head bolt MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 28 of 1216

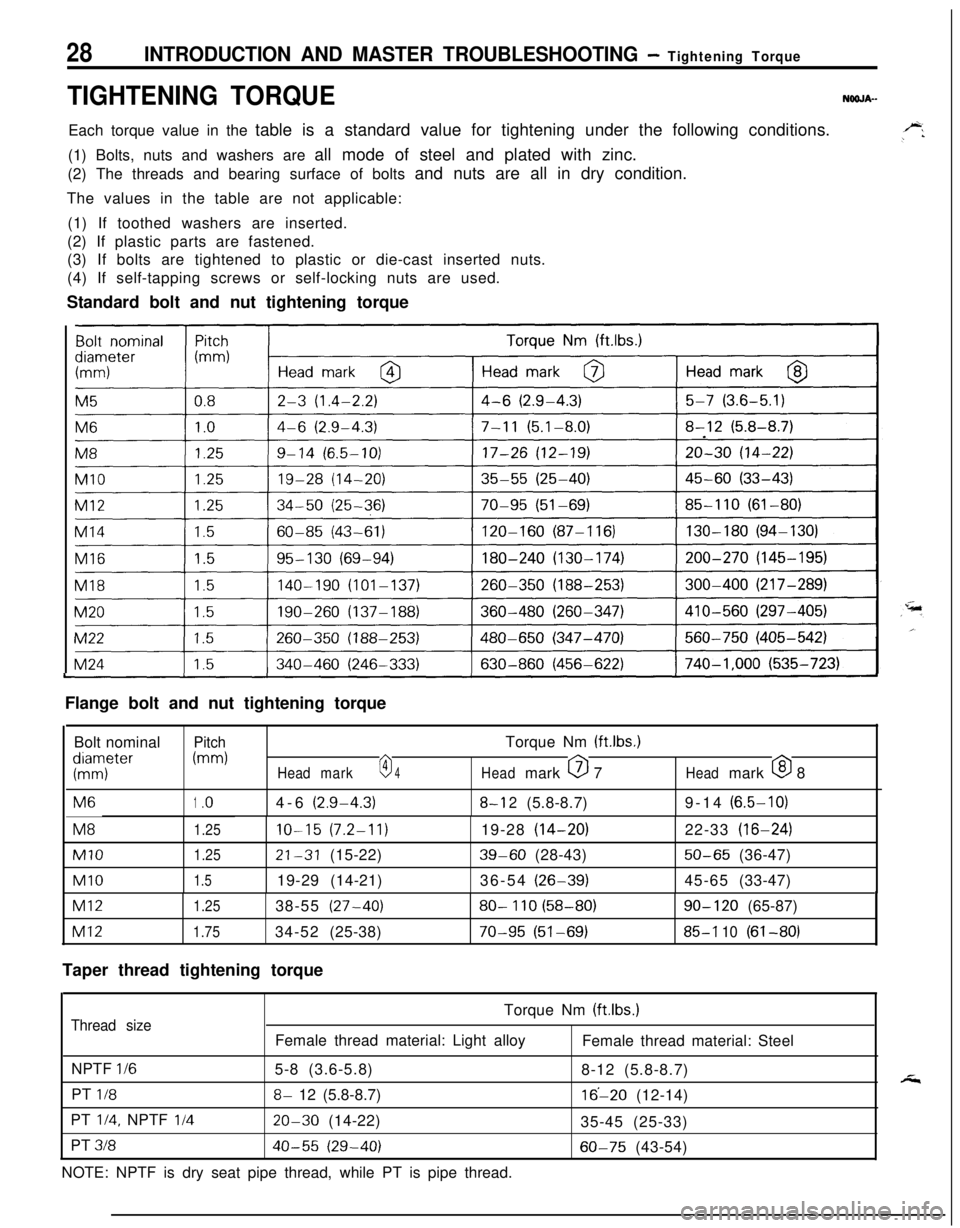

28INTRODUCTION AND MASTER TROUBLESHOOTING - Tightening Torque

TIGHTENING TORQUENOOJA-Each torque value in the table is a standard value for tightening under the following conditions.

(1) Bolts, nuts and washers are all mode of steel and plated with zinc.

(2) The threads and bearing surface of bolts and nuts are all in dry condition.

The values in the table are not applicable:

(1) If toothed washers are inserted.

(2) If plastic parts are fastened.

(3) If bolts are tightened to plastic or die-cast inserted nuts.

(4) If self-tapping screws or self-locking nuts are used.

Standard bolt and nut tightening torque

I

I

ILFlange bolt and nut tightening torque

Bolt nominal

PitchTorque Nm (ftlbs.)

KTter

(mm)

Headmark0 4Headmark 0 7Headmark 0 8M6

1.o4-6(2.9-4.3)8-l 2(5.8-8.7)9-14(6.5-10)M8

1.25IO-15(7.2-11)19-28(14-20)22-33(16-24)

Ml01.2521-31(15-22)39-60(28-43)50-65(36-47)

Ml01.519-29(14-21)36-54(26-39)45-65(33-47)

Ml21.2538-55(27-40)80- 110 (58-80)90- 120(65-87)

Ml21.7534-52(25-38)70-95 (51-69)85-l 10(61-80)

Taper thread tightening torque

Torque Nm (ftlbs.)

Thread sizeFemale thread material: Light alloy

Female thread material: Steel

NPTF

l/65-8 (3.6-5.8)

8-12 (5.8-8.7)

PT

l/88- 12 (5.8-8.7)16’-20 (12-14)

PT

l/4, NPTF I/420-30 (14-22)

35-45 (25-33)

PT

31840-55 (29-40)60-75 (43-54)

NOTE: NPTF is dry seat pipe thread, while PT is pipe thread.

