MITSUBISHI ECLIPSE 1993 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1993, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1993Pages: 57, PDF Size: 4.18 MB

Page 41 of 57

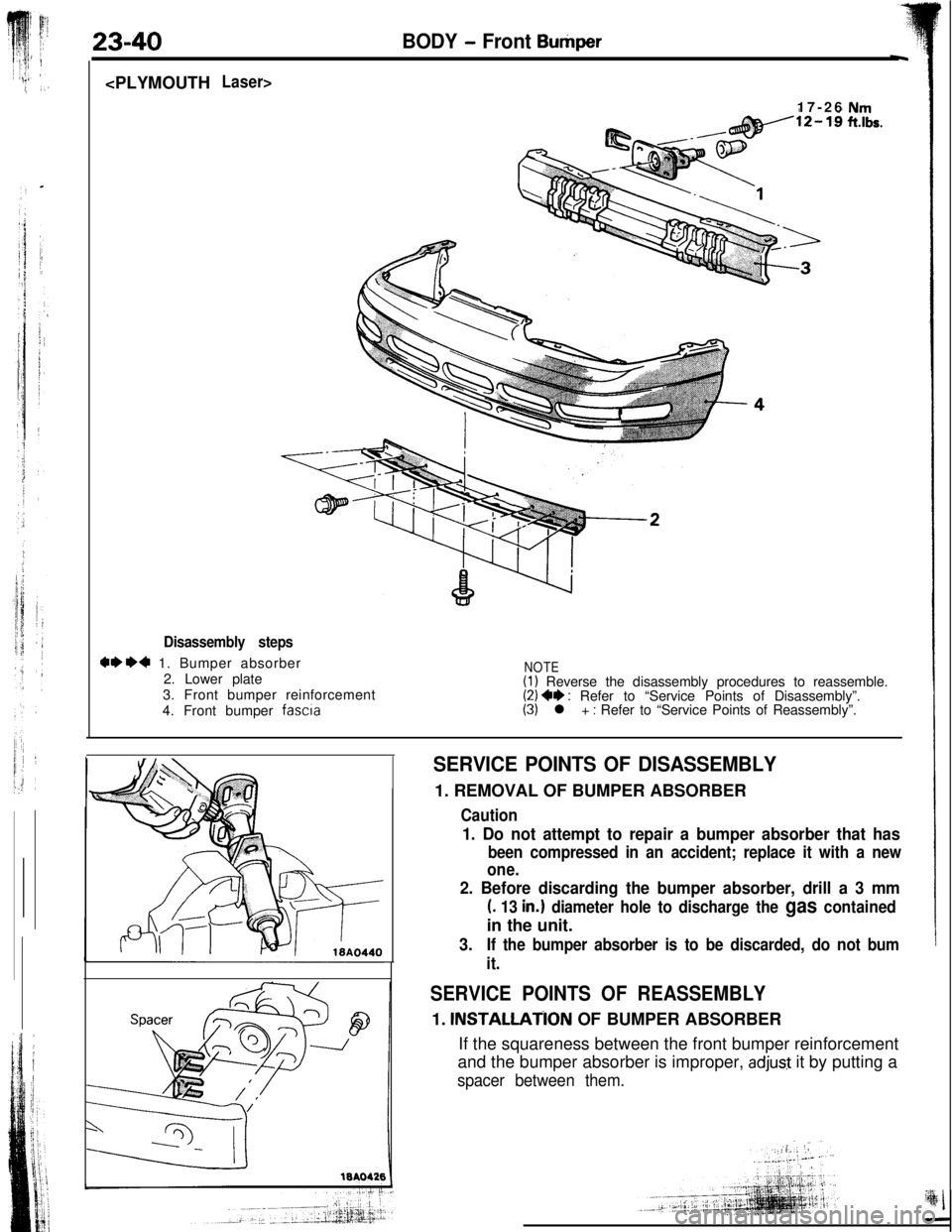

23-40BODY - Front Buripr

Disassembly steps

WI)* 1. Bumper absorber

2. Lower plate

3. Front bumper reinforcement

4. Front bumper

fascia

NOTE(1) Reverse the disassembly procedures to reassemble.(2) W : Refer to “Service Points of Disassembly”.(3) l + : Refer to “Service Points of Reassembly”.

SERVICE POINTS OF DISASSEMBLY1. REMOVAL OF BUMPER ABSORBER

Caution

1. Do not attempt to repair a bumper absorber that has

been compressed in an accident; replace it with a new

one.

2. Before discarding the bumper absorber, drill a 3 mm

(. 13 in.) diameter hole to discharge the gas containedin the unit.

3.If the bumper absorber is to be discarded, do not bum

it.

SERVICE POINTS OF REASSEMBLY1.

INSTALLATiON OF BUMPER ABSORBER

If the squareness between the front bumper reinforcement

and the bumper absorber is improper,

adjusj it by putting a

spacer between them.

