differential MITSUBISHI ECLIPSE 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 695 of 1216

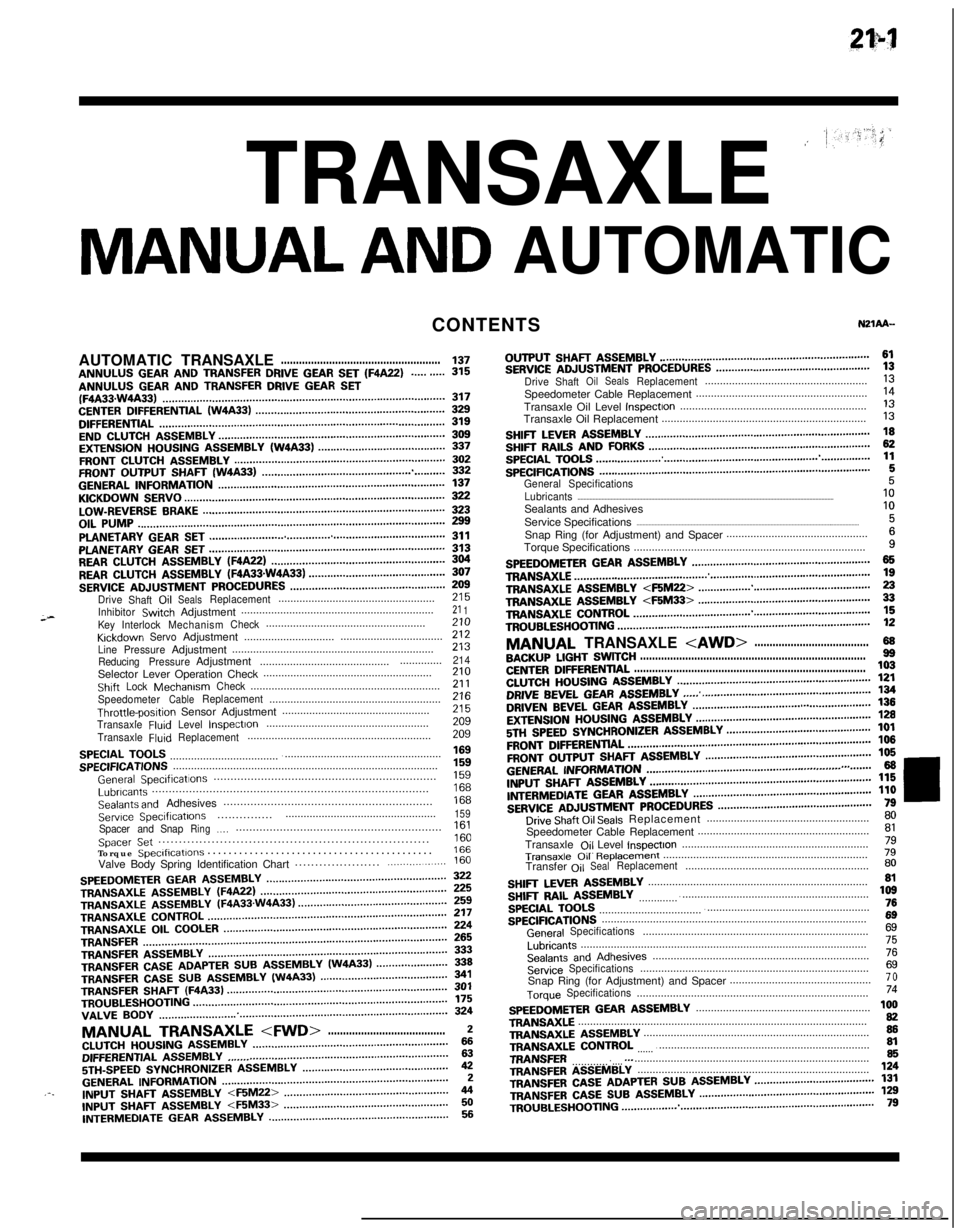

TRANSAXLE ’

MANUAL AND AUTOMATICCONTENTS

;-AUTOMATICTRANSAXLE

.....................................................137ANNULUS GEAR AND TRANSFER DRIVE GEAR SET (F4A22)..........315ANNULUS GEAR AND TRANSFER DRIVE GEAR SET(F4A33.W4A33)...........................................................................................317CENTERDIFFERENTIAL(W4A33).............................................................329DIFFERENTIAL............................................................................................319ENDCLUTCHASSEMBLY.........................................................................309EXTENSIONHOUSINGASSEMBLY(W4A33).........................................337FRONTCLUTCHASSEMBLY....................................................................302FRONTOUTPUTSHAFT(W4A33)...........................................................332GENERALINFORMATION.........................................................................137KICKDOWNSERVO....................................................................................322LOW-REVERSEBRAKE..............................................................................323OILPUMP...................................................................................................299PLANETARYGEARSET............................................................................311PLANETARYGEARSET............................................................................313REARCLUTCHASSEMBLY(F4A22)........................................................304REARCLUTCHASSEMBLY(FQA33sW4A33)............................................307SERVICEADJUSTMENTPROCEDURES..................................................Drive

Shaft,OilSealsReplacement....................................................;;;

InhibitorSwtchAdjustment................................................................21 1KeyInterlockMechanismCheck.....................................................KrckdownServoAdjustment..................................zii..............................

LinePressureAdjustment...................................................................213

ReducingPressureAdjustment.........................................................214Selector Lever Operation Check........................................................210ShiftLockMechanismCheck...............................................................21 1SpeedometerCableReplacement.........................................................Throttle-posltipn Sensor Adjustment.................................................z2:

TransaxleFluIdLevelInspectIon......................................................209

TransaxleFluidReplacement.............................................................209

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................;“5”9

GeneralSpeclficatlons..................................................................1%Lubricants..................................................................................Sealants and Adhesives..............................................................izi

Serwce Speclflcatlons..................................................159...............Spacer andSnapRing.,.,.............................................................Spacer Set..................................................................1::Torque Speclflcatlons...........................................166Valve Body Spring Identification Chart.....................

