MITSUBISHI ECLIPSE 1991 Service Manual

ECLIPSE 1991

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57104/w960_57104-0.png

MITSUBISHI ECLIPSE 1991 Service Manual

Trending: wipers, alternator belt, check oil, open hood, turn signal, oil, recommended oil

Page 861 of 1216

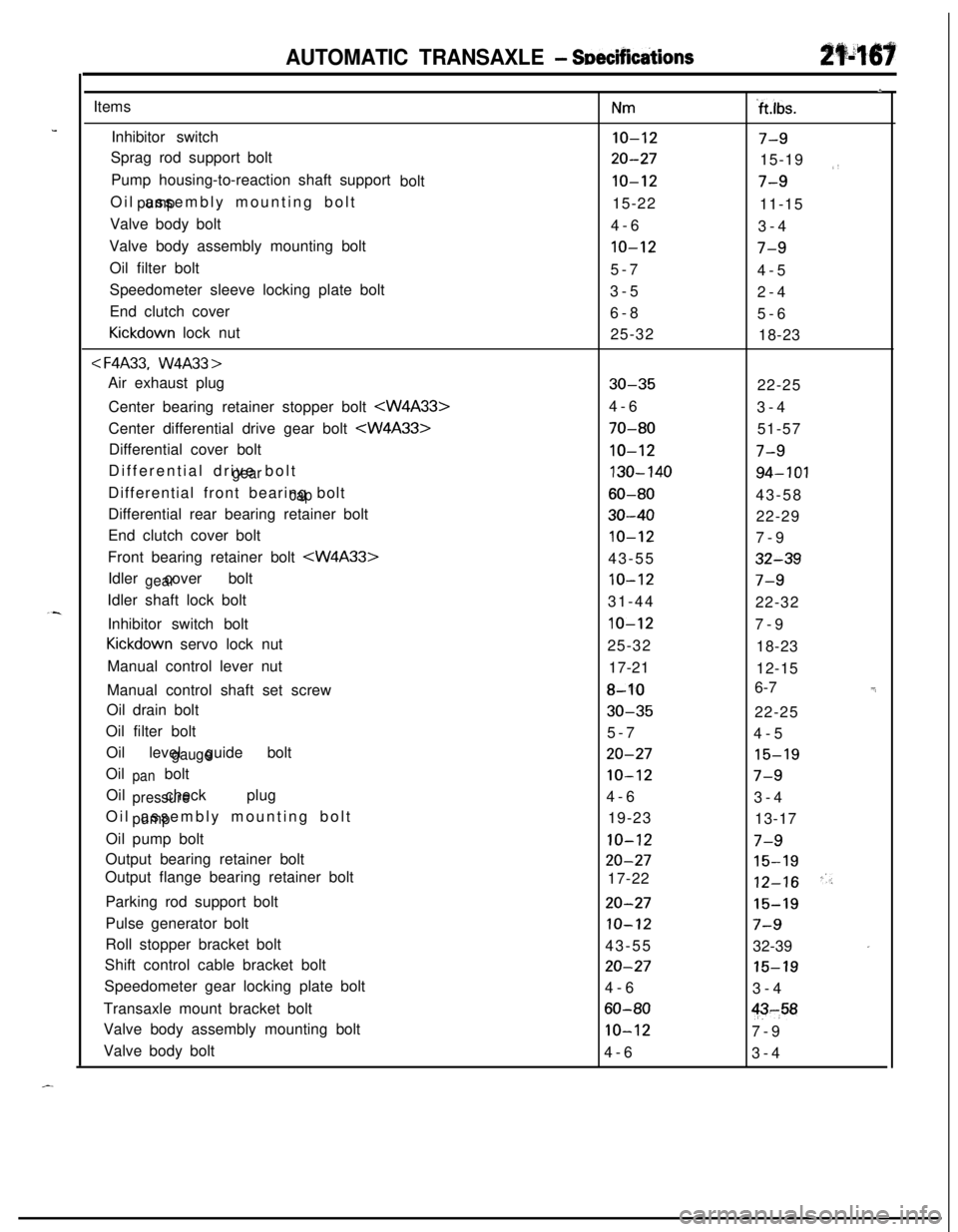

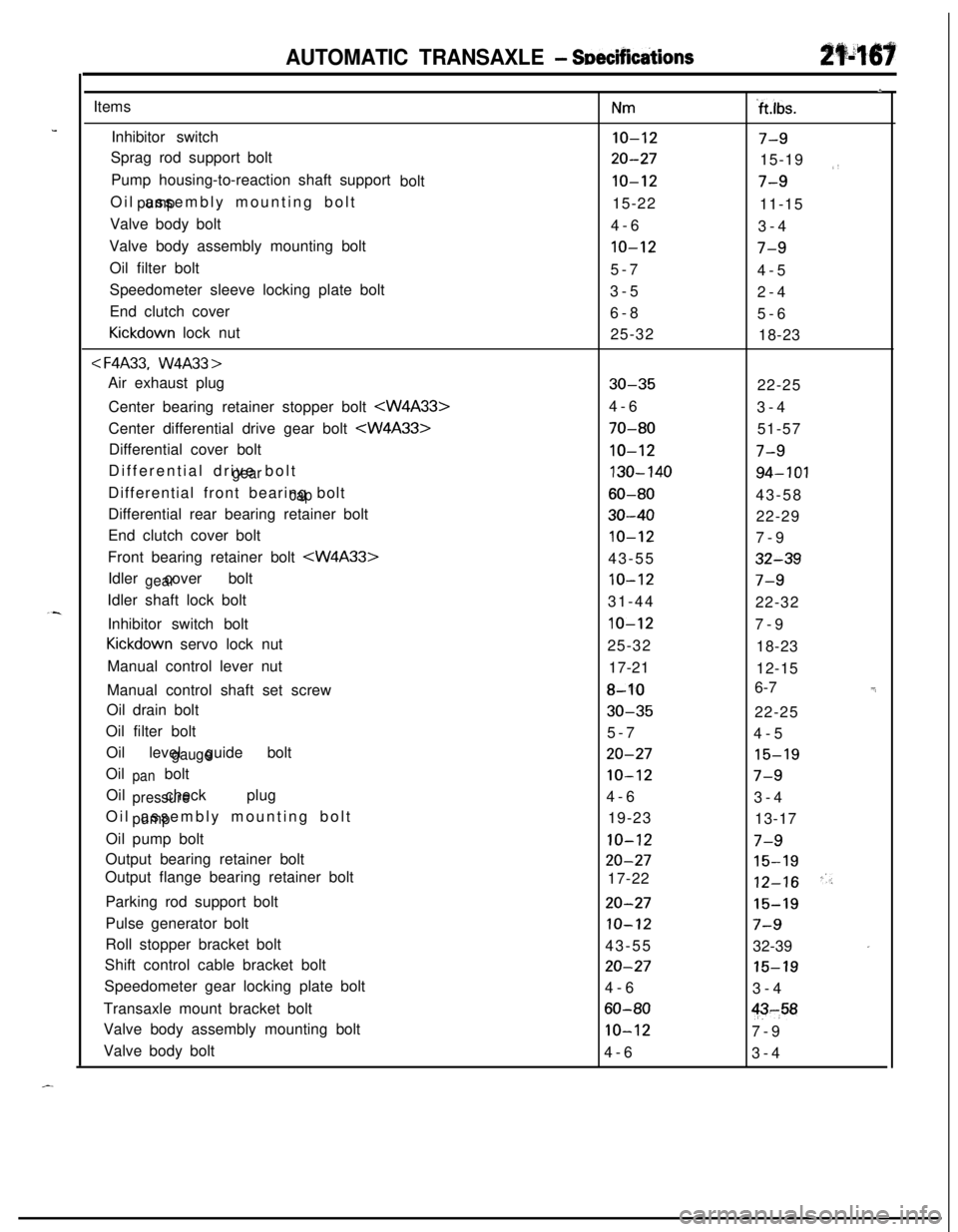

AUTOMATIC TRANSAXLE - SeecificdionsItems

Inhibitor switch

Sprag rod support bolt

Pump housing-to-reaction shaft support

bolt

Oil assembly mounting bolt

pumpValve body bolt

Valve body assembly mounting bolt

Oil filter bolt

Speedometer sleeve locking plate bolt

End clutch cover

Kickdown lock nut

< F4A33.W4A33 >Air exhaust plug

Center bearing retainer stopper bolt

Center differential drive gear bolt

Differential cover bolt

Differential drive bolt

gearDifferential front bearing bolt

capDifferential rear bearing retainer bolt

End clutch cover bolt

Front bearing retainer bolt

Idler cover bolt

gearIdler shaft lock bolt

Inhibitor switch bolt

Kickdown servo lock nut

Manual control lever nut

Manual control shaft set screw

Oil drain bolt

Oil filter bolt

Oil level guide bolt

gaugeOil bolt

panOil check plug

pressureOil assembly mounting bolt

pumpOil pump bolt

Output bearing retainer bolt

Output flange bearing retainer bolt

Nm

IO-12

20-27

10-1215-22

4-6

10-125-7

3-5

6-8

25-32

30-354-6

70-80

10-12

130-140

60-80

30-40

10-1243-55

10-1231-44

IO-1225-32

17-21

8-10

30-355-7

20-27

10-124-6

19-23

10-12

20-2717-22

,I

‘ft.lbs.

7-915-19

,,

7-911-15

3-4

7-94-5

2-4

5-6

18-23

22-25

3-4

51-57

7-9

94-10143-58

22-29

7-9

32-39

7-922-32

7-9

18-23

12-15

6-7

-_22-25

4-5

15-19

7-93-4

13-17

7-9

15-19

12-16"/Parking rod support bolt

20-2715-19Pulse generator bolt

IO-127-9Roll stopper bracket bolt

43-55

32-39

'Shift control cable bracket bolt

20-2715-19Speedometer gear locking plate bolt

4-6

3-4

Transaxle mount bracket bolt

60-80$-,58Valve body assembly mounting bolt

10-127-9

Valve body bolt

4-6

3-4

-.

