cooling MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 264 of 1216

7-16COOLING - Thermostat

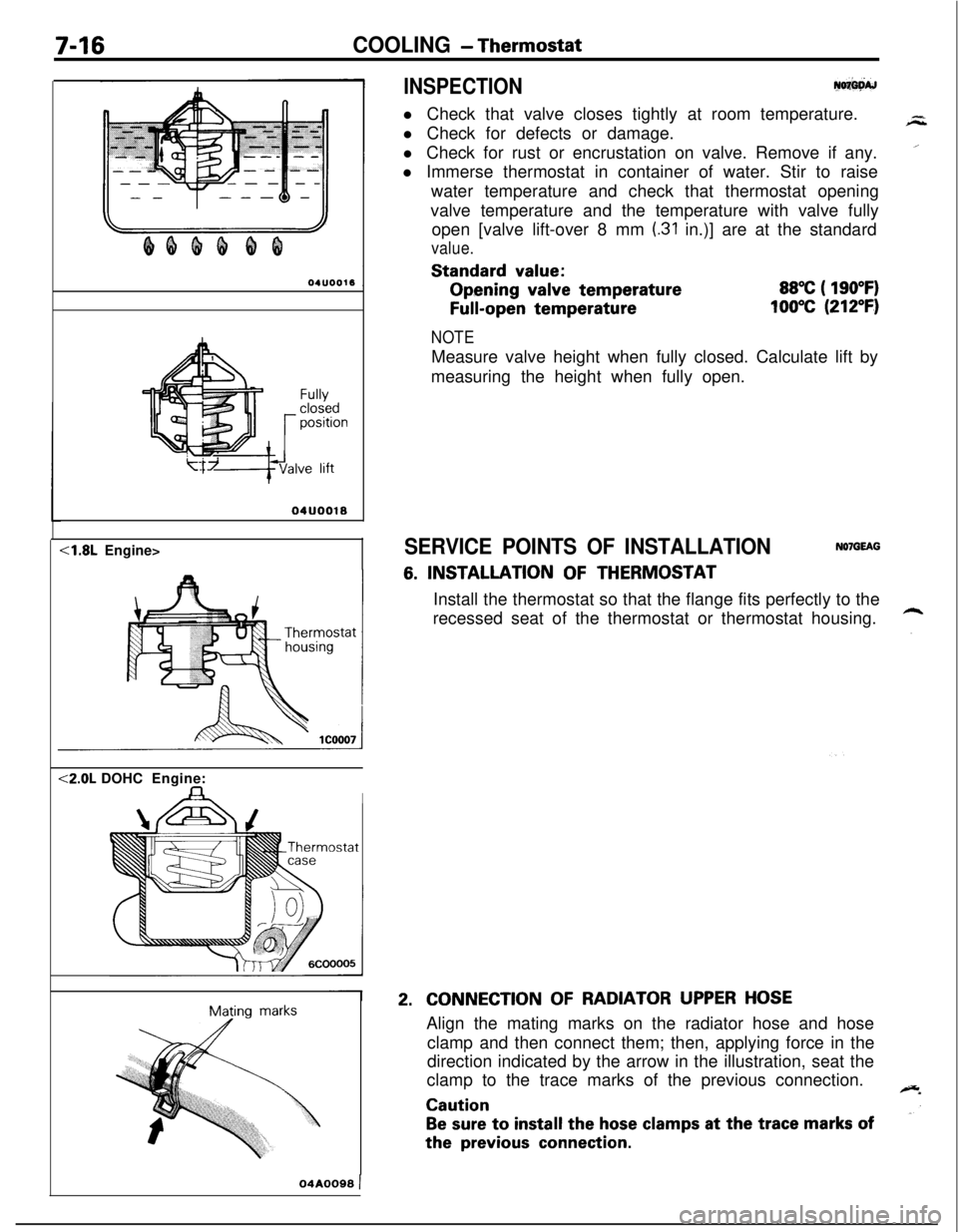

INSPECTIONy+w

l Check that valve closes tightly at room temperature.

l Check for defects or damage.

l Check for rust or encrustation on valve. Remove if any.

l Immerse thermostat in container of water. Stir to raise

water temperature and check that thermostat opening

valve temperature and the temperature with valve fully

open [valve lift-over 8 mm

(.31 in.)] are at the standard

value.Standard

value:Opening

valve temperature

Full-open temperature

88°C ( 190°F)

100°C (212°F)

Fullyclosedpositionve lift

04UOO18<1.8L Engine><2.0L DOHCEngine:

IMating

marks

NOTEMeasure valve height when fully closed. Calculate lift by

measuring the height when fully open.

SERVICE POINTS OF INSTALLATIONNOlGEAG

6. INSTALLATION OF THERMOSTAT

Install the thermostat so that the flange fits perfectly to the

recessed seat of the thermostat or thermostat housing.

2.CONNECTION OF RADIATOR UPPER HOSEAlign the mating marks on the radiator hose and hose

clamp and then connect them; then, applying force in the

direction indicated by the arrow in the illustration, seat the

clamp to the trace marks of the previous connection.

Caution

Be sure to install the hose clamps at the trace marks ofthe

previous connection.

04A0099 )