Page 251 of 1216

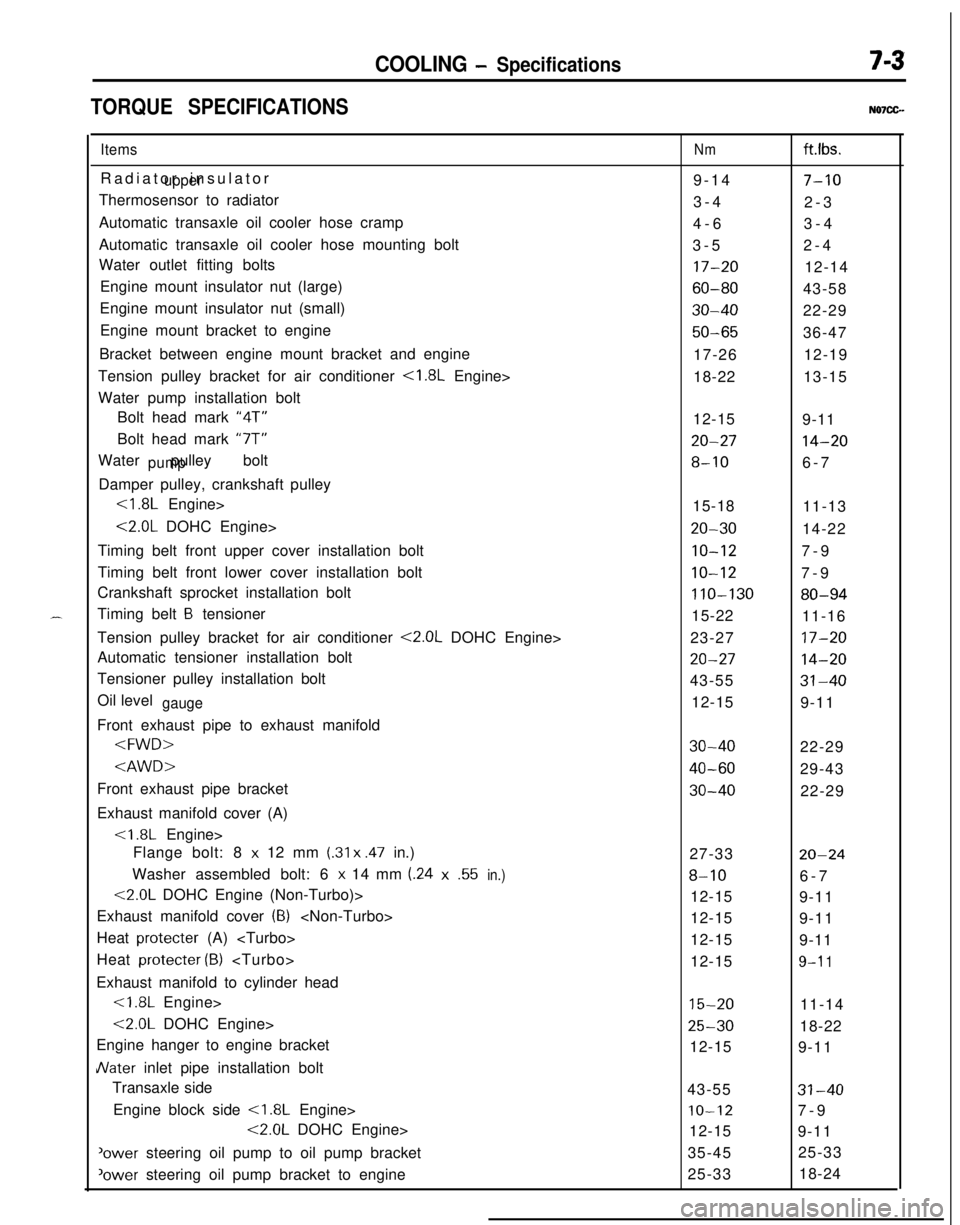

COOLING - Specifications7-3

TORQUE SPECIFICATIONSN07CG.

ItemsRadiator insulator

upperThermosensor to radiator

Automatic transaxle oil cooler hose cramp

Automatic transaxle oil cooler hose mounting bolt

Water outlet fitting bolts

Engine mount insulator nut (large)

Engine mount insulator nut (small)

Engine mount bracket to engine

Bracket between engine mount bracket and engine

Tension pulley bracket for air conditioner

<1.8L Engine>

Water pump installation bolt

Bolt head mark “4T”

Bolt head mark “7T”

Water pulley bolt

pumpDamper pulley, crankshaft pulley

<1.8L Engine>

<2.0L DOHC Engine>

Timing belt front upper cover installation bolt

Timing belt front lower cover installation bolt

Crankshaft sprocket installation bolt

Timing belt

B tensioner

Tension pulley bracket for air conditioner

<2.0L DOHC Engine>

Automatic tensioner installation bolt

Tensioner pulley installation bolt

Oil level

gaugeFront exhaust pipe to exhaust manifold

Exhaust manifold cover (A)

Flange bolt: 8

x 12 mm (.31 x .47 in.)

Washer assembled bolt: 6

x 14 mm (.24x.55in.)

<2.0L DOHC Engine (Non-Turbo)>

Exhaust manifold cover

(8)

Heat protecter (A)

Heat protecter

(B)

Exhaust manifold to cylinder head<1.8L Engine>

<2.0L DOHC Engine>

Engine hanger to engine bracket

JVater inlet pipe installation bolt

Transaxle side

Engine block side

<1.8L Engine>

<2.0L DOHC Engine>

'ower steering oil pump to oil pump bracket

‘ower steering oil pump bracket to engine

Nmft.lbs.

