differential MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 128 of 1216

3-26REAR AXLE - Differential Carrier

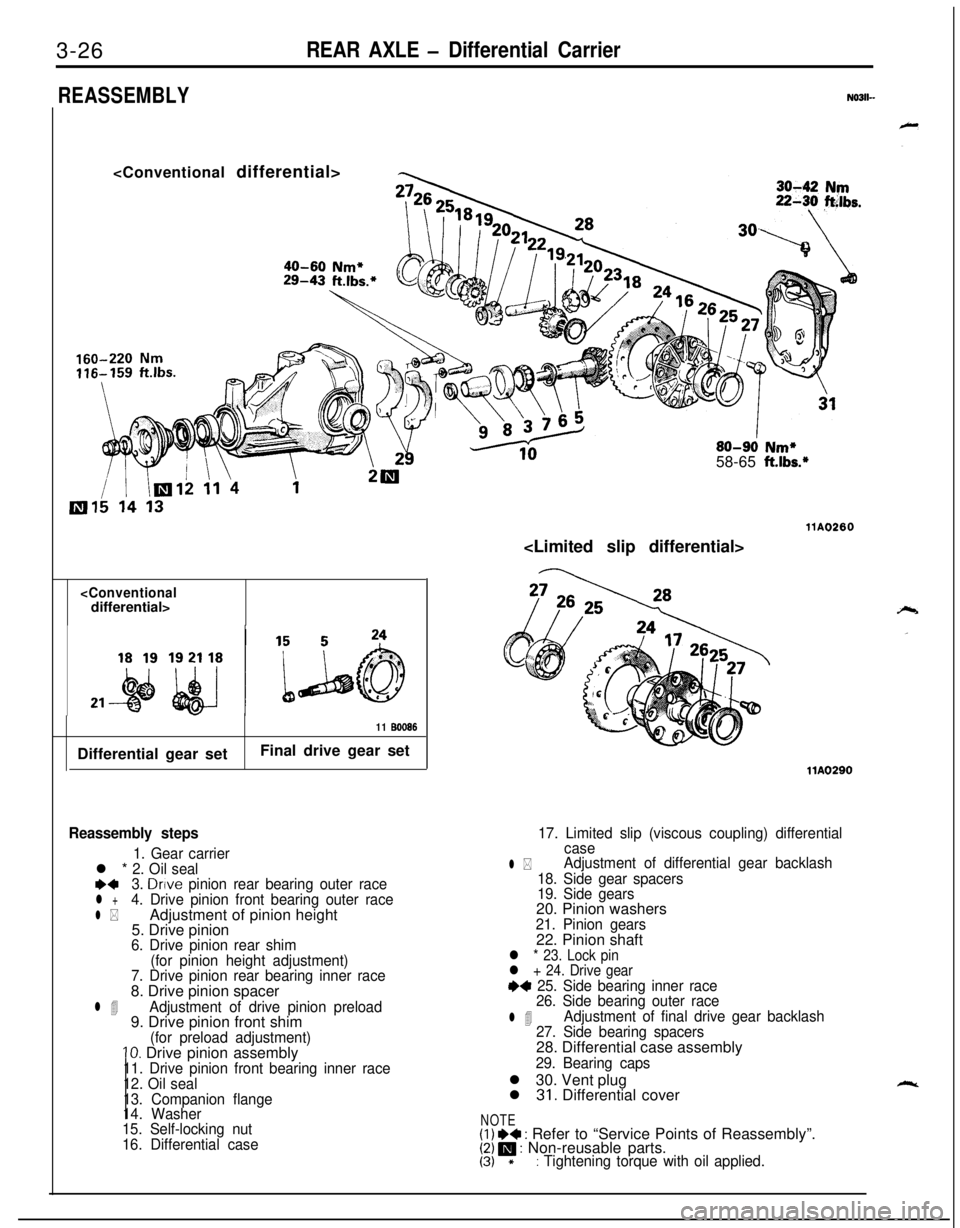

REASSEMBLYN0311-

Nm*B-43 ft.lbs.*

80-90 Nm*58-65 ft.lbs.*

11 BOO86Differential gear setFinal drive gear set

Reassembly steps

1. Gear carrierl * 2. Oil seale+3. Drive pinion rear bearing outer racel +4. Drive pinion front bearing outer race

l *Adjustment of pinion height

5. Drive pinion

6. Drive pinion rear shim

(for pinion height adjustment)

7. Drive pinion rear bearing inner race8. Drive pinion spacer

l 4Adjustment of drive pinion preload9. Drive pinion front shim

(for preload adjustment)10. Drive pinion assembly11. Drive pinion front bearing inner race

12. Oil seal

13. Companion flange

14. Washer

15. Self-locking nut

16. Differential case

17. Limited slip (viscous coupling) differential

case

l *Adjustment of differential gear backlash

18. Side gear spacers

19. Side gears20. Pinion washers

21. Pinion gears22. Pinion shaft

l * 23. Lock pin

l + 24. Drive gear

+4 25. Side bearing inner race

26. Side bearing outer race

l 4Adjustment of final drive gear backlash

27. Side bearing spacers28. Differential case assembly

29. Bearing capsl 30. Vent plug

l

31. Differential cover

NOTE(I) I)+ : Refer to “Service Points of Reassembly”.[Z!/ m : Non-reusable parts.*: Tightening torque with oil applied.

