MITSUBISHI ECLIPSE 1993 Owner's Guide

Manufacturer: MITSUBISHI, Model Year: 1993, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1993Pages: 57, PDF Size: 4.18 MB

Page 31 of 57

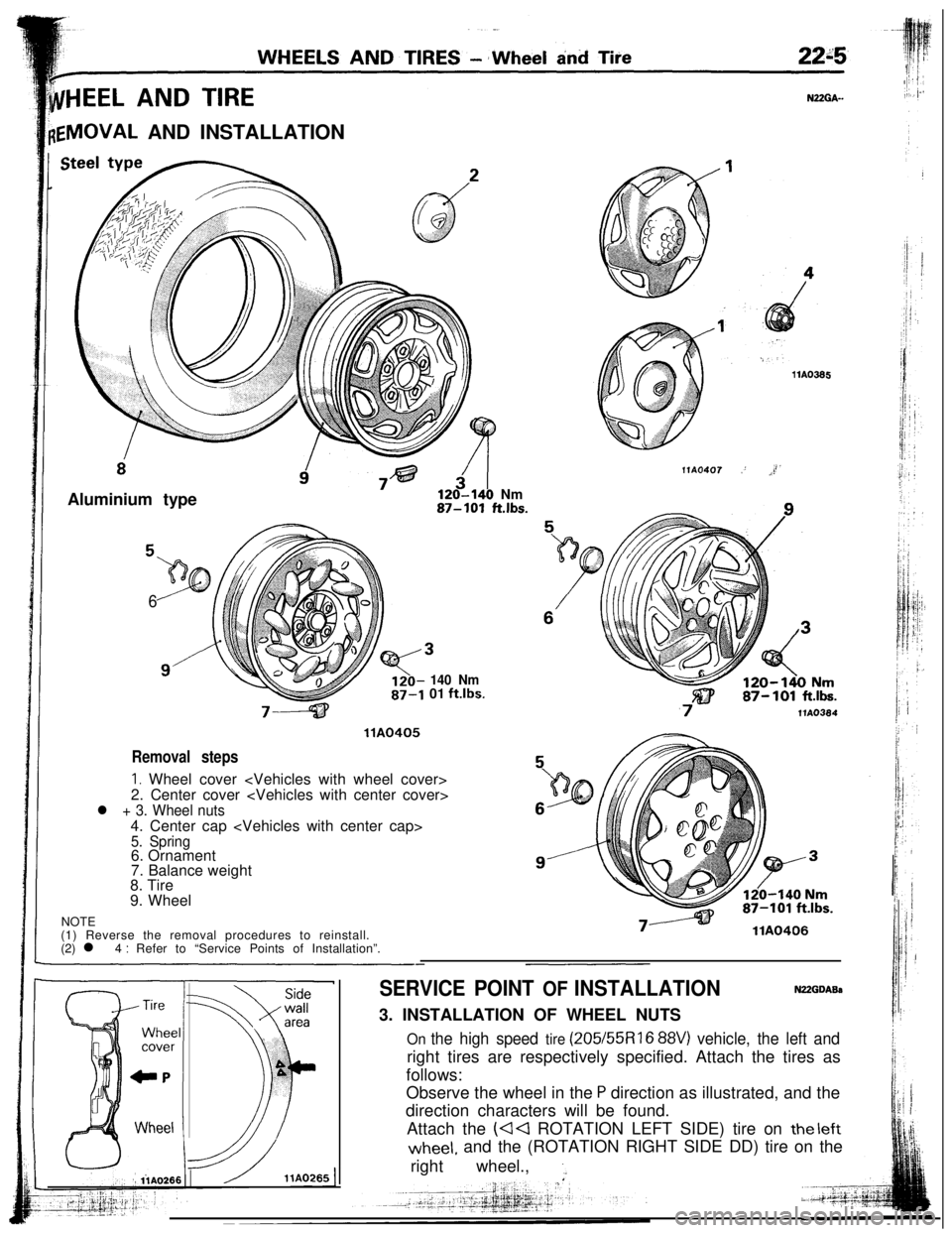

~~~HEEL AND TIREN22GA..

{EMOVAL AND INSTALLATION

Aluminium type

120-140 Nm87-101 ft.lbs.

6

140 Nm01 ft.lbs.

llA0405

Removal steps

I. Wheel cover

2. Center cover

l + 3. Wheel nuts4. Center cap

5. Spring6. Ornament

NOTE7. Balance weight

8. Tire

9. Wheel

(1) Reverse the removal procedures to reinstall.

(2) l 4

: Refer to “Service Points of Installation”.llA0366

llA0407,’ J’

7VA0364

llA0406

SERVICE POINT OF INSTALLATIONN22GDABs3. INSTALLATION OF WHEEL NUTS

On the high speed tire (205/55Rl6 88V) vehicle, the left andright tires are respectively specified. Attach the tires as

follows:

Observe the wheel in the

P direction as illustrated, and the

direction characters will be found.

Attach the

(44 ROTATION LEFT SIDE) tire on the leftwheel, and the (ROTATION RIGHT SIDE DD) tire on the

right wheel.,

1.

