MITSUBISHI ENDEAVOR 2004 Service Repair Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Repair Manual

Trending: high beam, interval, Battery terminal positive, spare tire, Egr valve, width, tailgate

Page 1521 of 3870

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA

.

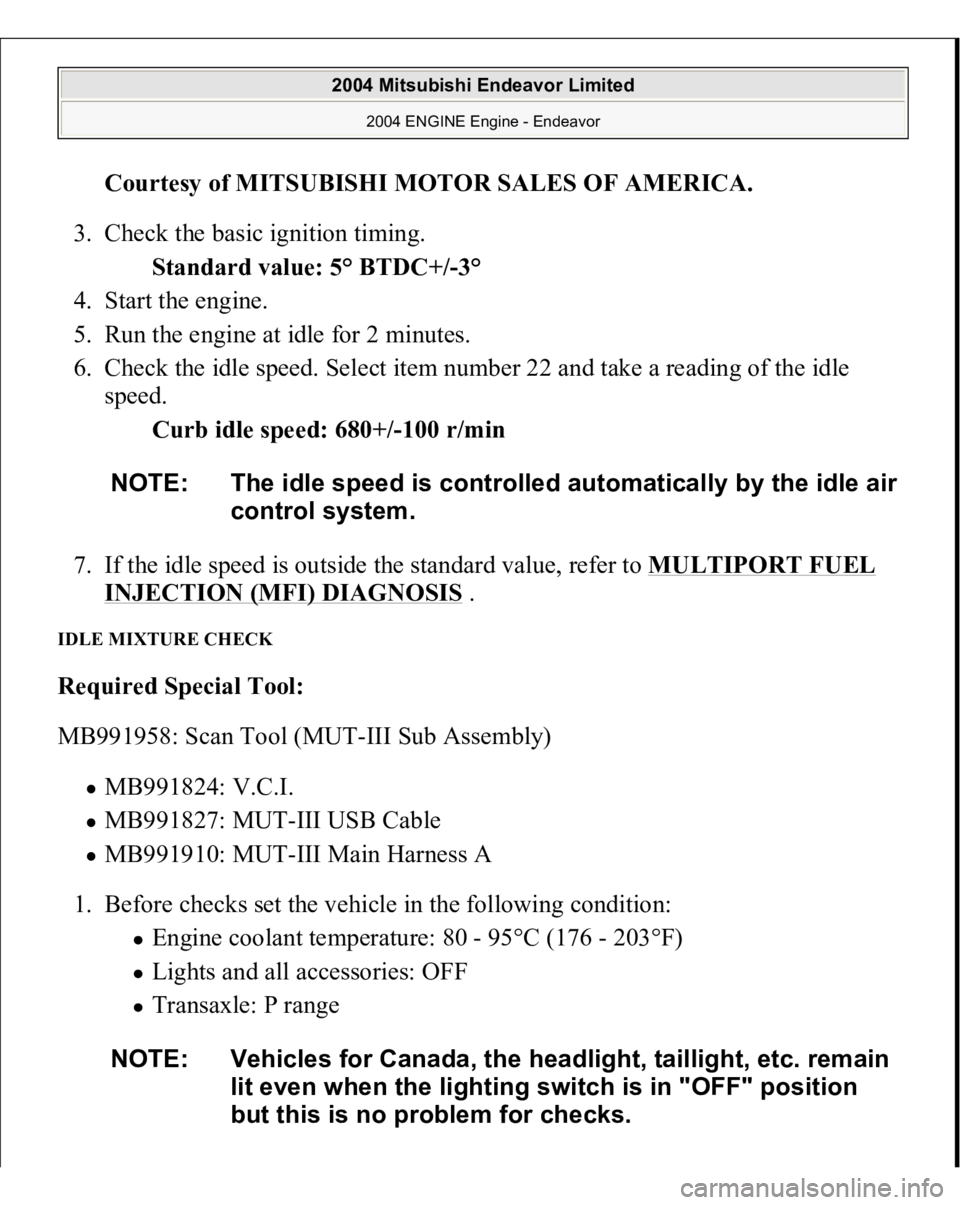

3. Check the basic ignition timing.

Standard value: 5° BTDC+/-3°

4. Start the engine.

5. Run the engine at idle for 2 minutes.

6. Check the idle speed. Select item number 22 and take a reading of the idle

speed.

