electric MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1 of 1216

BACKUPGROUP INDEX &ma

;r Service Manual

LASER

TALON

1991

Volume-l

Engine, Chassis

& Body

FOREWORDThis Service Manual has been prepared with the

latest service information available at the time of

‘* publication.It is subdivided into various group

categories and each section contains diagnosis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any servicing necessary to maintain or

restore the high levels of performance and reliabilitydesigned into these outstanding vehicles.

This BACKUP DSM manual IS to be used ONLY as a BACKUP. Please DO NOT REDISTRIBUTEWHOLE SECTIONS. This BACKUP was sold to you under the fact that you do indeed OWNa GENUINE DSM MANUAL. It CANNOT BE considered a REPLACEMENT (Unless your originalmanual was lost or destroyed.)Please See

README.N or README.HTML for additional information

Thank you. G~mm~emymanual@hotma~l.com

1,

wA

CHRYSLER

CORPORATION

Chrysler Corporation reserves the right to make changes in design 0’: tomake additions to or improvements in its products without lmqoslngd ., . any obligations upon itself to install them on its products previouslymanufactured.

0 1990 Mitsubishi Motors CorporationPrinted in U.S.A.Introduction and

Master

Troubleshooting. . . . . .,. . . . . . . . . r...m,

Lubrication and Maintenance . . . . . . . . ‘-0‘8

; “. i,

.Front Suspension. . . . . . . . . . . . . . ..*............d...Rear Axle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . ..‘.....................

/

ServiceBrakes-Parking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~......................‘t.

Cooling. . . . . . . . . . . . . . . . . ..i....................................

,., .‘,-,

Engine..i....~....r...............~....~.*,.~.~.~,‘~~...;..~~..Intake and Exhaust

. . . . . . ..L....................Fuel System

. . . . . . . . . . . ..ti.......r................~...Propeller Shaft

.......................................IRear

Suspensiori.............................y.f...

ManualSteering- Power.....................................Manual

I

transaxle-Automatic .............:;i...,;.....;Wheels

and Tires.................................

Body.............................................................Heater & Air Conditioning

..............Emission

Contr6l Systems..............

INOTE: For Electrical, refer toVolume-2 “Electrical”.

Page 14 of 1216

I4INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions before Service

mm (In.1smo59

PARTSWhen replacing parts, use MOPAR genuine parts.

VEHICLE WASHING

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least 300 mm (12 in.) from anyplastic parts and all opening parts (doors, luggage compart-

ment, etc.).

SERVICING ELECTRICAL SYSTEM

1. Note the following before proceeding with work on the

electrical system.

Note that the following must never be done:

Unauthorized modifications of any electrical device or

wiring, because such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that could result

in a fire in the vehicle.

2. When servicing the electrical system, disconnect the

negative cable terminal from the batten/.

Caution1. Before connecting or disconnecting the negative

cable, be sure to turn off the ignition switch and thelighting switch.

(If this is not done, there is the possibility of

semiconductor parts being damaged.)

2. For MPI-equipped models, after completion of the

work steps [when the battery’s negative

(-) termi-

nal is connected], warm up the engine and allow it

to idle for approximately five minutes under the

conditions described below, in order to stabilize

engine control conditions, and then check to be

sure that the idling is satisfactory.

Engine coolant temperature:

85-95°C (185-203°F)

Lights, electric fans, accessories: OFF

Transaxle: neutral position

(A/T models: “N” or “P”)

