differential MITSUBISHI ECLIPSE 1991 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 766 of 1216

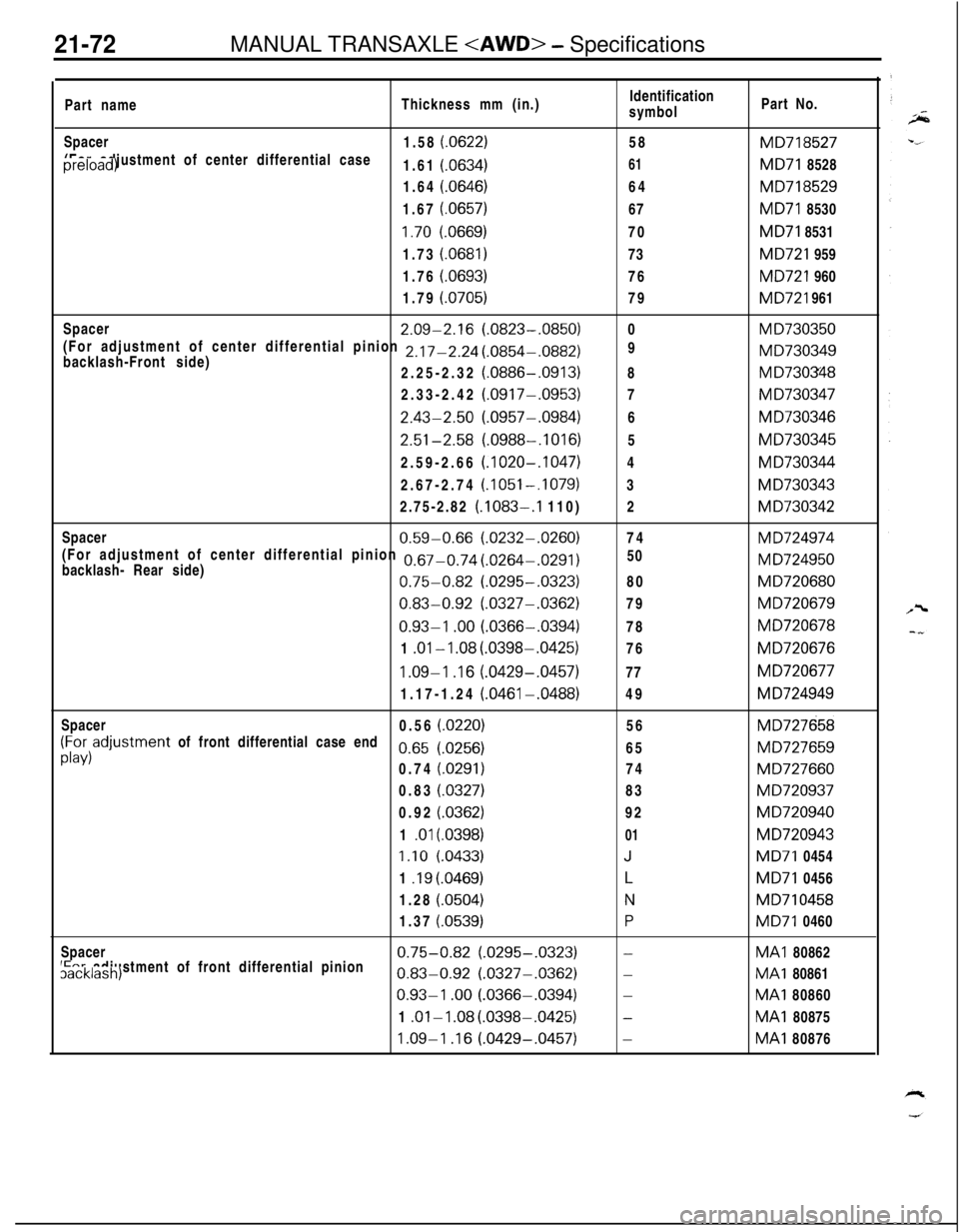

21-72MANUAL TRANSAXLE

Part nameThickness mm (in.)

Spacer

1.58

(.0622)(For adjustment of center differential casepreload)

1.61

(0634)1.64

(.0646)1.67

(0657)

1.70 (.0669)1.73

(.0681)1.76

i.0693)1.79

(.0705)Spacer

2.09-2.16 (.0823-.0850)(For adjustment of center differential pinion

2.17-2.24 (.0854-,0882)backlash-Front side)

2.25-2.32

(.0886-.0913)2.33-2.42

(.0917-.0953)

2.43-2.50 (.0957-.0984)

2.51-2.58 (.0988-.1016)2.59-2.66

(.1020-.1047)2.67-2.74

(.1051-.1079)2.75-2.82

(.1083-.I 110)

Spacer

0.59-0.66 (.0232-.0260)(For adjustment of center differential pinion

0.67-0.74 (,0264-.0291)backlash- Rear side)

0.75-0.82 (.0295-.0323)

0.83-0.92 (.0327-.0362)

0.93-I .OO (.0366-.0394)1

.01-l .08 (.0398-.0425)

1.09-I .I6 (.0429-.0457)1.17-1.24

(.0461-.0488)Spacer

0.56

(.0220)

6:;or)adjustment of front differential case end0.65 (,0256)0.74

(.0291)0.83

(.0327)0.92

(0362)1 .Ol

(.0398)

1.10 f.0433)1

.I9 (.0469)1.28

(.0504)1.37

(.0539)Spacer

0.75-0.82 (.0295-.0323)IFor adjustment of front differential pinionsacklash)

0.83-0.92 (.0327-.0362)

0.93-I .OO (.0366-.0394)1

.01-l .08 (.0398-.0425)

1.09-I .I6 (.0429-.0457)Identification

symbol

58

6164

67

70

73

76

79

0

9

8

7

6

5

4

3

2

74

50

80

79

78

76

77

49

56

65

74

83

92

01

J

LN

P

-

-

-

-

-Part No.

