engine MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 457 of 1216

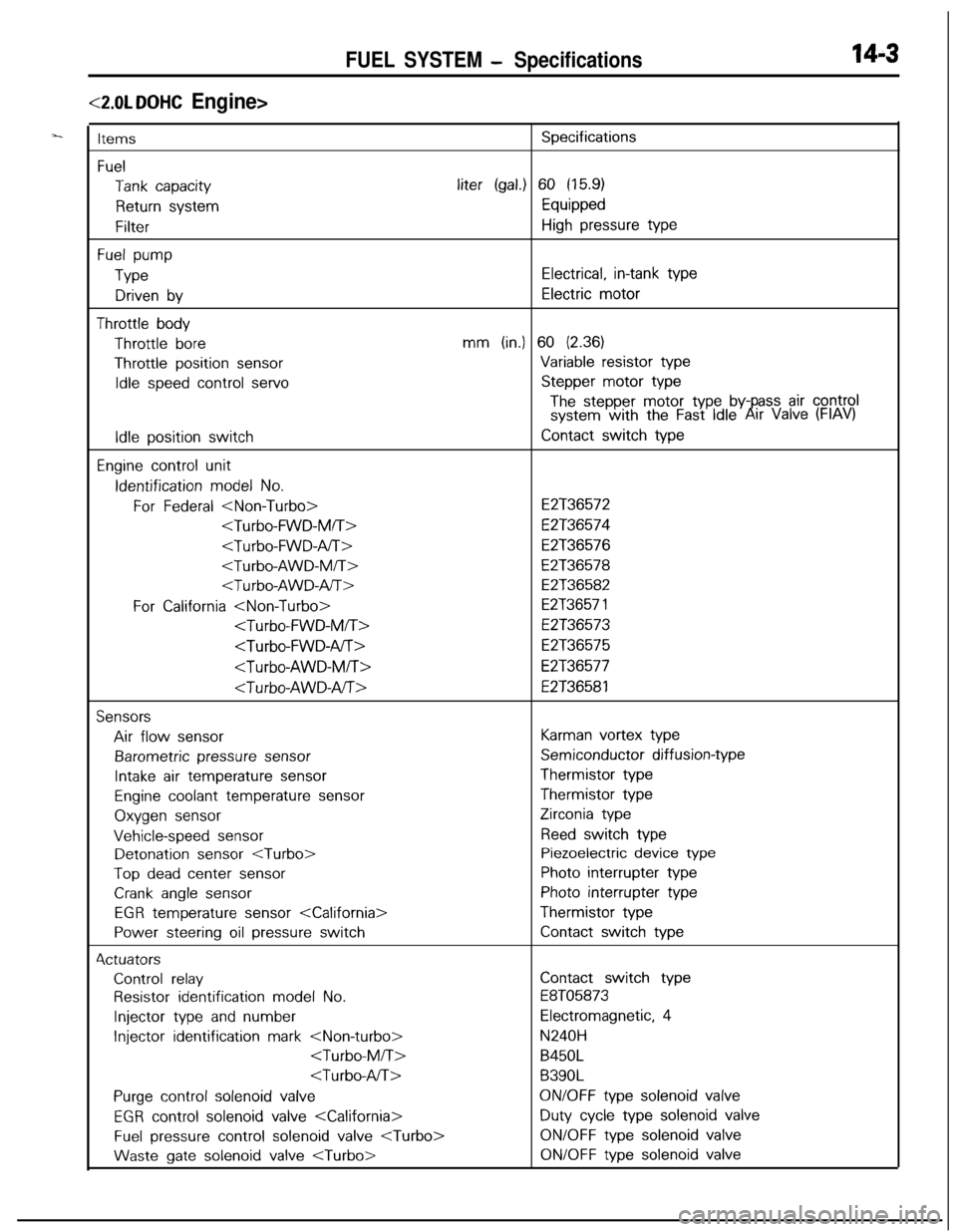

FUEL SYSTEM - Specifications14-3

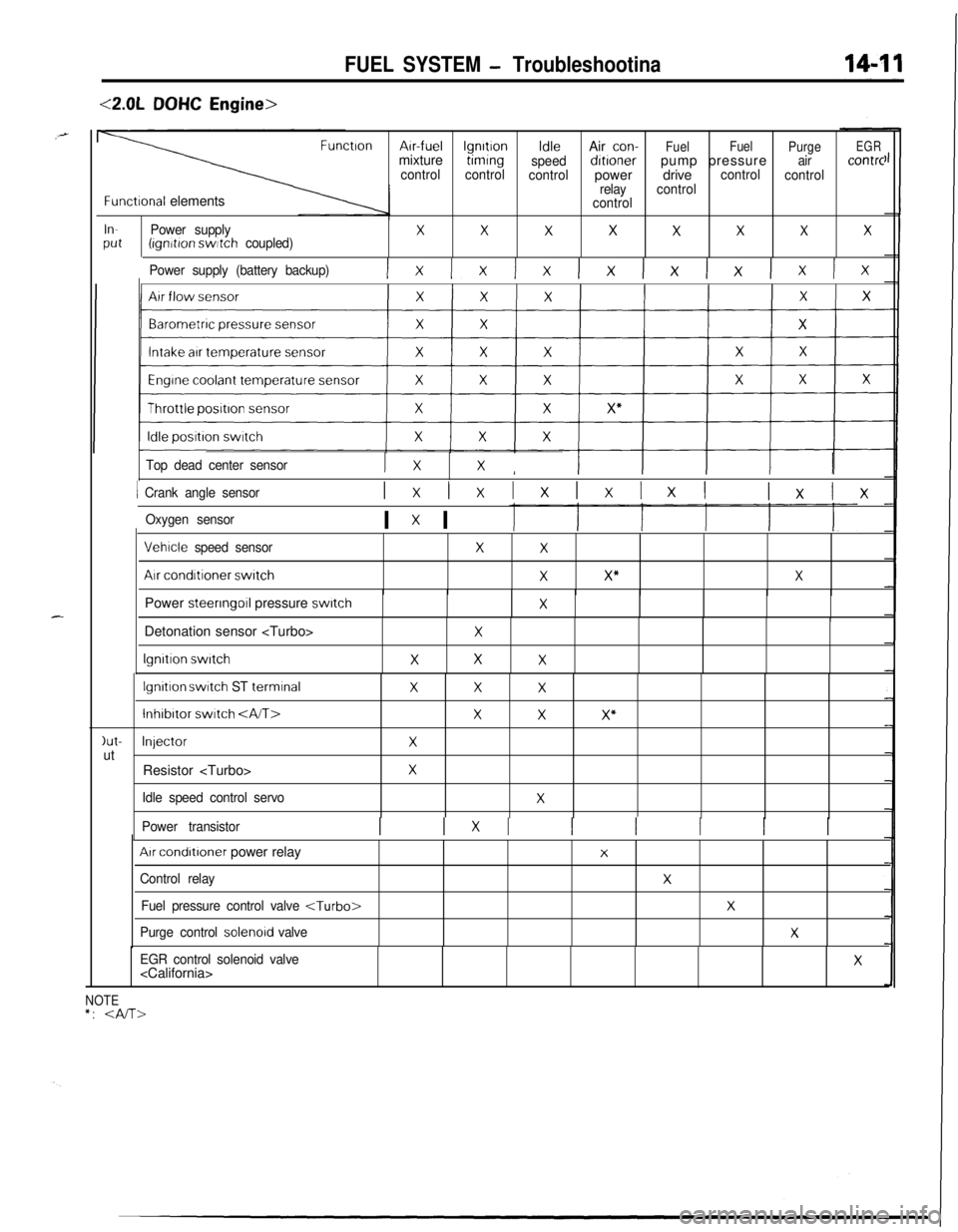

<2.0L DOHC Engine>

ItemsSpecifications

Fuel

Tank capacityliter (gal.) 60 (15.9)

Return systemEquipped

FilterHigh pressure type

Fuel pump

TypeElectrical, in-tank type

Driven byElectric motor

Throttle bodyThrottle

boremm (in.) 60 (2.36)Throttle position

sensorVariable resistor type

Idle speed control servoStepper motor type

The stepper motor type by- ass air controlsystem with the Fast Idle6!rr Valve (FIAV)

Idle position switchContact switch type

Engine control unitIdentification

model No.

For Federal

E2T36574

E2T36576

E2T36578

E2T36582

For California

E2T36573

E2T36575

E2T36577

E2T36581

SensorsAir flow

sensorKarman vortex type

