oil MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 13 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions befdre Service‘1 S

OOV663OOY192

FOOO 1.

FOOO18

0

OOD511

J7

PRECAUTIONS BEFORE SERVICE wxww

PROTECTING THE VEHICLEIf there is a likelihood of damaging painted or interior parts

during service operations, protect them with suitable covers

(such as seat covers, fender covers, etc.).

REMOVAL AND DISASSEMBLY

When checking a malfunction, find the cause of the problem. If

it is determined that removal and/or disassembly is necessary,

perform the work by following the procedures contained in thisService Manual.

If punch marks or mating marks are made to avoid error in

assembly and to facilitate the assembly work, be sure’to makethem in locations which will have no detrimental effect on

performance and/or appearances.

If an area having many parts, similar parts, and/or parts whichare symmetrical right and left is disassembled; be sure to

arrange the parts so that they do not become mixed during theassembly process.

1. Arrange the parts removed in the proper order.

2.Determine which parts are to be reused and which are to

be replaced.

3.If bolts, nuts, etc., are to be replaced, be sure to use only

the exact size specified.

i:c ” -,.> ‘..“i,. i” ,,‘. 5,

SPECIAL TOOLSIf other tools are substituted for the special tools to do service

or repair work, there is the danger that vehicle parts might be

damaged, or the technician might be injured; therefore, be sureto use the special tool whenever doing any work for which the

use of one is specified.

PARTS TO BE REPLACEDIf any of the following parts are removed, they must be

replaced with new parts.

1. Oil seals

2. Gaskets (except rocker cover gasket)

3. Packings

4. O-rings

5. Lock washers

6. Cotter pins

7. Self-locking nuts

Page 17 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions before Sew&e‘37