Curb idle speed: 680+/-100 r/min

7. If the idle speed is outside the standard value, refer to MULTIPORT FUEL

INJECTION (MFI) DIAGNOSIS

.

IDLE MIXTURE CHECK Required Special Tool:

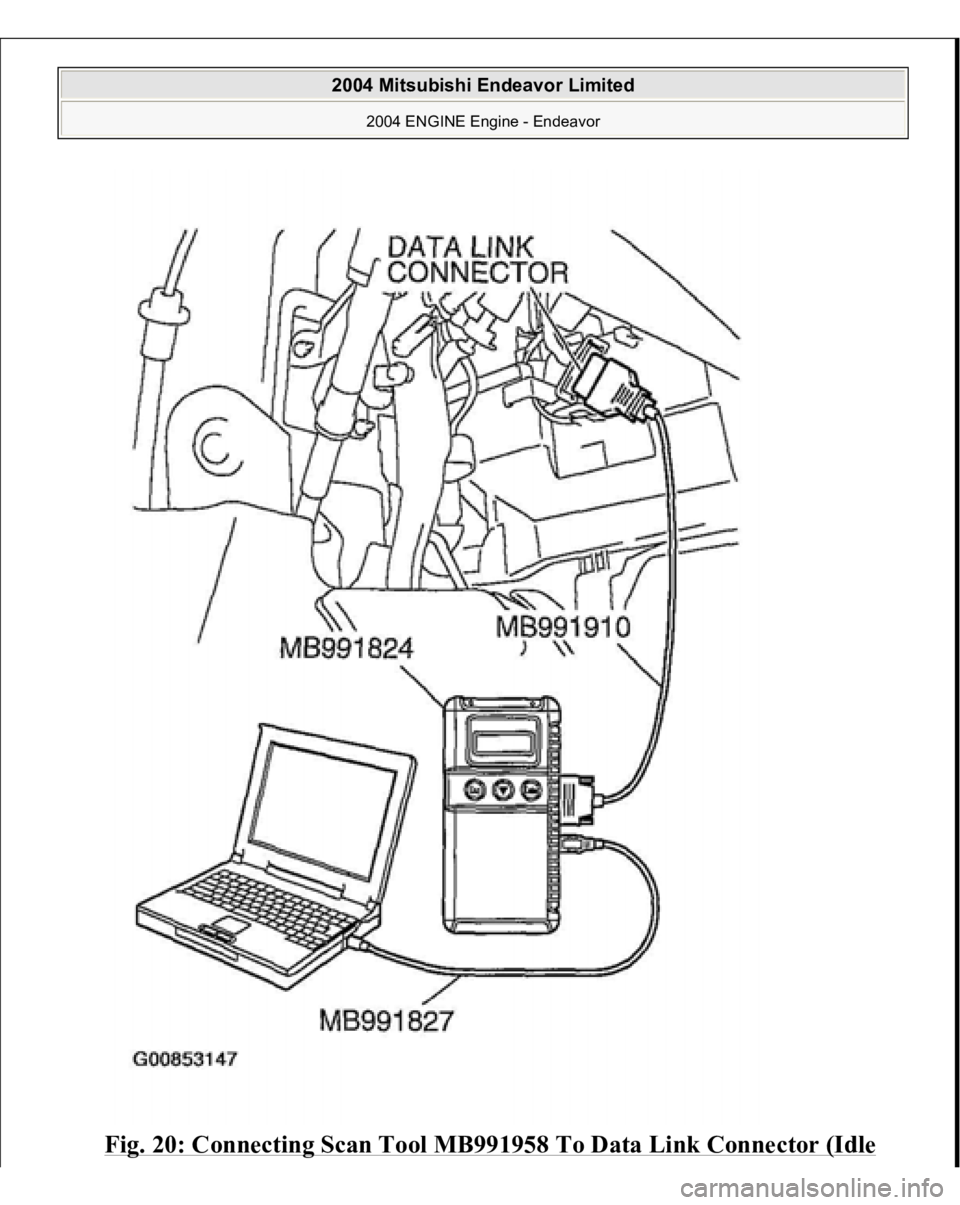

MB991958: Scan Tool (MUT-III Sub Assembly)