Page 129 of 1216

REAR AXLE - Differential Carrier3-27

llK010

71

llY181llY182

.MB990836(MB990835)

llrm3

V223

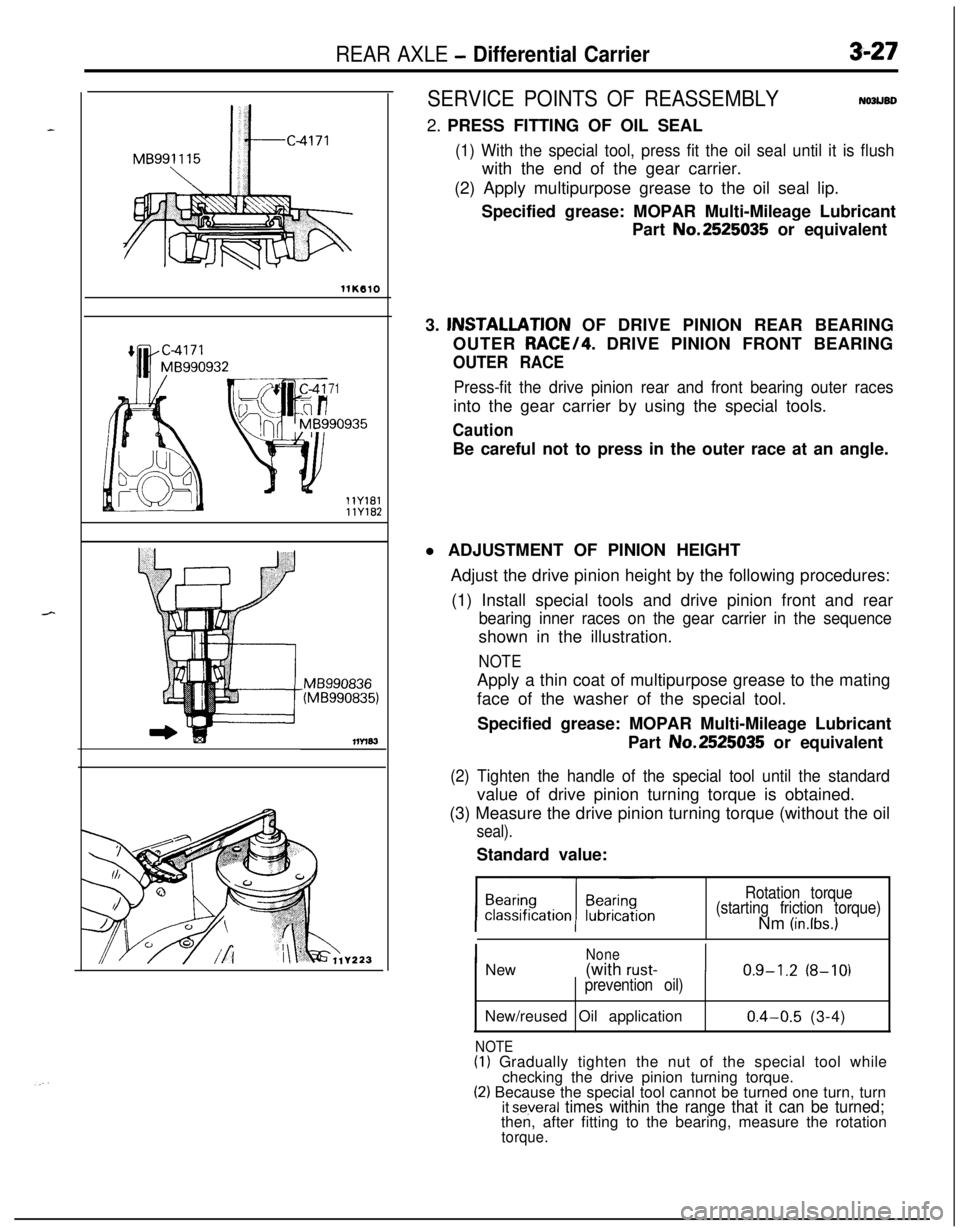

SERVICE POINTS OF REASSEMBLYNOJUBD2. PRESS FITTING OF OIL SEAL

(1) With the special tool, press fit the oil seal until it is flushwith the end of the gear carrier.

(2) Apply multipurpose grease to the oil seal lip.

Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

3. lNSTALLATlON OF DRIVE PINION REAR BEARING

OUTER RACE/4. DRIVE PINION FRONT BEARING

OUTER RACE

Press-fit the drive pinion rear and front bearing outer racesinto the gear carrier by using the special tools.

CautionBe careful not to press in the outer race at an angle.

l ADJUSTMENT OF PINION HEIGHT

Adjust the drive pinion height by the following procedures:

(1) Install special tools and drive pinion front and rear

bearing inner races on the gear carrier in the sequenceshown in the illustration.

NOTEApply a thin coat of multipurpose grease to the mating

face of the washer of the special tool.

Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

(2) Tighten the handle of the special tool until the standardvalue of drive pinion turning torque is obtained.

(3) Measure the drive pinion turning torque (without the oil

seal).Standard value:

Rotation torque

(starting friction torque)Nm

(in.lbs.)

I

NoneNew(with rust-I0.9-1.2 (8-10)prevention oil)New/reused Oil application

NOTE

0.4-0.5 (3-4)(I) Gradually tighten the nut of the special tool while

checking the drive pinion turning torque.

(2) Because the special tool cannot be turned one turn, turnit several times within the range that it can be turned;then, after fitting to the bearing, measure the rotation

torque.

