service MITSUBISHI ECLIPSE 1993 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1993, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1993Pages: 57, PDF Size: 4.18 MB

Page 33 of 57

BODY

CONTENTS

,I

i

1AEROPARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

; CENTRAL DOOR LOCKING SYSTEM . . . . . . . . . . .68

’DOORASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

DOOR GLASS AND REGULATOR................

64

DOOR HANDLE AND LATCH.....................67QUARTER WINDOWGLASS..

...............

..i..59

REAR BUMPER........................................41

REARSEAT.........................................;..93

SEATBELT.............................................

94

SERVICE ADJUSTMENT PROCEDURES........30

Door Adjustment....................................31

Door Glass Adjustment............................31

Door Inside Handle Play Check...................31

Door Outside Handle Play Check................31

Floor PanInspection..............................

32

Fuel Filler Door Adjustment.......................30

Hood Adjustment...................................30

Liftgate Adjustment.................................30

Water Test...........................................

32

SPECIAL TOOLS....................*..........c......

5

SPECIFICATIONS.....................................2

General Specifications...........................;..2

Lubricants.............................................5

Sealants and Adhesives...........................5

Service Specifications..............................3

Torque Specifications..............................3

SUNROOF...............................................

77

TRIMS....................................................

85

TROUBLESHOOTING................................6

WINDOWGLASS.....................................52

WINDSHIELD...........................................56

DOORMIRROR........................................

70

DOOR

MOULDING AND

DRIP LINE WEATHERSTRIP........................

70

DOORRUNCHANNEL...............................

69

DOOR TRIM AND WATERPROOF FILM........

63

ELECTRIC REMOTE CONTROLLED

MIRRORSWITCH.....................................

71

FENDER..................................................

49

FLOORCONSOLE....................................

84

FRONTBUMPER......................................37

FRONTSEAT...........................................90

FUEL TANK FILLER DOOR.........................

36

GARNISHES............................................45

HEADLINING...........................................89

HOOD....................................................

33

INSTRUMENTPANEL.,..............................

79

Lll=l’GATE...............................................

35

LIFTGATE WINDOW GLASS......................60

LOOSEPANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

MOULDING.............................................

