engine MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 418 of 1216

g-134 ENGINE <2.0L DOHC Engine>- Crankshaft, Flywheel and Drive Plate

3EN301CRANKSHAFT REAR OIL SEAL

(1) Check oil seal lip for wear and damage.

(2) Check rubber for deterioration or hardening.

(3) Check oil seal case for cracks and damage.

RING GEAR (Engine with a manual transaxle)

Check teeth of ring gear for wear and damage. If necessary,

replace the ring gear.

If the ring gear teeth are worn or damaged, also check the

starter motor pinion.

To remove the ring gear, strike the ring gear at several points

on its outer circumference. The ring gear cannot be removed ifit is heated.

To install the ring gear, heat the ring gear to

300°C (572°F) for

shrink fit.

FLYWHEEL (Engine with a manual transaxle)

(1) Check the clutch disc friction surface for ridge wear,

streaks, and seizure. If necessary, replace flywheel.

(2) If the

runout of flywheel exceeds the limit, replace.++.Limit: 0.13 mm

(.0051 in.)

DRIVE PLATE (Engine with an automatic transaxle)

Replace deformed, damaged, or cracked drive plates.

SERVICE POINTS OF REASSEMBLYNWUGAB

14. INSTALLATION OF CRANKSHAFT BEARING (UPPER)

Install the upper crankshaft bearing to the cylinder block.

There is an oil groove in the upper crankshaft bearing.

There is no difference between upper and lower bearings

for the center (with flange).

12. INSTALLATION OF CRANKSHAFT BEARING (LOWER)

Install the lower crankshaft bearing (with no oil groove;

there is no difference for center) to each bearing cap and

apply engine oil to bearing surfaces.

Page 419 of 1216

ENGINE <2.0L DOHC Engine> -Crankshaft, Flywheel and Drive Plate g-135

‘I. _

Front ofengine

(Timing

belt side)

BEN02

DEN063

6ENO48-

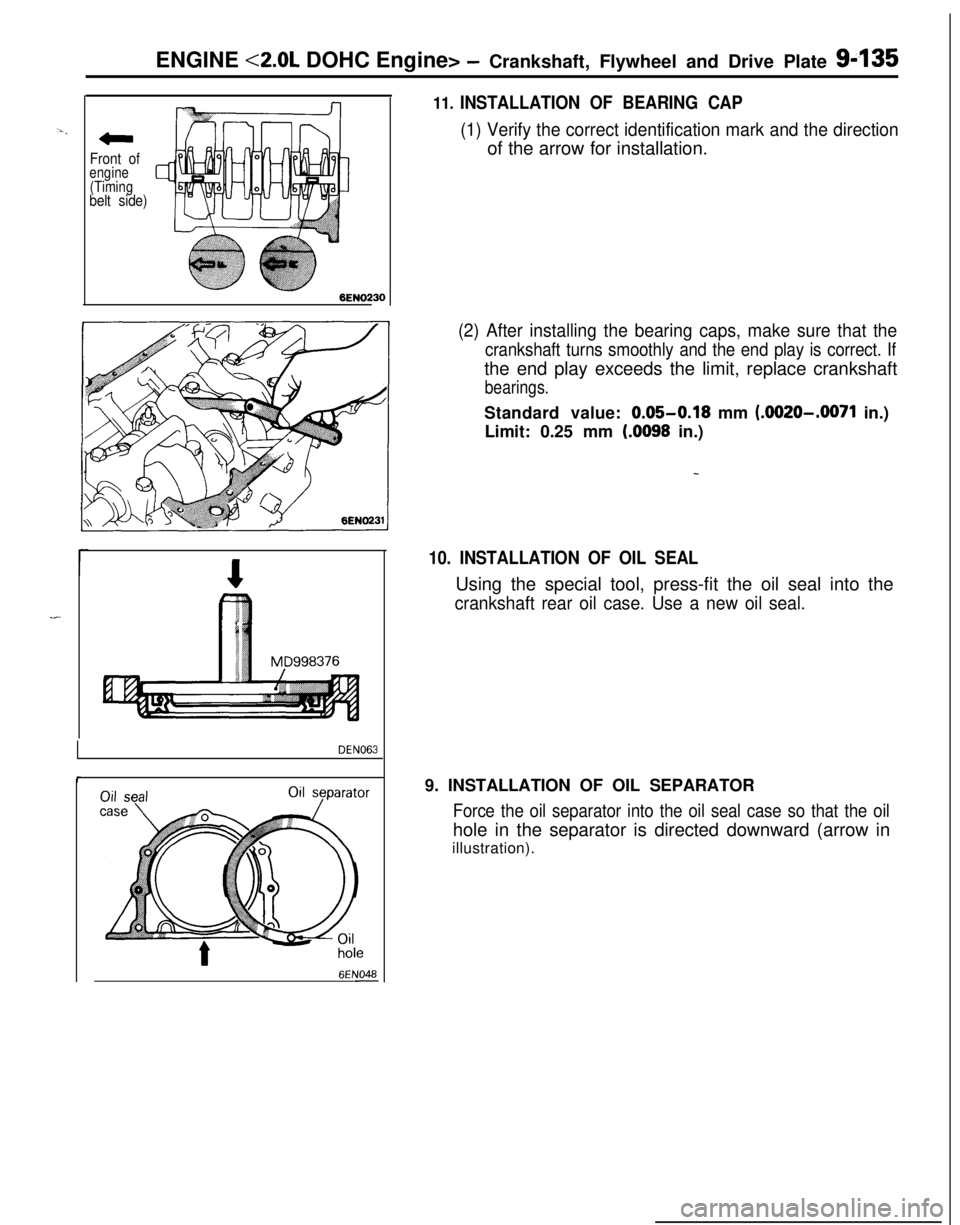

11. INSTALLATION OF BEARING CAP

(1) Verify the correct identification mark and the directionof the arrow for installation.

(2) After installing the bearing caps, make sure that the

crankshaft turns smoothly and the end play is correct. Ifthe end play exceeds the limit, replace crankshaft

bearings.Standard value:

0.05-0.18 mm (.0020-.0071 in.)

Limit: 0.25 mm

(.0098 in.)