MD718527

MD71 8528

MD718529

MD71 8530

MD71 8531

MD721 959

MD721 960

MD721 961

M D730350

MD730349

M D730348

M D730347

M D730346

MD730345

M D730344

M D730343

M D730342

M D724974

M D724950

MD720680

MD720679

MD720678

MD720676

MD720677

M D724949

MD727658

MD727659

MD727660

MD720937

MD720940

MD720943

MD71 0454

MD71 0456

MD710458

MD71 0460

MA1 80862

MA1 80861

MA1 80860

MA1 80875

MA1 80876

Page 769 of 1216

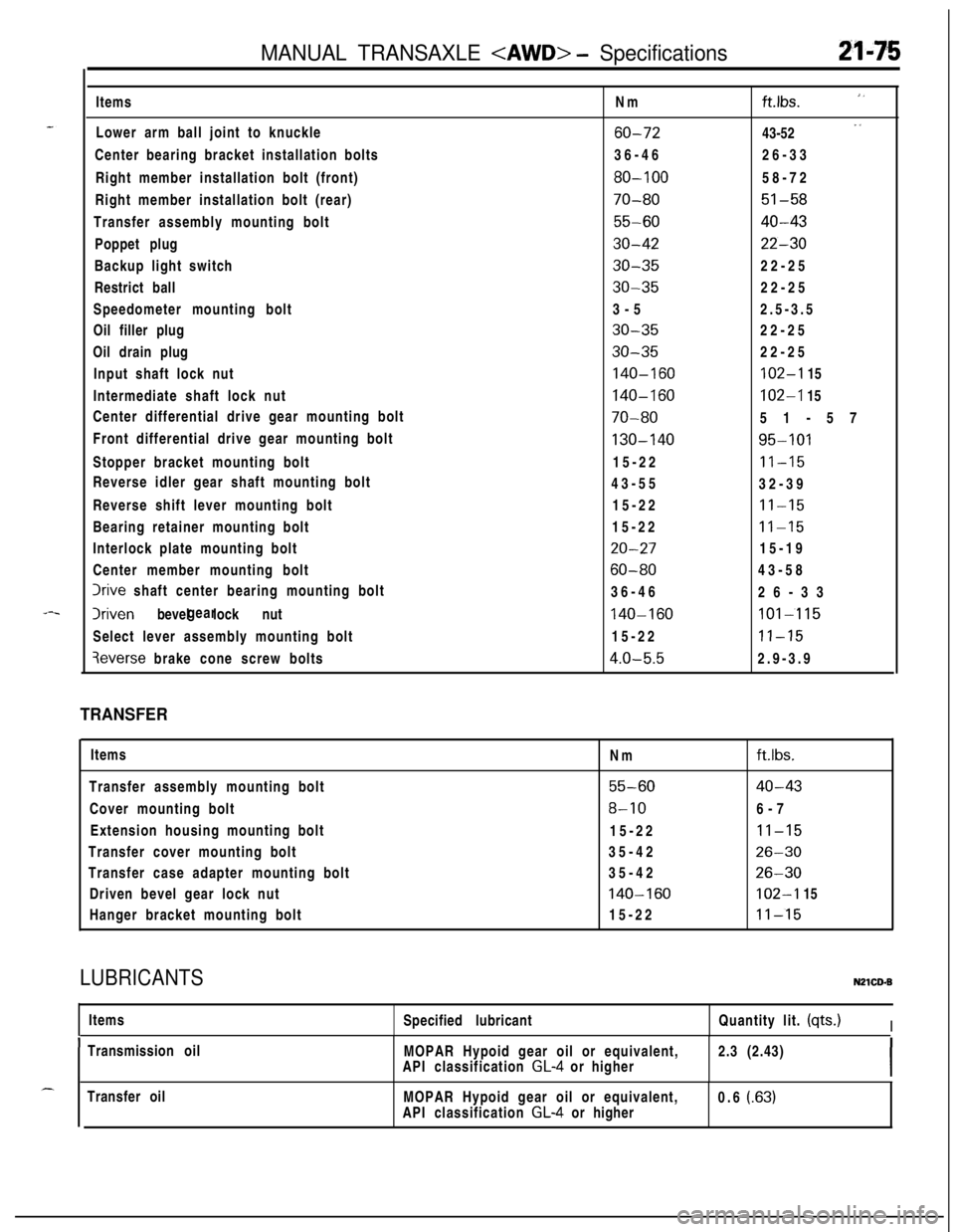

MANUAL TRANSAXLE

Lower arm ball joint to knuckle

Center bearing bracket installation bolts

Right member installation bolt (front)

Right member installation bolt (rear)

Transfer assembly mounting bolt

Poppet plug

Backup light switch

Restrict ball

Speedometer mounting bolt

Oil filler plug

Oil drain plug

Input shaft lock nut

Intermediate shaft lock nut

Center differential drive gear mounting bolt

Front differential drive gear mounting bolt

Stopper bracket mounting bolt

Reverse idler gear shaft mounting bolt

Reverse shift lever mounting bolt

Bearing retainer mounting bolt

Interlock plate mounting bolt

Center member mounting bolt

Irive shaft center bearing mounting bolt

Iriven bevel lock nutgear

Select lever assembly mounting bolt

3everse brake cone screw boltsNm

ft.Ibs. ”

60-7243-52 “

36-4626-33

80-10058-72

70-8051-58

55-6040-43

30-4222-30

30-3522-25

30-3522-25

3-52.5-3.5

30-3522-25

30-3522-25

140-160102-I 15

140-160102-I 15

70-8051-57

130-14095-10115-22

11-1543-55

32-39

15-22

11-1515-22

11-15

20-2715-19

60-8043-58

36-46

26-33

140-160101-11515-22

11-15

4.0-5.52.9-3.9

TRANSFERItems

Transfer assembly mounting bolt

Cover mounting bolt

Extension housing mounting bolt

Transfer cover mounting bolt

Transfer case adapter mounting bolt

Driven bevel gear lock nut

Hanger bracket mounting boltNm

ft.lbs.

55-6040-43

8-106-7

15-22

II-1535-42

26-3035-42

26-30

140-160102-I 15

15-22

11-15

LUBRICANTSN21CD.BItems

Specified lubricantQuantity lit. (qts.)