Page 862 of 1216

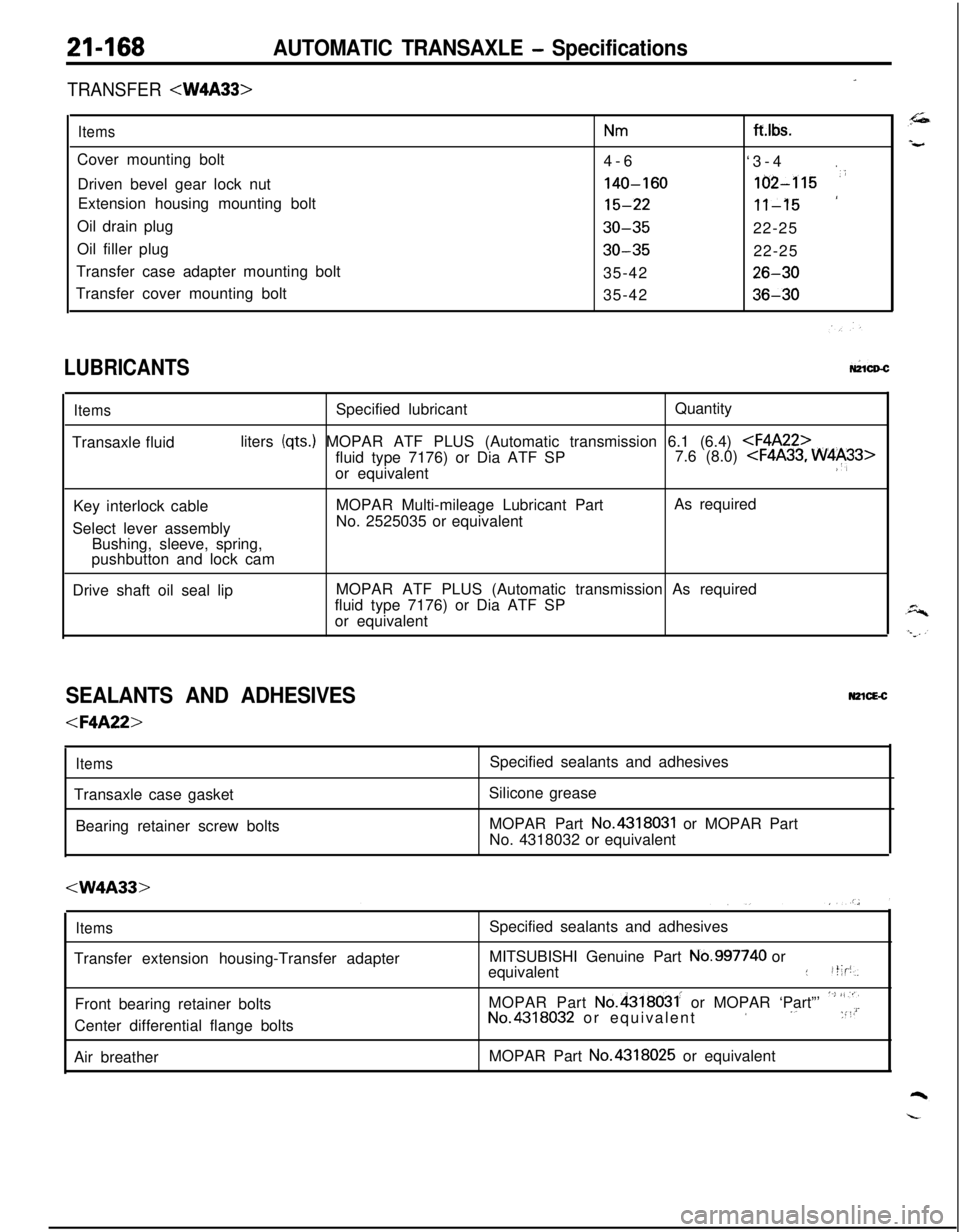

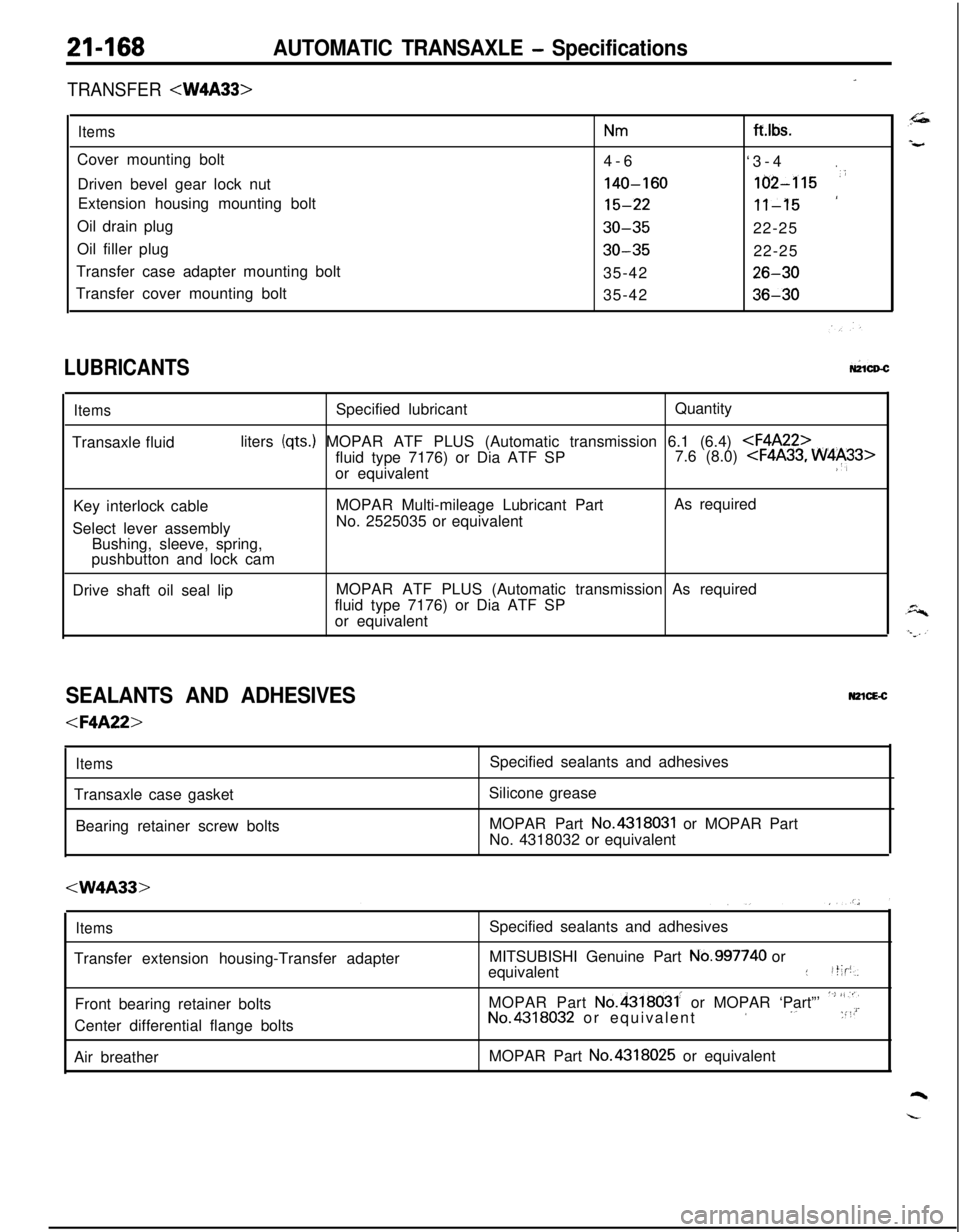

21-168AUTOMATIC TRANSAXLE - Specifications

-TRANSFER

ItemsNmCover mounting bolt

4-6

Driven bevel gear lock nut

140-160Extension housing mounting bolt

15-22Oil drain plug

30-35Oil filler plug

30-35Transfer case adapter mounting bolt

35-42

Transfer cover mounting bolt

35-42ft.lbs.

‘3-4

.

162-115 ‘i

‘11-1522-25

22-25

26-30

36-30

LUBRICANTSW1CD-C

ItemsSpecified lubricantQuantity

Transaxle fluidliters

(qts.) MOPAR ATF PLUS (Automatic transmission 6.1 (6.4) fluid type 7176) or Dia ATF SP7.6 (8.0)

or equivalent

:‘,Key interlock cableMOPAR Multi-mileage Lubricant PartAs required

Select lever assemblyNo. 2525035 or equivalent

Bushing, sleeve, spring,

pushbutton and lock cam

Drive shaft oil seal lipMOPAR ATF PLUS (Automatic transmission As required

fluid type 7176) or Dia ATF SP

or equivalent

SEALANTS AND ADHESIVESN2lcE-c

ItemsTransaxle case gasket

Bearing retainer screw boltsSpecified sealants and adhesives

Silicone grease

MOPAR Part

No.4318031 or MOPAR Part

No. 4318032 or equivalent

ItemsTransfer extension housing-Transfer adapter

Front bearing retainer bolts

Center differential flange bolts

Air breatherSpecified sealants and adhesives

MITSUBISHI Genuine Part

No.997740 or

equivalent::t;p,

MOPAR Part

No.4318031. or MOPAR ‘Part”’ ‘~’ “,“iNo.4318032 or equivalent’ ‘. :“’MOPAR Part No.4318025 or equivalent

