lock MITSUBISHI ECLIPSE 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 122 of 1216

3-20REAR AXLE - Differential CarrierMating marks

’

lODSO5

Beveled place

1 lA0274

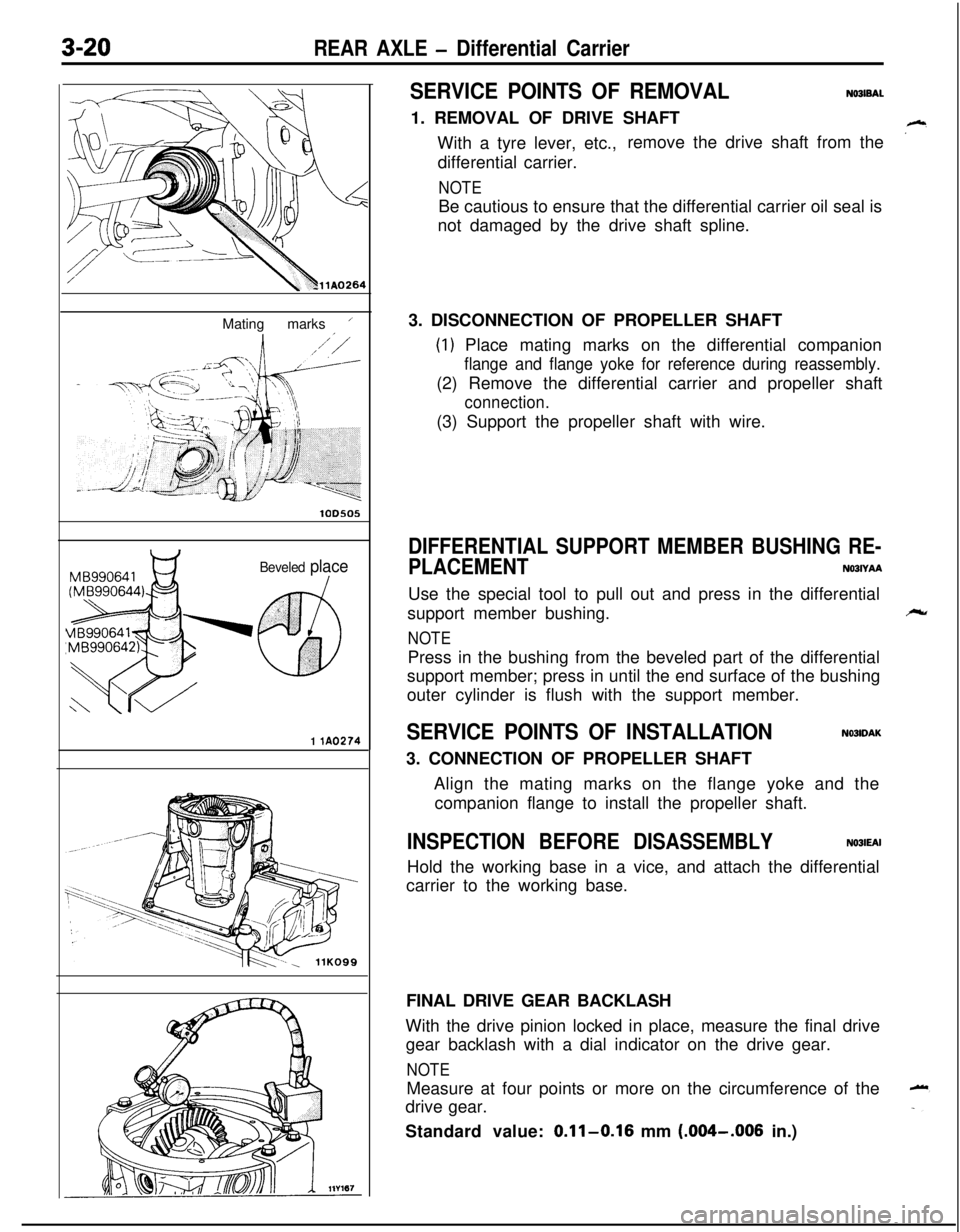

SERVICE POINTS OF REMOVALN031BAL1. REMOVAL OF DRIVE SHAFT

With a tyre lever, etc.,remove the drive shaft from the

differential carrier.

NOTEBe cautious to ensure that the differential carrier oil seal is

not damaged by the drive shaft spline.

3. DISCONNECTION OF PROPELLER SHAFT

(1) Place mating marks on the differential companion

flange and flange yoke for reference during reassembly.(2) Remove the differential carrier and propeller shaft

connection.(3) Support the propeller shaft with wire.

DIFFERENTIAL SUPPORT MEMBER BUSHING RE-

PLACEMENT

NOBIYAAUse the special tool to pull out and press in the differential

support member bushing.

NOTEPress in the bushing from the beveled part of the differential

support member; press in until the end surface of the bushing

outer cylinder is flush with the support member.

SERVICE POINTS OF INSTALLATIONN03lDAK3. CONNECTION OF PROPELLER SHAFT

Align the mating marks on the flange yoke and the

companion flange to install the propeller shaft.

INSPECTION BEFORE DISASSEMBLYNOJIEAIHold the working base in a vice, and attach the differential

carrier to the working base.

FINAL DRIVE GEAR BACKLASH

With the drive pinion locked in place, measure the final drive

gear backlash with a dial indicator on the drive gear.

NOTEMeasure at four points or more on the circumference of the

drive gear.

Standard value:

0.11-0.16 mm (.004-.006 in.)

