MITSUBISHI ECLIPSE 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 791 of 1216

MANUAL TRANSAXLE

I-2mmml

,

Snap r

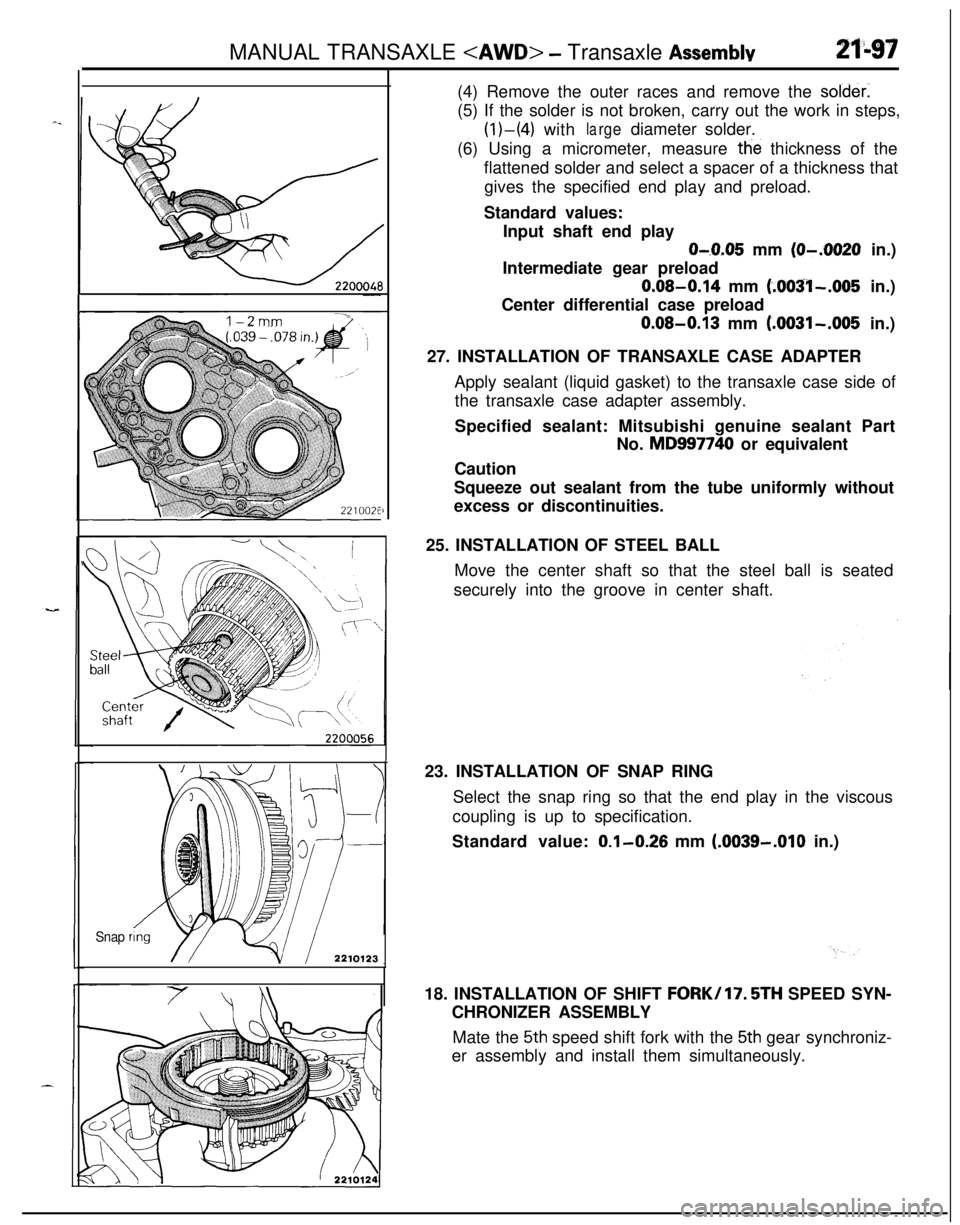

/ /221012:3(4) Remove the outer races and remove the

solder:(5) If the solder is not broken, carry out the work in steps,

(l)-(4) withlargediameter solder.

(6) Using a micrometer, measure ttie thickness of the

flattened solder and select a spacer of a thickness that

gives the specified end play and preload.

Standard values:

Input shaft end play

O-.0.05 mm (O-.0020 in.)

Intermediate gear preload

0.08-0.14 mm (.0031-.005 in.)

Center differential case preload

0.08-0.13 mm (.0031-,005 in.)

27. INSTALLATION OF TRANSAXLE CASE ADAPTER

Apply sealant (liquid gasket) to the transaxle case side of

the transaxle case adapter assembly.

Specified sealant: Mitsubishi genuine sealant Part

No. MD997740 or equivalent

Caution

Squeeze out sealant from the tube uniformly without

excess or discontinuities.

25. INSTALLATION OF STEEL BALL

Move the center shaft so that the steel ball is seated

securely into the groove in center shaft.

23. INSTALLATION OF SNAP RING

Select the snap ring so that the end play in the viscous

coupling is up to specification.

Standard value:

0.1-0.26 mm (.0039-.OlO in.)

18. INSTALLATION OF SHIFT FORK/17.

5TH SPEED SYN-

CHRONIZER ASSEMBLY

Mate the

5th speed shift fork with the 5th gear synchroniz-

er assembly and install them simultaneously.