Page 130 of 1216

3-28REAR AXLE - Differential Carrier

Y223

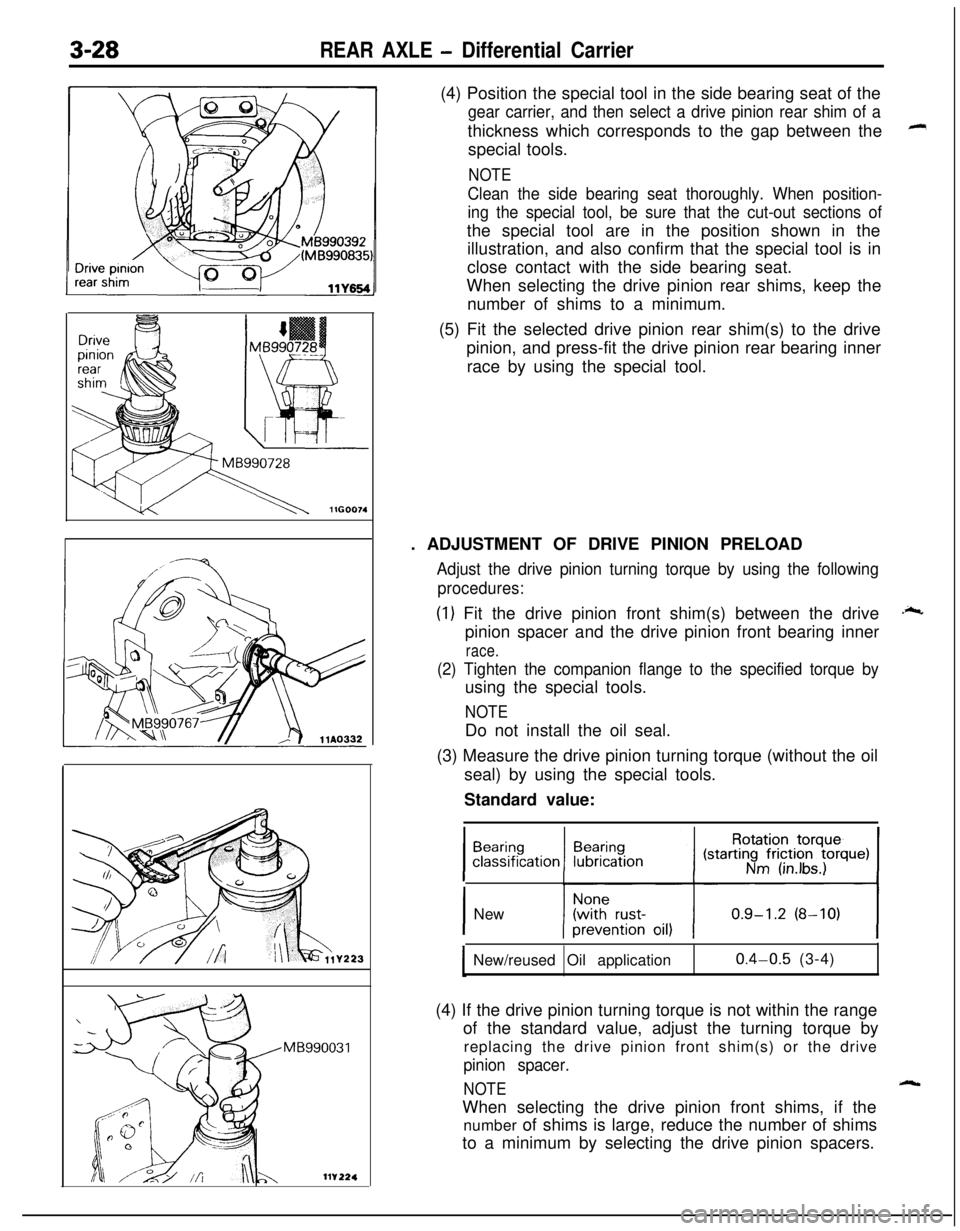

MB990031(4) Position the special tool in the side bearing seat of the

gear carrier, and then select a drive pinion rear shim of athickness which corresponds to the gap between the

special tools.

NOTE

Clean the side bearing seat thoroughly. When position-

ing the special tool, be sure that the cut-out sections ofthe special tool are in the position shown in the

illustration, and also confirm that the special tool is in

close contact with the side bearing seat.

When selecting the drive pinion rear shims, keep the

number of shims to a minimum.

(5) Fit the selected drive pinion rear shim(s) to the drive

pinion, and press-fit the drive pinion rear bearing inner

race by using the special tool.

. ADJUSTMENT OF DRIVE PINION PRELOAD

Adjust the drive pinion turning torque by using the following

procedures:

(1) Fit the drive pinion front shim(s) between the drive

pinion spacer and the drive pinion front bearing inner

race.

(2) Tighten the companion flange to the specified torque byusing the special tools.

NOTEDo not install the oil seal.

(3) Measure the drive pinion turning torque (without the oil

seal) by using the special tools.

Standard value:

21

.;c

1 New

New/reused Oil application

0.4-0.5 (3-4)

(4) If the drive pinion turning torque is not within the range

of the standard value, adjust the turning torque by

replacing the drive pinion front shim(s) or the drive

pinion spacer.

NOTEWhen selecting the drive pinion front shims, if the

number of shims is large, reduce the number of shims

to a minimum by selecting the drive pinion spacers.