MB991824: V.C.I. MB991827: MUT-III USB Cable MB991910: MUT-III Main Harness A

1. Before checks set the vehicle in the following condition:

Engine coolant temperature: 80 - 95°C (176 - 203°F) Lights and all accessories: OFF Transaxle: P range

NOTE: The idle speed is controlled automaticall

y by the idle air

control system.

NOTE: Vehicles for Canada, the headlight, taillight, etc. remain

lit even when the lighting switch is in "OFF" position

but this is no problem for checks.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1522 of 3870

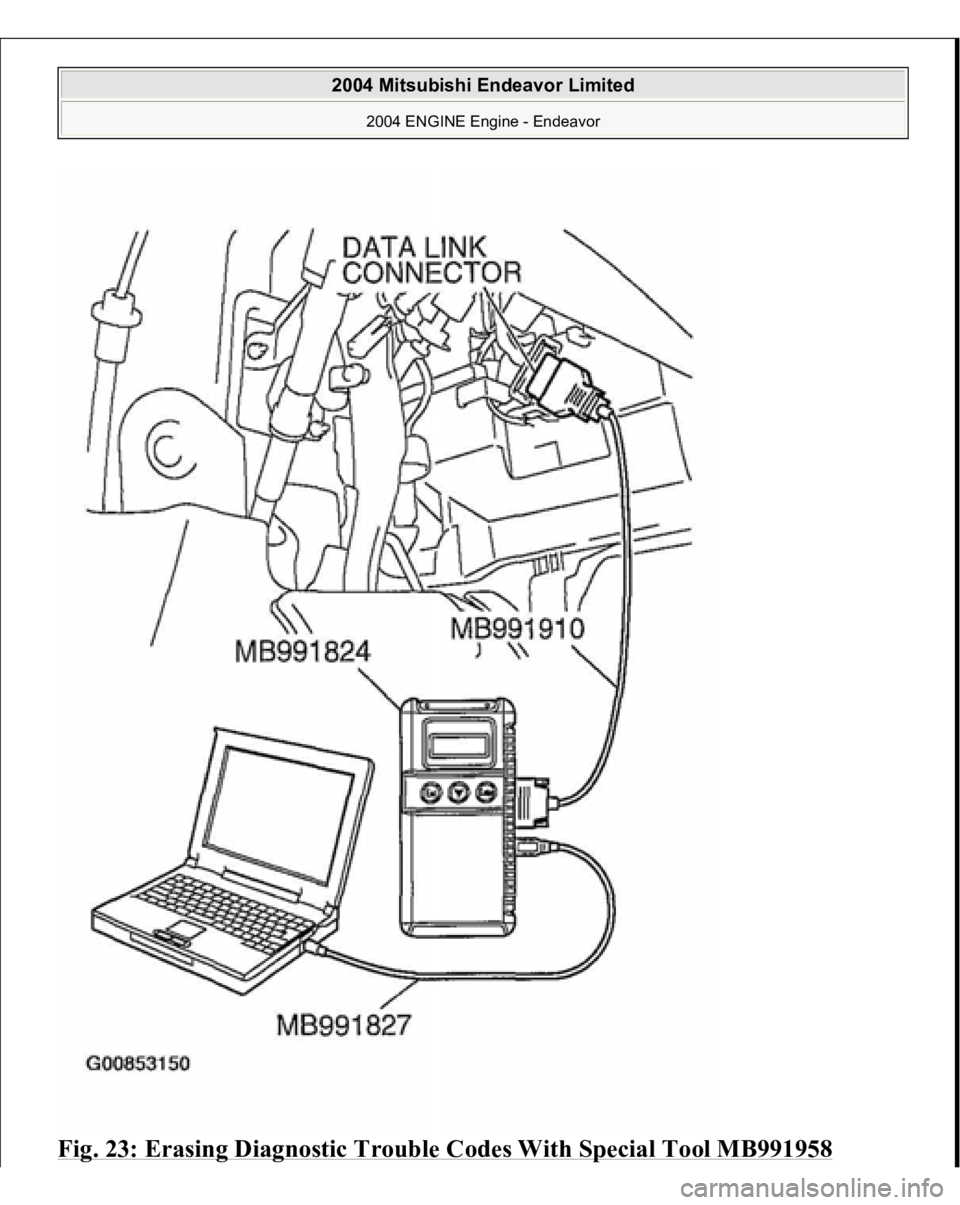

2. Connect scan tool MB991958 to the data link connec

tor.

CAUTION: To prevent damage to scan tool MB991958,

always turn the ignition switch to the

"LOCK" (OFF) position before connecting or

disconnecting scan tool MB991958.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1523 of 3870

Fig. 20: Connecting Scan Tool MB991958 To Data Link Connector (Idle

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1524 of 3870

Mixture Check)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Check that the basic ignition timing is within the standard value.

Standard value: 5° BTDC+/-3°

4. Start the engine and increase the engine speed to 2,500 r/min for 2 minutes.

5. Set the CO, HC tester.

6. Check the CO contents and the HC contents at idle.

Standard value:

CO contents: 0.5% or less

HC contents: 100 ppm or less

7. If the CO and HC contents do not remain inside the standard value, check the

following items:

Diagnostic output Closed-loop control (When the closed-loop control is carried out normally, the

output signal of the heated oxygen sensor changes between 0 - 400 mV and

600 - 1,000 mV at idle.) Fuel pressures Injector Ignition coil, spark plug EGR system and EGR valve leak Evaporative emission system Compression pressure

COMPRESSION PRESSURE CHECK Re

quired S

pecial Tool

:

NOTE: Replace the catalytic converter when the CO and HC

contents do not remain inside the standard value, even

though the result of the inspection is normal for all items.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1525 of 3870

MB991958: Scan Tool (MUT-III Sub Assembly)

MB991824: V.C.I. MB991827: MUT-III USB Cable MB991910: MUT-III Main Harness A

1. Before checks set the vehicle in the following condition:

Engine coolant temperature: 80 - 95°C (176 - 203°F) Lights and all accessories: OFF Transaxle: P range