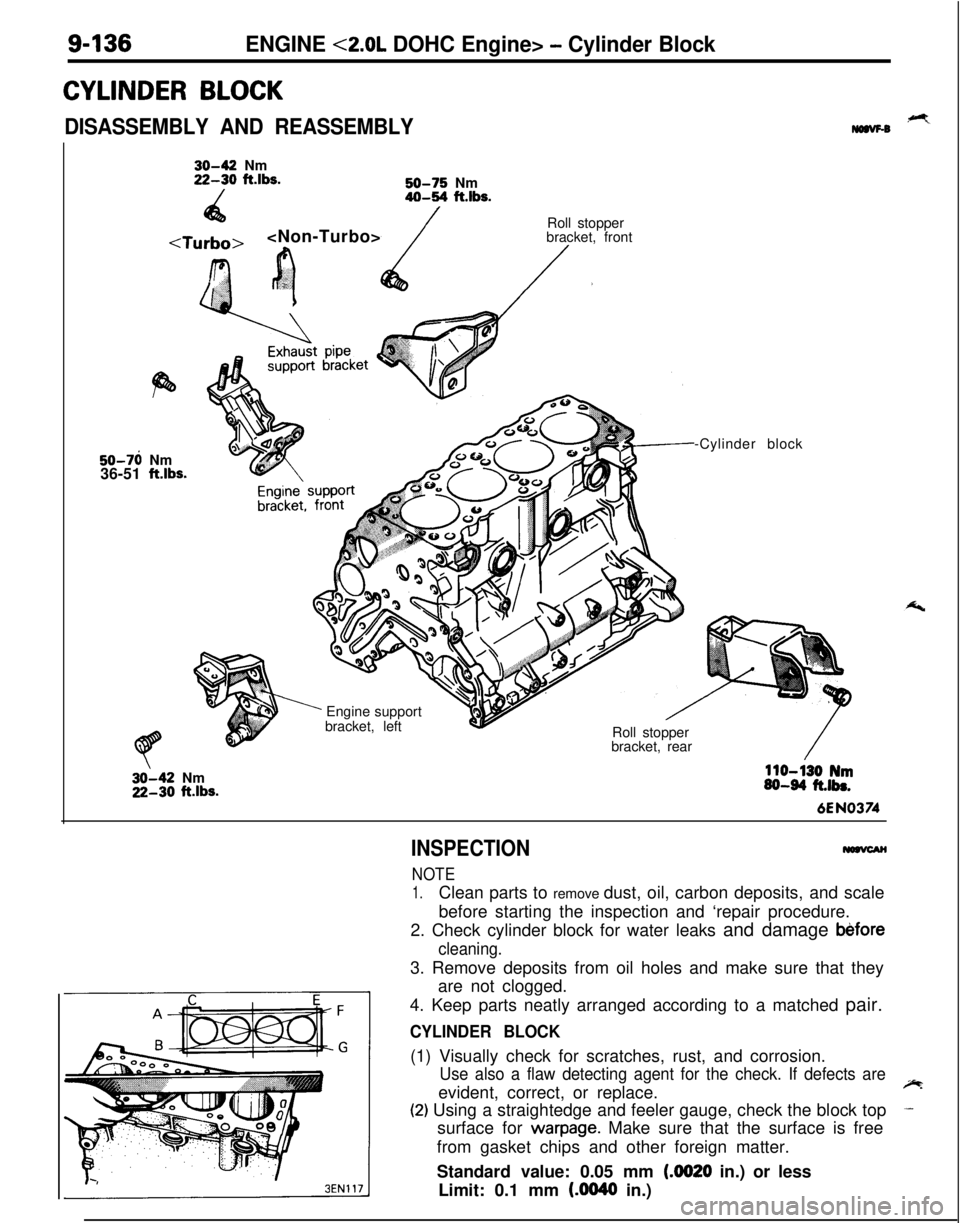

10. INSTALLATION OF OIL SEALUsing the special tool, press-fit the oil seal into the

crankshaft rear oil case. Use a new oil seal.9. INSTALLATION OF OIL SEPARATOR

Force the oil separator into the oil seal case so that the oilhole in the separator is directed downward (arrow in

illustration).