Page 131 of 1216

REAR AXLE - Differential Carrier3-29

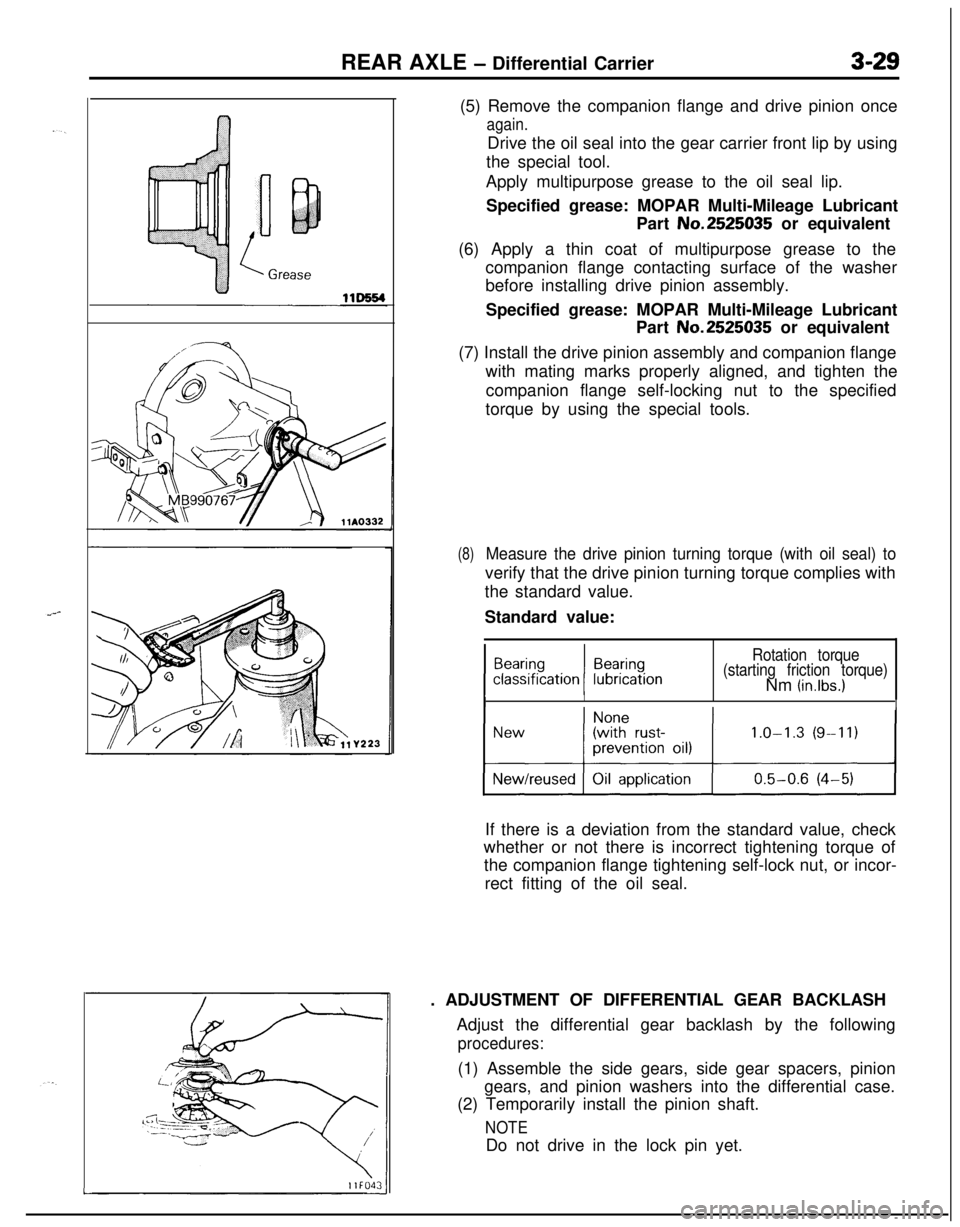

Y223(5) Remove the companion flange and drive pinion once

again.Drive the oil seal into the gear carrier front lip by using

the special tool.

Apply multipurpose grease to the oil seal lip.

Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

(6) Apply a thin coat of multipurpose grease to the

companion flange contacting surface of the washer

before installing drive pinion assembly.

Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

(7) Install the drive pinion assembly and companion flange

with mating marks properly aligned, and tighten the

companion flange self-locking nut to the specified

torque by using the special tools.

(8)Measure the drive pinion turning torque (with oil seal) toverify that the drive pinion turning torque complies with

the standard value.

Standard value:

Rotation torque

(starting friction torque)Nm

(in.lbs.)

IIIIIf there is a deviation from the standard value, check

whether or not there is incorrect tightening torque of

the companion flange tightening self-lock nut, or incor-

rect fitting of the oil seal.

. ADJUSTMENT OF DIFFERENTIAL GEAR BACKLASH

Adjust the differential gear backlash by the following

procedures:(1) Assemble the side gears, side gear spacers, pinion

gears, and pinion washers into the differential case.

(2) Temporarily install the pinion shaft.

NOTEDo not drive in the lock pin yet.