Page 123 of 1216

REAR AXLE -Differential Carrier3-21

.-11GOO73

-

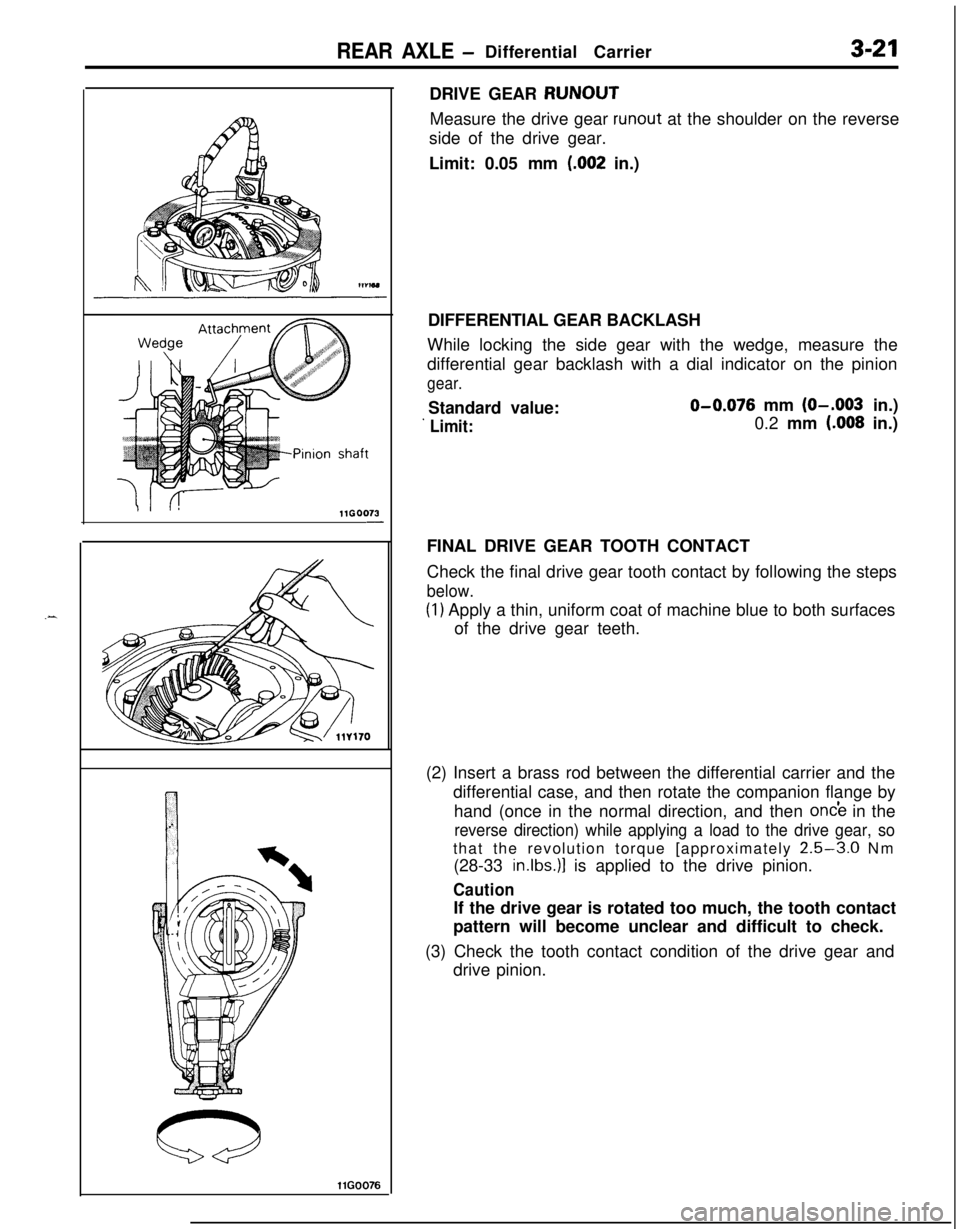

llG0076DRIVE GEAR RUNOUT

Measure the drive gear

runout at the shoulder on the reverse

side of the drive gear.

Limit: 0.05 mm

(.002 in.)

DIFFERENTIAL GEAR BACKLASH

While locking the side gear with the wedge, measure the

differential gear backlash with a dial indicator on the pinion

gear.Standard value:O-0.076 mm (O-.003 in.)

’ Limit:0.2 mm (.008 in.)

FINAL DRIVE GEAR TOOTH CONTACT

Check the final drive gear tooth contact by following the steps

below.

(1) Apply a thin, uniform coat of machine blue to both surfaces

of the drive gear teeth.

(2) Insert a brass rod between the differential carrier and the

differential case, and then rotate the companion flange by

hand (once in the normal direction, and then

on& in the

reverse direction) while applying a load to the drive gear, sothat the revolution torque [approximately

2.5-3.0 Nm

(28-33

in.lbs.)] is applied to the drive pinion.

CautionIf the drive gear is rotated too much, the tooth contact

pattern will become unclear and difficult to check.

(3) Check the tooth contact condition of the drive gear and

drive pinion.