Steering wheel: neutral (center) position

Page 16 of 1216

16INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions before Service

Cl6362

OOYSssOOV833

10A15A

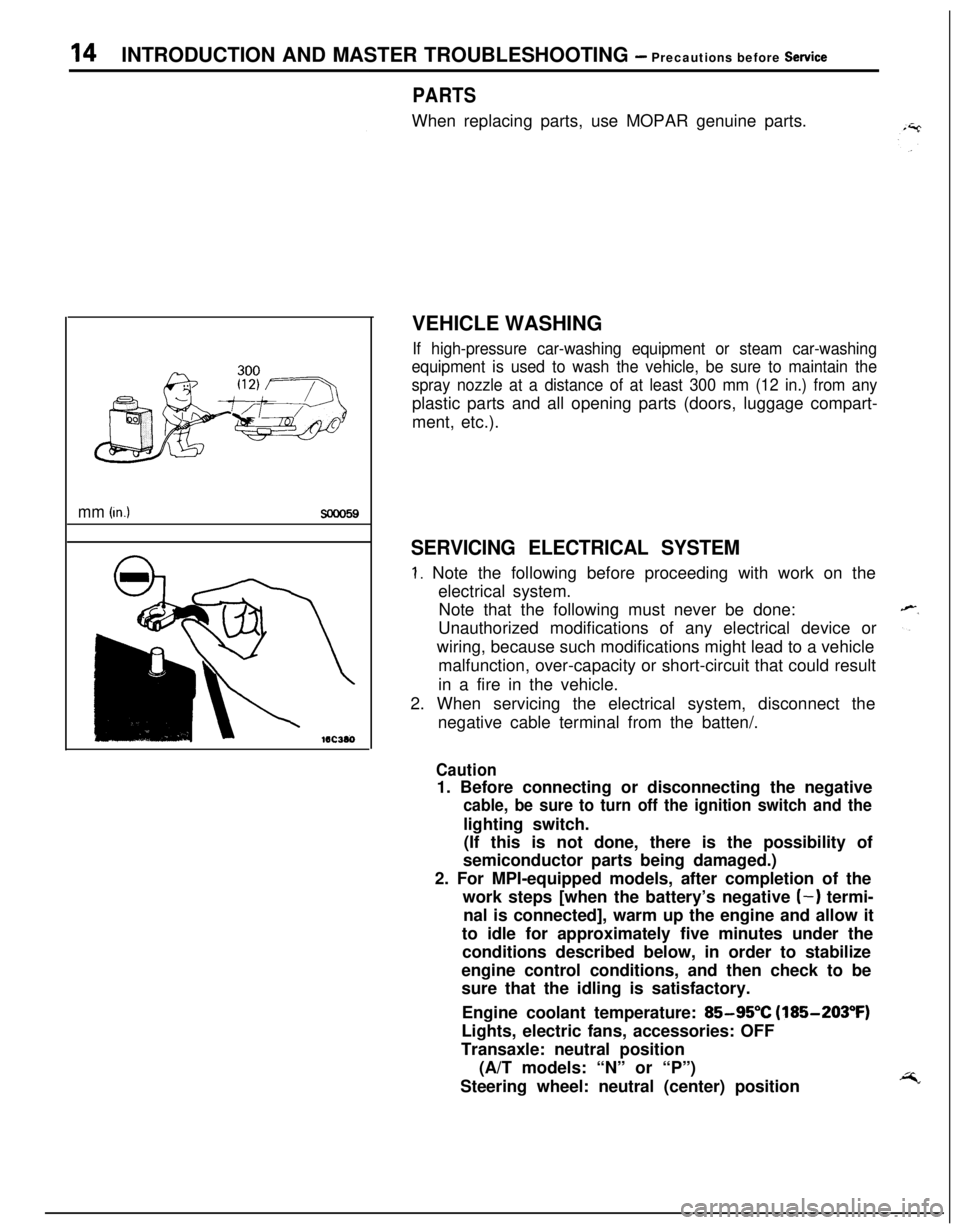

COY5695. Connect connectors which have catches by inserting the

connectors until they snap.

9%

ELECTRICAL COMPONENTS1. When installing any of the vehicle parts, be careful not to

pinch or damage any of the wiring harnesses.

2. Sensors, relays, etc.,are sensitive to strong impacts.

Handle them with care so that they are not dropped or

mishandled.

,**3. The electronic parts used for relays, etc., are sensitive to

heat. If any service which causes a temperature of

80°C

(176°F) or more is performed, remove the part or parts in

question before carrying out the service.

FUSES AND FUSIBLE LINKS

1.If a blown-out fuse is to be replaced, be sure to use only a

fuse of the specified capacity. If a fuse of a capacity larger

than that specified is used, parts may be damaged and thecircuit may not be protected adequately.

Caution

1.If a fuse is blown-out, be sure to eliminate the causeof the problem before installing a new fuse.

;i2.Check the condition of fuse holders. If rust or dirt isfound, clean metal parts with a fine-grained sand-

paper until proper metal-to-metal contact is

made.Poor contact of any fuse holder will

often lead tovoltage drop or heating in the circuit

and colildresult in improper circuit operation.

Page 17 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions before Sew&e‘37