9-14

7-103-4

2-3

4-63-4

3-52-4

17-2012-14

60-8043-58

30-4022-29

50-6536-47

17-2612-19

18-2213-15

12-15

9-11

20-2714-20

8-106-7

15-18

11-13

20-3014-22

IO-127-9

10-127-9

110-13080-9415-22

11-16

23-27

17-20

20-2714-2043-55

31-4012-15

9-11

30-4022-29

40-6029-43

30-4022-29

27-33

20-24

8-106-7

12-15

9-11

12-15

9-11

12-15

9-11

12-15

9-l 1

15-2011-14

25-3018-22

12-15

9-11

43-55

31-40

IO-127-9

12-15

9-11

35-4525-33

25-3318-24

Page 302 of 1216

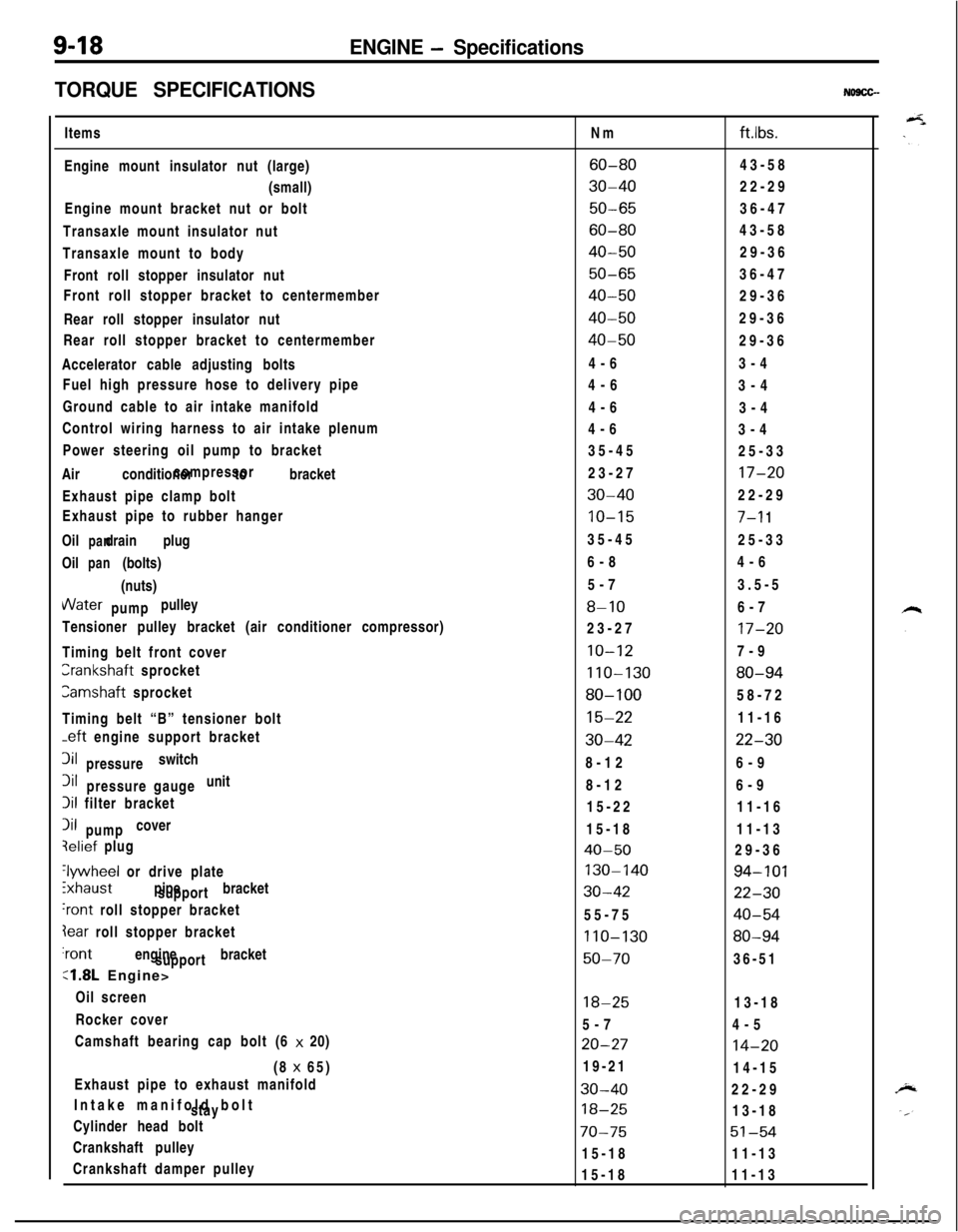

9-18ENGINE - Specifications

TORQUE SPECIFICATIONS

NO9CG-Items

Engine mount insulator nut (large)

(small)

Engine mount bracket nut or bolt

Transaxle mount insulator nut

Transaxle mount to body

Front roll stopper insulator nut

Front roll stopper bracket to centermember

Rear roll stopper insulator nut

Rear roll stopper bracket to centermember

Accelerator cable adjusting bolts

Fuel high pressure hose to delivery pipe

Ground cable to air intake manifold

Control wiring harness to air intake plenum

Power steering oil pump to bracket

Air conditioner to bracketcompressor

Exhaust pipe clamp bolt

Exhaust pipe to rubber hanger

Oil drain plug

panOil (bolts)

pan(nuts)VVater pulley

pump

Tensioner pulley bracket (air conditioner compressor)

Timing belt front coverCrankshaft sprocket

Camshaft sprocket

Timing belt “B” tensioner bolt

-eft engine support bracket3il switch

pressure3il unit

pressure gauge

Iii filter bracket

Iii cover

pumpqelief plug

‘lywheel or drive plate

ixhaust pipe bracket

support

‘rant roll stopper bracket

Iear roll stopper bracket‘rant engine bracket

support

:1.8L Engine>

Oil screen

Rocker cover

Camshaft bearing cap bolt (6 x 20)

(8 x 65)

Exhaust pipe to exhaust manifold

Intake manifold bolt

stay

Cylinder head bolt

Crankshaft pulley

Crankshaft damper pulleyNm

ftlbs.