Page 125 of 1216

REAR AXLE - Differential Carrier3-23

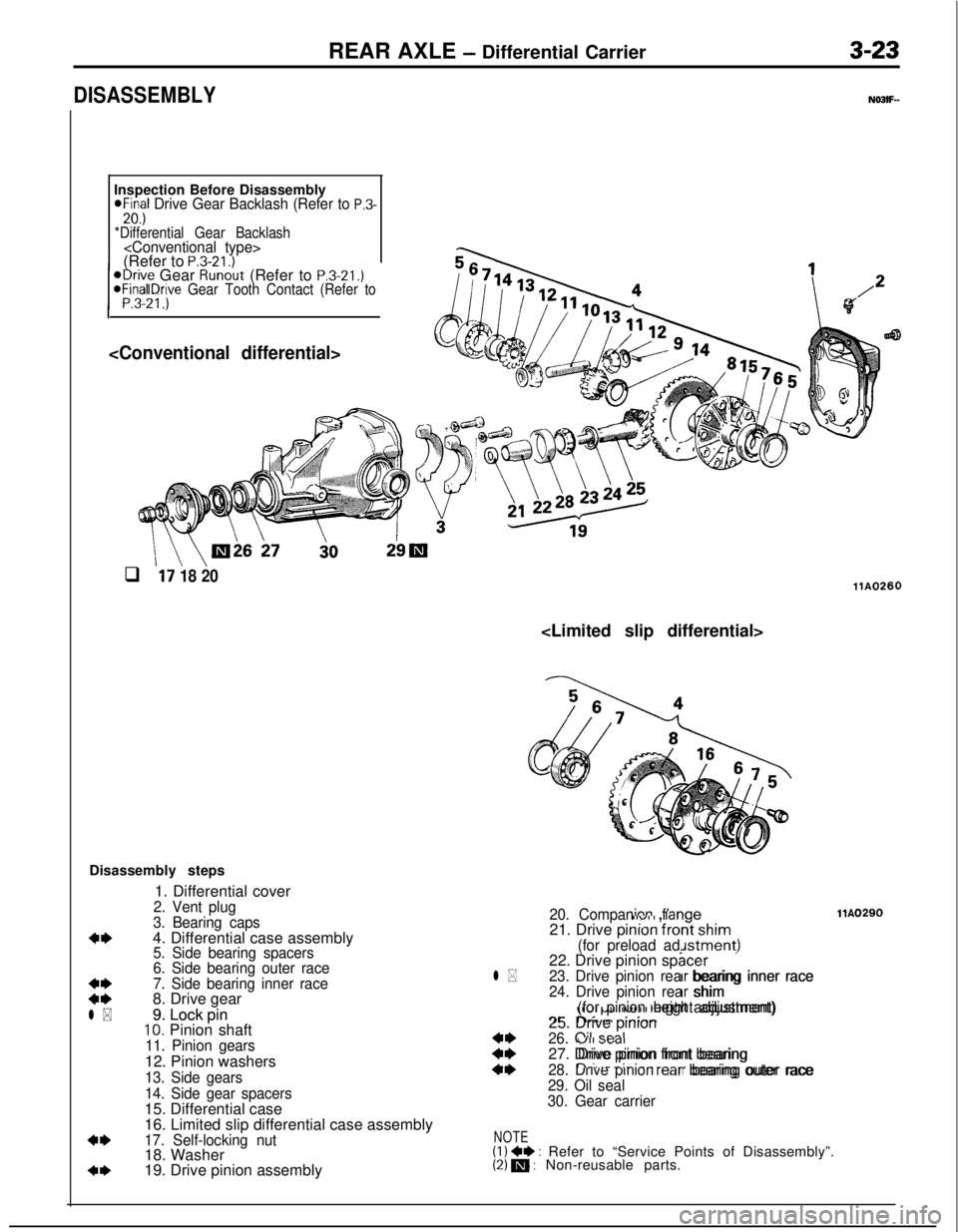

DISASSEMBLYInspection Before Disassembly

@Final Drive Gear Backlash (Refer to P.3-20.)*Differential Gear Backlash

/ ;3-21.)’1

@Drive Gear Runout (Refer to P.3-21.)aFInal Drove Gear Tooth Contact (Refer to

\ \\Oi6 27i0

q l7 18 20llA0260

Disassembly steps

1. Differential cover

2. Vent plug

3. Bearing caps

*I)4. Differential case assembly5. Side bearing spacers

6. Side bearing outer race

:z

7. Side bearing inner race8. Drive gear

l * l *9. Lock pin 9. Lock pin10. Pinion shaft11. Pinion gears12. Pinion washers

13. Side gears

14. Side gear spacers15. Differential case

16. Limited slip differential case assembly

*I)17. Self-locking nut18. Washer

4*19. Drive pinion assembly

20. Companion flangellvlI , ,,,igellA0290llA0290

21. Drive pinion front shim-:-- ‘--nt shim

(for preload adjustment)Jstment)22. Drive pinion spacer3cerl *23. Drive pinion rear bearing inner racerr bearing inner race

24. Drive pinion rear shimrr shim,Ivl PJ” llUl I I IcIyIit adjustment)(for pinion height adjustment)?Cl3.r;. I,-. ..:..;A-25. Drive pinion

::

26. Oil seal“II >twI27. Drive pinion front bearingDrive pinion front bearing

4*28. Drive pinion rear bearing outer racen-‘..- -‘-‘-- --lr bearing outer race

29. Oil seal

30. Gear carrier

NOTE(1) +I) : Refer to “Service Points of Disassembly”.(2) m : Non-reusable parts.

Page 126 of 1216

3-24REAR AXLE- Differential Carrier

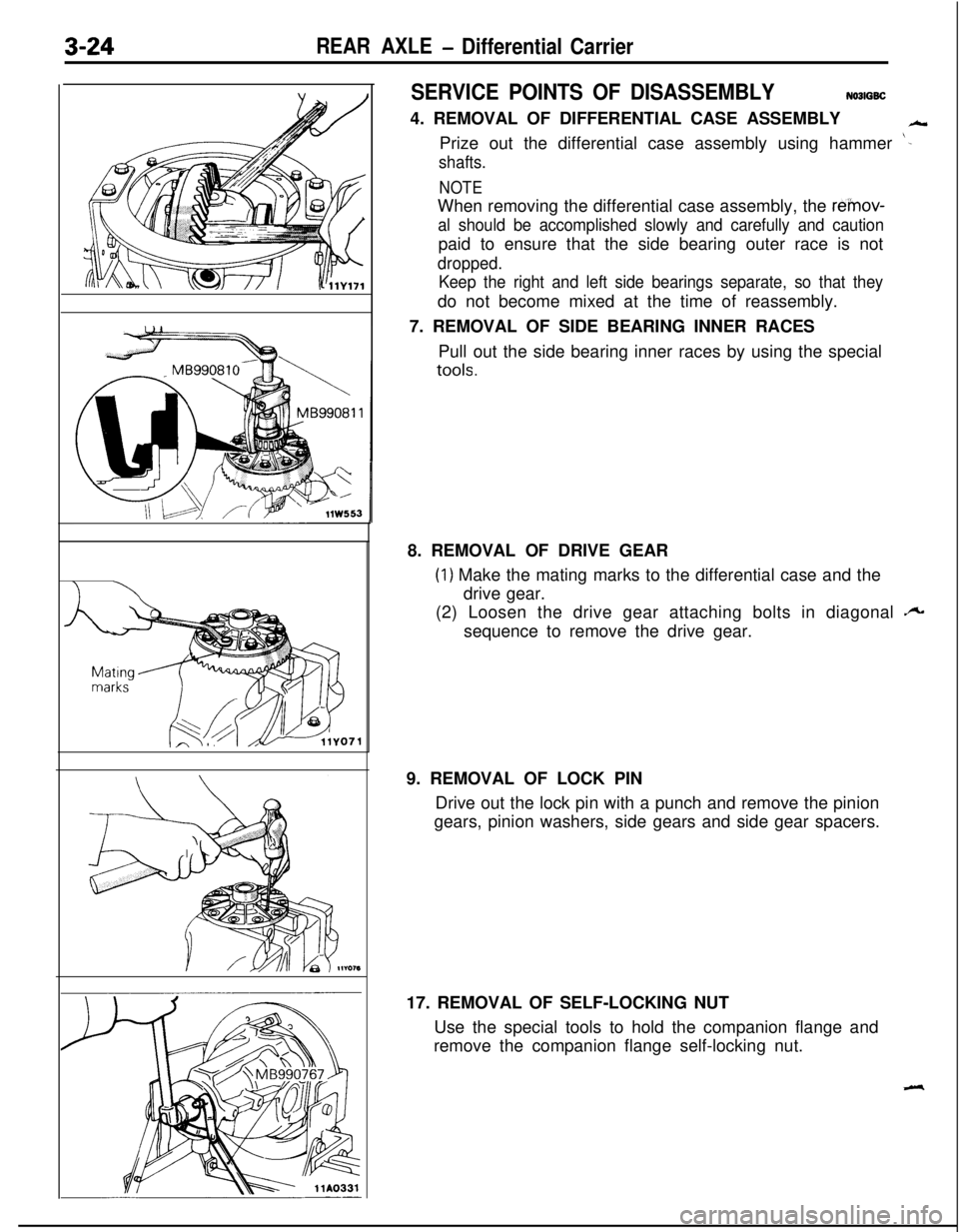

SERVICE POINTS OF DISASSEMBLYN03lGSC4. REMOVAL OF DIFFERENTIAL CASE ASSEMBLY

kPrize out the differential case assembly using hammer

‘-

shafts.