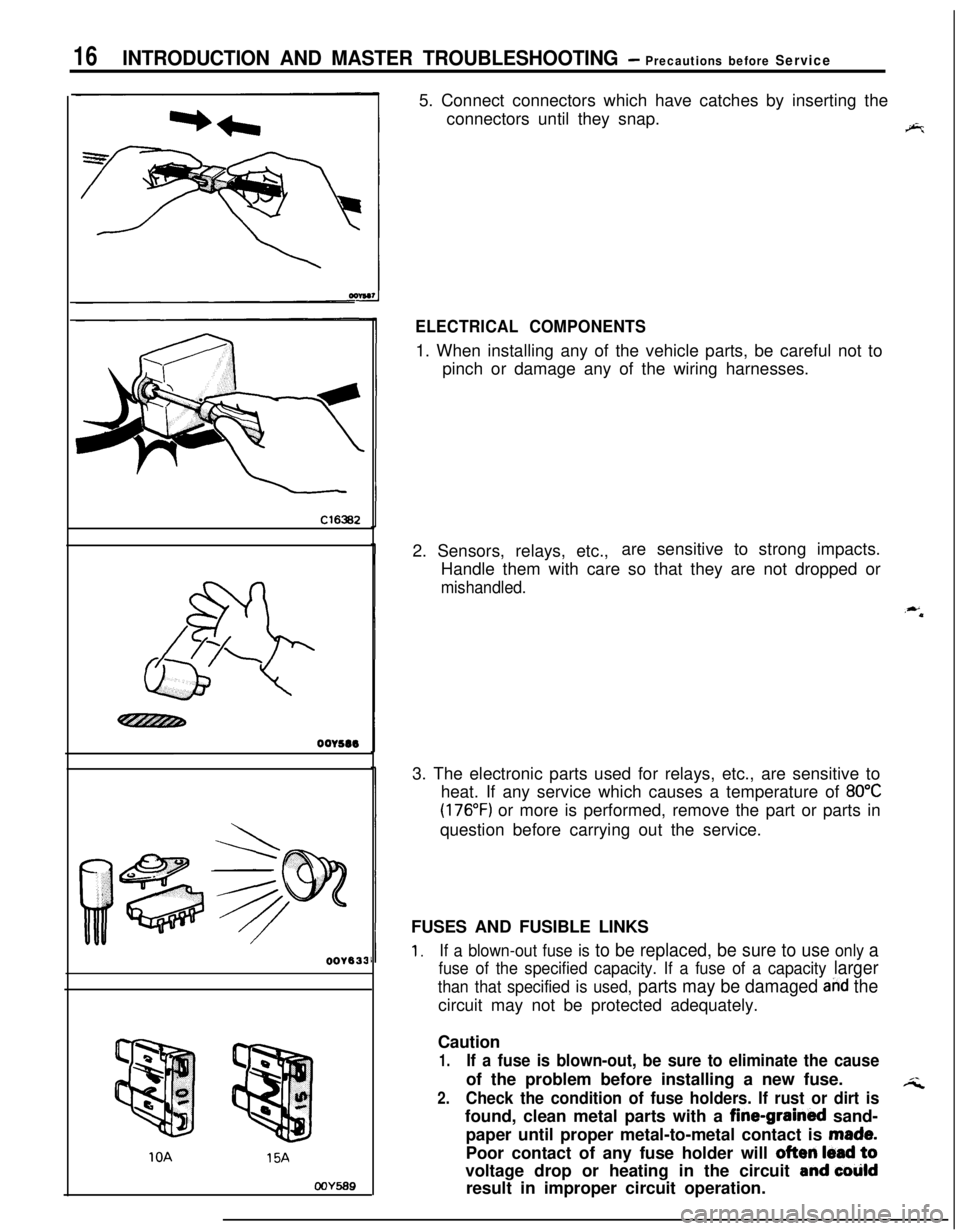

Nominal

sizeSAE

gi:ePermissible current

In engine

Othercompart-areasment

0.3mm2AWG22-5A

0.5

mm2AWG207A13A

0.85

mm’AWG189A17A

1.25

mm2AWG1612A22A

2.0mm2AWG1416A30A

3.0mm’AWG1221A40A

5.0mm2AWG1031A54A

r ‘.

oorsas

2. If additional optional equipment is to be installed, in ttievehicle, follow the procedure listed in the

ap@@priateinstruction manual; however, be sure to pay “careful

attention to the following points:

“9:(1) In order to avoid overloading the

wiring;’ take the

electrical current load of the optional

,equipment into

consideration, and determine the appropriate .wire size:(2) Where possible, route the wiring through the existing

harnesses.(3) If an ammeter or similar instrument is to be

connectedto a live-wire circuit, use tape to protect the wire, use a

clamp to secure the wire, and make sure that there is

no contact with any other parts.

(4) Be sure to provide a fuse for the load circuit of the

optional equipment.

TUBES AND OTHER RUBBER PARTS

Be careful to avoid spilling any gasoline, oil, etc., or rubber

parts, they might be adversely affected.

LUBRICANTSIn accordance with the instructions in this Service Manual,

apply the specified lubricants in the specified locations during

assembly and installation.

!’IV/ :>,I

BRAKE FLUID

Be careful to avoid spilling any brake fluid on painted surfaces,because the paint coat might be discolored or damaged.

Page 149 of 1216

BRAKES - Anti-lock Braking System Troubleshooting5-9

ANTI-LOCK BRAKING SYSTEM

-- TROUBLESHOOTINGNO!JEBAE

PARTICULAR CHARACTERISTICS OF

THE ANTI-LOCK BRAKING SYSTEMModels equipped with the anti-lock braking system

(A.B.S.) may exhibit one or more of the following

characteristics from time to time, but none of these

is abnormal.

(1) A pulsing feeling in the brake pedal, or vibration

of the body or the steering wheel, when the

anti-lock braking system is activated by sudden

braking or by braking on a slippery road surface.Actually, this phenomenon is an indication that

the anti-lock braking system is functioning nor-

mally.(2) When the vehicle speed reaches approximately

6 km/h (4 mph) after the engine is started and

the vehicle starts off (for the first time), a

whining motor noise may be heard from the

engine compartment if the vehicle is traveling in

a quiet place, but this noise is simply the result

of a self-check being made of the anti-lock

braking system operation.

TROUBLESHOOTING METHODSProblems related to the anti-lock braking system

(A.B.S.) can be classified into two general categor-

ies: problems in the electrical system and those in

the hydraulic system.For problems in the electrical system, the

self-diagnosis function is built into the electronic control

unit (E.C.U.) causing the A.B.S. warning light to

illuminate as a warning to the driver.

Problems in the hydraulic system (poor braking,

etc.) can be located in the same way as for ordinary

brakes. There is, however, the necessity to check todetermine whether the problem is related to ordin-

ary brake components or to the components relatedto the A.B.S.

HOW TO USE THE TROUBLESHOOTING

FLOW CHART(1) Using the flow chart, check the ABS warning

light light-up sequence and check the condition

of braking operation.

(2) Following the check chart listed in the remedy

column, perform the checks. There are [Explana-tion] and [Hint] in each check chart. Refer to

them when troubleshooting.