46

POWERWINDOW....................................65

N23AA--

Page 34 of 57

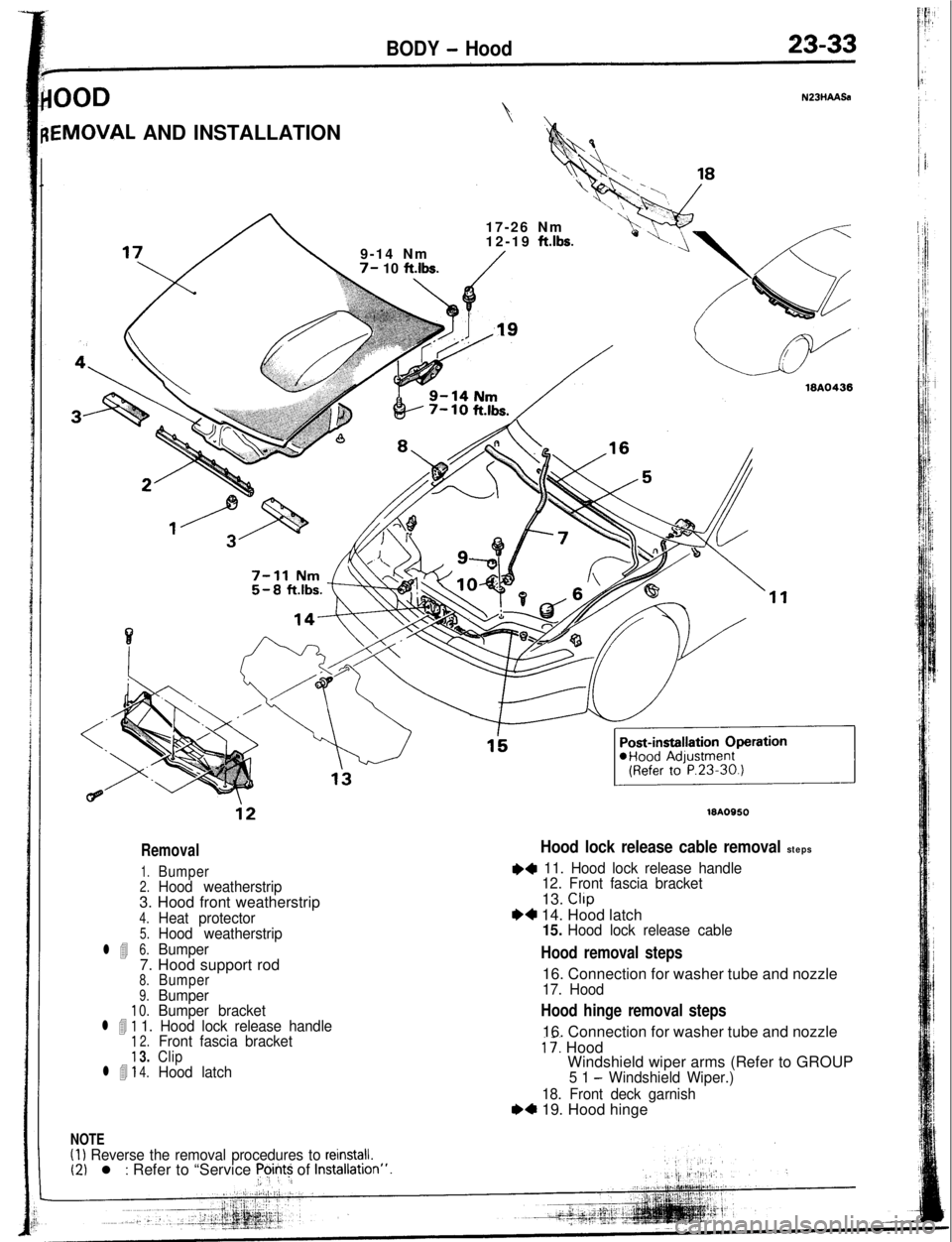

BODY - Hood23-33

IOODN23HAA.S

k

EMOVAL AND INSTALLATION9,17-26 Nm

12-19

ftlbs.11/9-14 Nm7- 10 ft.lbs./

!, 9-14Nm/

9-J/

l 4

l 4

l 4

Removal

1.Bumper2.Hood weatherstrip3. Hood front weatherstrip

4.Heat protector5.Hood weatherstrip

6.Bumper7. Hood support rod

8.Bumper9.Bumper0.Bumper bracket

1. Hood lock release handle

2.Front fascia bracket3.Clip4.Hood latch

NOTE(1) Reverse the removal procedures to reinstsll.(2) l : Refer to “Service Pyrnts of Installatron”.

19A0950

Hood lock release cable removal steps

+a 11. Hood lock release handle

12. Front fascia bracket13.

CllP

~~ 14. Hood latch15. Hood lock release cable

Hood removal steps16. Connection for washer tube and nozzle

17. Hood

Hood hinge removal steps16. Connection for washer tube and nozzle

i-I. Hood

Windshield wiper arms (Refer to GROUP

5 1 - Windshield Wiper.)

18. Front deck garnish

+d 19. Hood hinge

Page 35 of 57

-

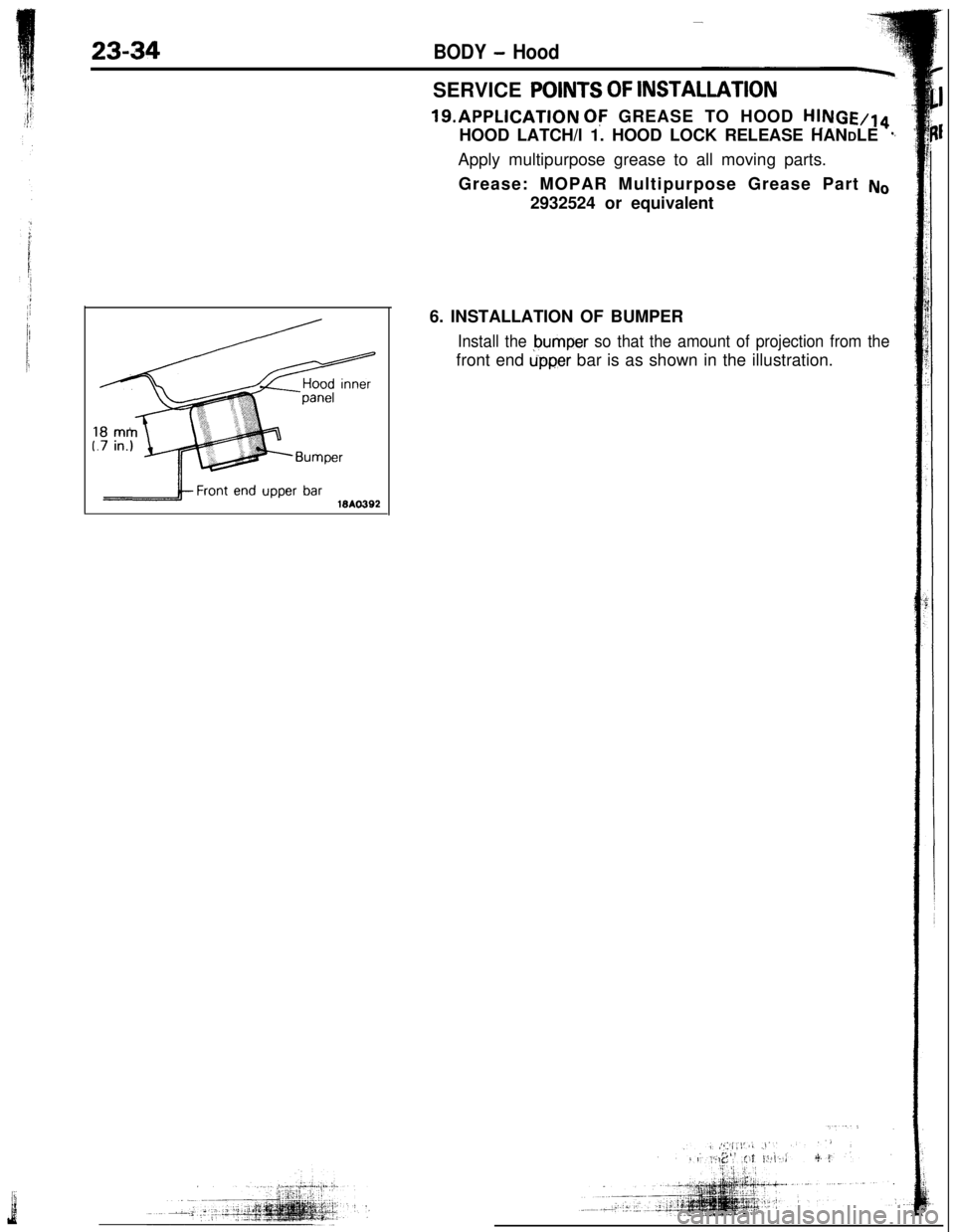

23-34BODY - HoodSERVICE POINTS

OF INSTALLATION

19.APPLICATION Or GREASE TO HOOD HINGE/l4HOOD LATCH/l 1. HOOD LOCK RELEASE HANDLE

’Apply multipurpose grease to all moving parts.