.................160

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLEASSEMBLY(WA22)............................................................zTRANSAXLE

ASSEMBLY(F4A33.W4A33)................................................TRANSAXLECONTROL.............................................................................;;;TRANSAXLE

OILCOOLER........................................................................TRANSFER..................................................................................................fg

TRANSFERASSEMBLY.............................................................................333TRANSFERCASEADAPTERSUBASSEMBLY(W4A33).......................339TRANSFER CASE SUB ASSEMBLY (W4A33)341TRANSFER SHAFT (F4A33)TROUBLESHOOTING..................................................................................................................................................................................................f;;VALVE

BODY.............................................................................................324

MANUAL TRANSAXLE

5TH-SPEEDSYNCHRONIZERASSEMBLY...............................................42GENERALINFORMATION.........................................................................2.-.INPUTfj,-,A,TASSEMBLY

INTERMEDIATE GEAR ASSEMBLY..........................................................56OUTPUT

SHAFT ASSEMBLY....................................................................61SERVICEADJUSTMENTPROCEDURES..................................................DriveShaftOilSealsReplacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle Oil Level

InspectIon..............................................................‘liTransaxle Oil Replacement....................................................................

I3

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILSANDFORKS........................................................................g

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................1:

General Specifications5Lubricants..........................................................................................................................................................................10Sealants and Adhesives

Service Specifications

....................................................................................................................................................1:Snap Ring (for Adjustment) and Spacer...............................................

Torque Specifications.............................................................................

i

SPEEDOMETERGEARASSEMBLY..........................................................TRANS&G.E................................................................................................zTRANSAXLEA!jSEMBLY

TROUBLESHOOTING..................................................................................12

MANUAL TRANSAXLE

CENTERDIFFERENTIAL.............................................................................103CLUTCHHOUSINGASSEMBLY...............................................................DRIVE BEVEL GEAR ASSEMBLY;g

...... .......................................................DRIVENBEVELGEARASSEMBLY...................................a......................EXTENSIONHOUSINGASSEMBLY.........................................................;g

5Tf.jSPEEDSYNCHRONIZERASSEMBLY...............................................101

FRONTDlFFERENTlAL...............................................................................106

FRONTOUTPUTSHAFTASSEMBLY......................................................106

GENERALI~~~~MATN)N...............................................................,.,.......66INPUTSHAFTASSEMBLY........................................................................l~ER,“,EDlATEGEARASSMBLY..........................................................;;i

SERVICEADJUSTMENTPROCEDURES..................................................Drive Shaft Oil Seals Replacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle

Ojl Level lnspectlon..............................................................;l

Transaxle 011 R~pb33ment....................................................................79Transfer

OilSealReplacement.............................................................80

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILASSEMBLY............................................................................,z

SPECIALTOOLS.........................................................................................76

SPECIFICATIONS........................................................................................6g

GeneralSpecifications...........................................................................6g

Lubricants...............................................................................................75

SealantsandAdhesives........................................................................76

ServiceSpecifications............................................................................6gSnap Ring (for Adjustment) and Spacer...............................................7 o

TorqueSpecifications.............................................................................74

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLE................................................................................................1:TRANSAXLEASSEMBLY...........................................................................86TRANSAXLE

CONTROL

.............................................................................TRANSFER...............................................................................................

g.._TRANSFERA!333lBLY.............................................................................,24

TRANSFERCASEADAPTERSUBASSEMBLY.......................................131TRANSFERCASESUBASSEMBLY.........................................................TR,,UBLES,,OO,,NG..................................................................................1;;

Page 697 of 1216

MANUAL TRANSAXLE

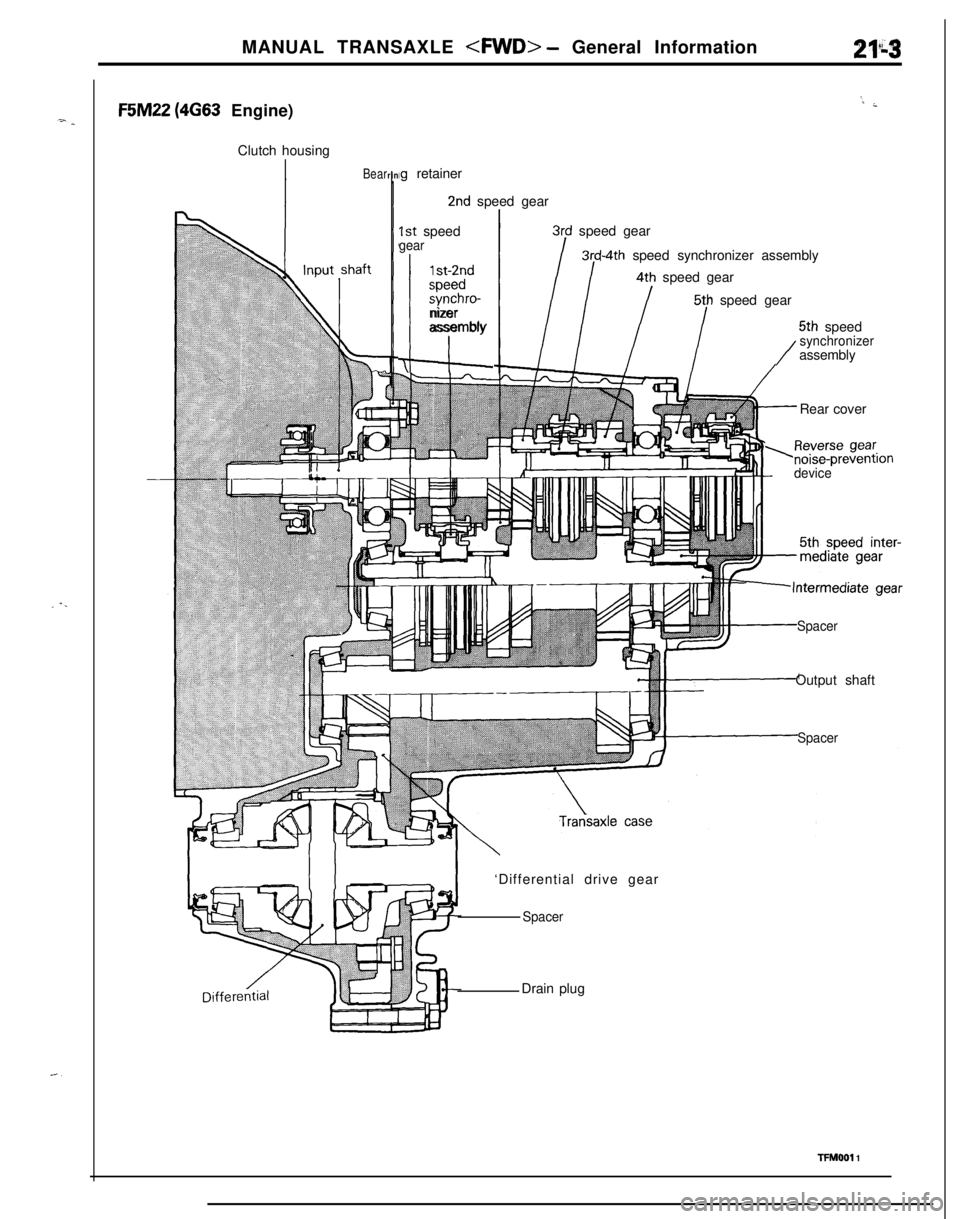

F5M22 (4G63 Engine)