L-

Page 132 of 1216

REAR AXLE - Differential Carrier

I\I I!llGOO73I

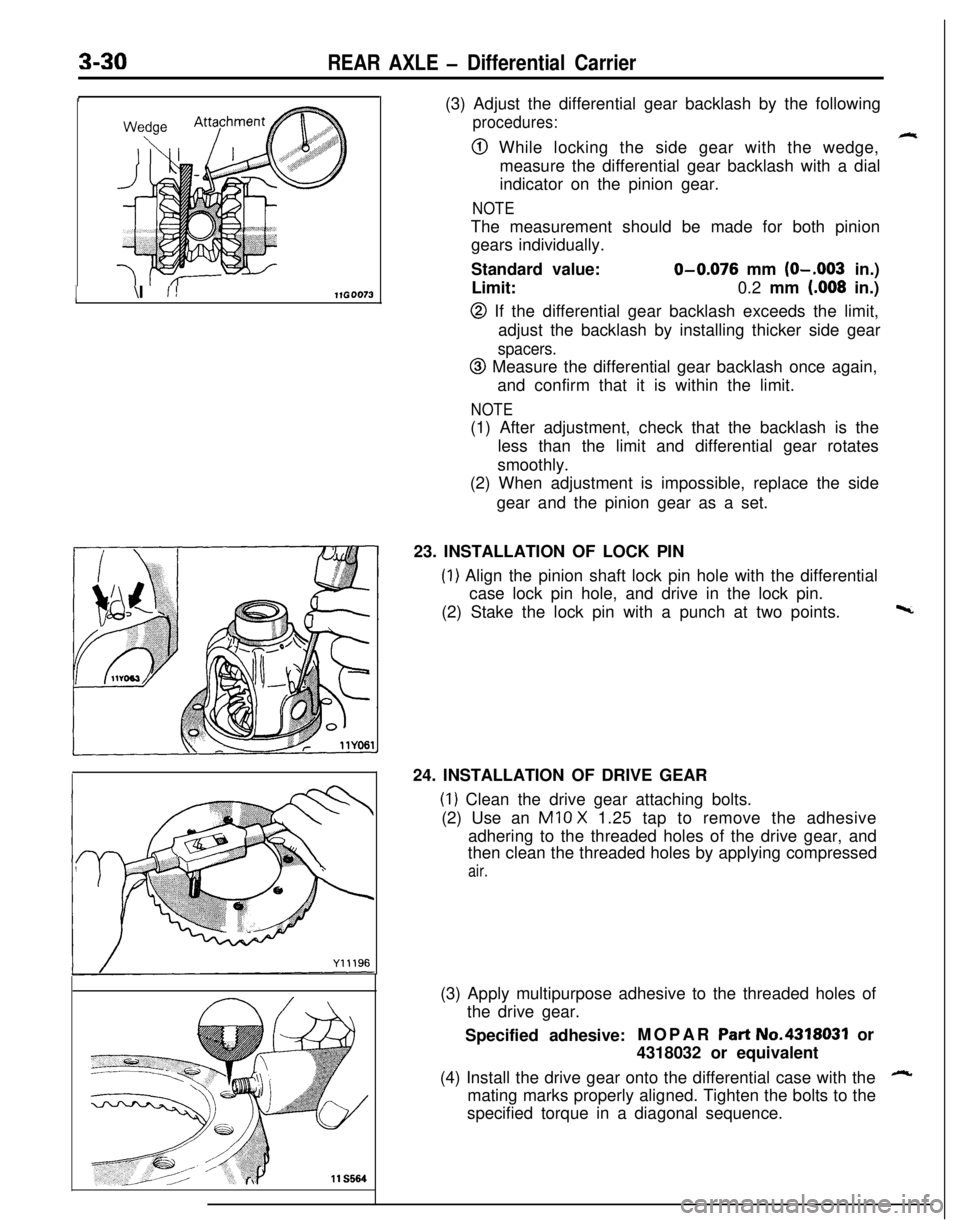

11 S564(3) Adjust the differential gear backlash by the following

procedures:

@ While locking the side gear with the wedge,

measure the differential gear backlash with a dial

indicator on the pinion gear.

NOTEThe measurement should be made for both pinion

gears individually.

Standard value:

O-0.076 mm (O-.003 in.)

Limit:0.2 mm

(.008 in.)

@ If the differential gear backlash exceeds the limit,

adjust the backlash by installing thicker side gear

spacers.

@ Measure the differential gear backlash once again,

and confirm that it is within the limit.

NOTE(1) After adjustment, check that the backlash is the

less than the limit and differential gear rotates

smoothly.

(2) When adjustment is impossible, replace the side

gear and the pinion gear as a set.

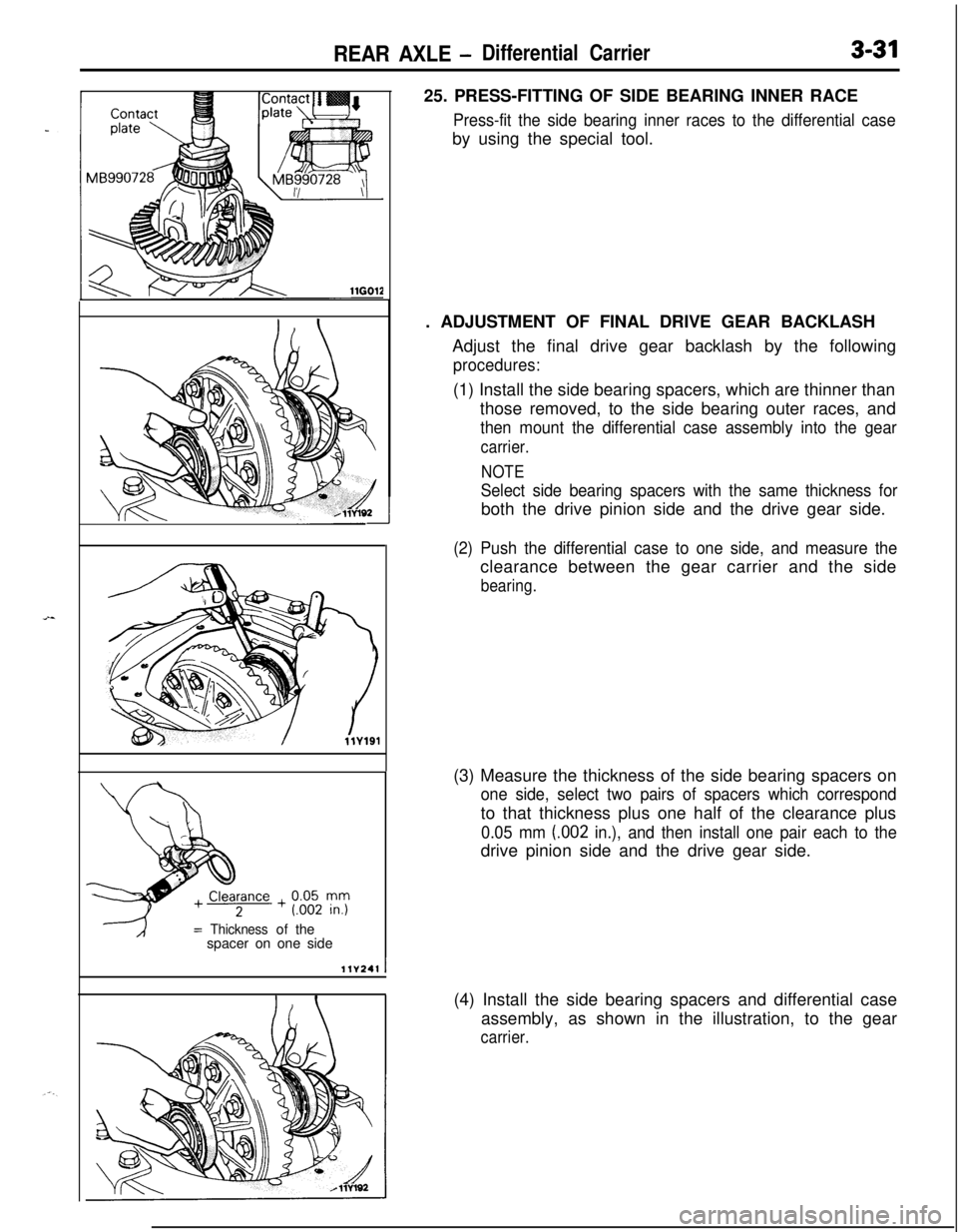

23. INSTALLATION OF LOCK PIN

(1) Align the pinion shaft lock pin hole with the differential

case lock pin hole, and drive in the lock pin.