Grease: MOPAR Multipurpose Grease Part

No2932524 or equivalent

18AO3926. INSTALLATION OF BUMPER

Install the bumper so that the amount of projection from thefront end

@per bar is as shown in the illustration.

Page 37 of 57

._-_,. -/a,_ . . ._ :-.

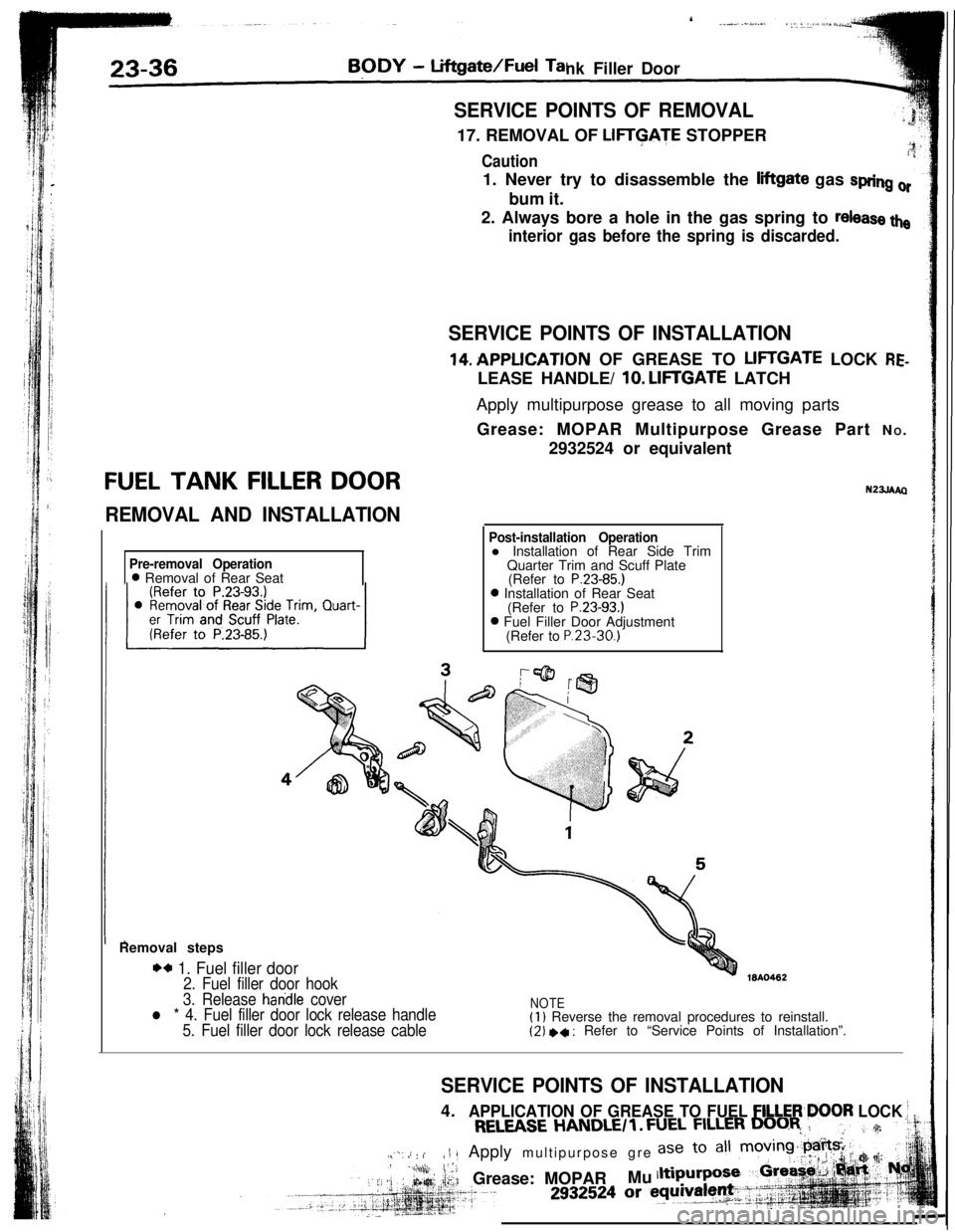

FUEL TANK FILLER DOOR

REMOVAL AND INSTALLATIONSERVICE POINTS OF REMOVAL17. REMOVAL OF

LIFTGATE STOPPER

Caution1. Never try to disassemble the

liigate gas spring crbum it.

2. Always bore a hole in the gas spring to

release the

interior gas before the spring is discarded.

SERVICE POINTS OF INSTALLATION14,APPLICATION OF GREASE TO

LIFTGATE LOCK RF-LEASE HANDLE/

10. LIFTGATE LATCH

Apply multipurpose grease to all moving parts

Grease: MOPAR Multipurpose Grease Part NO.

2932524 or equivalent

N23JAAa

Pre-removal Operation0 Removal of Rear Seat

Post-installation Operationl Installation of Rear Side Trim

Quarter Trim and Scuff Plate

(Refer to P.2385.)

0 Installation of Rear Seat

(Refer to P.23-93.)0 Fuel Filler Door Adjustment

(Refer to P.23-30.)Removal steps+a

1. Fuel filler door2. Fuel filler door hookWA0462

3. Release hatidle coverNOTEl * 4. Fuel filler door lock release handle(1) Reverse the removal procedures to reinstall.5. Fuel filler door lock release cable(2) +a : Refer to “Service Points of Installation”.

SERVICE POINTS OF INSTALLATION4.