NOTEWhen removing the differential case assembly, the

re’mov-

al should be accomplished slowly and carefully and cautionpaid to ensure that the side bearing outer race is not

dropped.

Keep the right and left side bearings separate, so that theydo not become mixed at the time of reassembly.

7. REMOVAL OF SIDE BEARING INNER RACES

Pull out the side bearing inner races by using the special

tools.8. REMOVAL OF DRIVE GEAR

(1) Make the mating marks to the differential case and the

drive gear.

(2) Loosen the drive gear attaching bolts in diagonal

fisequence to remove the drive gear.

9. REMOVAL OF LOCK PIN

Drive out the lock pin with a punch and remove the pinion

gears, pinion washers, side gears and side gear spacers.

17. REMOVAL OF SELF-LOCKING NUT

Use the special tools to hold the companion flange and

remove the companion flange self-locking nut.

Page 128 of 1216

3-26REAR AXLE - Differential Carrier

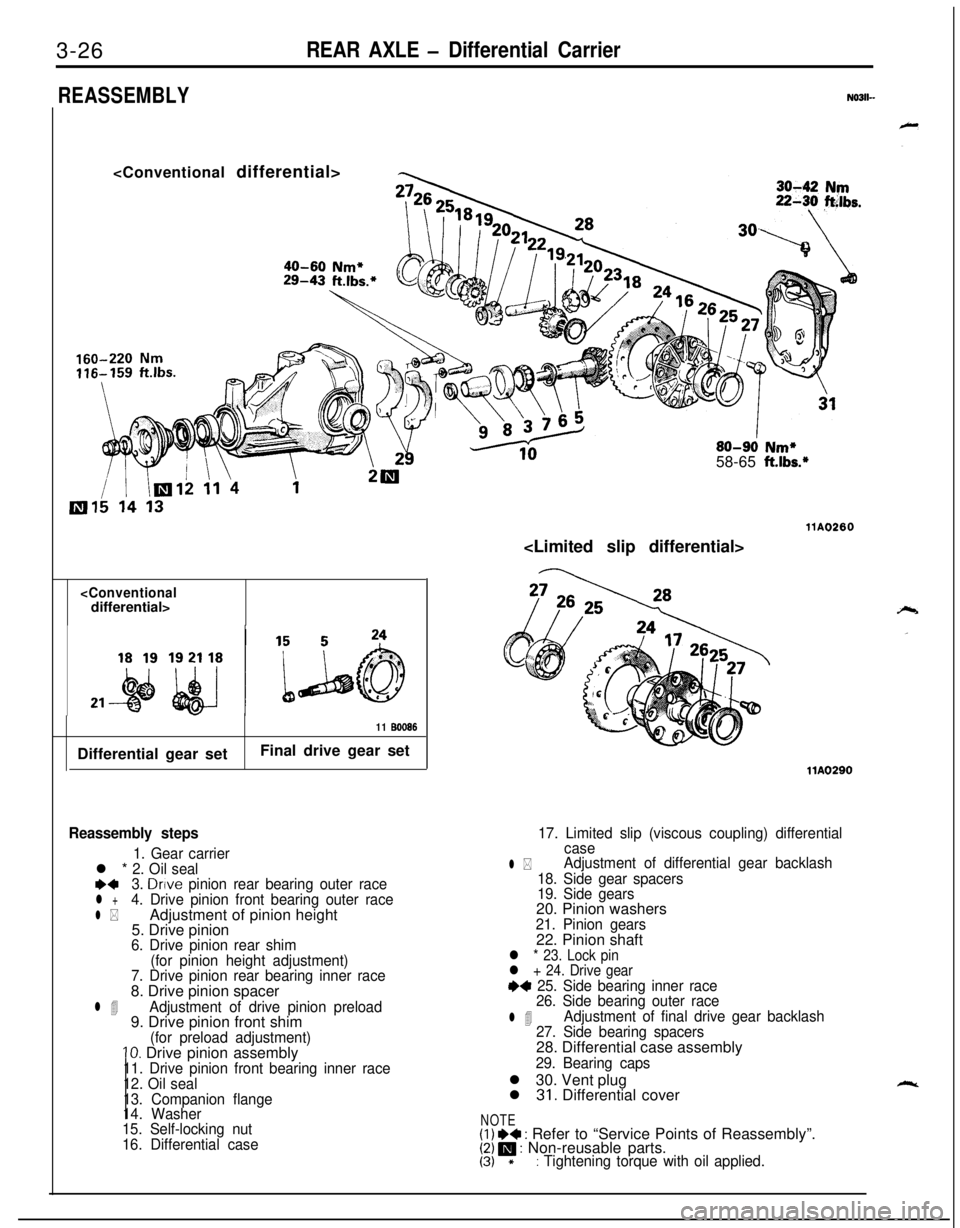

REASSEMBLYN0311-

Nm*B-43 ft.lbs.*

80-90 Nm*58-65 ft.lbs.*

11 BOO86Differential gear setFinal drive gear set

Reassembly steps

1. Gear carrierl * 2. Oil seale+3. Drive pinion rear bearing outer racel +4. Drive pinion front bearing outer race

l *Adjustment of pinion height

5. Drive pinion

6. Drive pinion rear shim

(for pinion height adjustment)

7. Drive pinion rear bearing inner race8. Drive pinion spacer

l 4Adjustment of drive pinion preload9. Drive pinion front shim

(for preload adjustment)10. Drive pinion assembly11. Drive pinion front bearing inner race

12. Oil seal

13. Companion flange

14. Washer

15. Self-locking nut

16. Differential case

17. Limited slip (viscous coupling) differential

case

l *Adjustment of differential gear backlash

18. Side gear spacers

19. Side gears20. Pinion washers

21. Pinion gears22. Pinion shaft

l * 23. Lock pin

l + 24. Drive gear

+4 25. Side bearing inner race

26. Side bearing outer race

l 4Adjustment of final drive gear backlash

27. Side bearing spacers28. Differential case assembly

29. Bearing capsl 30. Vent plug

l

31. Differential cover

NOTE(I) I)+ : Refer to “Service Points of Reassembly”.[Z!/ m : Non-reusable parts.*: Tightening torque with oil applied.