I

ITransmission oil

MOPAR Hypoid gear oil or equivalent,2.3 (2.43)

API classification GL-4 or higherITransfer oil

MOPAR Hypoid gear oil or equivalent,

API classification

GL-4 or higher0.6 (.63)

Page 770 of 1216

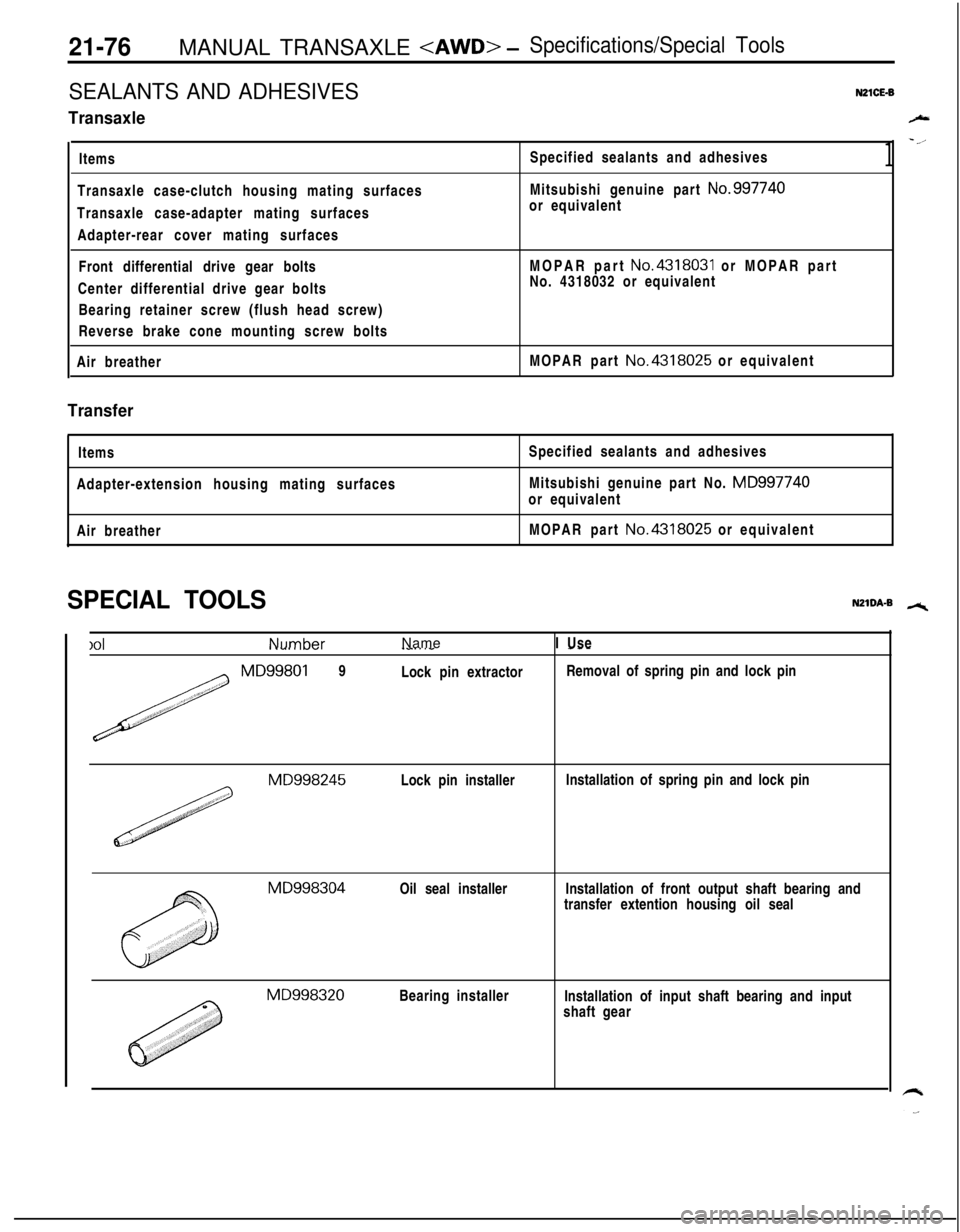

21-76MANUAL TRANSAXLE

SEALANTS AND ADHESIVESNZlCE-B

TransaxleH-

1

-/Items

Transaxle case-clutch housing mating surfaces

Transaxle case-adapter mating surfaces

Adapter-rear cover mating surfaces

Front differential drive gear bolts

Center differential drive gear bolts

Bearing retainer screw (flush head screw)

Reverse brake cone mounting screw bolts

Air breatherSpecified sealants and adhesives

Mitsubishi genuine part

No.997740or equivalent

MOPAR part

No.4318031 or MOPAR part

No. 4318032 or equivalent

MOPAR part

No.4318025 or equivalent

TransferItems

Adapter-extension housing mating surfacesSpecified sealants and adhesives

Mitsubishi genuine part No.