Page 265 of 1216

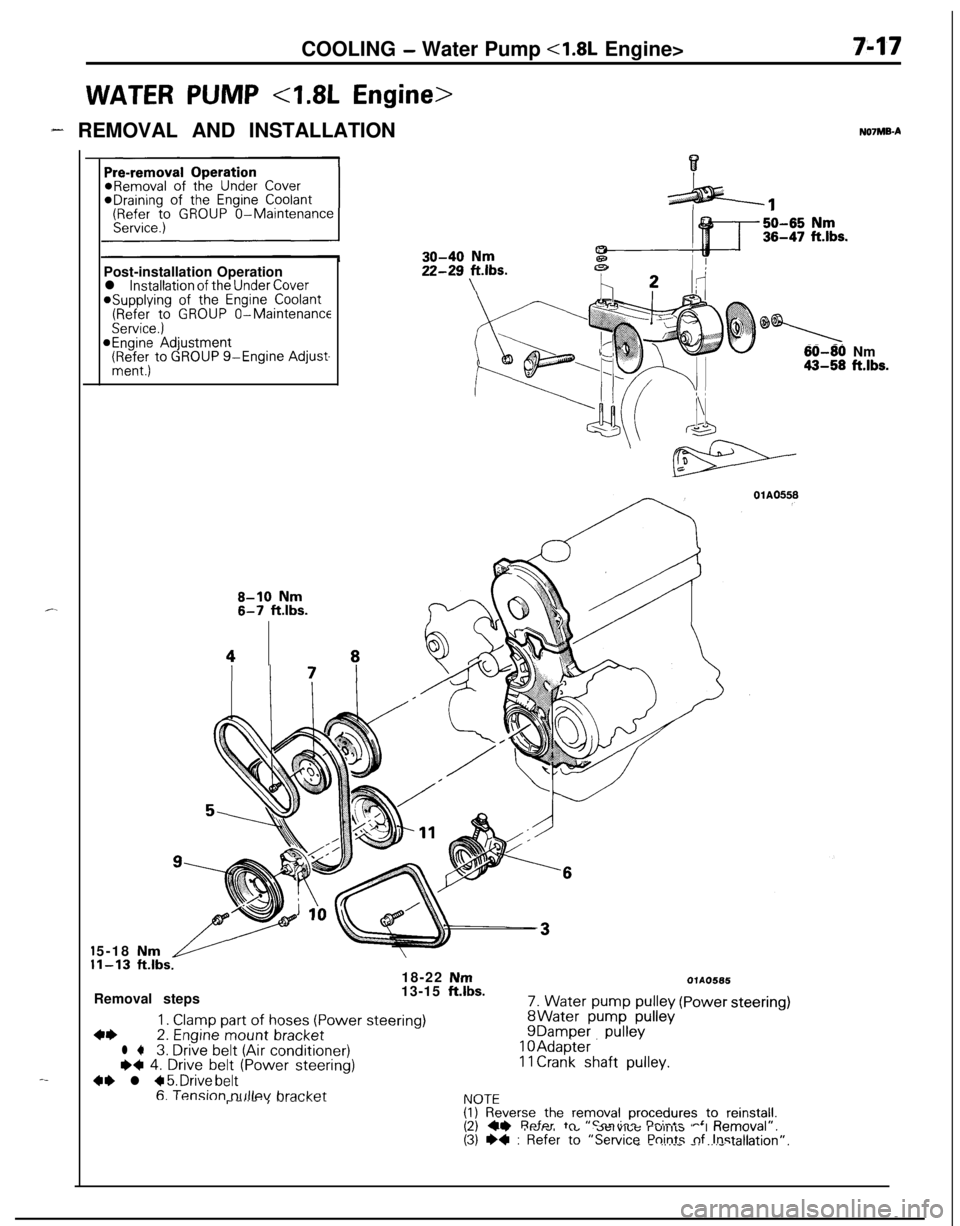

COOLING - Water Pump <1.8L Engine>

WATER PUMP 4.8L Engine>

7-17

- REMOVAL AND INSTALLATION

c.

-_*Draining of

the Engine Coolant(Refer to GROUP O-Maintenance

Post-installation Operation

l installation of the Under Cover@Supplying of the Engine Coolant(Refer to GROUP O-MaintenanceService.)@Engine Adjustment(RR:; to GROUP g-Engine Adjust-

8-10 Nm6-7 ftlbs.

48NOlMB-A

30-40 Nm

22-2g Fbs.

0

60-80 Nm43-58 ft.lbs.5-18

Nm1-13 ft.lbs.18-22 NmRemoval steps13-15 ft.lbs.

1. Clamp part of hoses (Power steering)4+2. Engine mount bracketl +3. Drive belt (Air conditioner)I)+ 4. Drive belt (Power steering)

4+ l + 5. Drive belt

7. Water pump pulleyWater pump pulleyDamper pullevAdapter. ’Crank shaft pulley.

OlAO566

(Powersteering)

6. Tension tx~llev bra&&I\lnTFr--‘--I -‘--‘.--I.VIL(I) Reverse the removal procedures to reinstall.I?\ CI Refer tn “Smvirr rh:-*- -‘ D---./al”,\-, --. I.VIw, .”..-..,u; r”llllb “I “allI”\(3) +4 : Refer to “Service Points nf Instalk_ - .,.__ -. _.._ .-Jion”.