Barometric pressure sensorSemiconductor diffusion-type

Intake air temperature sensorThermistor type

Engine coolant temperature sensorThermistor type

Oxygen sensorZirconia type

Vehicle-speed sensorReed switch typeDetonation

sensor

Top dead center sensorPhoto interrupter type

Crank angle sensorPhoto interrupter type

EGR temperature sensor

Power steering oil pressure switchContact switch type4ctuators

Control relayContact switch type

Resistor identification model No.E8T05873

Injector type and numberElectromagnetic, 4

Injector identification mark

B450L

B390L

Purge control solenoid valveON/OFF type solenoid valve

EGR control solenoid valve

Fuel pressure control solenoid valve

gate solenoid valve

Page 458 of 1216

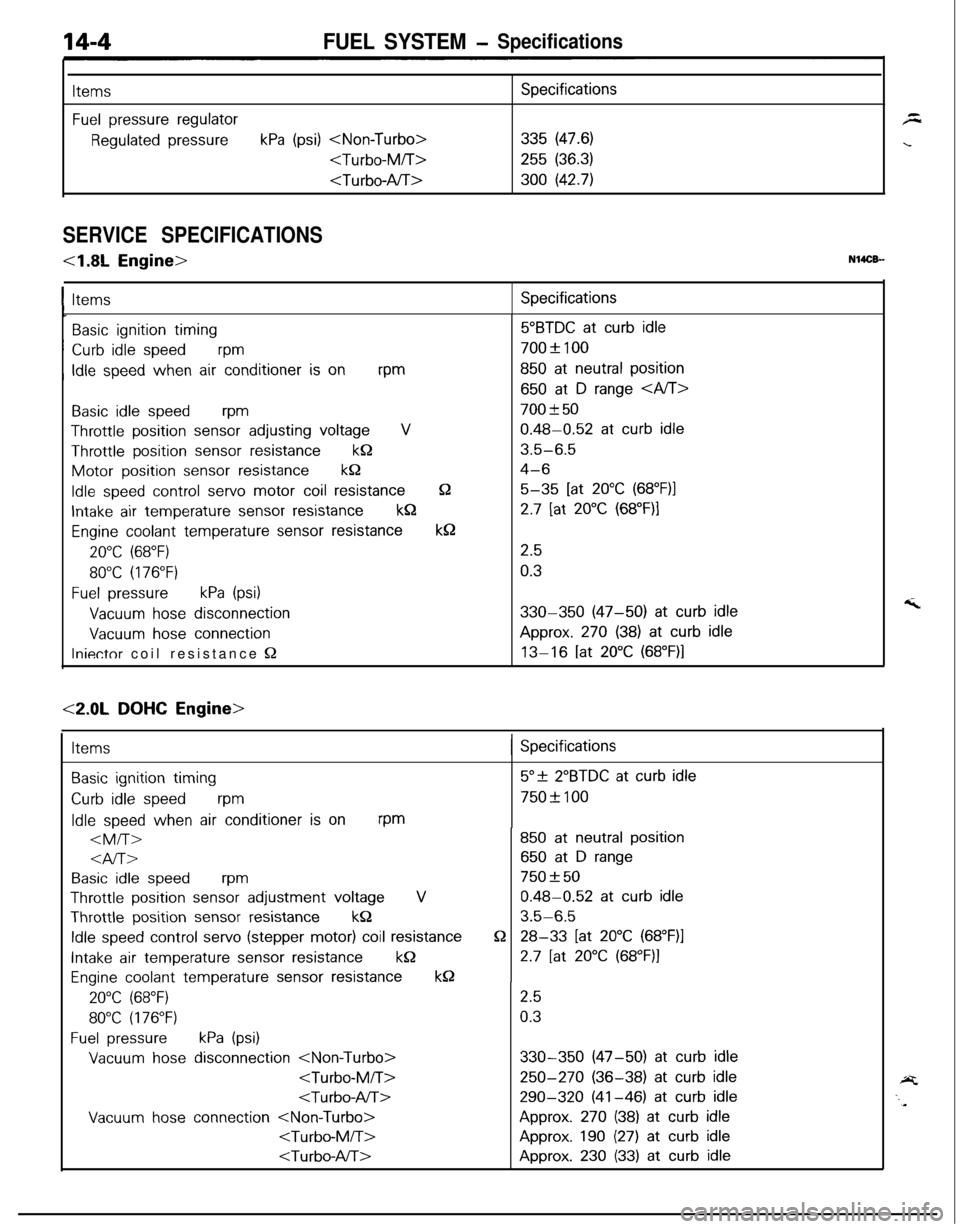

FUEL SYSTEM- Specifications

ItemsSpecifications

Fuel pressure regulator

Regulated pressurekPa (psi)