Page 420 of 1216

9-136ENGINE <2.0L DOHC Engine> - Cylinder Block

CYLINDER BLOCK

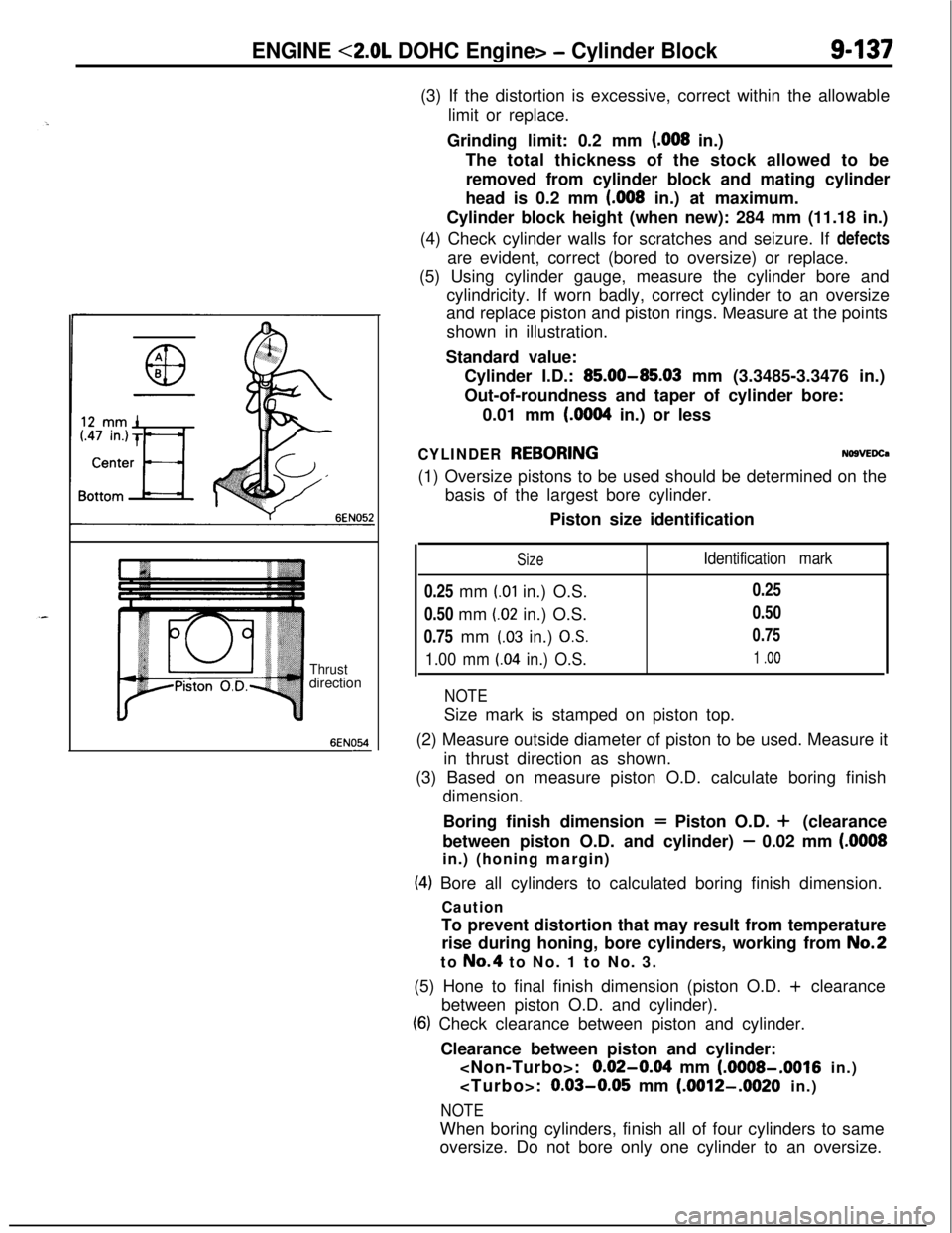

DISASSEMBLY AND REASSEMBLY,+Ymaw-030-42 Nm22-30 ft.lbs.

/50-75 Nm40-54 ft.lbs.

4a

r.‘?’

’ cRoll stopper

bracket, front/.50-76 Nm

36-51

ftlbs.

’ Engine support

bracket, left

Roll stopper

bracket, rear-Cylinder block32-42 Nm22-30

ftlbs.

110-130 Nm60-64 ft.lbs.6EN0374

INSPECTION

NOTE

1.Clean parts to remove dust, oil, carbon deposits, and scale

before starting the inspection and ‘repair procedure.

2. Check cylinder block for water leaks and damage

b&fore

cleaning.3. Remove deposits from oil holes and make sure that they

are not clogged.

4. Keep parts neatly arranged according to a matched pair.

CYLINDER BLOCK(1) Visually check for scratches, rust, and corrosion.

Use also a flaw detecting agent for the check. If defects areevident, correct, or replace.~

(2) Using a straightedge and feeler gauge, check the block top-surface for

warpage. Make sure that the surface is free

from gasket chips and other foreign matter.

Standard value: 0.05 mm

(4020 in.) or less

Limit: 0.1 mm

(AM40 in.)

Page 421 of 1216

ENGINE <2.0L DOHC Engine> - Cylinder Block9437

Thrustdirection

6EN054-(3) If the distortion is excessive, correct within the allowable

limit or replace.

Grinding limit: 0.2 mm

(008 in.)

The total thickness of the stock allowed to be

removed from cylinder block and mating cylinder

head is 0.2 mm

(008 in.) at maximum.

Cylinder block height (when new): 284 mm (11.18 in.)

(4) Check cylinder walls for scratches and seizure. If defects

are evident, correct (bored to oversize) or replace.

(5) Using cylinder gauge, measure the cylinder bore and

cylindricity. If worn badly, correct cylinder to an oversize

and replace piston and piston rings. Measure at the points

shown in illustration.

Standard value:

Cylinder I.D.:

85.00-85.03 mm (3.3485-3.3476 in.)

Out-of-roundness and taper of cylinder bore:

0.01 mm

(6064 in.) or less

CYLINDER REBORINGNO9VEDCa(1) Oversize pistons to be used should be determined on the

basis of the largest bore cylinder.

Piston size identification

Size0.25 mm

(.Ol in.) O.S.

0.50 mm

(.02 in.) O.S.

0.75 mm

(.03 in.) OS.

1.00 mm LO4 in.) O.S.

Identification mark0.25

0.50

0.75

1 .oo

NOTESize mark is stamped on piston top.

(2) Measure outside diameter of piston to be used. Measure it

in thrust direction as shown.

(3) Based on measure piston O.D. calculate boring finish

dimension.Boring finish dimension

= Piston O.D. + (clearance

between piston O.D. and cylinder)

- 0.02 mm (.OOOSin.) (honing margin)

(4) Bore all cylinders to calculated boring finish dimension.

CautionTo prevent distortion that may result from temperature

rise during honing, bore cylinders, working from

No.2to No.4 to No. 1 to No. 3.

(5) Hone to final finish dimension (piston O.D. + clearance

between piston O.D. and cylinder).

(6) Check clearance between piston and cylinder.

Clearance between piston and cylinder:

0.02-064 mm (AMOS-,001~ in.)

0.03-0.05 mm (.OOW-.O020 in.)

NOTEWhen boring cylinders, finish all of four cylinders to same

oversize. Do not bore only one cylinder to an oversize.

Page 423 of 1216

11-l

INTAKE AND

EXHAUSTAIR CLEANER

. . . . . . . ..*........................................8

EXHAUST MANIFOLD <1.8L Engine> . . . . . . . .26

EXHAUST MANIFOLD

<2.0L DOHC Engine

(Non-Turbo)>

. . . . . . ..*.*.......................................27EXHAUST MANIFOLD

<2.0L DOHC Engine

(Turbo)>

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .*...........................28

CONTENTSNllAA--

-EXHAUST PIPE AND MAIN MUFFLER<1.8L Engine,

2.0L DOHC Engine

(Non-Turbo)>

. . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .30EXHAUST PIPE AND MAIN MUFFLER<2.0L

DOHCEngine(Turbo)>. . . . . . . . . . . . . . . . . . . . .31INTAKE MANIFOLD

<1.8LEngine> . . . . . . . . . . . .13INTAKE MANIFOLD

<2.0L DOHC Engine> 17

INTERCOOLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11SERVICE ADJUSTMENT PROCEDURES..