APPLICATION OF GREASE TO FUEL FILLER,DOOR LOCK j

:(“‘: ,: : ,.-;gz/ :,; Apply multipurpose gre

:’ j:: -:l : :. ,;&r: &;iGrease: MOPARMu

; _

Page 40 of 57

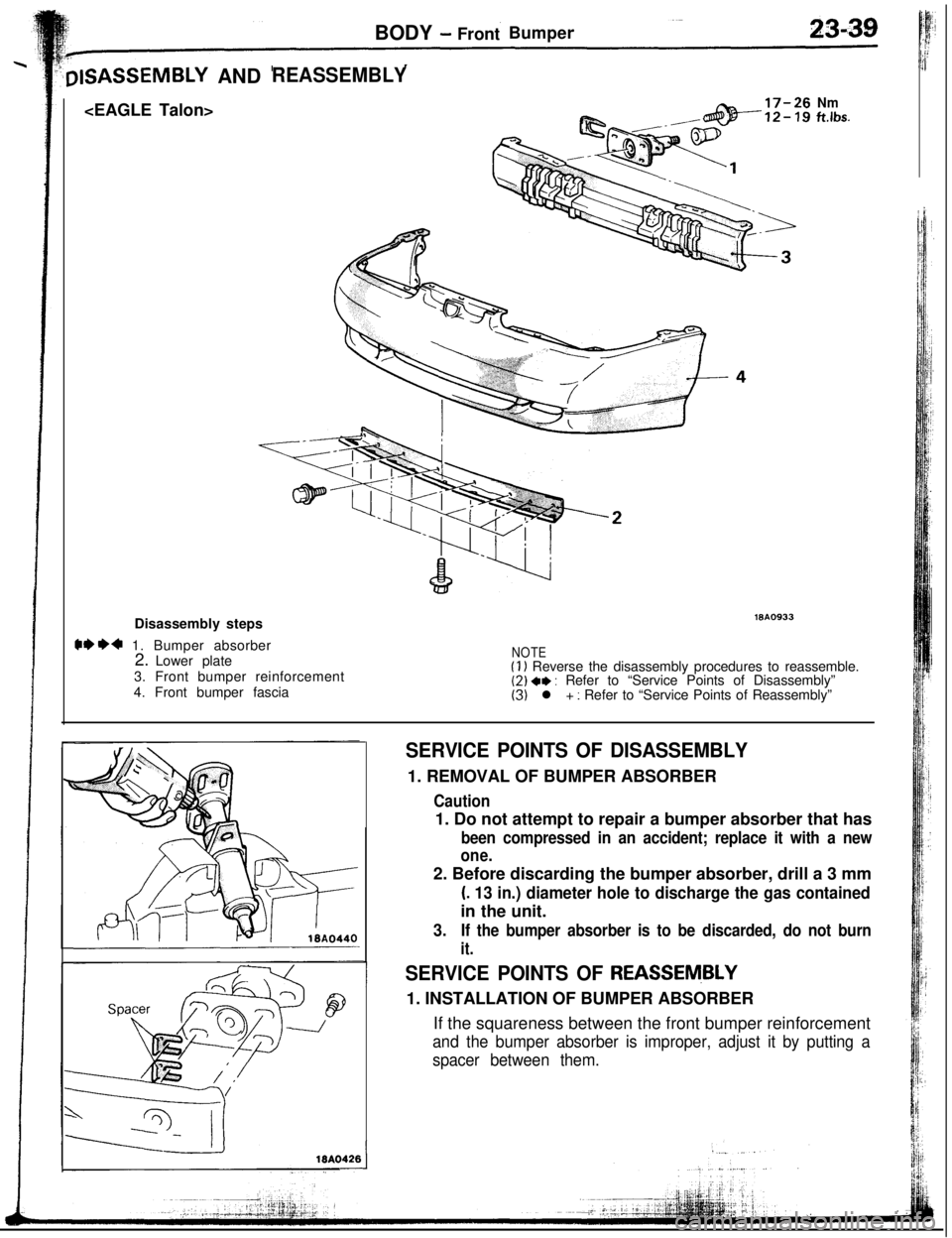

BODY - FrontBumper

‘plSASSEMBLY ANDREASSEMBLY

Nmftlbs.

Disassembly steps

@*I)* 1. Bumper absorber

2. Lower plate

3. Front bumper reinforcement

4. Front bumper fascia

19AQ933

NOTE(1) Reverse the disassembly procedures to reassemble.(2) ++ : Refer to “Service Points of Disassembly”(3) l + : Refer to “Service Points of Reassembly”

SERVICE POINTS OF DISASSEMBLY1. REMOVAL OF BUMPER ABSORBER

Caution1. Do not attempt to repair a bumper absorber that has

been compressed in an accident; replace it with a new

one.2. Before discarding the bumper absorber, drill a 3 mm

(. 13 in.) diameter hole to discharge the gas containedin the unit.

3.If the bumper absorber is to be discarded, do not burn

it.

SERVICE POINTS OF REASSEM.BLY1. INSTALLATION OF BUMPER ABSORBER

If the squareness between the front bumper reinforcement

and the bumper absorber is improper, adjust it by putting a

spacer between them.