Clutch housing

Bearrin

‘. ;

lg retainer

2nd speed gear

1st speedgear

1 st-2ndspeed

synchro-

I,

nizerassembly

3rd speed gear

3rd-4th speed synchronizer assembly4th speed gear

5th speed gear

5th speed

/

synchronizerassembly

Rear cover

,Reverse gear.norse-preventron

device

SpacerOutput shaft

Spacer‘Differential drive gear

SpacerDrain plug

TFMOOI 1

Page 698 of 1216

21-4MANUAL TRANSAXLE

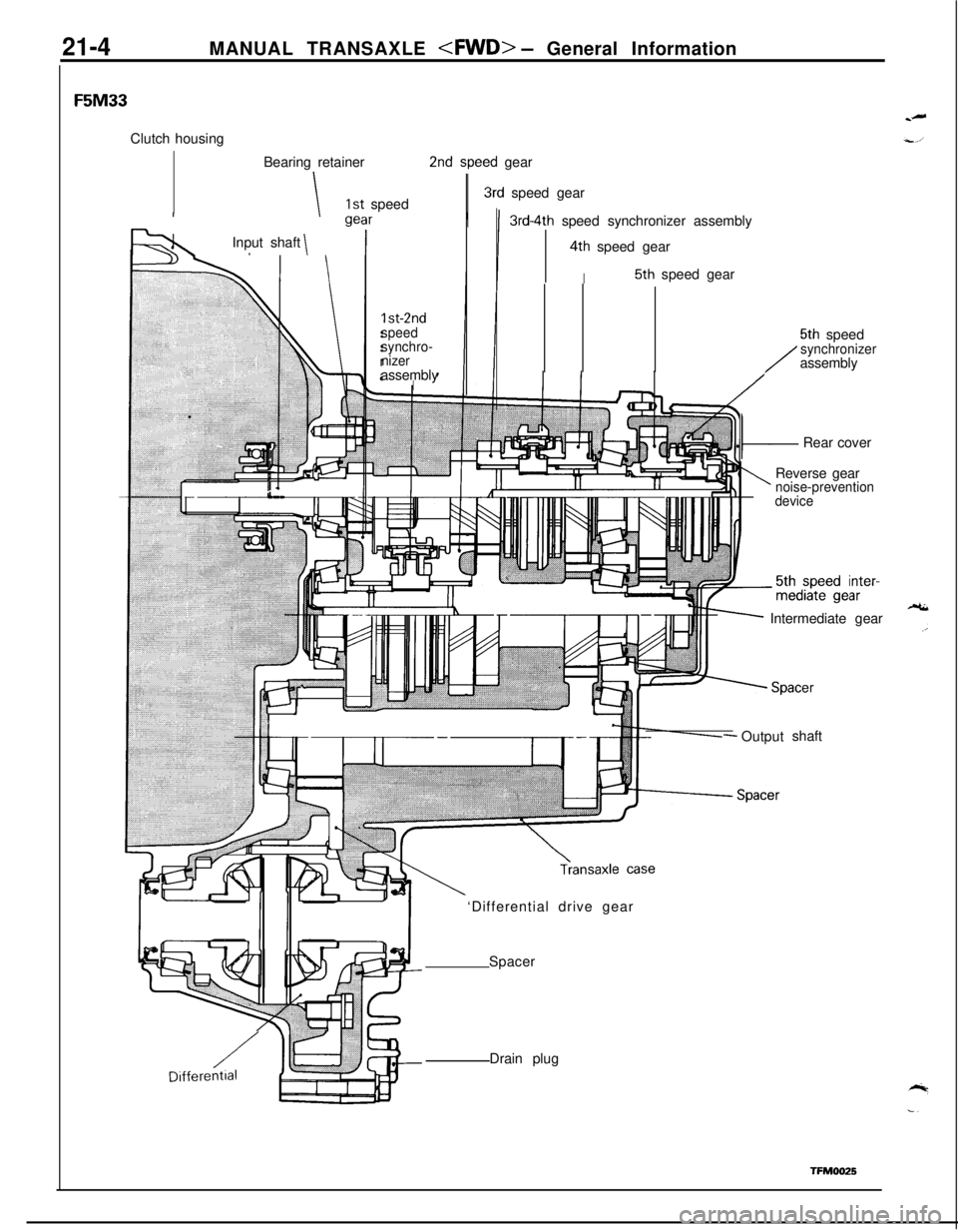

F5M33Clutch housing

Bearing retainer

2nd

1st speed

sPteed gear

3rd speed gear

ge’-

l--z& , I ii’Input shaft

3rd-4th speed synchronizer assembly

4th speed gear

I5th speed gear

1 st-2nd

speed

synchro-

nizerassembly

I

5th speed

/

synchronizerassembly

cRear cover

Reverse gear

noise-prevention

deviceIntermediate gear

- Outputshaft

‘Differential drive gear

Spacer

Drain plug

/Differentral

TFMOO25

Page 699 of 1216

MANUAL TRANSAXLE

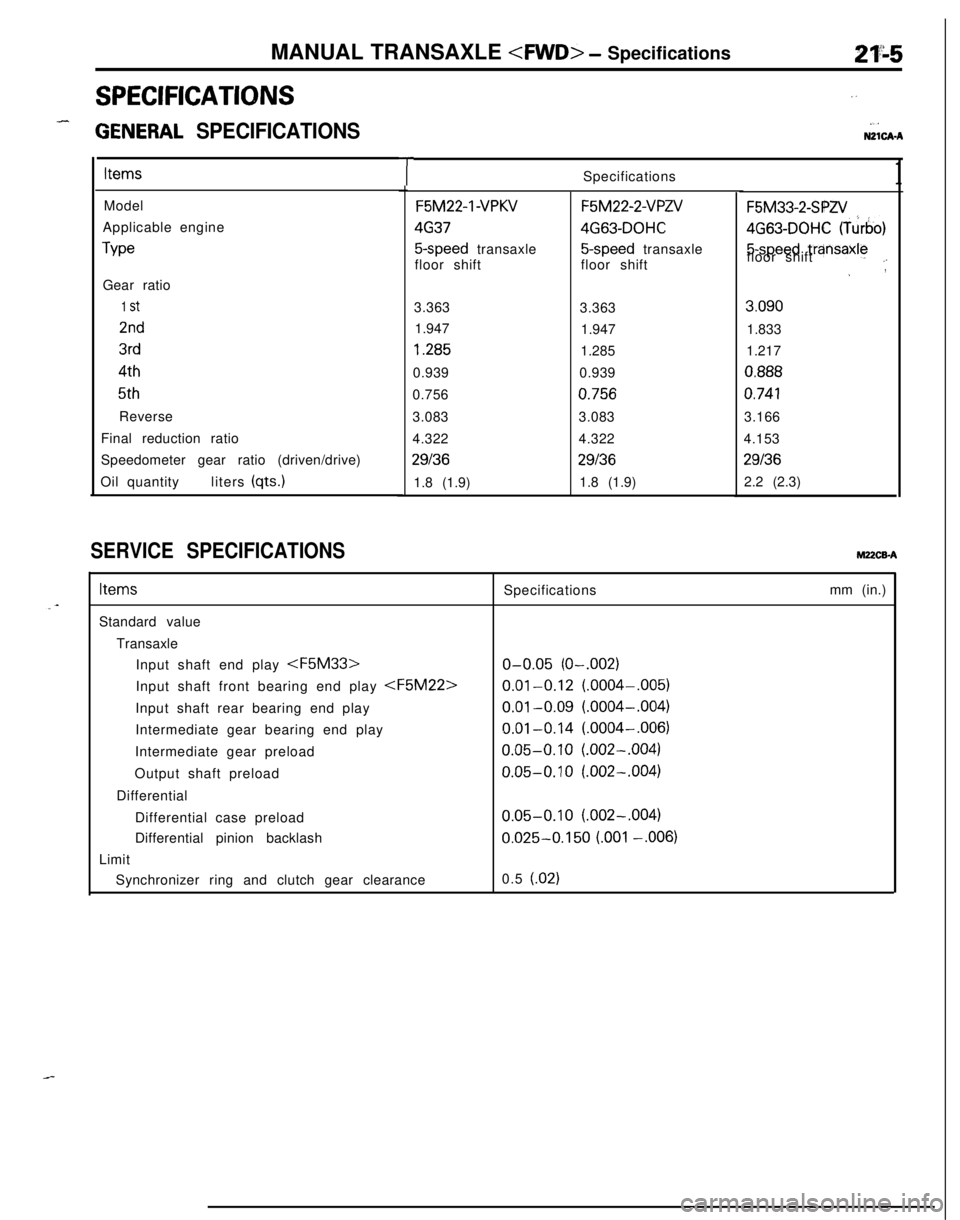

SPECIFICATIQNS

3ENERAL SPECIFICATIONS

ItemsModel

Applicable engine

TypeGear ratio

1 st2nd3rd

4th5th

Reverse

Final reduction ratio

Speedometer gear ratio (driven/drive)

Oil quantityliters (qts.)

SERVICE SPECIFICATIONShl22CBA

”

.,NZlCA-ASpecifications

1TF5M22-1

-VFWF5M22-2-VPZV

46374G63-DOHC

5-speed transaxle5-speed transaxle

floor shiftfloor shift

3.363

3.363

1.947

1.9471.285

1.285

0.9390.939

0.756

0.7563.0833.083

4.3224.322

29136291361.8 (1.9)1.8 (1.9)

F5M33-2-SPA!4G63-DOHC (Turbo)5-speed

trzinsaxlefloor shift.-~,3.090

1.833

1.217

0.888

0.7413.166

4.153

291362.2 (2.3)

ItemsStandard value

Transaxle

Input shaft end play

Intermediate gear bearing end play

Intermediate gear preload

Output shaft preload

Differential

Differential case preload

Differential pinion backlash

LimitSpecifications

o-0.05 (O-.002)

0.01-0.12 (.0004-.005)

0.01-0.09 (.0004-.004)

0.01-0.14 (.0004-,006)

0.05-0.10 (.002-.004)

0.05-0.10 (.002-.004)

0.05-0.10 (.002-.004)

0.025-0.150 LOO1 -.006)mm (in.)

Synchronizer ring and clutch gear clearance0.5 (.02)