NOTEECU: Electronic control unit

HU: Hydraulic unit

MUT: Multi-use tester

Page 150 of 1216

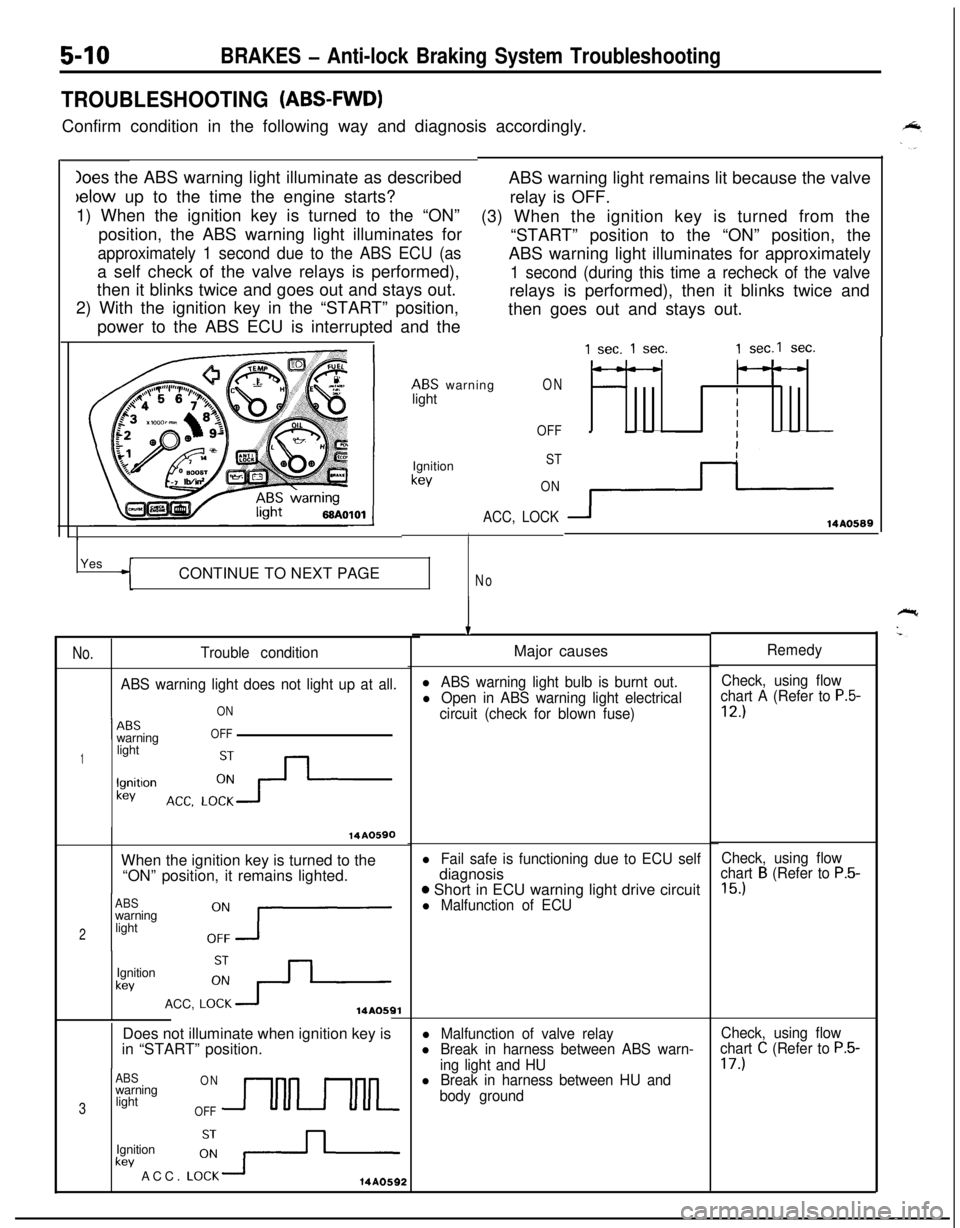

Ioes the ABS warning light illuminate as describedbelow up to the time the engine starts?

1) When the ignition key is turned to the “ON”

position, the ABS warning light illuminates for

approximately 1 second due to the ABS ECU (asa self check of the valve relays is performed),

then it blinks twice and goes out and stays out.

2) With the ignition key in the “START” position,

power to the ABS ECU is interrupted and the

5-10BRAKES - Anti-lock Braking System Troubleshooting

TROUBLESHOOTING (ABS-FWD)Confirm condition in the following way and diagnosis accordingly.

ABS warning light remains lit because the valve

relay is OFF.

(3) When the ignition key is turned from the

“START” position to the “ON” position, the

ABS warning light illuminates for approximately

1 second (during this time a recheck of the valverelays is performed), then it blinks twice and

then goes out and stays out.

ABS warning

lightON

OFF

1Ignition

kev

ST

ON

ACC, LOCK

IYes

CONTINUE TO NEXT PAGE

No

No.Trouble condition

ABS warning light does not light up at all.

ON

1 --ABSwarningOFF

1lightlgnitlon

kev

14A0590When the ignition key is turned to the

“ON” position, it remains lighted.

ABSwarning

2light

Ignition

kevACC,

LO:+14AOSQlDoes not illuminate when ignition key is

in “START” position.

ABSONwarning

3lightOFFUULkev ACC.

LO:-+-Ignition14A0592

1 sec. 1 sec.1 sec.1 sec.

---

IIII

3114AO589

IMajor causes

l ABS warning light bulb is burnt out.Check, using flow

l Open in ABS warning light electricalchart A (Refer to P.5-

circuit (check for blown fuse)12.)

l Fail safe is functioning due to ECU selfdiagnosis

o Short in ECU warning light drive circuitl Malfunction of ECU

l Malfunction of valve relayl Break in harness between ABS warn-

ing light and HU

l Break in harness between HU and

body groundRemedy

Check, using flow

chart

B (Refer to P.5-

15.)

Check, using flow

chart C (Refer to P.5-17.)