Page 863 of 1216

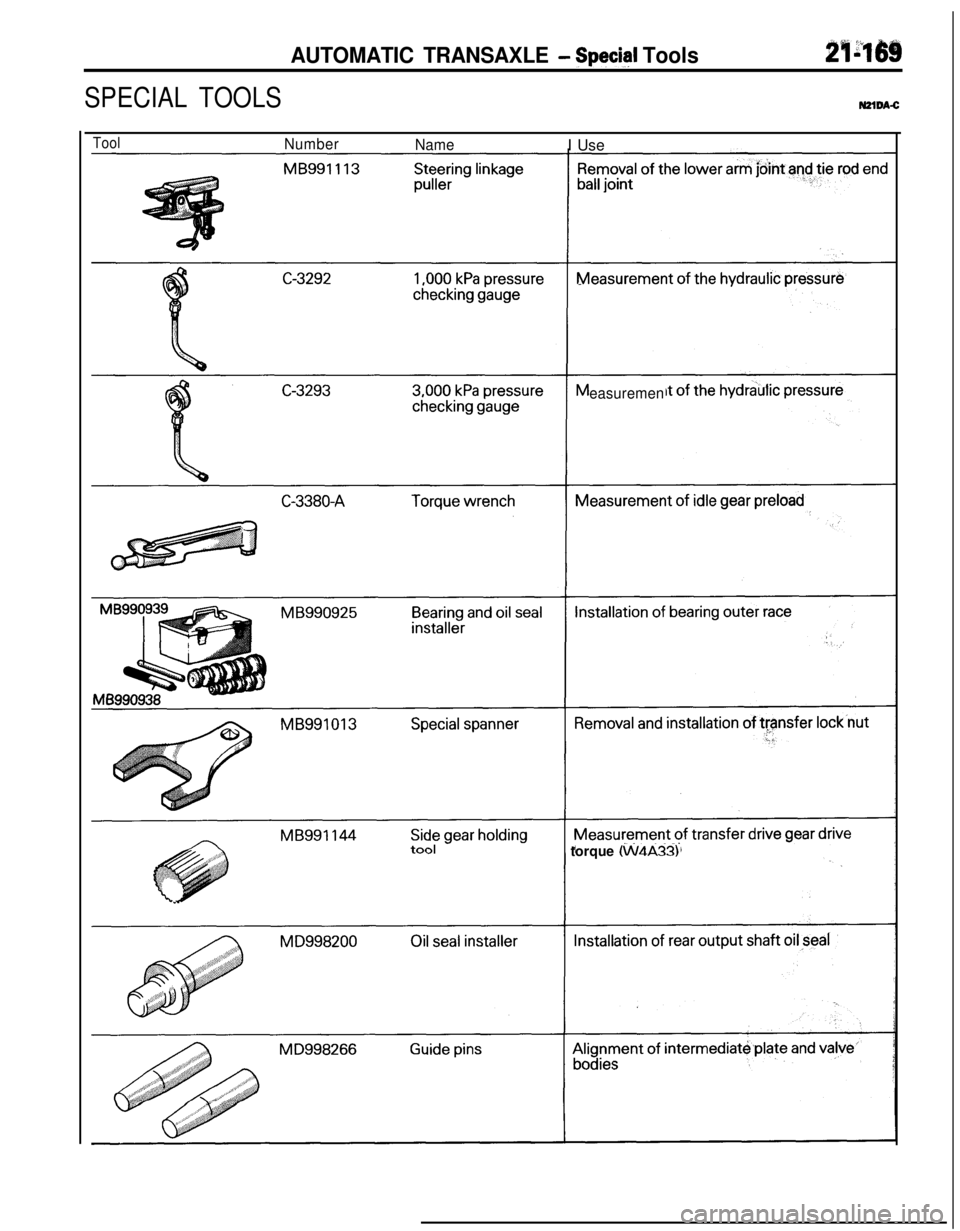

AUTOMATIC TRANSAXLE - Special Tools

SPECIAL TOOLSN2lDA-C

ToolNumber

NameI Use

easurementorque (W4A33)

Page 864 of 1216

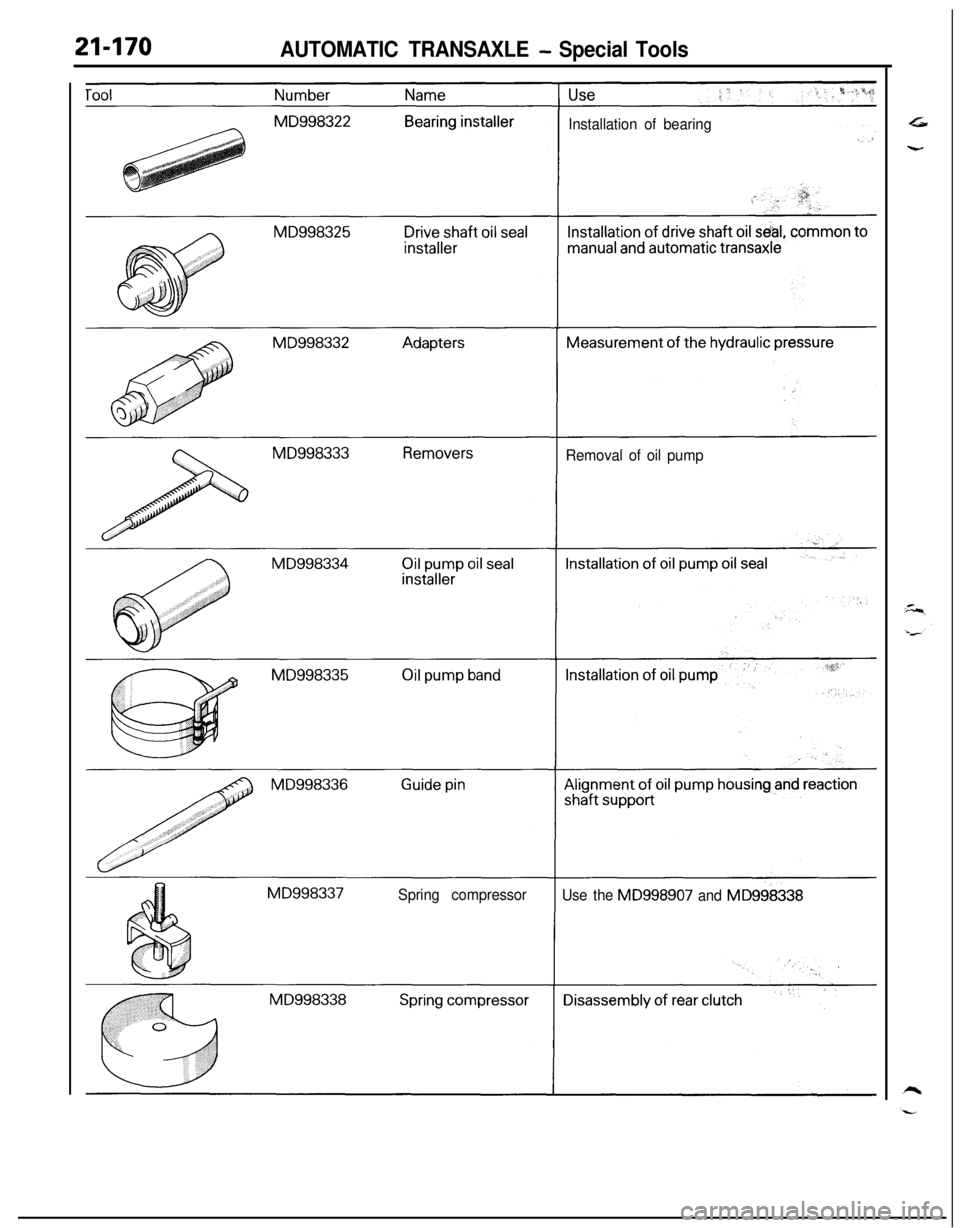

21-170AUTOMATIC TRANSAXLE - Special Tools

Installation of bearing‘.