255 (36.3)

SERVICE SPECIFICATIONS

<1.8L Engine>N14CB-

ItemsSpecifications

Basic ignition timing~

Curb idle speedvm

, Idle speed when air conditioner is onrpm

Basic idle speedwm

Throttle position sensor adjusting voltageV

Throttle position sensor resistancekQMotor position

sensor resistancek&

Idle speed control servo motor coil resistance

Intake air temperature sensor resistancekQ

Engine coolant temperature sensor resistance

20°C (68°F)

80°C (176°F)

Fuel pressurekPa (psi)

Vacuum hose disconnection

Vacuum hose connection

Iniectnr coil resistance Q

52

k8

5”BTDC at curb idle

700f 100

850 at neutral position

650 at D range

700 f 50

0.48-0.52 at curb idle

3.5-6.5

4-6

5-35 [at 20°C (68”F)l

2.7 [at 20°C (68”F)I

2.5

0.3

330-350 (47-50) at curb idleApprox.

270 (38) at curb idle

13-16 [at 20°C (68”F)l

<2.0L DOHC Engine>

Items( Specifications

Basic ignition timing

Curb idle speedrpm

Idle speed when air conditioner is onrpm

al-r>

Basic idle speedrpm

Throttle position sensor adjustment voltageVThrottle position

sensor resistancekQ

Idle speed control servo (stepper motor) coil resistance

Intake air temperature sensor resistancekQ

Engine coolant temperature sensor resistancek0

20°C (68°F)

80°C (176°F)

Fuel pressurekPa (psi)

Vacuum hose disconnection

Vacuum hose connection

Q

5”+ 2”BTDC at curb idle

750+ 100

850 at neutral position

650 at D range

750 f 50

0.48-0.52 at curb idle

3.5-6.5

28-33 [at 20°C (68”F)l

2.7 [at 20°C (68”F)I

2.5

0.3

330-350 (47-50) at curb idle

250-270 (36-38) at curb idle

290-320 (41-46) at curb idleApprox.

270 (38) at curb idle

Approx. 190 (27) at curb idle

Approx. 230 (33) at curb idle

Page 459 of 1216

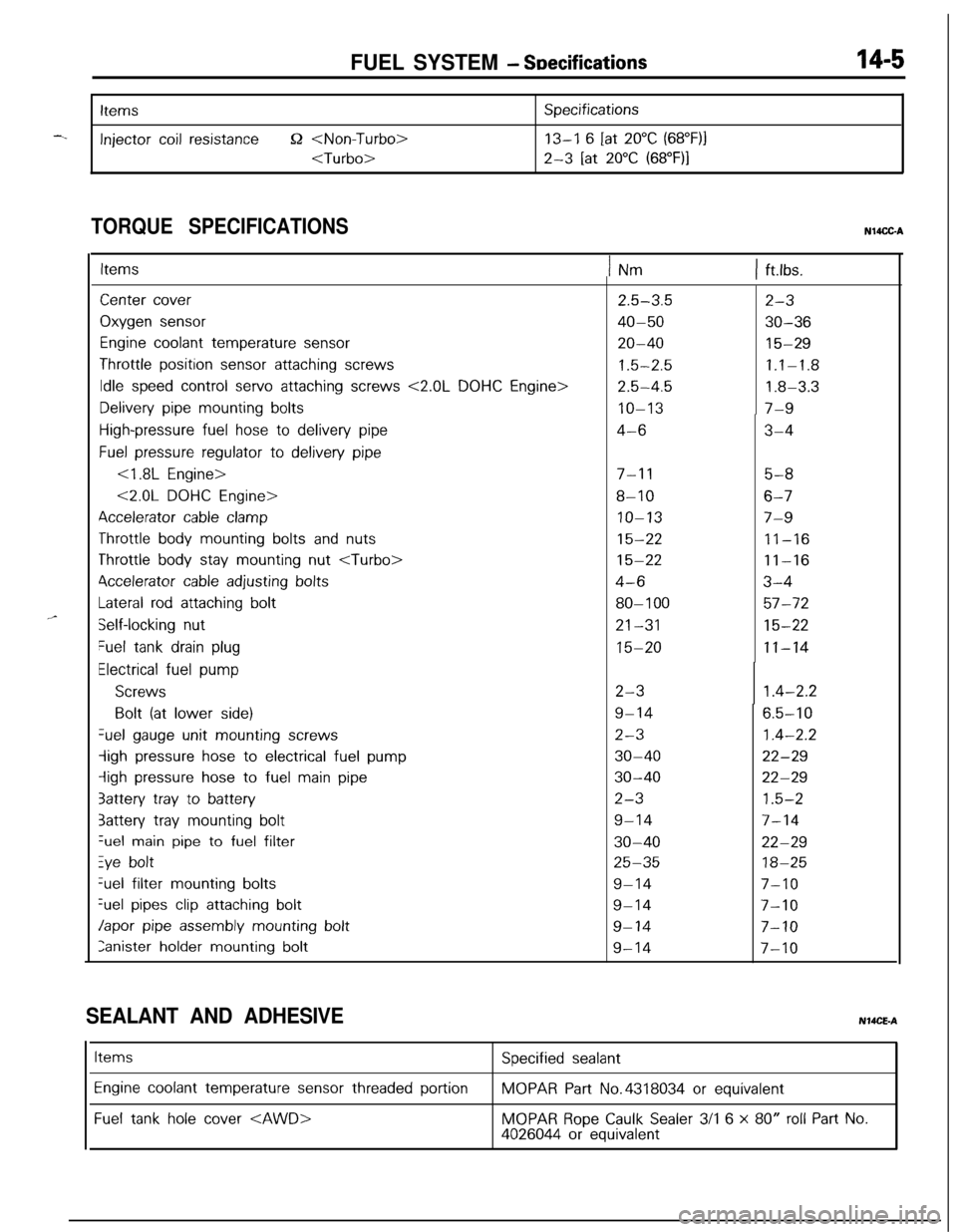

FUEL SYSTEM - SDecifications14-5

-.

Items

Injector coil resistance52

Specifications

13-I 6 [at 20°C (68”F)j

2-3 [at 20°C (68”F)I

TORQUE SPECIFICATIONSN14CC-A

,,-

ItemsINm1 ft.lbs.