Page 41 of 57

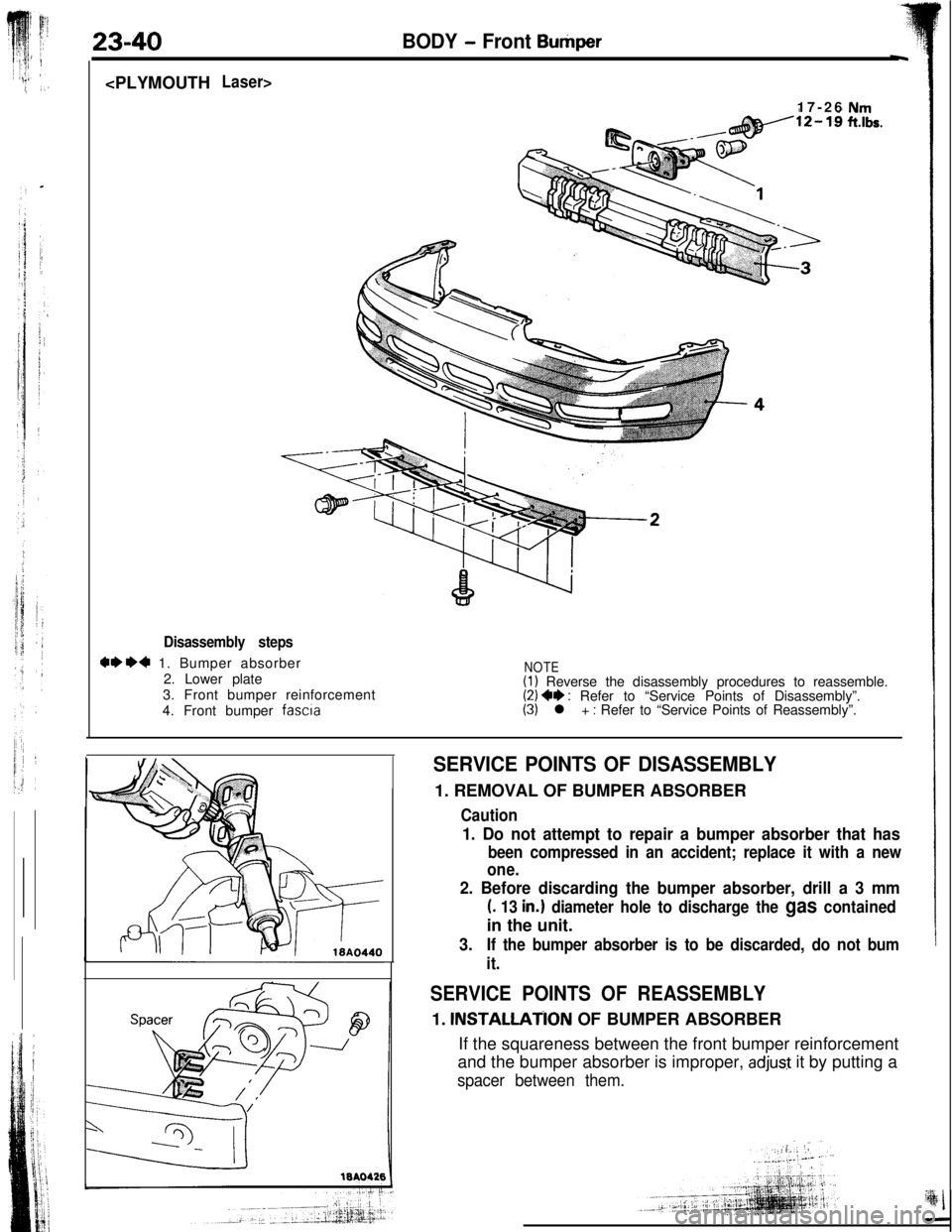

23-40BODY - Front Buripr

Disassembly steps

WI)* 1. Bumper absorber

2. Lower plate

3. Front bumper reinforcement

4. Front bumper

fascia

NOTE(1) Reverse the disassembly procedures to reassemble.(2) W : Refer to “Service Points of Disassembly”.(3) l + : Refer to “Service Points of Reassembly”.

SERVICE POINTS OF DISASSEMBLY1. REMOVAL OF BUMPER ABSORBER

Caution

1. Do not attempt to repair a bumper absorber that has

been compressed in an accident; replace it with a new

one.

2. Before discarding the bumper absorber, drill a 3 mm

(. 13 in.) diameter hole to discharge the gas containedin the unit.

3.If the bumper absorber is to be discarded, do not bum

it.

SERVICE POINTS OF REASSEMBLY1.

INSTALLATiON OF BUMPER ABSORBER

If the squareness between the front bumper reinforcement

and the bumper absorber is improper,

adjusj it by putting a

spacer between them.