Removal of oil pump

MD998337

Spring compressor

Use theMD998907 andMD998338

Page 865 of 1216

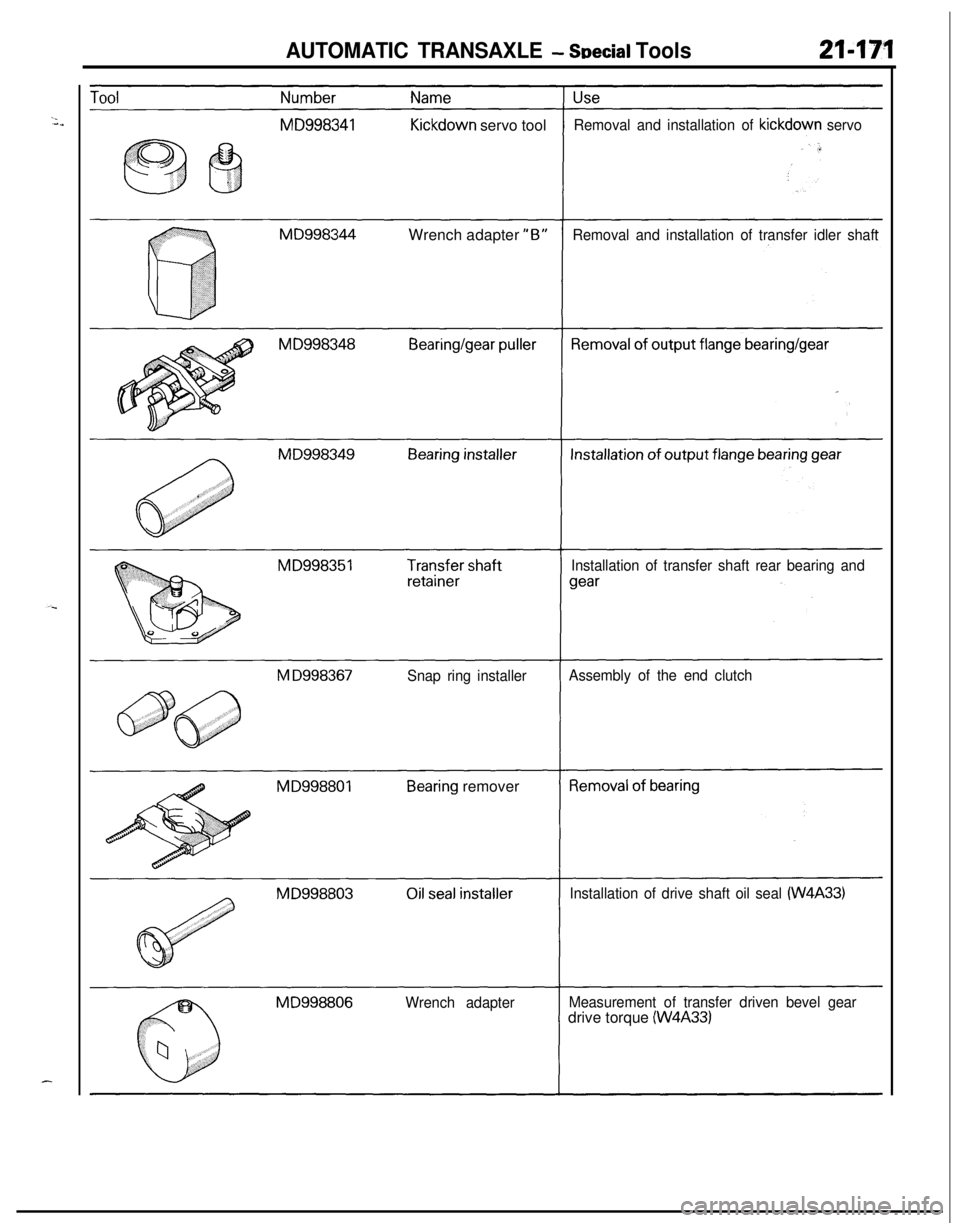

AUTOMATIC TRANSAXLE - SDecial Tools21~171

MD998341Kickdown servo toolRemoval and installation of kickdown servoWrench adapter

“6”Removal and installation of transfer idler shaft

Installation of transfer shaft rear bearing and

M D998367Snap ring installerAssembly of the end clutch

eanng remover

Installation of drive shaft oil seal (W4A33)

Wrench adapterMeasurement of transfer driven bevel geardrive torque (W4A33)

Page 866 of 1216

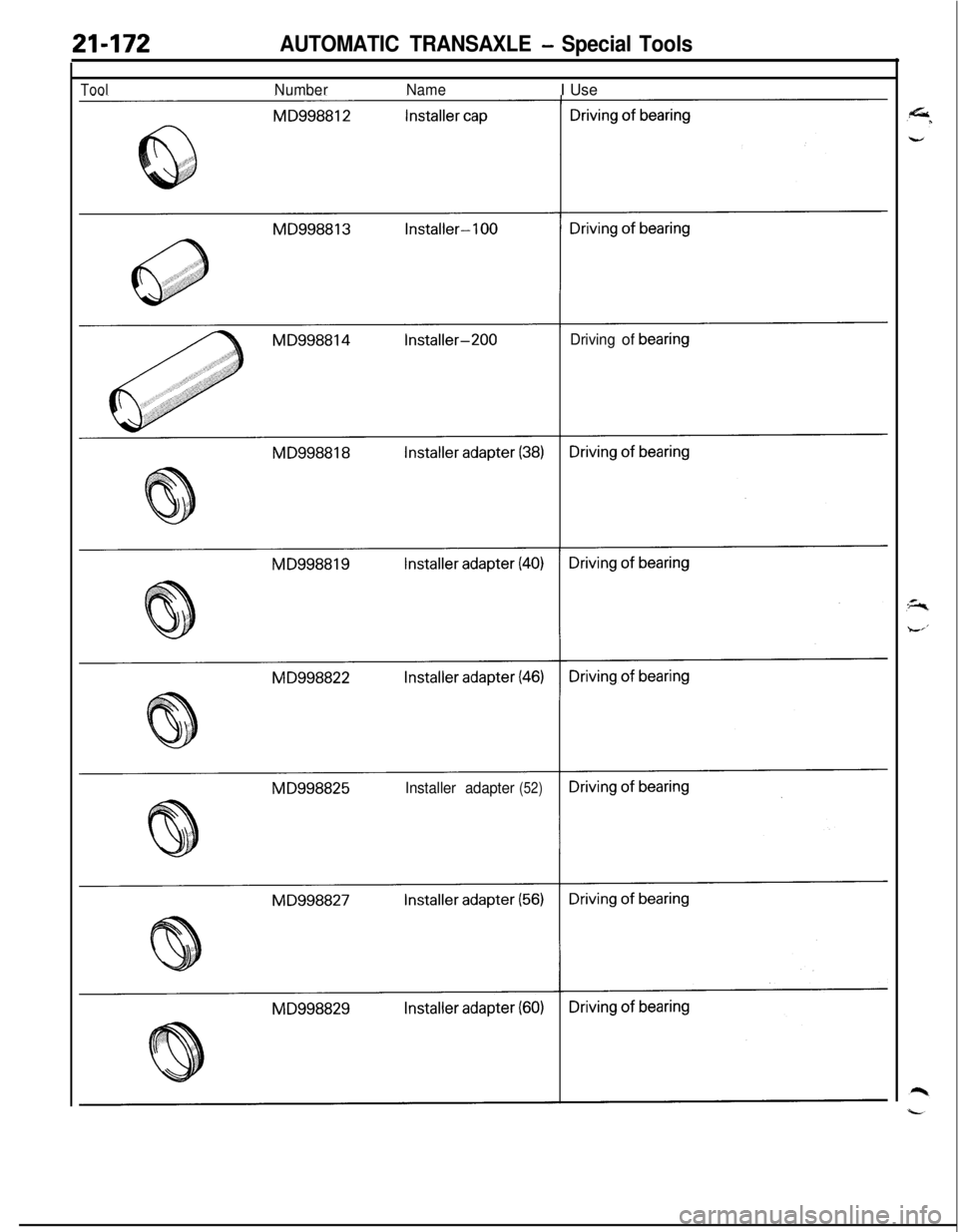

21-172AUTOMATIC TRANSAXLE - Special Tools

ToolNumberNameI Use

Installer-200Drivingof beanng

Installer adapter

(52)