Center cover

Oxygen sensor

Engine coolant temperature sensor

Throttle position sensor attaching screws

Idle speed control servo attaching screws <2.0L DOHC Engine>

Delivery pipe mounting bolts

High-pressure fuel hose to delivery pipe

Fuel pressure regulator to delivery pipe

<1.8L Engine>

<2.0L DOHC Engine>

Accelerator cable clamp

Throttle body mounting bolts and nuts

Throttle body stay mounting nut

4ccelerator cable adjusting bolts

Lateral rod attaching bolt

Self-locking nut

Fuel tank drain plug

Electrical fuel pump

Screws

Bolt (at lower side)Gel

gauge unit mounting screws

-ligh pressure hose to electrical fuel pump

iigh pressure hose to fuel main pipe

3attery tray to battery

3attery tray mounting boltGel

main pipe to fuel filter

Zye boltGel filter

mounting bolts

%el pipes clip attaching bolt

Japor pipe assembly mounting bolt

Ianister holder mounting bolt

2.5-3.5

40-50

20-40

1.5-2.5

2.5-4.5

IO-13

4-6

7-l 15-8

8-106-7

IO-137-9

15-2211-16

15-2211-16

4-63-4

80-l 0057-72

21-3115-22

15-2011-14

2-3

9-14

2-3

30-40

30-40

2-3

9-14

30-40

25-35

9-14

9-14

9-14

9-14

2-3

30-36

15-29

1.1-1.8

1.8-3.3

7-9

3-4

1.4-2.2

6.5-10

1.4-2.2

22-29

22-29

1.5-2

7-14

22-29

18-25

7-10

7-10

7-10

7-10

SEALANT AND ADHESIVENMCE-A

Items

Engine coolant temperature sensor threaded portion

Fuel tank hole cover

Specified sealant

MOPAR Part No.4318034 or equivalent

MOPAR Rope Caulk Sealer 3/l 6 x 80” roll Part No.4026044 or equivalent

Page 460 of 1216

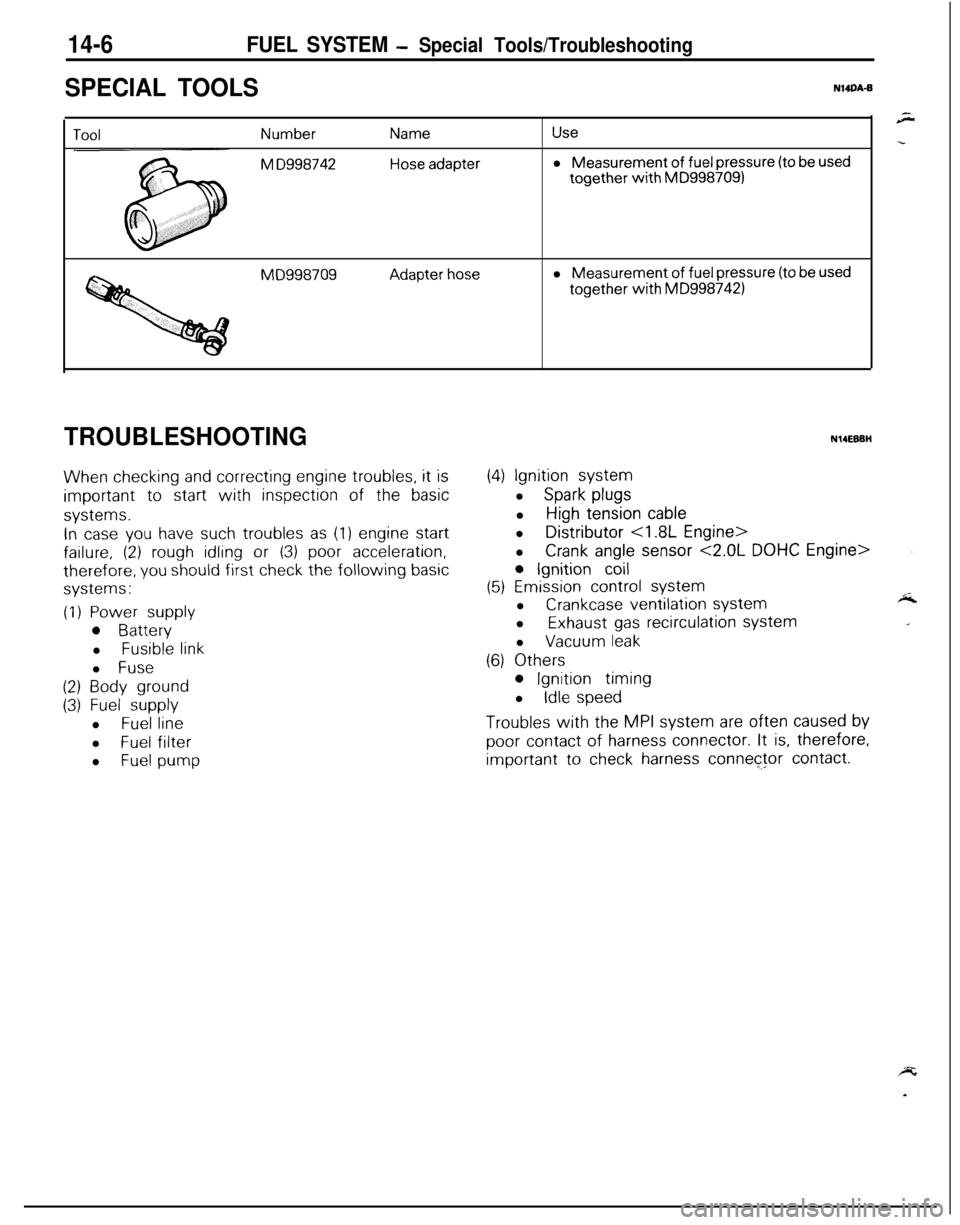

14-6FUEL SYSTEM - Special Tools/Troubleshooting

SPECIAL TOOLSNWA-B

Number

M D998742

Name

Hose adapter

Usel Measurement

of fuel pressure (to be usedtogether

with MD9987091

MD998709Adapter hosel Measurement of fuel pressure (to be usedtogether

with MD9987421

TROUBLESHOOTING

When checking and correcting engine troubles, it is

important to start with inspection of the basic

systems.

In case you have such troubles as (1) engine start

failure, (2) rough idling or (3) poor acceleration,

therefore, you should first check the following basic

systems:

(1) Power supply

0 Batteryl

Fusible linkl

Fuse

(2) Body ground

(3) Fuel supplyl

Fuel linel

Fuel filter

l

Fuel pump

N14EBBH

(4) Ignition systeml

Spark plugsl

High tension cablel Distributor

<1.8L Engine>

l

Crank angle sensor <2.0L DOHC Engine>

0 Ignition coil

(5) Emission control systeml

Crankcase ventilation systeml

Exhaust gas recirculation systeml

Vacuum leak

(6) Others

0 Ignition timing

l

Idle speed

Troubles with the MPI system are often caused by

poor contact of harness connector. It is, therefore,

important to check harness connector contact.