MD997740or equivalent

Air breatherMOPAR part

No.4318025 or equivalent

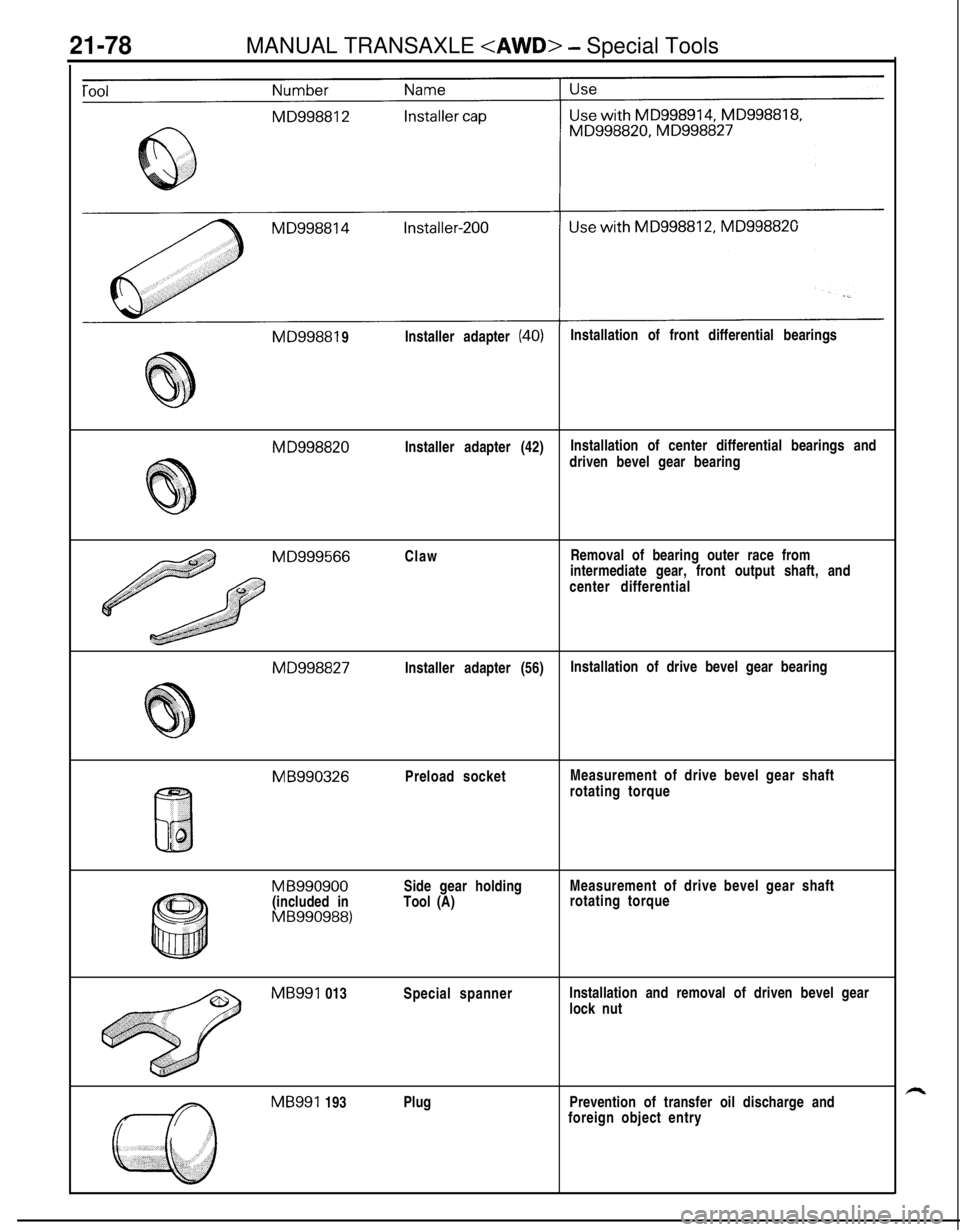

SPECIAL TOOLSNZlDA-B AI

NllmherName

I Use,“I. .-. * ,--.

~ MD99801 9

.-...-Lock pin extractor---Removal of spring pin and lock pin

MD998245Lock pin installerInstallation of spring pin and lock pin

0

MD998304Oil seal installerInstallation of front output shaft bearing and

transfer extention housing oil seal

MD998320Bearing installer

Installation of input shaft bearing and input

shaft gear

Page 771 of 1216

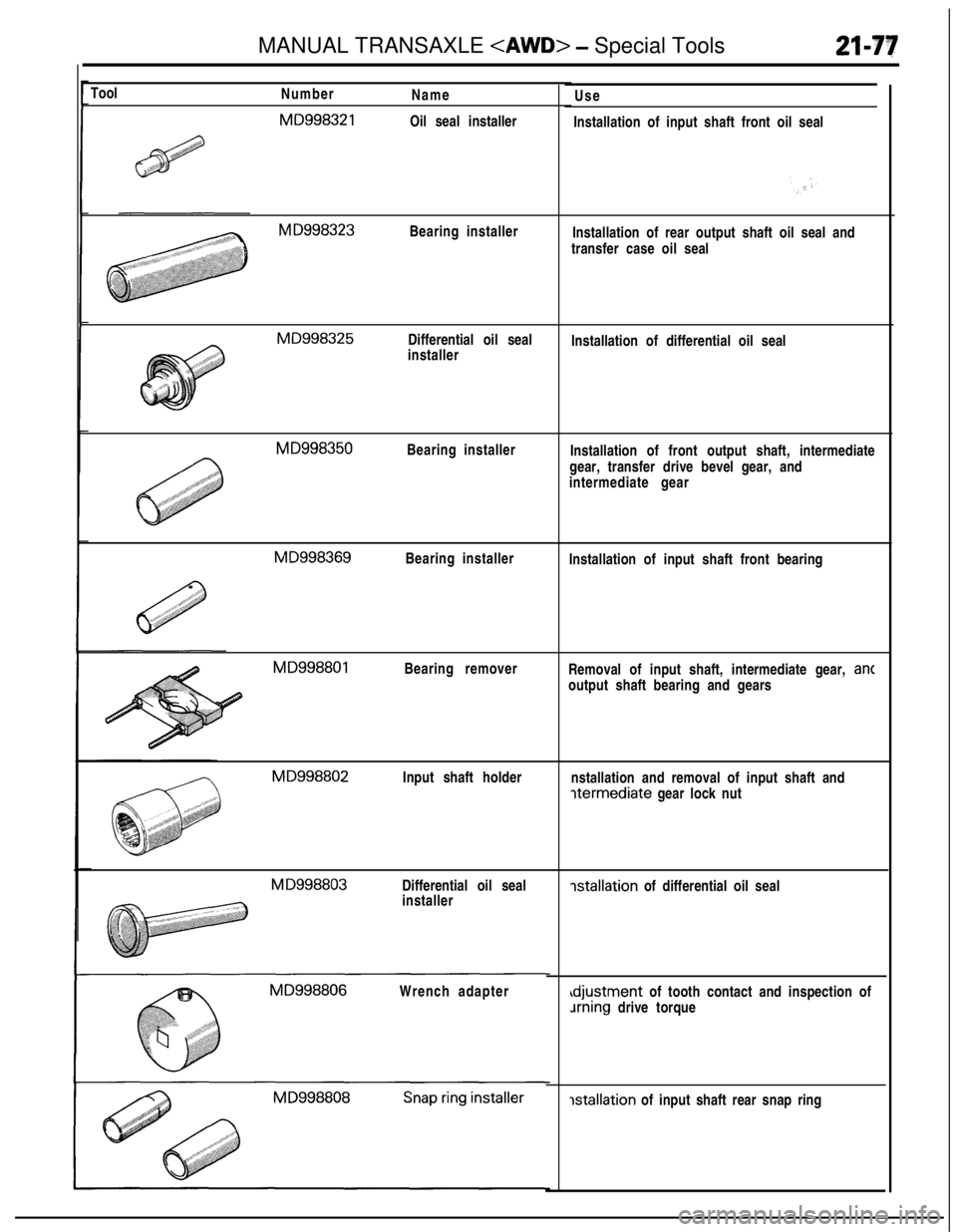

MANUAL TRANSAXLE

Number

Name

MD998321Oil seal installer

M D998323Bearing installer

MD998325Differential oil seal

installer

MD998350Bearing installer

MD998369Bearing installer

MD998806Wrench adapter

MD998801Bearing remover

MD998802Input shaft holder

M D998803Differential oil seal

installerUse

Installation of input shaft front oil seal

Installation of rear output shaft oil seal and

transfer case oil seal

Installation of differential oil seal

Installation of front output shaft, intermediate

gear, transfer drive bevel gear, and

intermediate gear

Installation of input shaft front bearing

Removal of input shaft, intermediate gear, ant

output shaft bearing and gears

nstallation and removal of input shaft and

Ttermediate gear lock nut

lstallation of differential oil seal

rdjustment of tooth contact and inspection ofJrning drive torquexstallation of input shaft rear snap ring

