MITSUBISHI ECLIPSE 1991 Service Manual

ECLIPSE 1991

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57104/w960_57104-0.png

MITSUBISHI ECLIPSE 1991 Service Manual

Trending: horn, brakes, air conditioning, check engine, lock, tightening sequence, service interval

Page 821 of 1216

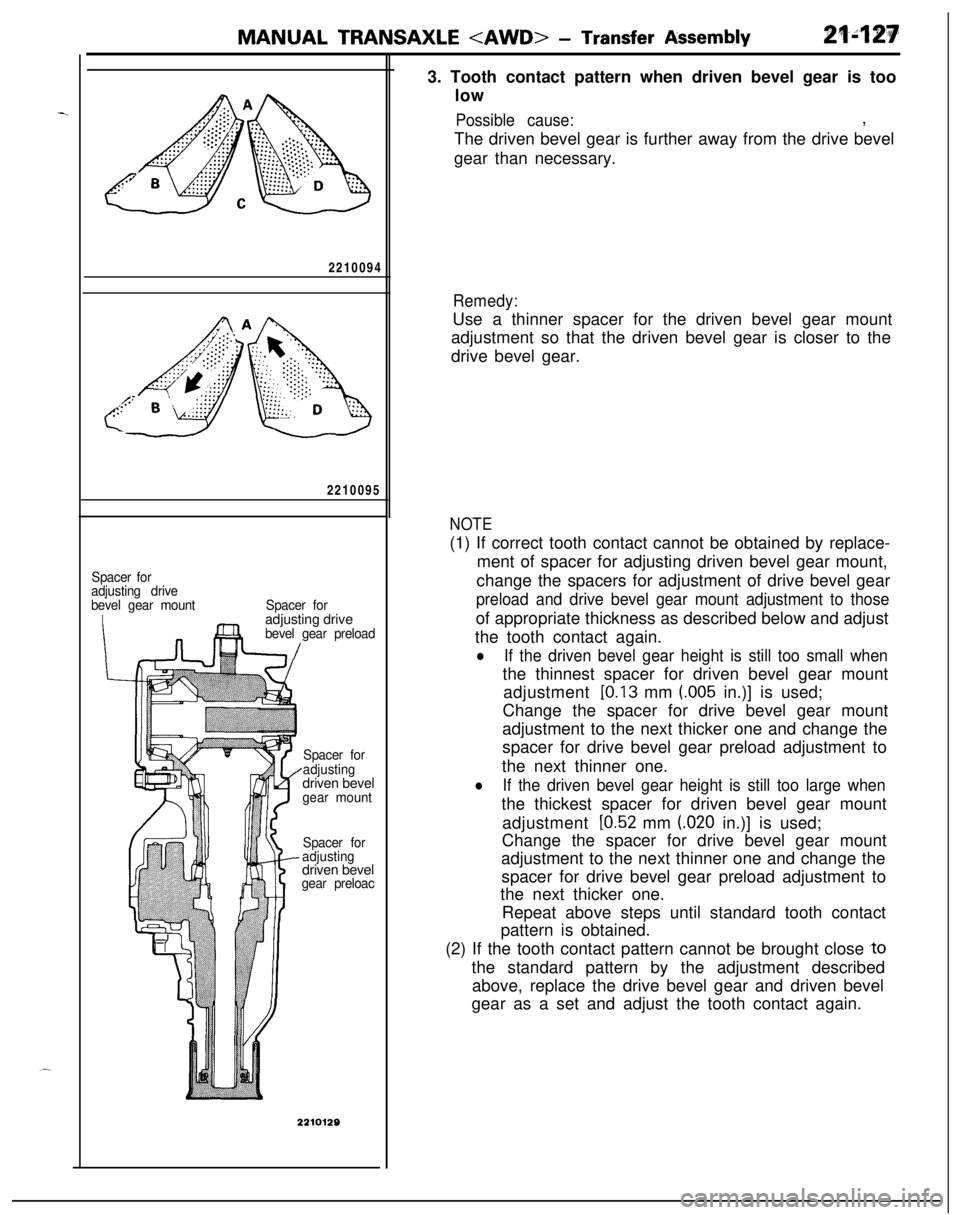

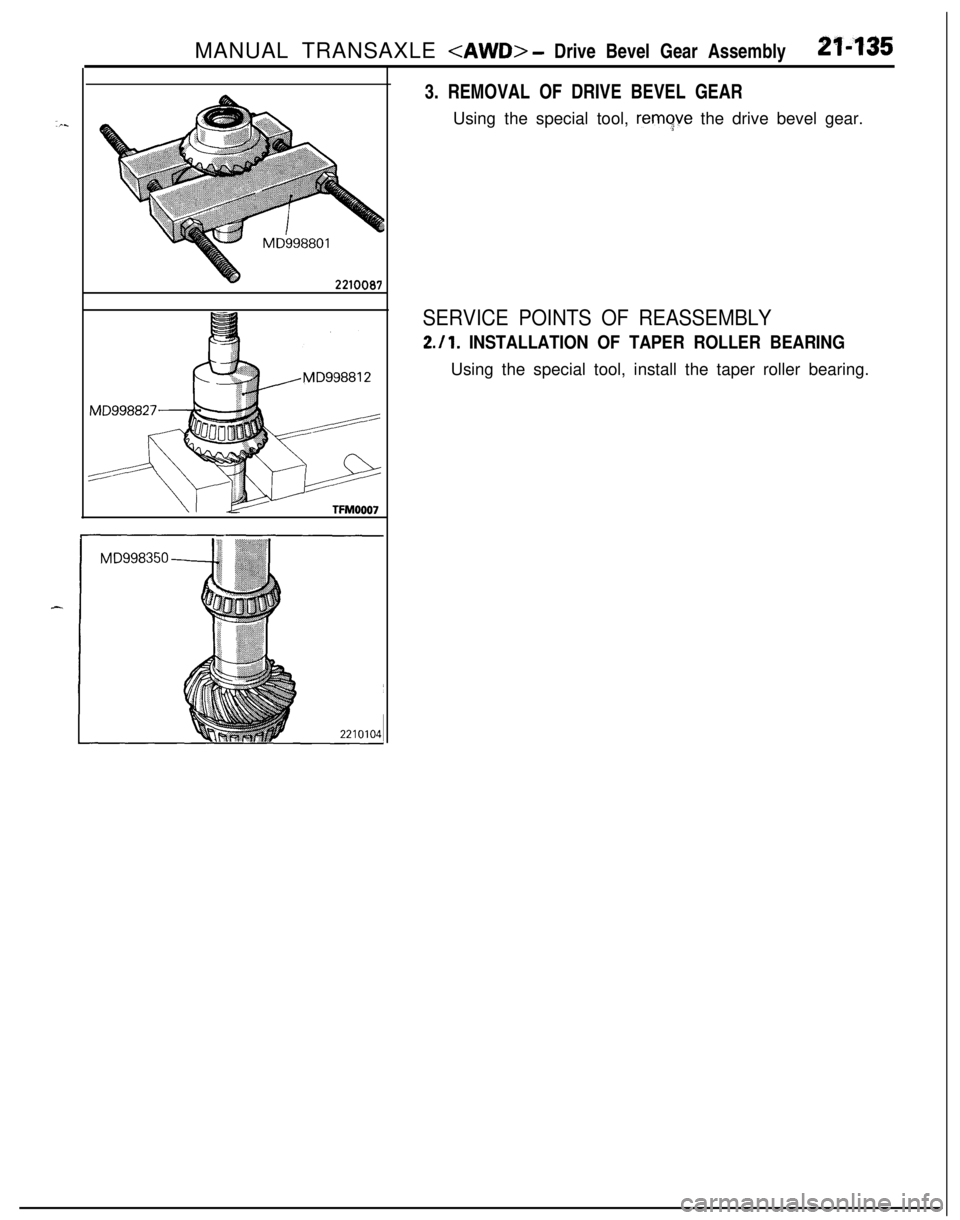

MANUAL TRANSAXLE - Transfer Assembly2210094

2210095

Spacer for

adjusting drive

bevel gear mount

ISpacer foradjusting drive

bevel gear preload

Spacer for

adjustingdriven bevel

gear mount

Spacer for

adjustingdriven bevel

gear preloac3. Tooth contact pattern when driven bevel gear is too

low

Possible cause:,

The driven bevel gear is further away from the drive bevel

gear than necessary.

Remedy:Use a thinner spacer for the driven bevel gear mount

adjustment so that the driven bevel gear is closer to the

drive bevel gear.

NOTE(1) If correct tooth contact cannot be obtained by replace-

ment of spacer for adjusting driven bevel gear mount,

change the spacers for adjustment of drive bevel gear

preload and drive bevel gear mount adjustment to thoseof appropriate thickness as described below and adjust

the tooth contact again.

lIf the driven bevel gear height is still too small whenthe thinnest spacer for driven bevel gear mount

adjustment

[0.13 mm (.005 in.)] is used;

Change the spacer for drive bevel gear mount

adjustment to the next thicker one and change the

spacer for drive bevel gear preload adjustment to

the next thinner one.

lIf the driven bevel gear height is still too large whenthe thickest spacer for driven bevel gear mount

adjustment

[0.52 mm (020 in.)] is used;

Change the spacer for drive bevel gear mount

adjustment to the next thinner one and change the

spacer for drive bevel gear preload adjustment to

the next thicker one.

Repeat above steps until standard tooth contact

pattern is obtained.

(2) If the tooth contact pattern cannot be brought close

,tothe standard pattern by the adjustment described

above, replace the drive bevel gear and driven bevel

gear as a set and adjust the tooth contact again.