Page 867 of 1216

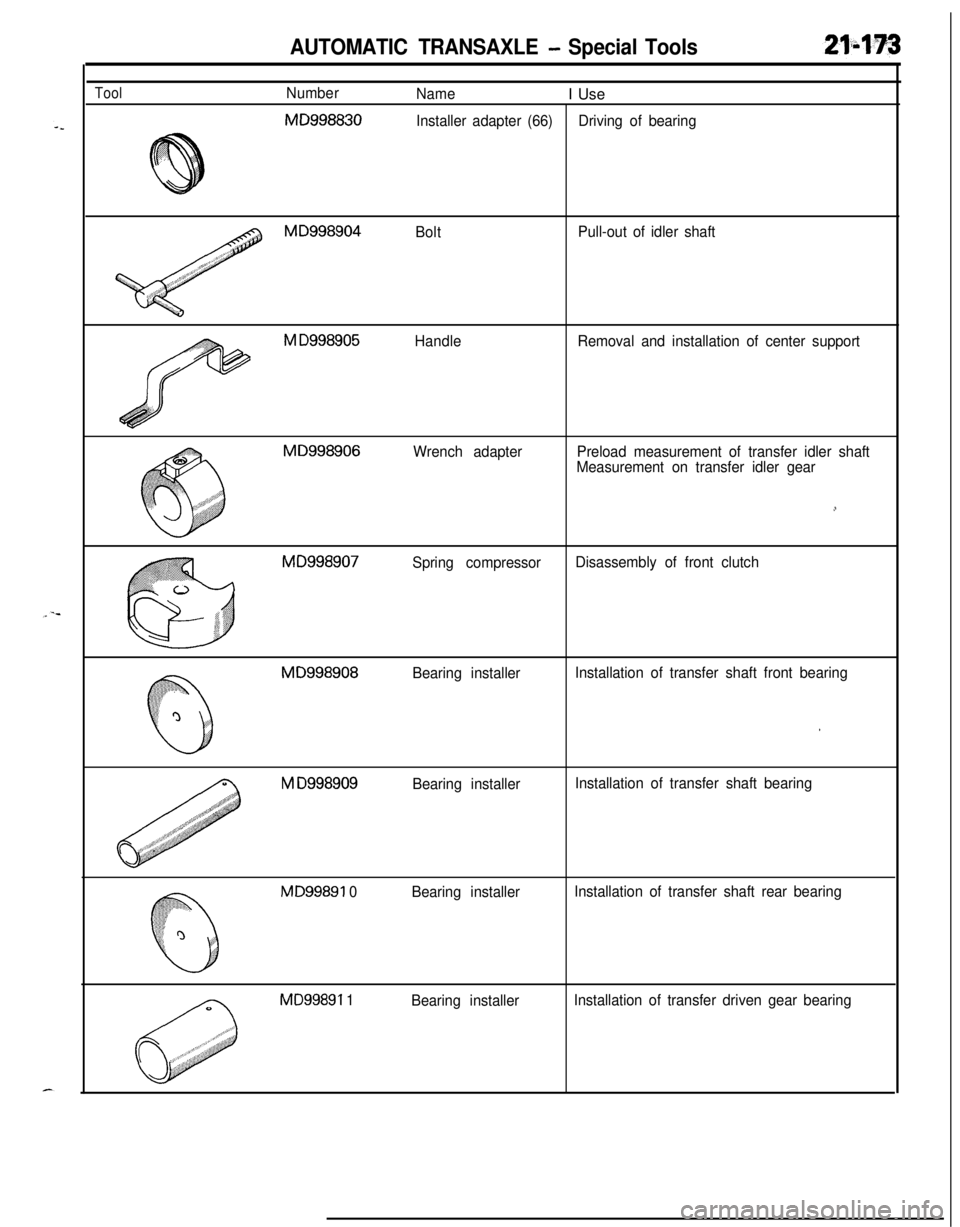

AUTOMATIC TRANSAXLE - Special Tools

ToolNumber

NameI UseMD998830

Installer adapter (66)Driving of bearingMD998904

BoltPull-out of idler shaft

M D998905HandleRemoval and installation of center supportMD998906

Wrench adapterPreload measurement of transfer idler shaft

Measurement on transfer idler gearMD998907

Spring compressorDisassembly of front clutchMD998908

Bearing installerInstallation of transfer shaft front bearing

’