Page 792 of 1216

21-98MANUAL TRANSAXLE

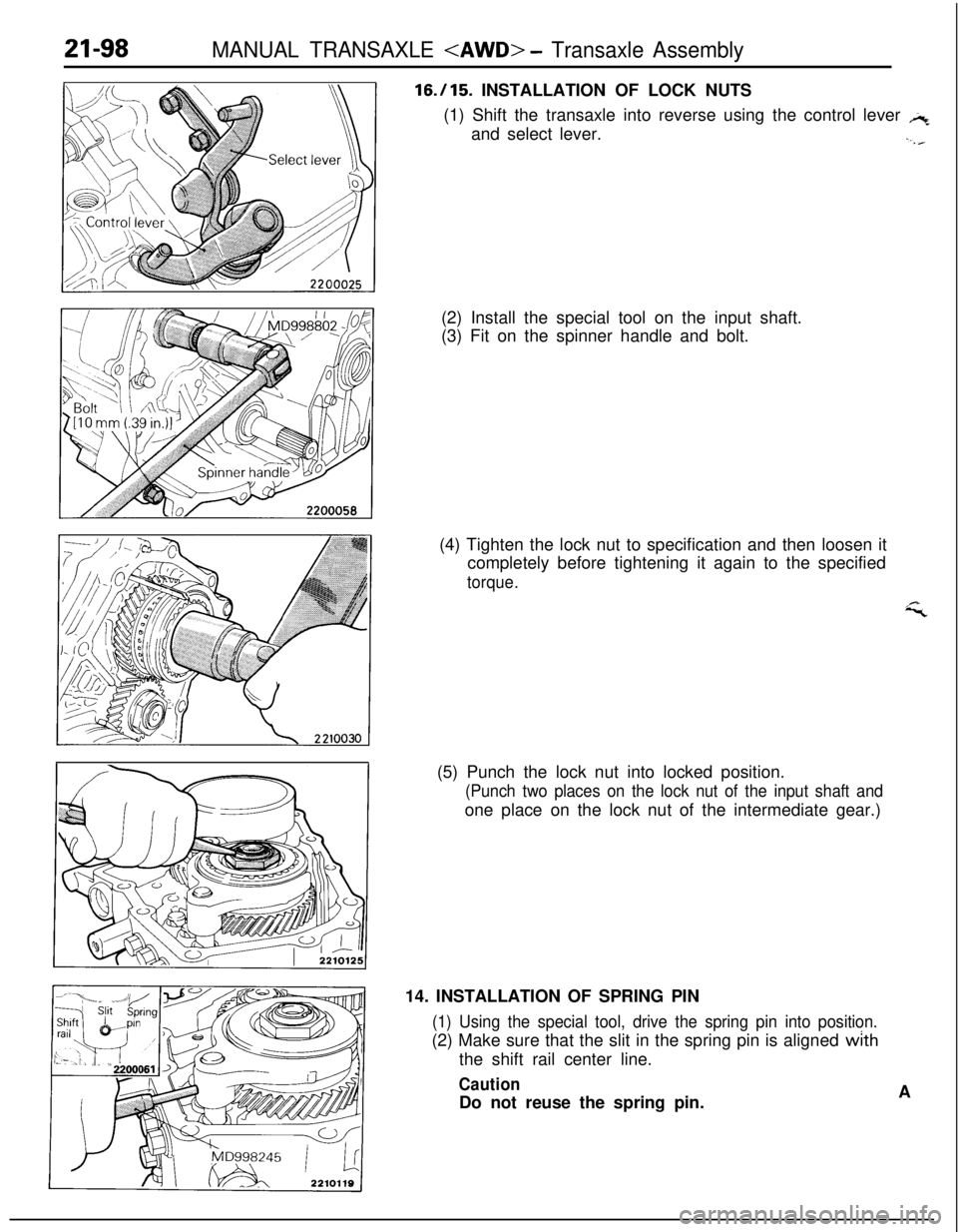

16.115. INSTALLATION OF LOCK NUTS

(1) Shift the transaxle into reverse using the control lever

,+and select lever.

.,./(2) Install the special tool on the input shaft.

(3) Fit on the spinner handle and bolt.

(4) Tighten the lock nut to specification and then loosen it

completely before tightening it again to the specified

torque.

i;(5) Punch the lock nut into locked position.

(Punch two places on the lock nut of the input shaft andone place on the lock nut of the intermediate gear.)

14. INSTALLATION OF SPRING PIN

(1) Using the special tool, drive the spring pin into position.(2) Make sure that the slit in the spring pin is aligned with

the shift rail center line.