60-8043-58

30-4022-29

50-6536-47

60-8043-58

40-5029-36

50-6536-47

40-5029-36

40-5029-36

40-5029-36

4-63-4

4-6

3-4

4-6

3-4

4-6

3-4

35-45

25-33

23-27

17-20

30-4022-29

10-157-l 135-45

25-33

6-84-6

5-73.5-5

8-106-7

23-27

17-20

10-127-9

110-13080-94

80-10058-72

15-2211-16

30-4222-308-126-9

8-126-9

15-2211-16

15-1811-13

40-5029-36

130-14094-101

30-4222-3055-75

40-54

110-13080-94

50-7036-51

18-2513-18

5-74-5

20-2714-2019-21

14-15

30-4022-29

18-2513-18

70-7551-5415-1811-13

15-1811-13

Page 303 of 1216

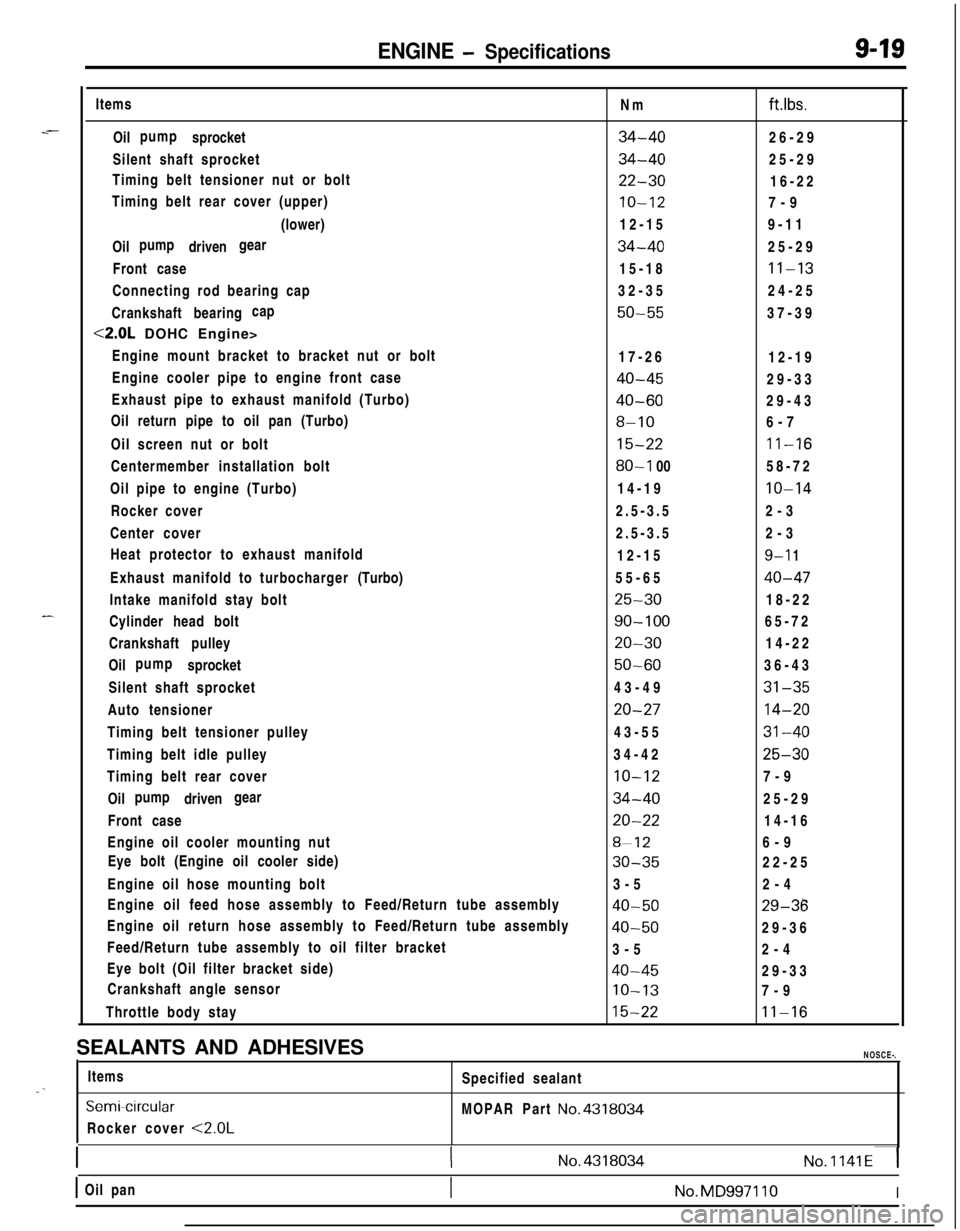

-

ENGINE - Specifications9-19Items

Oil sprocketpump

Silent shaft sprocket

Timing belt tensioner nut or bolt

Timing belt rear cover (upper)

(lower)

Oil drivenpump gear

Front case

Connecting rod bearing cap

Crankshaft bearingcap

<2.0L DOHC Engine>

Engine mount bracket to bracket nut or bolt

Engine cooler pipe to engine front case

Exhaust pipe to exhaust manifold (Turbo)

Oil return pipe to oil pan (Turbo)

Oil screen nut or bolt

Centermember installation bolt

Oil pipe to engine (Turbo)

Rocker cover

Center cover

Heat protector to exhaust manifold

Exhaust manifold to turbocharger(Turbo)

Intake manifold stay bolt

Cylinder head bolt

Crankshaft pulley

Oil sprocketpump

Silent shaft sprocket

Auto tensioner

Timing belt tensioner pulley

Timing belt idle pulley

Timing belt rear cover

Oil drivenpump gear

Front case

Engine oil cooler mounting nut

Eye bolt (Engine oil cooler side)

Engine oil hose mounting bolt

Engine oil feed hose assembly to Feed/Return tube assembly

Engine oil return hose assembly to Feed/Return tube assembly

Feed/Return tube assembly to oil filter bracket

Eye bolt (Oil filter bracket side)

Crankshaft angle sensor

Throttle body stayNm

ft.lbs.

34-4026-29

34-4025-29

22-3016-22

IO-127-9

12-159-11

34-4025-29

15-18

11-1332-3524-25

50-5537-39

17-26

12-19

40-4529-33

40-6029-43

8-106-7

15-2211-16

80-l 0058-72

14-19

10-142.5-3.52-3

2.5-3.52-3

12-15

9-l 155-65

40-47

25-3018-22

90-10065-72

20-3014-22

50-6036-43

43-49

31-35

20-2714-2043-55

31-4034-42

25-30

10-127-9

34-4025-29

20-2214-16

8-126-9

30-3522-25

3-52-4

40-5029-36

40-5029-36

3-52-4

40-4529-33

IO-137-9

15-2211-16SEALANTS AND ADHESIVES

NOSCE-.Items

Specified sealant

“. _

SemiWrcularMOPAR Part No.4318034Rocker cover

<2.0L

1(No.4318034No.1141~1

1 Oil pan1No.MD997110I

Page 311 of 1216

ENGINE <1.8L Engine> -Service Adjustment Procedures9-27

I.