Page 131 of 1216

REAR AXLE - Differential Carrier3-29

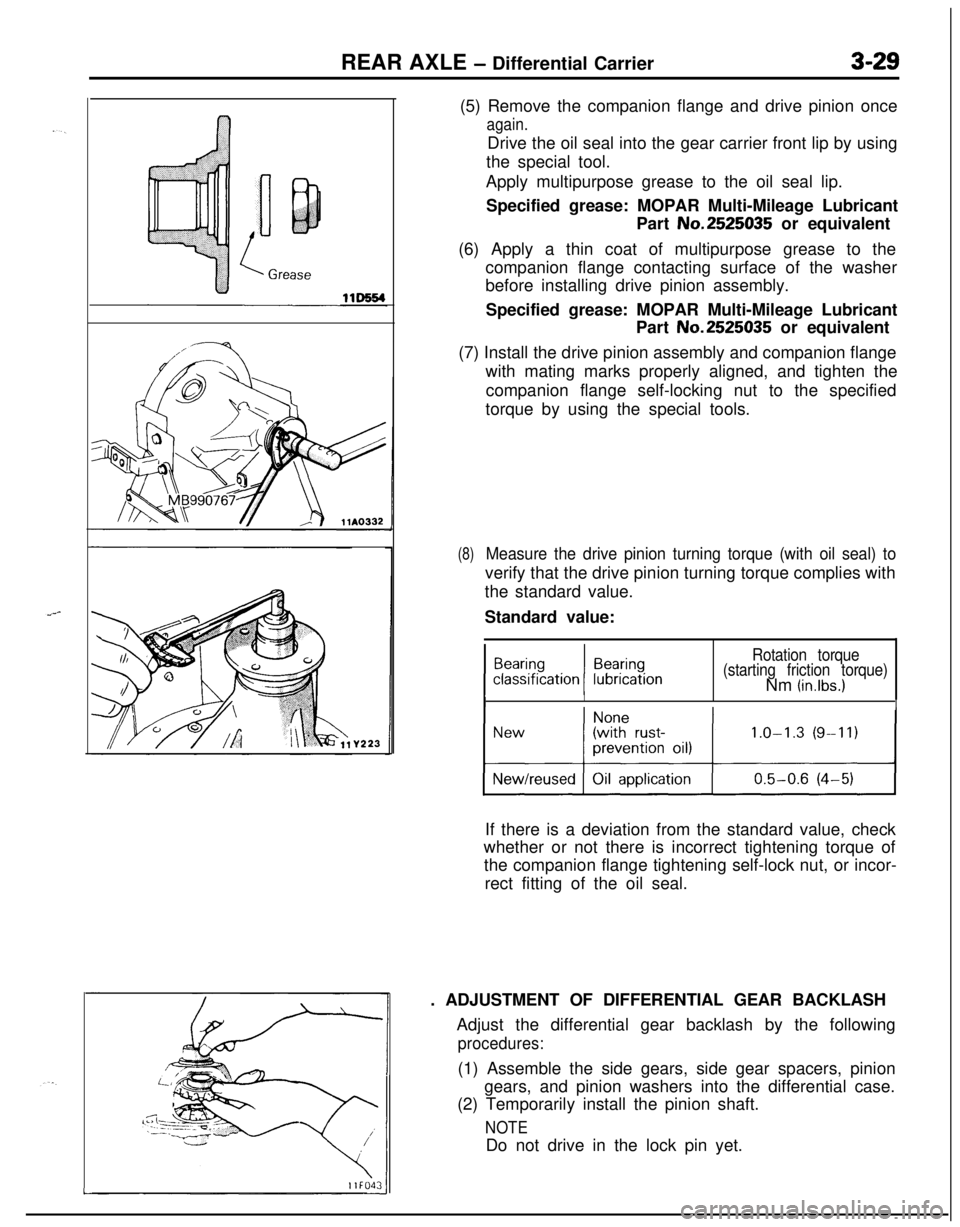

Y223(5) Remove the companion flange and drive pinion once

again.Drive the oil seal into the gear carrier front lip by using

the special tool.

Apply multipurpose grease to the oil seal lip.

Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

(6) Apply a thin coat of multipurpose grease to the

companion flange contacting surface of the washer

before installing drive pinion assembly.

Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

(7) Install the drive pinion assembly and companion flange

with mating marks properly aligned, and tighten the

companion flange self-locking nut to the specified

torque by using the special tools.

(8)Measure the drive pinion turning torque (with oil seal) toverify that the drive pinion turning torque complies with

the standard value.

Standard value:

Rotation torque

(starting friction torque)Nm

(in.lbs.)

IIIIIf there is a deviation from the standard value, check

whether or not there is incorrect tightening torque of

the companion flange tightening self-lock nut, or incor-

rect fitting of the oil seal.