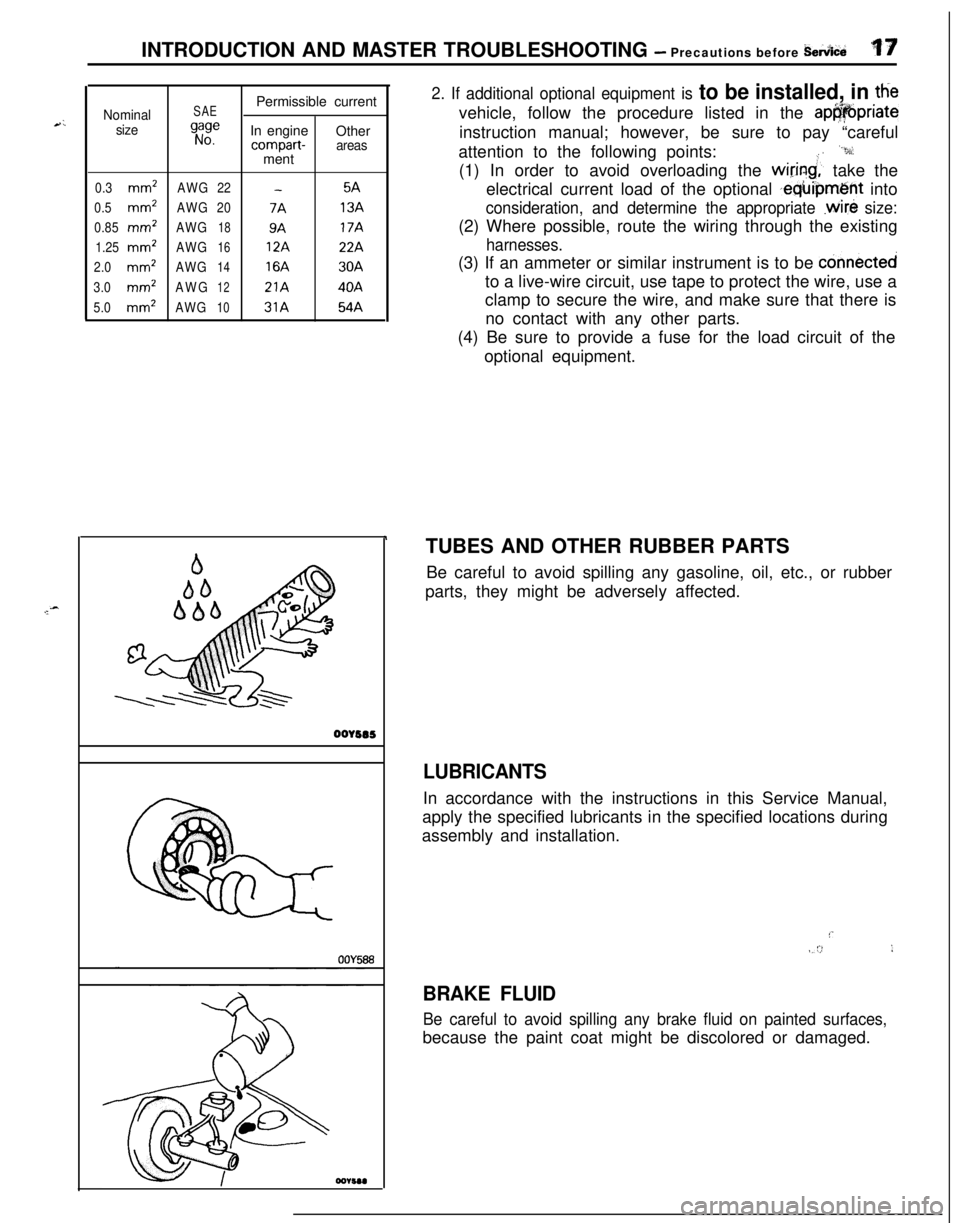

Nominal

sizeSAE

gi:ePermissible current

In engine

Othercompart-areasment

0.3mm2AWG22-5A

0.5

mm2AWG207A13A

0.85

mm’AWG189A17A

1.25

mm2AWG1612A22A

2.0mm2AWG1416A30A

3.0mm’AWG1221A40A

5.0mm2AWG1031A54A

r ‘.

oorsas

2. If additional optional equipment is to be installed, in ttievehicle, follow the procedure listed in the

ap@@priateinstruction manual; however, be sure to pay “careful

attention to the following points:

“9:(1) In order to avoid overloading the

wiring;’ take the

electrical current load of the optional

,equipment into

consideration, and determine the appropriate .wire size:(2) Where possible, route the wiring through the existing

harnesses.(3) If an ammeter or similar instrument is to be

connectedto a live-wire circuit, use tape to protect the wire, use a

clamp to secure the wire, and make sure that there is

no contact with any other parts.

(4) Be sure to provide a fuse for the load circuit of the

optional equipment.

TUBES AND OTHER RUBBER PARTS

Be careful to avoid spilling any gasoline, oil, etc., or rubber

parts, they might be adversely affected.

LUBRICANTSIn accordance with the instructions in this Service Manual,

apply the specified lubricants in the specified locations during

assembly and installation.

!’IV/ :>,I

BRAKE FLUID

Be careful to avoid spilling any brake fluid on painted surfaces,because the paint coat might be discolored or damaged.