CautionDo not reuse the spring pin.A

Page 793 of 1216

MANUAL TRANSAXLE

sealant

TFM0041

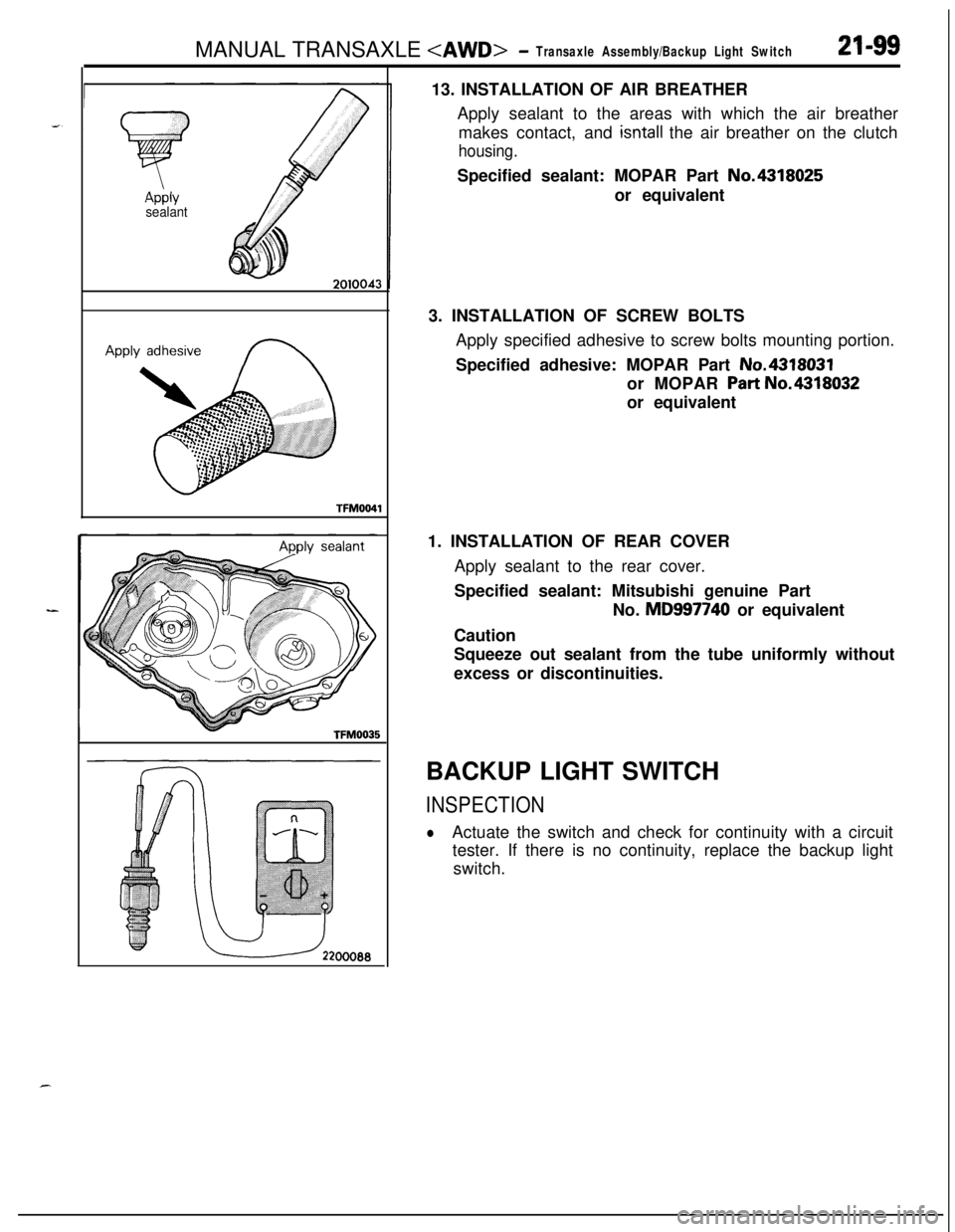

TFM003513. INSTALLATION OF AIR BREATHER

Apply sealant to the areas with which the air breather

makes contact, and

isntall the air breather on the clutch

housing.Specified sealant: MOPAR Part No.4318025

or equivalent

3. INSTALLATION OF SCREW BOLTS

Apply specified adhesive to screw bolts mounting portion.

Specified adhesive: MOPAR Part No.4318031

or MOPAR

Part No.4318032

or equivalent

1. INSTALLATION OF REAR COVER

Apply sealant to the rear cover.

Specified sealant: Mitsubishi genuine Part

No. MD997740 or equivalent

Caution

Squeeze out sealant from the tube uniformly without

excess or discontinuities.

BACKUP LIGHT SWITCH

INSPECTION

lActuate the switch and check for continuity with a circuit

tester. If there is no continuity, replace the backup light

switch.

Page 794 of 1216

21-100MANUAL TRANSAXLE

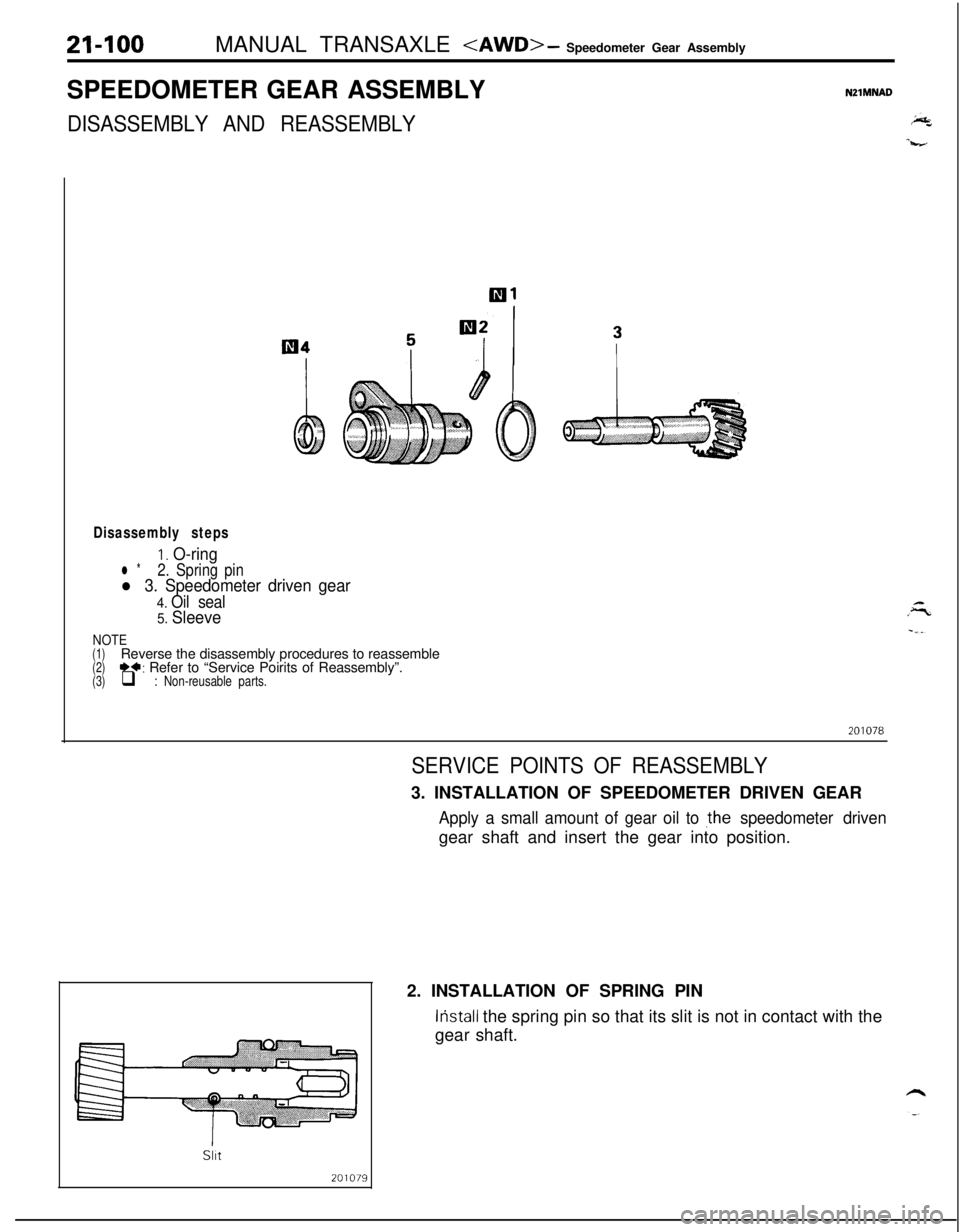

SPEEDOMETER GEAR ASSEMBLY

NZlMNAD

DISASSEMBLY AND REASSEMBLY

Disassembly steps

I. O-ringl *2. Spring pinl 3. Speedometer driven gear

4. Oil seal5. Sleeve

NOTE(1)Reverse the disassembly procedures to reassemble(2)**: Refer to “Service Poirits of Reassembly”.(3)q : Non-reusable parts.