Page 461 of 1216

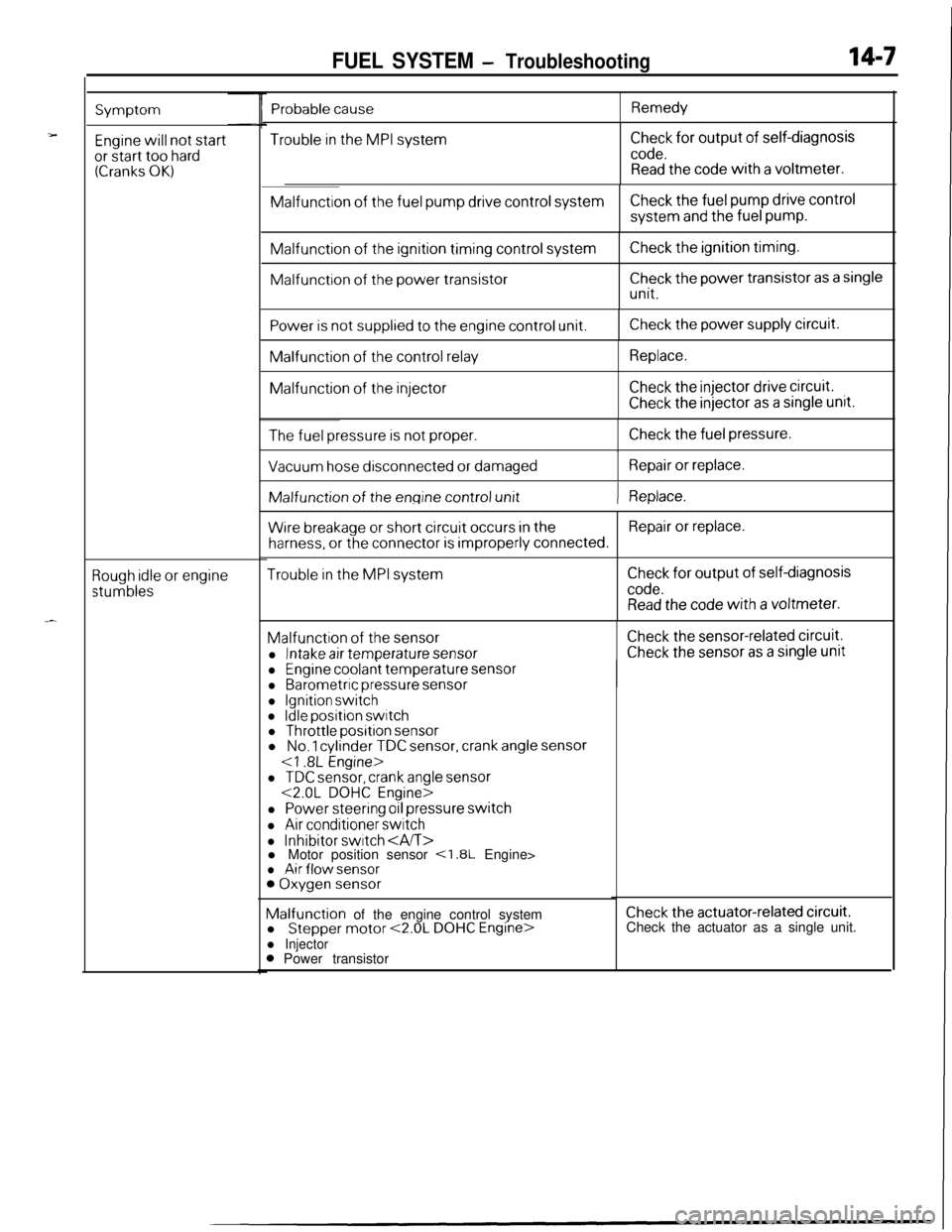

FUEL SYSTEM - Troubleshooting14-7

Symptom

Engine will not startor start too hard(Cranks OK)

Rough idle or engine

stumbles

Trouble in the MPI systemCheck for output of self-diagnosis

code.Read the code with a voltmeter.Malfunction

of the fuel pump drive control systemCheck the fuel pump drive controlsystem

and the fuel pump.Malfunction

of the ignition timing control systemMalfunction

of the power transistor

Check the ignition timing.

Check the power transistor as a single

unit.

Power is not supplied to the engine control unit.Check the power supply circuit.Malfunction

of the control relayMalfunction

of the injector

Replace.

Check the injector drive circuit.

Check the injector as a single unit.

The fuel pressure is not proper.Check the fuel pressure.

I

Vacuum hose disconnected or damagedRepair or replace.IMalfunction of

the engine control unit) Replace.

Wire breakage or short circuit occurs in theRepair or replace.

harness, or the connector is improperly connected.

Trouble in the MPI systemCheck for output of self-diagnosis

code.Read the code with a voltmeter.Malfunction

of the sensor

l Intake air temperature sensor

Check the sensor-related circuit.

Check the sensor as a single unit

Probable causeRemedy

l Engine coolant temperature sensorl Barometric pressure sensor

l Ignition switchl Idle position switchl Throttle position sensorl No. 1 cylinder TDC sensor, crank angle sensor

l TDC sensor, crank angle sensor<2.0L DOHC Engine>

l Power steering oil pressure switch

l Air conditioner switch

l Inhibitor switch l Motor position sensor <1.8L Engine>l Air flow sensor0 Oxygen sensorMalfunction of the engine control system

l

Stepper motor <2.0L DOHC Engine>l Injector0 Power transistor

Check the actuator-related circuit.Check the actuator as a single unit.