Page 772 of 1216

21-78MANUAL TRANSAXLE

MD99881 9Installer adapter (40)Installation of front differential bearings

M D998820Installer adapter (42)Installation of center differential bearings and

driven bevel gear bearing

MD999566ClawRemoval of bearing outer race from

intermediate gear, front output shaft, and

center differential

MD998827Installer adapter (56)Installation of drive bevel gear bearing

MB990326Preload socketMeasurement of drive bevel gear shaft

rotating torque

M B990900(included in

MB990988)Side gear holding

Tool (A)Measurement of drive bevel gear shaft

rotating torque

MB991 013Special spannerInstallation and removal of driven bevel gear

lock nut

MB991 193PlugPrevention of transfer oil discharge and

foreign object entry

Page 781 of 1216

--

MANUAL TRANSAXLE

i5 r)

p$---al3743-55 Nm

3632-39 ft.lbs.

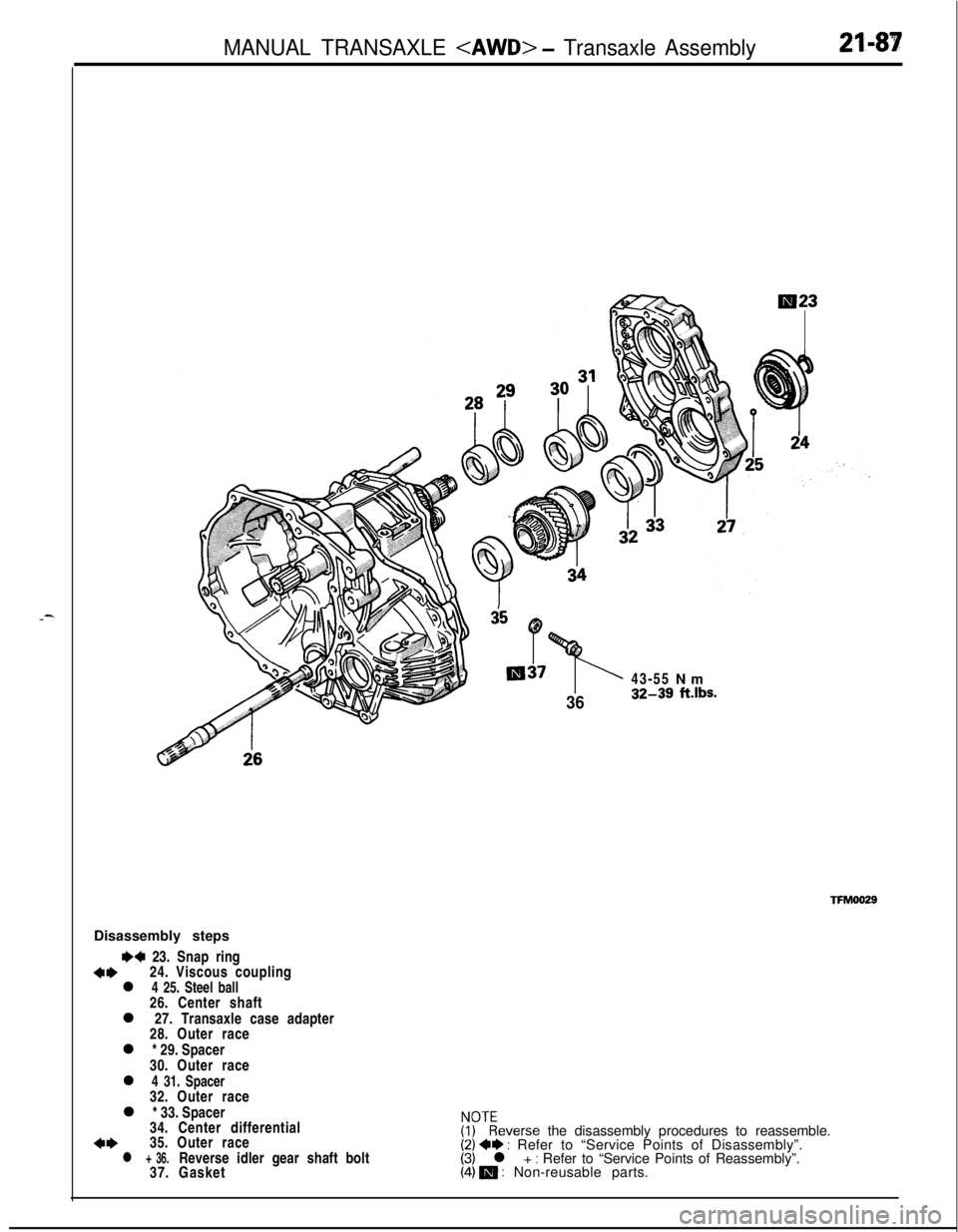

TFM0029Disassembly steps

I)+ 23. Snap ring

4*24. Viscous couplingl 4 25. Steel ball26. Center shaft

l 27. Transaxle case adapter

28. Outer race

l * 29. Spacer

30. Outer race

l 4 31. Spacer32. Outer race

l * 33. Spacer

34. Center differential

4*35. Outer race$?everse the disassembly procedures to reassemble.

Reverse idler gear shaft bolt(2) +I) : Refer to “Service Points of Disassembly”.l + 36.(3) l + : Refer to “Service Points of Reassembly”.