(2) Stake the lock pin with a punch at two points.

w24. INSTALLATION OF DRIVE GEAR

(1) Clean the drive gear attaching bolts.

(2) Use an

Ml0 X 1.25 tap to remove the adhesive

adhering to the threaded holes of the drive gear, and

then clean the threaded holes by applying compressed

air.(3) Apply multipurpose adhesive to the threaded holes of

the drive gear.

Specified adhesive:MOPAR

Part No.4318031 or

4318032 or equivalent

(4) Install the drive gear onto the differential case with the

Amating marks properly aligned. Tighten the bolts to the

specified torque in a diagonal sequence.

Page 133 of 1216

REAR AXLE -Differential Carrier3-31

= Thicknessof the

spacer on one side

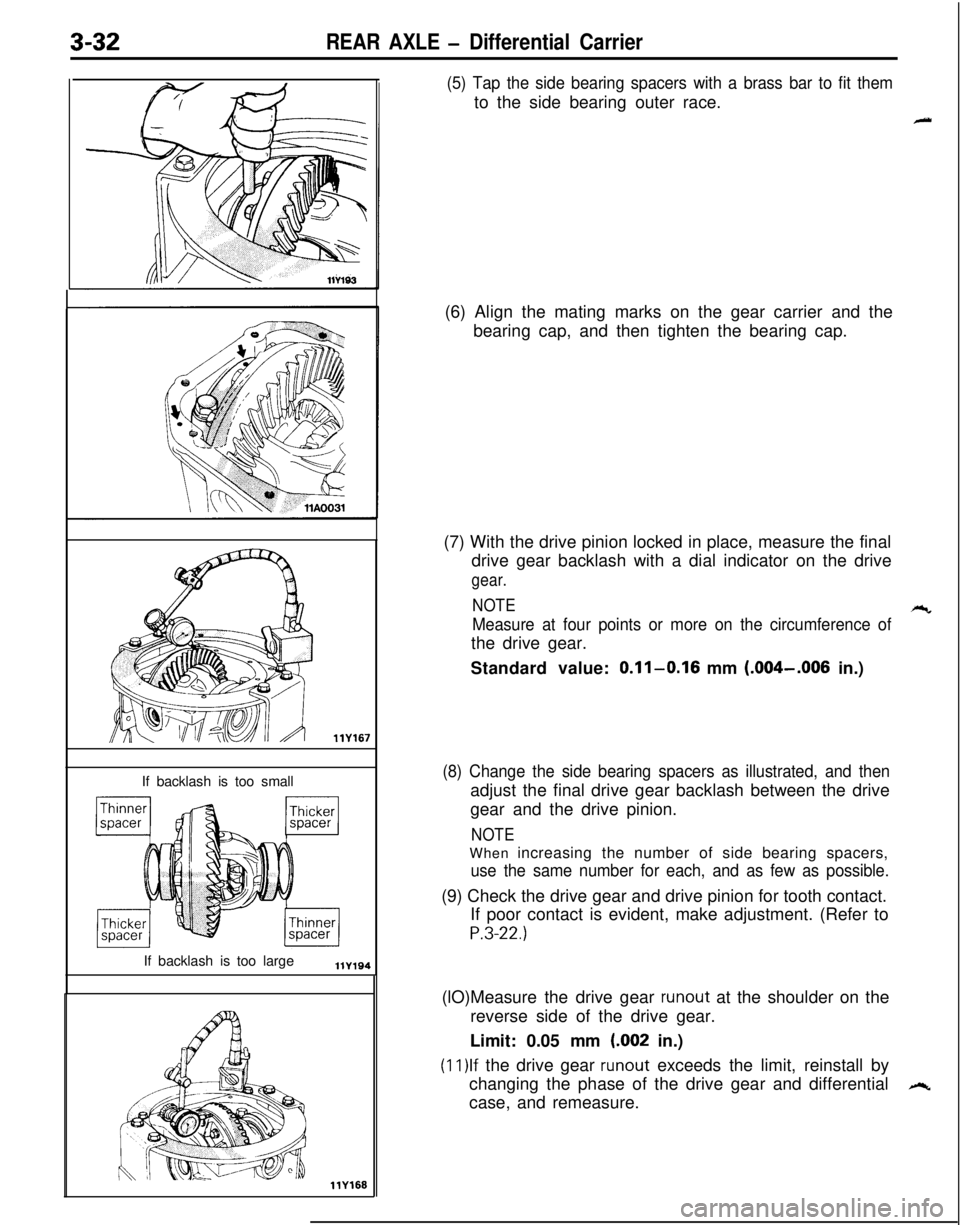

llV241I25. PRESS-FITTING OF SIDE BEARING INNER RACE

Press-fit the side bearing inner races to the differential caseby using the special tool.

. ADJUSTMENT OF FINAL DRIVE GEAR BACKLASH

Adjust the final drive gear backlash by the following

procedures:(1) Install the side bearing spacers, which are thinner than

those removed, to the side bearing outer races, and

then mount the differential case assembly into the gear

carrier.

NOTE

Select side bearing spacers with the same thickness forboth the drive pinion side and the drive gear side.

(2) Push the differential case to one side, and measure theclearance between the gear carrier and the side

bearing.(3) Measure the thickness of the side bearing spacers on

one side, select two pairs of spacers which correspondto that thickness plus one half of the clearance plus

0.05 mm (.002 in.), and then install one pair each to thedrive pinion side and the drive gear side.

(4) Install the side bearing spacers and differential case

assembly, as shown in the illustration, to the gear

carrier.

Page 134 of 1216

3-32REAR AXLE - Differential Carrier

llY167If backlash is too small

If backlash is too large

llY168

(5) Tap the side bearing spacers with a brass bar to fit themto the side bearing outer race.

4(6) Align the mating marks on the gear carrier and the

bearing cap, and then tighten the bearing cap.

(7) With the drive pinion locked in place, measure the final

drive gear backlash with a dial indicator on the drive

gear.