Page 462 of 1216

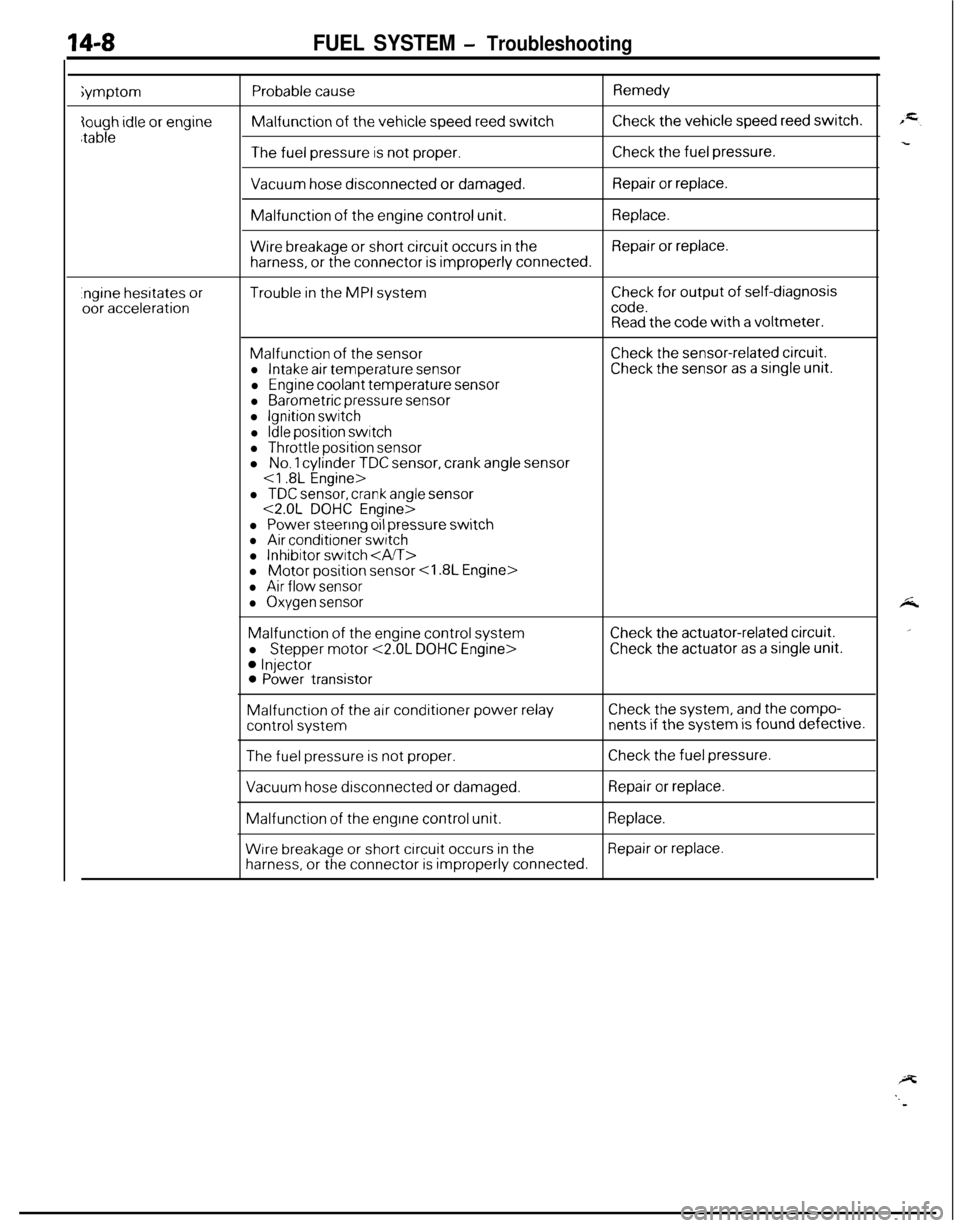

14-8FUEL SYSTEM - Troubleshootingiymptom

Probable causeMalfunction

of the vehicle speed reed switch

Remedy

Check the vehicle speed reed switch.

The fuel pressure is not proper.Check the fuel pressure.

Vacuum hose disconnected or damaged.Repair or replace.Malfunction

of the engine control unit.Replace.

Wire breakage or short circuit occurs in theRepair or replace.

harness, or the connector is improperly connected.

.ngine hesrtates oroor accelerationTrouble in the MPI systemCheck for output of self-diagnosiscode.Read the code with a voltmeter.

Malfunction of the sensorl Intake air temperature sensor

l Engine coolant temperature sensor

l Barometric pressure sensorl Ignition switch

l Idle position switchl Throttle position sensor

Check the sensor-related circuit.Check the sensor as a single unit.l

No. 1 cylinder TDC sensor, crank angle sensor

l TDC sensor, crank angle sensor<2.0L DOHC Engine>

l Power steering oil pressure switchl Air conditioner switchl Inhibitor switch l Motor position sensor

l Air flow sensor

l Oxygen sensorMalfunction

of the engine control system

l

Stepper motor <2.0L DOHC Engine>

0 Injector0 Power transistor

Check the actuator-related circuit.

Check the actuator as a single unit.Malfunction

of the air conditioner power relayCheck the system, and the compo-

control systemnents if the system is found defective.

The fuel pressure is not proper.Check the fuel pressure.

Vacuum hose disconnected or damaged.Repair or replace.Malfunction

of the engine control unit.Replace.

Wrre breakage or short circuit occurs in theRepair or replace.

harness, or the connector is improperly connected.