Page 22 of 1216

22 INTRODUCTION AND MASTER TROUBLESHOOTING - %%c%:k! ‘nstructions

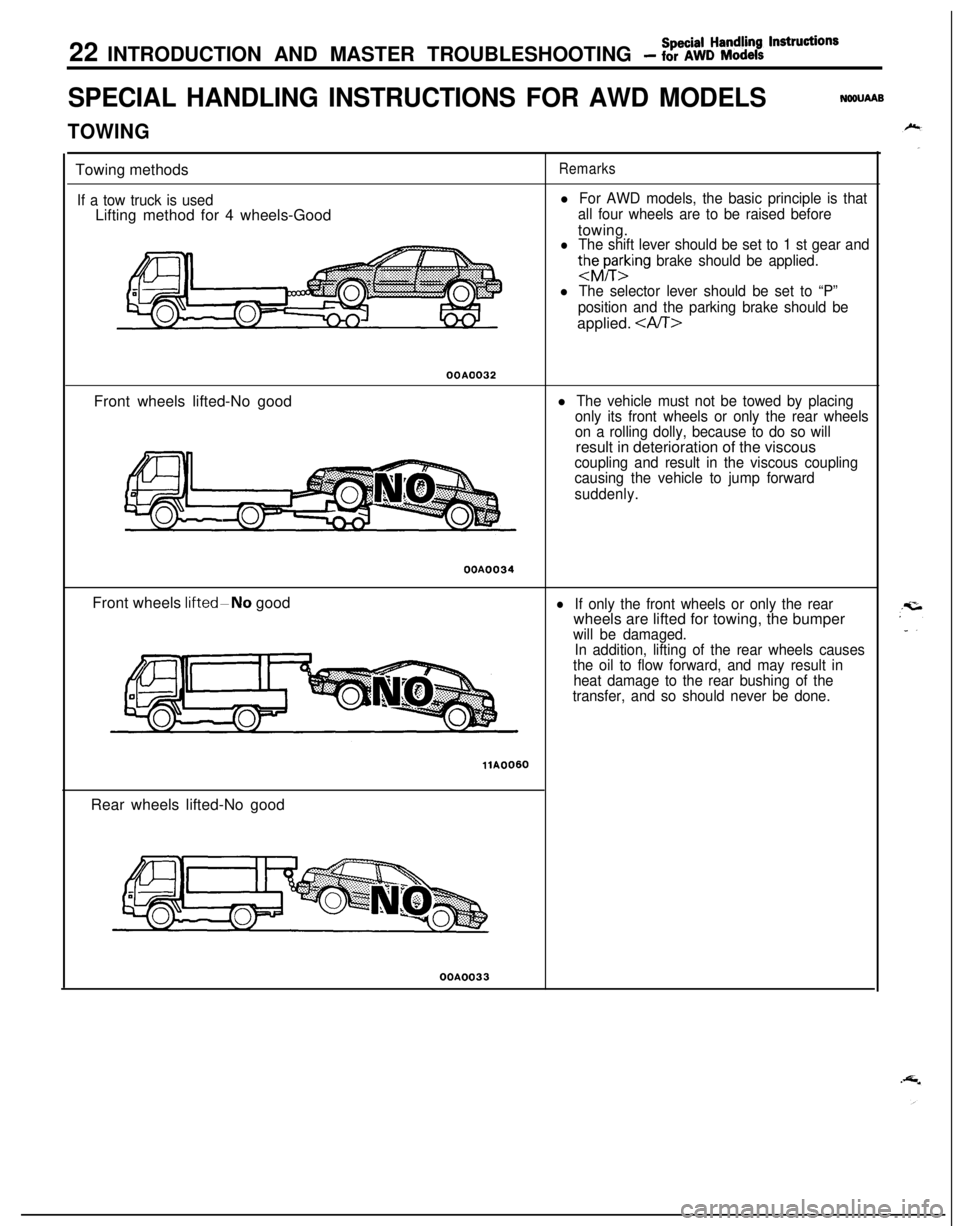

SPECIAL HANDLING INSTRUCTIONS FOR AWD MODELSNWUAAB

TOWINGTowing methods

If a tow truck is usedLifting method for 4 wheels-Good

Remarks

l For AWD models, the basic principle is that

all four wheels are to be raised beforetowing.

l The shift lever should be set to 1 st gear and

thhrting brake should be applied.

l The selector lever should be set to “P”

position and the parking brake should beapplied.

OOAO032Front wheels lifted-No good

l The vehicle must not be towed by placing

only its front wheels or only the rear wheels

on a rolling dolly, because to do so willresult in deterioration of the viscous

coupling and result in the viscous coupling

causing the vehicle to jump forward

suddenly.OOA0034

Front wheels

IifteddNo goodlIf only the front wheels or only the rearwheels are lifted for towing, the bumper

will be damaged.

In addition, lifting of the rear wheels causes

the oil to flow forward, and may result in

heat damage to the rear bushing of the

transfer, and so should never be done.

llA0060Rear wheels lifted-No goodOOA0033

Page 30 of 1216

30INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting

ENGINE HESITATES OR POOR ACCELERATION

SymptomEngine hesitates or poor

accelerationProbable causeIgnition system problem

Vacuum leaks

l Purge control valve hose

l Vacuum hosesl Intake manifoldl Air intake plenum

l Throttle bodyl EGR valveReference page

8-169

11-525-4

Air cleaner clogged

Fuel line clogged

Fuel injection system problem

Emission control system problem

l EGR system always on

Engine overheats

Compression too low

-

-

-25-15

7-5

9-23

ENGINE

DIESELING

SymptomEngine dieseling (runs after

ignition switch is turned off)Probable causeIncorrect ignition timingReference page

8-169

EXCESSIVE OIL CONSUMPTION

Symptom

Excessive oil consumptionProbable cause

Oil leak

Positive crankcase ventilation line clogged.

Valve stem seal worn or damaged.Valve stem worn.