2. Remove all of the ignition coils and spark plugs.

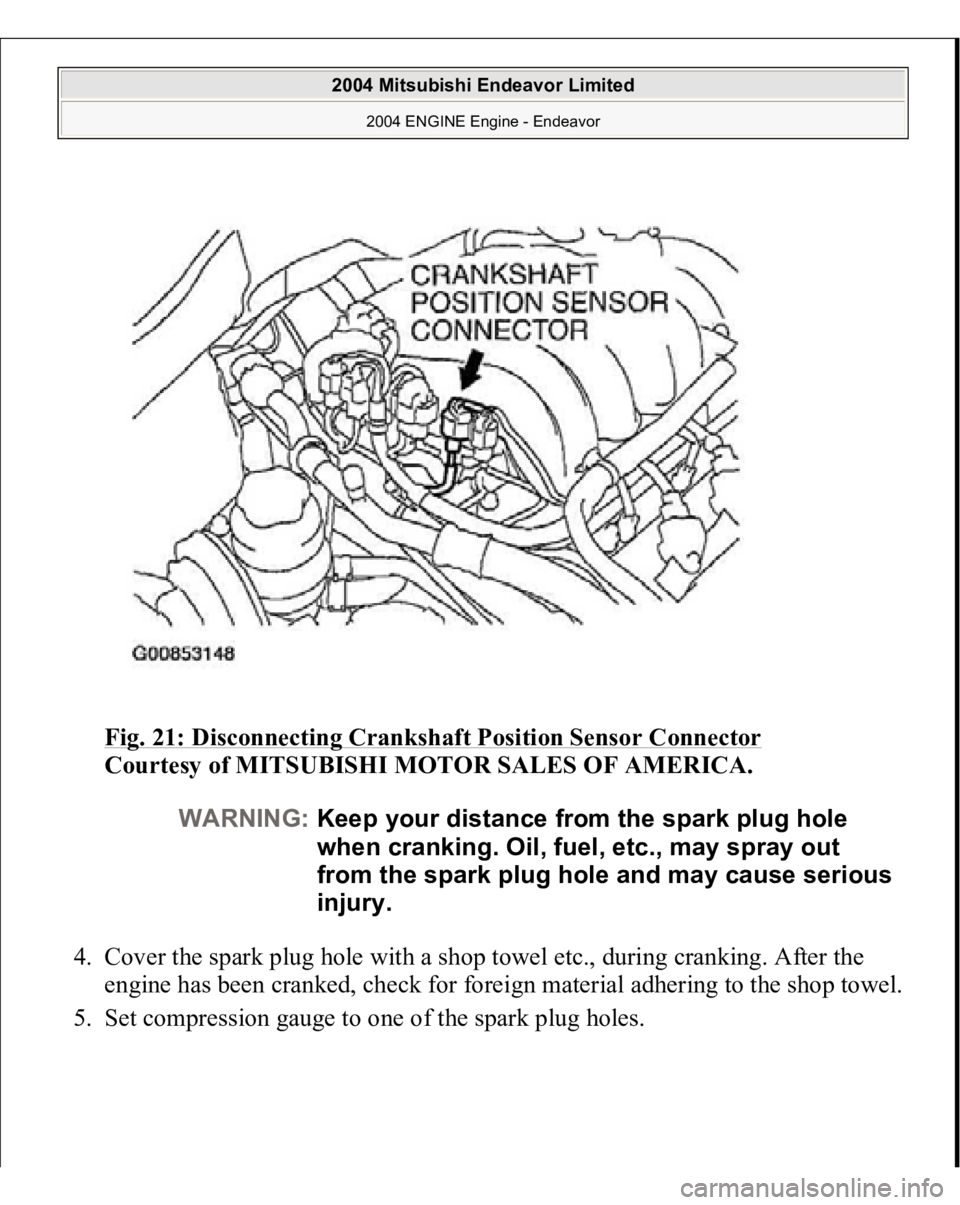

3. Disconnect the crankshaft position sensor connector.

NOTE: Vehicles for Canada, the headlight, taillight, etc. remain

lit even when the lighting switch is in "OFF" position

but this is no problem for checks.

NOTE: Doing this will prevent the engine control module from

carrying out ignition and fuel injection.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1526 of 3870

Fig. 21: Disconnecting Crankshaft Position Sensor Connector

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

4. Cover the spark plug hole with a shop towel etc., during cranking. After the

engine has been cranked, check for foreign material adhering to the shop towel.