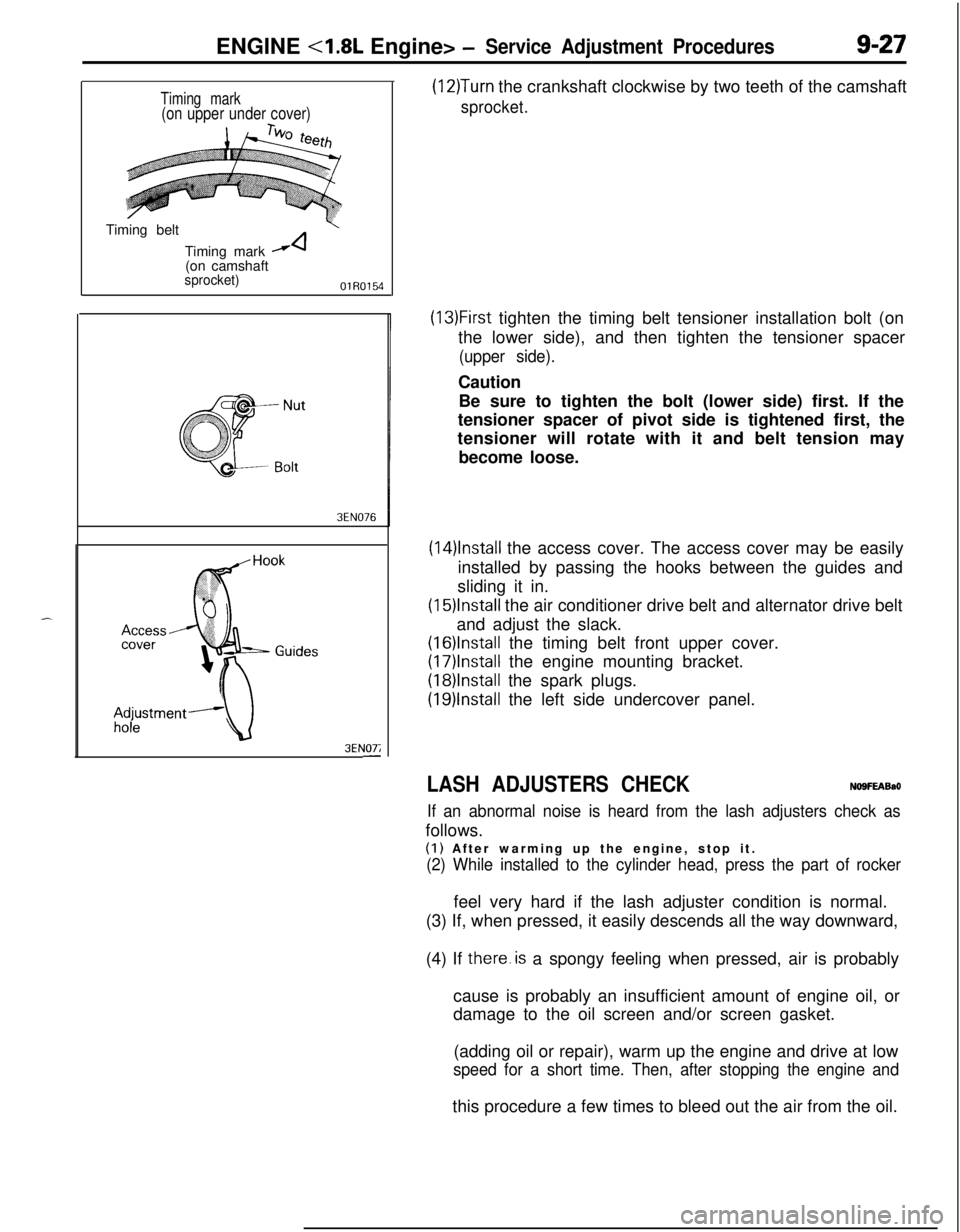

Timing mark(on upper under cover)Timing belt

Timing mark

A(on camshaft

sprocket)OlR0154

3EN076

3EN07;-

(12)Turn the crankshaft clockwise by two teeth of the camshaft

sprocket.

(13)First tighten the timing belt tensioner installation bolt (on

the lower side), and then tighten the tensioner spacer

(upper side).Caution

Be sure to tighten the bolt (lower side) first. If the

tensioner spacer of pivot side is tightened first, the

tensioner will rotate with it and belt tension may

become loose.

(14)lnstall the access cover. The access cover may be easily

installed by passing the hooks between the guides and

sliding it in.

(15)lnstall the air conditioner drive belt and alternator drive belt

and adjust the slack.

(16)lnstalI the timing belt front upper cover.

(17)lnstall the engine mounting bracket.

(18)lnstalI the spark plugs.

(19)lnstall the left side undercover panel.

LASH ADJUSTERS CHECKNO9FEABaO

If an abnormal noise is heard from the lash adjusters check asfollows.

(I) After warming up the engine, stop it.

(2) While installed to the cylinder head, press the part of rockerfeel very hard if the lash adjuster condition is normal.

(3) If, when pressed, it easily descends all the way downward,

(4) If there.is a spongy feeling when pressed, air is probably

cause is probably an insufficient amount of engine oil, or

damage to the oil screen and/or screen gasket.

(adding oil or repair), warm up the engine and drive at low

speed for a short time. Then, after stopping the engine andthis procedure a few times to bleed out the air from the oil.

Page 323 of 1216

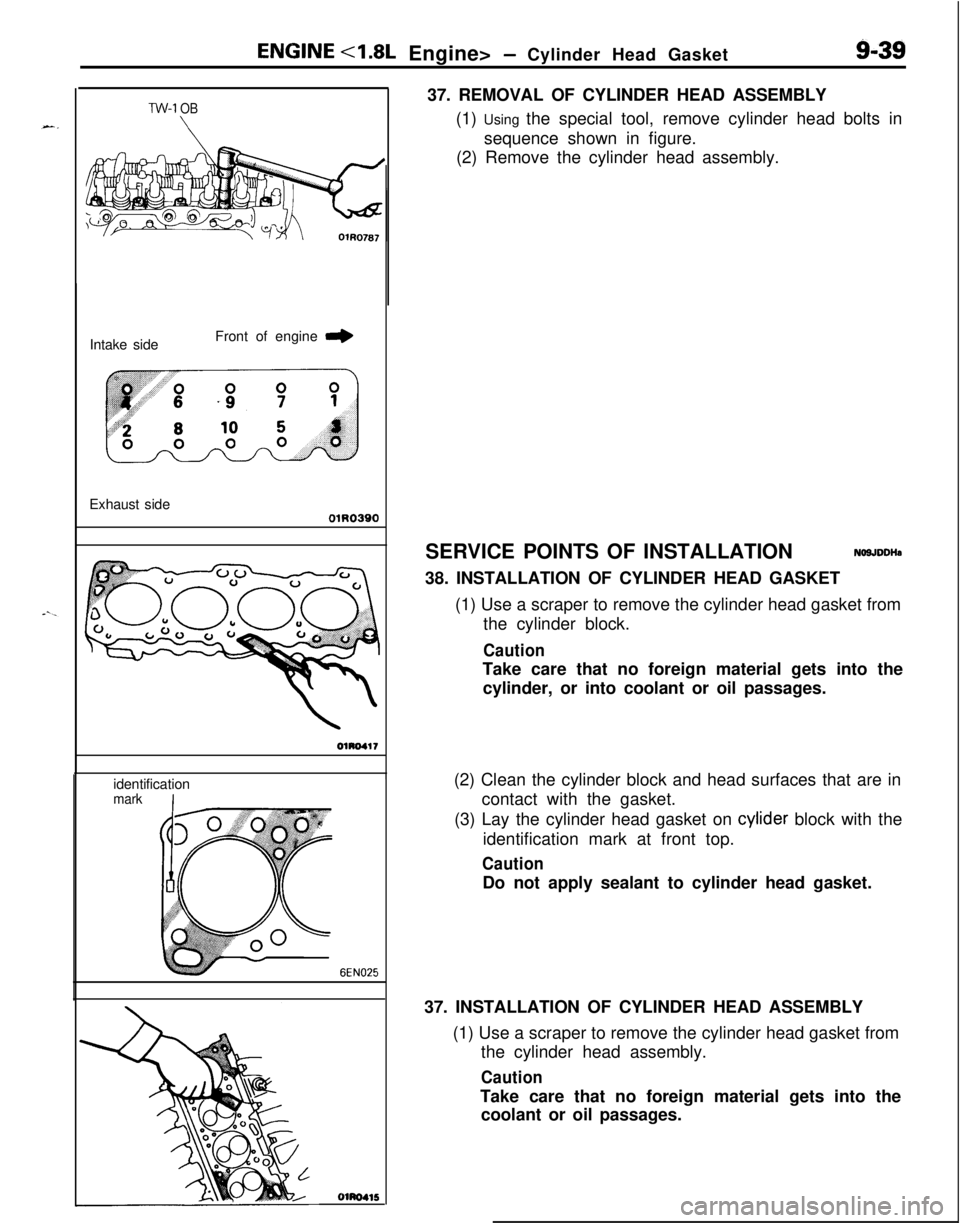

ENGlNE <1.8L Engine> - Cylinder Head Gasket9-3937. REMOVAL OF CYLINDER HEAD ASSEMBLY

(1) Using the special tool, remove cylinder head bolts in

sequence shown in figure.