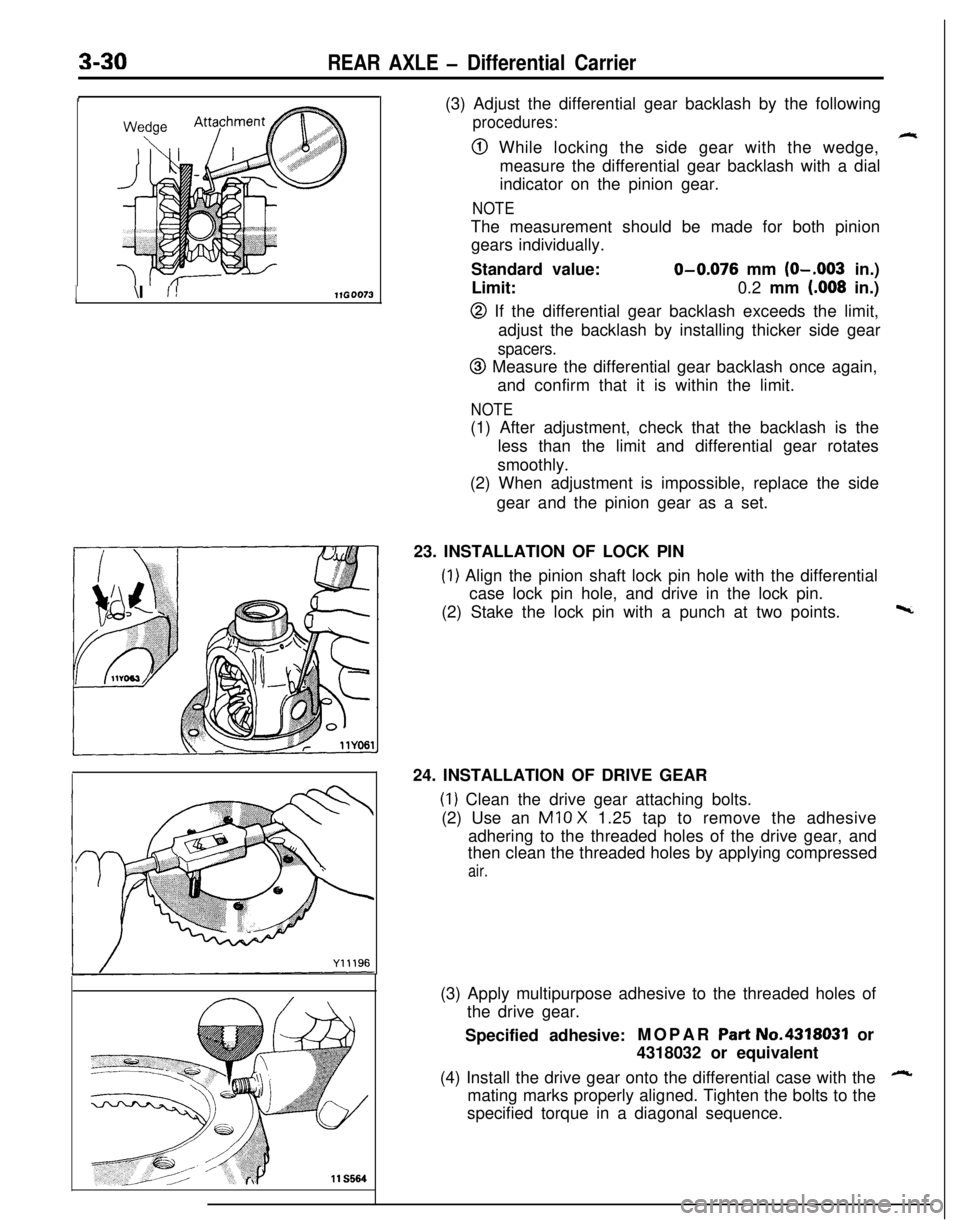

. ADJUSTMENT OF DIFFERENTIAL GEAR BACKLASH

Adjust the differential gear backlash by the following

procedures:(1) Assemble the side gears, side gear spacers, pinion

gears, and pinion washers into the differential case.

(2) Temporarily install the pinion shaft.

NOTEDo not drive in the lock pin yet.

L-

Page 132 of 1216

REAR AXLE - Differential Carrier

I\I I!llGOO73I

11 S564(3) Adjust the differential gear backlash by the following

procedures:

@ While locking the side gear with the wedge,

measure the differential gear backlash with a dial

indicator on the pinion gear.

NOTEThe measurement should be made for both pinion

gears individually.

Standard value:

O-0.076 mm (O-.003 in.)

Limit:0.2 mm

(.008 in.)

@ If the differential gear backlash exceeds the limit,

adjust the backlash by installing thicker side gear

spacers.

@ Measure the differential gear backlash once again,

and confirm that it is within the limit.

NOTE(1) After adjustment, check that the backlash is the

less than the limit and differential gear rotates

smoothly.

(2) When adjustment is impossible, replace the side

gear and the pinion gear as a set.

23. INSTALLATION OF LOCK PIN

(1) Align the pinion shaft lock pin hole with the differential

case lock pin hole, and drive in the lock pin.

(2) Stake the lock pin with a punch at two points.

w24. INSTALLATION OF DRIVE GEAR

(1) Clean the drive gear attaching bolts.

(2) Use an

Ml0 X 1.25 tap to remove the adhesive

adhering to the threaded holes of the drive gear, and

then clean the threaded holes by applying compressed

air.(3) Apply multipurpose adhesive to the threaded holes of

the drive gear.

Specified adhesive:MOPAR

Part No.4318031 or

4318032 or equivalent

(4) Install the drive gear onto the differential case with the

Amating marks properly aligned. Tighten the bolts to the

specified torque in a diagonal sequence.