Page 822 of 1216

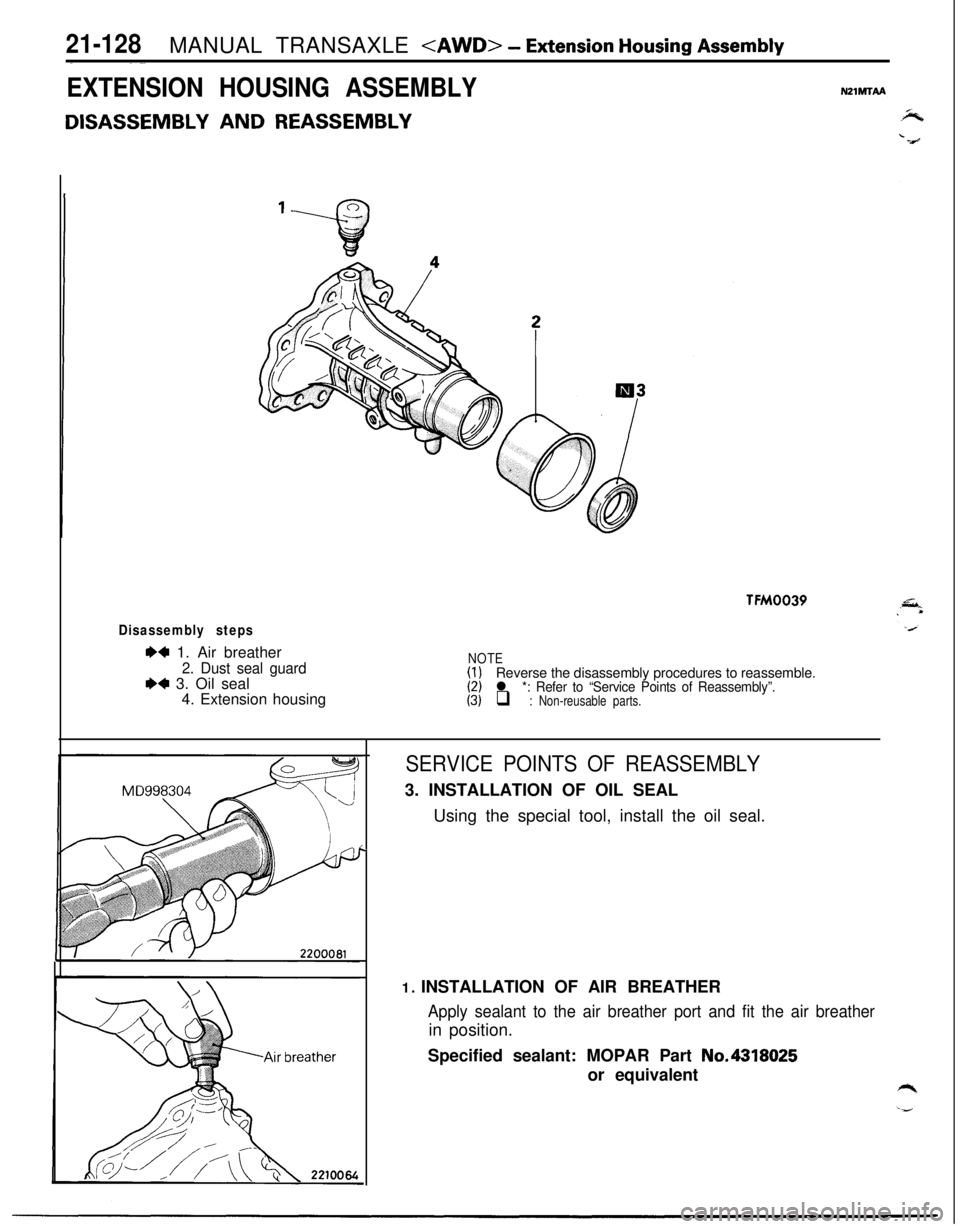

21-128MANUAL TRANSAXLE - Extension Housing Assembly

EXTENSION HOUSING ASSEMBLYN21MTAA

DISASSEMBLY AND REASSEMBLY

TFM0039

Disassembly steps

6+ 1. Air breather

2. Dust seal guardI)+ 3. Oil seal

4. Extension housing

NOTE(I)(2)Reverse the disassembly procedures to reassemble.(3)l *: Refer to “Service Points of Reassembly”.q : Non-reusable parts.

.

SERVICE POINTS OF REASSEMBLY3. INSTALLATION OF OIL SEAL

Using the special tool, install the oil seal.

1. INSTALLATION OF AIR BREATHER

Apply sealant to the air breather port and fit the air breatherin position.

Specified sealant: MOPAR Part No.4318025

or equivalent

Page 823 of 1216

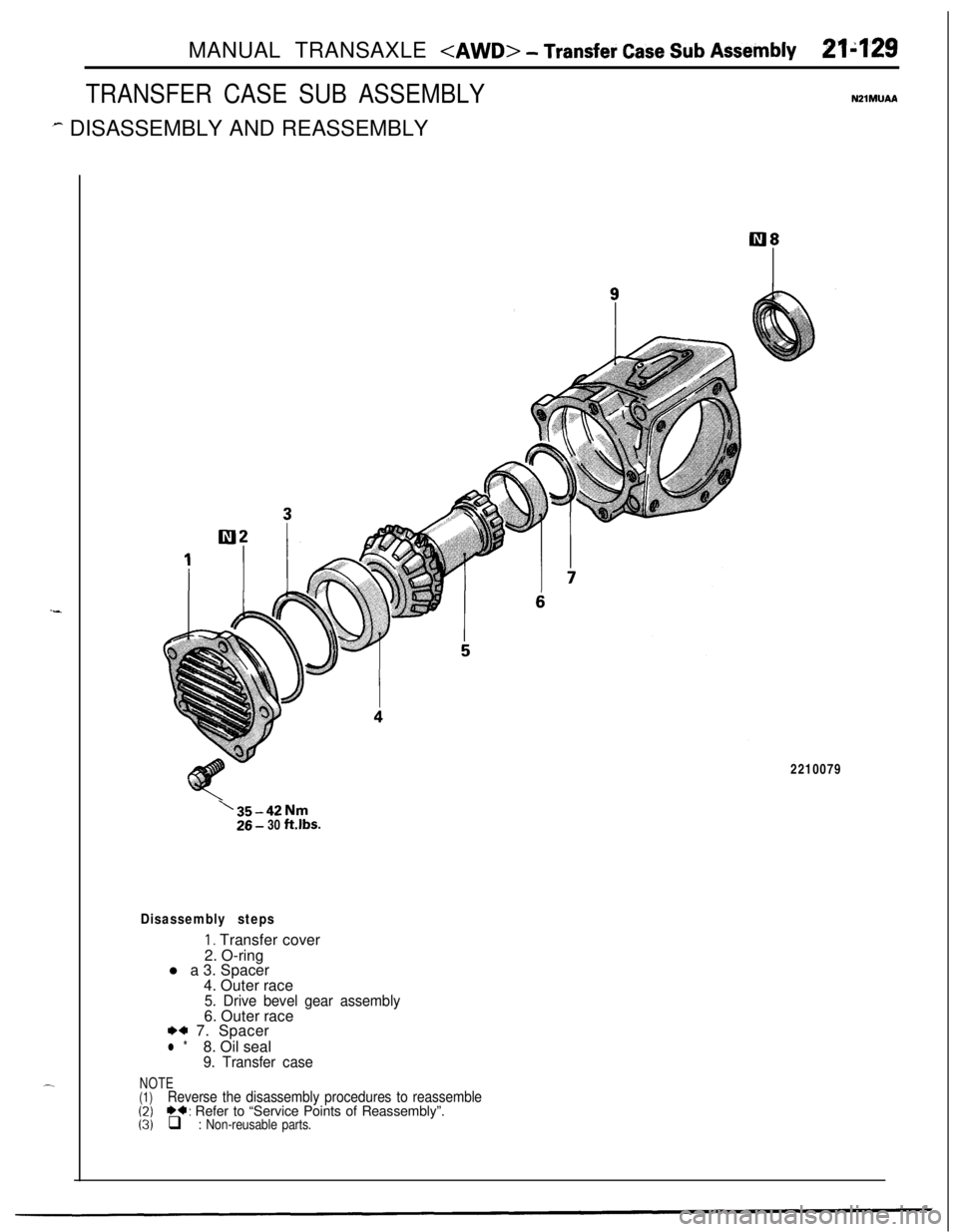

MANUAL TRANSAXLE - Transfer Case Sub Assembly21;129

TRANSFER CASE SUB ASSEMBLYN21MUAA

- DISASSEMBLY AND REASSEMBLY

I-

-2210079

‘35-42Nm26 - 30 ft.lbs.

Disassembly steps

I. Transfer cover

2. O-ring

l a 3. Spacer

4. Outer race

5. Drive bevel gear assembly6. Outer race

*a 7. Spacer

l *8. Oil seal

9. Transfer case

NOTE(1)Reverse the disassembly procedures to reassemble(2)*a: Refer to “Service Points of Reassembly”.(3)q : Non-reusable parts.