(2) Remove the cylinder head assembly.

TW-1 OBIntake sideFront of engine

r,Exhaust side

01R0390identification

I

mark

6EN025

Olm415SERVICE POINTS OF INSTALLATION

NO9JDDHs38. INSTALLATION OF CYLINDER HEAD GASKET

(1) Use a scraper to remove the cylinder head gasket from

the cylinder block.

CautionTake care that no foreign material gets into the

cylinder, or into coolant or oil passages.

(2) Clean the cylinder block and head surfaces that are in

contact with the gasket.

(3) Lay the cylinder head gasket on cylider block with the

identification mark at front top.

CautionDo not apply sealant to cylinder head gasket.

37. INSTALLATION OF CYLINDER HEAD ASSEMBLY

(1) Use a scraper to remove the cylinder head gasket from

the cylinder head assembly.

CautionTake care that no foreign material gets into the

coolant or oil passages.

Page 324 of 1216

ENGINE <1.8L Engine> - Cylinder Head Gasket

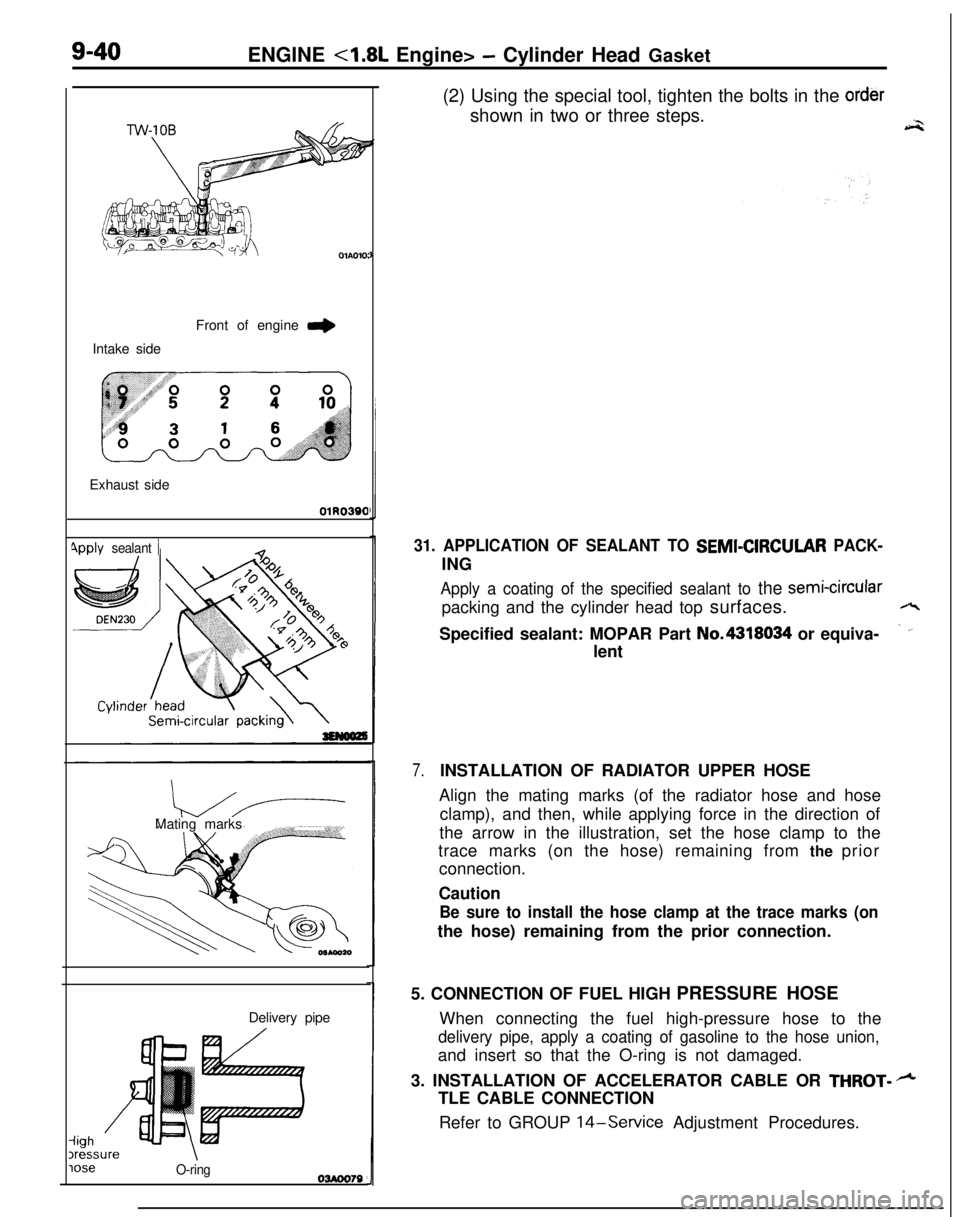

OlAOlO:Intake sideFront of engine

I,Exhaust side

01R0390

4pply

sealant 1Mating marks

.,

iighDelivery pipe3ressureloseO-ring03Aoo79(2) Using the special tool, tighten the bolts in the

ordershown in two or three steps.

a-2

31. APPLICATION OF SEALANT TO SEMI-CIRCULAR PACK-ING

Apply a coating of the specified sealant to the semi-circularpacking and the cylinder head top surfaces.

/LSpecified sealant: MOPAR Part No.4318034 or equiva-

_ ‘-lent

7.INSTALLATION OF RADIATOR UPPER HOSE

Align the mating marks (of the radiator hose and hose

clamp), and then, while applying force in the direction of

the arrow in the illustration, set the hose clamp to the

trace marks (on the hose) remaining from the prior

connection.

Caution

Be sure to install the hose clamp at the trace marks (onthe hose) remaining from the prior connection.

5. CONNECTION OF FUEL HIGH PRESSURE HOSE

When connecting the fuel high-pressure hose to the

delivery pipe, apply a coating of gasoline to the hose union,and insert so that the O-ring is not damaged.

3. INSTALLATION OF ACCELERATOR CABLE OR

THROT- +TLE CABLE CONNECTION

Refer to GROUP

14-Service Adjustment Procedures.