SERVICE POINTS OF REASSEMBLY3. INSTALLATION OF SPEEDOMETER DRIVEN GEAR

Apply a small amount of gear oil to the speedometer drivengear shaft and insert the gear into position.

2. INSTALLATION OF SPRING PIN

lristall the spring pin so that its slit is not in contact with the

gear shaft.

Page 795 of 1216

MANUAL TRANSAXLE

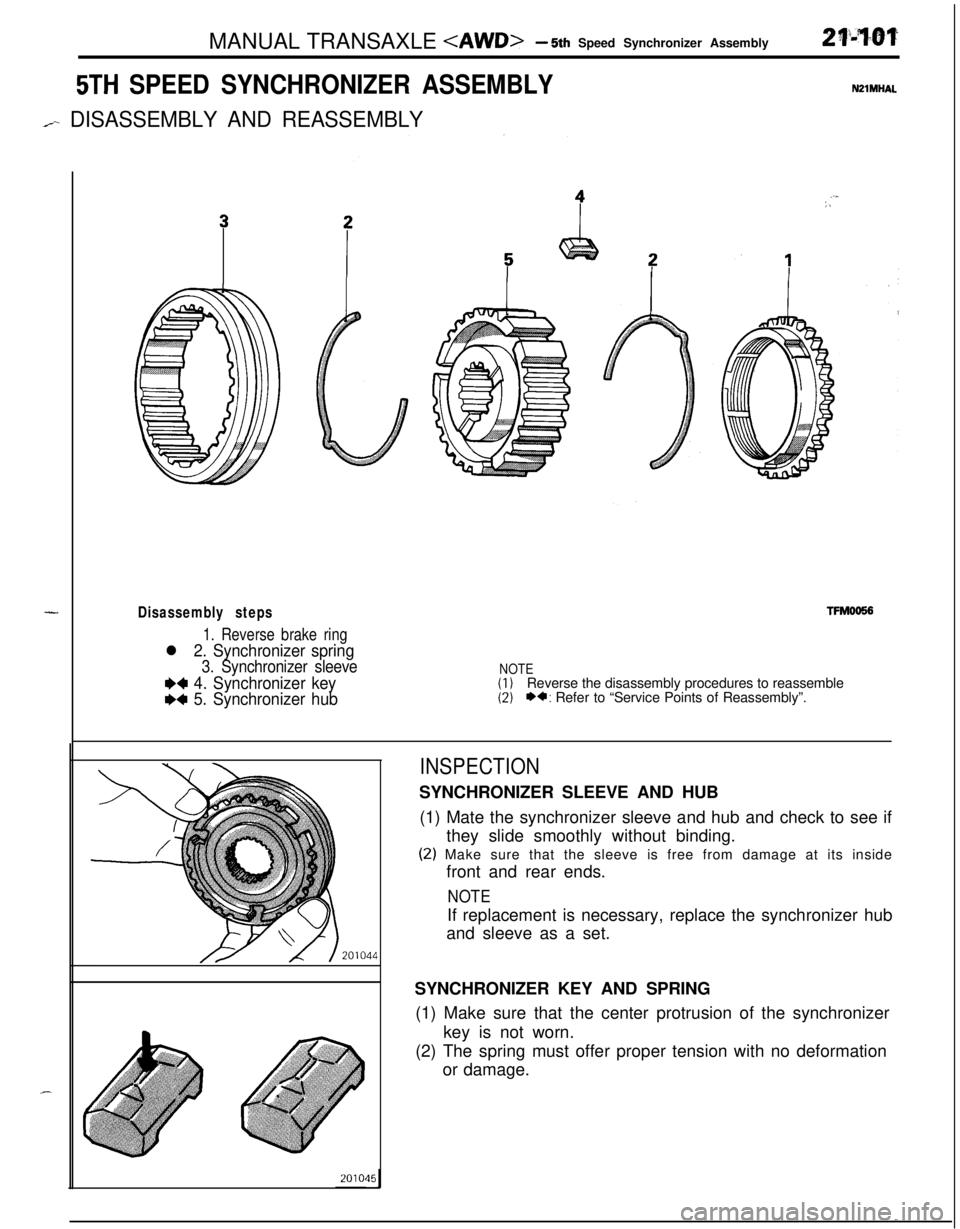

5TH SPEED SYNCHRONIZER ASSEMBLY

/-- DISASSEMBLY AND REASSEMBLY

-Disassembly steps

1. Reverse brake ring

l 2. Synchronizer spring

3. Synchronizer sleeve

W 4. Synchronizer key

I)+ 5. Synchronizer hub

WlMHAL

. . I:,

TFMOO!56

NOTE(1)Reverse the disassembly procedures to reassemble(2)*a: Refer to “Service Points of Reassembly”.

INSPECTIONSYNCHRONIZER SLEEVE AND HUB

(1) Mate the synchronizer sleeve and hub and check to see if

they slide smoothly without binding.

(2) Make sure that the sleeve is free from damage at its inside

front and rear ends.

NOTEIf replacement is necessary, replace the synchronizer hub

and sleeve as a set.

SYNCHRONIZER KEY AND SPRING

(1) Make sure that the center protrusion of the synchronizer

key is not worn.

(2) The spring must offer proper tension with no deformation

or damage.