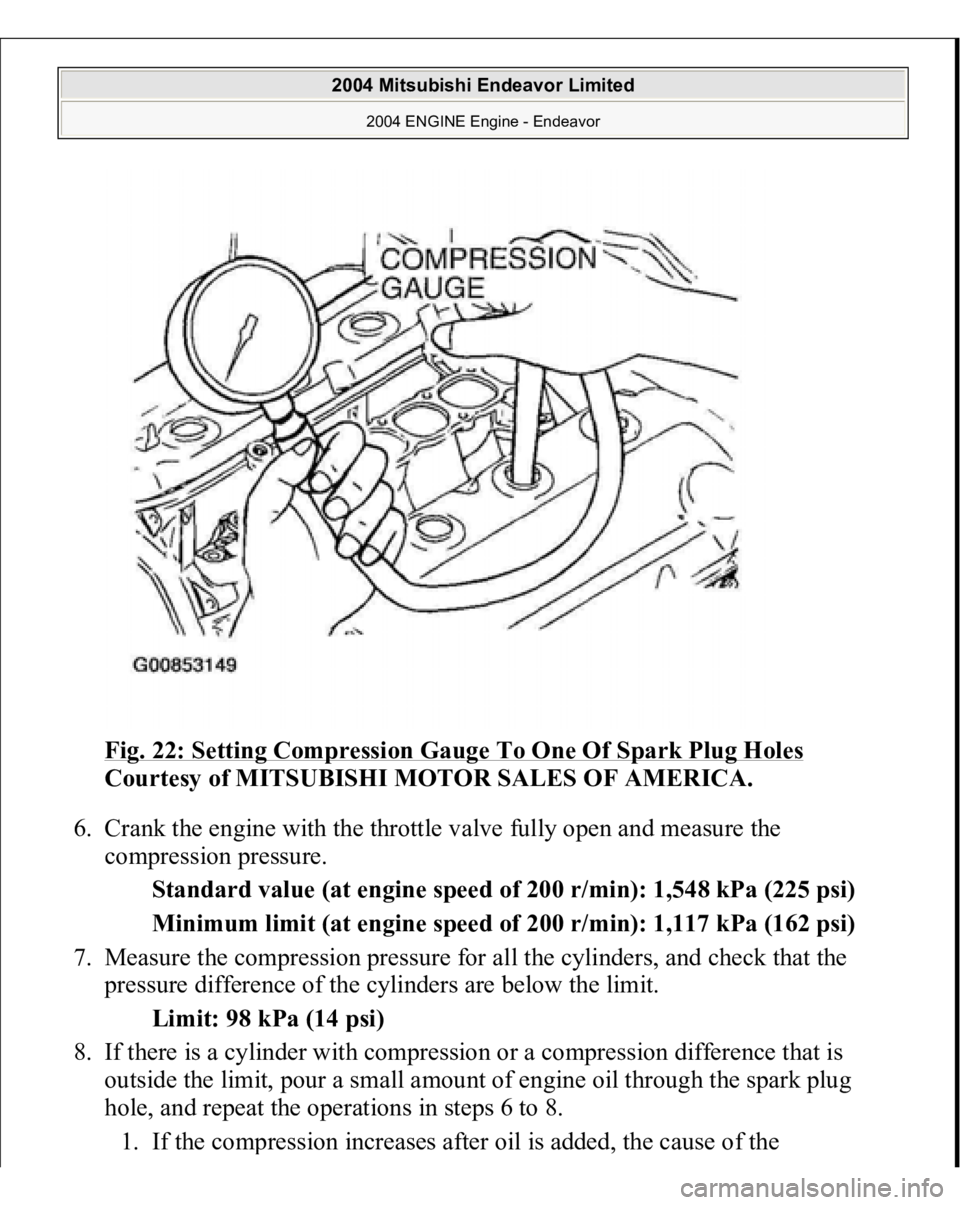

5. Set compression gauge to one of the spark plug holes.

WARNING:Keep your distance from the spark plug hole

when cranking. Oil, fuel, etc., may spray out

from the spark plug hole and may cause serious

injury.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1527 of 3870

Fig. 22: Setting Compression Gauge To One Of Spark Plug Holes

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

6. Crank the engine with the throttle valve fully open and measure the

compression pressure.

Standard value (at engine speed of 200 r/min): 1,548 kPa (225 psi)

Minimum limit (at engine speed of 200 r/min): 1,117 kPa (162 psi)

7. Measure the compression pressure for all the cylinders, and check that the

pressure difference of the cylinders are below the limit.

Limit: 98 kPa (14 psi)

8. If there is a cylinder with compression or a compression difference that is

outside the limit, pour a small amount of engine oil through the spark plug

hole, and repeat the operations in steps 6 to 8.

1. If the com

pression increases after oil is added, the cause of the

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1528 of 3870

malfunction is a worn or damaged piston ring and/or cylinder inner

surface.

2. If the compression does not rise after oil is added, the cause is a burnt or

defective valve seat, or pressure is leaking from the gasket.