Page 334 of 1216

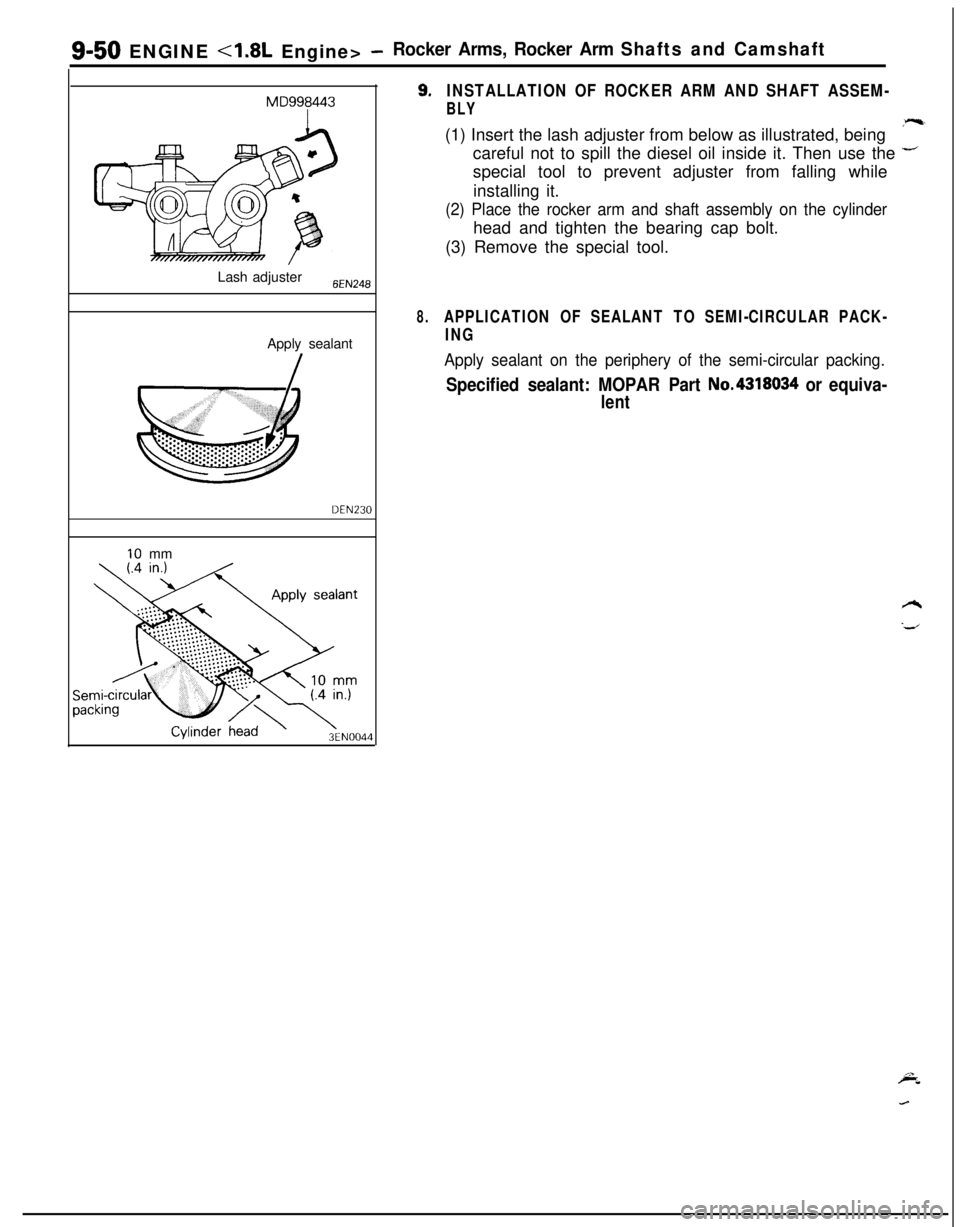

S-50 ENGINE 4.8L Engine> -Rocker Arms, Rocker Arm Shafts and Camshaft

MD998443Lash adjuster

6EN248Apply sealant

DEN230

10 mm

3EN0044

9.INSTALLATION OF ROCKER ARM AND SHAFT ASSEM-

BLY(1) Insert the lash adjuster from below as illustrated, being

*-careful not to spill the diesel oil inside it. Then use the

+special tool to prevent adjuster from falling while

installing it.

(2) Place the rocker arm and shaft assembly on the cylinderhead and tighten the bearing cap bolt.

(3) Remove the special tool.

8.APPLICATION OF SEALANT TO SEMI-CIRCULAR PACK-

ING

Apply sealant on the periphery of the semi-circular packing.

Specified sealant: MOPAR Part No.4318034 or equiva-

lent

Page 337 of 1216

ENGINE <1.8L Engine>- Cylinder Head and Valve9-53

CYLINDERHEADAND VALVE

-’DISASSEMBLY AND REASSEMBLYNDSPE-A

C;;d ;;g$;

51154 ftlbs.