Page 796 of 1216

21-102MANUAL TRANSAXLE

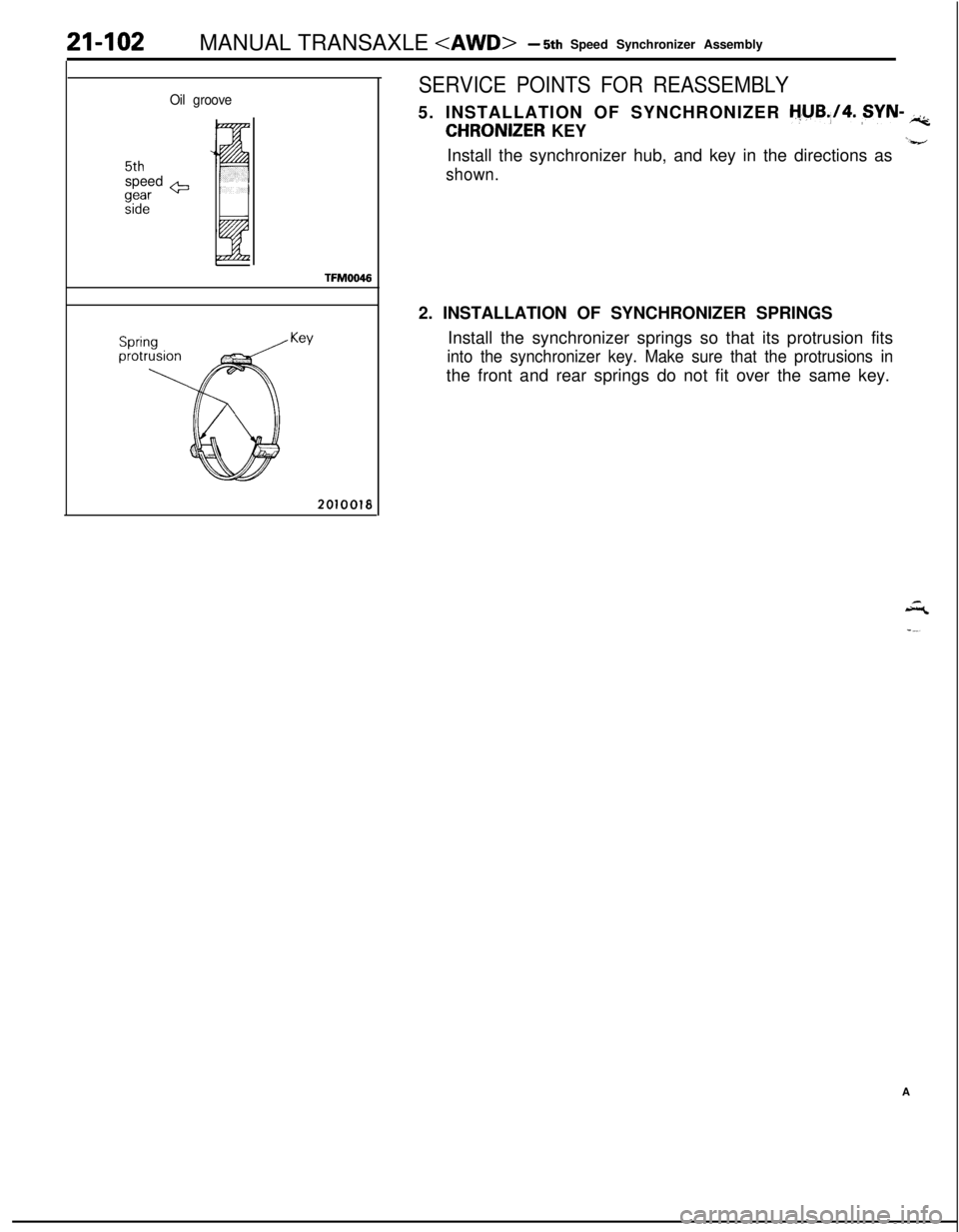

Oil groove

5thspeed +

$2

TFM0046

201001a,

SERVICE POINTS FOR REASSEMBLY5. INSTALLATION OF SYNCHRONIZER

tjyB.,/4. ,SYN- iic;

CHRONIZER KEY‘-a-/Install the synchronizer hub, and key in the directions as

shown.2. INSTALLATION OF SYNCHRONIZER SPRINGS

Install the synchronizer springs so that its protrusion fits

into the synchronizer key. Make sure that the protrusions inthe front and rear springs do not fit over the same key.