Page 824 of 1216

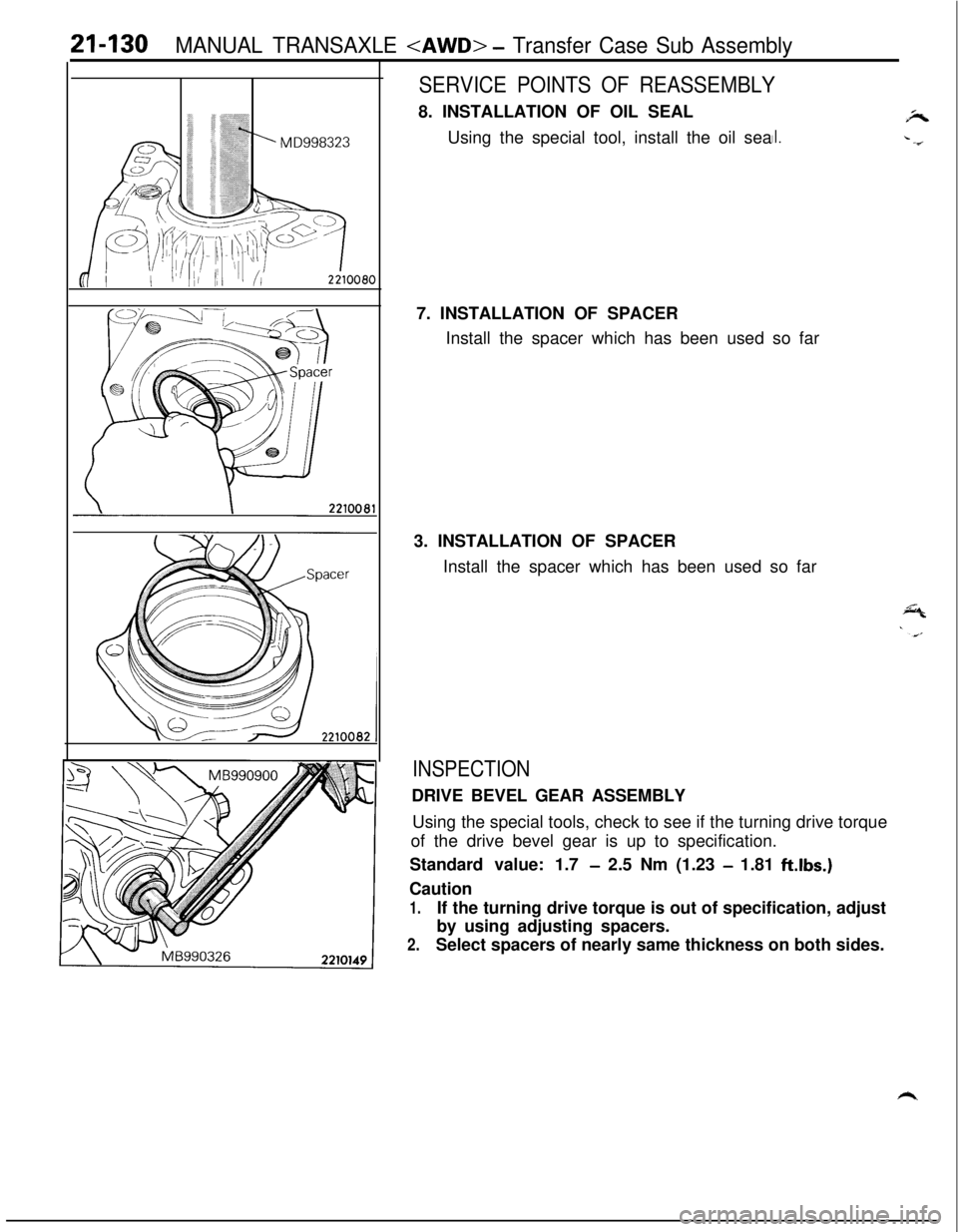

21-130MANUAL TRANSAXLE - Transfer Case Sub Assembly

SERVICE POINTS OF REASSEMBLY8. INSTALLATION OF OIL SEAL

Using the special tool, install the oil sea

jP,

II..-67. INSTALLATION OF SPACER

Install the spacer which has been used so far

3. INSTALLATION OF SPACER

Install the spacer which has been used so far

INSPECTIONDRIVE BEVEL GEAR ASSEMBLY

Using the special tools, check to see if the turning drive torque

of the drive bevel gear is up to specification.

Standard value: 1.7

- 2.5 Nm (1.23 - 1.81 ft.lbs.)Caution

1.If the turning drive torque is out of specification, adjust

by using adjusting spacers.

2.Select spacers of nearly same thickness on both sides.