Piston ring worn or damaged.Reference page or remedy

Repair as necessary.25-7

g-55.114

g-55.114

g-66,128

Page 31 of 1216

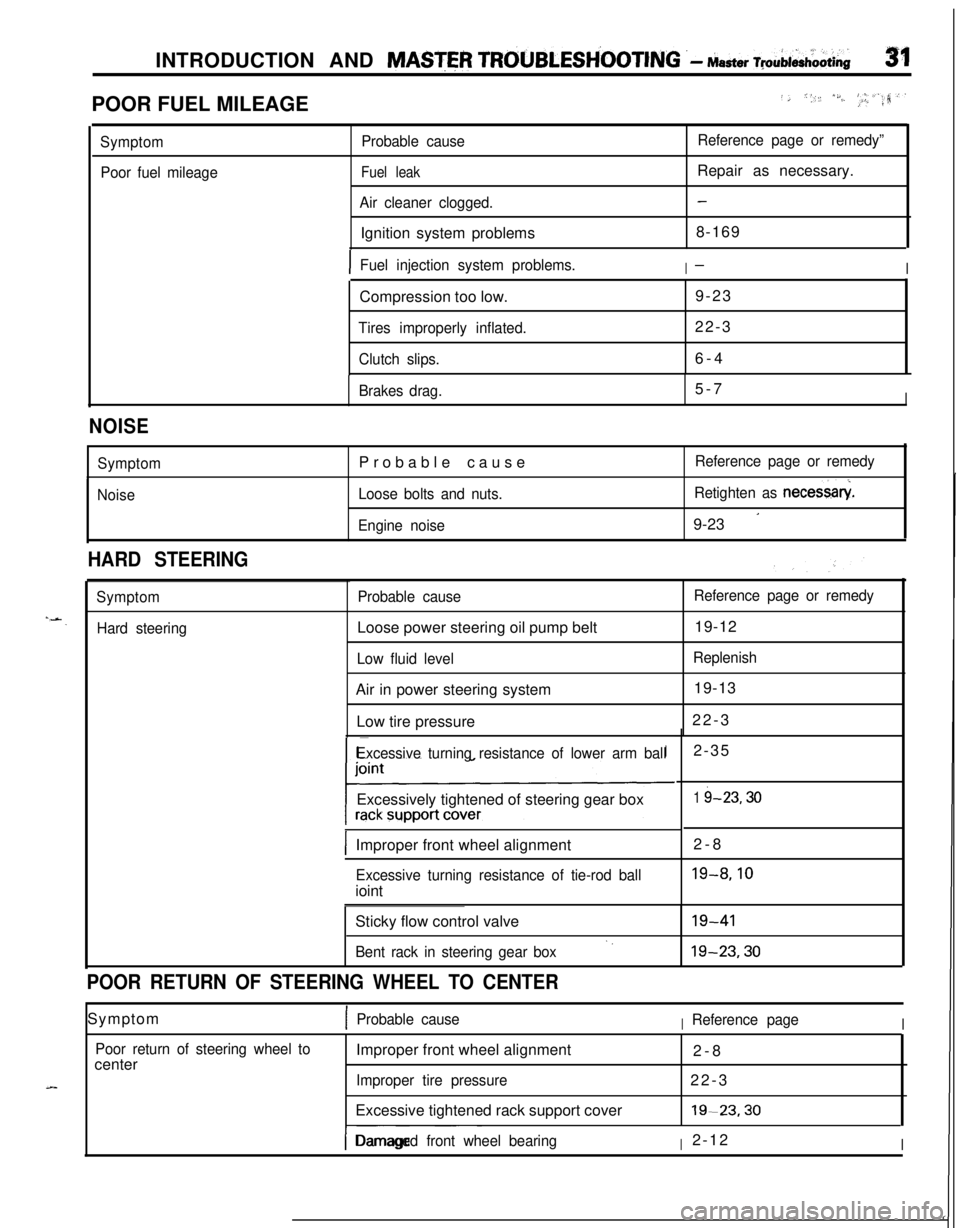

INTRODUCTION AND MASTER TROUBLESH’OOTING .- Master ~pAi&oOti~31POOR FUEL MILEAGE

../, *,, /S./..‘, _I, #_.a,‘.rr?

Symptom

Poor fuel mileageProbable cause

Fuel leak

Air cleaner clogged.Ignition system problems

Reference page or remedy”Repair as necessary.

-8-169

IFuel injection system problems.I-ICompression too low.9-23

Tires improperly inflated.22-3

Clutch slips.6-4

Brakes drag.5-7I

NOISE

Symptom

NoiseProbable cause

Loose bolts and nuts.

Engine noiseReference page or remedy

Retighten as necessary

9-23

’

HARD STEERING

Symptom

Hard steeringProbable causeLoose power steering oil pump belt

Low fluid levelAir in power steering system

Low tire pressure

Reference page or remedy19-12

Replenish19-13

22-3

Excessive turning resistance of lower arm ballExcessively tightened of steering gear box