&

, tP-----5

1g-.-a

105 y----2g&---l4

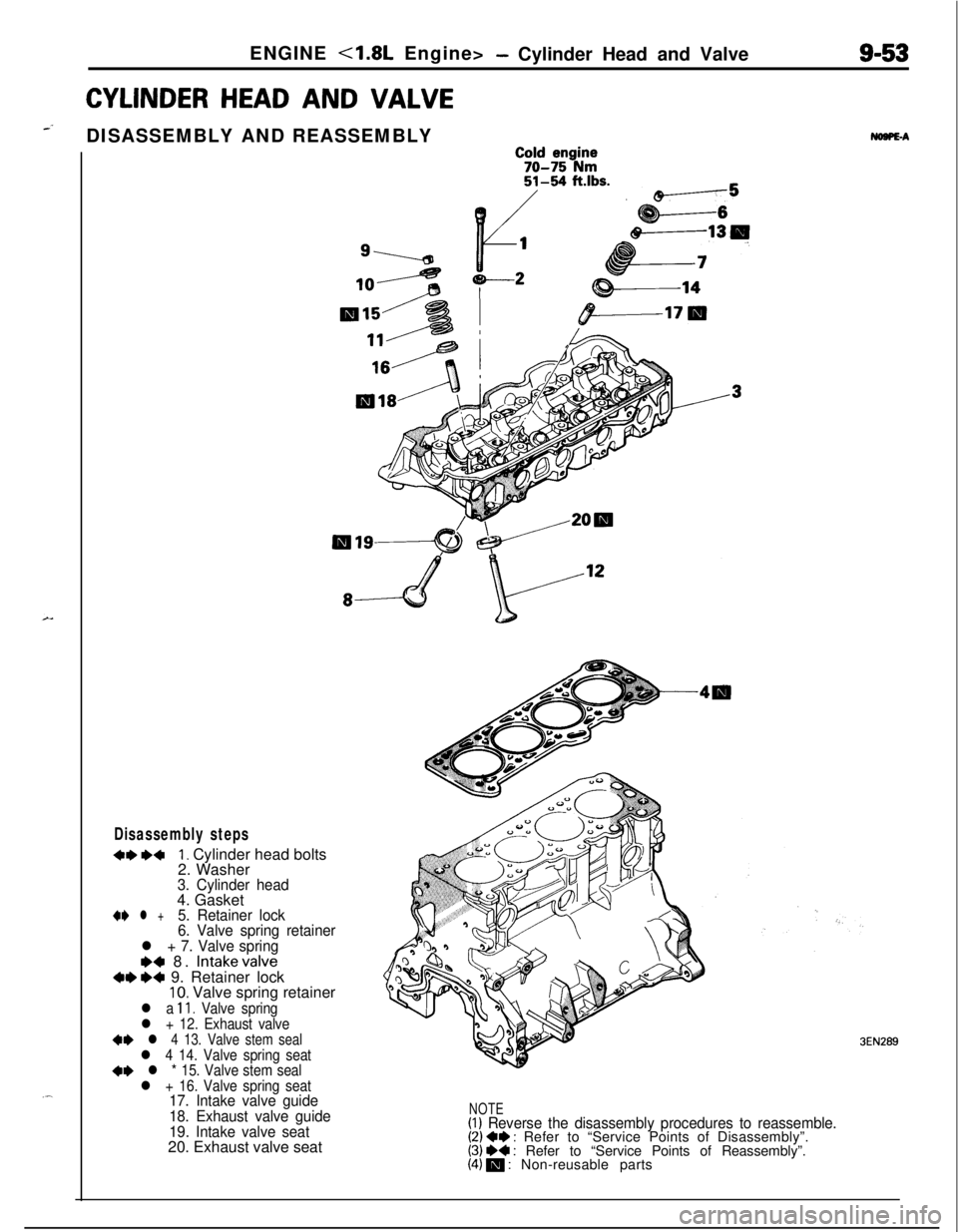

Disassembly steps

+e ~~I. Cylinder head bolts

2. Washer

3. Cylinder head4. Gasket

+e l +5. Retainer lock

6. Valve spring retainer

l + 7. Valve spring

~~ 8. Intakevalve+e e+ 9. Retainer lock10. Valve spring retainer

l a 11. Valve springl + 12. Exhaust valve+* l 4 13. Valve stem seall 4 14. Valve spring seat4I) l * 15. Valve stem seall + 16. Valve spring seat17. Intake valve guide

18. Exhaust valve guide

19. Intake valve seat20. Exhaust valve seatNOTE(I) Reverse the disassembly procedures to reassemble.(2) +e : Refer to “Service Points of Disassembly”.(3) ~~ : Refer to “Service Points of Reassembly”.(4) m : Non-reusable parts

3EN289

Page 338 of 1216

ENGINE - Cylinder Head and ValveSERVICE POINTS OF DISASSEMBLY

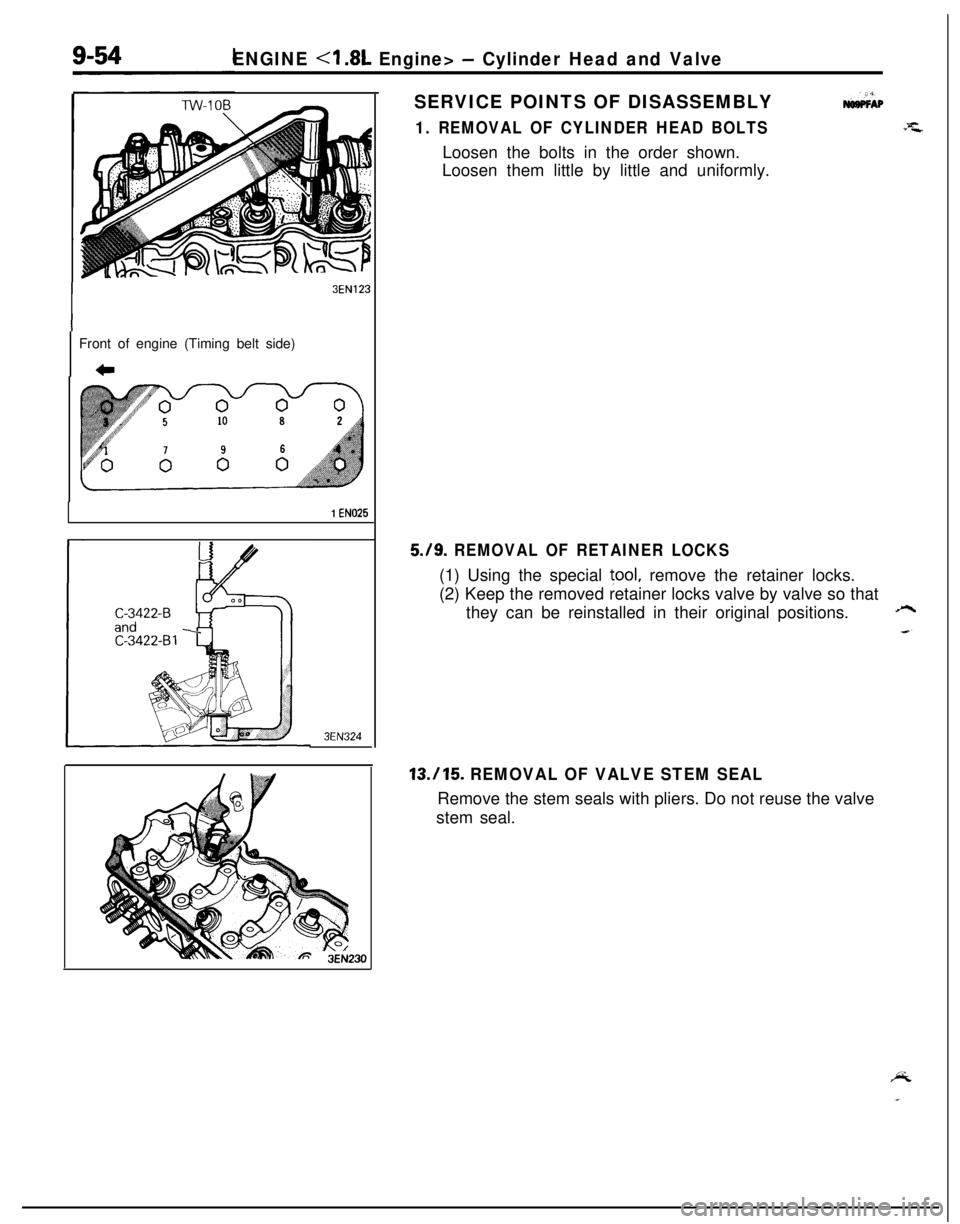

1. REMOVAL OF CYLINDER HEAD BOLTS

3EN123Front of engine (Timing belt side)

c

1 EN025

3EN324Loosen the bolts in the order shown.

Loosen them little by little and uniformly.

5./9. REMOVAL OF RETAINER LOCKS(1) Using the special

tool, remove the retainer locks.

(2) Keep the removed retainer locks valve by valve so that

they can be reinstalled in their original positions.

A

13.115. REMOVAL OF VALVE STEM SEALRemove the stem seals with pliers. Do not reuse the valve

stem seal.