h

Page 825 of 1216

MANUAL TRANSAXLE - Transfer Case Adapter Sub Assembly

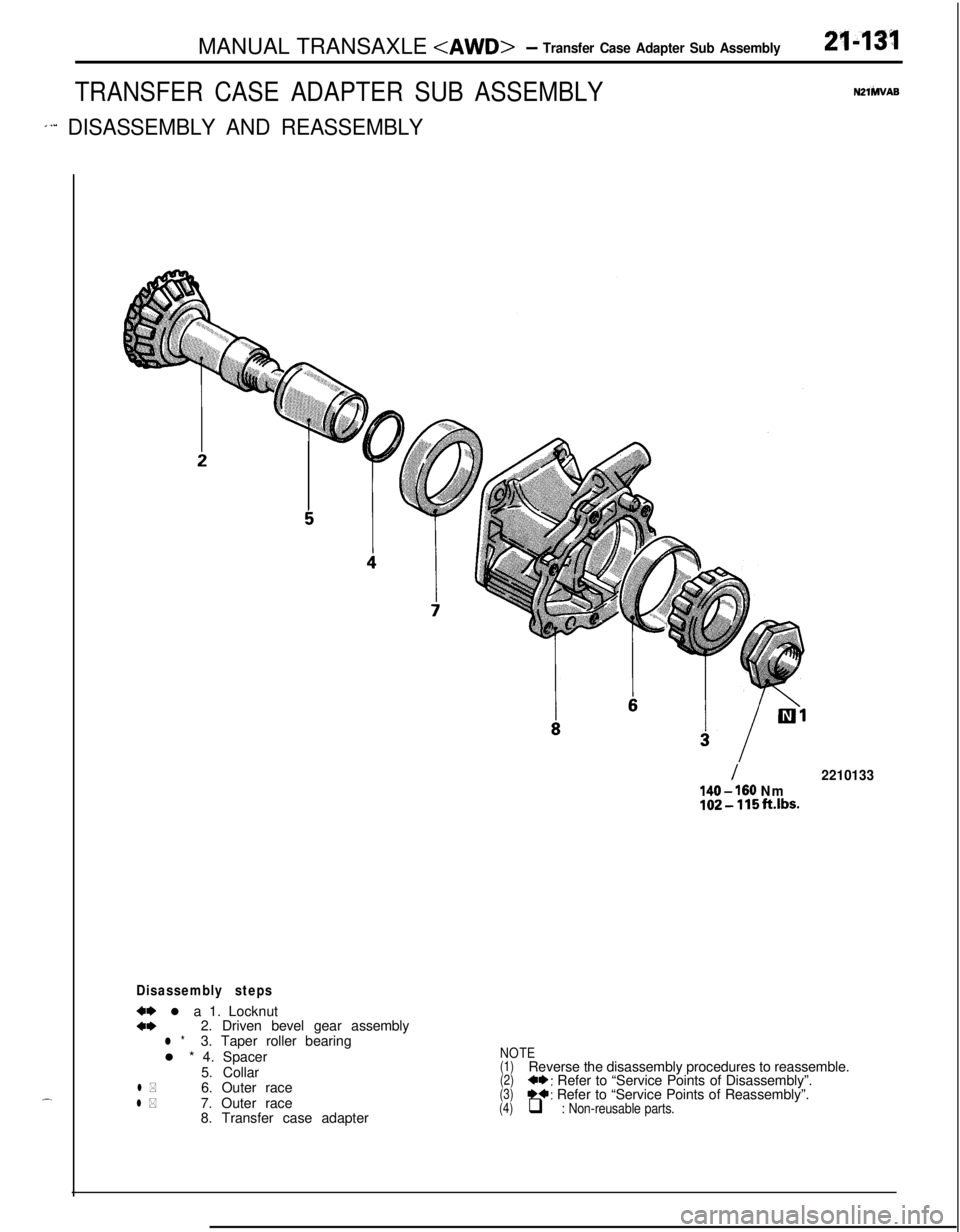

TRANSFER CASE ADAPTER SUB ASSEMBLY

1’” DISASSEMBLY AND REASSEMBLY

2143’1

N2lhlVAS.-

Disassembly steps

w l a 1. Locknuta*2. Driven bevel gear assemblyl *3. Taper roller bearing

l * 4. Spacer

5. Collar

l *6. Outer racel *7. Outer race

8. Transfer case adapter

I2210133

140 - 160 Nm102-115ft.lbs.

NOTE(1)Reverse the disassembly procedures to reassemble.(2)+*: Refer to “Service Points of Disassembly”.(3)*+: Refer to “Service Points of Reassembly”.(4)q : Non-reusable parts.

Page 826 of 1216

21-132MANUAL TRANSAXLE - Transfer Case Adapter Sub Assembly

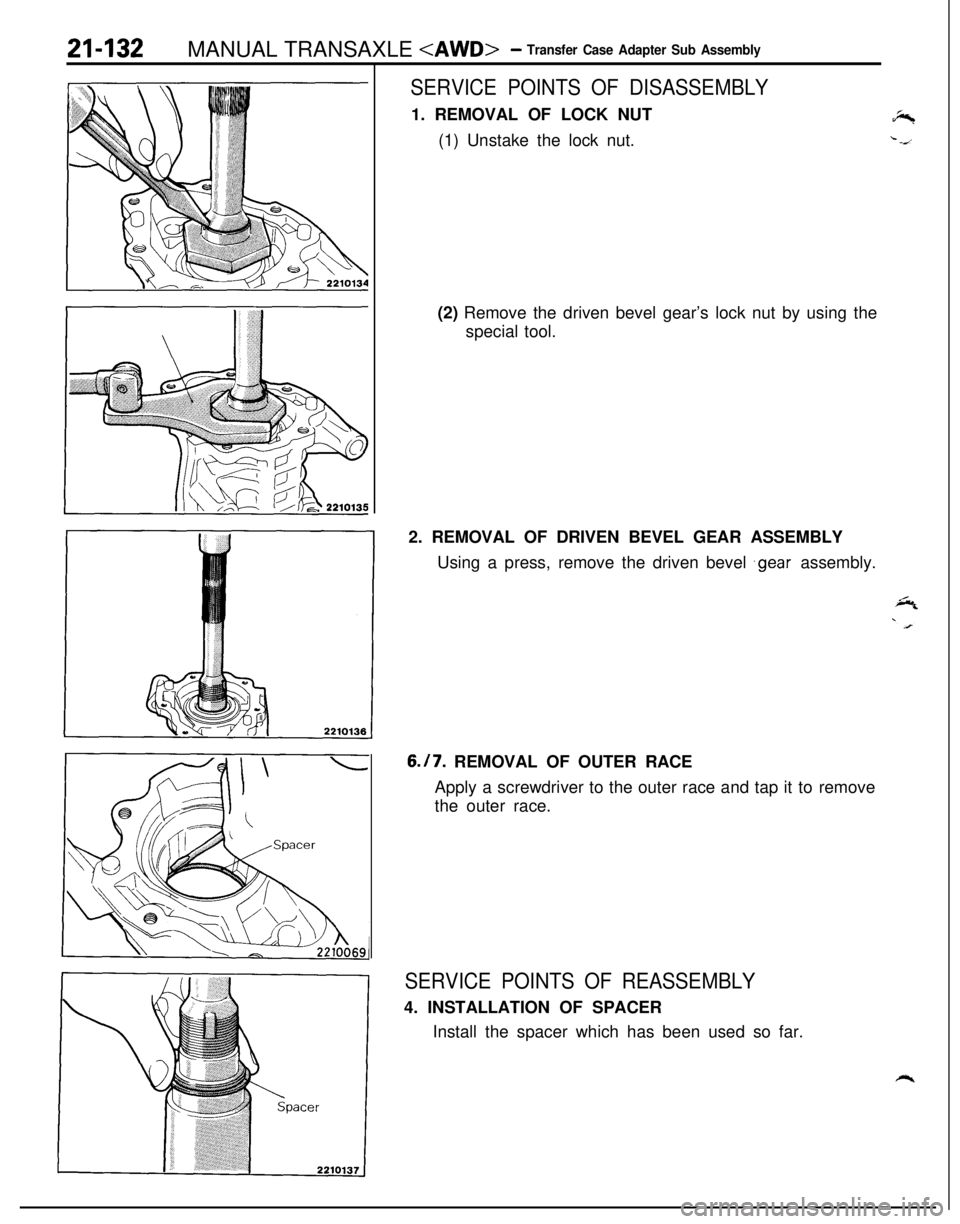

SERVICE POINTS OF DISASSEMBLY1. REMOVAL OF LOCK NUT

(1) Unstake the lock nut.