.....5Air

Bypass ValveInspection........................7Air Cleaner Element Inspection and

Replacement . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5Supercharging Pressure Control System

Inspection

.,...... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . .6Supercharging Pressure Relief Solenoid

Valve Inspection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7Turbocharger Supercharging Pressure

Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6SPECIAL TOOL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..#................4

SPECIFICATIONS.............................................2General Specifications

..................................2Service Specifications

...................................2Torque Specifications

...................................2

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Abnormal Noise

Exhaust Gas Leakage

TURBOCHARGER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Page 425 of 1216

--

INTAKE AND EXHAUST - SDecificationsII-3

ItemsIntake manifold

<1.8L Engine>

Accelerator cable to air intake plenum

Fuel high pressure hose to delivery pipe

Delivery pipe to intake manifold

Intake manifold stay

Engine hanger

Intake manifold to engine

Throttle body

Air intake plenum stay

Air intake plenum to intake manifold

Water outlet fitting

EGR valveEGR temperature sensor

Ground cable to air intake plenum

Control harness protector to air intake plenum

CoverIntake manifold

<2.0L DOHC Engine>

Accelerator cable to intake manifold

Throttle body stay

Fuel high pressure hose to delivery pipe

Delivery pipe to engine

Intake manifold stay

Intake manifold to engine

Mounting bolt

(M8)Mounting nut and bolt (MIO)

Ignition coil

Power transistor unit

Throttle body

EGR valveEGR temperature sensor

Control harness protector to intake manifold

Control harness clamp bolt

ixhaust manifold

<1.8L Engine>

Front exhaust pipe to exhaust manifold

Front exhaust pipe to engine

Exhaust manifold cover (A) to exhaust manifold

Exhaust manifold cover (B) to exhaust manifold

Exhaust manifold cover (A) to exhaust manifold cover (B)

Exhaust manifold to engine

Oxygen sensor

Engine oil level gauge guide mounting bolt

ixhaust manifold

<2.0L DOHC Engine (Non-Turbo)>

Front exhaust pipe to exhaust manifold

Front exhaust pipe to engine

Heat protector (A), (B)

Exhaust manifold to engine

Oxygen sensor

Engine hanger to engine

ixhaust manifold and turbocharger

<2.0L DOHC Engine (Turbo)>

Front exhaust pipe to exhaust fitting

Front exhaust pipe to engine

Heat protector (A),

(B)

Nmft.lbs.

4-6

3-4

4-6

3-4

IO-137-9

18-25

13-18

15-20II-14

15-2011-14

15-22II-16

15-2011-14

15-2011-14

17-2012-14

IO-157-11

IO-127-9

10-127-9

4-6

3-4

IO-137-9

4-6

3-4

15-22

11-16

4-6

3-4

IO-137-9

25-3018-22

15-2011-14

30-4222-30

20-2714-20

IO-127-9

15-22

11-16

15-22II-16

IO-127-9

4-6

3-4

IO-127-9

30-4022-29

30-4022-29

27-33

20-24

20-2814-20

8-106-7

15-2011-14

40-5029-36

12-15

9-l 1

30-4022-29

30-4022-29

12-15

9-l 1

25-3018-22

40-5029-36

12-15

9-l 1

40-6029-43

30-4022-29

12-15

9-11

Page 426 of 1216

11-4INTAKE AND EXHAUST- Specifications/Special Tool/Troubleshooting

ItemsEngine oil level gauge guide mounting bolt

Engine hanger to engine

Exhaust manifold to engine

Exhaust manifold to turbocharger

Oil pipe to engine

Water pipe

(B) to water inlet pipe

Waste gate actuator

Oxygen sensor

Water pipe

(B) to turbocharger

Air outlet fitting

Oil pipe to turbocharger

Water pipe (A) to turbocharger

Water pipe (A) mounting bolt

Exhaust fitting

Oil return pipe

Exhaust pipe and main muffler

Front exhaust pipe to exhaust manifold

Front exhaust pipe to exhaust fitting

Front exhaust pipe clamp

Rubber hangerFront exhaust pipe to catalytic converter

Catalytic converter to center exhaust pipe

Hanger bracket to body

Hook to center exhaust pipe

Center exhaust pipe to main muffler

Moulding to main muffler

Nmft.lbs.