Page 266 of 1216

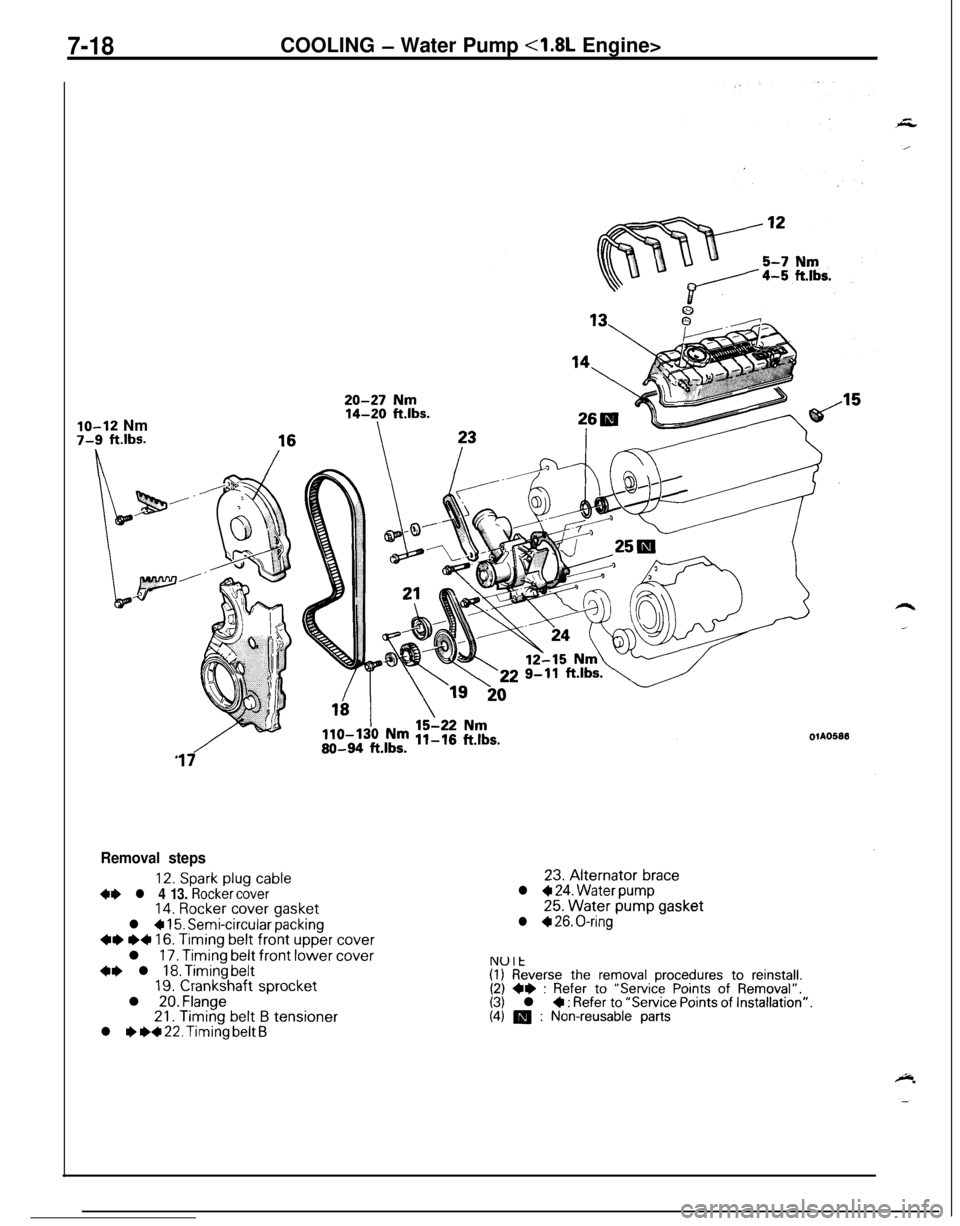

7-18COOLING - Water Pump <1.8L Engine>

lo-12 Nm7-9 ft.lbs.OlA05813

17

Removal steps

12. Spark plug cable+e l 4 13. Rocker cover14. Rocker cover gasket

l + 15. Semi-circular packing~~ e+ 16. Timing belt front upper coverl

17. Timing belt front lower cover+e l 18. Timing belt19. Crankshaft sprocketl 20. Flange21.

Timing belt B tensionerl I) ~~ 22. Timing belt B23.

Alternator bracel + 24. Water pump25.

Water pump gasketl + 26. O-ring

NUlt(I) Reverse the removal procedures to reinstall.(2) ** : Refer to “Service Points of Removal”.(3) l 4 : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

Page 267 of 1216

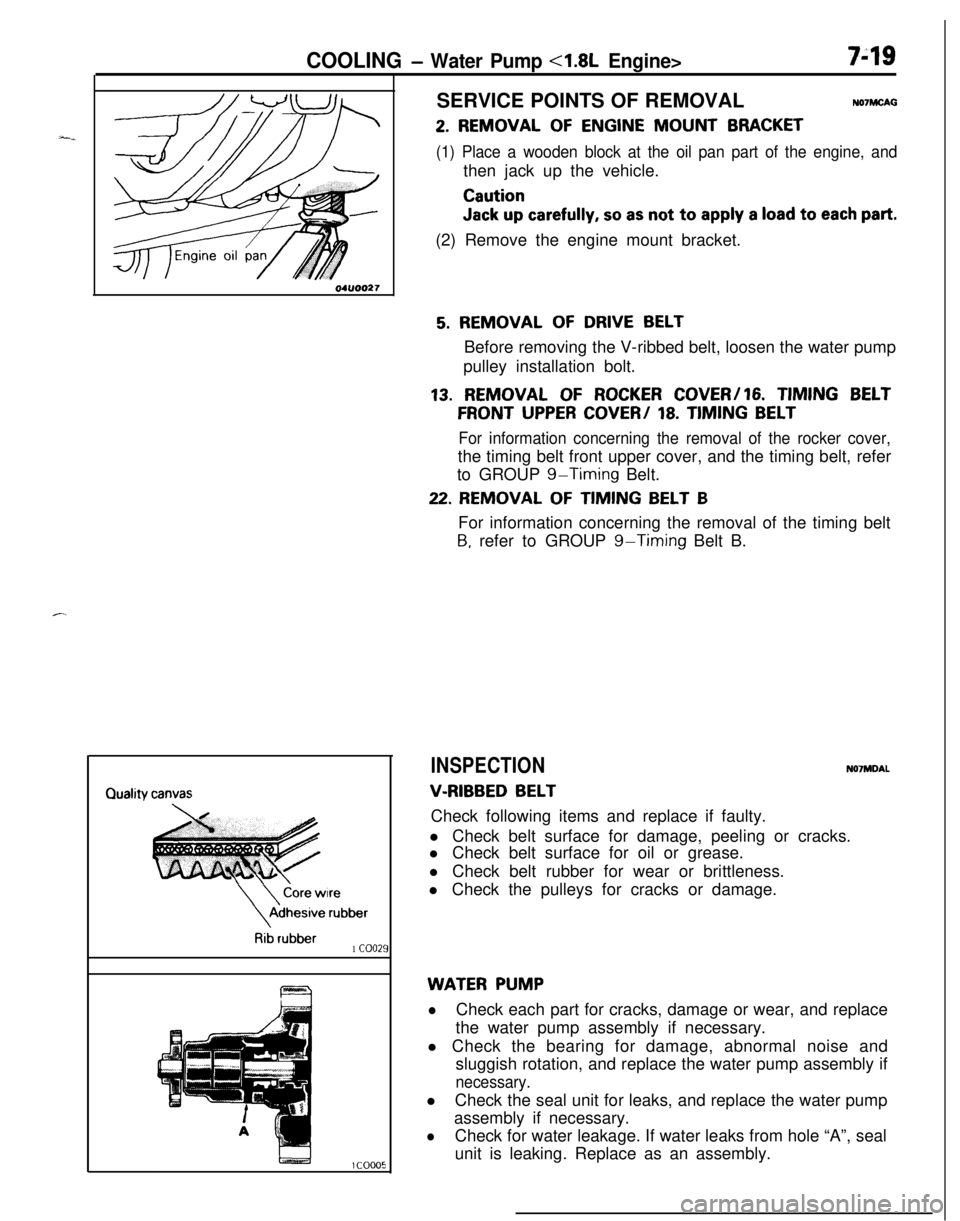

COOLING - Water Pump <1.8L Engine>749SERVICE POINTS OF REMOVAL

NO’IMCAG

2. REMOVAL OF ENGINE MOUNT BRACKET

(1) Place a wooden block at the oil pan part of the engine, andthen jack up the vehicle.

Caution

Jack up carefully, so as not to apply a load to each part.(2) Remove the engine mount bracket.

\

\

Core wireAdhesive

rubber

Rib rubber1 coo21

5. REMOVAL OF DRIVE BELTBefore removing the V-ribbed belt, loosen the water pump

pulley installation bolt.