37. Gasket(4) m : Non-reusable parts.

Page 782 of 1216

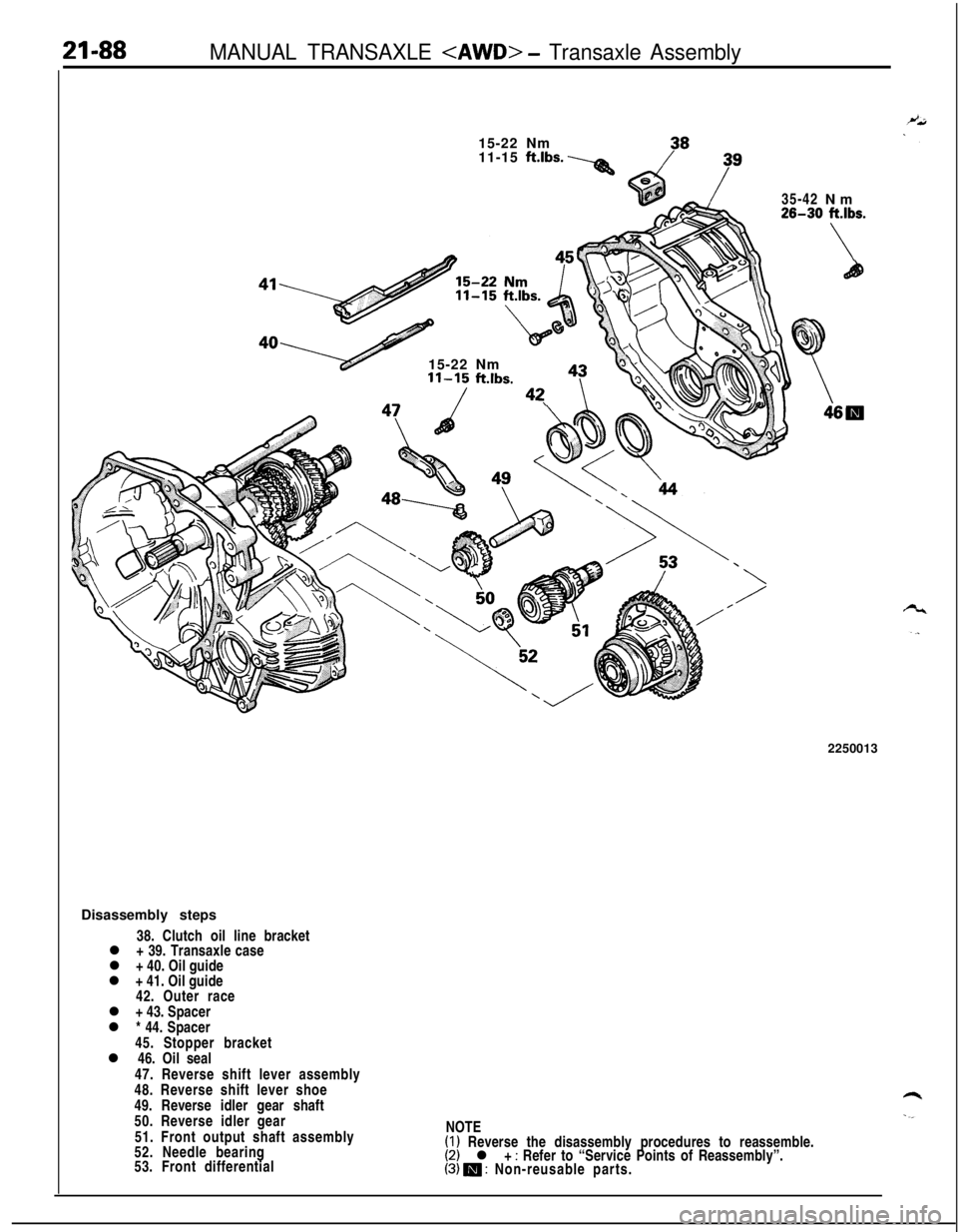

21-88MANUAL TRANSAXLE

11-15 ft.lbs.

-.@&35-42 Nm

26-30 ft.lbs.

\15-22 Nm

11-15 ft.lbs.

/4?2250013

Disassembly steps

38. Clutch oil line bracket

l + 39. Transaxle case

l + 40. Oil guide

l + 41. Oil guide

42. Outer race

l + 43. Spacer

l * 44. Spacer

45. Stopper bracket

l 46. Oil seal

47. Reverse shift lever assembly

48. Reverse shift lever shoe

49. Reverse idler gear shaft

50. Reverse idler gear

51. Front output shaft assembly

52. Needle bearing

53. Front differentialNOTE

(I) Reverse the disassembly procedures to reassemble.(2) l + : Refer to “Service Points of Reassembly”.(3) m : Non-reusable parts.