A

Page 797 of 1216

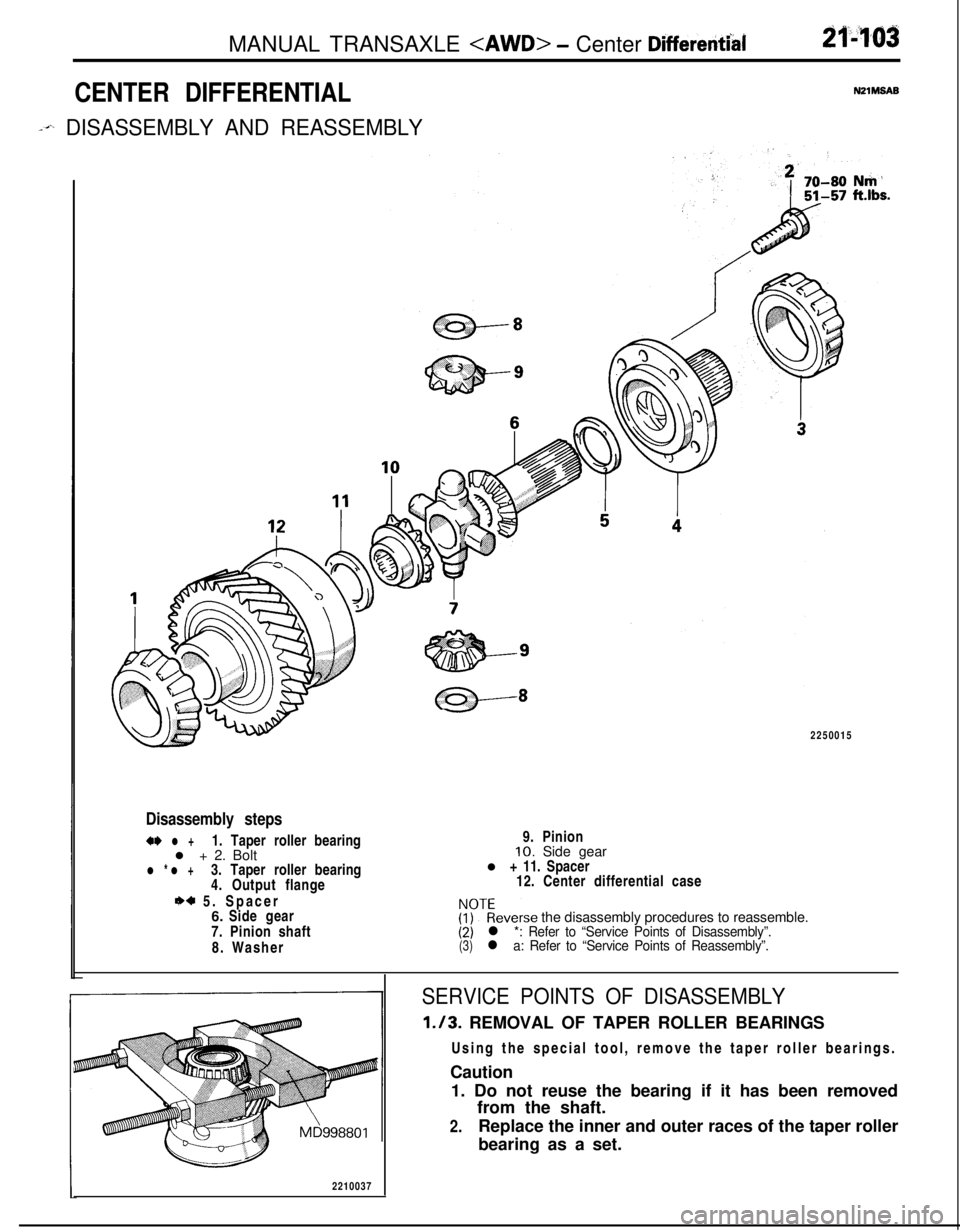

MANUAL TRANSAXLE

CENTER DIFFERENTIAL

-4~ DISASSEMBLY AND REASSEMBLY

2210037

-

2250015

Disassembly steps

+* l +1. Taper roller bearing

l + 2. Bolt

l * l +3. Taper roller bearing

4. Output flange

I)* 5. Spacer

6. Side gear

7. Pinion shaft

8. Washer9. Pinion

10. Side gear

l + 11. Spacer

12. Center differential case

FJ)TEeverse the disassembly procedures to reassemble.(2)l *: Refer to “Service Points of Disassembly”.(3)l a: Refer to “Service Points of Reassembly”.

SERVICE POINTS OF DISASSEMBLY

1.13. REMOVAL OF TAPER ROLLER BEARINGS

Using the special tool, remove the taper roller bearings.

Caution

1. Do not reuse the bearing if it has been removed

from the shaft.

2.Replace the inner and outer races of the taper roller

bearing as a set.