M D998909Bearing installerInstallation of transfer shaft bearing

MD99891 0Bearing installerInstallation of transfer shaft rear bearing

MD99891 1

Bearing installerInstallation of transfer driven gear bearing

Page 868 of 1216

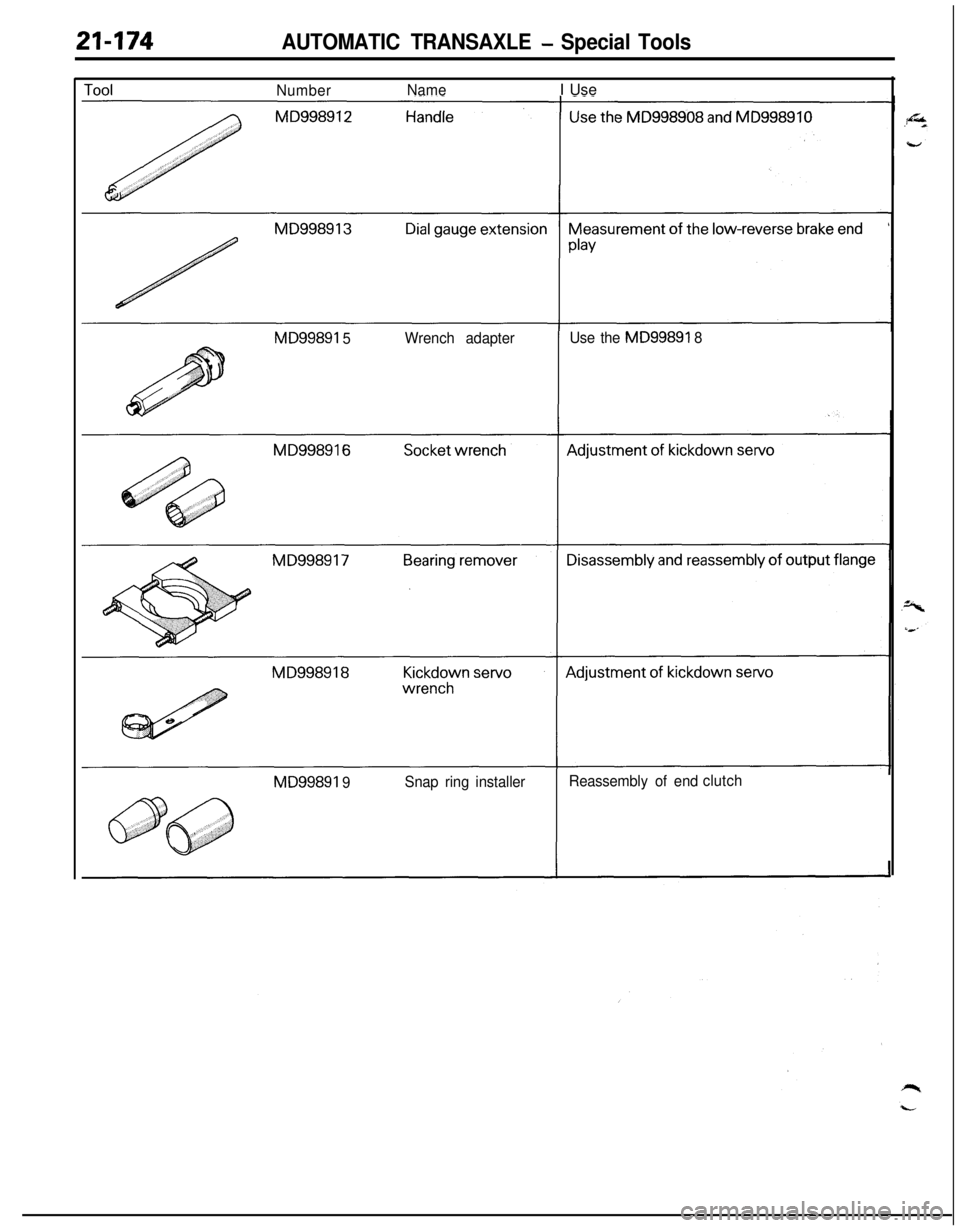

21-174AUTOMATIC TRANSAXLE - Special Tools

NumberNameI Use

MD99891 5Wrench adapterUse the MD99891 8

MD99891 9Snap ring installerReassembly of endclutch

Page 869 of 1216

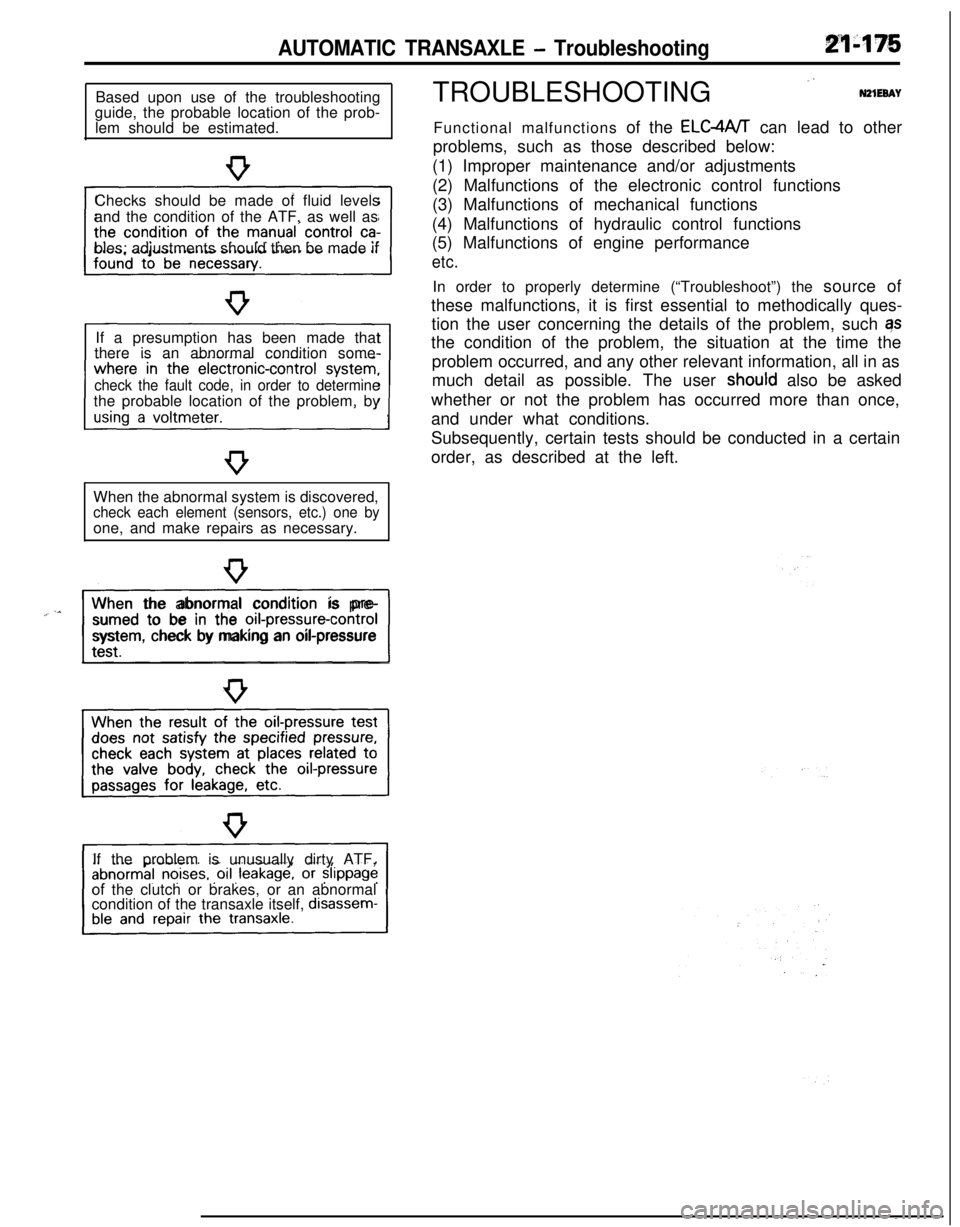

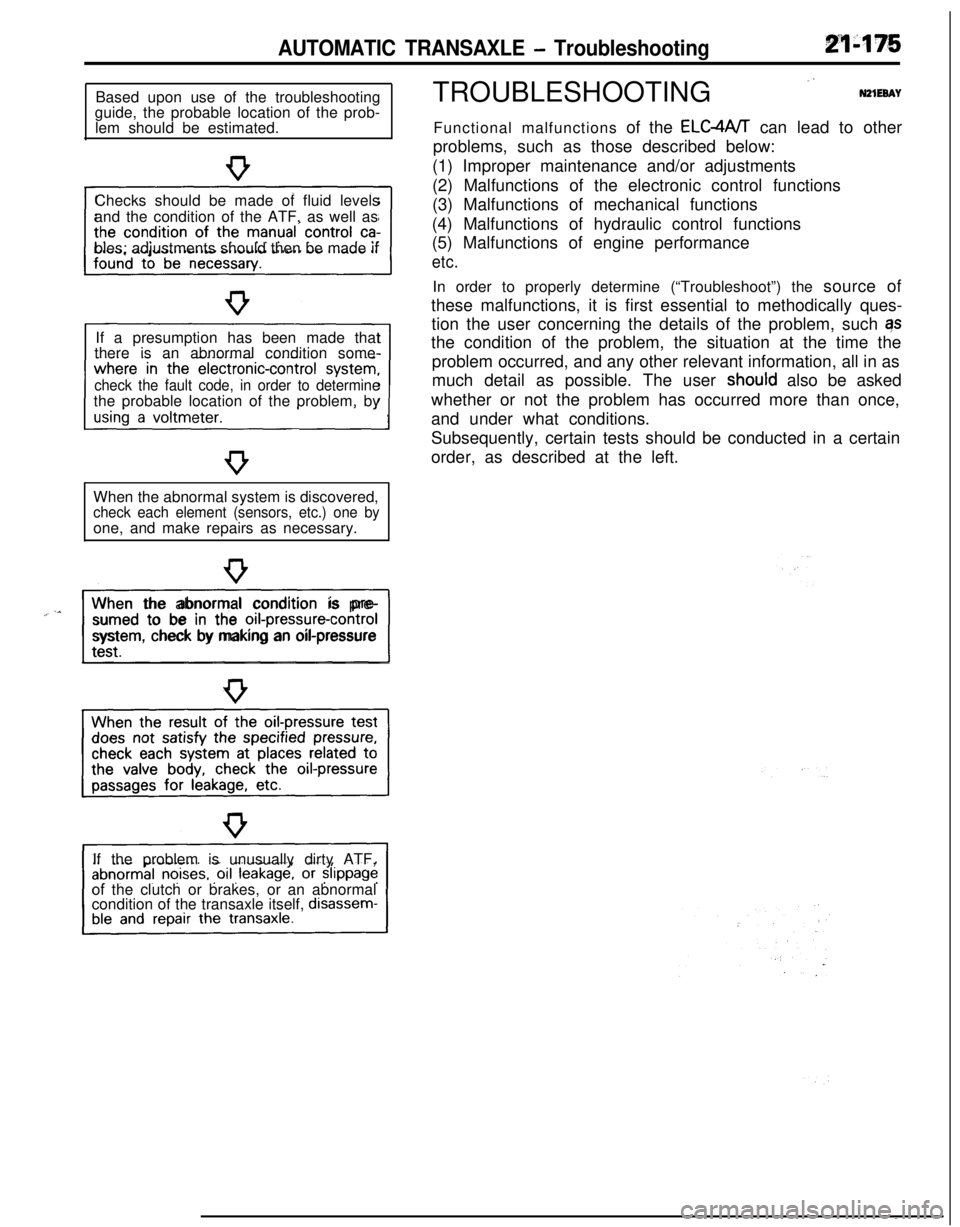

AUTOMATIC TRANSAXLE - TroubleshootingBased upon use of the troubleshooting

guide, the probable location of the prob-

lem should be estimated.

Checks should be made of fluid levels

and the condition of the ATF, as well as

bles; adjustments should then be made if

If a presumption has been made that

there is an abnormal condition some-