Page 44 of 57

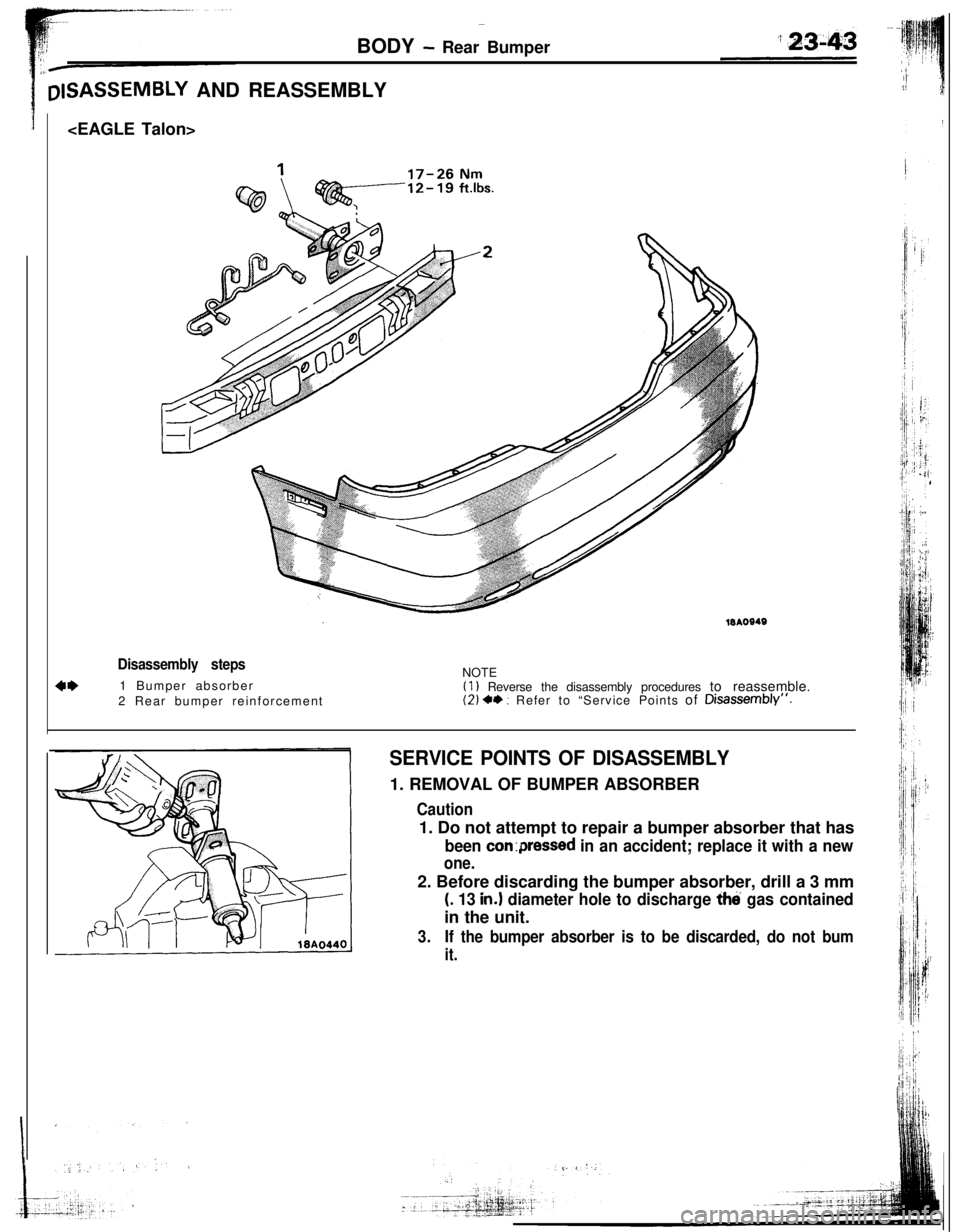

-BODY

- Rear Bumper

DISASSEMBLY AND REASSEMBLY

Disassembly steps1 Bumper absorber

2 Rear bumper reinforcementNOTE(1) Reverse the disassembly procedures to reassemble.(2)

++ : Refer to “Service Points of Disassembly”.

SERVICE POINTS OF DISASSEMBLY1. REMOVAL OF BUMPER ABSORBER

Caution1. Do not attempt to repair a bumper absorber that has

been con:pressed in an accident; replace it with a new

one.2. Before discarding the bumper absorber, drill a 3 mm

(. 13 in.1 diameter hole to discharge thii gas containedin the unit.

3.If the bumper absorber is to be discarded, do not bum

it.