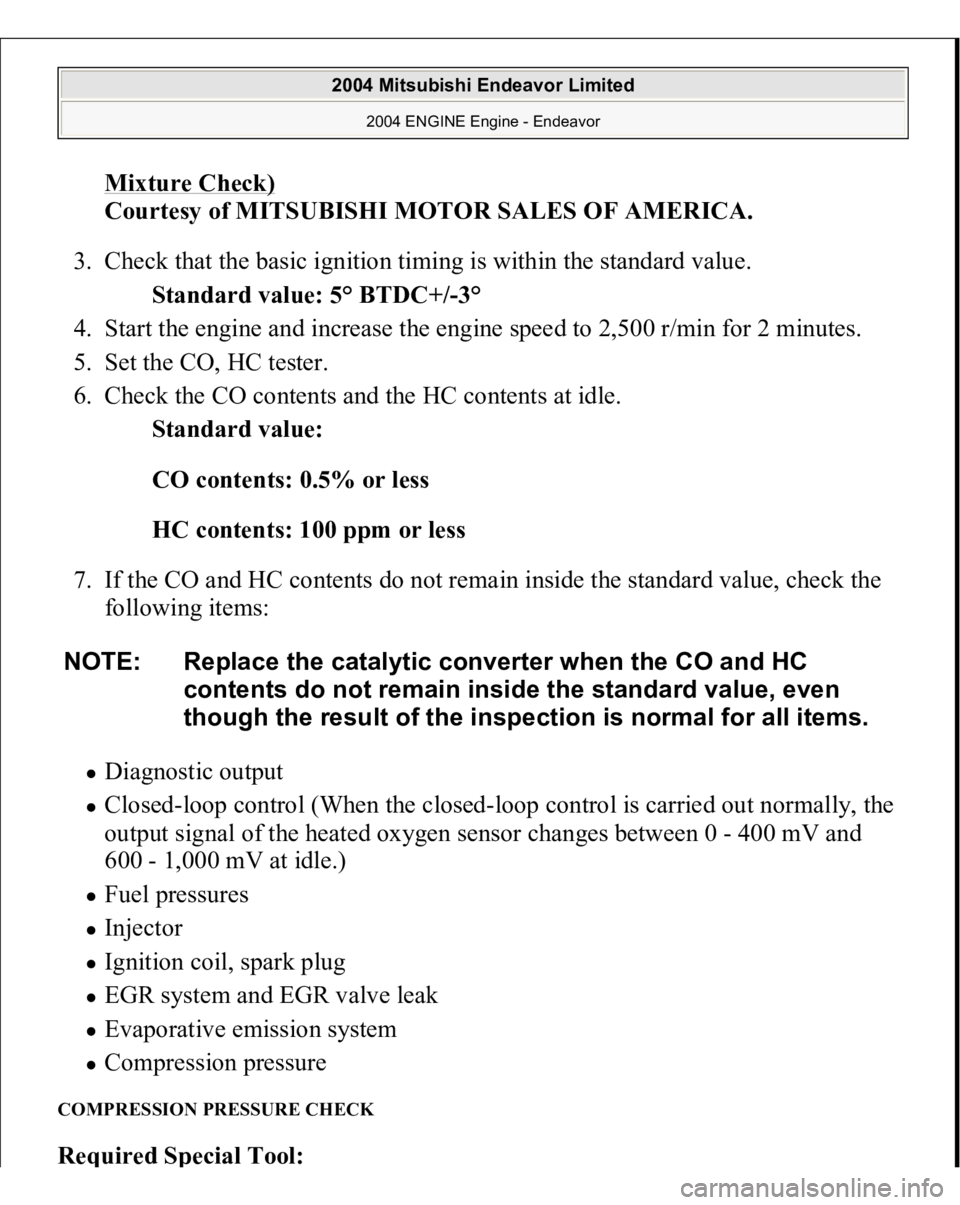

9. Connect the crankshaft position sensor connector.

10. Install the spark plugs and ignition coils.

11. Use the scan tool MB991958 to erase the diagnostic trouble codes.

NOTE: This will erase the diagnostic trouble code resulting from

the crankshaft position sensor connector being

disconnected.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1529 of 3870

Fig. 23: Erasin

g Dia

gnostic Trouble Codes With S

pecial Tool MB991958

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1530 of 3870

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA

.