IImproper front wheel alignment2-8

Excessive turning resistance of tie-rod ballioint2-35

1 i-23.30

19-8.10Sticky flow control valve

Bent rack in steering gear box‘.19-4119-23.30

POOR RETURN OF STEERING WHEEL TO CENTERSymptom

1Probable causeIReference pageI

Poor return of steering wheel tocenterImproper front wheel alignment

2-8

Improper tire pressure22-3

Excessive tightened rack support cover19-23.30

I-- ~~~Damaged front wheel bearingI2-12I

Page 32 of 1216

32INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting

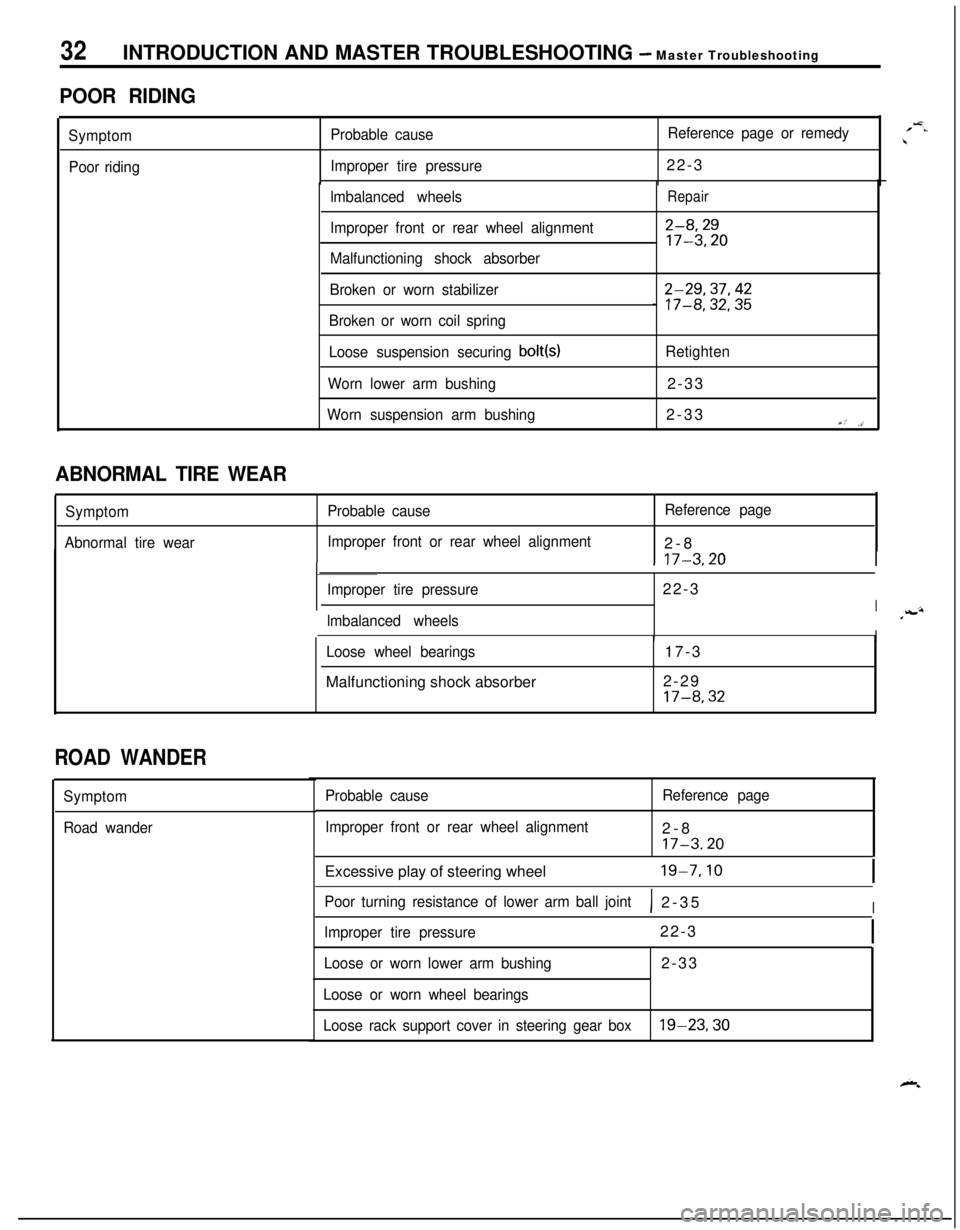

POOR RIDING

Symptom

Poor ridingProbable causeReference page or remedy

Improper tire pressure22-3

lmbalanced wheels

Improper front or rear wheel alignment

Malfunctioning shock absorberRepair

2-8,2917-3.20

Broken or worn stabilizer

Broken or worn coil spring2-29,37,42_ 17-8,32,35

Loose suspension securing bolt(s)Retighten

Worn lower arm bushing2-33

Worn suspension arm bushing2-33Y,’ ,>’