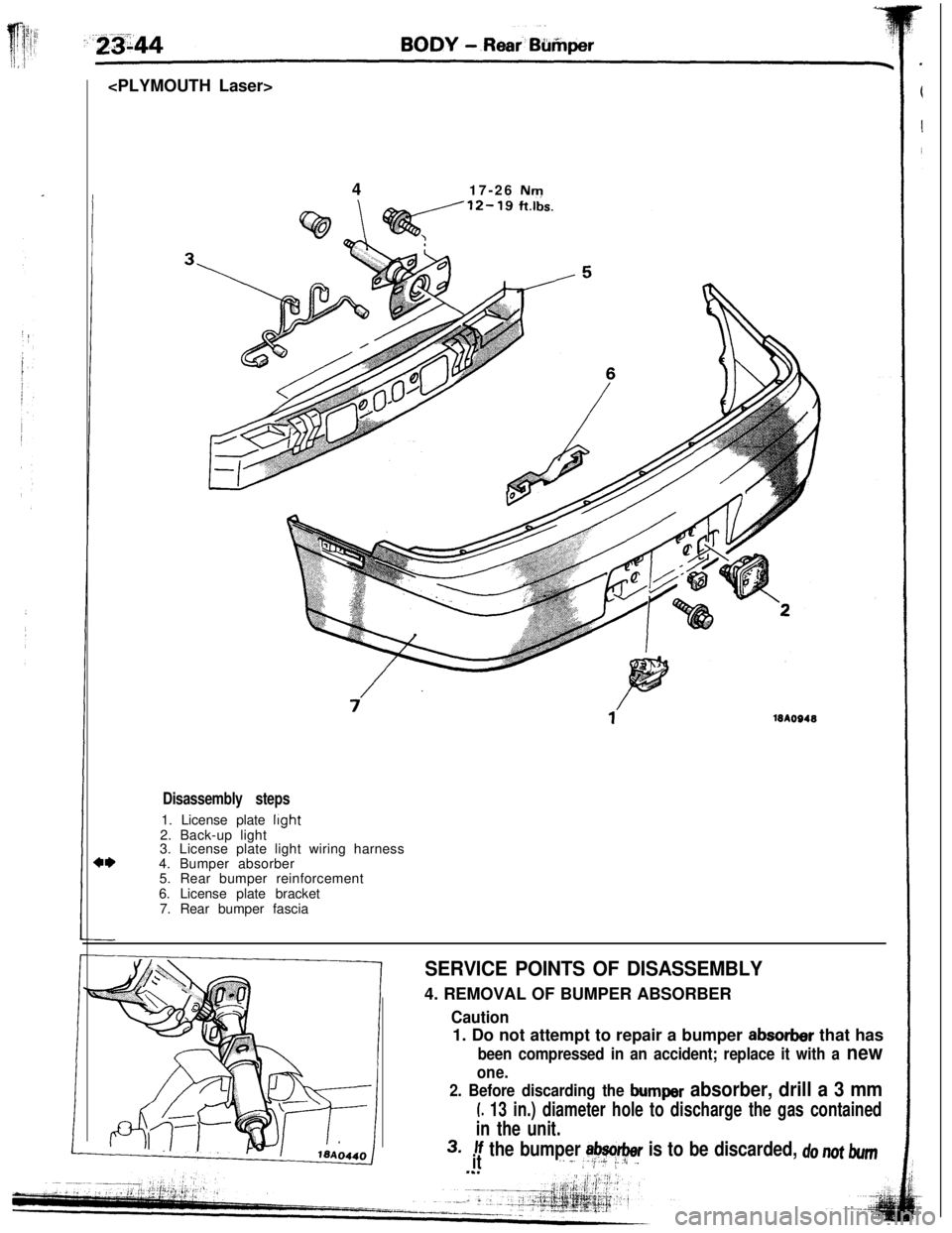

Page 45 of 57

417-26 Nm

18AO948

Disassembly steps1. License plate

light2. Back-up light

3. License plate light wiring harness

4. Bumper absorber

5. Rear bumper reinforcement

6. License plate bracket

7. Rear bumper fascia

SERVICE POINTS OF DISASSEMBLY4. REMOVAL OF BUMPER ABSORBER

2. Before discarding the bumper absorber, drill a 3 mm

L 13 in.) diameter hole to discharge the gas contained

in the unit.

3.If the bumper absorber is to be discarded, do not bumit,. _..2;+ i_.I/~.L I

Caution1. Do not attempt to repair a bumper

absorber that has

been compressed in an accident; replace it with a new

one.

Page 47 of 57

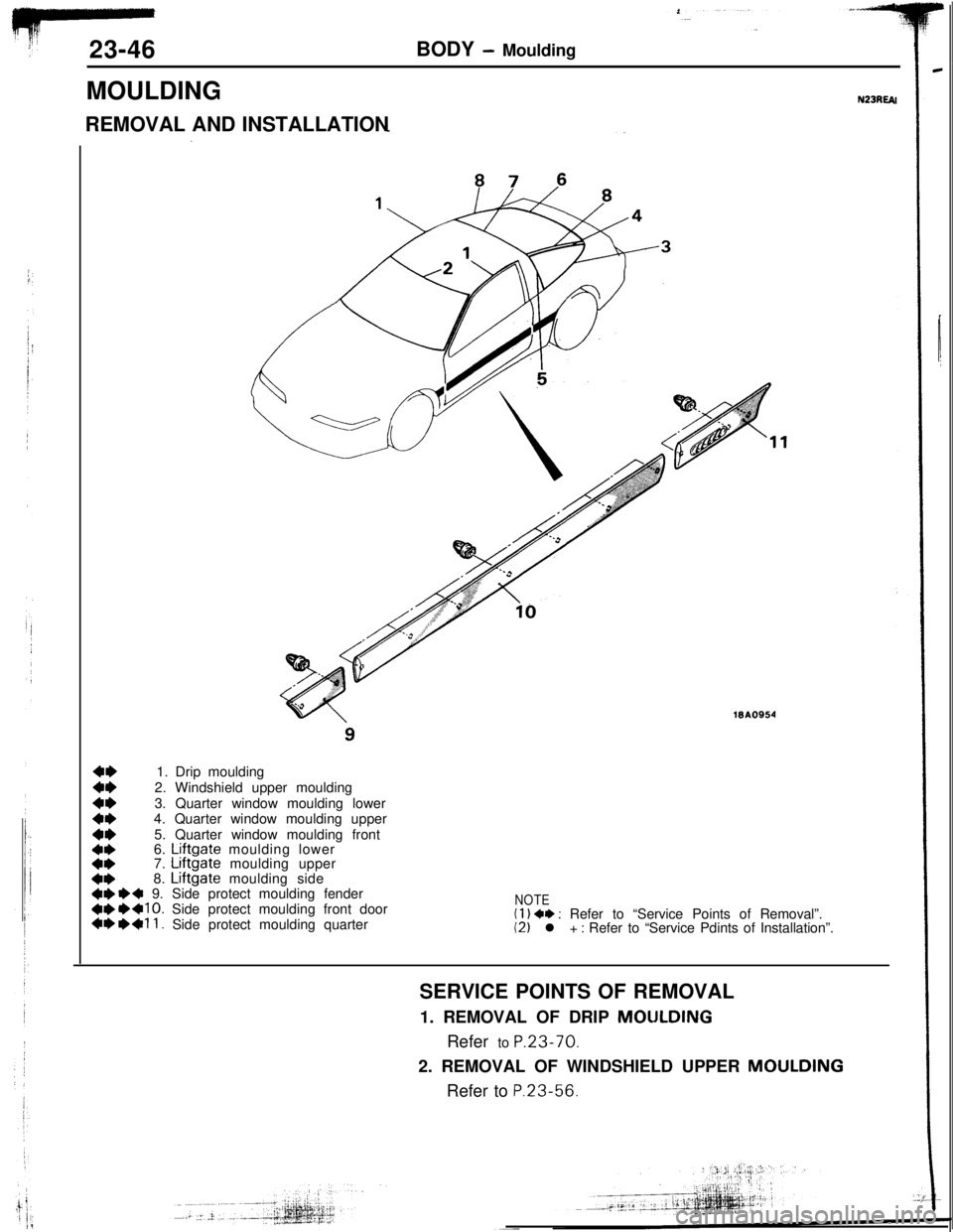

23-46BODY - Moulding

MOULDING

REMOVAL AND INSTALLATION

WA0954

N23REIU1. Drip moulding

2. Windshield upper moulding

z3. Quarter window moulding lower

4. Quarter window moulding upper

4*5. Quarter window moulding front

:+’6.

Liftgate moulding lower

7. Liftgate moulding upper

4*8. Liftgate moulding side+e+* 9. Side protect moulding fender4+1)+10. Side protect moulding front door4**+11. Side protect moulding quarter

NOTE(1) a* : Refer to “Service Points of Removal”.12) l + : Refer to “Service Pdints of Installation”.