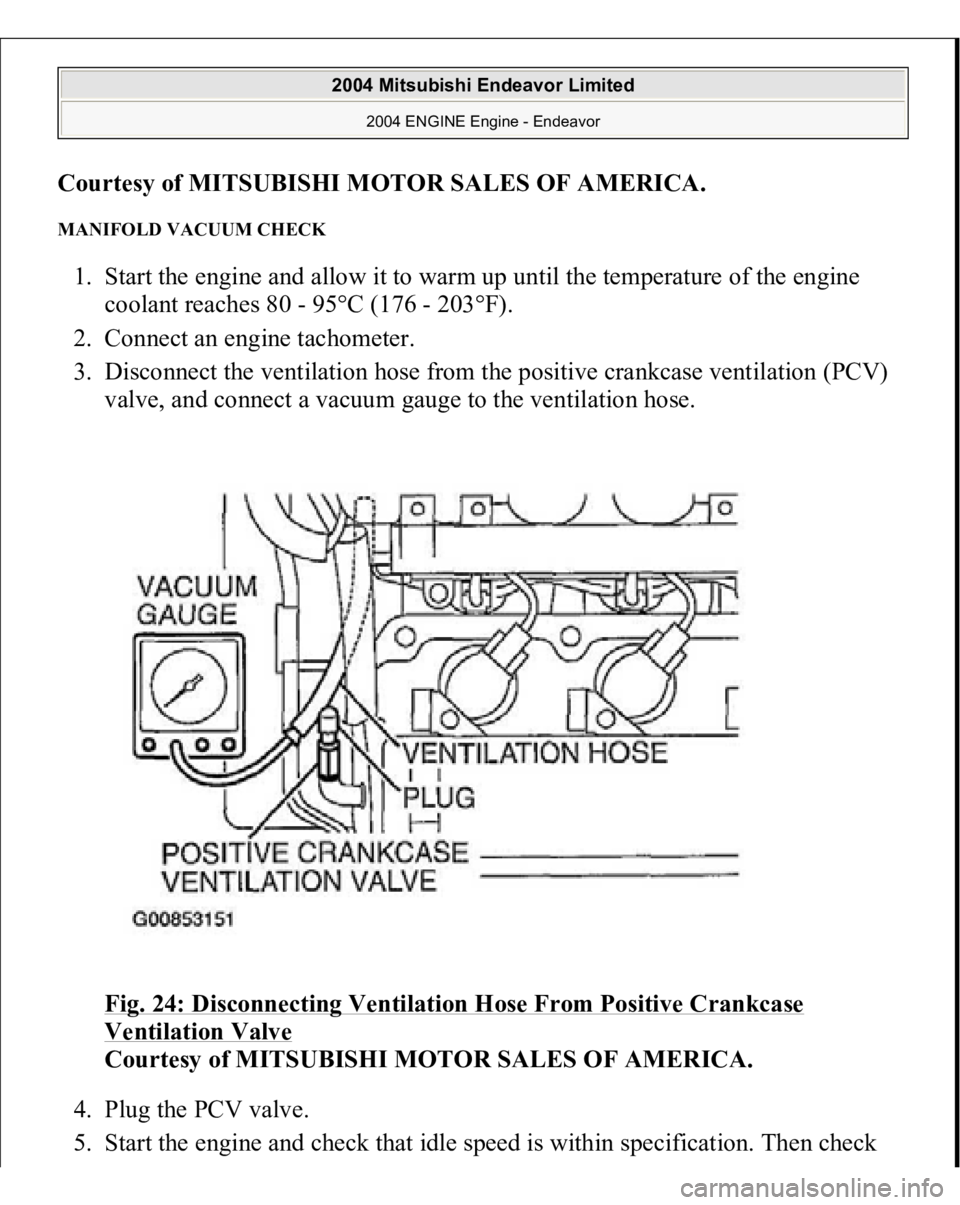

MANIFOLD VACUUM CHECK 1. Start the engine and allow it to warm up until the temperature of the engine

coolant reaches 80 - 95°C (176 - 203°F).

2. Connect an engine tachometer.

3. Disconnect the ventilation hose from the positive crankcase ventilation (PCV)

valve, and connect a vacuum gauge to the ventilation hose.

Fig. 24: Disconnecting Ventilation Hose From Positive Crankcase

Ventilation Valve

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

4. Plug the PCV valve.

5. Start the en

gine and check that idle s

peed is within s

pecification. Then check

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Trending: jump start terminals, airbag, Windows, ESP, engine, Amplifier, crankshaft pulley