NOTE

-cc

Measure at four points or more on the circumference ofthe drive gear.

Standard value:

0.11-0.16 mm (.004-.006 in.)

(8) Change the side bearing spacers as illustrated, and thenadjust the final drive gear backlash between the drive

gear and the drive pinion.

NOTEWhen increasing the number of side bearing spacers,

use the same number for each, and as few as possible.(9) Check the drive gear and drive pinion for tooth contact.

If poor contact is evident, make adjustment. (Refer to

P.3-22.)(lO)Measure the drive gear

runout at the shoulder on the

reverse side of the drive gear.

Limit: 0.05 mm

(.002 in.)

(ll)lf the drive gear runout exceeds the limit, reinstall by

changing the phase of the drive gear and differential

,+case, and remeasure.

Page 135 of 1216

REAR AXLE - Differential Carrier3-3311

K60411K625

30. INSTALLATION OF VENT PLUG/31. DIFFERENTIAL

COVERApply specified sealant to the installation surface of

vent plug and differential cover.

Specified sealant: 3M ATD Part No.8661, 8663 or

equivalent

Page 136 of 1216

3-34REAR AXLE - Differential Carrier (Limited Slip Differential)

DIFFERENTIAL CARRIER (LIMITED SLIP DIFFERENTIAL)

DISASSEMBLY AND REASSEMBLYNO31K--

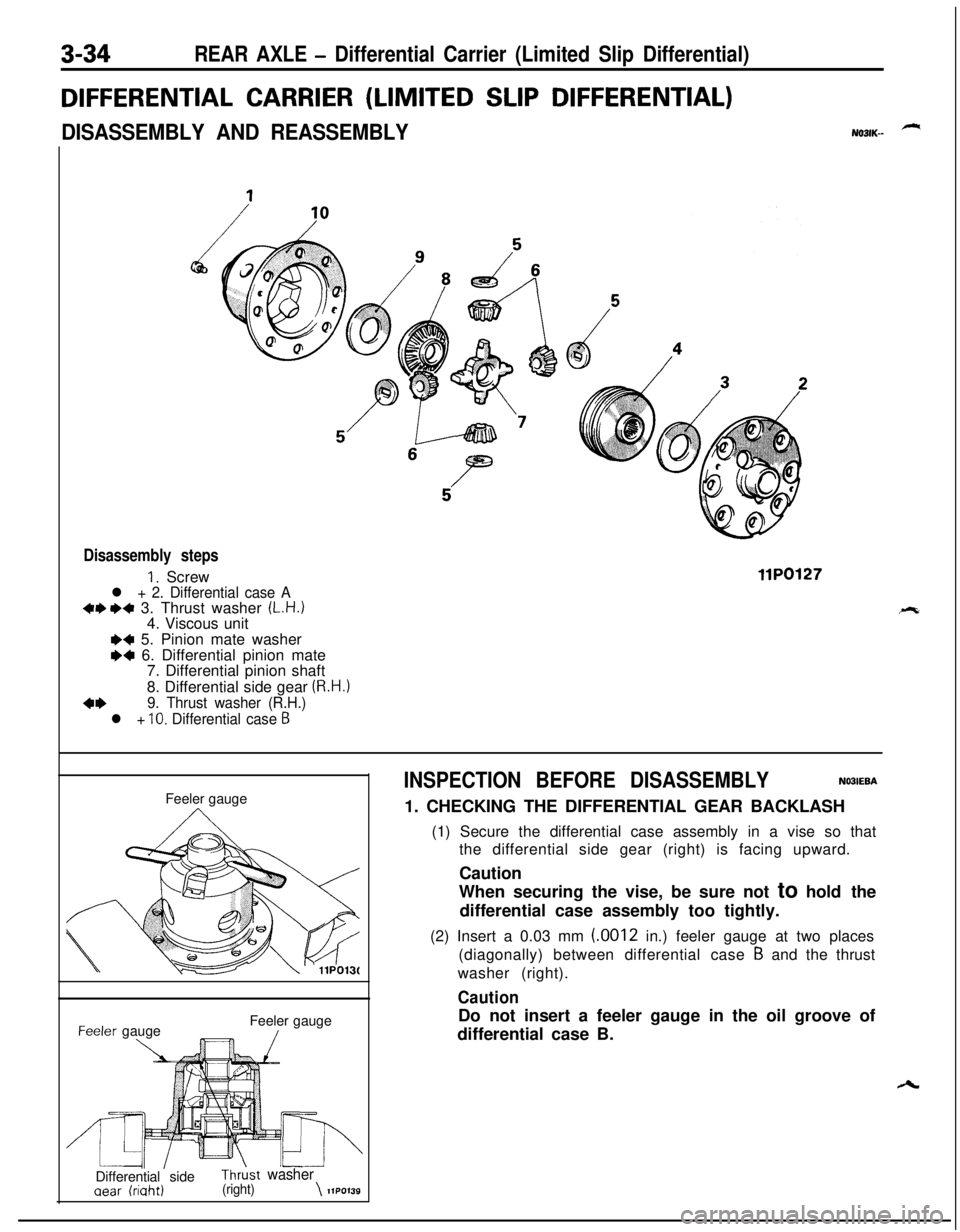

Disassembly steps

1. Screwl + 2. Differential case A+e I)+ 3. Thrust washer (L.H.)4. Viscous unit

llP0127

I)+ 5. Pinion mate washer

M 6. Differential pinion mate

7. Differential pinion shaft

8. Differential side gear

(R.H.)

4+9. Thrust washer (R.H.)

l +

10. Differential case 6Feeler gauge-eeler gauge

\Feeler gauge/

’ IL4l\’IIDifferential sideThrkt washer

aear (riaht)(right)\llPO139

INSPECTION BEFORE DISASSEMBLYNO3IEBA1. CHECKING THE DIFFERENTIAL GEAR BACKLASH

(1) Secure the differential case assembly in a vise so that

the differential side gear (right) is facing upward.