Page 151 of 1216

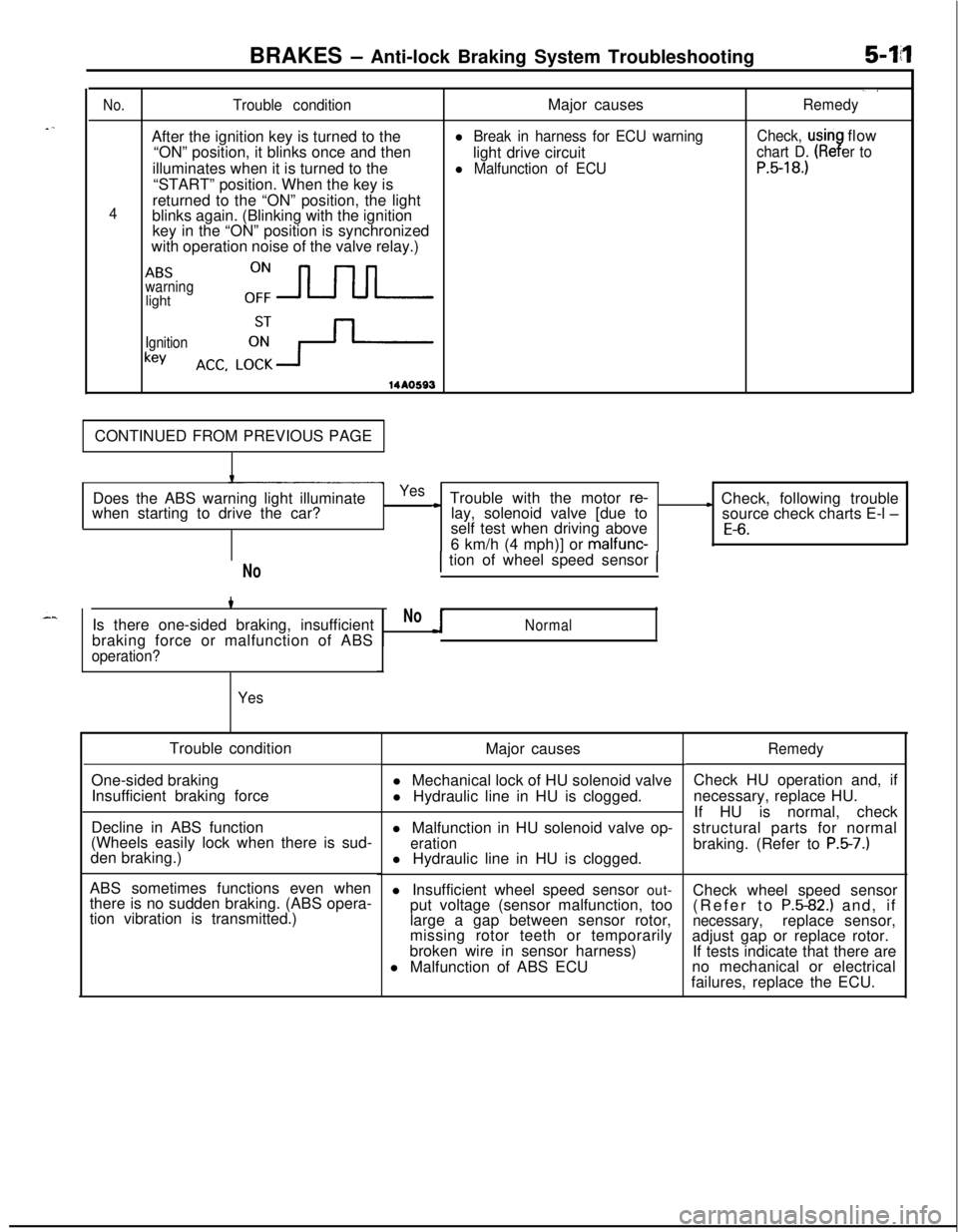

BRAKES - Anti-lock Braking System Troubleshooting5-14

./

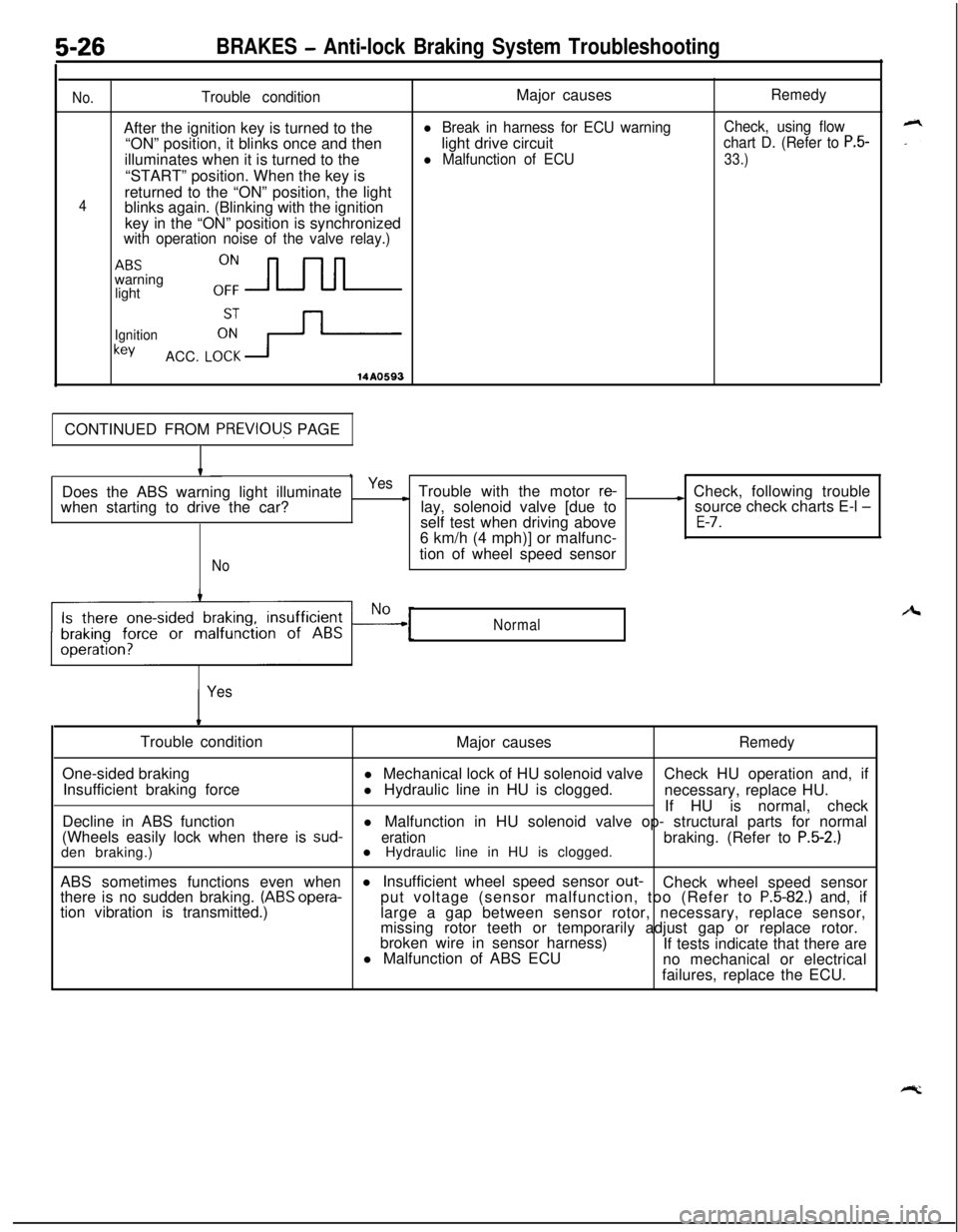

No.Trouble conditionMajor causesRemedyAfter the ignition key is turned to the

l Break in harness for ECU warningCheck, usinflow

“ON” position, it blinks once and then

light drive circuit

chart D. (Re er to9illuminates when it is turned to the

l Malfunction of ECUP.5-18.)“START” position. When the key is

4returned to the “ON” position, the light

blinks again. (Blinking with the ignition

key in the “ON” position is synchronized

with operation noise of the valve relay.)

ABSwarninglighto:-

Ignition

keyACC. LCi+-

14*0593CONTINUED FROM PREVIOUS PAGE

Does the ABS warning light illuminate

when starting to drive the car?

Yes~ Trouble with the motor re-lay, solenoid valve [due toL Check, following trouble

source check charts E-l -self test when driving above

E-6.6 km/h (4 mph)] or malfunc-

NoIs there one-sided braking, insufficient

braking force or malfunction of ABS

operation?

YesTrouble condition

Major causes

One-sided braking

Insufficient braking forcel Mechanical lock of HU solenoid valve

l Hydraulic line in HU is clogged.

Decline in ABS function

(Wheels easily lock when there is sud-

den braking.)

ABS sometimes functions even when

there is no sudden braking. (ABS opera-

tion vibration is transmitted.)

1 tion of wheel speed sensor 1

NoNormall Malfunction in HU solenoid valve op-

erationl Hydraulic line in HU is clogged.

l Insufficient wheel speed sensor out-

put voltage (sensor malfunction, too

large a gap between sensor rotor,

missing rotor teeth or temporarily

broken wire in sensor harness)

l Malfunction of ABS ECU

RemedyCheck HU operation and, if

necessary, replace HU.

If HU is normal, check

structural parts for normal

braking. (Refer to

P.5-7.)Check wheel speed sensor

(Refer to

P.5-82.) and, ifnecessary,replace sensor,

adjust gap or replace rotor.

If tests indicate that there are

no mechanical or electrical

failures, replace the ECU.