Page 32 of 57

INSTRUCTIONS FOR ALUMINUM TYPE

WHEELSN2zGFM

1. Aluminum is vulnerable to alkalies. If a vehicle

washing detergent has been used, or salt from

sea water or road chemicals has adhered, washthe vehicle as soon as possible. After washing

the vehicle, apply body or wheel wax to the

aluminum type wheels to prevent corrosion.

2. When cleaning the vehicle with steam, do not

direct steam onto the aluminum type wheels.

When tightening nuts for aluminum type

wheels, particularly observe the following:

(1) Cl;Zl;lsthe hub surface of aluminum type

(2) After finger-tightening wheel nuts, tighten

them to specifications.

(3) Do not use an impact wrench or push the

wrench by foot to tighten the wheel nuts.

(4) Do not apply oil to the threaded portions.

INSTRUCTIONS FOR TIRE CHAINS AND

SNOW TIRES

1.Use tire chains only on front wheels. Do not usetire chains on rear wheels.

2. When using snow tires, use them on all four

wheels for maneuverability and safety.

INSTRUCTIONS FOR COMPACT

TIRE

1. The compact spare tire is designed

space in the luggage compartment,

lighter weight makes it easier to use if

occurs.g

2.-- IThe following instructions for the compact spare .,z,tire should be observed.

i/(1) Check the inflation pressure after installing ii,the spare, and adjust to the specified

pres-..$i

sure.t’

(2) Avoid driving through automatic car washes

and over obstacles that could possiblyage the vehicle’s undercarriage. Because

the tire is smaller than the

original tire,

ground clearance is slightly reduced,

(3) The compact spare tire should not be

used: i5iS:on any other wheels, nor should standard

i;:?tires, snow tires, wheel covers or trim rings

Ibe used with the compact spare wheel. If.

1.;such use is attempted, damage to these

items or other vehicle components may

’

occur.

,i

Page 33 of 57

BODY

CONTENTS

,I

i

1AEROPARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

; CENTRAL DOOR LOCKING SYSTEM . . . . . . . . . . .68

’DOORASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

DOOR GLASS AND REGULATOR................

64

DOOR HANDLE AND LATCH.....................67QUARTER WINDOWGLASS..

...............

..i..59

REAR BUMPER........................................41

REARSEAT.........................................;..93

SEATBELT.............................................

94

SERVICE ADJUSTMENT PROCEDURES........30

Door Adjustment....................................31

Door Glass Adjustment............................31

Door Inside Handle Play Check...................31

Door Outside Handle Play Check................31

Floor PanInspection..............................

32

Fuel Filler Door Adjustment.......................30

Hood Adjustment...................................30

Liftgate Adjustment.................................30

Water Test...........................................

32

SPECIAL TOOLS....................*..........c......

5

SPECIFICATIONS.....................................2

General Specifications...........................;..2

Lubricants.............................................5

Sealants and Adhesives...........................5

Service Specifications..............................3

Torque Specifications..............................3

SUNROOF...............................................

77

TRIMS....................................................

85

TROUBLESHOOTING................................6

WINDOWGLASS.....................................52

WINDSHIELD...........................................56

DOORMIRROR........................................

70

DOOR

MOULDING AND

DRIP LINE WEATHERSTRIP........................

70

DOORRUNCHANNEL...............................

69

DOOR TRIM AND WATERPROOF FILM........

63

ELECTRIC REMOTE CONTROLLED

MIRRORSWITCH.....................................

71

FENDER..................................................

49

FLOORCONSOLE....................................

84

FRONTBUMPER......................................37

FRONTSEAT...........................................90

FUEL TANK FILLER DOOR.........................

36

GARNISHES............................................45

HEADLINING...........................................89

HOOD....................................................

33

INSTRUMENTPANEL.,..............................

79

Lll=l’GATE...............................................

35

LIFTGATE WINDOW GLASS......................60

LOOSEPANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

MOULDING.............................................

46

POWERWINDOW....................................65

N23AA--

Page 34 of 57

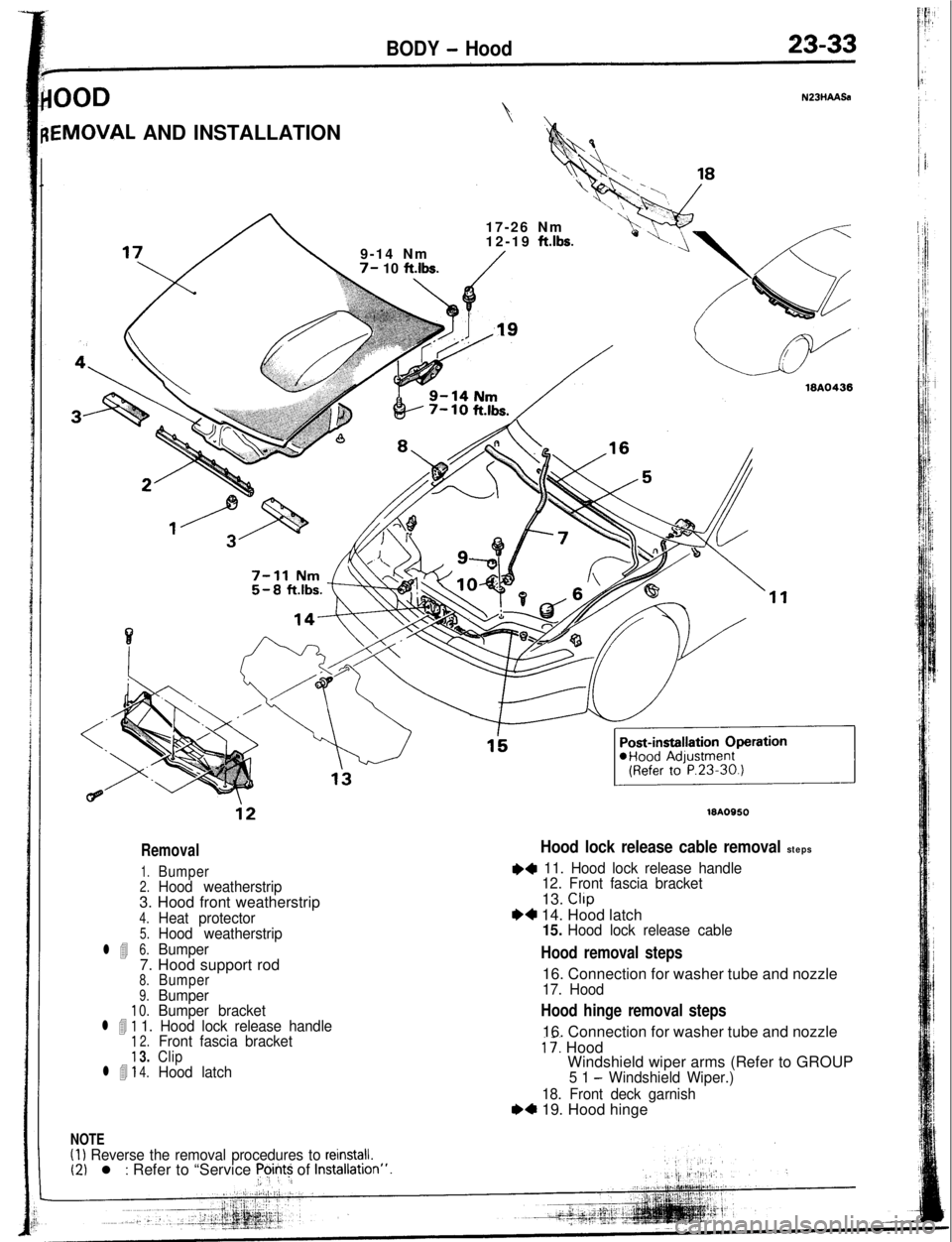

BODY - Hood23-33

IOODN23HAA.S

k

EMOVAL AND INSTALLATION9,17-26 Nm

12-19

ftlbs.11/9-14 Nm7- 10 ft.lbs./

!, 9-14Nm/

9-J/

l 4

l 4

l 4

Removal

1.Bumper2.Hood weatherstrip3. Hood front weatherstrip

4.Heat protector5.Hood weatherstrip

6.Bumper7. Hood support rod

8.Bumper9.Bumper0.Bumper bracket

1. Hood lock release handle

2.Front fascia bracket3.Clip4.Hood latch

NOTE(1) Reverse the removal procedures to reinstsll.(2) l : Refer to “Service Pyrnts of Installatron”.

19A0950

Hood lock release cable removal steps

+a 11. Hood lock release handle

12. Front fascia bracket13.

CllP

~~ 14. Hood latch15. Hood lock release cable

Hood removal steps16. Connection for washer tube and nozzle

17. Hood

Hood hinge removal steps16. Connection for washer tube and nozzle

i-I. Hood

Windshield wiper arms (Refer to GROUP

5 1 - Windshield Wiper.)

18. Front deck garnish

+d 19. Hood hinge

Page 35 of 57

-

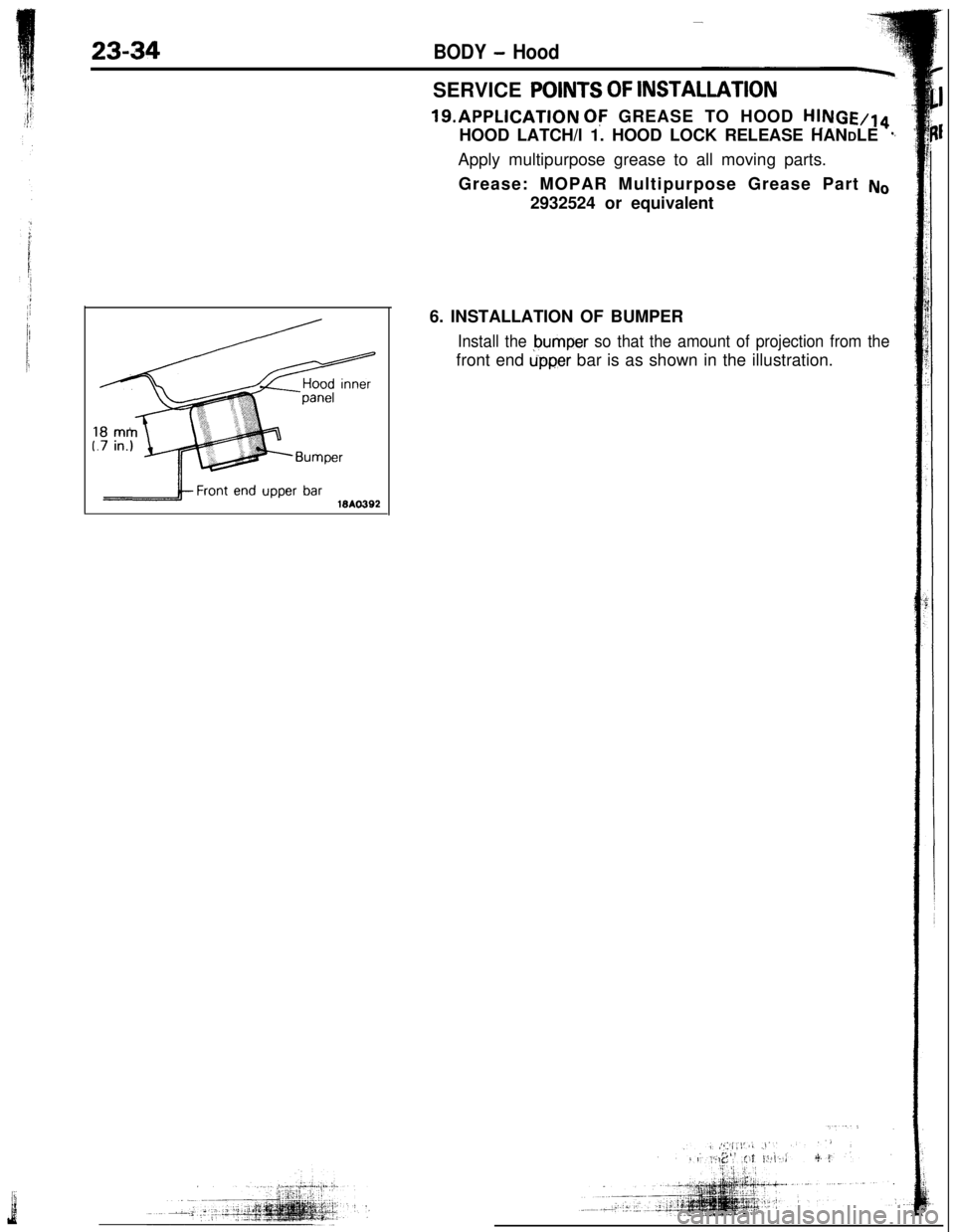

23-34BODY - HoodSERVICE POINTS

OF INSTALLATION

19.APPLICATION Or GREASE TO HOOD HINGE/l4HOOD LATCH/l 1. HOOD LOCK RELEASE HANDLE

’Apply multipurpose grease to all moving parts.

Grease: MOPAR Multipurpose Grease Part

No2932524 or equivalent

18AO3926. INSTALLATION OF BUMPER

Install the bumper so that the amount of projection from thefront end

@per bar is as shown in the illustration.

Page 36 of 57

BODY - Liftgate23-35

FTGATEN230AAT

EMOVAL AND INSTALLATION

11-16 Nm

8- 12 ft.lbs.\9-14 Nm

7- 10 ftlbs.

1. Bumper

2. Llftgate damper (upper)

3. Liftgate outer weatherstrip

4. Liftgate damper (lower)

5. Liftgate opening weatherstrip

Liftgate hinge removal stepsHeadlining (Refer to

P.23-89.)6. Connection for rear washer tube

Center pillar trim (drtver’s side)

Quarter trim (driver’s side)

1(Refer toP.23-85.)7. Connection for liftgate wiring harness

8. Liftgate

9. Liftgate hinge

Liftgate removal steps6. Connection for rear washer tube

Center pillar trim (driver’s side)(Refer to

Quarter trim (driver’s side)

1P.23-85.)7. Connection for

liftgate wiring harness

8. Liftgate

Liftgate lock release cable removal stepsRear seat (Refer to

P.23-93.)Scuff plate (driver’s side)

Quarter trim (driver’s side)

(Refer to

Rear end trim

’ P.23-85.)Rear side trim

l

10. Liftgate latch5-8 ftlbs.

4/

1118AO973

Liftgate lock release handle removal stepsScuff plate (driver’s side)

(Refer to

P.23-85.)13 Release handle cover

l * 14.

Liftgate lock release handle

Liftgate latch removal stepsRear end trim (Refer to

P.23-85.)l *

10. Liftgate latch

Liftgate lock cylinder removal stepsRear end trim (Refer to P-23-85.)

1 1 Retainer

4*12.

Liftgate lock cylinder

Liftgate striker removal steps

Liftgate trim (Refer to P.23-86.)16

Liftgate striker

Liftgate stopper removal stepsRear side trim (Refer

td P.23-85.)

17. Liftgate stopper

Page 37 of 57

._-_,. -/a,_ . . ._ :-.

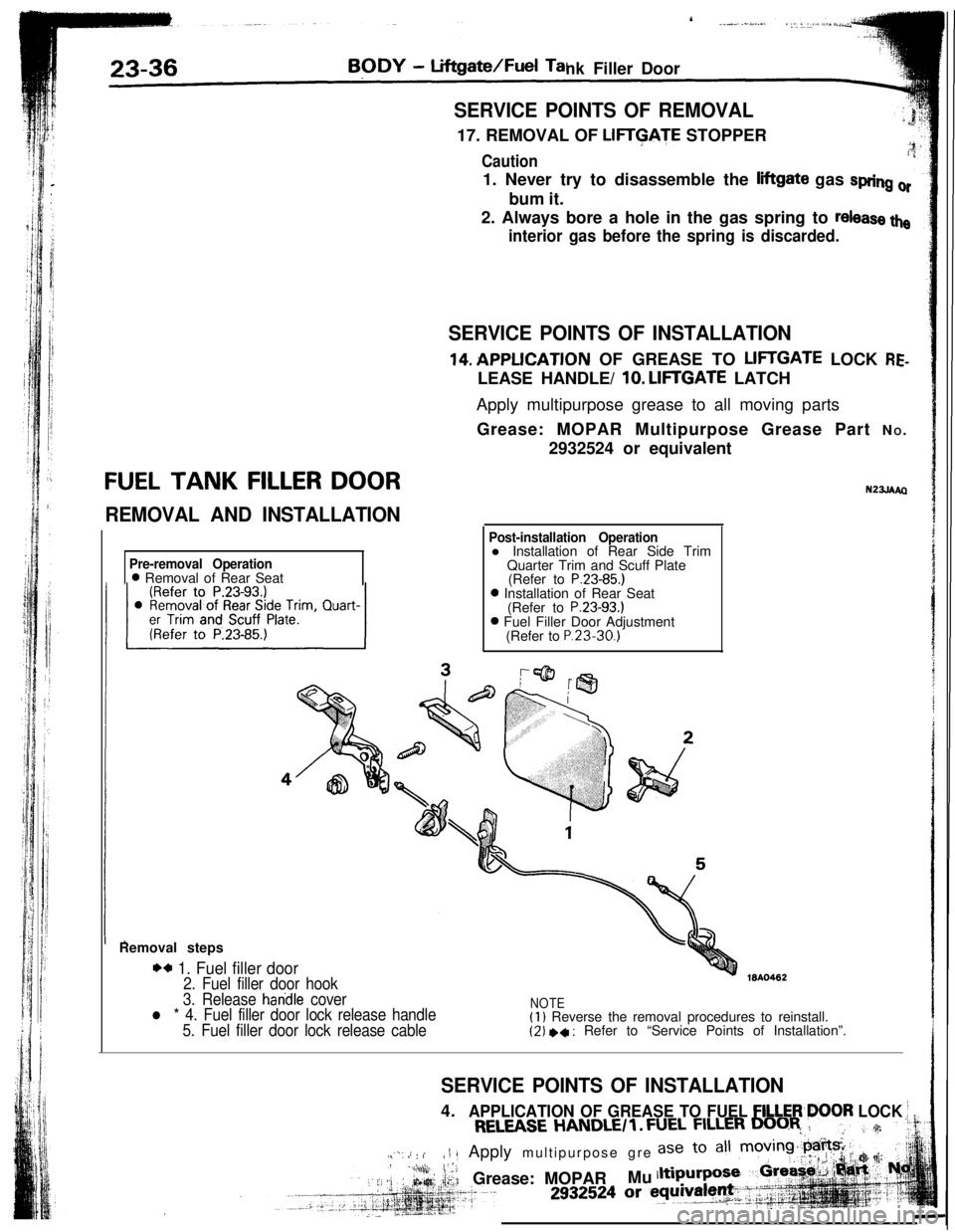

FUEL TANK FILLER DOOR

REMOVAL AND INSTALLATIONSERVICE POINTS OF REMOVAL17. REMOVAL OF

LIFTGATE STOPPER

Caution1. Never try to disassemble the

liigate gas spring crbum it.

2. Always bore a hole in the gas spring to

release the

interior gas before the spring is discarded.

SERVICE POINTS OF INSTALLATION14,APPLICATION OF GREASE TO

LIFTGATE LOCK RF-LEASE HANDLE/

10. LIFTGATE LATCH

Apply multipurpose grease to all moving parts

Grease: MOPAR Multipurpose Grease Part NO.

2932524 or equivalent

N23JAAa

Pre-removal Operation0 Removal of Rear Seat

Post-installation Operationl Installation of Rear Side Trim

Quarter Trim and Scuff Plate

(Refer to P.2385.)

0 Installation of Rear Seat

(Refer to P.23-93.)0 Fuel Filler Door Adjustment

(Refer to P.23-30.)Removal steps+a

1. Fuel filler door2. Fuel filler door hookWA0462

3. Release hatidle coverNOTEl * 4. Fuel filler door lock release handle(1) Reverse the removal procedures to reinstall.5. Fuel filler door lock release cable(2) +a : Refer to “Service Points of Installation”.

SERVICE POINTS OF INSTALLATION4.

APPLICATION OF GREASE TO FUEL FILLER,DOOR LOCK j

:(“‘: ,: : ,.-;gz/ :,; Apply multipurpose gre

:’ j:: -:l : :. ,;&r: &;iGrease: MOPARMu

; _

Page 38 of 57

-- .__.,_...__

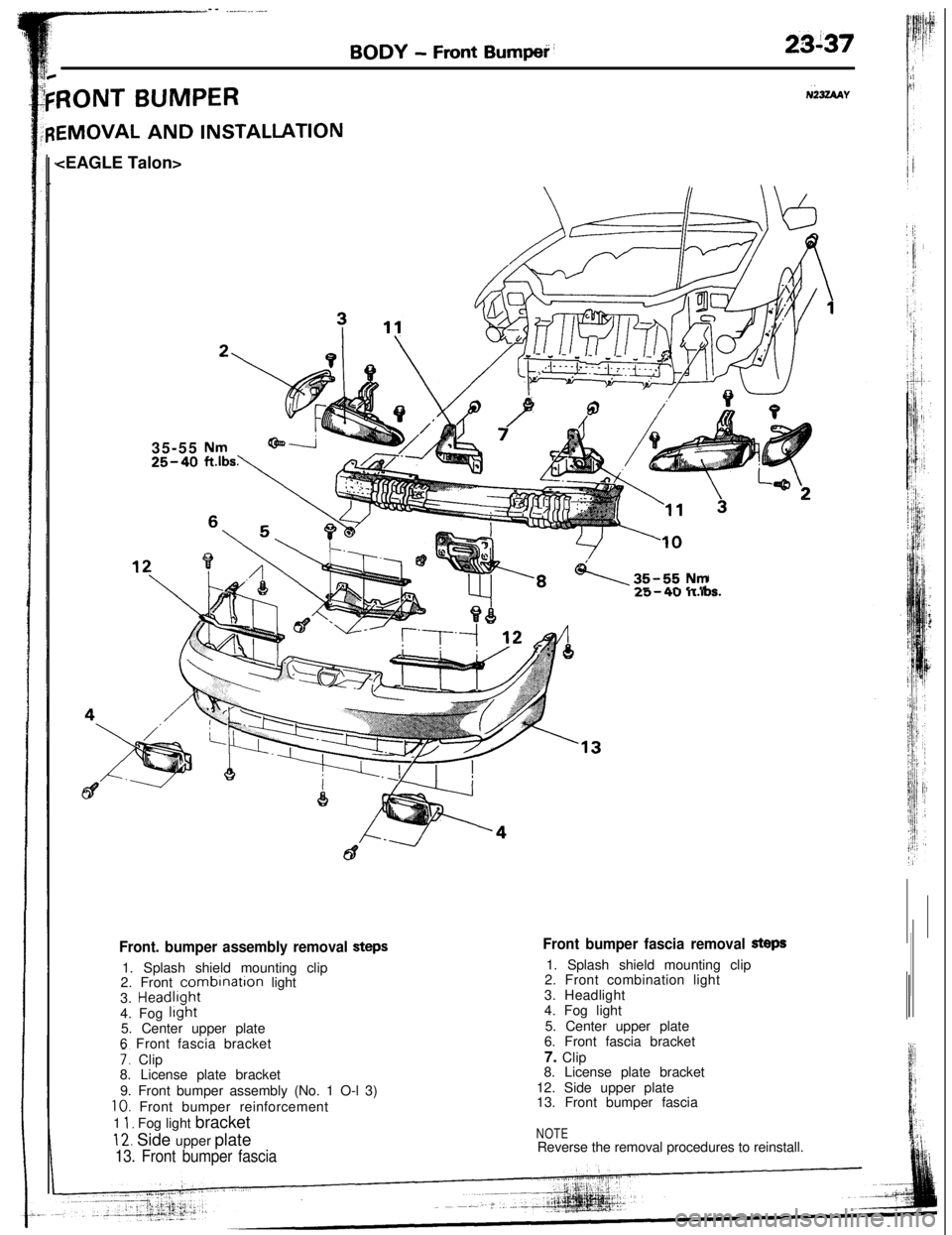

BODY - Front Bumped’23i37

RONT BUMPERNk4AY

EMOVAL AND INSTALLATION

35-55

25-40

\35-55Nma.-11 ._ II

Front bumper fascia removal Steps1. Splash shield mounting clip

2. Front combination light

3. Headlight

4. Fog light

5. Center upper plate

6. Front fascia bracket

7. Clip

8. License plate bracket

12. Side upper plate

13. Front bumper fasciaFront. bumper assembly removal steps1. Splash shield mounting clip

2. Front

combrnation light

3. Headlrght

4. Fog

light5. Center upper plate

6 Front fascia bracket

7. Clip

8. License plate bracket

9. Front bumper assembly (No. 1 O-l 3)

10. Front bumper reinforcement

1

1, Fog light bracket

12. Side upper plate

13. Front bumper fascia

NOTEReverse the removal procedures to reinstall.

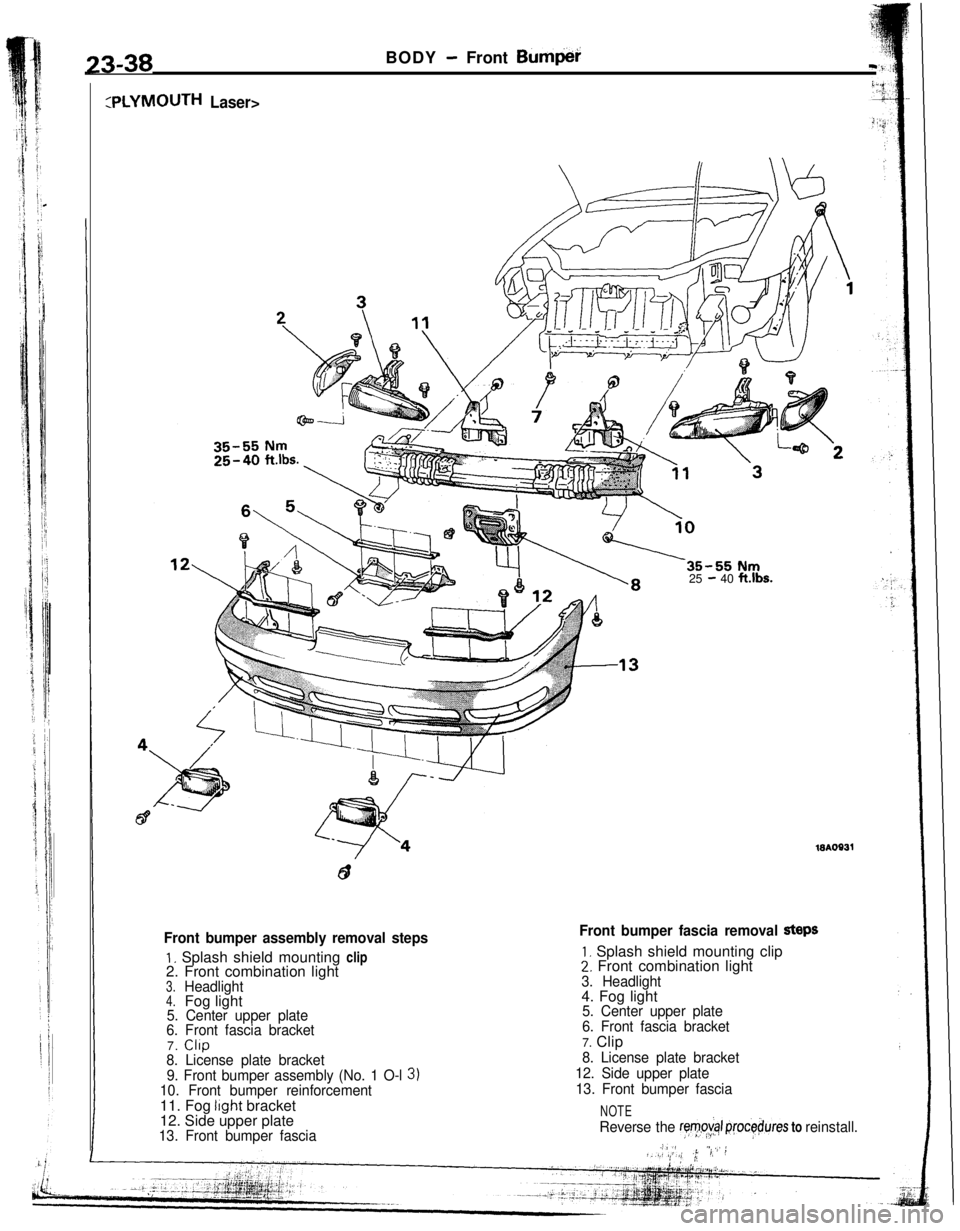

Page 39 of 57

:PLYMOUTH Laser>25

- 40 ft.lbs.

23-38BODY - Front Bum$i

Front bumper assembly removal steps

1. Splash shield mounting clip

2. Front combination light

3.Headlight4.Fog light5. Center upper plate

6. Front fascia bracket7.

CllP8. License plate bracket

9. Front bumper assembly (No. 1 O-l

3)10. Front bumper reinforcement11. Fog light bracket

12. Side upper plate

13. Front bumper fascia

Front bumper fascia removal StePS

1, Splash shield mounting clip2. Front combination light

3. Headlight4. Fog light

5. Center upper plate

6. Front fascia bracket7. Clip

8. License plate bracket

12. Side upper plate

13. Front bumper fascia

NOTE

Reverse the ryv,o&+ ,rjrocebures to reinstall.,.,ir ,’.!,I,(1 ,(, /.; 1, !

Page 40 of 57

BODY - FrontBumper

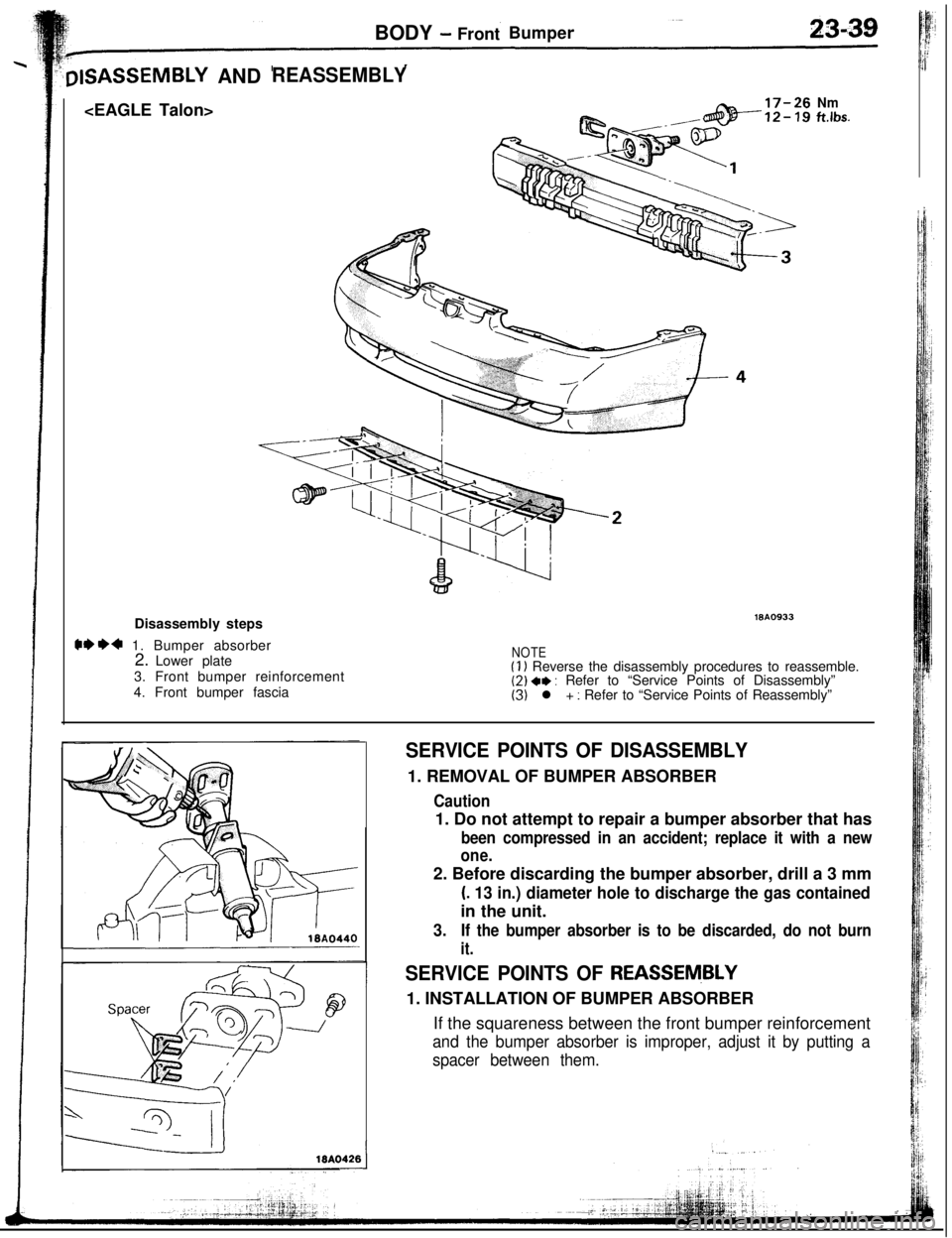

‘plSASSEMBLY ANDREASSEMBLY

Nmftlbs.

Disassembly steps

@*I)* 1. Bumper absorber

2. Lower plate

3. Front bumper reinforcement

4. Front bumper fascia

19AQ933

NOTE(1) Reverse the disassembly procedures to reassemble.(2) ++ : Refer to “Service Points of Disassembly”(3) l + : Refer to “Service Points of Reassembly”

SERVICE POINTS OF DISASSEMBLY1. REMOVAL OF BUMPER ABSORBER

Caution1. Do not attempt to repair a bumper absorber that has

been compressed in an accident; replace it with a new

one.2. Before discarding the bumper absorber, drill a 3 mm

(. 13 in.) diameter hole to discharge the gas containedin the unit.

3.If the bumper absorber is to be discarded, do not burn

it.

SERVICE POINTS OF REASSEM.BLY1. INSTALLATION OF BUMPER ABSORBER

If the squareness between the front bumper reinforcement

and the bumper absorber is improper, adjust it by putting a

spacer between them.