SERVICE POINTS OF REMOVAL

1. REMOVAL OF DRIP MOULDING

Refer to

P.23-70.2. REMOVAL OF WINDSHIELD UPPER MOULDING

Refer to

P.23-56.

Page 48 of 57

BODY - Moulding23-47

?8UO387

3.REMOVAL OF QUARTER WINDOW MOULDING LOWER/

4. QUARTER WINDOW MOULDING UPPER/B. QUARTER

WINDOW MOULDING FRONTRefer to P.23-59.

6. REMOVAL OF

LIFTGATE MOULDING LOWER17. LIFT-GATE MOULDING

UPPER/8. LIFTGATE MOULDING

SIDERefer to P.23-60.

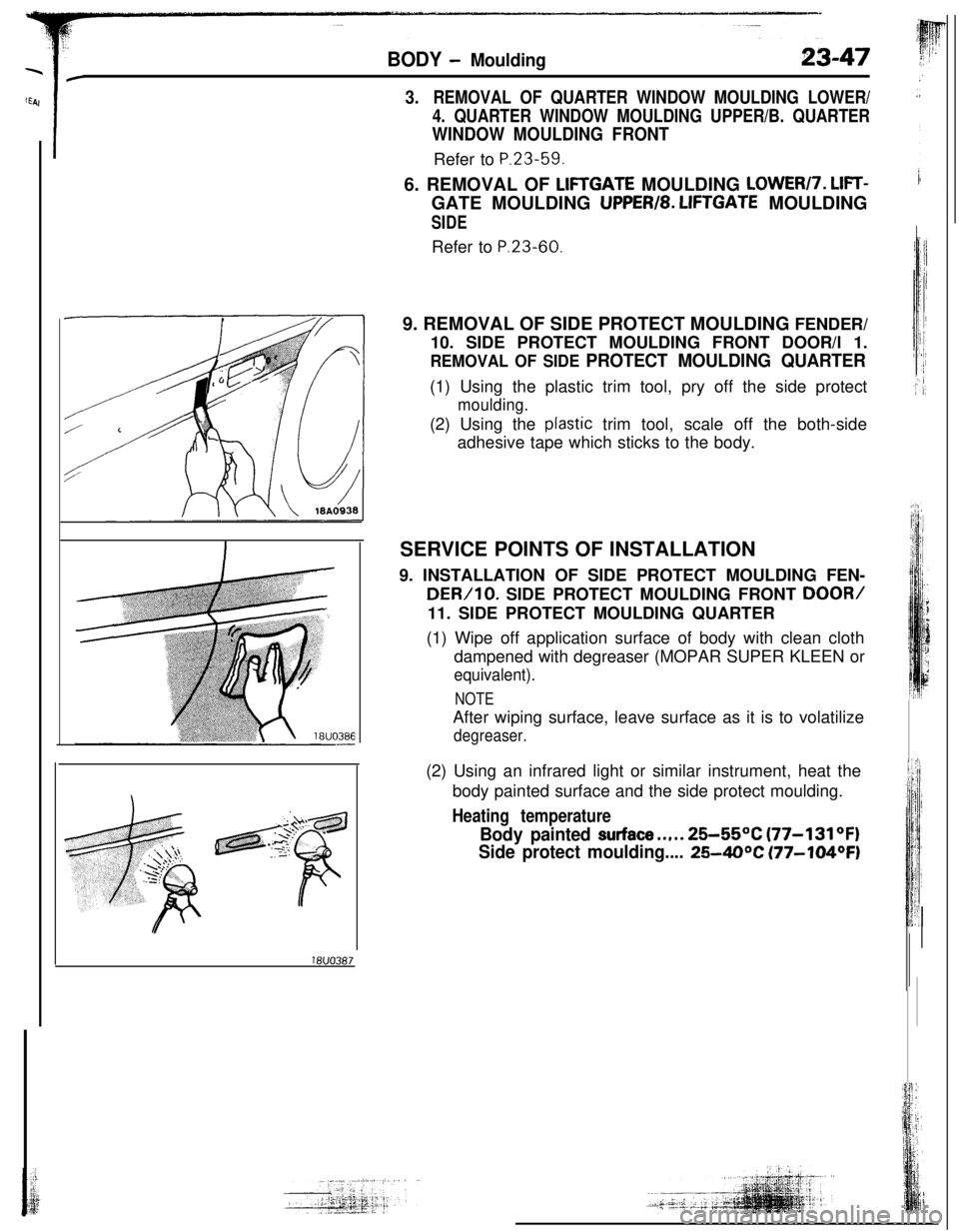

9. REMOVAL OF SIDE PROTECT MOULDING FENDER/

10. SIDE PROTECT MOULDING FRONT DOOR/l 1.

REMOVAL OF SIDE PROTECT MOULDING QUARTER(1) Using the plastic trim tool, pry off the side protect

moulding.(2) Using the

ptastic trim tool, scale off the both-side

adhesive tape which sticks to the body.

SERVICE POINTS OF INSTALLATION

9. INSTALLATION OF SIDE PROTECT MOULDING FEN-

DER/10. SIDE PROTECT MOULDING FRONT DOOR/11. SIDE PROTECT MOULDING QUARTER

(1) Wipe off application surface of body with clean cloth

dampened with degreaser (MOPAR SUPER KLEEN or

equivalent).

NOTEAfter wiping surface, leave surface as it is to volatilize

degreaser.(2) Using an infrared light or similar instrument, heat the

body painted surface and the side protect moulding.

Heating temperature

Body painted surface..,.. 25-55OC (77-131OF)

Side protect moulding....

25-40°C (77-104OF)