Page 165 of 1216

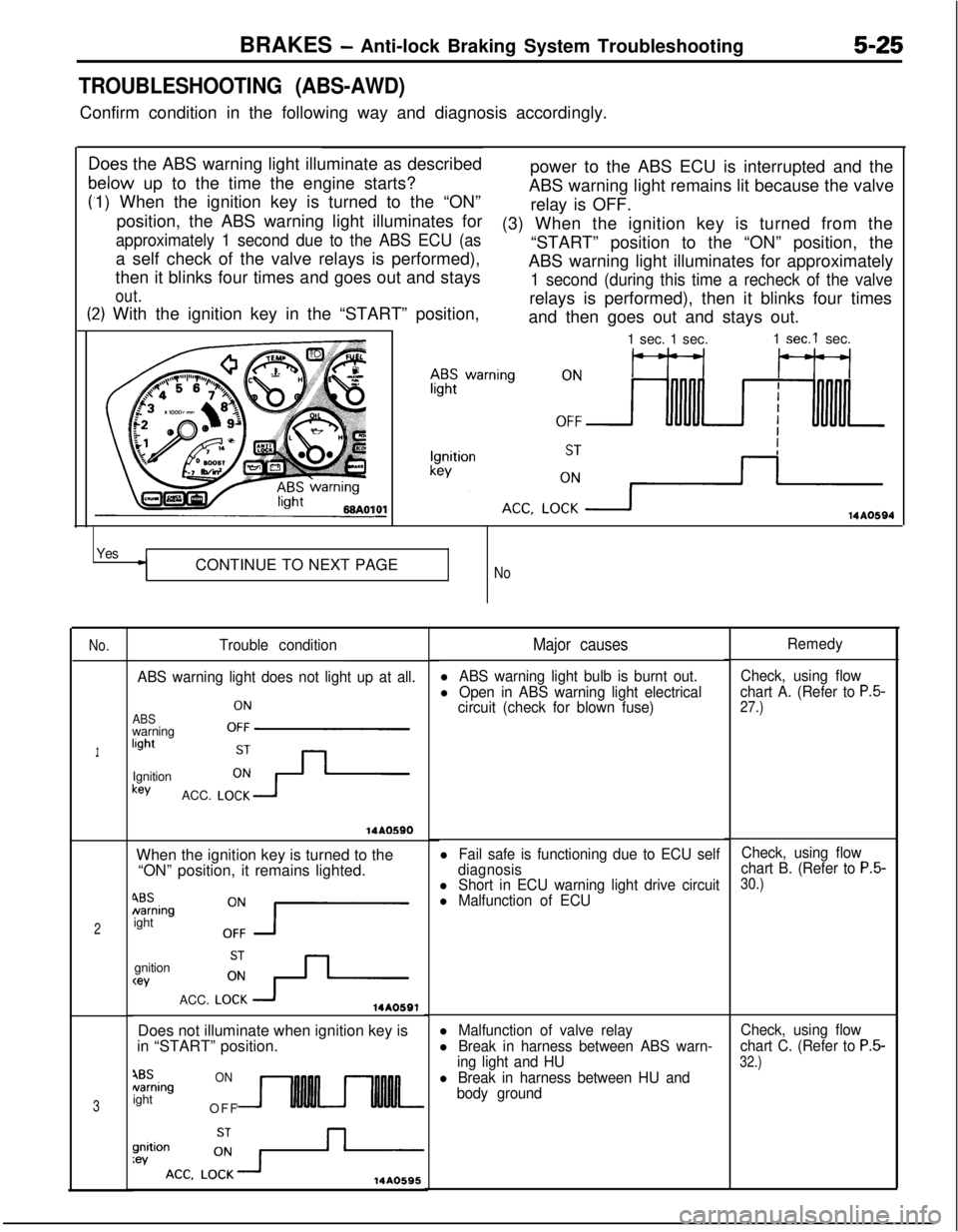

BRAKES - Anti-lock Braking System Troubleshooting5-25

TROUBLESHOOTING (ABS-AWD)Confirm condition in the following way and diagnosis accordingly.

C

F

>oes the ABS warning light illuminate as described

relow up to the time the engine starts?

1) When the ignition key is turned to the “ON”

position, the ABS warning light illuminates for

approximately 1 second due to the ABS ECU (asa self check of the valve relays is performed),

then it blinks four times and goes out and stays

out.power to the ABS ECU is interrupted and the

ABS warning light remains lit because the valve

relay is OFF.

t:2) With the ignition key in the “START” position,(3) When the ignition key is turned from the

“START” position to the “ON” position, the

ABS warning light illuminates for approximately

1 second (during this time a recheck of the valverelays is performed), then it blinks four times

and then goes out and stays out.IO1

-1 sec. 1 sec.1

sec.1 sec.

14AO594

YesCONTINUE TO NEXT PAGE

No

No.

1

2

3

Trouble condition

ABS warning light does not light up at all.

ABSwarninglightOFFIgnitionkey

ACC.

LO;-+

14AOSSOWhen the ignition key is turned to the

“ON” position, it remains lighted.

4BSNamingight

0:7gnition

wACC.

LO:+14A0591Does not illuminate when ignition key is

in “START” position.

4BSNamingightONOFF

14A0595

Major causes

l ABS warning light bulb is burnt out.

l Open in ABS warning light electrical

circuit (check for blown fuse)

l Fail safe is functioning due to ECU self

diagnosis

l Short in ECU warning light drive circuitl Malfunction of ECU

l Malfunction of valve relay

l Break in harness between ABS warn-

ing light and HU

l Break in harness between HU and

body groundRemedy

Check, using flow

chart A. (Refer to

P.5-27.)

Check, using flow

chart B. (Refer to P.5-30.)

Check, using flow

chart C. (Refer to

P.5-

32.)

Page 166 of 1216

5-26BRAKES - Anti-lock Braking System Troubleshooting

No.Trouble conditionMajor causesRemedyAfter the ignition key is turned to the

l Break in harness for ECU warningCheck, using flow“ON” position, it blinks once and thenlight drive circuitchart D. (Refer to P.5-illuminates when it is turned to the

l Malfunction of ECU33.)“START” position. When the key is

returned to the “ON” position, the light

4blinks again. (Blinking with the ignition

key in the “ON” position is synchronized

with operation noise of the valve relay.)

ABSwarning

light

0:~

Ignition

keyACC. iv-

14A0593CONTINUED FROM

PREVIOU? PAGE

I ,

Does the ABS warning light illuminateYes* Check, following trouble

when starting to drive the car?L Trouble with the motor re-lay, solenoid valve [due to

self test when driving above

6 km/h (4 mph)] or malfunc-source check charts E-l -E-7.

Notion of wheel speed sensor

Normal

YesTrouble condition

Major causes

RemedyOne-sided brakingl Mechanical lock of HU solenoid valveCheck HU operation and, if

Insufficient braking forcel Hydraulic line in HU is clogged.

necessary, replace HU.

If HU is normal, check

Decline in ABS functionl Malfunction in HU solenoid valve op- structural parts for normal

(Wheels easily lock when there is

sud-

erationbraking. (Refer to P.5-2.)den braking.)l Hydraulic line in HU is clogged.

ABS sometimes functions even whenl Insufficient wheel speed sensor

out-Check wheel speed sensor

there is no sudden braking. (ABS opera-put voltage (sensor malfunction, too (Refer to P.5-82.) and, if

tion vibration is transmitted.)

large a gap between sensor rotor, necessary, replace sensor,

missing rotor teeth or temporarily adjust gap or replace rotor.

broken wire in sensor harness)

If tests indicate that there are

l Malfunction of ABS ECU

no mechanical or electrical

failures, replace the ECU.