Page 789 of 1216

MANUAL TRANSAXLE

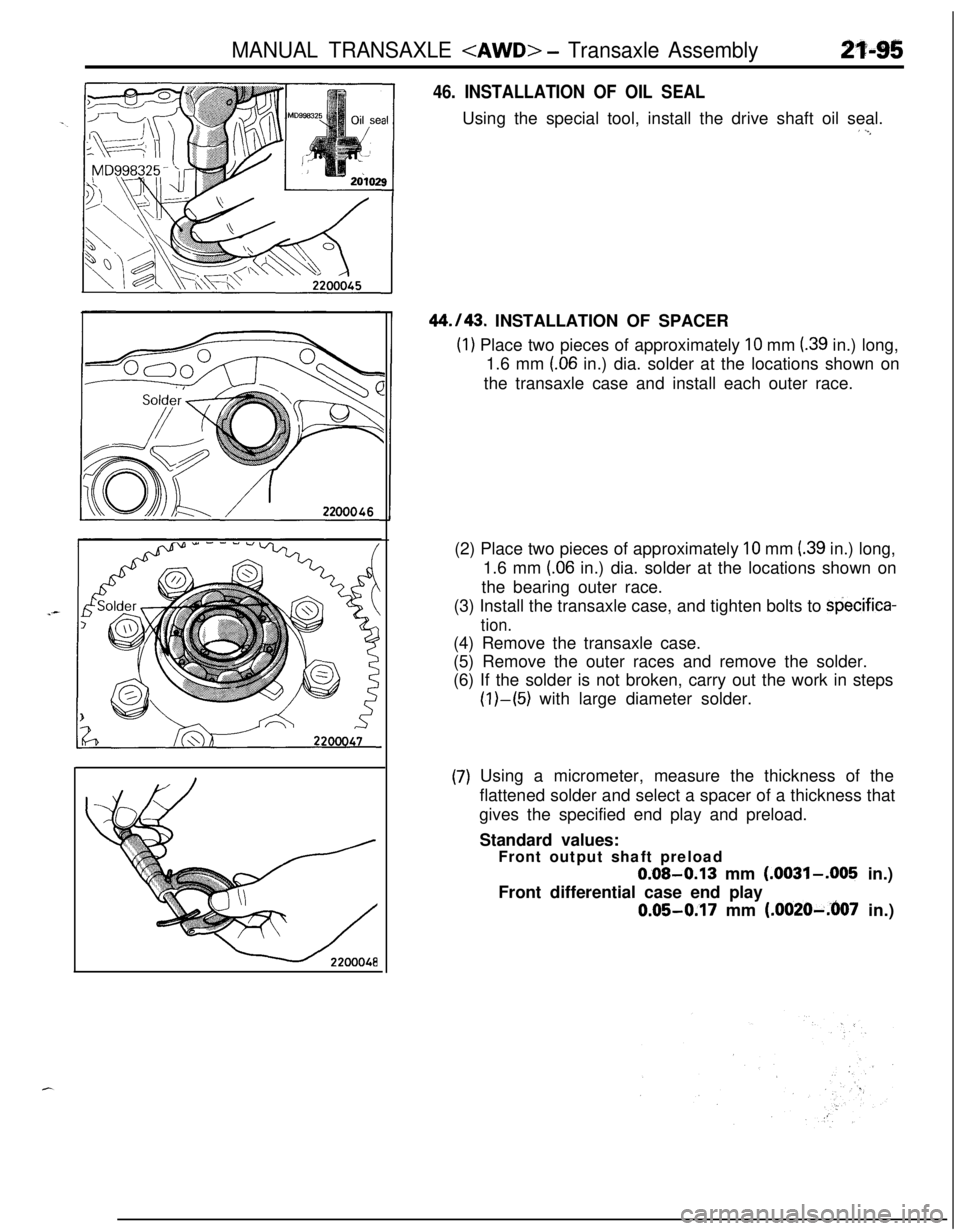

46. INSTALLATION OF OIL SEALUsing the special tool, install the drive shaft oil seal.

I -.,44.143. INSTALLATION OF SPACER

(1) Place two pieces of approximately 10 mm (39 in.) long,

1.6 mm

(.06 in.) dia. solder at the locations shown on

the transaxle case and install each outer race.

(2) Place two pieces of approximately

10 mm (.39 in.) long,

1.6 mm

(.06 in.) dia. solder at the locations shown on

the bearing outer race.

(3) Install the transaxle case, and tighten bolts to

specifiea-

tion.(4) Remove the transaxle case.

(5) Remove the outer races and remove the solder.

(6) If the solder is not broken, carry out the work in steps

(l)-(5) with large diameter solder.

(7) Using a micrometer, measure the thickness of the

flattened solder and select a spacer of a thickness that

gives the specified end play and preload.

Standard values:

Front output shaft preload

0.08-0.13 mm (.0031-.005 in.)

Front differential case end play

0.05-0.17 mm (.0020-.a07 in.)

Page 791 of 1216

MANUAL TRANSAXLE

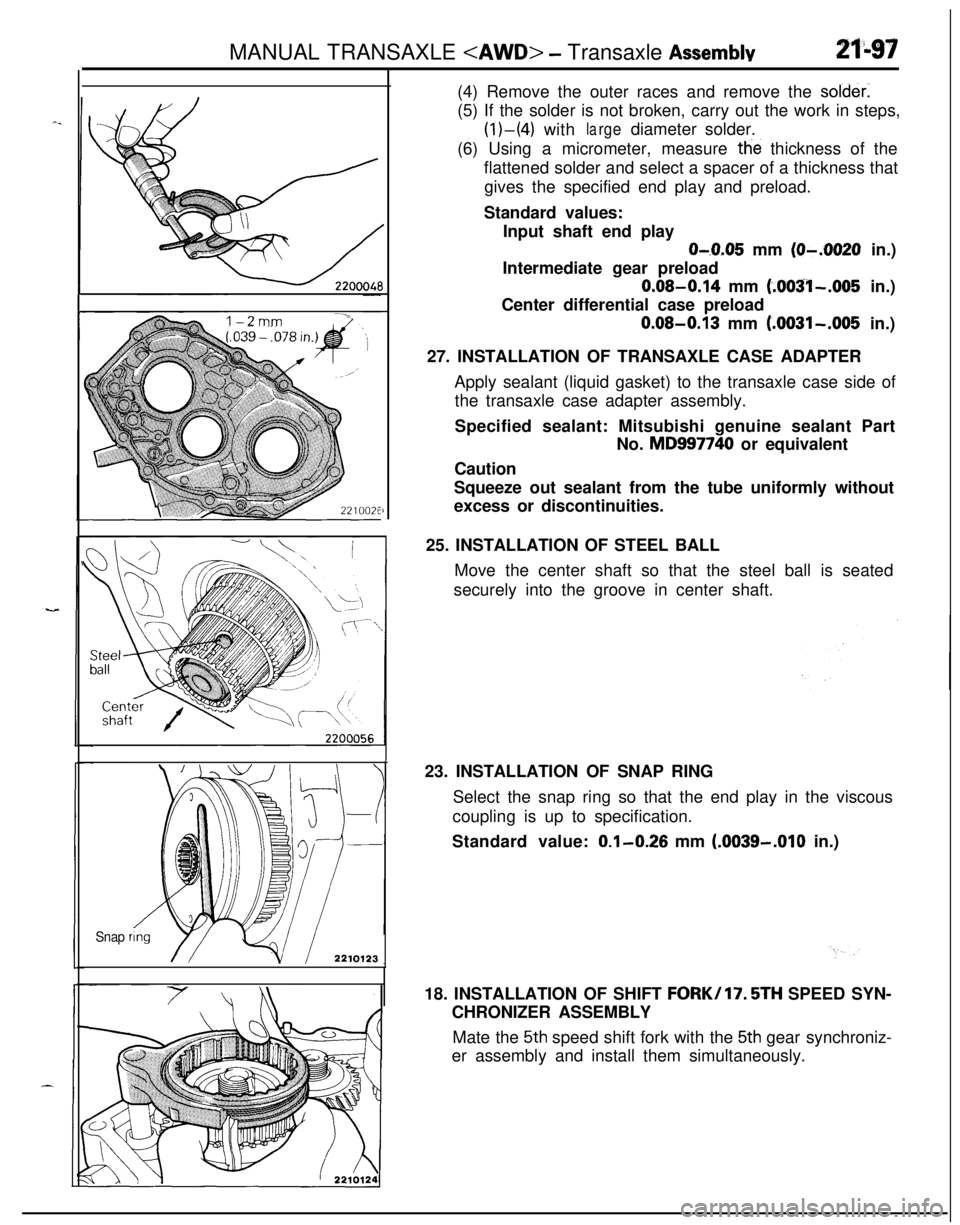

I-2mmml

,

Snap r

/ /221012:3(4) Remove the outer races and remove the

solder:(5) If the solder is not broken, carry out the work in steps,

(l)-(4) withlargediameter solder.