Page 702 of 1216

21-8MANUAL TRANSAXLE

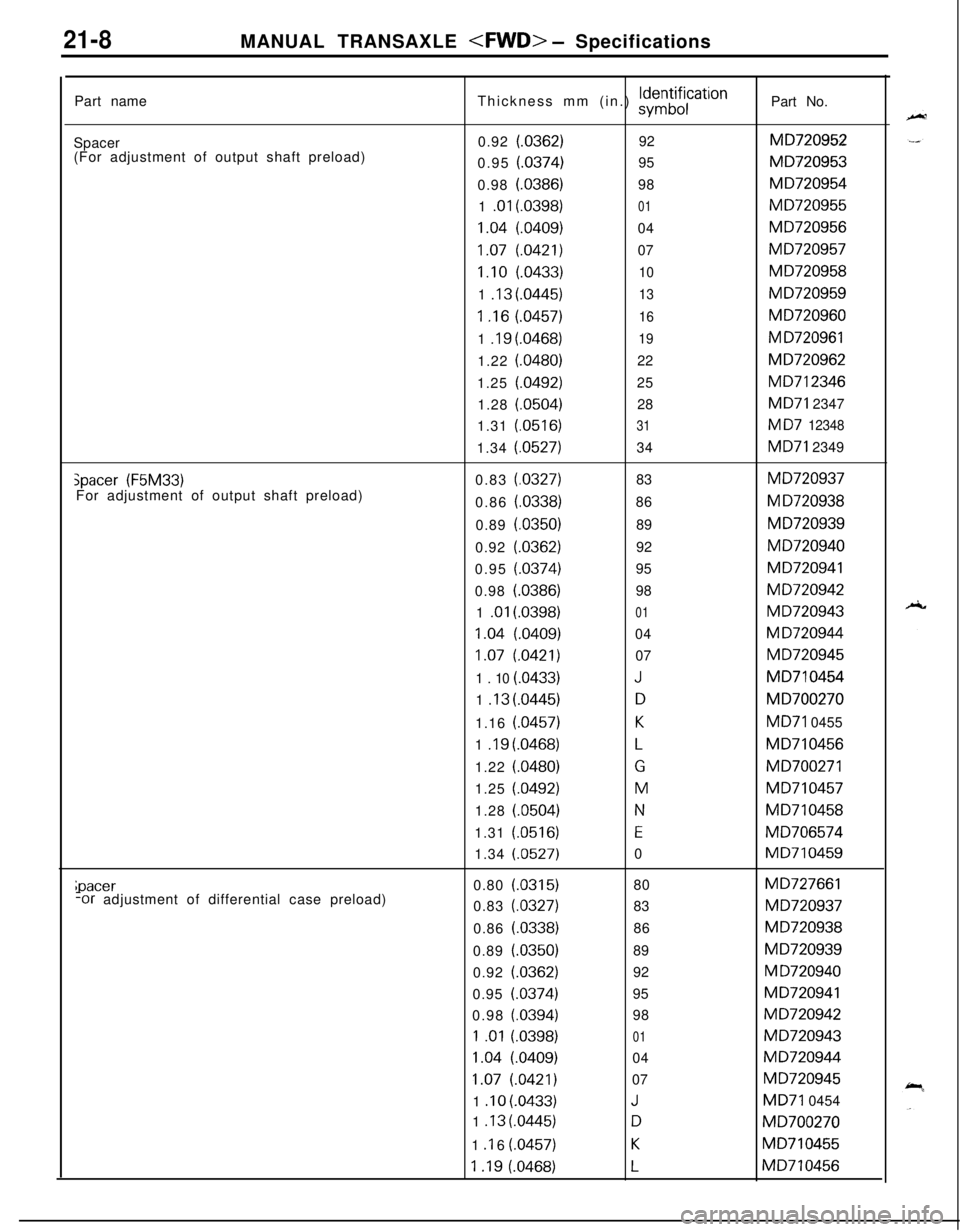

Part name

Spacer

(For adjustment of output shaft preload)spacer(F5M33)

For adjustment of output shaft preload)

ipacer'or adjustment of differential case preload)Thickness mm (in.)

~dyemnt$j~at'on0.92

(0362)92

0.95

(0374)95

0.98 (.0386)98

1 .Ol t.0398)

011.04 (.0409)041.07 (.0421)071.10

(0433)101

.I3 (0445)13

1 .16 (0457)161

.I9 (0468)191.22 (.0480)22

1.25 (.0492)25

1.28

(0504)28

1.31

(0516)311.34 (.0527)34

0.83

(0327)83

0.86

(0338)86

0.89

(0350)89

0.92

(0362)92

0.95 (.0374)95

0.98

(0386)98

1 .Ol

l.0398)011.04 (.0409)041.07

(0421)07

1 . 10 (.0433)J1

.I3 (0445)D1.16 (.0457)

K1

.I9 (0468)L1.22 (.0480)

G1.25 (.0492)M

1.28 (.0504)

N1.31 (.0516)

E1.34 (.0527)0

0.80 (.0315)80

0.83 (.0327)83

0.86 (.0338)86

0.89

(0350)89

0.92 (.0362)92

0.95 (.0374)95

0.98 (.0394)98

1 .Ol t.0398)011.04

i.0409)041.07 (.0421)07

1

.I0 (0433)J1

.I3 (0445)D1

.I 6 (.0457)K

1 .19 (0468)LPart No.