12-15

9-l 112-159-11

25-3018-?255-65

40-4714-19

IO-l+

40-5029-36

IO-137-9

40-5029-36

35-5025-36

9-14

7-1028-34

20-25

35-5025-36

IO-127-9

55-65

40-47

8-106-7

30-4022-29

40-6029-43

30-4022-29

IO-157-11

40-6029-43

30-4022-29

10-157-11

10-157-11

30-4022-29

4-63-4

TROUBLESHOOTINGNllEAAB

Symptom

Exhaust gas leakage

Abnormal noiseProbable cause

Loose joints

Broken pipe or muffler

Broken separator in muffler

Broken rubber hangersInterference of pipe or muffler with vehicle body

Broken pipe or mufflerRemedy

Retighten

Repair or replace

Replace

Correct

Repair or replace

.-*

SPECIAL TOOLNllDA-

I ToolNumberNameI UseIRemoval/Installation of oxygen sensor

Removal/Installation of oxygen sensor

Fs\

Page 427 of 1216

INTAKE AND EXHAUST - Service Adjustment Procedures11-5

SERVICE ADJUSTMENT PROCEDURES

AIR CLEANER ELEMENT INSPECTION AND RE-PLACEMENTNllQBAF

< 1.8L Engine, 2.0L DOHC Engine (Non-Turbo) >

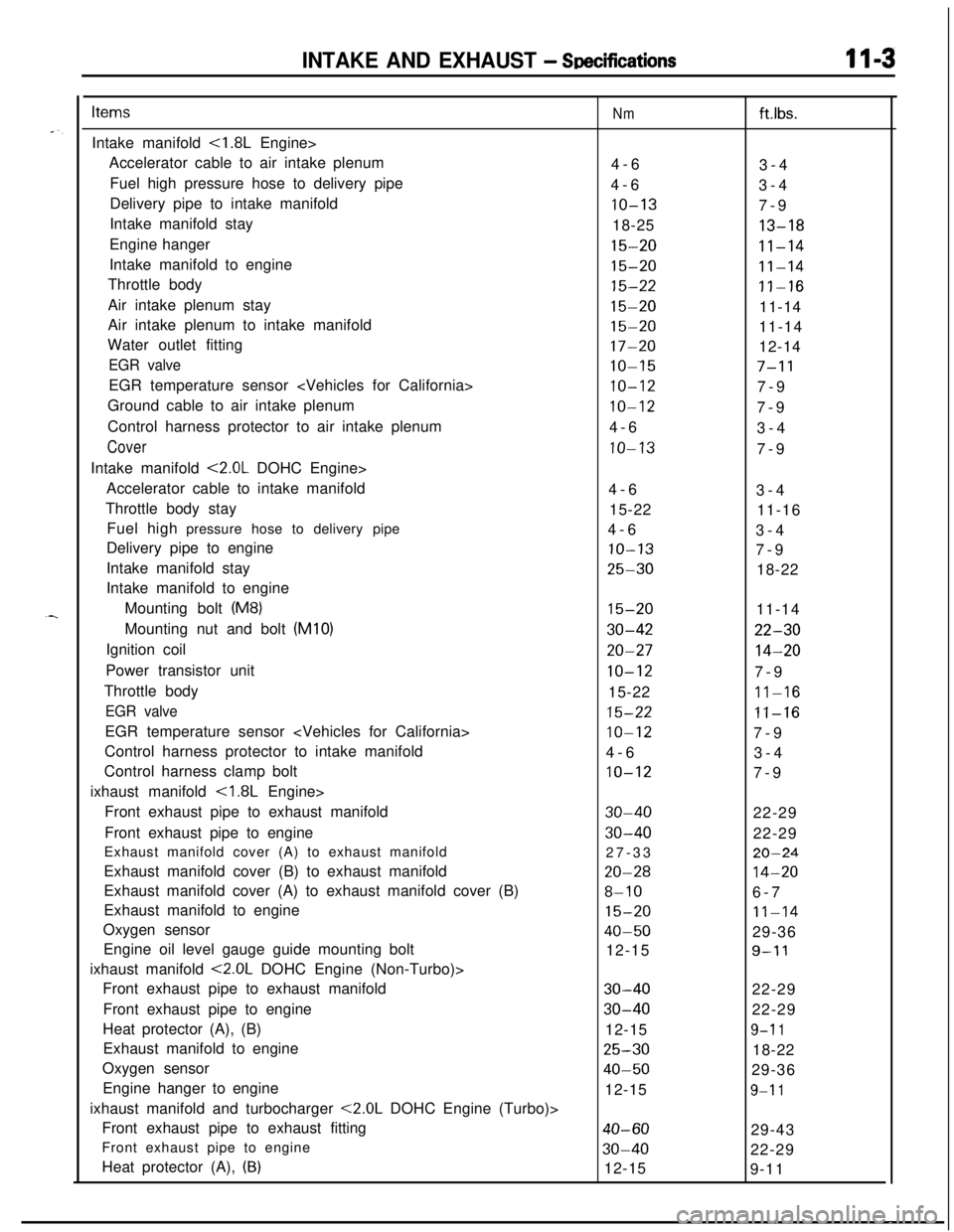

(1) Disconnect the air-flow sensor connector.

(2) Remove the air intake hose.

(3) Unclamp the air cleaner cover.

(4) Push the air intake hose backward, and remove the air

cleaner cover.

CautionCare must be taken when removing the air cleaner

cover, because the air-flow sensor is attached.

(5) Take out the air cleaner element.

(6) Check the air cleaner element for dirt or clogging.

(7) Replace the air cleaner element if the dirt or clogging is

serious.

(8) Insert the element into the air cleaner body and install the

air cleaner cover.

(9) Install the air intake hose.

(10)Connect the air intake hose and the air-flow sensor

connector.

