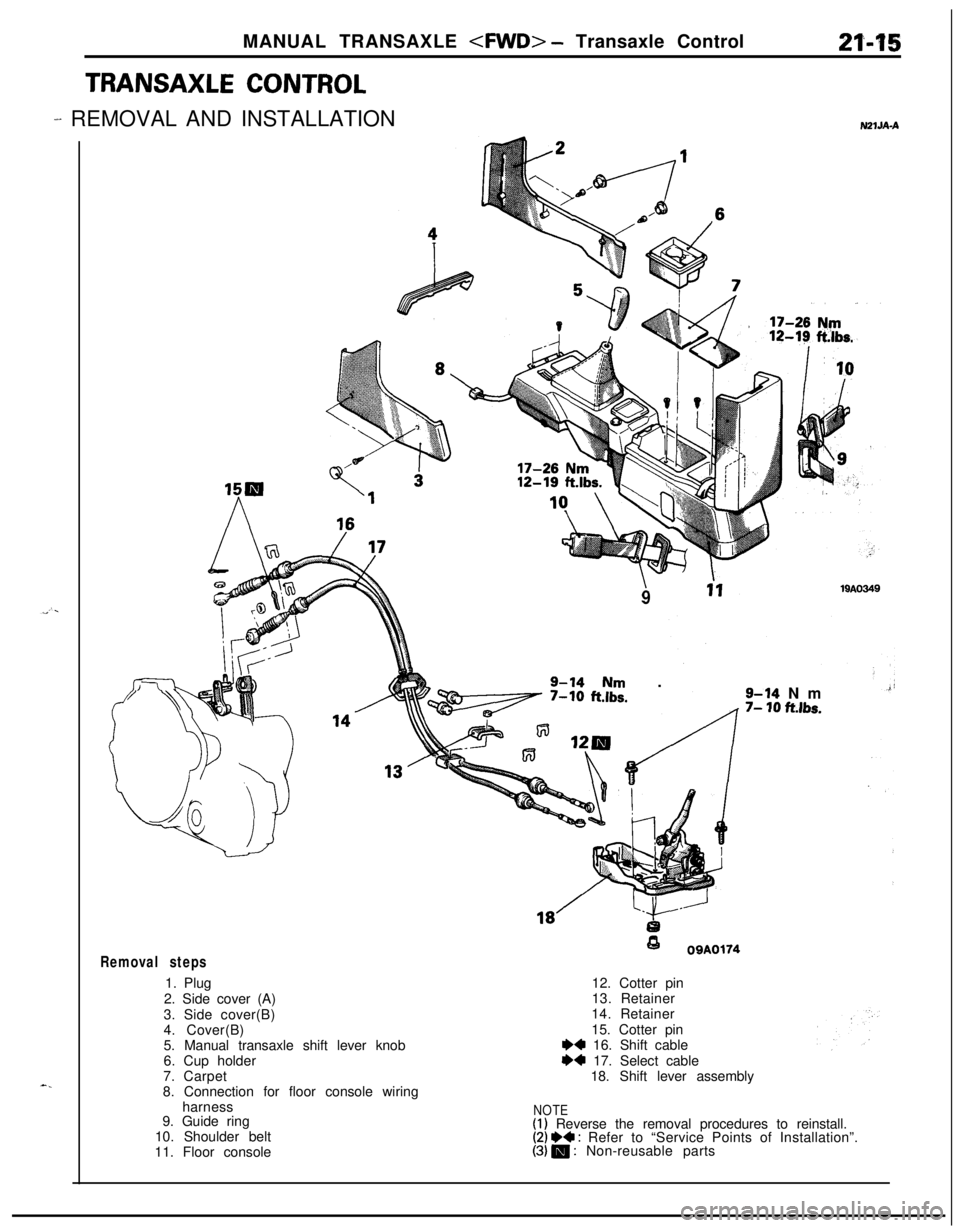

Page 709 of 1216

MANUAL TRANSAXLE

TRANSAXLE CONTROL

-^ REMOVAL AND INSTALLATION

Removal steps1. Plug

2. Side cover (A)

3. Side cover(B)

4. Cover(B)

N21JA-A

919AO349

9-14 Nm .

+-

0

0OQA017412. Cotter pin

13. Retainer

14. Retainer

15. Cotter pin

9-14 Nm7- 10 ftlbs.5. Manual transaxle shift lever knob

6. Cup holder

7. Carpet

8. Connection for floor console wiring

I)4 16. Shift cable

I)+ 17. Select cable

18. Shift lever assembly

harness

9. Guide ring

10. Shoulder belt

11. Floor console

NOTE(1) Reverse the removal procedures to reinstall.(2) *a : Refer to “Service Points of Installation”.(3) m : Non-reusable parts