(6) Using a micrometer, measure ttie thickness of the

flattened solder and select a spacer of a thickness that

gives the specified end play and preload.

Standard values:

Input shaft end play

O-.0.05 mm (O-.0020 in.)

Intermediate gear preload

0.08-0.14 mm (.0031-.005 in.)

Center differential case preload

0.08-0.13 mm (.0031-,005 in.)

27. INSTALLATION OF TRANSAXLE CASE ADAPTER

Apply sealant (liquid gasket) to the transaxle case side of

the transaxle case adapter assembly.

Specified sealant: Mitsubishi genuine sealant Part

No. MD997740 or equivalent

Caution

Squeeze out sealant from the tube uniformly without

excess or discontinuities.

25. INSTALLATION OF STEEL BALL

Move the center shaft so that the steel ball is seated

securely into the groove in center shaft.

23. INSTALLATION OF SNAP RING

Select the snap ring so that the end play in the viscous

coupling is up to specification.

Standard value:

0.1-0.26 mm (.0039-.OlO in.)

18. INSTALLATION OF SHIFT FORK/17.

5TH SPEED SYN-

CHRONIZER ASSEMBLY

Mate the

5th speed shift fork with the 5th gear synchroniz-

er assembly and install them simultaneously.

Page 797 of 1216

MANUAL TRANSAXLE

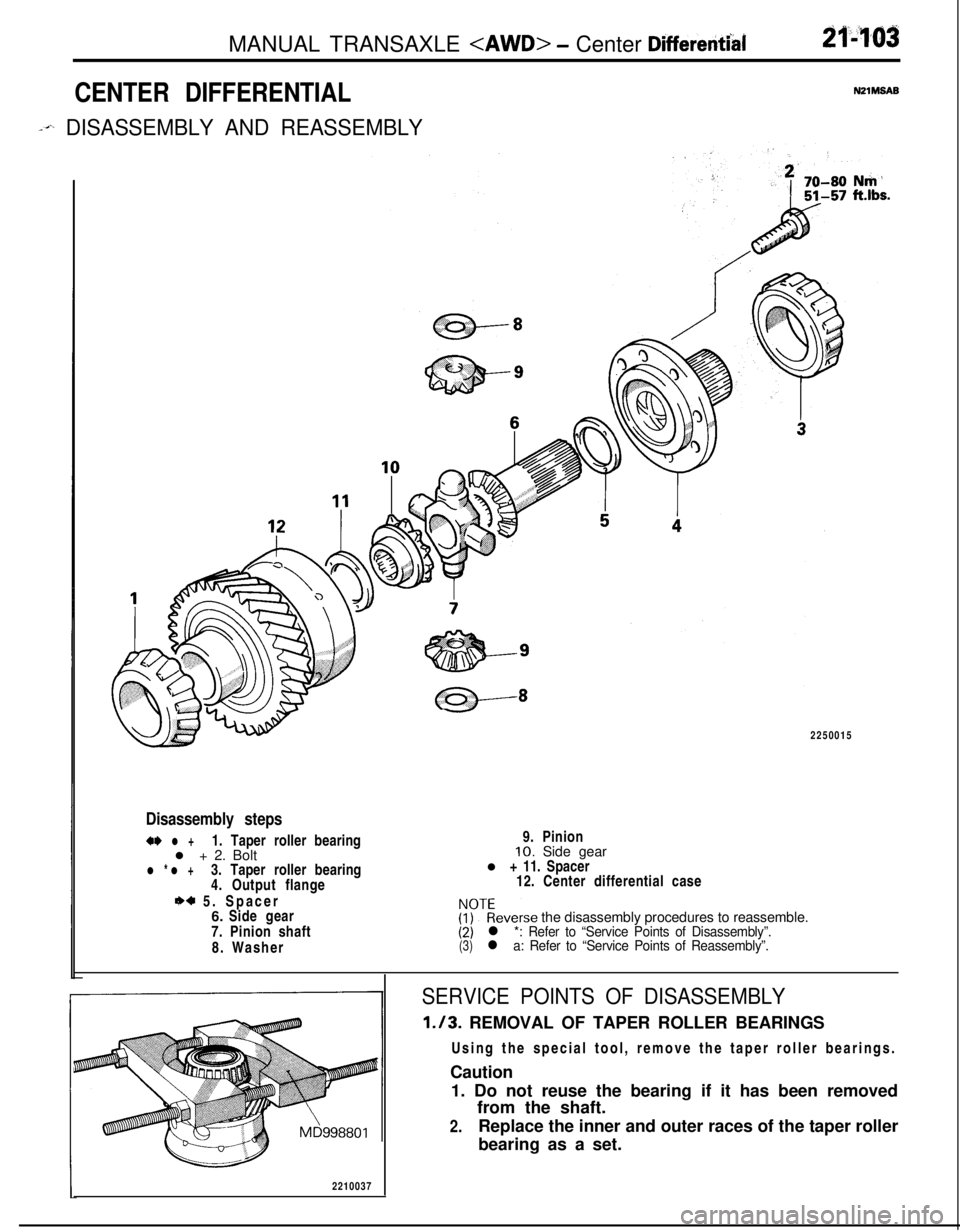

CENTER DIFFERENTIAL

-4~ DISASSEMBLY AND REASSEMBLY

2210037

-

2250015

Disassembly steps

+* l +1. Taper roller bearing

l + 2. Bolt

l * l +3. Taper roller bearing

4. Output flange

I)* 5. Spacer

6. Side gear

7. Pinion shaft

8. Washer9. Pinion

10. Side gear

l + 11. Spacer

12. Center differential case

FJ)TEeverse the disassembly procedures to reassemble.(2)l *: Refer to “Service Points of Disassembly”.(3)l a: Refer to “Service Points of Reassembly”.

SERVICE POINTS OF DISASSEMBLY

1.13. REMOVAL OF TAPER ROLLER BEARINGS

Using the special tool, remove the taper roller bearings.

Caution

1. Do not reuse the bearing if it has been removed

from the shaft.

2.Replace the inner and outer races of the taper roller

bearing as a set.