check the fault code, in order to determinethe probable location of the problem, by

When the abnormal system is discovered,

check each element (sensors, etc.) one byone, and make repairs as necessary.

“~^II_When the abnormal condition is pre-

sumed to be in the

orI-pressure-controlsystem, check by making an oil-pressure

If the problem is unusually dirty ATF,

of the clutch or brakes, or an abnormal

condition of the transaxle itself,

disassem-TROUBLESHOOTING

”N21EeAYFunctional malfunctions of the ELC4A/T can lead to other

problems, such as those described below:

(1) Improper maintenance and/or adjustments

(2) Malfunctions of the electronic control functions

(3) Malfunctions of mechanical functions

(4) Malfunctions of hydraulic control functions

(5) Malfunctions of engine performance

etc.In order to properly determine (“Troubleshoot”) the source of

these malfunctions, it is first essential to methodically ques-

tion the user concerning the details of the problem, such qs

the condition of the problem, the situation at the time the

problem occurred, and any other relevant information, all in as

much detail as possible. The user

shoutd also be asked

whether or not the problem has occurred more than once,

and under what conditions.

Subsequently, certain tests should be conducted in a certain

order, as described at the left.

Page 870 of 1216

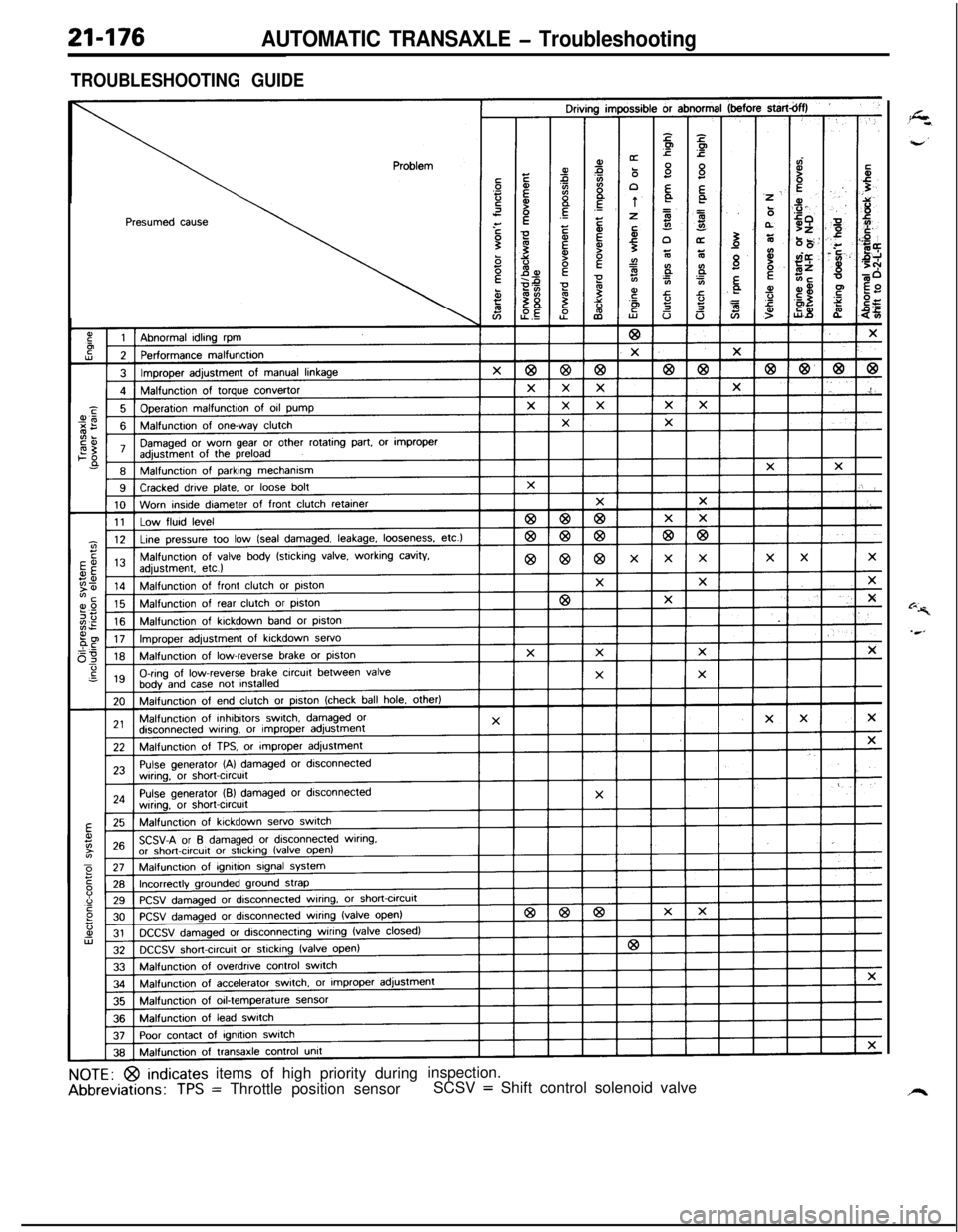

21-176AUTOMATIC TRANSAXLE - Troubleshooting

TROUBLESHOOTING GUIDE

Presumed causeitems of high priority during= Throttle position sensorinspection.

SCSV = Shift control solenoid valve

Trending: change time, battery capacity, USB, maintenance schedule, spare wheel, instrument cluster, Fuel pump relay