MD720952

MD720953

MD720954

MD720955

MD720956

MD720957

MD720958

MD720959

MD720960M

D720961

MD720962

MD712346MD71 2347M

D7 12348MD71 2349

MD720937M

D720938

MD720939

MD720940MD720941

MD720942

MD720943M

D720944

MD720945

MD710454

MD700270MD71 0455

MD710456MD700271

MD710457

MD710458

MD706574

MD710459MD727661

MD720937

MD720938

MD720939M

D720940MD720941

MD720942

MD720943

MD720944

MD720945MD71 0454

MD700270

MD710455

MD710456

Page 703 of 1216

MANUAL TRANSAXLE

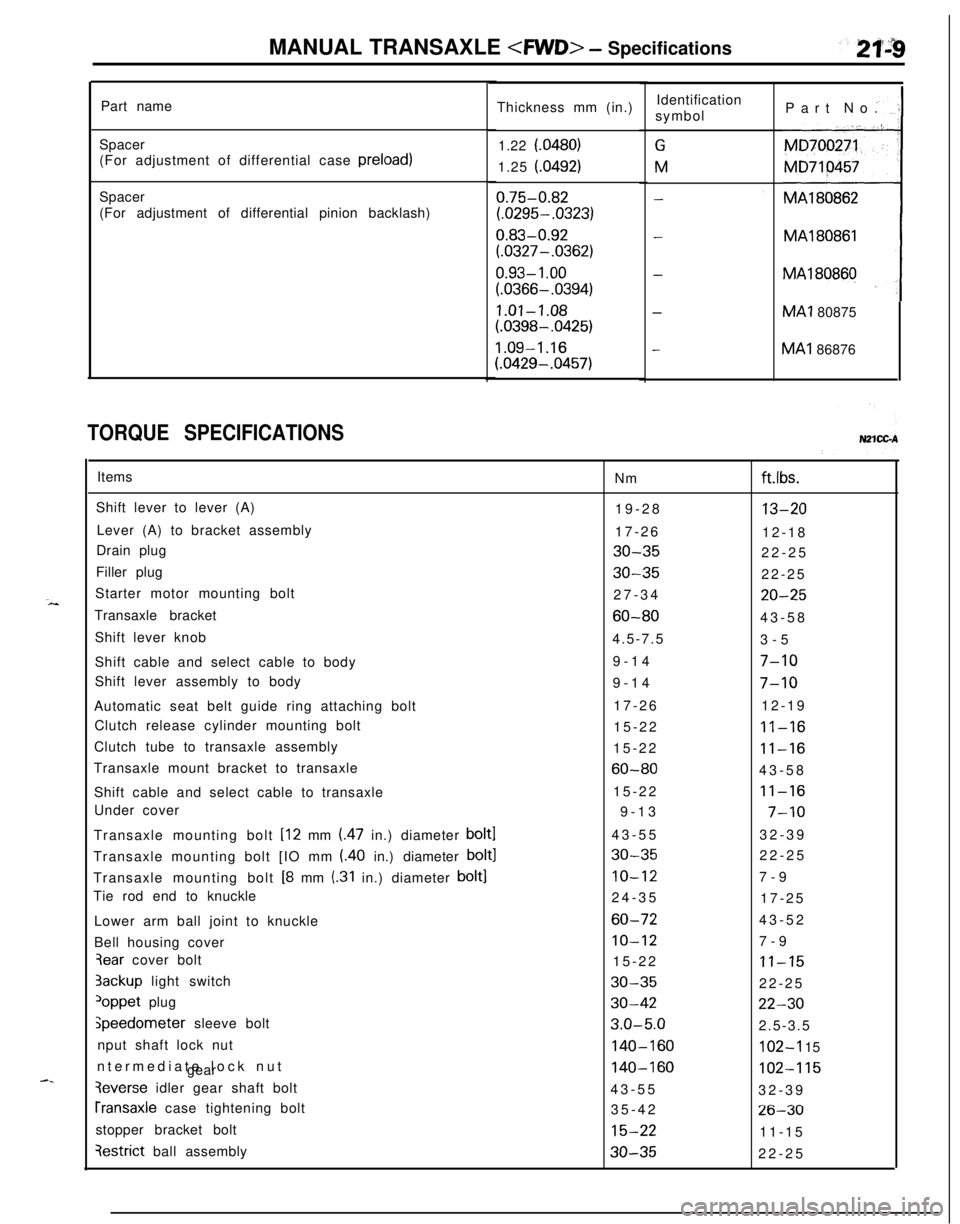

Part name

Spacer

(For adjustment of differential case preload)

Spacer

(For adjustment of differential pinion backlash)

TORQUE SPECIFICATIONSThickness mm (in.)

1.22 f.0480)

1.25 (.0492)

0.75-0.82

(.0295-.0323)

0.83-0.92

(.0327-.0362)

0.93- 1 .oo

(.0366-.0394)

1.01-1.08

(.0398-.0425)

1.09-1.16

(.0429-.0457)Identification

symbol

GM

-

-

-

-Part No.

MA180862MA1

80866MA1 80875MA1 86876

Items

Nm

Shift lever to lever (A)

19-28

Lever (A) to bracket assembly

17-26

Drain plug

30-35Filler plug

30-35Starter motor mounting bolt

27-34

Transaxle bracket

60-80Shift lever knob

4.5-7.5

Shift cable and select cable to body9-14

Shift lever assembly to body

9-14

Automatic seat belt guide ring attaching bolt17-26

Clutch release cylinder mounting bolt

15-22

Clutch tube to transaxle assembly

15-22

Transaxle mount bracket to transaxle

60-80Shift cable and select cable to transaxle15-22

Under cover

9-13

Transaxle mounting bolt [12 mm (.47 in.) diameter

bolt143-55

Transaxle mounting bolt [IO mm (.40 in.) diameter

bolt130-35Transaxle mounting bolt

[8 mm (.31 in.) diameter bolt]IO-12Tie rod end to knuckle

24-35

Lower arm ball joint to knuckle

60-72Bell housing cover

IO-123ear cover bolt

15-223ackup light switch

30-35

loppet plug30-42

jpeedometer sleeve bolt3.0-5.0nput shaft lock nut

140-160ntermediate lock nut

gear

140-160

3everse idler gear shaft bolt

43-55

rransaxle case tightening bolt

35-42

stopper bracket bolt

15-22

qestrict ball assembly30-35

ft.lbs.