(2) Remove the driven bevel gear’s lock nut by using the

special tool.

2. REMOVAL OF DRIVEN BEVEL GEAR ASSEMBLY

Using a press, remove the driven bevel

‘gear assembly.6.17. REMOVAL OF OUTER RACE

Apply a screwdriver to the outer race and tap it to remove

the outer race.

SERVICE POINTS OF REASSEMBLY4. INSTALLATION OF SPACER

Install the spacer which has been used so far.

Page 827 of 1216

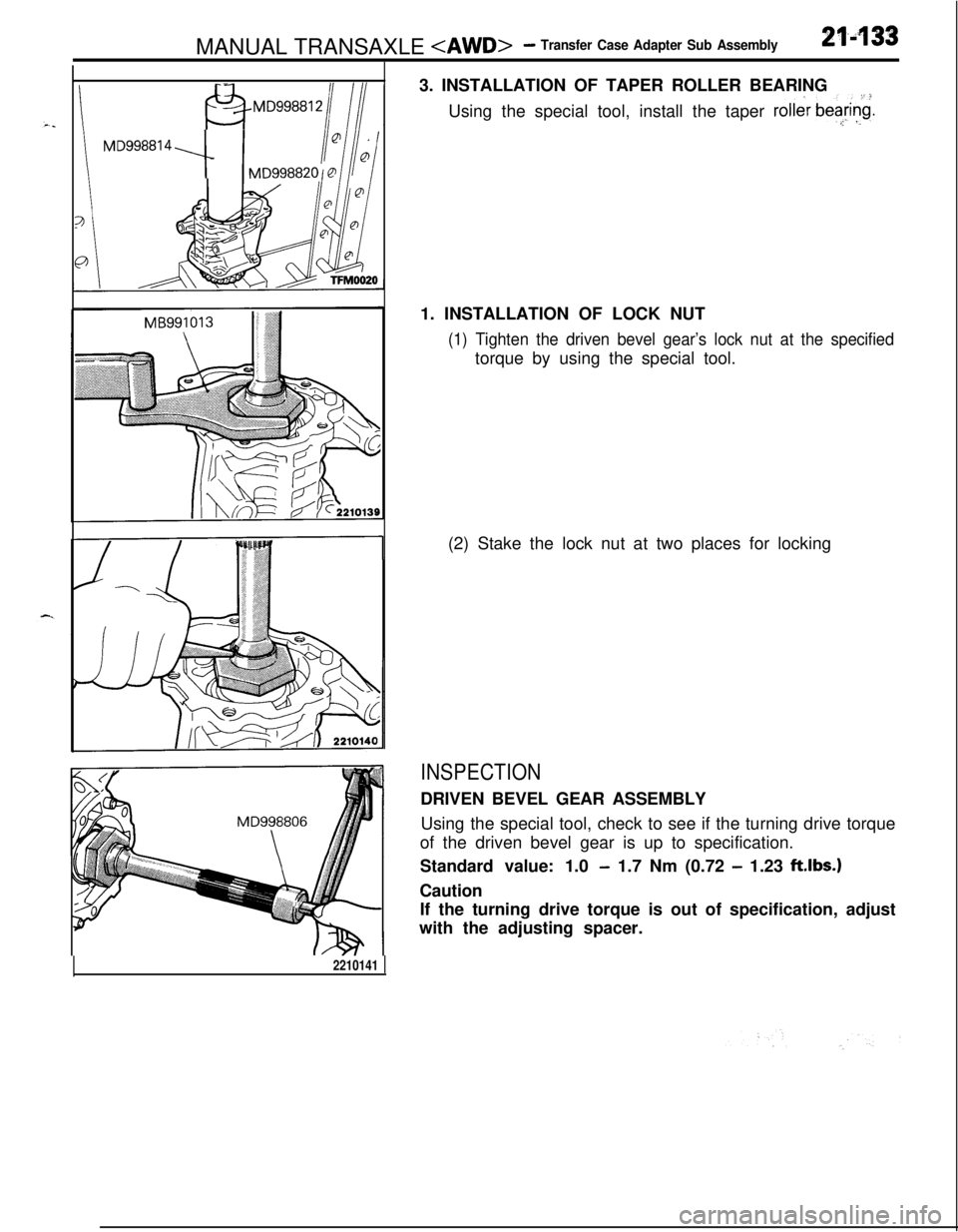

MANUAL TRANSAXLE - Transfer Case Adapter Sub Assemblyml33

\

BMD9988121 11

MDgg881 4 --I-3. INSTALLATION OF TAPER ROLLER BEARING

Using the special tool, install the taper

roller bea&.z, ‘.1. INSTALLATION OF LOCK NUT

(1) Tighten the driven bevel gear’s lock nut at the specifiedtorque by using the special tool.

(2) Stake the lock nut at two places for locking

INSPECTIONDRIVEN BEVEL GEAR ASSEMBLY

Using the special tool, check to see if the turning drive torque

of the driven bevel gear is up to specification.

Standard value: 1.0

- 1.7 Nm (0.72 - 1.23 ftlbs.)Caution

If the turning drive torque is out of specification, adjust

with the adjusting spacer.