Page 463 of 1216

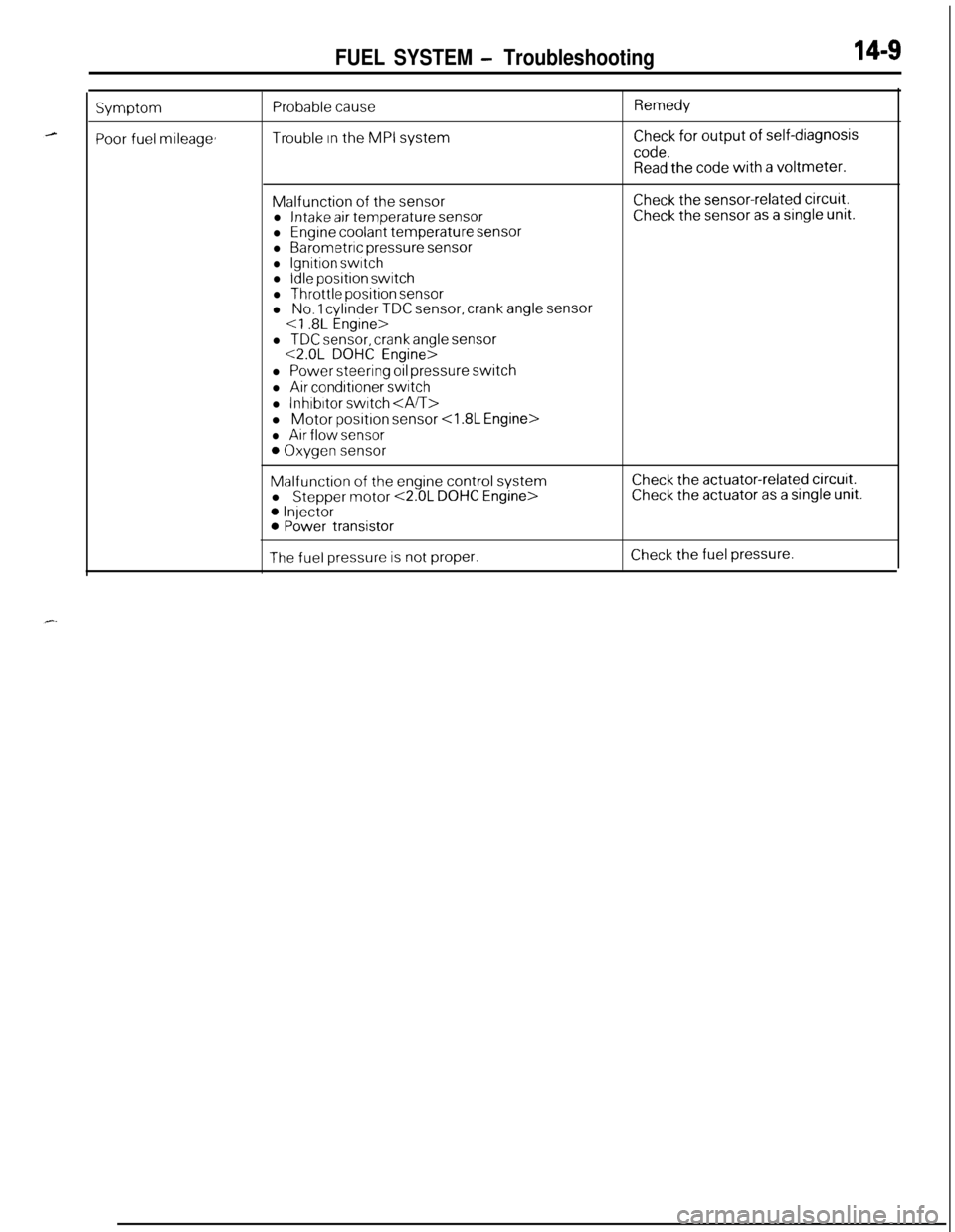

FUEL SYSTEM - Troubleshooting14-S

Symptom

Poor fuel mileage,

Probable cause

Trouble In the MPI system

Remedy

Check for output of self-diagnosis

code.Read the code with a voltmeter.Malfunction

of the sensorl Intake air temperature sensorl Engine coolant temperature sensorl Barometric pressure sensorl Ignition switchl Idle position switch

l Throttle position sensorl No. 1 cylinder TDC sensor, crank angle sensor

Check the sensor-related circuit.Check the sensor as a single unit.

l TDC sensor, crank angle sensor<2.0L DOHC Engine>

l Power steering oil pressure switch

l Air conditioner switch

l lnhrbrtor switch l Motor

position sensor

l Air flow sensor

0 Oxygen sensor

Malfunction of the engine control system

l Stepper motor <2.0L DOHC Engine>

0 Injector0 Power transistor

Check the actuator-related circurt.Check the actuator as a single unit.

The fuel pressure is not proper.Check the fuel pressure.

Page 464 of 1216

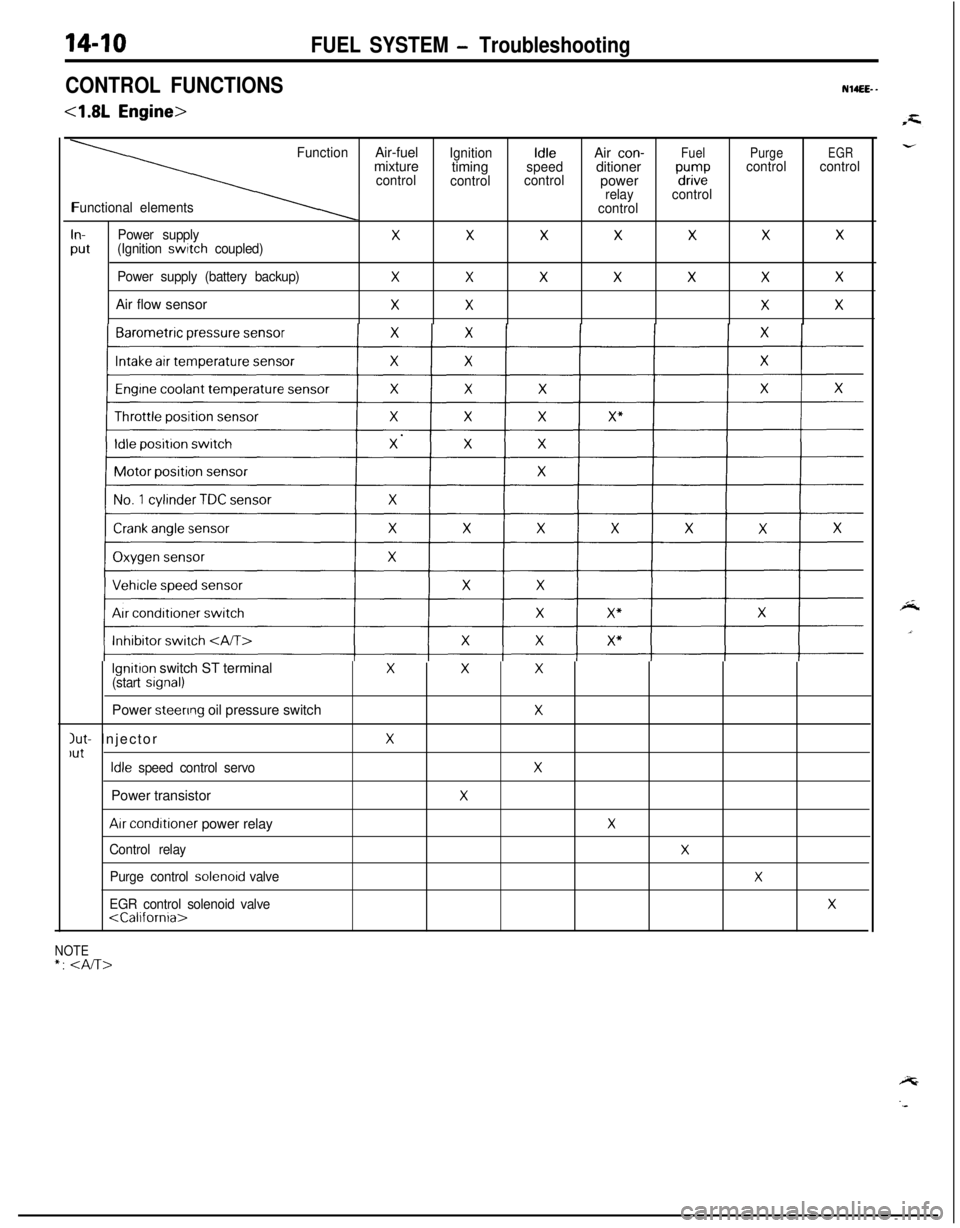

CONTROL FUNCTIONS

<1.8L Engine>

NWEEE- -

FunctionAir-fuelIgnitionIdleAir con-FuelPurgeEGRmixture

timingspeedditionercontrol

controlcontrolpower“d”,i2controlcontrol

relaycontrol

Functional elements

control

In-Power supplyXXXXXXX

Put(Ignition switch coupled)