Page 716 of 1216

21-22MANUAL TRANSAXLE

1 Transaxleside1 Radiator lower hose

1 Transaxle side1 Radiator lower hosepart ofdrive shaft

I

-Transaxle

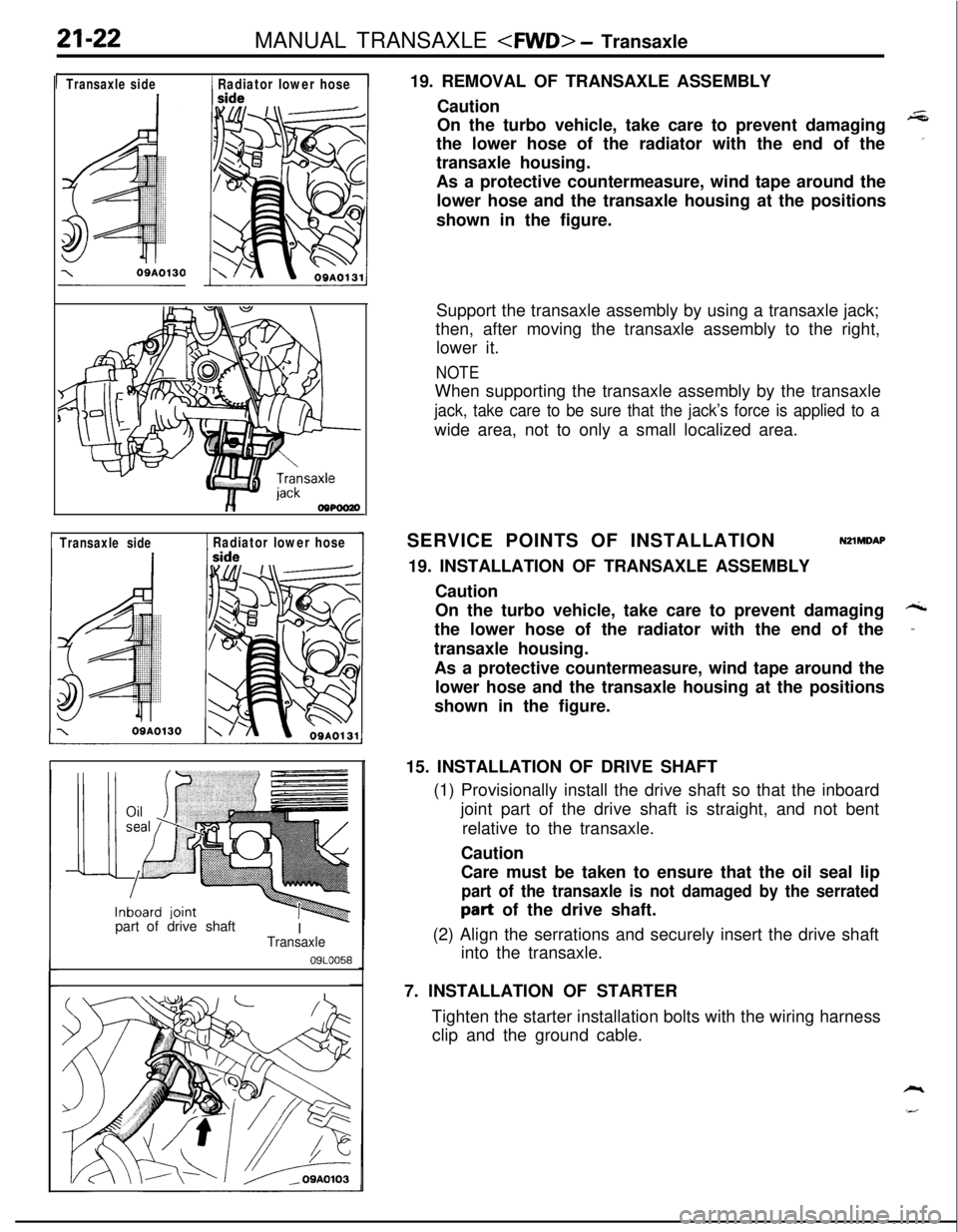

09LOO5819. REMOVAL OF TRANSAXLE ASSEMBLY

Caution

On the turbo vehicle, take care to prevent damaging

+Gthe lower hose of the radiator with the end of the

’transaxle housing.

As a protective countermeasure, wind tape around the

lower hose and the transaxle housing at the positions

shown in the figure.

Support the transaxle assembly by using a transaxle jack;

then, after moving the transaxle assembly to the right,

lower it.

NOTEWhen supporting the transaxle assembly by the transaxle

jack, take care to be sure that the jack’s force is applied to awide area, not to only a small localized area.

SERVICE POINTS OF INSTALLATION

NZlMDAP19. INSTALLATION OF TRANSAXLE ASSEMBLY

Caution

On the turbo vehicle, take care to prevent damaging

Athe lower hose of the radiator with the end of the

-transaxle housing.

As a protective countermeasure, wind tape around the

lower hose and the transaxle housing at the positions

shown in the figure.

15. INSTALLATION OF DRIVE SHAFT

(1) Provisionally install the drive shaft so that the inboard

joint part of the drive shaft is straight, and not bent

relative to the transaxle.

Caution

Care must be taken to ensure that the oil seal lip

part of the transaxle is not damaged by the serratedpart of the drive shaft.

(2) Align the serrations and securely insert the drive shaft

into the transaxle.

7. INSTALLATION OF STARTER

Tighten the starter installation bolts with the wiring harness

clip and the ground cable.