2210141 1

Page 828 of 1216

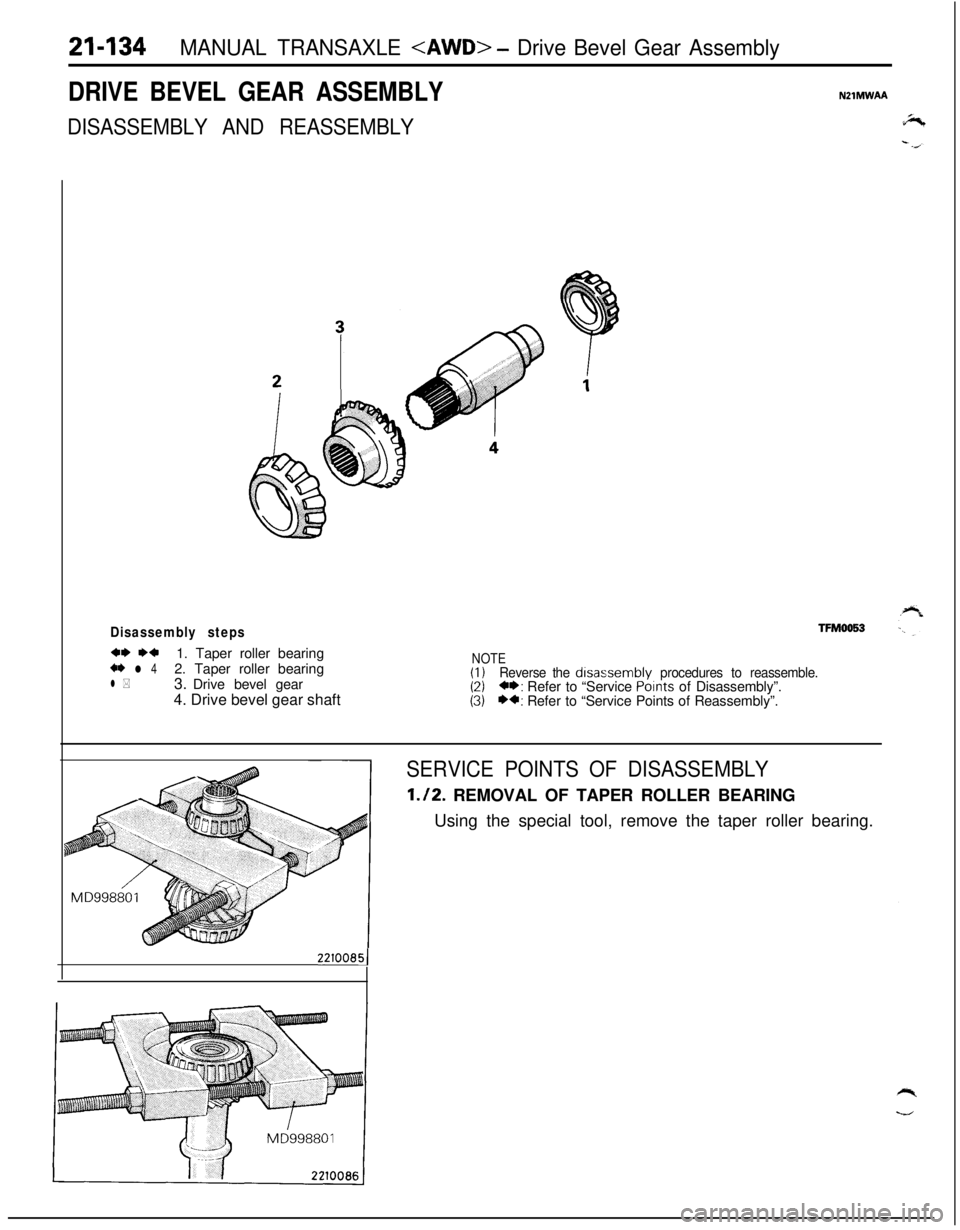

21-134MANUAL TRANSAXLE - Drive Bevel Gear Assembly

DRIVE BEVEL GEAR ASSEMBLYNZlMWAA

DISASSEMBLY AND REASSEMBLY

Disassembly steps

4~ WI1. Taper roller bearing+* l 42. Taper roller bearing

3. Drive bevel gearl *4. Drive bevel gear shaft

TFM0053

NOTE(I)Reverse the disassembly procedures to reassemble.(2)**: Refer to “Service Points of Disassembly”.(3)*a: Refer to “Service Points of Reassembly”.

22100851

SERVICE POINTS OF DISASSEMBLY

1.12. REMOVAL OF TAPER ROLLER BEARING

Using the special tool, remove the taper roller bearing.

Page 829 of 1216

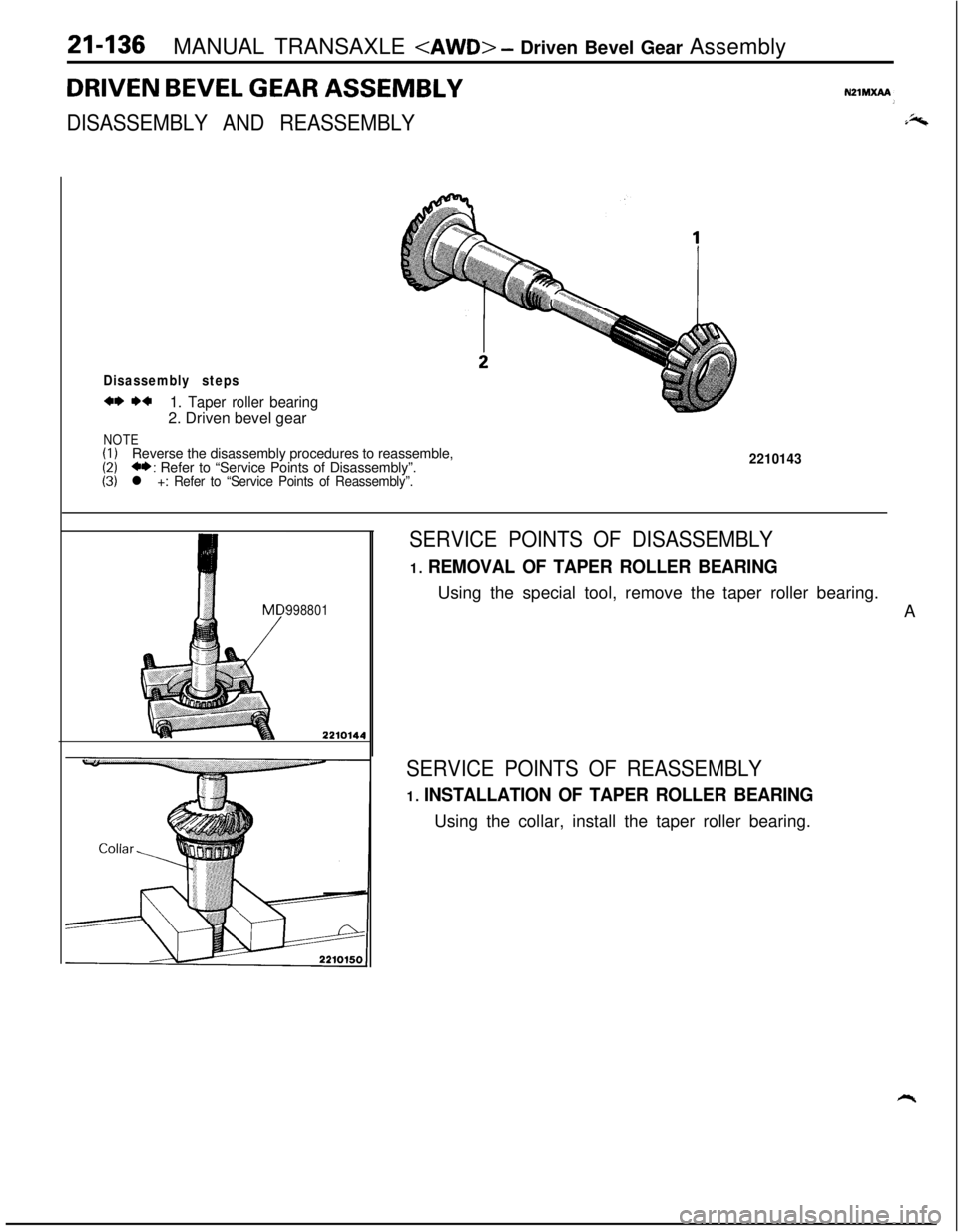

MANUAL TRANSAXLE - Drive Bevel Gear Assembly2f-135

v22100873. REMOVAL OF DRIVE BEVEL GEAR

Using the special tool,

remgve the drive bevel gear.

SERVICE POINTS OF REASSEMBLY

2.11. INSTALLATION OF TAPER ROLLER BEARINGUsing the special tool, install the taper roller bearing.

Page 830 of 1216

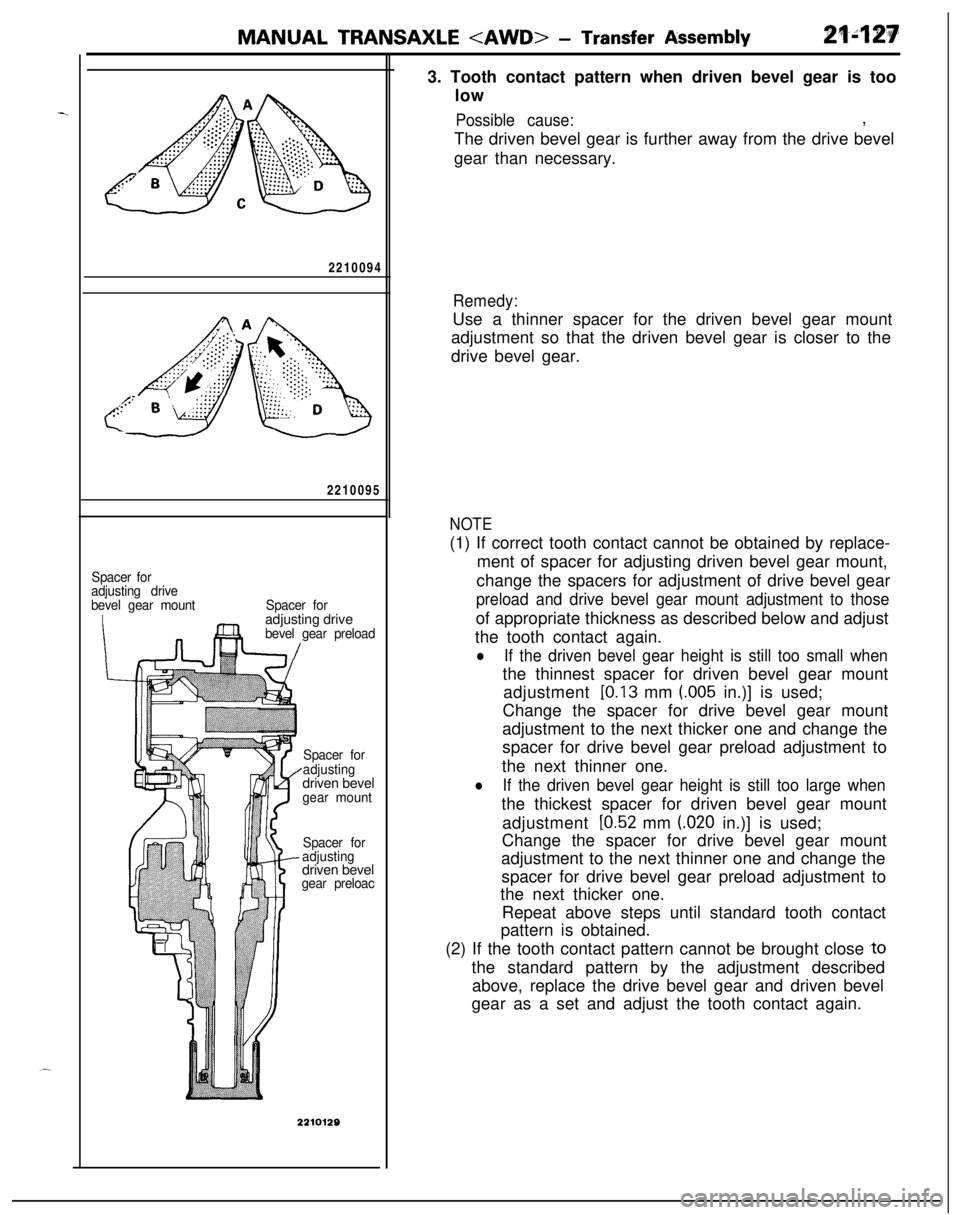

21-136MANUAL TRANSAXLE - Driven Bevel Gear Assembly

DRIVEN BEVEL GEAR ASSEMBLY

DISASSEMBLY AND REASSEMBLY

Disassembly steps

a* I)*1. Taper roller bearing2. Driven bevel gear

NOTE(I)(2)Reverse the disassembly procedures to reassemble,(3)+*: Refer to “Service Points of Disassembly”.l +: Refer to “Service Points of Reassembly”.

2210143

9988012210144

SERVICE POINTS OF DISASSEMBLY

1. REMOVAL OF TAPER ROLLER BEARINGUsing the special tool, remove the taper roller bearing.

A

SERVICE POINTS OF REASSEMBLY

1. INSTALLATION OF TAPER ROLLER BEARINGUsing the collar, install the taper roller bearing.

Trending: fuel fill door release, engine, wiring, height, coolant level, emergency towing, lights