13-2012-18

22-25

22-25

20-2543-58

3-5

7-10

7-1012-19

11-16

11-1643-58

11-16

7-1032-39

22-25

7-9

17-25

43-52

7-9

11-1522-25

22-302.5-3.5

102-I 15

102-11532-39

26-3011-15

22-25

Page 704 of 1216

MANUAL TRANSAXLE

ItemsNm

ftlbs.Reverse shift lever assembly attaching bolt

15-2211-15

Bearing retainer bolt15-2211-15

Differential drivegear

bolt

130-14094-101Interlock plate bolt

20-2715-19

Select lever assemblymountingbolt15-2211-15

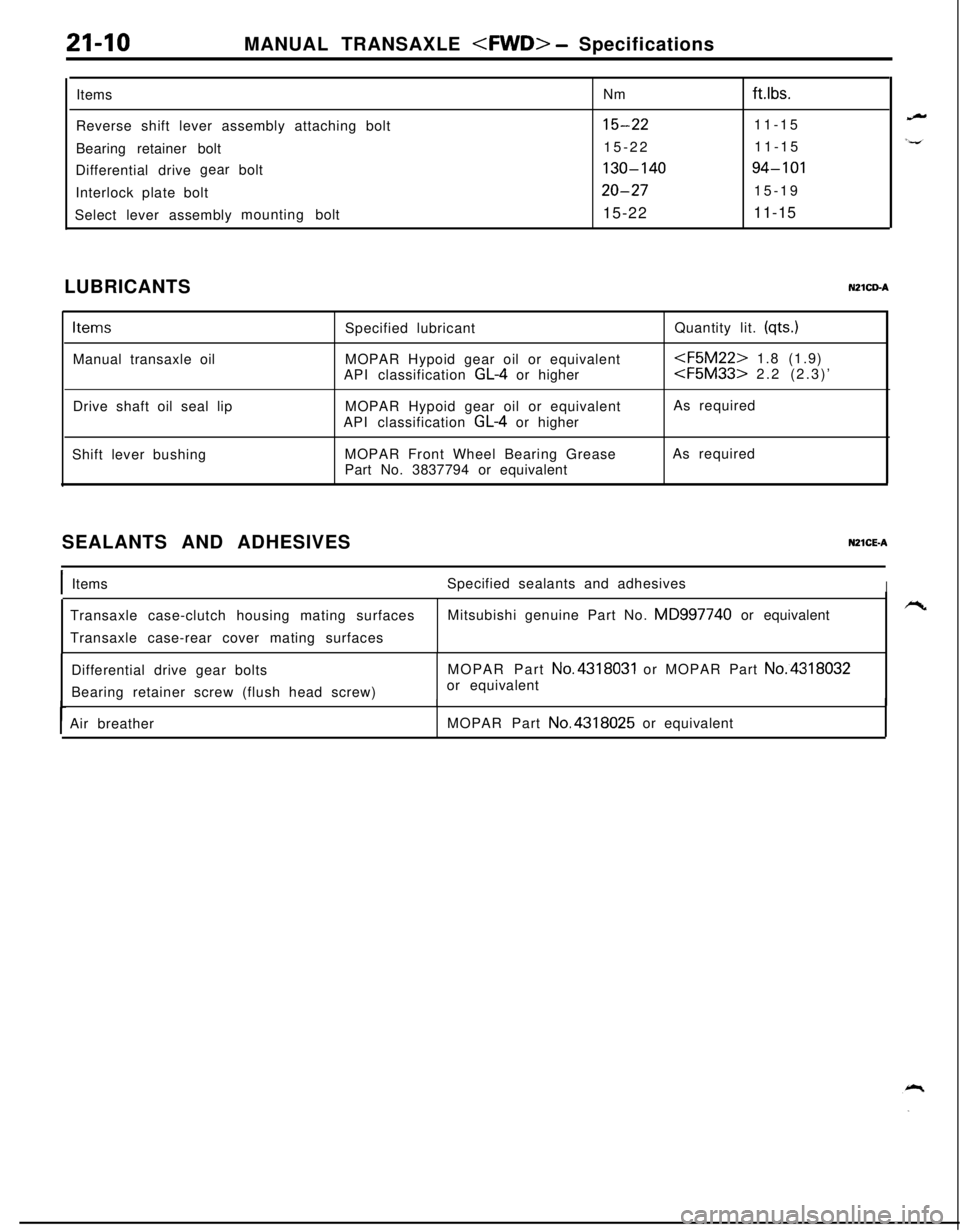

LUBRICANTS

NZlCD-A

ItemsManual transaxle oil

Drive shaft oil seal lipSpecified lubricant

MOPAR Hypoid gear oil or equivalent

API classification GL-4 or higher

MOPAR Hypoid gear oil or equivalent

API classification GL-4 or higherQuantity lit. (qts.)

As required

Shift lever bushingMOPAR Front Wheel Bearing Grease

Part No. 3837794 or equivalentAs required

SEALANTS AND ADHESIVES

NZlCE-A

IItemsSpecified sealants and adhesivesITransaxle case-clutch housing mating surfacesMitsubishi genuine Part No.

MD997740 or equivalent

Transaxle case-rear cover mating surfaces

Differential drive gear bolts

Bearing retainer screw (flush head screw)MOPAR Part

No.4318031 or MOPAR Part No.4318032or equivalent

Air breather

IMOPAR Part