Page 42 of 57

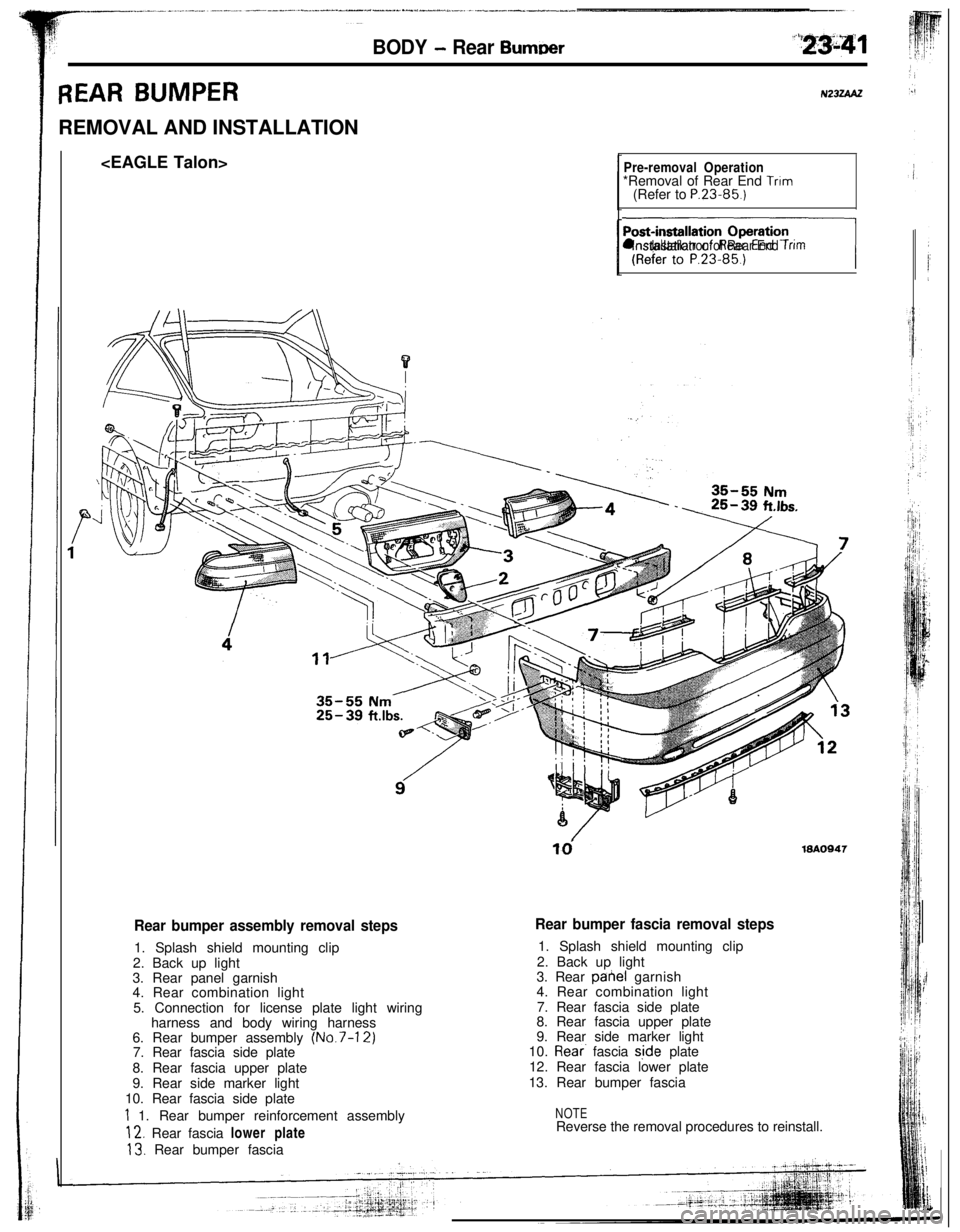

BODY - Rear Burn-r

REAR BUMPERREMOVAL AND INSTALLATION

Pre-removal Operation*Removal of Rear End Trim(Refer to P.23.85.)

nl lnstallatron of Rear End Trim

td19AO947

Rear bumper assembly removal steps1. Splash shield mounting clip

2. Back up light

3. Rear panel garnish

4. Rear combination light

5. Connection for license plate light wiring

harness and body wiring harness

6. Rear bumper assembly

(No.7-12)7. Rear fascia side plate

8. Rear fascia upper plate

9. Rear side marker light

10. Rear fascia side plate

1 1. Rear bumper reinforcement assembly

12. Rear fascia lower plate

13. Rear bumper fascia

Rear bumper fascia removal steps1. Splash shield mounting clip

2. Back up light

3. Rear pahel garnish

4. Rear combination light

7. Rear fascia side plate

8. Rear fascia upper plate

9. Rear side marker light

10.

Rear. fascia s,ide plate

12. Rear fascia lower plate

13. Rear bumper fascia

NOTEReverse the removal procedures to reinstall.