Page 798 of 1216

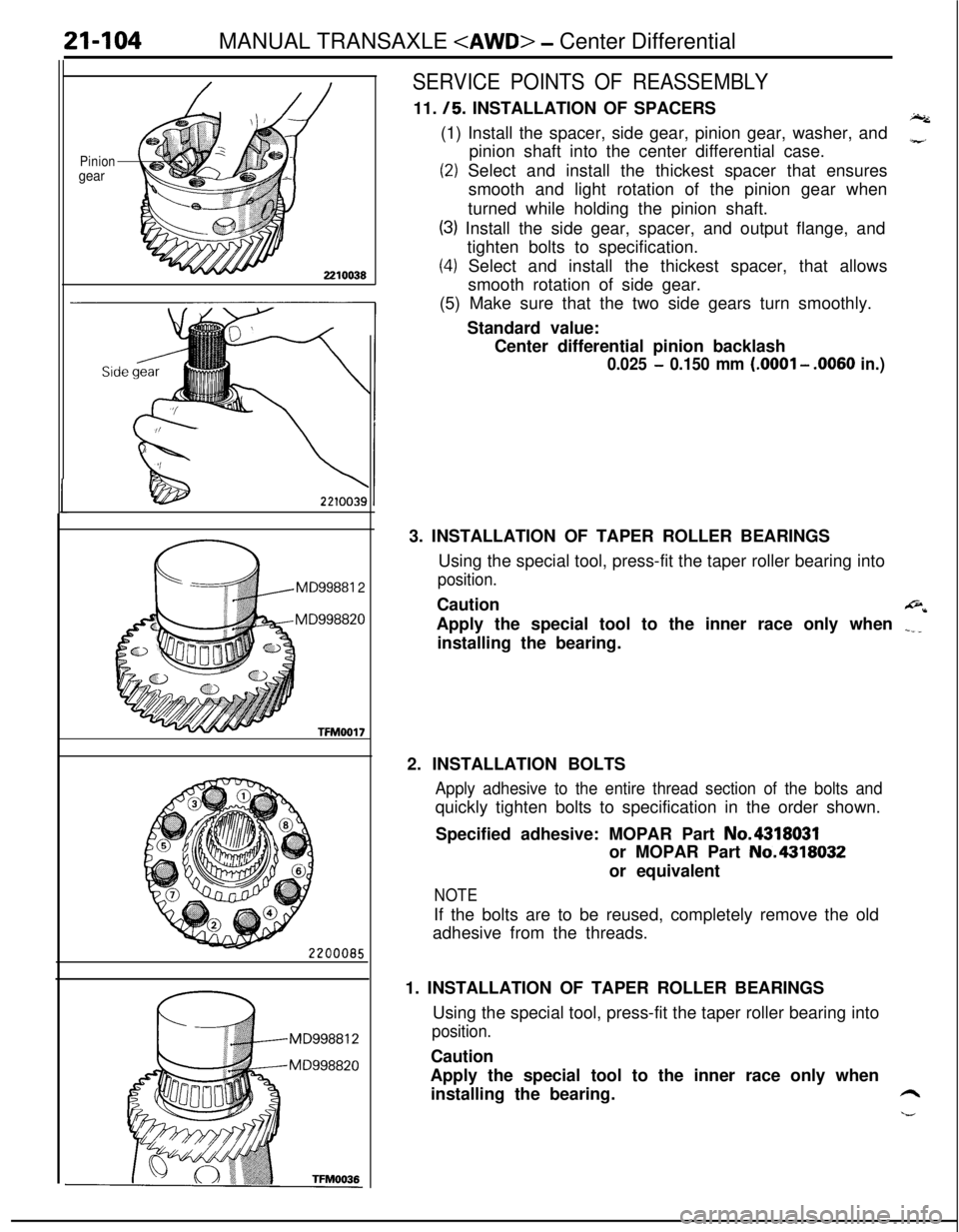

21-104MANUAL TRANSAXLE

Piniongear

MD99881 2

MD998820

TFM0017

SERVICE POINTS OF REASSEMBLY11.

/5. INSTALLATION OF SPACERSI.(1) Install the spacer, side gear, pinion gear, washer, and

pinion shaft into the center differential case.

z

(2) Select and install the thickest spacer that ensures

smooth and light rotation of the pinion gear when

turned while holding the pinion shaft.

(3) Install the side gear, spacer, and output flange, and

tighten bolts to specification.

(4) Select and install the thickest spacer, that allows

smooth rotation of side gear.

(5) Make sure that the two side gears turn smoothly.

Standard value:

Center differential pinion backlash

0.025 - 0.150 mm (.OOOl - .0060 in.)3. INSTALLATION OF TAPER ROLLER BEARINGS

Using the special tool, press-fit the taper roller bearing into

position.Caution

@*Apply the special tool to the inner race only when

.___installing the bearing.

2. INSTALLATION BOLTS

Apply adhesive to the entire thread section of the bolts andquickly tighten bolts to specification in the order shown.

Specified adhesive: MOPAR Part No.4318031

or MOPAR Part No.4318032

or equivalent

NOTEIf the bolts are to be reused, completely remove the old

adhesive from the threads.

1. INSTALLATION OF TAPER ROLLER BEARINGS

Using the special tool, press-fit the taper roller bearing into

position.Caution

Apply the special tool to the inner race only when

installing the bearing.

6

h--

Page 799 of 1216

MANUAL TRANSAXLE

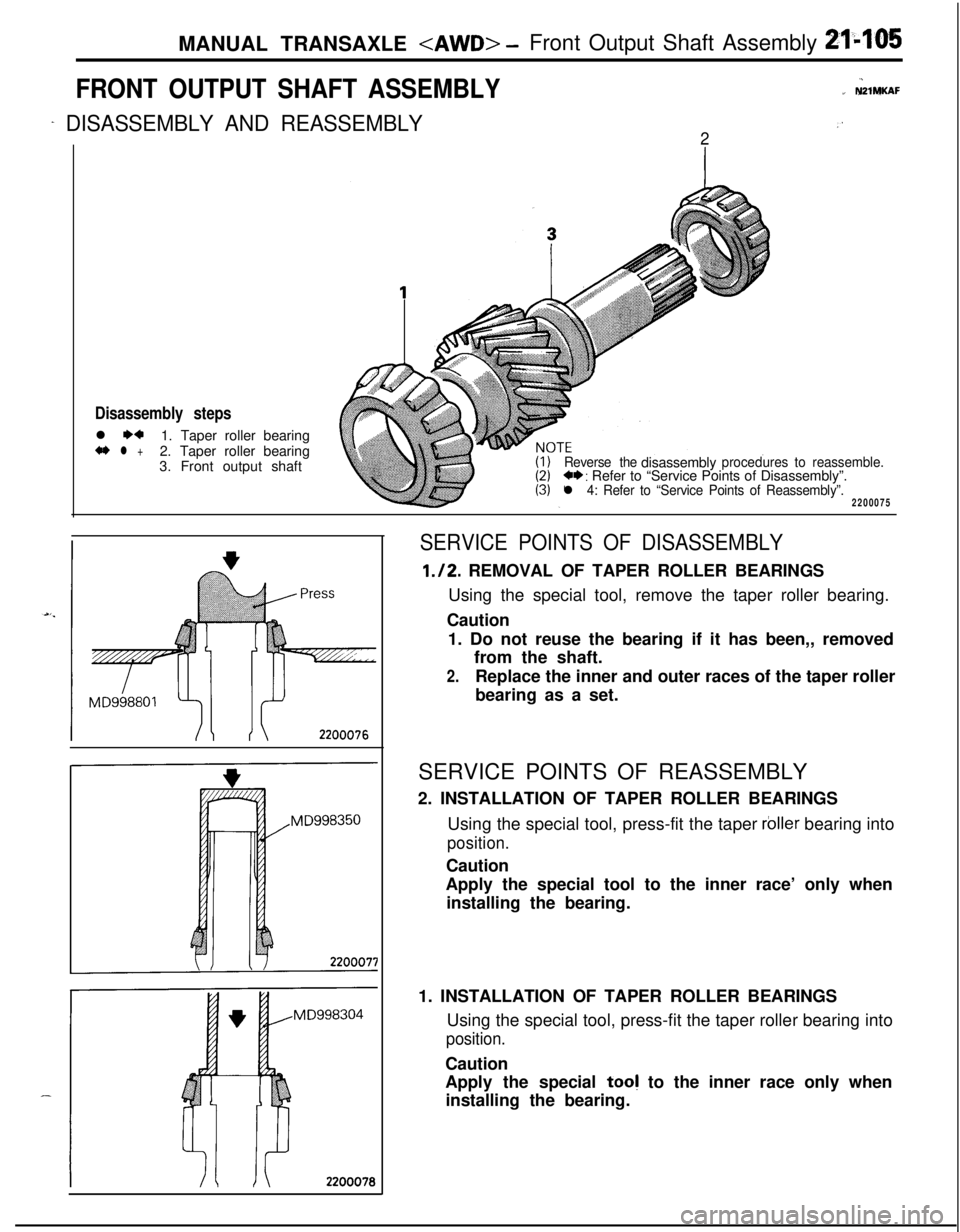

FRONT OUTPUT SHAFT ASSEMBLY”,I N21MKAF

- DISASSEMBLY AND REASSEMBLY,’

2

Disassembly stepsl

*a1. Taper roller bearing+* l +2. Taper roller bearing

3. Front output shaftReverse thedisassemblyproceduresto reassemble.4*: Refer to “Service Points of Disassembly”.l 4: Refer to “Service Points of Reassembly”.2200075

SERVICE POINTS OF DISASSEMBLY

1./2. REMOVAL OF TAPER ROLLER BEARINGS

Using the special tool, remove the taper roller bearing.