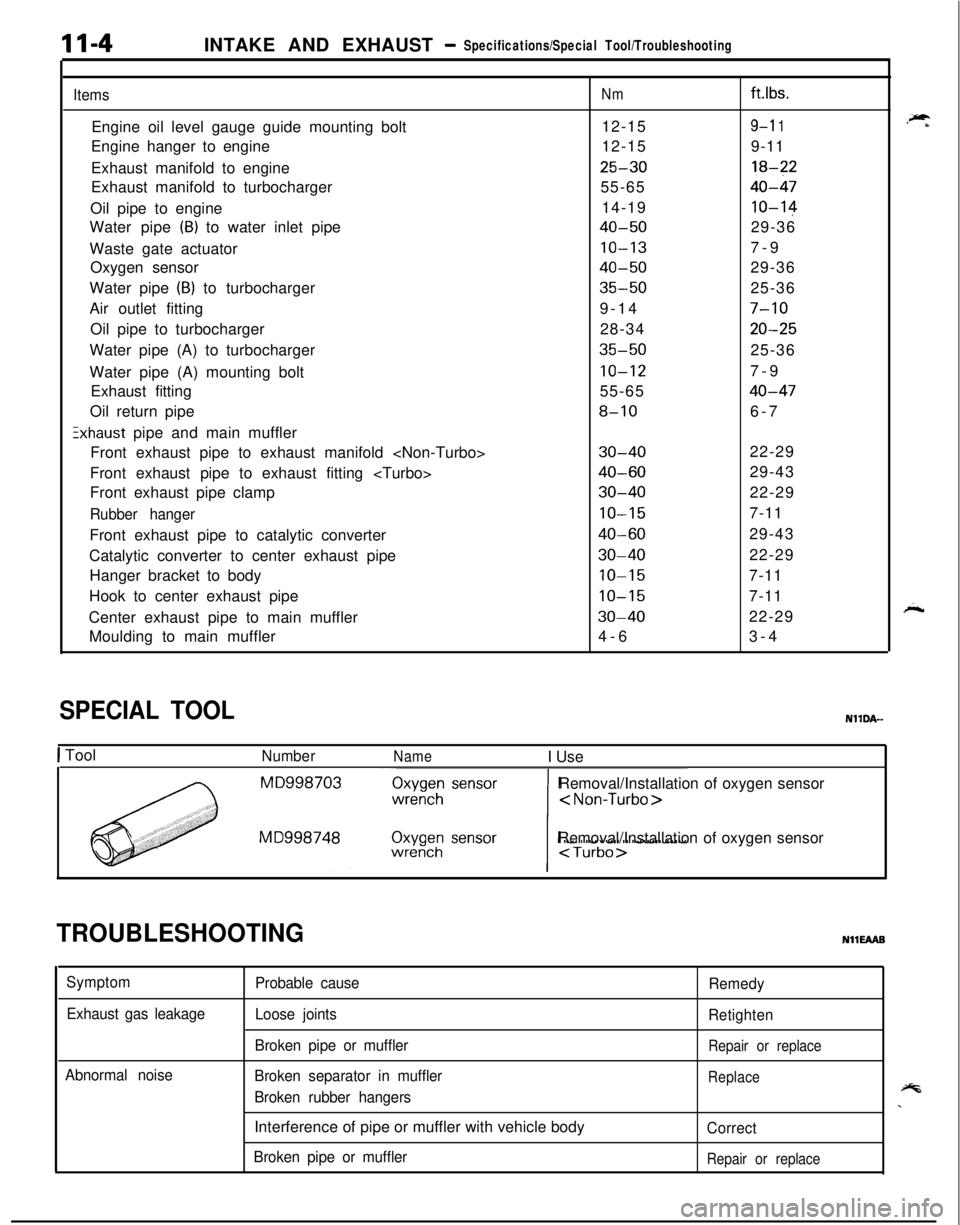

<2.0L DOHC Engine (Turbo)>(I

1 Disconnect the air-flow sensor connector.

(2) Disconnect the boost hose.

(3) Disconnect the solenoid valve with hoses.

(4) Disconnect the air intake hose.

(5) Remove the air cleaner retaining bolts.

(6) Remove the air cleaner assembly.

(7) Unclamp the air cleaner cover.

Caution

Care must be taken when removing the air cleaner cover,

because the air-flow sensor is attached.

(8) Take out the air cleaner element.

(9) Check the air cleaner element for dirt or clogging.

(10)Replace the air cleaner element if the dirt or clogging is

serious.

(11) Insert the element into the air cleaner body.

(12)Clamp the air cleaner cover.

(13)lnstall and tighten the air cleaner retaining bolts to the

specified torque.

(14)Connect the air intake hose and the solenoid valve.

(15)Connect the vaccum hose and the air-flow sensor

connector.