Power supply (battery backup)

XXXXXXXAir flow sensor

XXXX

lgnitron switch ST terminalXXX(start srgnal)Power

steenng oil pressure switchX

Jut- InjectorXlutIdle speed control servoXPower transistor

X

Arr conditioner power relayX

Control relayX

Purge control solenord valveX

EGR control solenoid valveX

NOTE*:

FUEL SYSTEM - Troubleshooting

Page 465 of 1216

FUEL SYSTEM - Troubleshootina

<2.0LDOHC Engine>

FunctronArr-fuellgnrtronIdleAir con-

FuelFuel

PurgeEGRmixturetimrng

speeddrtronerpump pressureaircontrc

controlcontrol

controlpowerdrivecontrol

control

relaycontrol

Functronal elementscontrol

InPower supplyXXXXXXXXPut(ignrtron switch coupled)

Power supply (battery backup)

Ix Ix Ix lx lx lx lx Ix

Top dead center sensorI xXI

1 Crank angle sensorIxlxIxIxIxI lxlx

Oxygen sensorI x I

Vehrcle speed sensor

Air conditioner switch

XX

XX”XPower steering

011 pressure switchXIDetonation sensor

lgnrtron switch

X

XXX

lgnrtron switch ST terminalXXX

lnhibrtor switch XXX”

)ut-InjectorXutResistor

Idle speed control servoX

Power transistorI 1x1 I I I I I

Arr condrtroner power relay

Control relay

Fuel pressure control valve

Purge control solenord valve

X

X

X

X

EGR control solenoid valve

NOTE*:

Page 466 of 1216

FUEL SYSTEM - Troubleshootinn

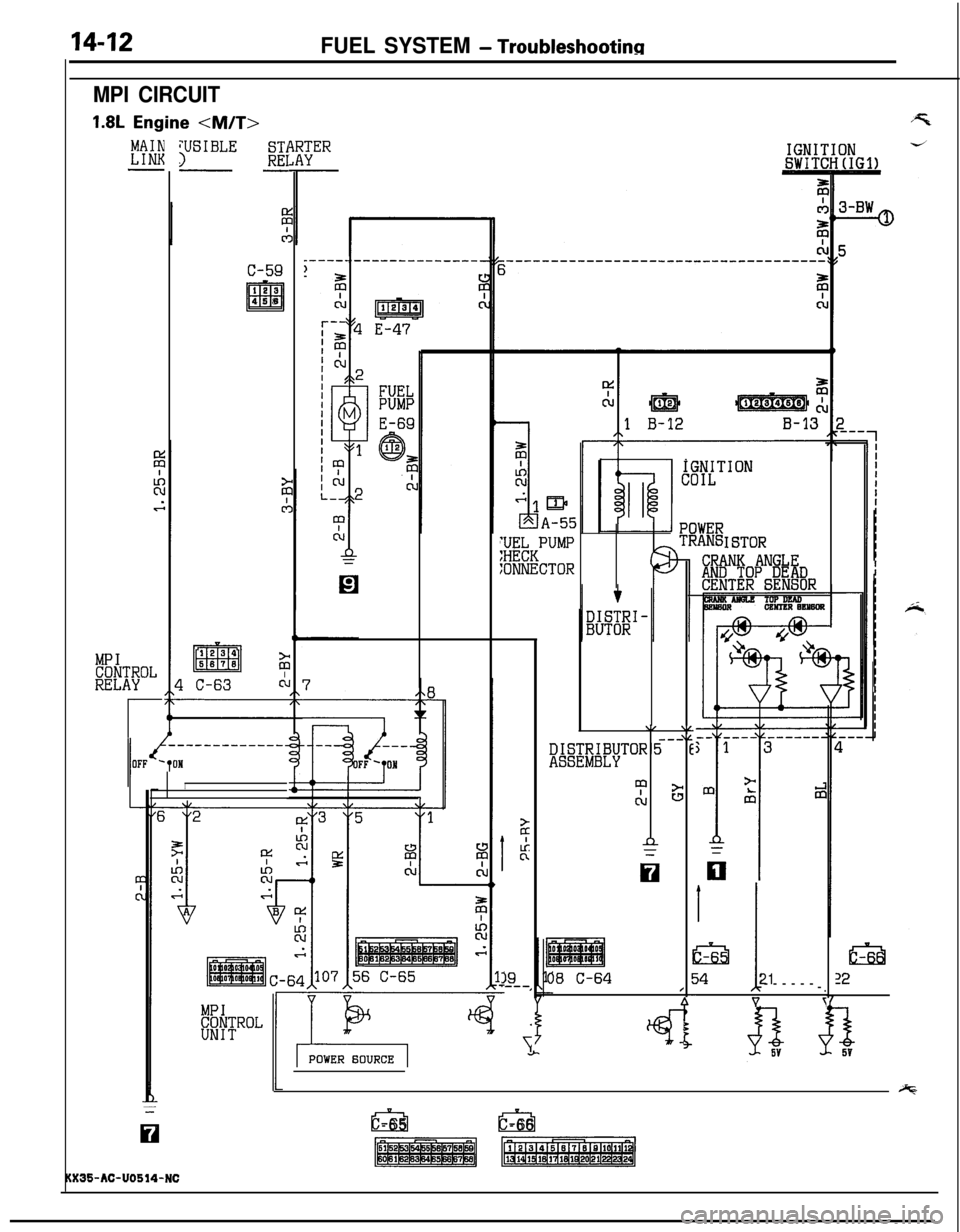

MPI CIRCUIT1.8L

Engine

VSIBLE3ST1REI--

IGNITIONSWITCHtIGl)

c-59

12s

m458

j;WKPUMP

:ONNECTOR

IGNITIONCOIL

ISTOR

CRANK ANGLAND TOP DE!iDCENTER SENSOR

\/---DISTRIBUTOR5ASSEMBLY

'pcuc

n

,L)‘E

;

6

b

E-

5

5

08 C-64/1

tci3j4

I21

------

-.Vr

MPICONTROLRELAY

r

I

h

Lkn

39‘---,

i

lsil12

iz;.

c-65a-66

135-AC-U0514-NC