1 17-3.20I

ABNORMAL TIRE WEAR

Symptom

Abnormal tire wearProbable causeReference page

Improper front or rear wheel alignment2-8

Improper tire pressure22-3

Ilmbalanced wheelsIILoose wheel bearingsMalfunctioning shock absorber17-3

2-29

17-8,32

ROAD WANDER

Symptom

Road wanderProbable cause

Improper front or rear wheel alignmentReference page2-8

17-3.20Excessive play of steering wheel

19-7.10

Poor turning resistance of lower arm ball joint1 2-35I

Improper tire pressure22-3

Loose or worn lower arm bushing2-33

Loose or worn wheel bearings

Loose rack support cover in steering gear box

19-23,30

/-=..\

Page 33 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting

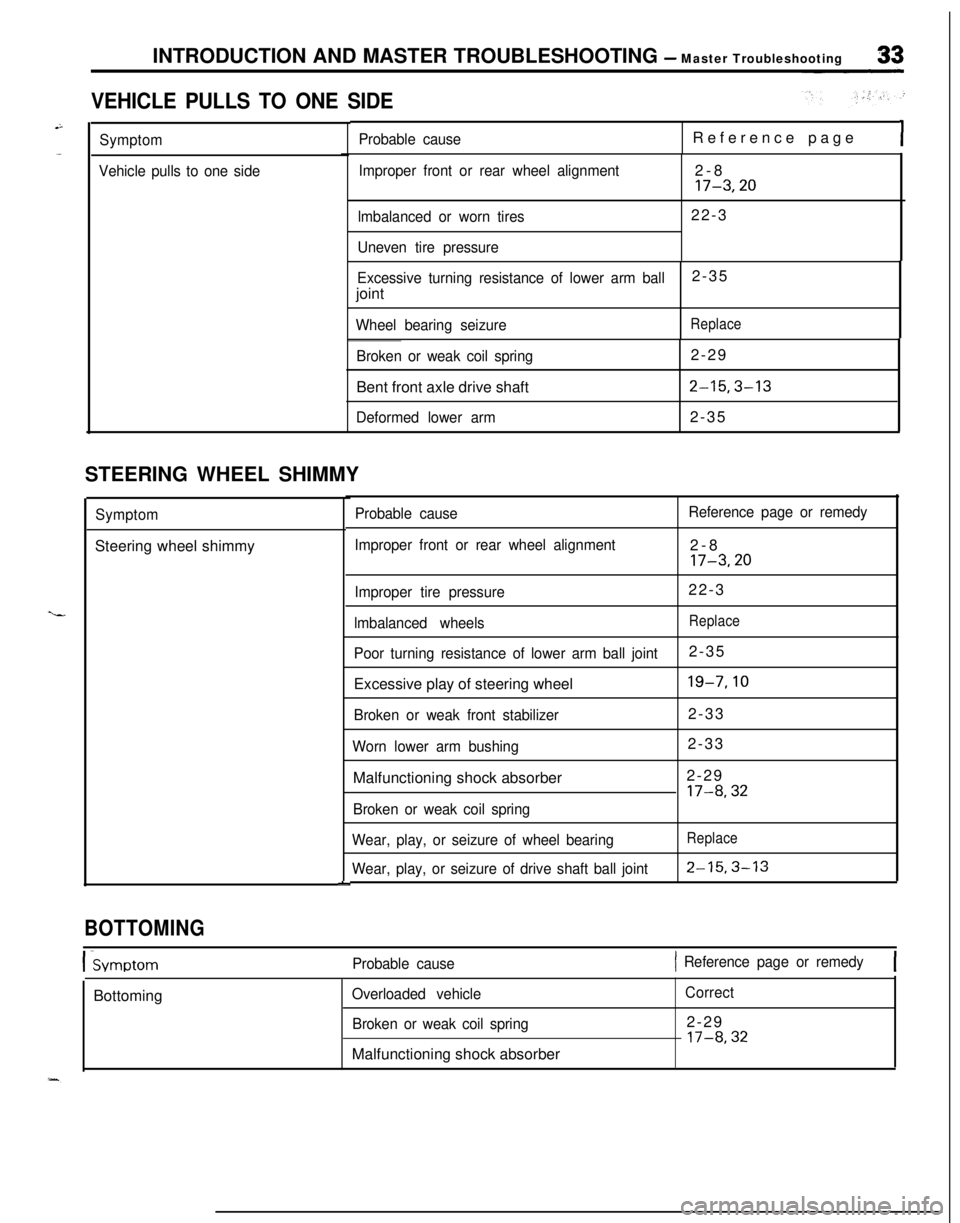

VEHICLE PULLS TO ONE SIDE

Symptom

Vehicle pulls to one sideProbable causeReference pageI

Improper front or rear wheel alignment

lmbalanced or worn tires

Uneven tire pressure2-817-3,2022-3

Excessive turning resistance of lower arm ball2-35

joint

Wheel bearing seizureReplace

Broken or weak coil spring2-29

Bent front axle drive shaft

2-15,3-13

Deformed lower arm2-35

STEERING WHEEL SHIMMY

SymptomSteering wheel shimmy

L

Probable cause

Improper front or rear wheel alignmentReference page or remedy2-8

17-3,20

Improper tire pressure22-3

lmbalanced wheelsReplace

Poor turning resistance of lower arm ball joint2-35

Excessive play of steering wheel

19-7,lO

Broken or weak front stabilizer2-33

Worn lower arm bushing2-33

Malfunctioning shock absorber2-29

17-8,32

Broken or weak coil spring

Wear, play, or seizure of wheel bearing

Wear, play, or seizure of drive shaft ball joint

Replace

2-15.3-13

BOTTOMING

I-SvmotomProbable cause1 Reference page or remedy[Bottoming

Overloaded vehicle

Broken or weak coil springMalfunctioning shock absorberCorrect2-29

l7-8,32

Page 34 of 1216

34INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting

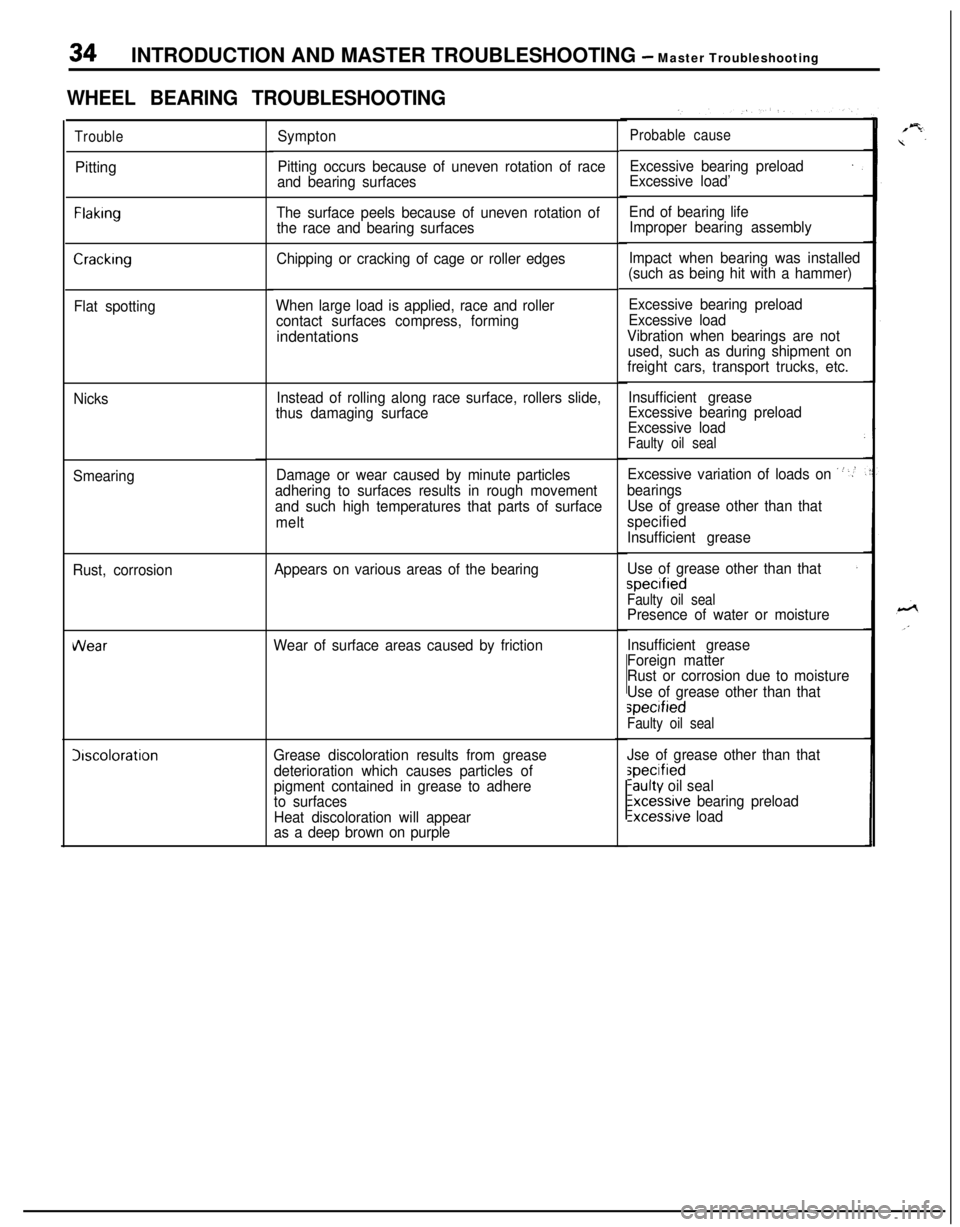

WHEEL BEARING TROUBLESHOOTING

TroublePitting