Page 428 of 1216

11-6INTAKE AND EXHAUST - Service Adjustment Procedwes

Wasie gate actuator05AOlSO

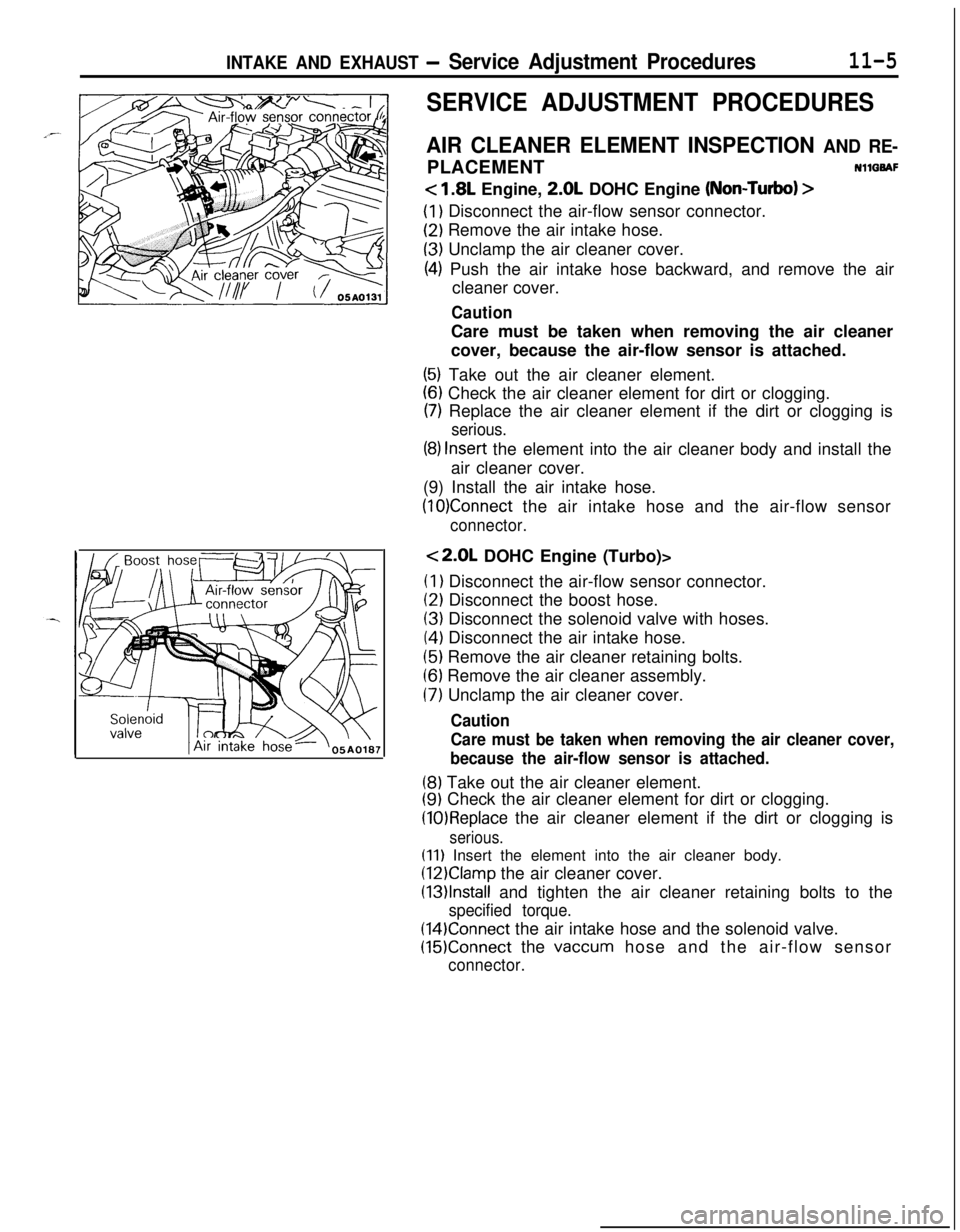

TURBOCHARGER SUPERCHARGING PRESSURE

INSPECTIONN1mAAB!PTCautionPerform running inspection with two passengers in the

-’vehicle and where full throttle acceleration can be safely

made.The pressure gauge reading is taken by a front seat

passenger.

(1) Disconnect the supercharging pressure control hose at the

solenoid valve (fixed to the air cleaner) and plug the nipple.Attach the pressure gauge to the hose.

(2) Drive the vehicle with full throttle and accelerate the engineto a speed of more than 3,500 rpm at

2nd gear. Measure

the supercharging pressure when the pointer is stabilized.Standard value:

M/T41-75

kPa (6.0-10.8 psi)

A/T37-68

kPa (5.4-9.9 psi)

Caution

If the supercharging pressure deviates from the standard

value, check the following items for possible causes.

When pressure is high:Waste gate actuator malfunction

When pressure is low:

Waste gate actuator malfunction

Supercharging pressure leaks

Faulty turbocharger

+-

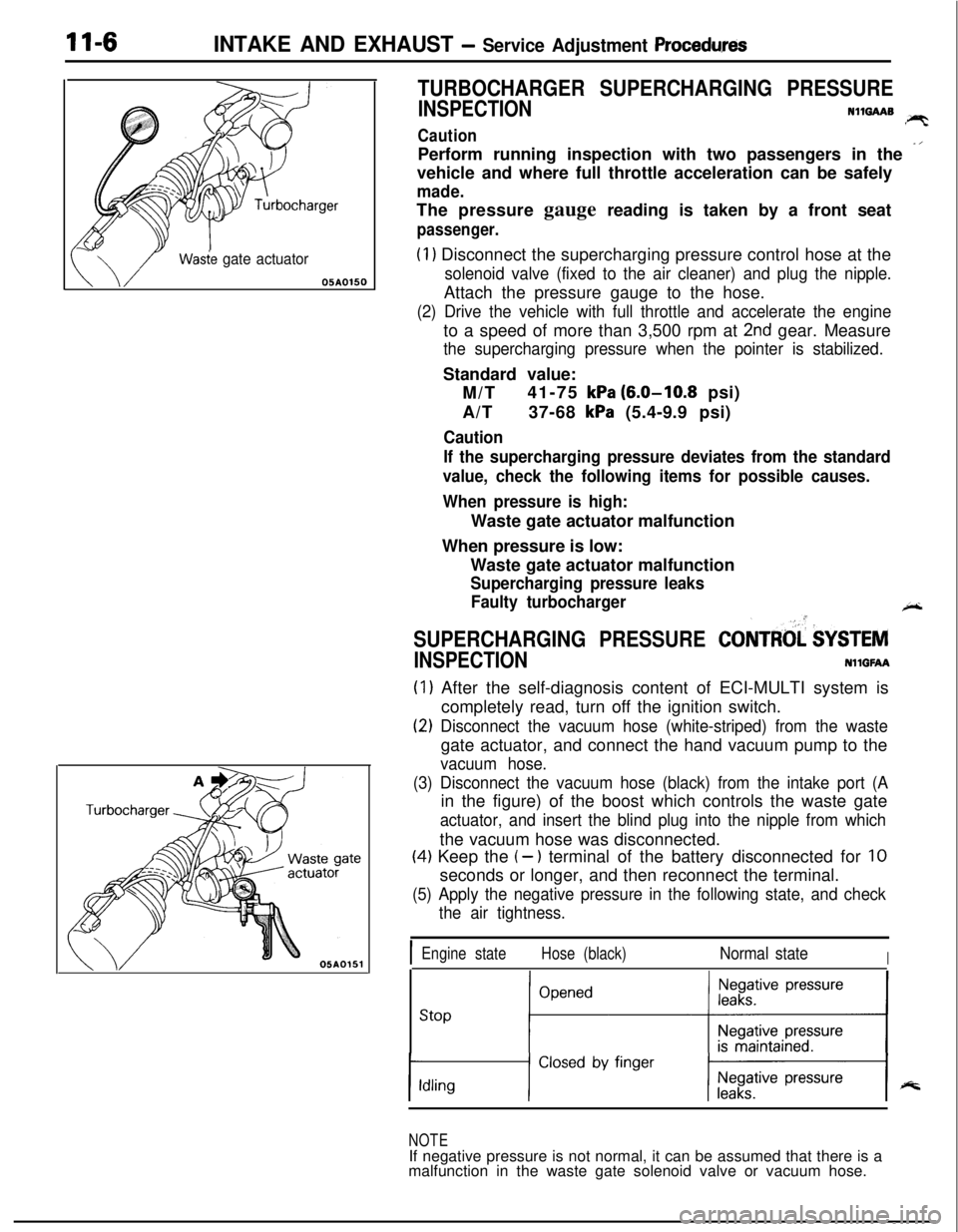

SUPERCHARGING PRESSURE CONTRtd $YSTEM

INSPECTIONNllGFAA

(1) After the self-diagnosis content of ECI-MULTI system is

completely read, turn off the ignition switch.

(2) Disconnect the vacuum hose (white-striped) from the wastegate actuator, and connect the hand vacuum pump to the

vacuum hose.

(3) Disconnect the vacuum hose (black) from the intake port (Ain the figure) of the boost which controls the waste gate

actuator, and insert the blind plug into the nipple from whichthe vacuum hose was disconnected.