No.4318025 or equivalent

Page 706 of 1216

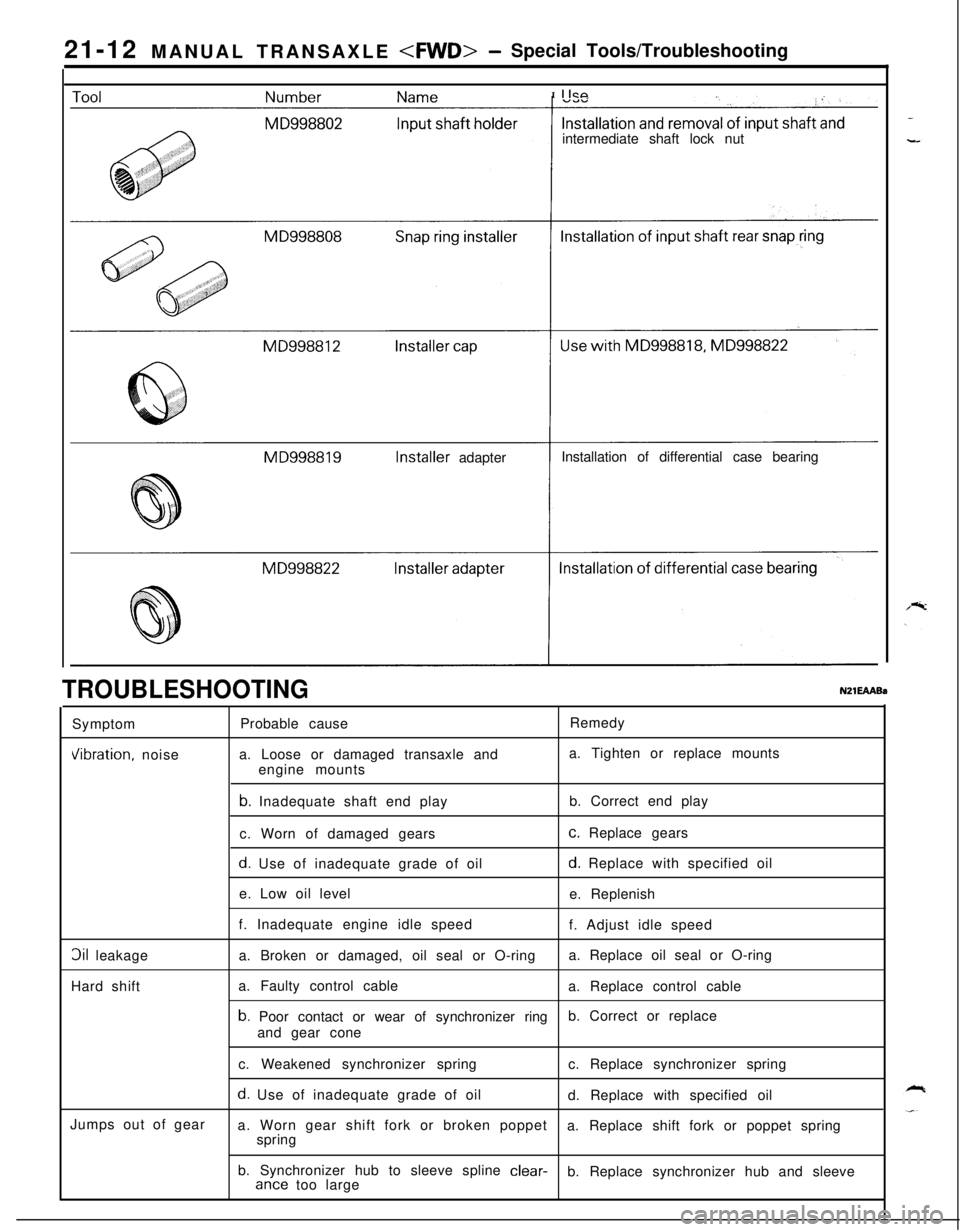

21-12 MANUAL TRANSAXLE

I

IICPintermediate shaft lock nut

MD998819Installer adapterInstallation of differential case bearing

TROUBLESHOOTINGNZlEAABsSymptomVibration, noise

3il leakage

Hard shift

Jumps out of gearProbable causeRemedy

a. Loose or damaged transaxle anda. Tighten or replace mounts

engine mounts

b. Inadequate shaft end playb. Correct end play

c. Worn of damaged gears

c. Replace gears

d. Use of inadequate grade of oild. Replace with specified oil

e. Low oil level

e. Replenish

f. Inadequate engine idle speed

f. Adjust idle speed

a. Broken or damaged, oil seal or O-ringa. Replace oil seal or O-ring

a. Faulty control cable

a. Replace control cable

b. Poor contact or wear of synchronizer ring

and gear coneb. Correct or replace

c. Weakened synchronizer springc. Replace synchronizer spring

d. Use of inadequate grade of oil

d. Replace with specified oil

a. Worn gear shift fork or broken poppet

springa. Replace shift fork or poppet spring

b. Synchronizer hub to sleeve spline

clear-ante too largeb. Replace synchronizer hub and sleeve

Page 719 of 1216

MANUAL TRANSAXLE

2i &

15-22 Nm50 11-15 ft.lbs.

Disassembly steps

l +49. Bolt50. Screw

51. Bearing retainer

+e l + 52.Intermediate gear assemblyl + 53.Input shaft assembly54. Output shaft assembly

55. Differential gear assembly

56. Bearing outer race57. Oil guide

58. Bearing outer race

59. Bearing outer race

l 4 60. Oil seal

W 61. Oil seal

62. Magnet

63. Magnet holder

64. Clutch housing assembly

NOTE(1) Reverse the disassembly procedures to reassemble.(2) ~~ : Refer to “Service Points of Disassembly”.(3) e+ : Refer to “Service Points of Reassembly”.

(4) m : Non-reusable parts

21421

Page 723 of 1216

MANUAL TRANSAXLE

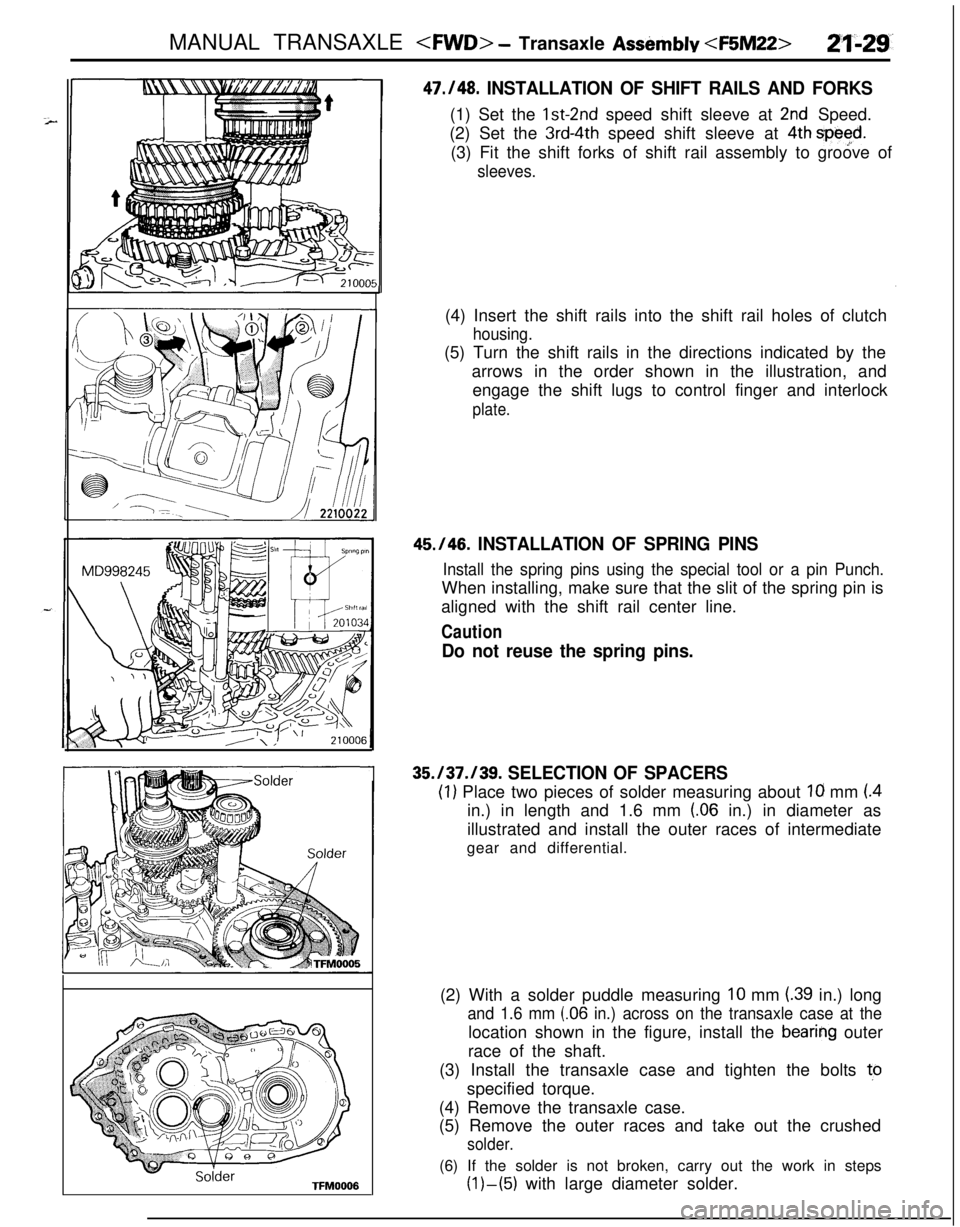

47./48. INSTALLATION OF SHIFT RAILS AND FORKS(1) Set the

lst-2nd speed shift sleeve at 2nd Speed.

(2) Set the

3rd-4th speed shift sleeve at 4th spe$d.(3) Fit the shift forks of shift rail assembly to groove of

sleeves.(4) Insert the shift rails into the shift rail holes of clutch

housing.(5) Turn the shift rails in the directions indicated by the

arrows in the order shown in the illustration, and

engage the shift lugs to control finger and interlock

plate.

45.146. INSTALLATION OF SPRING PINS

Install the spring pins using the special tool or a pin Punch.When installing, make sure that the slit of the spring pin is

aligned with the shift rail center line.

Caution

Do not reuse the spring pins.

35.137.139. SELECTION OF SPACERS

(1) Place two pieces of solder measuring about Ia mm (.4in.) in length and 1.6 mm

(.06 in.) in diameter as

illustrated and install the outer races of intermediate

gear and differential.

(2) With a solder puddle measuring

10 mm (.39 in.) long

and 1.6 mm (.06 in.) across on the transaxle case at thelocation shown in the figure, install the

bearing outer

race of the shaft.

(3) Install the transaxle case and tighten the bolts to

specified torque.

(4) Remove the transaxle case.

(5) Remove the outer races and take out the crushed

solder.(6) If the solder is not broken, carry out the work in steps

(l)-(5) with large diameter solder.