Flakrng

Crackrng

Flat spotting

Nicks

Smearing

Rust, corrosionwear

3rscolorationSympton

Pitting occurs because of uneven rotation of race

and bearing surfaces

The surface peels because of uneven rotation of

the race and bearing surfaces

Chipping or cracking of cage or roller edges

When large load is applied, race and roller

contact surfaces compress, formingindentations

Instead of rolling along race surface, rollers slide,

thus damaging surface

Damage or wear caused by minute particles

adhering to surfaces results in rough movement

and such high temperatures that parts of surface

melt

Appears on various areas of the bearing

Wear of surface areas caused by friction

Grease discoloration results from grease

deterioration which causes particles of

pigment contained in grease to adhere

to surfaces

Heat discoloration will appear

as a deep brown on purple

Probable cause

Excessive bearing preload

Excessive load’

End of bearing life

Improper bearing assembly

Impact when bearing was installed

(such as being hit with a hammer)

Excessive bearing preload

Excessive load

Vibration when bearings are not

used, such as during shipment on

freight cars, transport trucks, etc.

Insufficient grease

Excessive bearing preload

Excessive load

Faulty oil seal

Excessive variation of loads on ” .j’

bearings

Use of grease other than that

specified

Insufficient grease

Use of grease other than that

specrfied

Faulty oil sealPresence of water or moisture

Insufficient grease

Foreign matter

Rust or corrosion due to moisture

Use of grease other than that

specified

Faulty oil seal

Jse of grease other than thatspecified

-aulty oil seallxcessive bearing preloadExcessive load

Page 35 of 1216

LUBRICATION AND’ I

MAINTENANCE

CONTENTSGENERAL INFORMATION

..............................2MAINTENANCE SERVICE

...............................7Air

CleanerElement.....................................7Automatic Transaxle....................................