(4) Keep the (- ) terminal of the battery disconnected for 10seconds or longer, and then reconnect the terminal.

(5) Apply the negative pressure in the following state, and check

the air tightness.

IEngine stateHose (black)Normal stateI

stop ;“““*I

NOTEIf negative pressure is not normal, it can be assumed that there is a

malfunction in the waste gate solenoid valve or vacuum hose.

Page 429 of 1216

INTAKE AND EXHAUST - Service Adjustment ProceduresII-7

w05A0155

h61

NO06061

NO0616 I

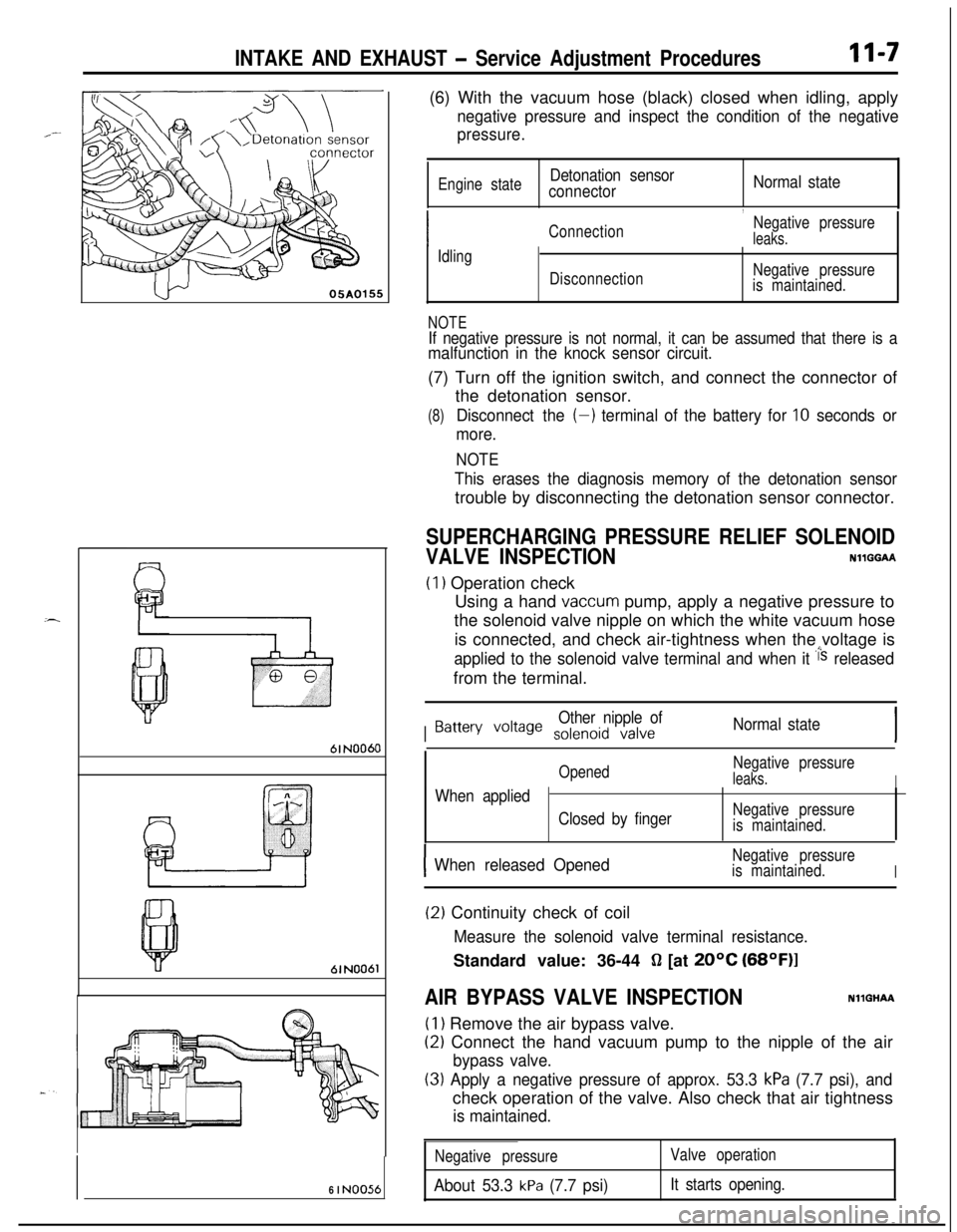

NO056(6) With the vacuum hose (black) closed when idling, apply

negative pressure and inspect the condition of the negative

pressure.

Engine stateDetonation sensor

connectorNormal state

,

ConnectionNegative pressureleaks.

Idling

DisconnectionNegative pressure

is maintained.

NOTEIf negative pressure is not normal, it can be assumed that there is amalfunction in the knock sensor circuit.(7) Turn off the ignition switch, and connect the connector of

the detonation sensor.

(8)Disconnect the (-) terminal of the battery for 10 seconds or

more.

NOTE

This erases the diagnosis memory of the detonation sensortrouble by disconnecting the detonation sensor connector.

SUPERCHARGING PRESSURE RELIEF SOLENOID

VALVE INSPECTIONNllGGAA

(1) Operation check

Using a hand

vaccum pump, apply a negative pressure to

the solenoid valve nipple on which the white vacuum hose

is connected, and check air-tightness when the voltage is

applied to the solenoid valve terminal and when it i‘s releasedfrom the terminal.

I

Other nipple ofBattery voile solenoid valveNormal state

OpenedNegative pressureleaks.IWhen applied

Closed by fingerNegative pressure

is maintained.

IWhen released OpenedNegative pressure

is maintained.

I

(2) Continuity check of coil

Measure the solenoid valve terminal resistance.Standard value: 36-44

fl [at 20°C (68OF)l

AIR BYPASS VALVE INSPECTIONNllGHAA

(1) Remove the air bypass valve.

(2) Connect the hand vacuum pump to the nipple of the air

bypass valve.

(3) Apply a negative pressure of approx. 53.3 kPa (7.7 psi), andcheck operation of the valve. Also check that air tightness

is maintained.

Negative pressure

About 53.3 kPa (7.7 psi)

Valve operation

It starts opening.