Page 43 of 57

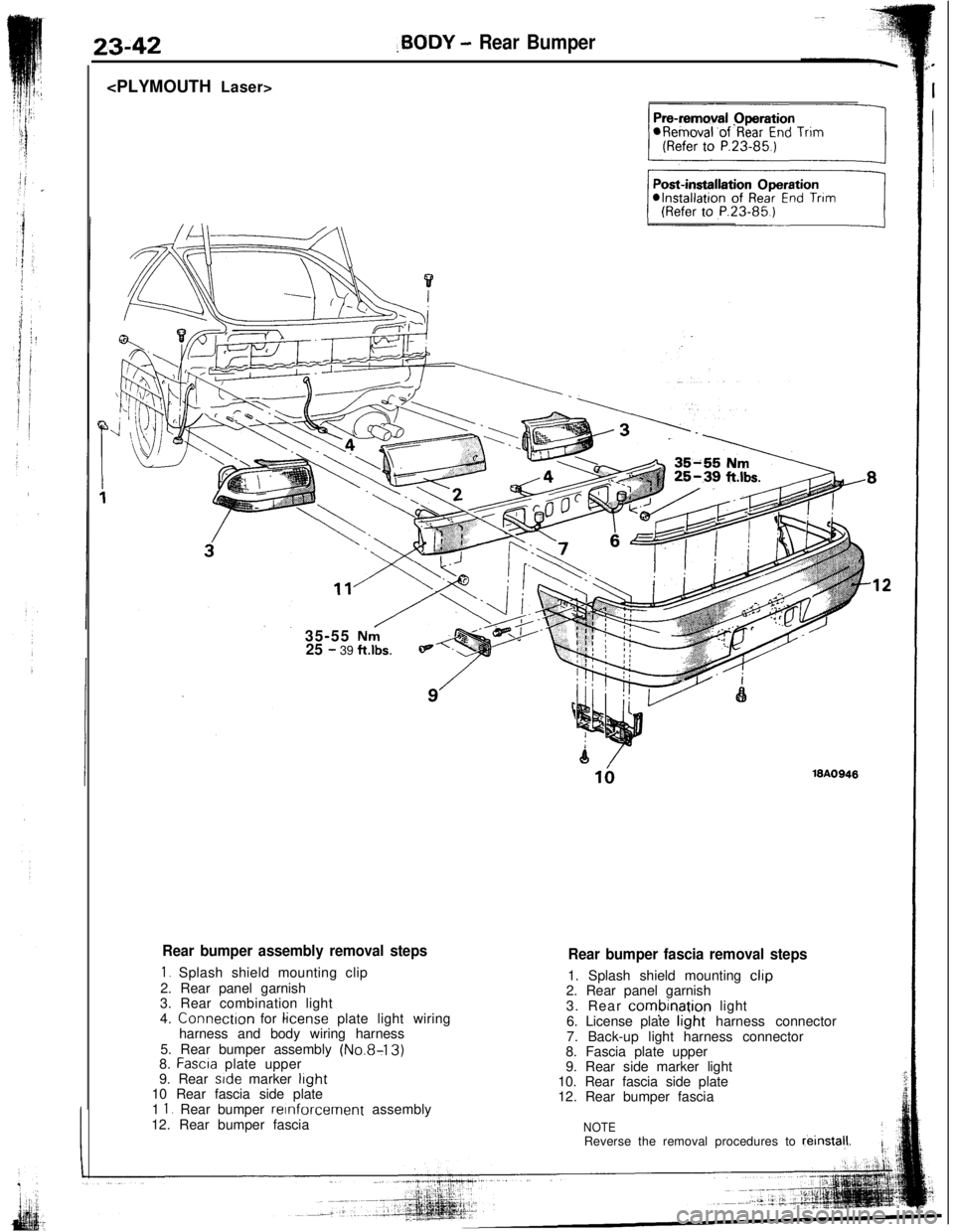

23-42,BODY - Rear Bumper

35-55

Nni25 - 39 ft.lbs.

Rear bumper assembly removal steps

1. Splash shield mounting clip

2. Rear panel garnish

3. Rear combination light

4. Connectron for

license plate light wiring

harness and body wiring harness

5. Rear bumper assembly

(No.8-13)8. Fascra plate upper

9. Rear side marker light10 Rear fascia side plate

1

1. Rear bumper reinforcement assembly

12. Rear bumper fascia

18A0948

Rear bumper fascia removal steps1. Splash shield mounting

clip2. Rear panel garnish

3. Rear

combinatjon light

6. License plate light harness connector

7. Back-up light harness connector

8. Fascia plate upper

9. Rear side marker light

10. Rear fascia side plate

12. Rear bumper fascia

NOTEReverse the removal procedures to reinstal,l.

Page 44 of 57

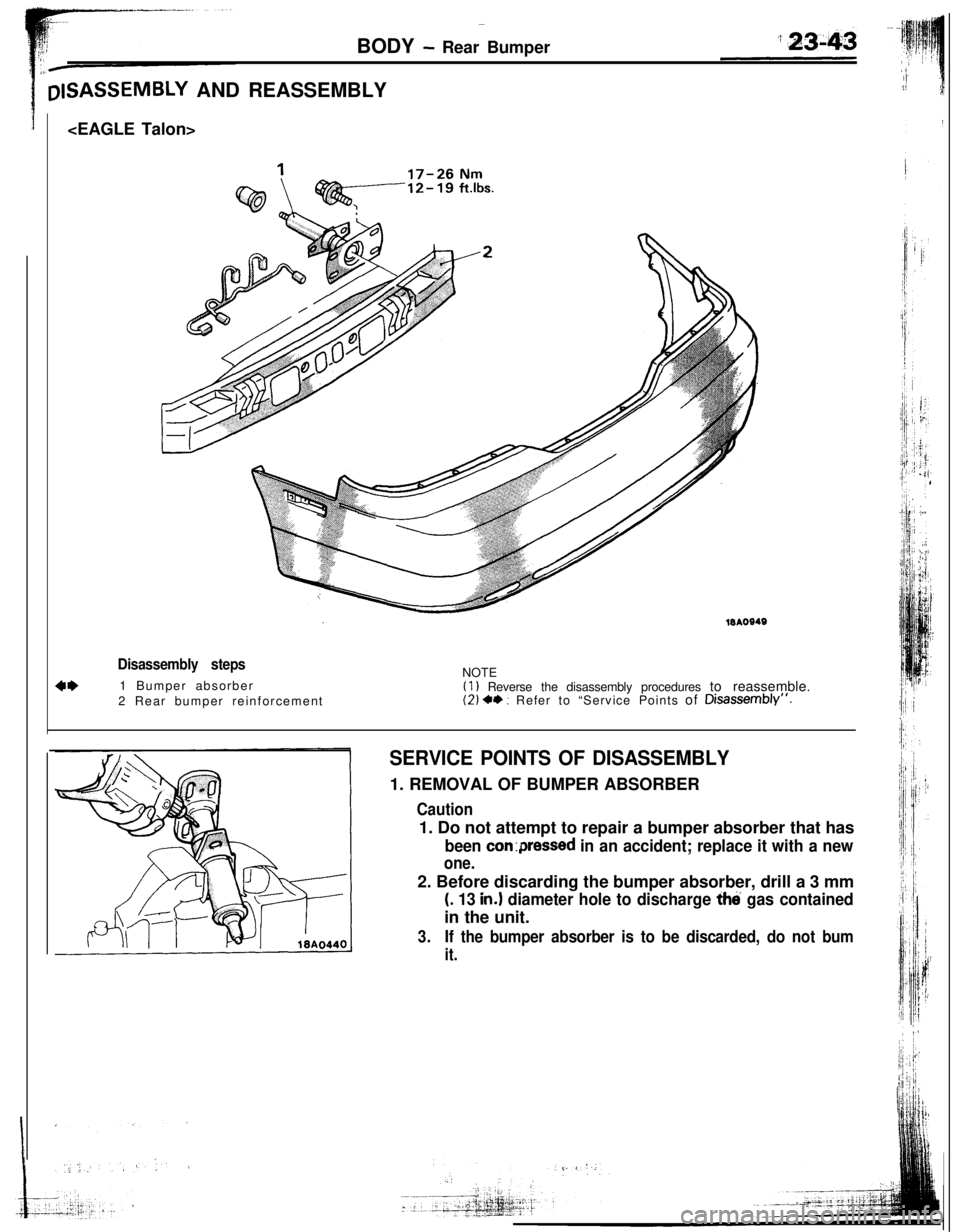

-BODY

- Rear Bumper

DISASSEMBLY AND REASSEMBLY

Disassembly steps1 Bumper absorber

2 Rear bumper reinforcementNOTE(1) Reverse the disassembly procedures to reassemble.(2)

++ : Refer to “Service Points of Disassembly”.

SERVICE POINTS OF DISASSEMBLY1. REMOVAL OF BUMPER ABSORBER

Caution1. Do not attempt to repair a bumper absorber that has

been con:pressed in an accident; replace it with a new

one.2. Before discarding the bumper absorber, drill a 3 mm

(. 13 in.1 diameter hole to discharge thii gas containedin the unit.

3.If the bumper absorber is to be discarded, do not bum

it.

Page 45 of 57

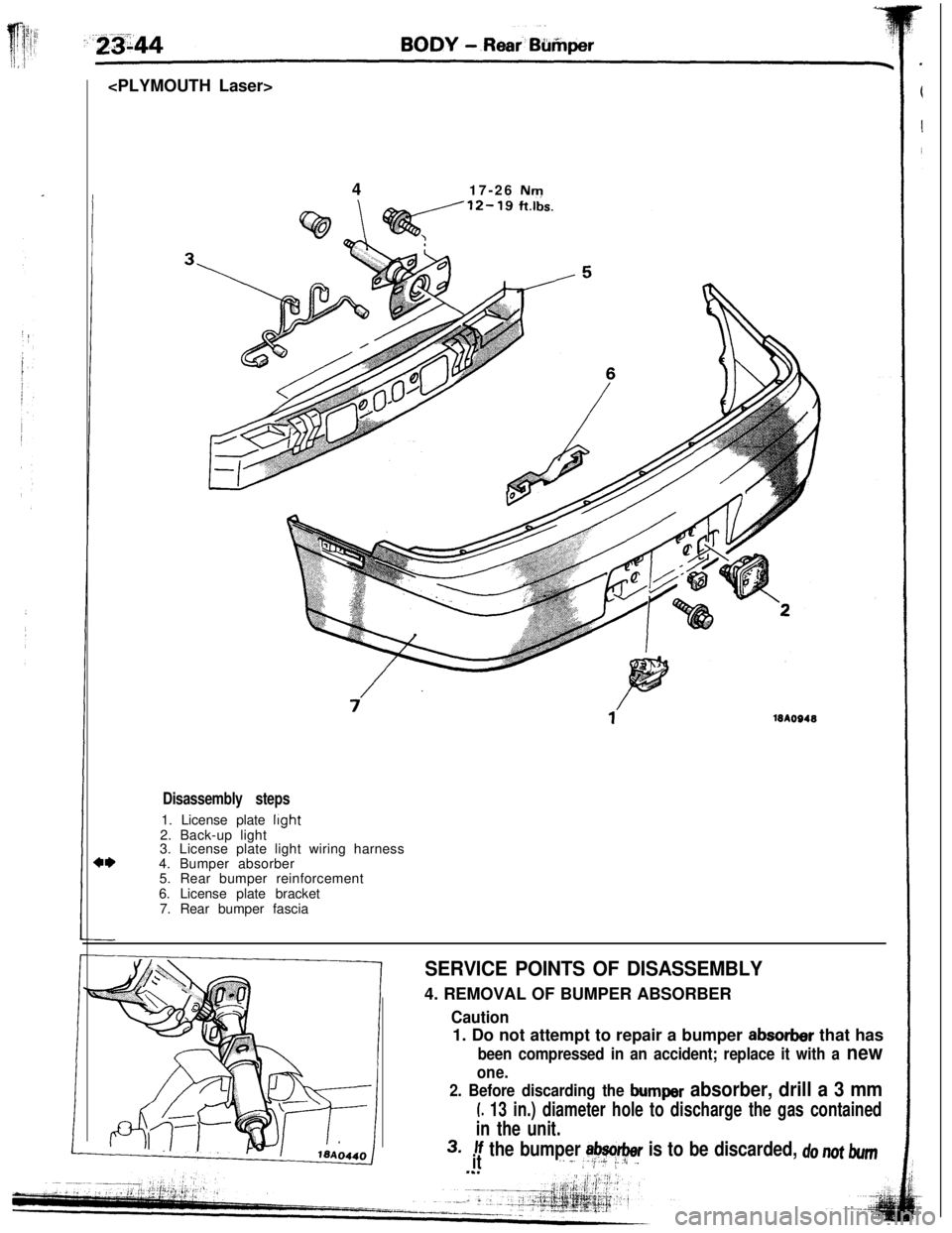

417-26 Nm

18AO948

Disassembly steps1. License plate

light2. Back-up light

3. License plate light wiring harness

4. Bumper absorber

5. Rear bumper reinforcement

6. License plate bracket

7. Rear bumper fascia

SERVICE POINTS OF DISASSEMBLY4. REMOVAL OF BUMPER ABSORBER

2. Before discarding the bumper absorber, drill a 3 mm

L 13 in.) diameter hole to discharge the gas contained

in the unit.

3.If the bumper absorber is to be discarded, do not bumit,. _..2;+ i_.I/~.L I

Caution1. Do not attempt to repair a bumper

absorber that has

been compressed in an accident; replace it with a new

one.

Page 46 of 57

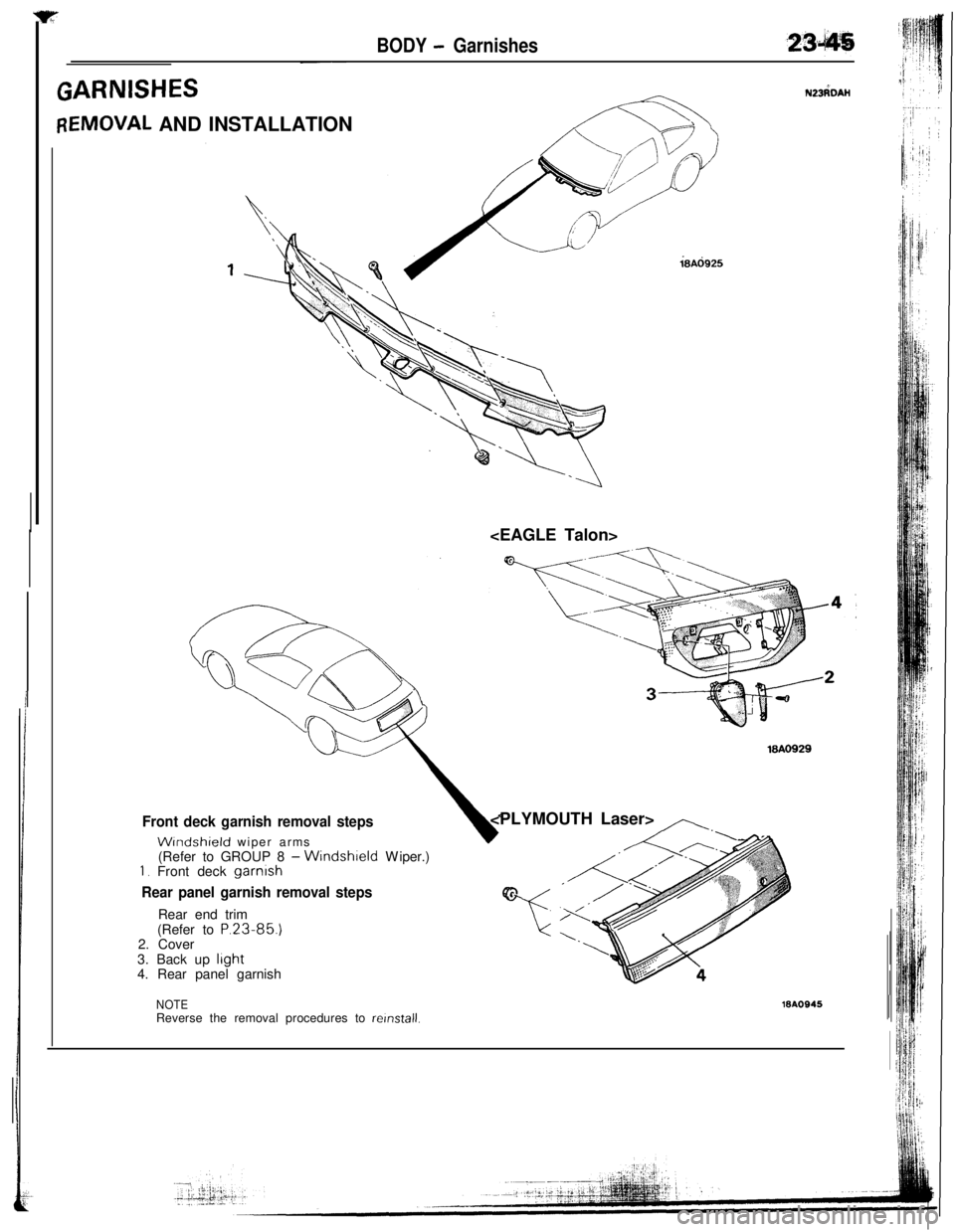

BODY - Garnishes-~

ZARNISHESN23dDAH

IEMOVAL AND INSTALLATION

18Ad925

18AO929

Front deck garnish removal steps

WIndshield wiper arms

(Refer to GROUP 8 -Windshield Wiper.)1. Front deck garnish

Rear panel garnish removal stepsRear end trim

(Refer to

P.23-85.)2. Cover

3. Back up

light4. Rear panel garnish

,,-..,.,-

E

“c

NOTEReverse the removal procedures to relnstall.16AOS45

Page 47 of 57

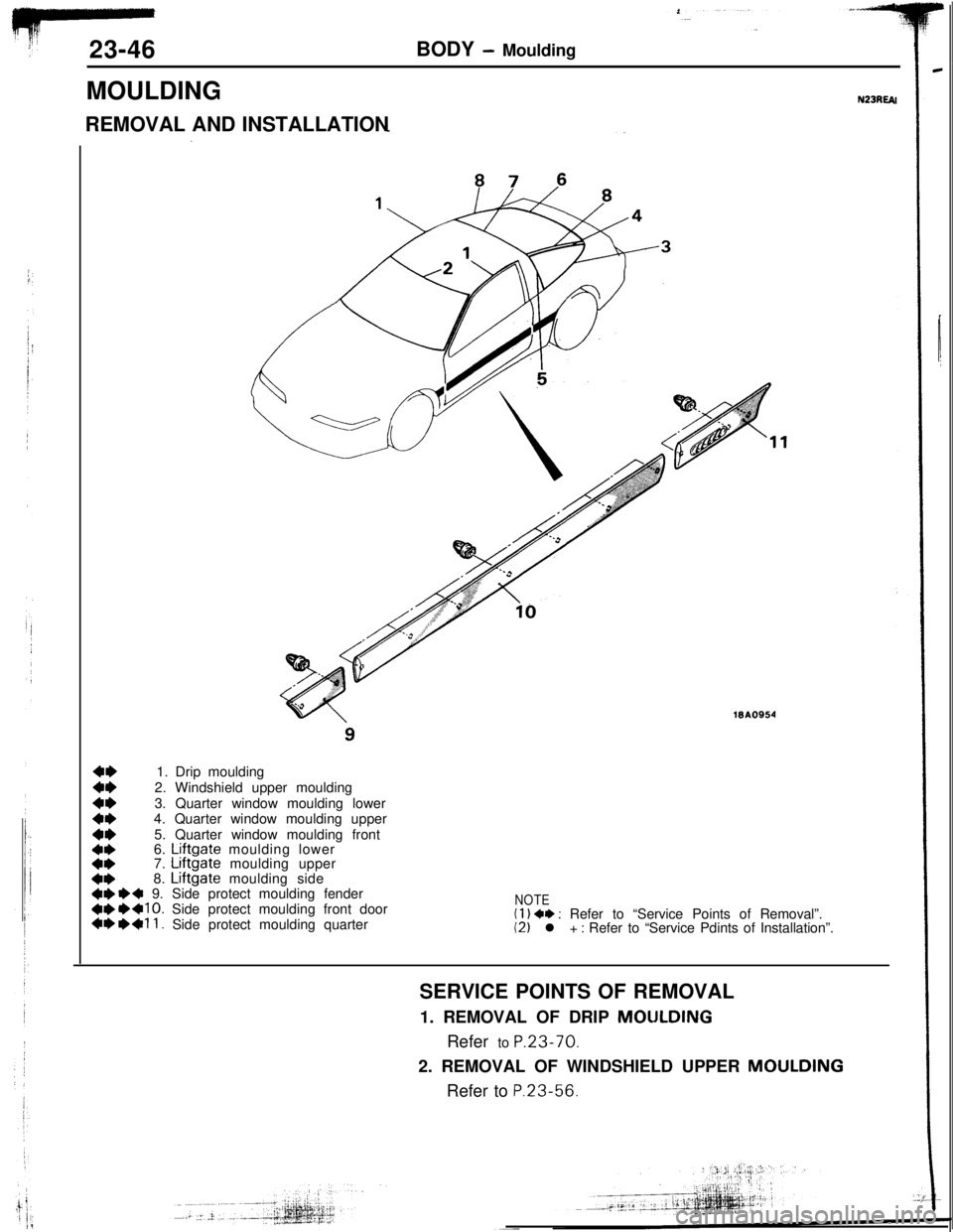

23-46BODY - Moulding

MOULDING

REMOVAL AND INSTALLATION

WA0954

N23REIU1. Drip moulding

2. Windshield upper moulding

z3. Quarter window moulding lower

4. Quarter window moulding upper

4*5. Quarter window moulding front

:+’6.

Liftgate moulding lower

7. Liftgate moulding upper

4*8. Liftgate moulding side+e+* 9. Side protect moulding fender4+1)+10. Side protect moulding front door4**+11. Side protect moulding quarter

NOTE(1) a* : Refer to “Service Points of Removal”.12) l + : Refer to “Service Pdints of Installation”.

SERVICE POINTS OF REMOVAL

1. REMOVAL OF DRIP MOULDING

Refer to

P.23-70.2. REMOVAL OF WINDSHIELD UPPER MOULDING

Refer to

P.23-56.

Page 48 of 57

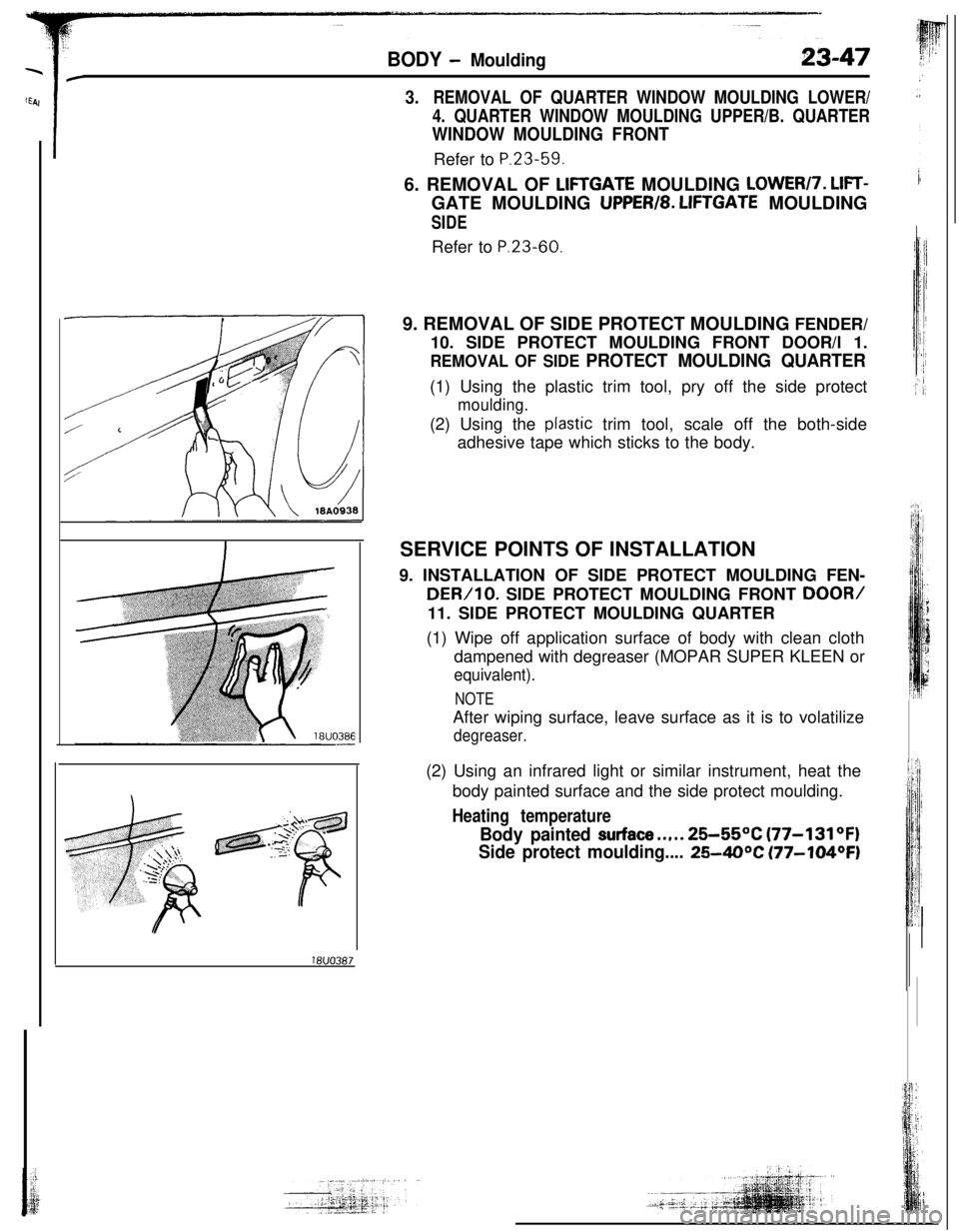

BODY - Moulding23-47

?8UO387

3.REMOVAL OF QUARTER WINDOW MOULDING LOWER/

4. QUARTER WINDOW MOULDING UPPER/B. QUARTER

WINDOW MOULDING FRONTRefer to P.23-59.

6. REMOVAL OF

LIFTGATE MOULDING LOWER17. LIFT-GATE MOULDING

UPPER/8. LIFTGATE MOULDING

SIDERefer to P.23-60.

9. REMOVAL OF SIDE PROTECT MOULDING FENDER/

10. SIDE PROTECT MOULDING FRONT DOOR/l 1.

REMOVAL OF SIDE PROTECT MOULDING QUARTER(1) Using the plastic trim tool, pry off the side protect

moulding.(2) Using the

ptastic trim tool, scale off the both-side

adhesive tape which sticks to the body.

SERVICE POINTS OF INSTALLATION

9. INSTALLATION OF SIDE PROTECT MOULDING FEN-

DER/10. SIDE PROTECT MOULDING FRONT DOOR/11. SIDE PROTECT MOULDING QUARTER

(1) Wipe off application surface of body with clean cloth

dampened with degreaser (MOPAR SUPER KLEEN or

equivalent).

NOTEAfter wiping surface, leave surface as it is to volatilize

degreaser.(2) Using an infrared light or similar instrument, heat the

body painted surface and the side protect moulding.

Heating temperature

Body painted surface..,.. 25-55OC (77-131OF)

Side protect moulding....

25-40°C (77-104OF)

Page 49 of 57

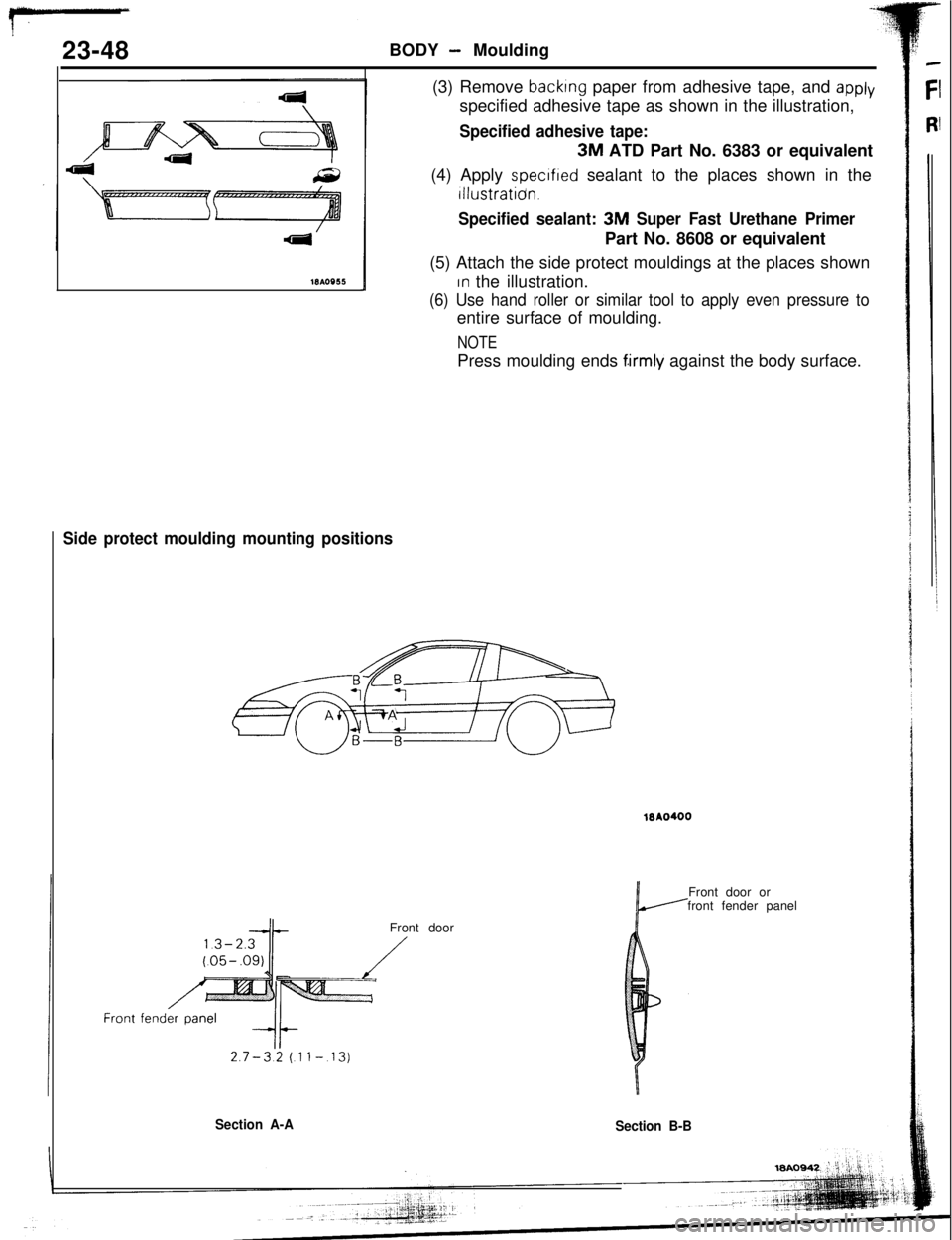

23-48BODY - Moulding

lBAOO55(3) Remove

backrng paper from adhesive tape, and applyspecified adhesive tape as shown in the illustration,

Specified adhesive tape:

3M ATD Part No. 6383 or equivalent

(4) Apply

specrfred sealant to the places shown in the

rllustratidn.

Specified sealant: 3M Super Fast Urethane PrimerPart No. 8608 or equivalent

(5) Attach the side protect mouldings at the places shown

In the illustration.

(6) Use hand roller or similar tool to apply even pressure toentire surface of moulding.

NOTEPress moulding ends

f.irmly against the body surface.

Side protect moulding mounting positionsMA0400

Front doorFront door or

front fender panel

Section A-A

Section B-B

Page 50 of 57

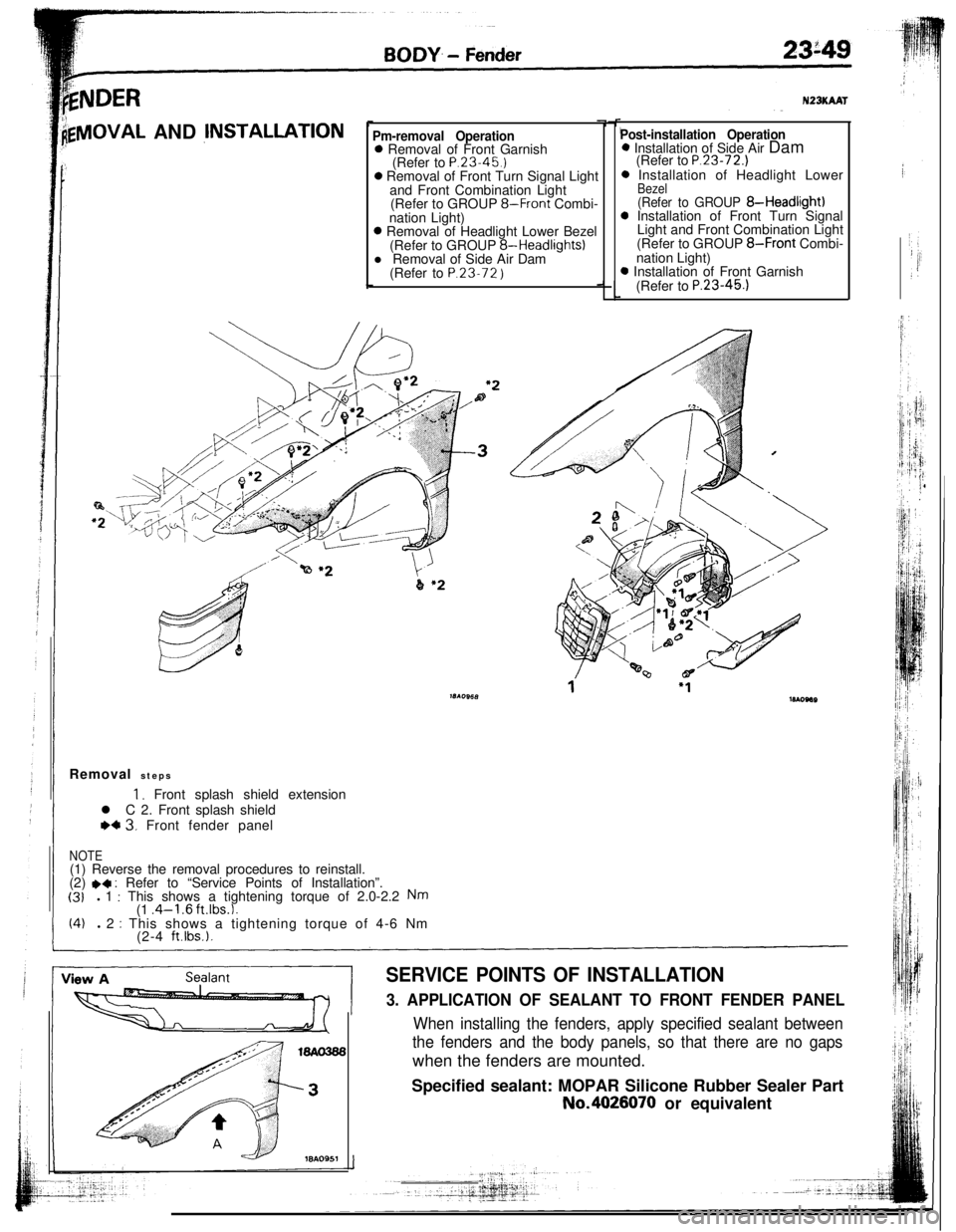

kNDER

lgVlOVAL AND jNSTALLATIONPm-removal Operation0 Removal of Front Garnish

(Refer to P.23.45.)0 Removal of Front Turn Signal Light

and Front Combination Light

(Refer to GROUP

8-Front Combi-

nation Light)0 Removal of Headlight Lower Bezel

(Refer to GROUP 8-Headlights)

l Removal of Side Air Dam

(Refer to P.23.72

)

N23KAAT

Post-installation Operation0 Installation of Side Air Dam

(Refer to

P.23-72.)0 Installation of Headlight Lower

Bezel(Refer to GROUP 8-Headlight)0 Installation of Front Turn Signal

Light and Front Combination Light

(Refer to GROUP

8-Front Combi-

nation Light)0 Installation of Front Garnish

(Refer to

P.23-45.1Removal steps

1, Front splash shield extension

l C 2. Front splash shield

WC 3. Front fender panel

NOTE(1) Reverse the removal procedures to reinstall.

(2)

.4 : Refer to “Service Points of Installation”.(31l 1 : This shows a tightening torque of 2.0-2.2 Nm(1 .4-l .6 ft.lbs.1.(4)l 2 : This shows a tightening torque of 4-6 Nm

(2-4 ft.lbs.).

SERVICE POINTS OF INSTALLATION

3. APPLICATION OF SEALANT TO FRONT FENDER PANEL

When installing the fenders, apply specified sealant between

the fenders and the body panels, so that there are no gapswhen the fenders are mounted.

Specified sealant: MOPAR Silicone Rubber Sealer PartNo.4026070 or equivalent