Page 250 of 1216

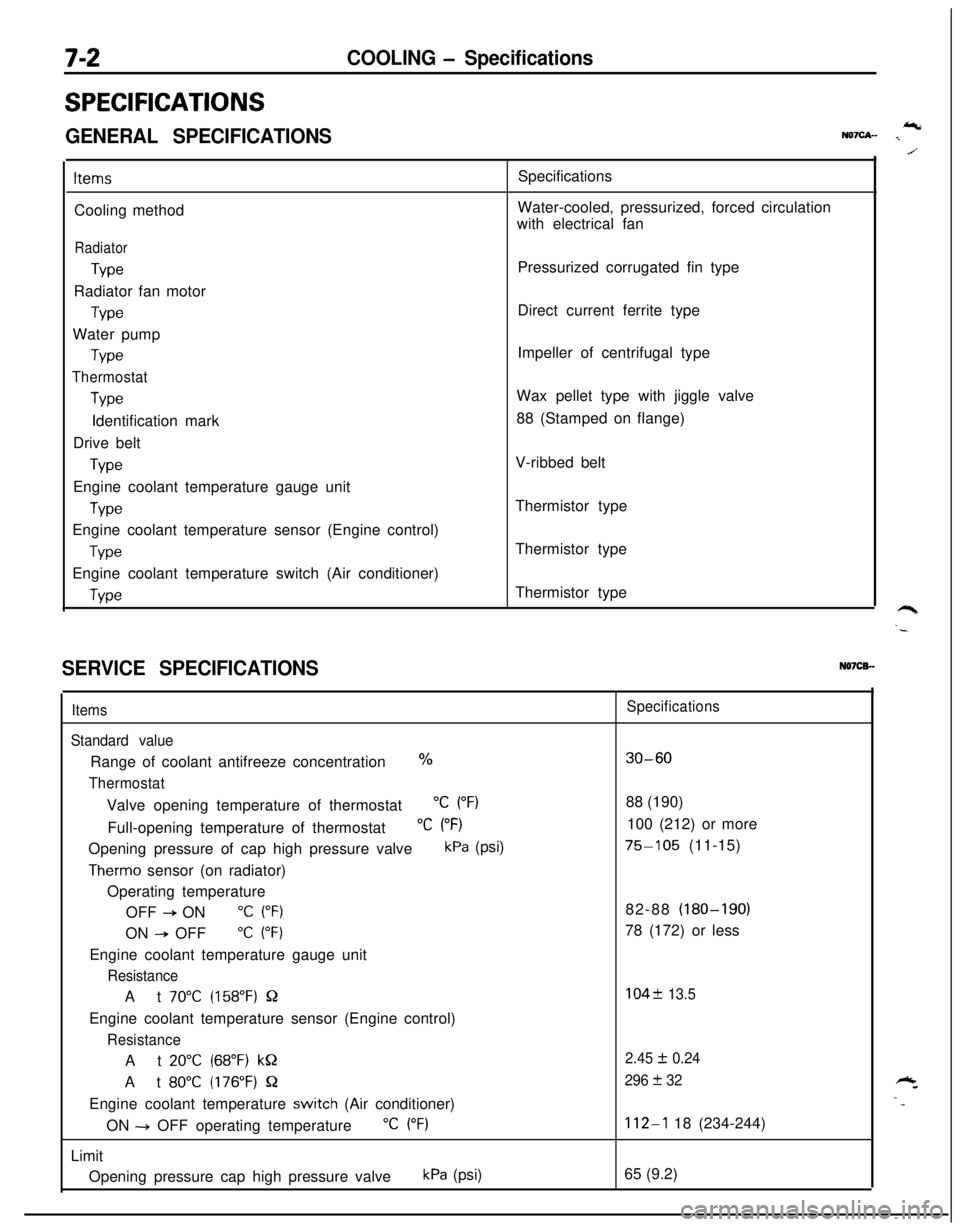

7-2COOLING - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSIcNQ7cA- I

ItemsCooling method

Radiator

TypeRadiator fan motor

TypeWater pump

Type

Thermostat

TypeIdentification mark

Drive belt

TypeEngine coolant temperature gauge unit

WeEngine coolant temperature sensor (Engine control)

TypeEngine coolant temperature switch (Air conditioner)

WeSpecifications

Water-cooled, pressurized, forced circulation

with electrical fan

Pressurized corrugated fin type

Direct current ferrite type

Impeller of centrifugal type

Wax pellet type with jiggle valve

88 (Stamped on flange)

V-ribbed belt

Thermistor type

Thermistor type

Thermistor type

SERVICE SPECIFICATIONSN07CB.-

Items

Standard valueRange of coolant antifreeze concentration

%

ThermostatValve opening temperature of thermostat

“C (“F)Full-opening temperature of thermostat

“C (“F)Opening pressure of cap high pressure valve

kPa (psi)

Therm0 sensor (on radiator)

Operating temperature

OFF

+ ON“C (“F)ON

--P OFF“C (“F)Engine coolant temperature gauge unit

ResistanceAt

70°C (158°F) QEngine coolant temperature sensor (Engine control)

ResistanceAt

20°C (68°F) kQAt

80°C (176°F) QEngine coolant temperature

switch (Air conditioner)

ON -+ OFF operating temperature

“C (“F)Limit

Opening pressure cap high pressure valve

kPa (psi)

Specifications

30-6088 (190)

100 (212) or more

75-105 (11-15)

82-88 (180-190)

78 (172) or less

104f 13.5

2.45

I!I 0.24

296

+ 32

112-l 18 (234-244)

65 (9.2)