Caution

1. Do not reuse the bearing if it has been,, removed

from the shaft.

2.Replace the inner and outer races of the taper roller

bearing as a set.

SERVICE POINTS OF REASSEMBLY

2. INSTALLATION OF TAPER ROLLER BEARINGS

Using the special tool, press-fit the taper

rbller bearing into

position.Caution

Apply the special tool to the inner race’ only when

installing the bearing.

1. INSTALLATION OF TAPER ROLLER BEARINGS

Using the special tool, press-fit the taper roller bearing into

position.Caution

Apply the special too! to the inner race only when

installing the bearing.

Page 800 of 1216

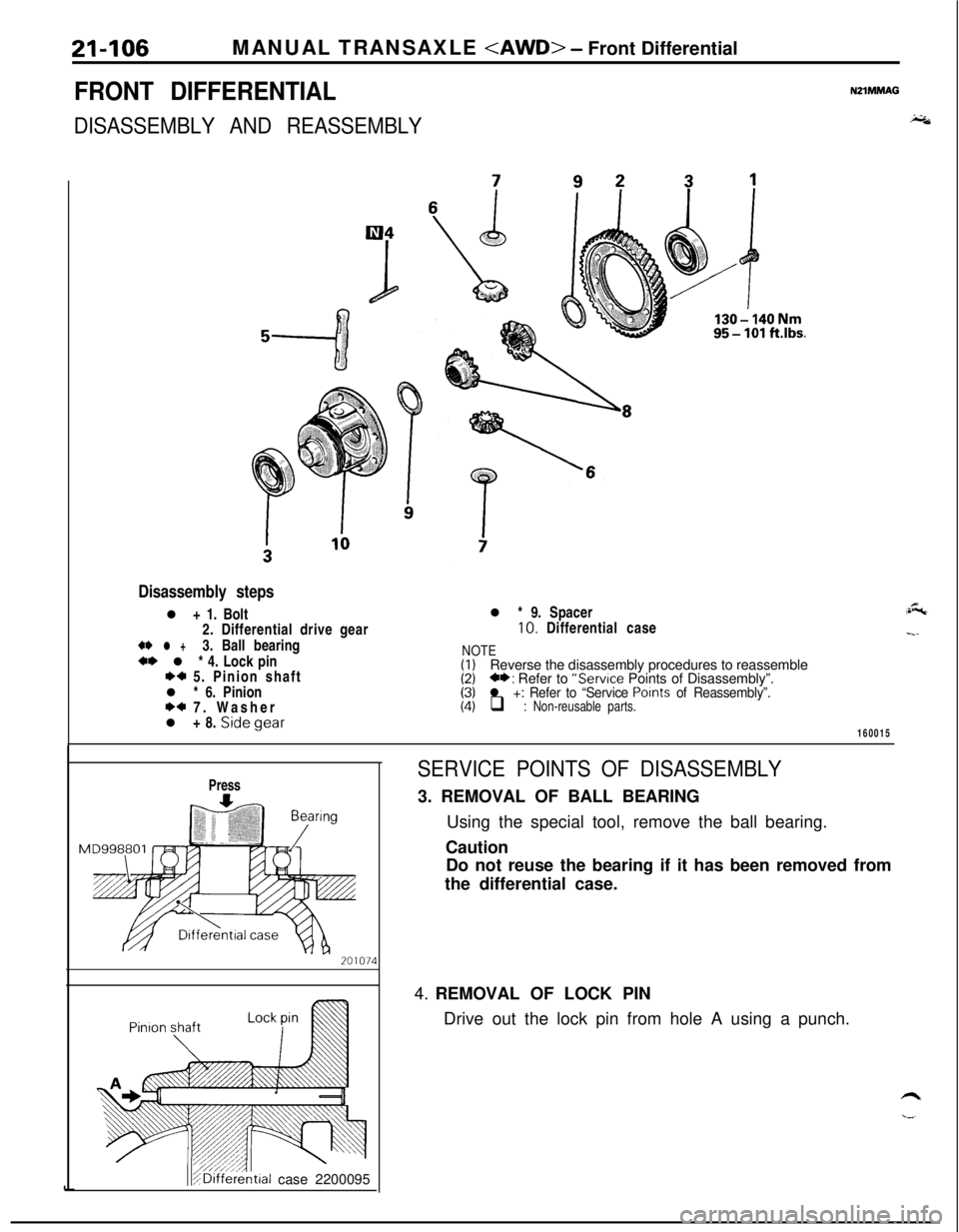

21-106MANUAL TRANSAXLE

FRONT DIFFERENTIAL

DISASSEMBLY AND REASSEMBLY

NZIMMAG

i;&

Disassembly stepsl + 1. Bolt

2. Differential drive gear

** l +3. Ball bearing+* l * 4. Lock pinI)+ 5. Pinion shaft

l * 6. Pinion

I)+ 7. Washer

l + 8. Sidegear

95-lOl ft.lbs.l * 9. Spacer10. Differential case

NOTE(I)Reverse the disassembly procedures to reassemble(2)C*: Refer to “Service Points of Disassembly”.(3)l +: Refer to “Service Points of Reassembly”.(4)q : Non-reusable parts.

:&

-_-

160015

Press

teal case 2200095

SERVICE POINTS OF DISASSEMBLY3. REMOVAL OF BALL BEARING

Using the special tool, remove the ball bearing.

Caution

Do not reuse the bearing if it has been removed from

the differential case.

4. REMOVAL OF LOCK PIN

Drive out the lock pin from hole A using a punch.