Caution

When securing the vise, be sure not to hold the

differential case assembly too tightly.

(2) Insert a 0.03 mm (.0012 in.) feeler gauge at two places

(diagonally) between differential case

B and the thrust

washer (right).

CautionDo not insert a feeler gauge in the oil groove of

differential case B.

Page 137 of 1216

REAR AXLE - Differential Carrier (Limited Slip Differential)3-35ferential side gear

(right)Differential

Differential

pinion mate

llPO12BThrust washer

Pinion mate

Pinion mate

washerThrust washer

,,po,29Differential case

BerentiieA11

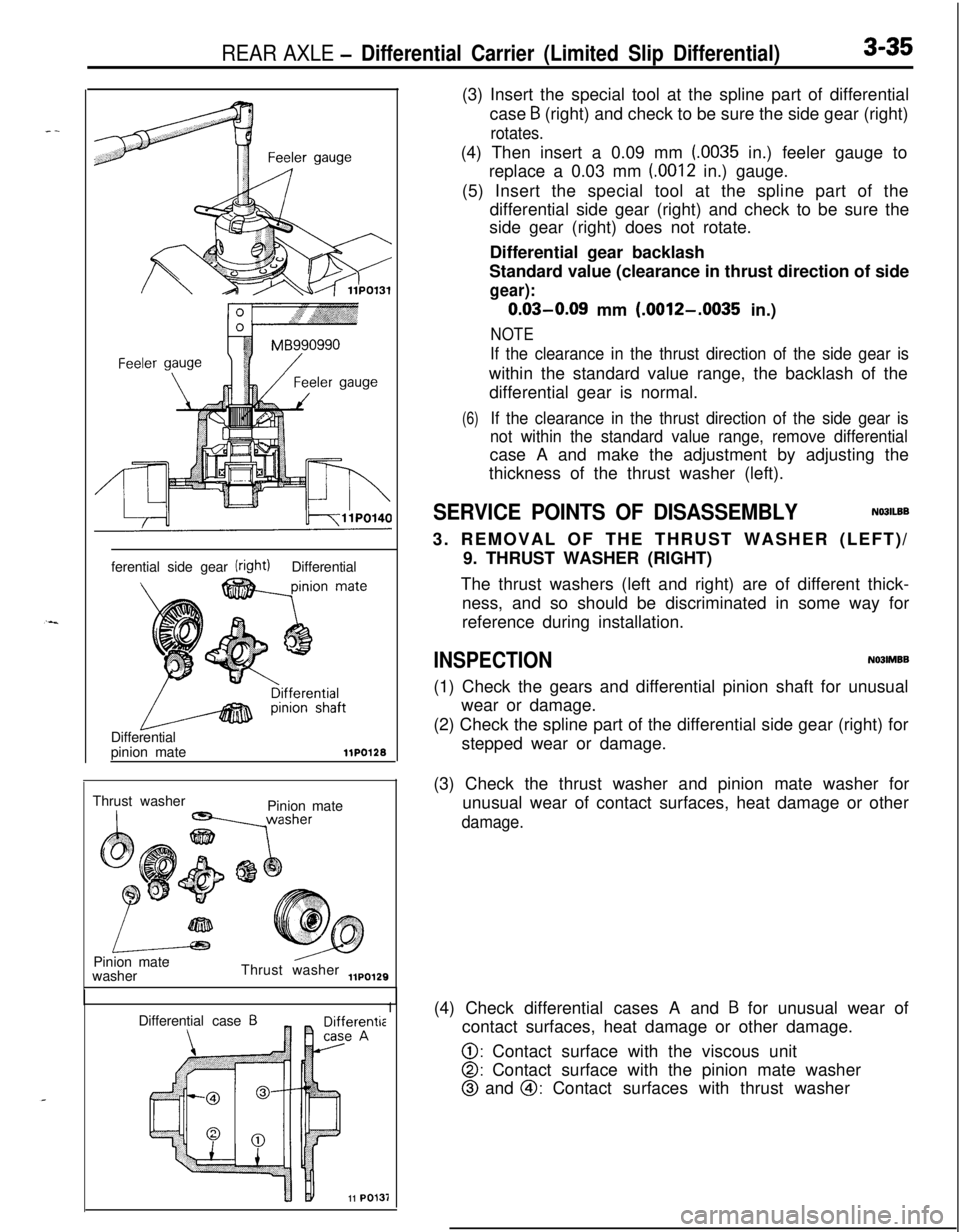

PO1311(3) Insert the special tool at the spline part of differential

case

B (right) and check to be sure the side gear (right)

rotates.(4) Then insert a 0.09 mm

(.0035 in.) feeler gauge to

replace a 0.03 mm (0012 in.) gauge.

(5) Insert the special tool at the spline part of the

differential side gear (right) and check to be sure the

side gear (right) does not rotate.

Differential gear backlash

Standard value (clearance in thrust direction of side

gear):

0.03-0.09 mm (.0012-.0035 in.)

NOTE

If the clearance in the thrust direction of the side gear iswithin the standard value range, the backlash of the

differential gear is normal.

(6)If the clearance in the thrust direction of the side gear is

not within the standard value range, remove differentialcase A and make the adjustment by adjusting the

thickness of the thrust washer (left).

SERVICE POINTS OF DISASSEMBLYNO3lLBB3. REMOVAL OF THE THRUST WASHER (LEFT)/

9. THRUST WASHER (RIGHT)

The thrust washers (left and right) are of different thick-

ness, and so should be discriminated in some way for

reference during installation.

INSPECTIONN03lMBB(1) Check the gears and differential pinion shaft for unusual

wear or damage.

(2) Check the spline part of the differential side gear (right) for

stepped wear or damage.

(3) Check the thrust washer and pinion mate washer for

unusual wear of contact surfaces, heat damage or other

damage.(4) Check differential cases A and

B for unusual wear of

contact surfaces, heat damage or other damage.

0: Contact surface with the viscous unit

0: Contact surface with the pinion mate washer

@ and @I: Contact surfaces with thrust washer