11Ball Joint and Steering Linkage Seals

........13Brake Hoses

.................................................12

DiscBrakePads...........................................12-lbDrive Belt (For Water Pump and

Alternator).....................................................8

DriveShaftBoots.........................................13

EngineCoolant.............................................12

EngineOil.....................................................9

EngineOilFilter...........................................9Exhaust System

............................................13

FuelHose.....................................................7

FuelSystem.................................................7

ManualTransaxle..........................................10

RearAxle......................................................13

SparkPlugs...................................................8

TimingBelt......................................................8RECOMMENDED LUBRICANTS AND

LUBRICANT CAPACITIES TABLE

..................4SCHEDULED MAINTENANCE TABLE

............3

Page 36 of 1216

o-2LUBRICATION AND MAINTENANCE - General Information

GENERAL INFORMATIONNGQPA--Maintenance and lubrication service recommenda-

tions have been compiled to provide maximum

protection for the vehicle owner’s investment

against all reasonable types of driving conditions.

Since these conditions vary with the individual

vehicle owner’s driving habits, the area in which the

vehicle is operated and the type of driving to which

the vehicle is subjected, it is necessary to prescribe

lubrication and maintenance service on a time

frequency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by theSociety of Automotive Engineers (SAE), the Amer-

ican Petroleum Institute (API) and the National

Lubricating Grease Institute

(NLGI).MAINTENANCE SCHEDULES

Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required

Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”.

Item numbers in the “SCHEDULED MAINTE-

NANCE TABLE” correspond to the item numbers in

the “MAINTENANCE SERVICE” section.

SEVERE SERVICEVehicles operating under severe service conditions

will require more frequent service.

Component service information is included in

appropriate units for vehicles operating under one ormore of the following conditions:

1.Trailer towing or police, taxi, or commercial type

operation2. Operation of Vehicle

(1) Short-trip operation at freezing temperature

(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city

traffic during hot weather above

32°C (90°F)(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

The SAE grade number indicates the viscosity of

engine oils, for example, SAE 30, which is a single

grade oil. Engine oils are also identified by a dual

number, for example, SAE

lOW-30, which indicates

a multigrade oil.

The API classification system defines oil perform-

ance in terms of engine usage. Only engine oil

designed “For Service SG” or “For Service

SGKD”,when available, should be used. These oils contain

sufficient chemical additives to provide maximum

engine protection. Both the SAE grade and the API

designation can be found on the container.Caution

Test results submitted to EPA have shown thatlaboratory animals develop skin cancer after

prolonged contact with used engine oil. Accor-

dingly, the potential exists for humans

to de-

velop a number of skin disorders, including

cancer, from such exposure to used engine oil.

Care should be’ taken, therefore, when changingengine oil, to minimize the amount and length of

exposure time to used engine

pi! on your skin.

Protective clothing and gloves, that cannot be

penetrated by oil, should be worn. The skin

should be thoroughly washed with soap and

water, or use waterless hand cleaner, to removeany used engine oil. Do not use gasoline,

thinners, or solvents.

GEAR LUBRICANTSThe SAE grade number also indicates the viscosity

of Multi-Purpose Gear Lubricants.

The API classfication system defines gear lubricants

in terms of usage. Typically gear lubricants conform-ing to API

GL-4 or GL-5 with a viscosity of SAE

75W-85W are recommended for manual transaxle.

LUBRICANTS

- GREASES

Semi-solid lubricants, bear the NLGI designation andare further classified as grades 0, 1, 2, 3 etc.

Whenever “Chassis Lubricant” is specified, Multi-

Purpose Grease,

NLGI grade 2 should be used.

MOPAR Multi-Mileage Lubricant, P&t Number

2525035 or equivalent, meets these requirement

and is recommended.

FUEL USAGE STATEMENT

Use gasolines having a minimum anti-knock index

(Octane Value) of 87,

(R + M)/2. This designation is

comparable to a Research Octane Number of 91.

Unleaded gasolines only must be used in vehicles

equipped with catalyst emission control systems.

All vehicles, so equipped, have labels located on the

instrument panel and on the back of fuel filler lid that

state, “UNLEADED GASOLINE ONLY”. These vehi-

cles also have fuel filler tubes especially designed toaccept the smaller diameter unleaded gasoline

dispensing nozzles only.

MATERIALS ADDED

TO FUELIndiscriminate use of fuel system cleanng agents

should be avoided. Many of these materials in-

tended for gum and varnish removal may contain

highly active solvents or similar ingredients that can

be harmful to gasket and diaphragm materials usedin fuel system component parts.