Page 134 of 1216

3-32REAR AXLE - Differential Carrier

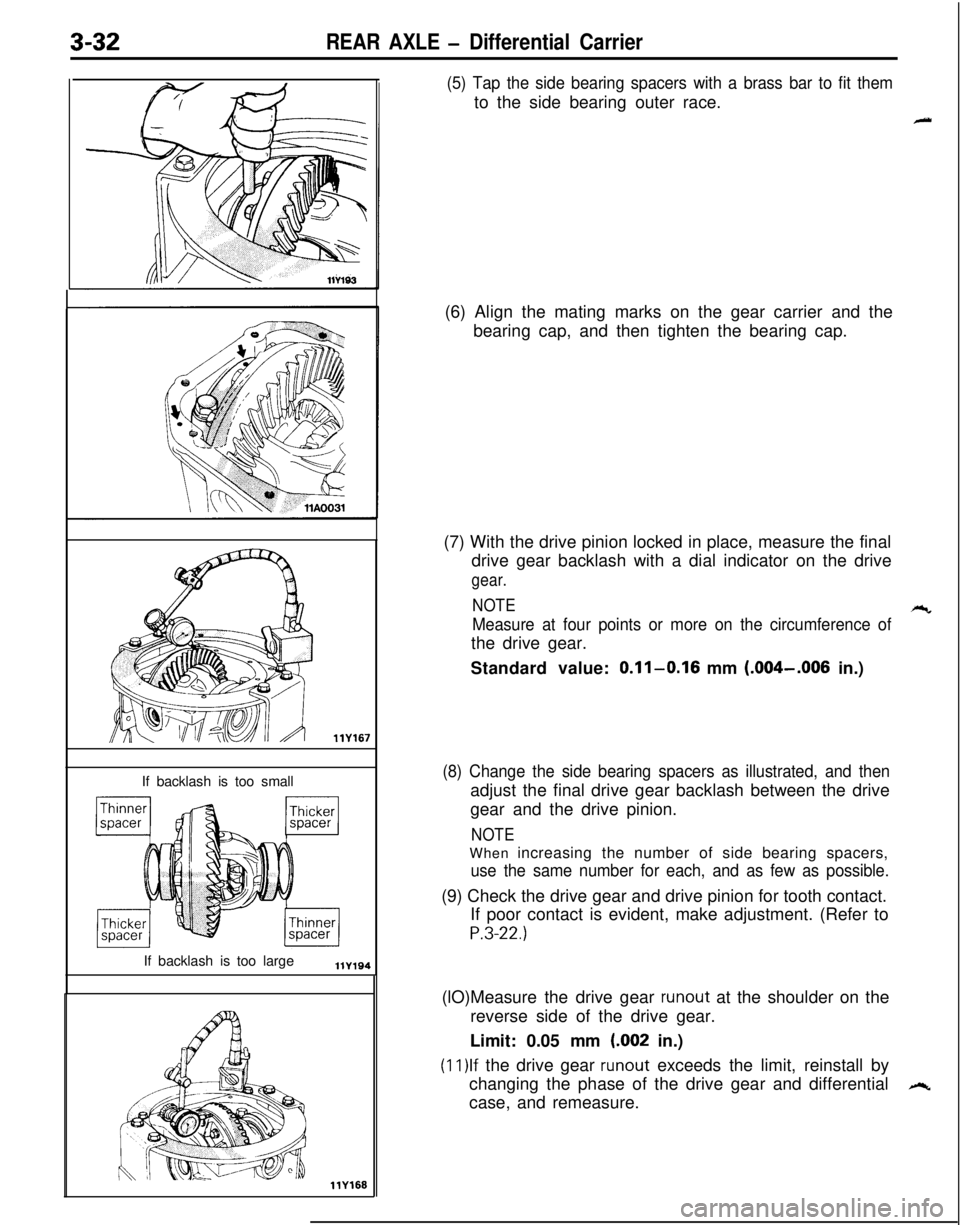

llY167If backlash is too small

If backlash is too large

llY168

(5) Tap the side bearing spacers with a brass bar to fit themto the side bearing outer race.

4(6) Align the mating marks on the gear carrier and the

bearing cap, and then tighten the bearing cap.

(7) With the drive pinion locked in place, measure the final

drive gear backlash with a dial indicator on the drive

gear.

NOTE

-cc

Measure at four points or more on the circumference ofthe drive gear.

Standard value:

0.11-0.16 mm (.004-.006 in.)

(8) Change the side bearing spacers as illustrated, and thenadjust the final drive gear backlash between the drive

gear and the drive pinion.

NOTEWhen increasing the number of side bearing spacers,

use the same number for each, and as few as possible.(9) Check the drive gear and drive pinion for tooth contact.

If poor contact is evident, make adjustment. (Refer to

P.3-22.)(lO)Measure the drive gear

runout at the shoulder on the

reverse side of the drive gear.

Limit: 0.05 mm

(.002 in.)

(ll)lf the drive gear runout exceeds the limit, reinstall by

changing the phase of the drive gear and differential

,+case, and remeasure.

Page 141 of 1216

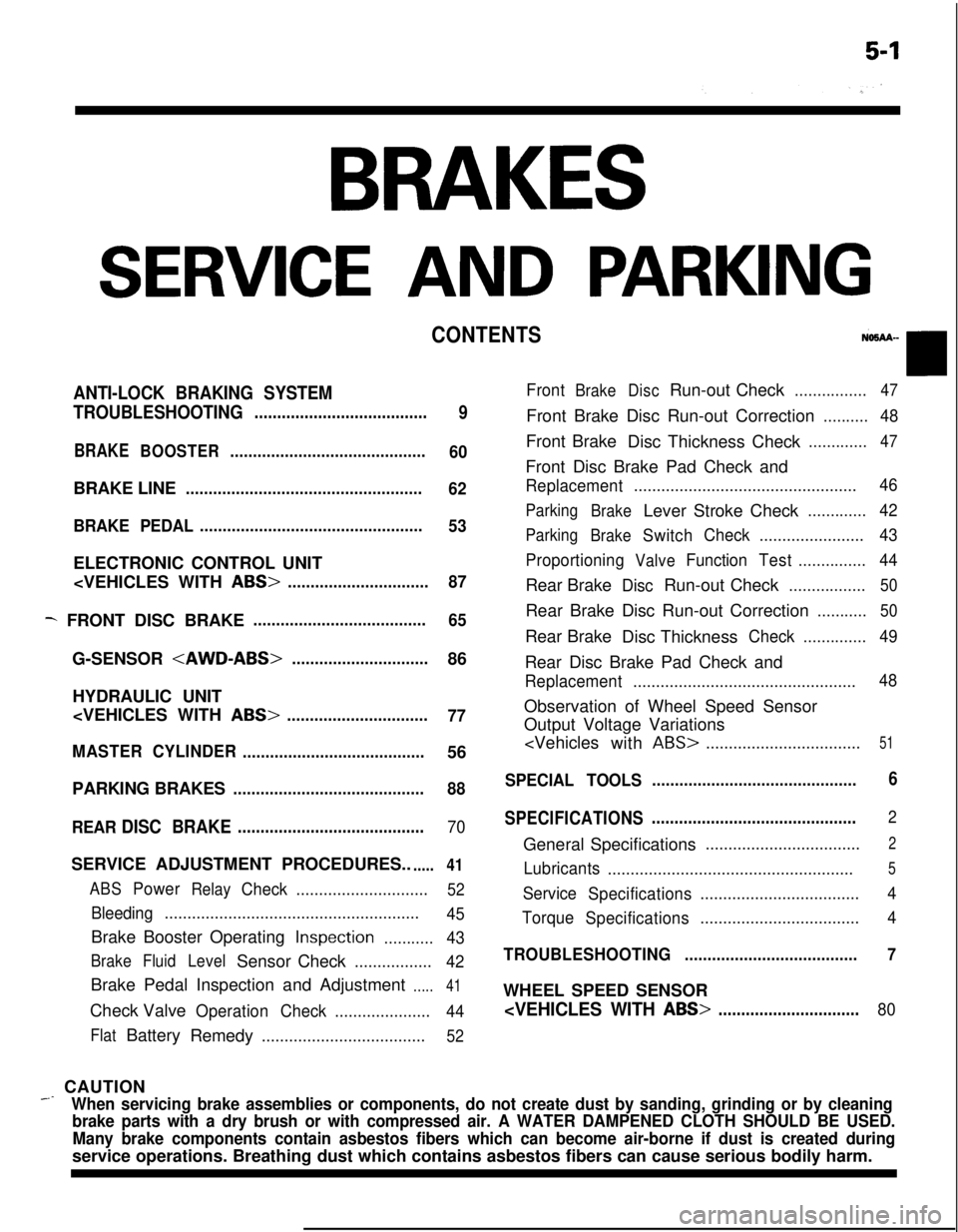

BRAKES

SERVICE AND PARKING

CONTENTS

ANTI-LOCK BRAKING SYSTEM

TROUBLESHOOTING

......................................

9

BRAKEBOOSTER...........................................

60BRAKE LINE

....................................................

62

BRAKE PEDAL.................................................

53ELECTRONIC CONTROL UNIT

- FRONT DISC BRAKE......................................

65G-SENSOR

HYDRAULIC UNIT

77

MASTERCYLINDER

........................................56

PARKING BRAKES

..........................................88

REAR

DISC BRAKE.........................................70SERVICE ADJUSTMENT PROCEDURES..

.....41

ABSPowerRelayCheck.............................52

Bleeding........................................................

45Brake Booster Operating

Inspection...........43

BrakeFluidLevelSensor Check.................