13. REMOVAL OF ROCKER COVER/16. TIMING BELT

FRONT UPPER COVER/ 18. TIMING BELT

For information concerning the removal of the rocker cover,the timing belt front upper cover, and the timing belt, refer

to GROUP

g-Timing Belt.

22. REMOVAL OF TIMING BELT BFor information concerning the removal of the timing belt

B, refer to GROUP g-Timing Belt B.

INSPECTIONN07MDAL

V-RIBBED BELTCheck following items and replace if faulty.

l Check belt surface for damage, peeling or cracks.

l Check belt surface for oil or grease.

l Check belt rubber for wear or brittleness.

l Check the pulleys for cracks or damage.

WATER PUMP

lCheck each part for cracks, damage or wear, and replace

the water pump assembly if necessary.

l Check the bearing for damage, abnormal noise and

sluggish rotation, and replace the water pump assembly if

necessary.lCheck the seal unit for leaks, and replace the water pump

assembly if necessary.

lCheck for water leakage. If water leaks from hole “A”, seal

unit is leaking. Replace as an assembly.

Page 268 of 1216

7-20COOLING - Water Pump <1.8L Engine>

aWater pump*<

l-----r,//

O-ringWater

pipe

04ROO24Identification

mark04lJoo25Alternater

brace

404uoo22

J

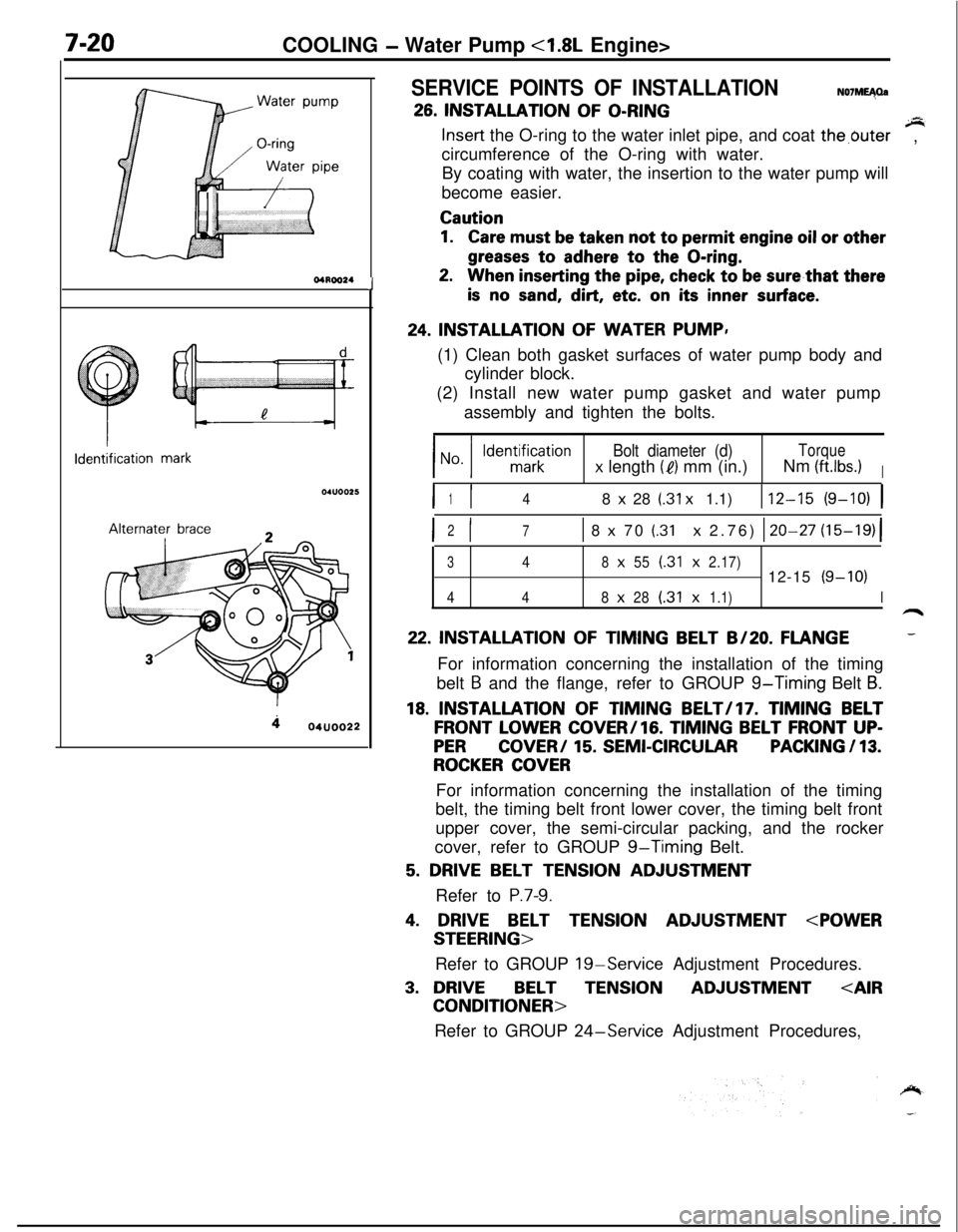

SERVICE POINTS OF INSTALLATIONN07ME40a

26. INSTALLATION OF O-RINGsInsert the O-ring to the water inlet pipe, and coat the,buter

circumference of the O-ring with water.,

By coating with water, the insertion to the water pump will

become easier.

Caution

1.Care must be taken not to permit engine oil or other

greases to adhere to the O-ring.

2.When inserting the pipe, check to be sure,that there

is no sand, dirt, etc. on its inner surface.

24. INSTALLATION OF WATER PUMP,

(1) Clean both gasket surfaces of water pump body and

cylinder block.

(2) Install new water pump gasket and water pump

assembly and tighten the bolts.

Bolt diameter (d)Torque

x length (e) mm (in.)Nm (ftlbs.)I

I I148 x 28 (.31 x 1.1)112-15 (9-10) 1

I I2

71 8 x 70 (.31 x 2.76) 120-27 (15-19)(

348x55(.31x2.17)12-15(9-10)

448x28(.31x1.1)I

22. INSTALLATION OF TIMING BELT B/20. FLANGE-For information concerning the installation of the timing

belt

B and the flange, refer to GROUP g-Timing Belt B.

18. INSTALLATION OF TIMING BELT/l7. TIMING BELT

FRONT LOWER COVER/lG. TIMING BELT FRONT UP-

PERCOVER/ 15. SEMI-CIRCULARPACKING / 13.

ROCKER COVERFor information concerning the installation of the timing

belt, the timing belt front lower cover, the timing belt front

upper cover, the semi-circular packing, and the rocker

cover, refer to GROUP

g-Timing Belt.

5. DRIVE BELT TENSION ADJUSTMENT

Refer to

P.7-9.

4. DRIVE BELT TENSION ADJUSTMENT

Refer to GROUP

19-Service Adjustment Procedures.

3. DRIVEBELTTENSIONADJUSTMENT

Refer to GROUP

24-Service Adjustment Procedures,

Page 269 of 1216

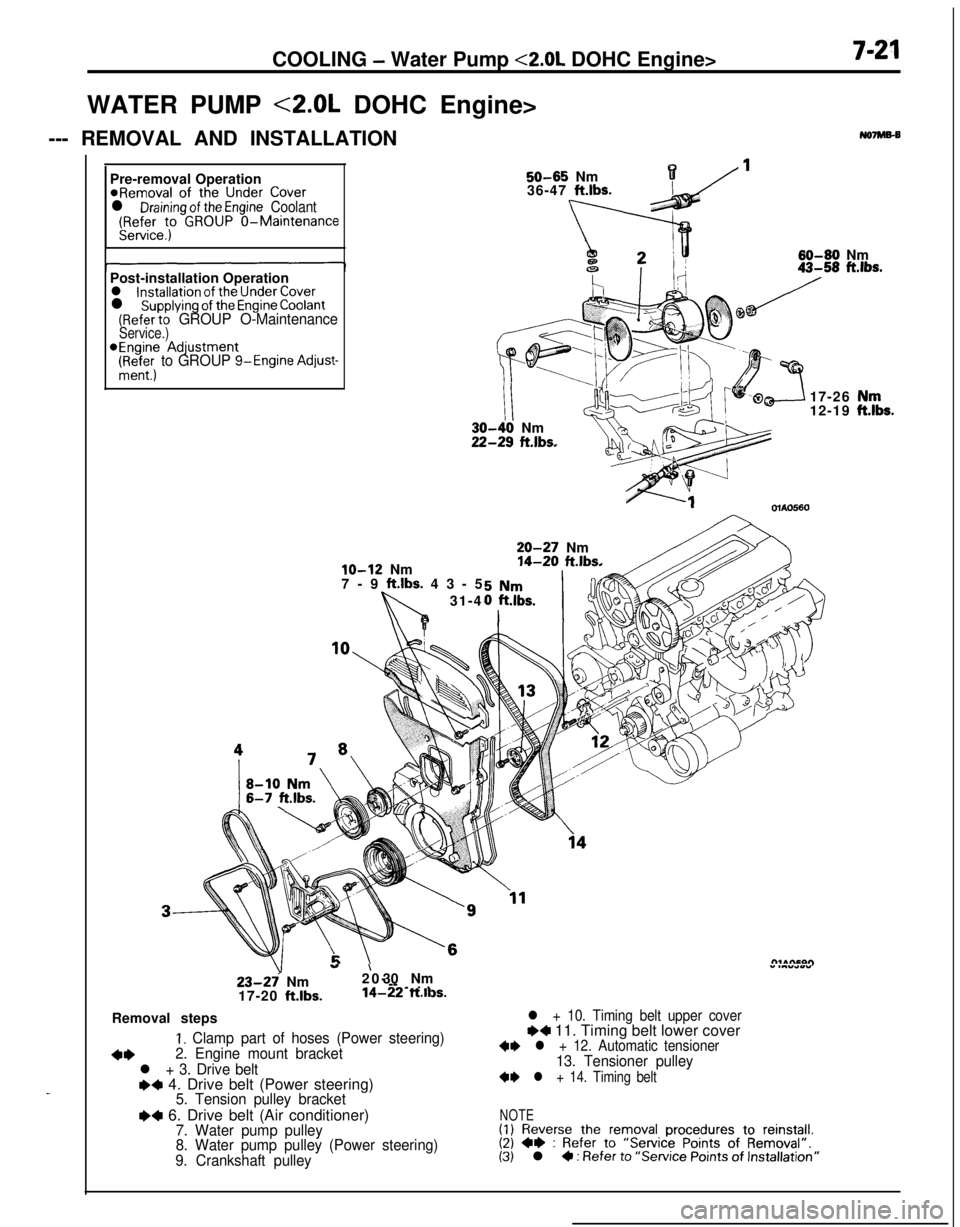

COOLING - Water Pump <2.0L DOHC Engine>7-21WATER PUMP <2.0L DOHC Engine>

--- REMOVAL AND INSTALLATION

No7Ms-B

_Pre-removal Operation

@Removal of the Under Coverl Draining of the Engine Coolant(Refer to GROUP O-MaintenanceService.)

50-65 Nm136-47 ft.lbs.

60-60 Nm

Post-installation Operation

l installation of the Under Coverl supplying of the Engine Coolant(Refer to GROUP O-MaintenanceService.)*Engine Adjustment

(Ri+&; to GROUP g-Engine Adjust-

lo-12 Nm

7-9 ft.lbs. 43-5

31-4

III-40 Nm!-29 ft.lbs.17-26

12-19OlAO560

20-27 Nm14-20 ft.lbs.

23-27 Nm

17-20 ft.lbs.

”20-’ 30 Nm” .““*wY--

-~ . .14-22 ft.ll3s.Removal steps

I. Clamp part of hoses (Power steering)

+*2. Engine mount bracket

l + 3. Drive belte+ 4. Drive belt (Power steering)5. Tension pulley bracket

I)4 6. Drive belt (Air conditioner)7. Water pump pulley

8. Water pump pulley (Power steering)

9. Crankshaft pulley

l + 10. Timing belt upper coverI)4 11. Timing belt lower cover+I) l + 12. Automatic tensioner13. Tensioner pulley

+I) l + 14. Timing belt

NOTE(1) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) l 4 : Refer to “Service Points of Installation”

,“k.

Page 270 of 1216

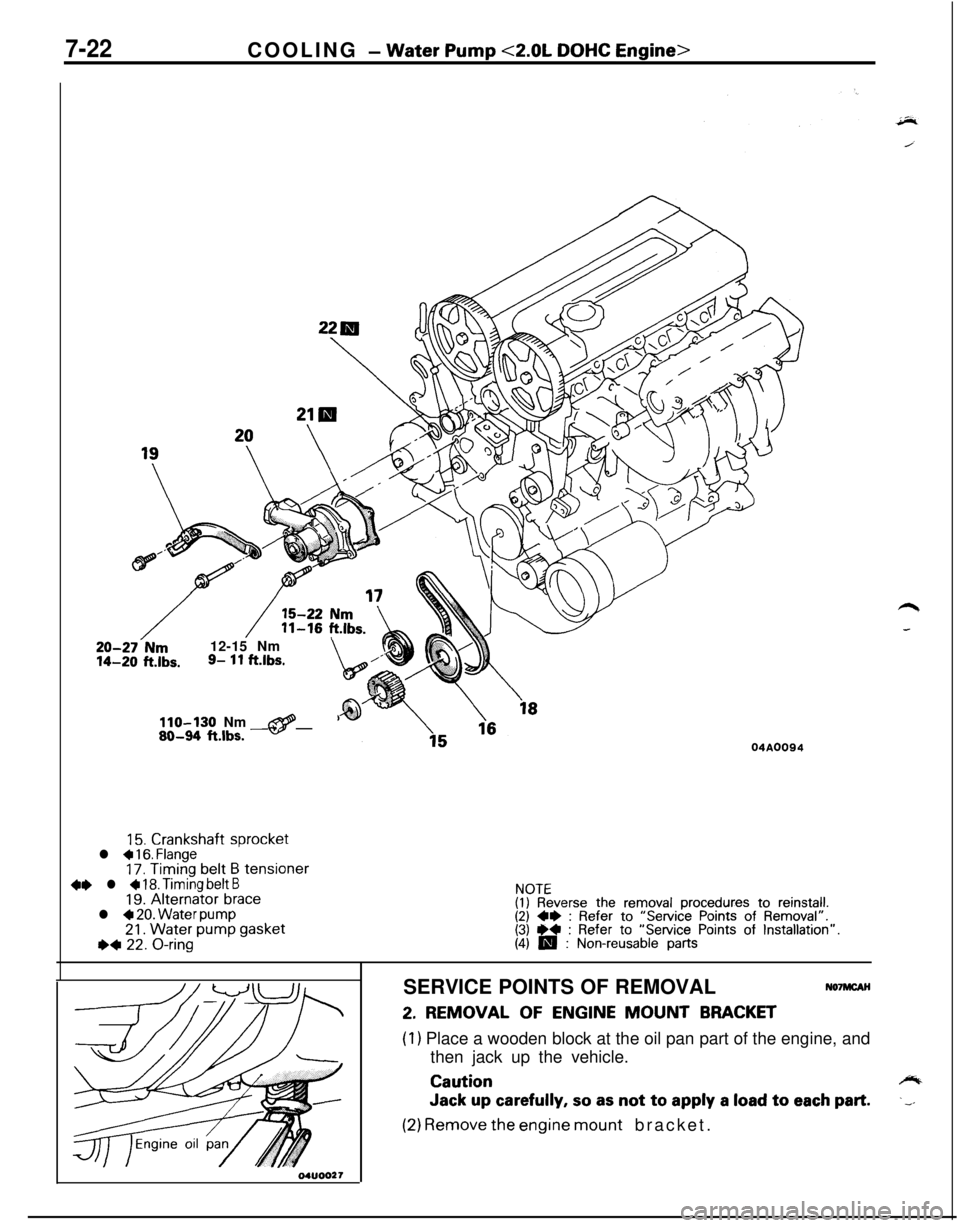

7-22COOLING - Water Pump <2.0L DOHC Engine>

20-27-Nm12-15 Nm14-20 ft.lbs.9- 11 ftlbs.\,/”

110-130 Nm@80-94 ftlbs. -04A0094

15. Crankshaft sprocketl a 16. Flange17. Timing belt B tensioner4e l + 18. Timing belt B19. Alternator bracel 4 20. Water pump21. Water pump gasketI)* 22. O-ring

NOTE(I) Reverse the removal procedures to reinstall.(2) 4* : Refer to “Service Points of Removal”.(3) ** : Refer to “Service Points of Installation”.(4) m : Non-reusable partsSERVICE POINTS OF REMOVAL

NO’IMCAH

2. REMOVAL OF ENGINE MOUNT BRACKET

(1) Place a wooden block at the oil pan part of the engine, and

then jack up the vehicle.

Cautioncylb

Jack up carefully, so as not to apply a load to each part..__

(2) Remove the engine mount bracket.

Page 271 of 1216

COOLING - Water Pump <2.0L DOHC Engine>7-2’3

12. REMOVAL OF AUTOMATIC TENSIONERI14. TIMING

BELTFor information concerning removal of the automatic

tensioner and the timing belt, refer to GROUP

g-Timing

Belt.

18. REMOVAL OF TIMING BELT BFor information concerning the removal of timing belt

6,refer to GROUP

g-Timing Belt B.Quality

canvas

\

\

Core wireAdhesive

rubber

Rib rubberlCOO2I

MRM2.

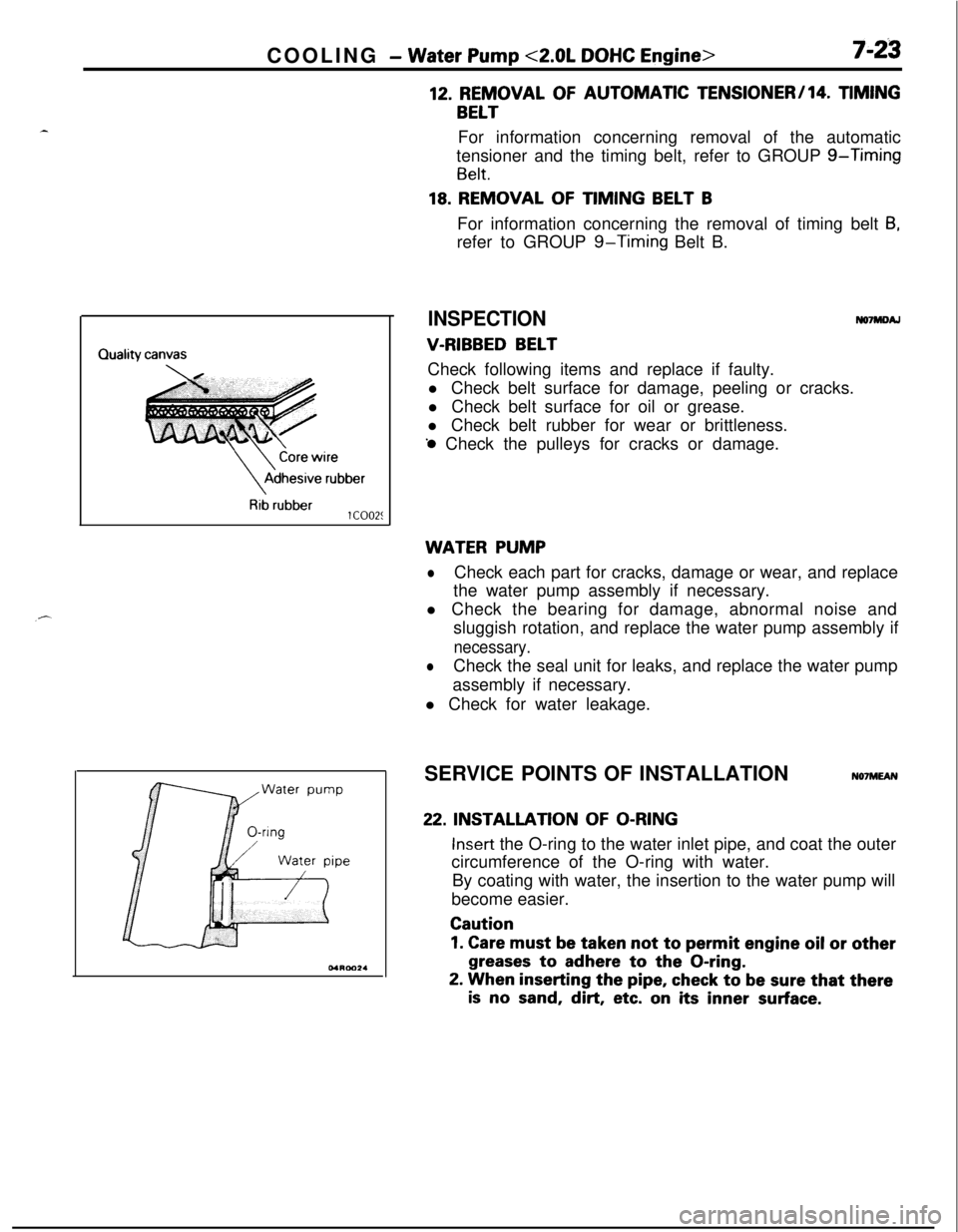

INSPECTION

V-RIBBED BELT

No7mDA.lCheck following items and replace if faulty.

l Check belt surface for damage, peeling or cracks.

l Check belt surface for oil or grease.

l Check belt rubber for wear or brittleness.

‘0 Check the pulleys for cracks or damage.

WATER PUMP

lCheck each part for cracks, damage or wear, and replace

the water pump assembly if necessary.

l Check the bearing for damage, abnormal noise and

sluggish rotation, and replace the water pump assembly if

necessary.

lCheck the seal unit for leaks, and replace the water pump

assembly if necessary.

l Check for water leakage.

SERVICE POINTS OF INSTALLATION

N07MEAN

22. INSTALLATION OF O-RING

Insert the O-ring to the water inlet pipe, and coat the outer

circumference of the O-ring with water.

By coating with water, the insertion to the water pump will

become easier.

Caution

1. Care must be taken not to permit engine oil or other

greases to adhere to the O-ring.

2. When inserting the pipe, check to be sure that there

is no sand, dirt, etc. on its inner surface.

Page 272 of 1216

7-24COOLING - Water Pump <2.0L DOHC Engine>

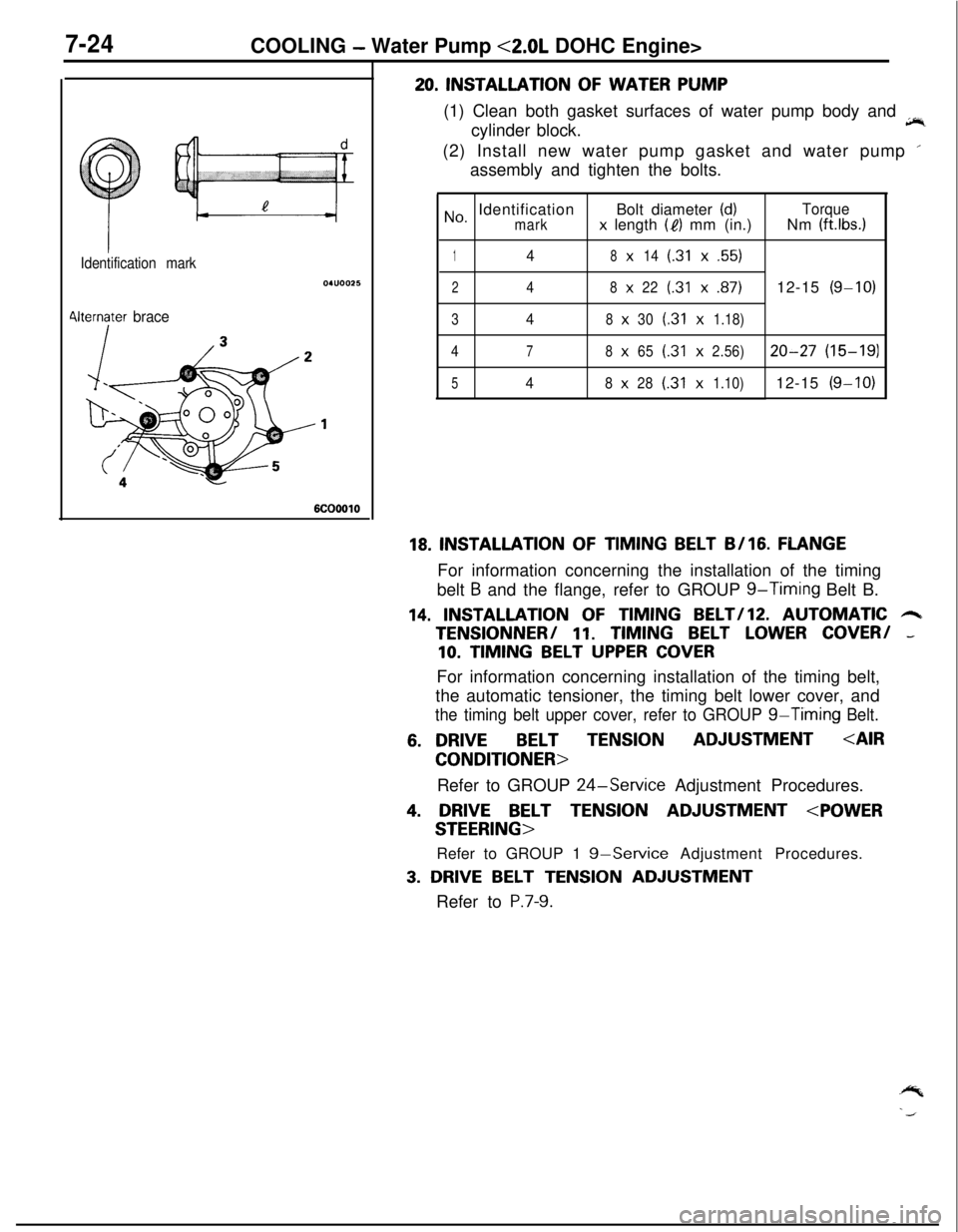

Identification mark

4lternater brace

6COOOlO

20. INSTALLATION OF WATER PUMP

(1) Clean both gasket surfaces of water pump body and

jir,cylinder block.

(2) Install new water pump gasket and water pump ’

assembly and tighten the bolts.

No, IdentificationBolt diameter (d)Torquemarkx length (I?) mm (in.)Nm (ft.lbs.1

148x14(.31x.55)

248x22(.31x.87)12-15(g-10)

348x30(.31x1.18)

4

78x65(.31x2.56)20-27(15-191

548x28(.31x1.10)12-15(g-10)

18. INSTALLATION OF TIMING BELT B/16. FLANGEFor information concerning the installation of the timing

belt

B and the flange, refer to GROUP g-Timing Belt B.

14. INSTALLATION OF TIMING BELT/lZ. AUTOMATIC 6TENSlONNER/

11. TIMING BELT LOWER COVER/ -

10. TIMING BELT UPPER COVERFor information concerning installation of the timing belt,

the automatic tensioner, the timing belt lower cover, and

the timing belt upper cover, refer to GROUP g-Timing Belt.

6. DRIVEBELT TENSIONADJUSTMENT

Refer to GROUP

24-Service Adjustment Procedures.

4. DRIVE BELT TENSION ADJUSTMENT

Refer to GROUP 1

g-Service Adjustment Procedures.

3. DRIVE BELT TENSION ADJUSTMENT

Refer to

P.7-9.

Page 273 of 1216

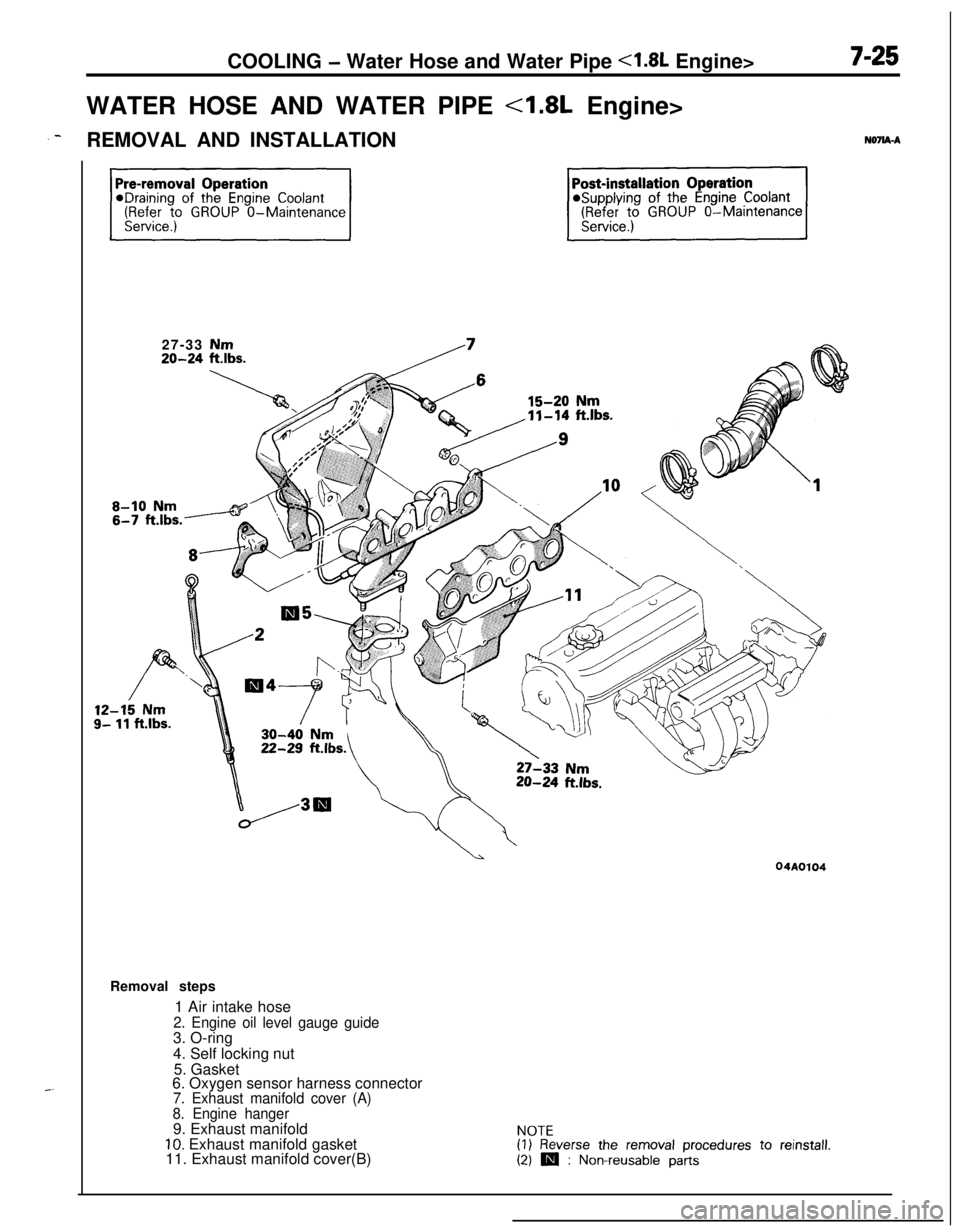

COOLING - Water Hose and Water Pipe <1.8L Engine>

WATER HOSE AND WATER PIPE

<1.8L Engine>

_-REMOVAL AND INSTALLATIONNO’IIA-A27-33 Nm

20-24 ftlbs.

12-15 Nms- 11 ft.lbs.Removal steps

1 Air intake hose

2. Engine oil level gauge guide3. O-ring

4. Self locking nut

5. Gasket

6. Oxygen sensor harness connector

7. Exhaust manifold cover (A)

8. Engine hanger9. Exhaust manifold

IO. Exhaust manifold gasket

11. Exhaust manifold cover(B)NOTE(1) Reverse the removal procedures to reinstall.(2) m : Non-reusable parts