42Brake Pedal Inspection and Adjustment

.....41Check Valve

OperationCheck.....................

44

FlatBattery

Remedy....................................52

FrontBrakeDiscRun-out Check................47Front Brake Disc Run-out Correction

..........48Front Brake

Disc Thickness Check

.............47Front Disc Brake Pad Check and

Replacement.................................................46

Parking

BrakeLever Stroke Check.............42

Parking

BrakeSwitchCheck.......................43

Proportioning

ValveFunctionTest...............44Rear Brake

DiscRun-out Check.................50Rear Brake Disc Run-out Correction

...........50Rear Brake

Disc Thickness

Check..............49Rear Disc Brake Pad Check and

Replacement.................................................48Observation of Wheel Speed Sensor

Output Voltage Variations

ABS>..................................51

SPECIAL TOOLS.............................................6

SPECIFICATIONS.............................................

2General Specifications

..................................2

Lubricants

......................................................5

Service

Specifications...................................4

Torque

Specifications...................................4

TROUBLESHOOTING......................................7WHEEL SPEED SENSOR

_ CAUTION

When servicing brake assemblies or components, do not create dust by sanding, grinding or by cleaning

brake parts with a dry brush or with compressed air. A WATER DAMPENED CLOTH SHOULD BE USED.

Many brake components contain asbestos fibers which can become air-borne if dust is created duringservice operations. Breathing dust which contains asbestos fibers can cause serious bodily harm.

Page 145 of 1216

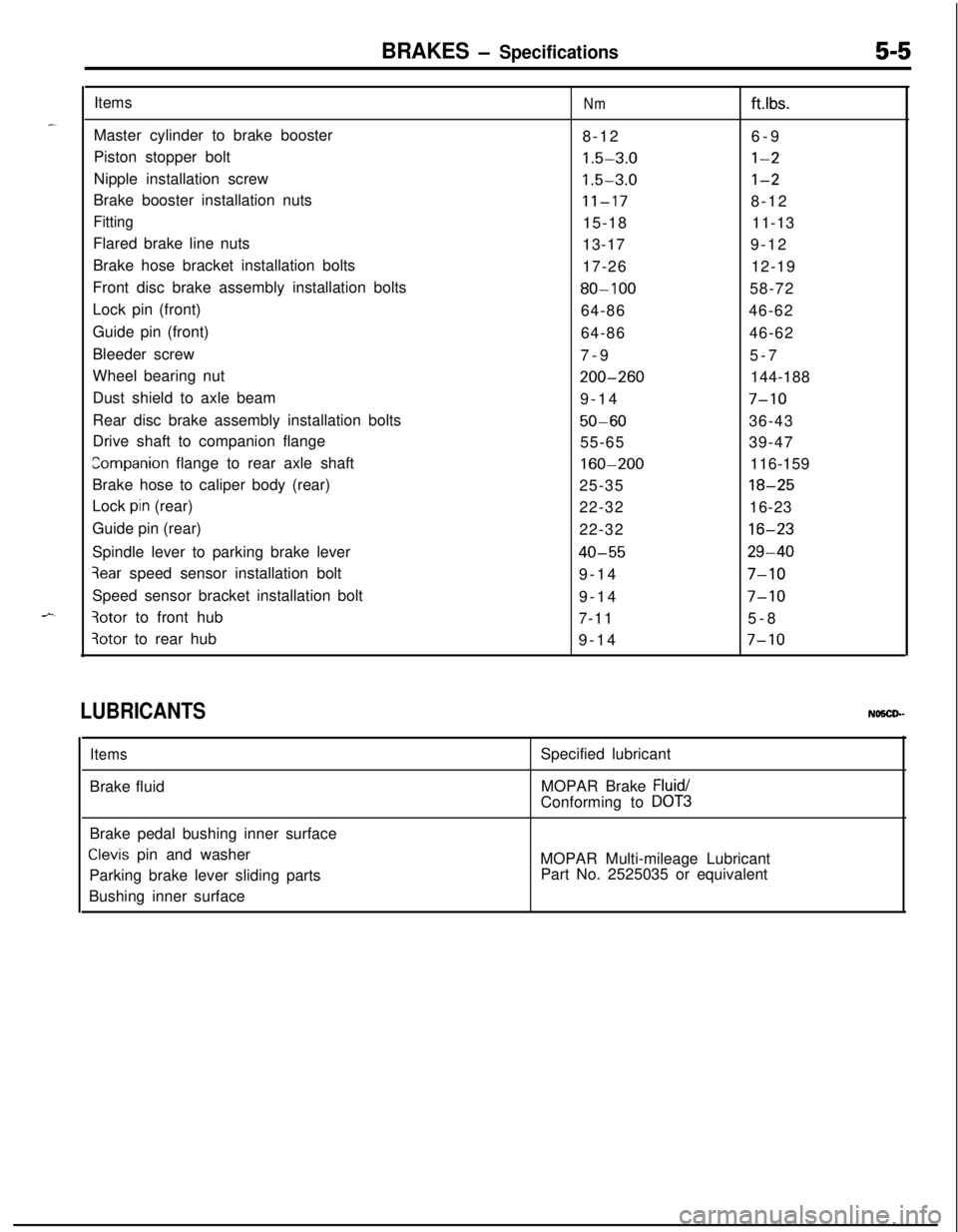

BRAKES - Specifications5-5Items

Nmftlbs.Master cylinder to brake booster

8-126-9

Piston stopper bolt

1.5-3.0l-2Nipple installation screw

1.5-3.0l-2Brake booster installation nuts

11-178-12

Fitting15-1811-13

Flared brake line nuts

13-179-12

Brake hose bracket installation bolts

17-2612-19

Front disc brake assembly installation bolts

80-10058-72

Lock pin (front)

64-8646-62

Guide pin (front)

64-8646-62

Bleeder screw

7-95-7

Wheel bearing nut

200-260144-188

Dust shield to axle beam

9-14

7-10Rear disc brake assembly installation bolts

50-6036-43

Drive shaft to companion flange

55-6539-47

companion flange to rear axle shaft160-200116-159

Brake hose to caliper body (rear)

25-35

18-25Lock

pin (rear)

22-3216-23

Guide pin (rear)

22-32

16-23Spindle lever to parking brake lever

40-5529-40

3ear speed sensor installation bolt

9-147-10Speed sensor bracket installation bolt

9-14

7-10

3otor to front hub

7-115-8

3otor to rear hub

9-147-10

LUBRICANTSNO5CP-

ItemsBrake fluidSpecified lubricant

MOPAR Brake

Fluid/Conforming to

DOT3Brake pedal bushing inner surface

Clevis pin and washer

Parking brake lever sliding parts

Bushing inner surfaceMOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent