air suspension MITSUBISHI ENDEAVOR 2004 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 1934 of 3870

the direction of the spline chamfered side. See Fig. 13

.

C. Using Bar (Snap-In Type) (MB990938) and Installer Adapter (MB990932),

press-fit the center bearing into the center bearing bracket. See Fig. 18

.

D. Apply the specified great (from the repair kit) to the rear surface of all dust

seals. Using Rear Suspension Bushing Base (MB990890), Bar (Snap-In type)

(MB990838), and Installer Adapter (MB990934), press the dust seals into the

center bearing bracket until they are flush with each other. See Fig. 19 . Apply

repair kit grease to the lip of each dust seal.

E. Using Inner Shaft Installer Base (MB991172), hold the center bearing inner

race, and then press-in the inner shaft. See Fig. 20

. Apply repair kit grease to

the inner shaft spline, then press-fit it into the PTJ case.

F. After applying the specified grease to the PTJ case, insert the axle shaft and

apply grease again.

G. Set the PTJ boot bands at the specified distance to adjust the amount of air

inside the PTJ joint, and then tighten the small and large PTJ boot bands. See

Fi

g. 12

. CAUTION: When applying grease, make sure that it does not

adhere to anything outside the lip.

NOTE: When press-fitting the inner shaft into the PTJ case,

apply a thin coat of repair kit grease to the dust seal

outer lip part and the outside edge of the PTJ axial part.

CAUTION: The axle shaft joint uses special grease. DO NOT

mix old, new, or different types of grease.

NOTE: The grease in the repair kit should be divided in half for

use, respectively, at the joint and inside the boot.

2004 Mitsubishi Endeavor LS

2004 DRIVE AXLES Axle Shafts - Front - Endeavor

Page 1939 of 3870

If the front suspension is faulty, the vehicle will not run straightforward or noise

will occur. Incorrect wheel alignment, malfunction of strut assembly, stabilizer bar,

coil spring, or worn or out-of-balance tires can cause these problems. FRONT SUSPENSION DIAGNOSIS TROUBLESHOOTING STRATEGY Use these steps to plan your diagnostic strategy. If you follow them carefully, you

will be sure that you have exhausted most of the possible ways to find a front

suspension fault.

1. Gather information from the customer.

2. Verify that the condition described by the customer exists.

3. Find and repair the malfunction by following the Symptom Chart and

Symptom Procedures.

4. Verify malfunction is eliminated. SYMPTOM CHART Fig. 2: Symptom Chart

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

SYMPTOM PROCEDURES INSPECTION PROCEDURE 1: Steering Wheel Is Heavy, Vibrates Or Pulls To One Side DIAGNOSIS

STEP 1. Check the tires.

2004 Mitsubishi Endeavor LS 2004 SUSPENSION Front - Endeavor

Page 1971 of 3870

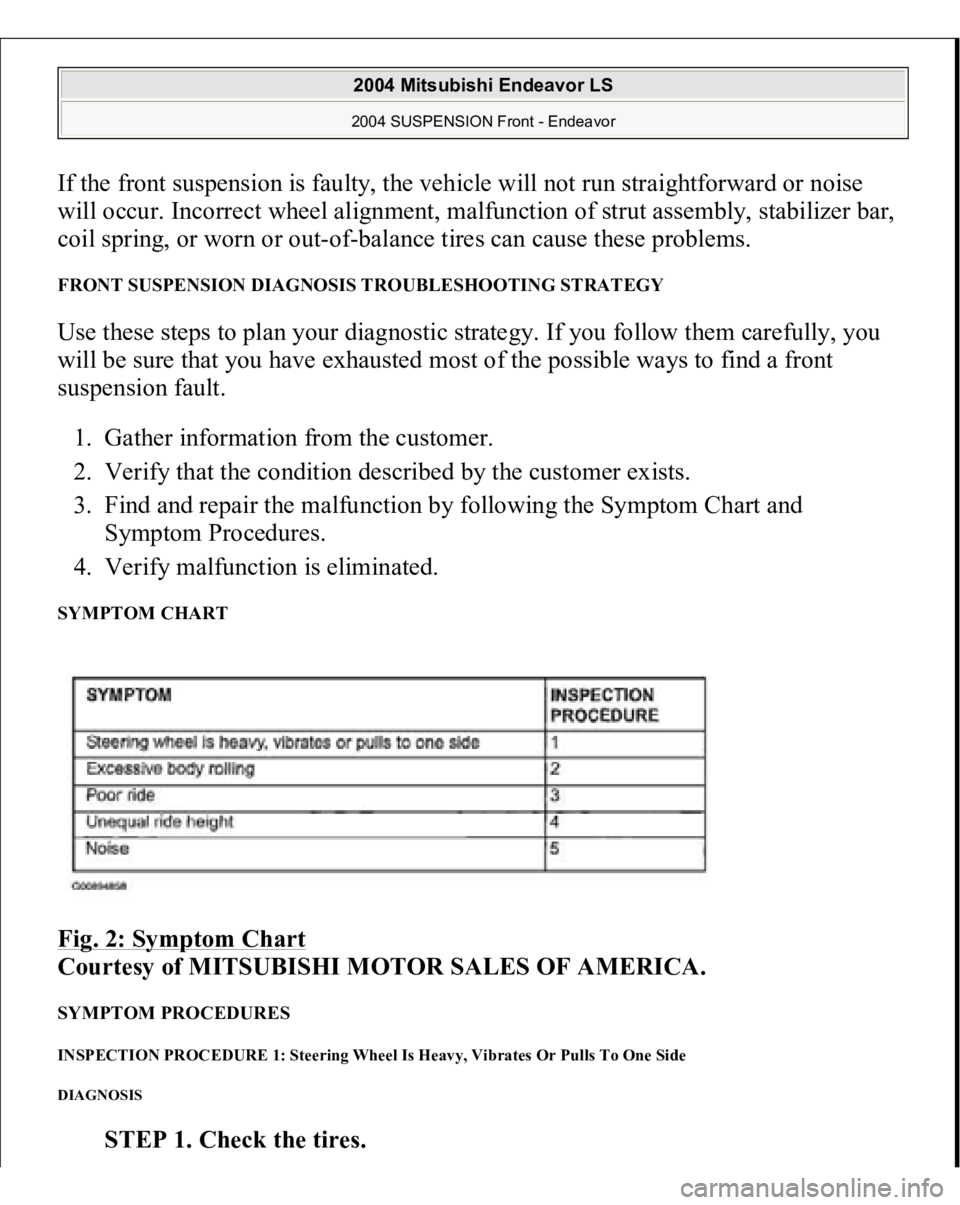

Fig. 29: Installing Lower Arm Bushing

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

STABILIZER BAR REMOVAL AND INSTALLATION

CAUTION:

Before removin

g the steerin

g wheel and air ba

g

2004 Mitsubishi Endeavor LS 2004 SUSPENSION Front - Endeavor

Page 1972 of 3870

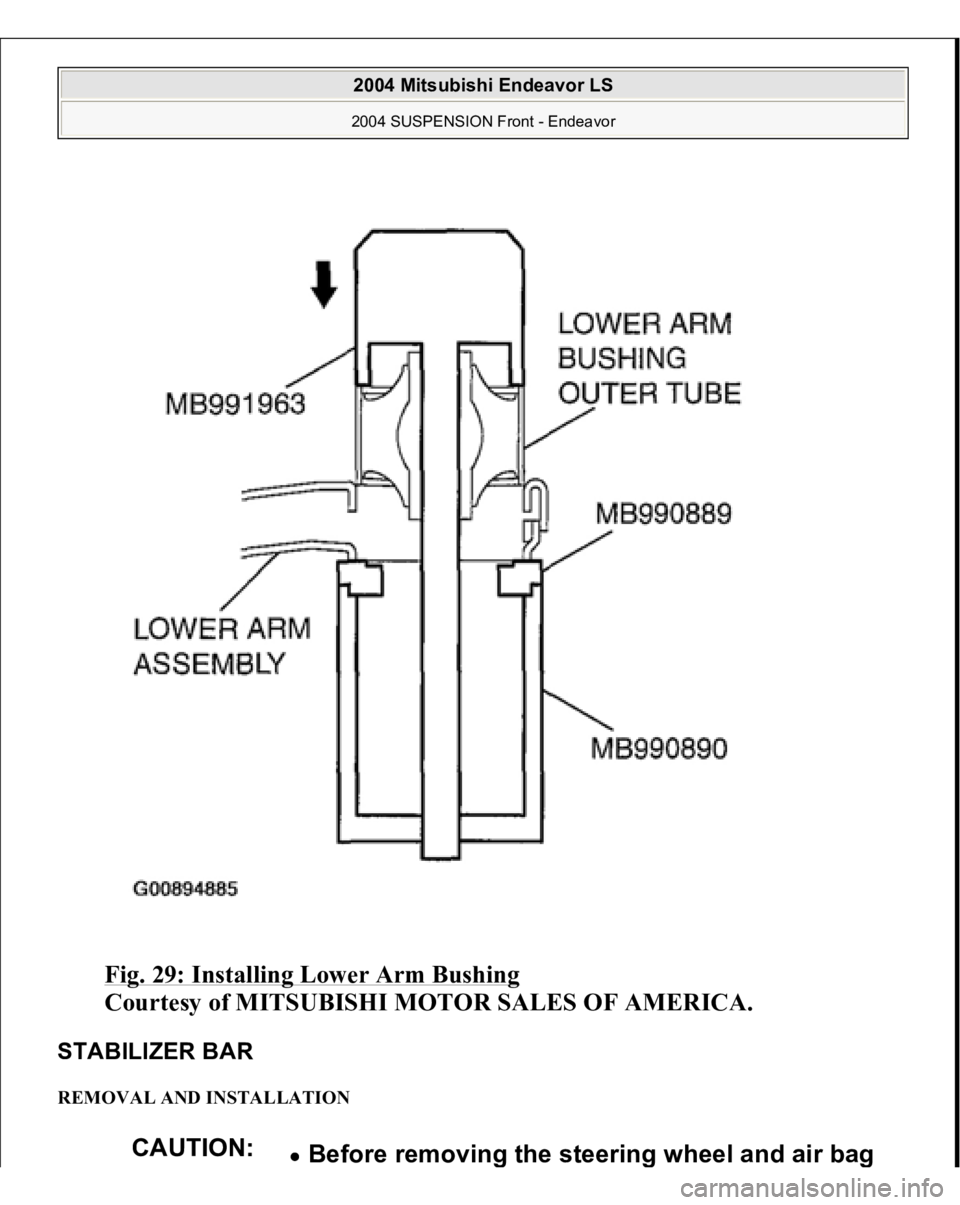

Fig. 30: Removing & Installing Stabilizer Bar (1 Of 2)

Courtes

y of MITSUBISHI MOTOR SALES OF AMERICA

.

module assembly, refer to AIR BAG SAFETY PRECAUTIONS

and DRIVER

-SIDE AIR BAG

MODULE & CLOCKSPRING

. Also, put the front

wheels in straight-ahead position. Failure to do

so may damage the SRS clock spring and render

the SRS air bag inoperative, which results

serious driver injury.

*: Indicates parts which should be temporarily

tightened, and then fully tightened with the

vehicle on the ground in an unladen condition.

2004 Mitsubishi Endeavor LS 2004 SUSPENSION Front - Endeavor

Page 2930 of 3870

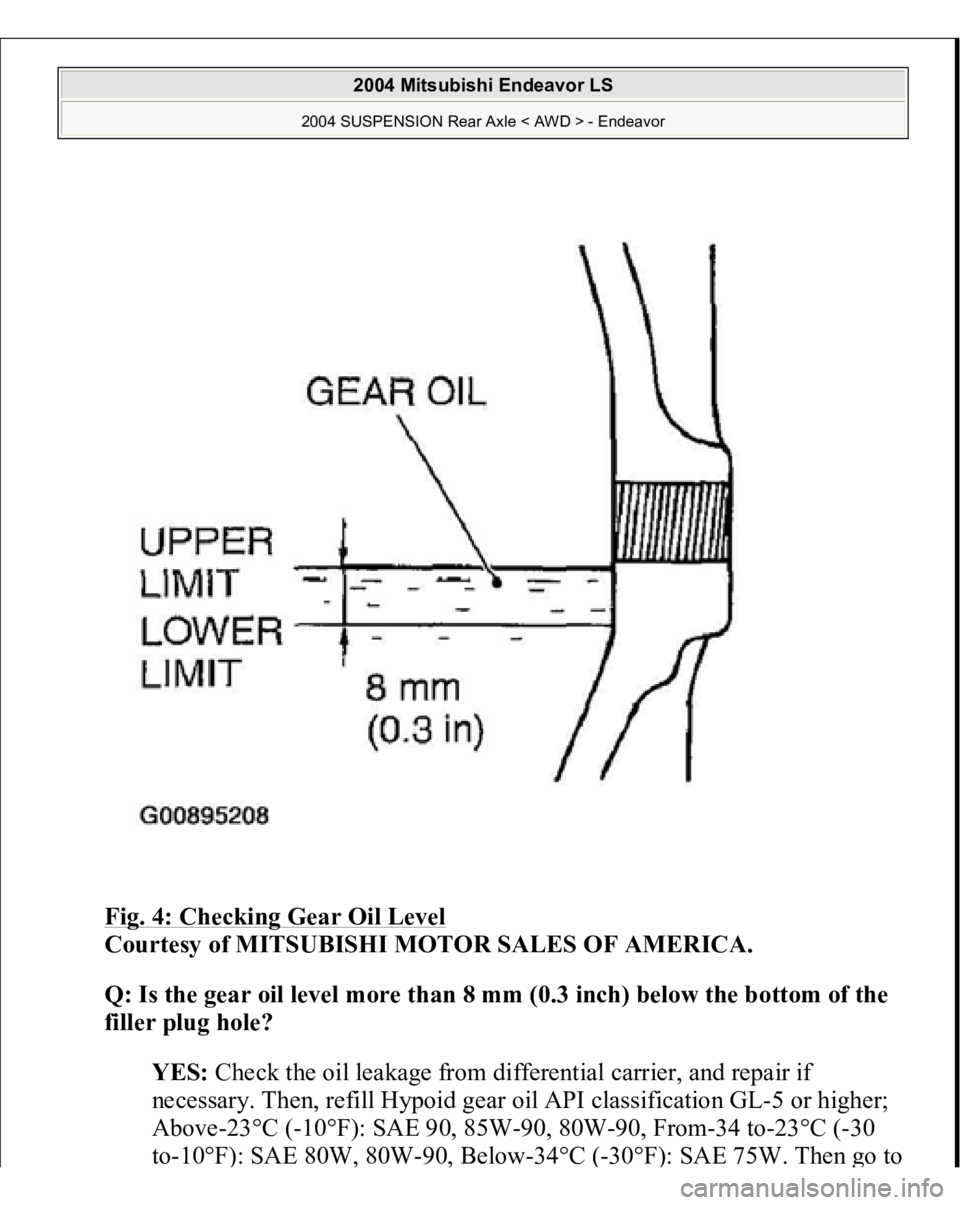

Fig. 4: Checking Gear Oil Level

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Q: Is the gear oil level more than 8 mm (0.3 inch) below the bottom of the

filler plug hole?

YES: Check the oil leakage from differential carrier, and repair if

necessary. Then, refill Hypoid gear oil API classification GL-5 or higher;

Above-23°C (-10°F): SAE 90, 85W-90, 80W-90, From-34 to-23°C (-30

to-10°F

): SAE 80W

, 80W-90

, Below-34°C

(-30°F

): SAE 75W. Then

go to

2004 Mitsubishi Endeavor LS

2004 SUSPENSION Rear Axle < AWD > - Endeavor

Page 2933 of 3870

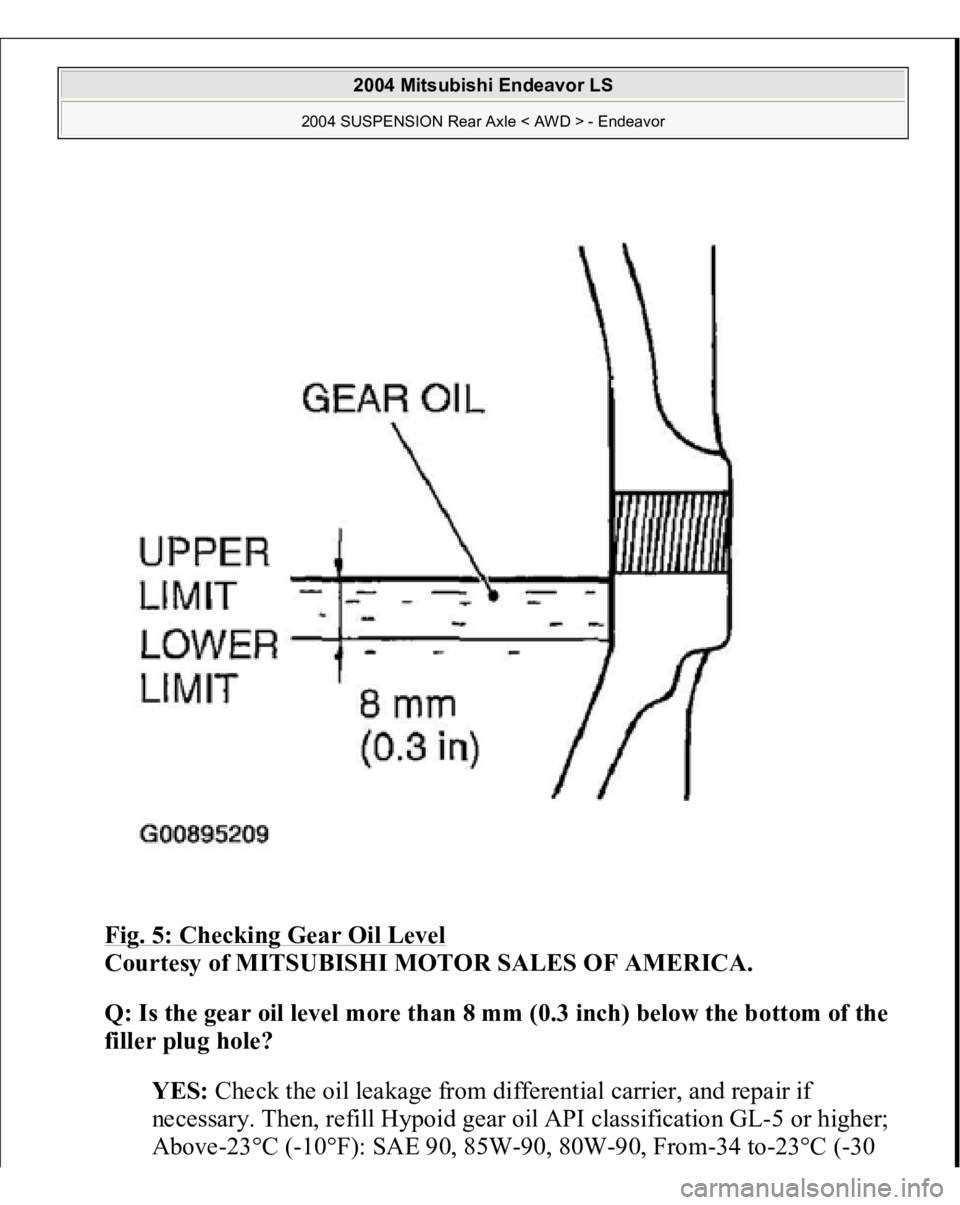

Fig. 5: Checking Gear Oil Level

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Q: Is the gear oil level more than 8 mm (0.3 inch) below the bottom of the

filler plug hole?

YES: Check the oil leakage from differential carrier, and repair if

necessary. Then, refill Hypoid gear oil API classification GL-5 or higher;

Above-23°C

(-10°F): SAE 90, 85W-90, 80W-90, Fro

m-34 to-23°C

(-30

2004 Mitsubishi Endeavor LS

2004 SUSPENSION Rear Axle < AWD > - Endeavor

Page 2937 of 3870

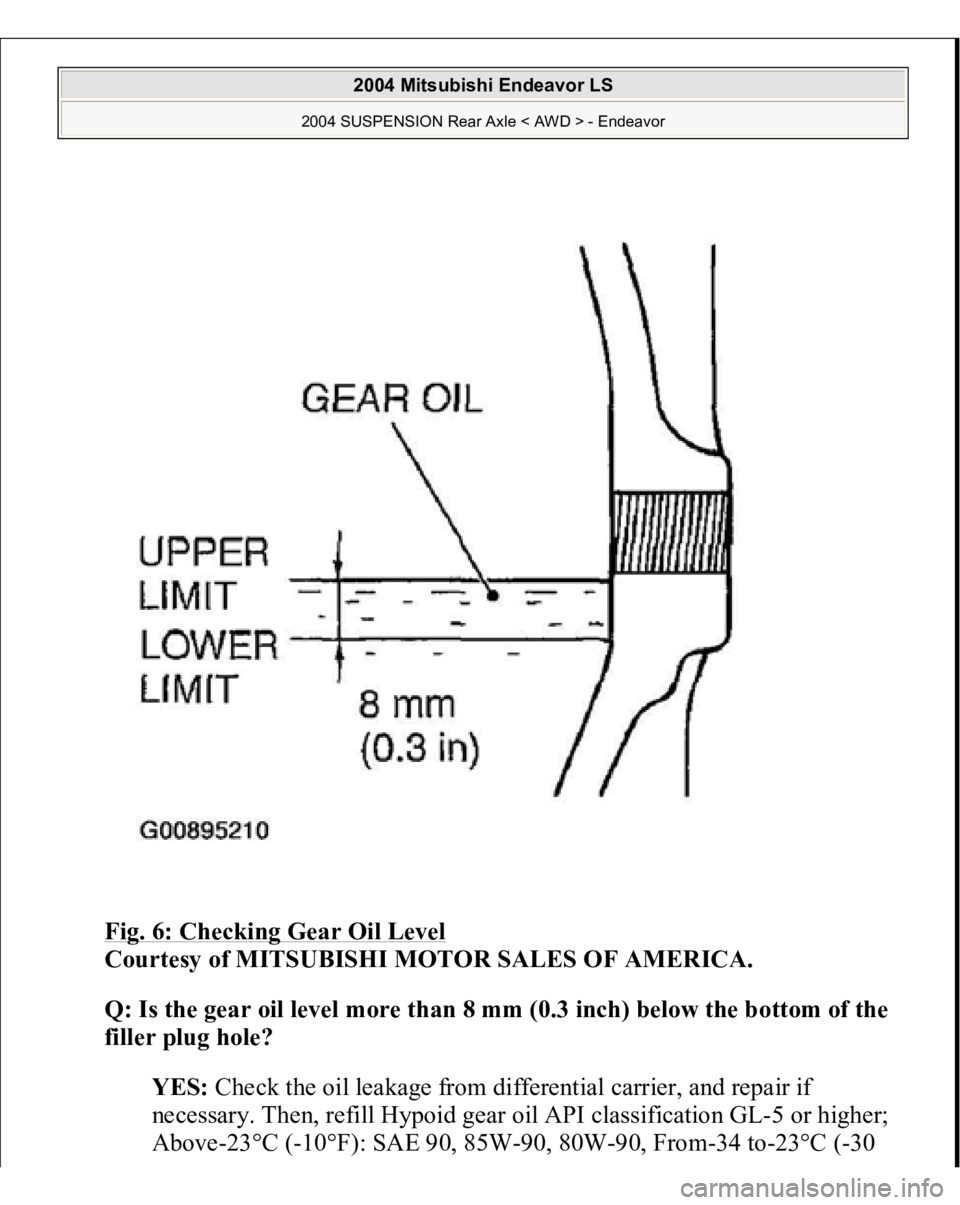

Fig. 6: Checking Gear Oil Level

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Q: Is the gear oil level more than 8 mm (0.3 inch) below the bottom of the

filler plug hole?

YES: Check the oil leakage from differential carrier, and repair if

necessary. Then, refill Hypoid gear oil API classification GL-5 or higher;

Above-23°C

(-10°F

): SAE 90, 85W-90, 80W-90, Fro

m-34 to-23°C

(-30

2004 Mitsubishi Endeavor LS

2004 SUSPENSION Rear Axle < AWD > - Endeavor

Page 2938 of 3870

to-10°F): SAE 80W, 80W-90, Below-34°C (-30°F): SAE 75W. Then go to

Step 3 .

NO: Go to Step 2.

STEP 2. Check for excessive gear backlash (Refer to DISASSEMBLY

).

Q: Is the gear backlash correct?

YES: Go to Step 3.

NO: Adjust the backlash. Then go to step 3.

STEP 3. Retest the system.

Q: Is the heat eliminated?

YES: The procedure is complete.

NO: Start over at Step 1.

INSPECTION PROCEDURE 8: OIL LEAKAGE {{DIFFERENTIAL}} DIAGNOSIS

STEP 1. Check the cover installation.

Q: Is the cover installed correctly?

YES: Go to Step 2.

NO: Repair. Then go to Step 4 .

STEP 2. Check the oil seal for wear or damage.

Q: Is the oil seal worn or damaged?

YES: Replace the seal. Then go to Step 4 .

NO: Go to Step 3.

STEP 3. Check the oil level.

Remove the filler

plug and check the

gear oil level.

2004 Mitsubishi Endeavor LS

2004 SUSPENSION Rear Axle < AWD > - Endeavor

Page 2974 of 3870

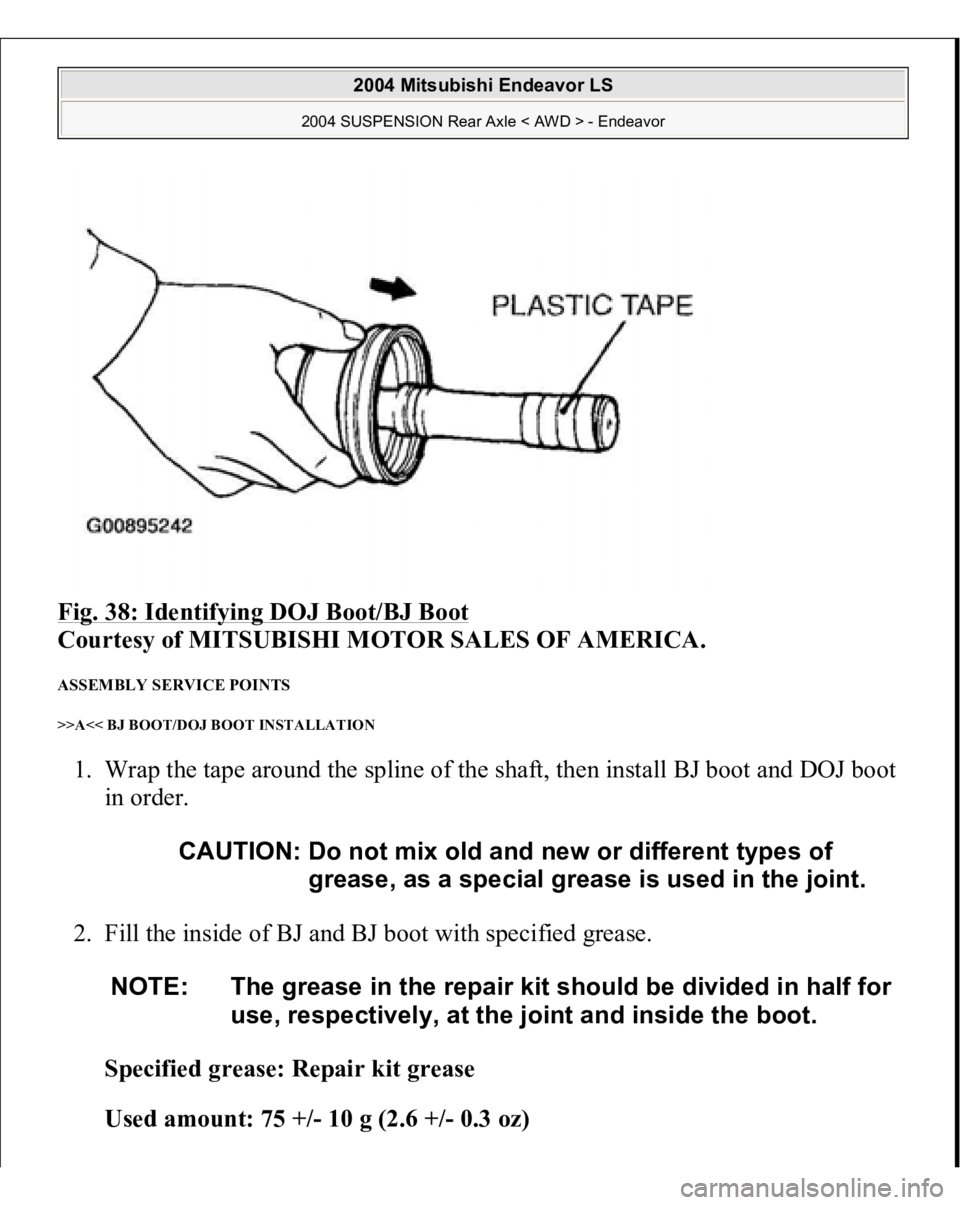

Fig. 38: Identifying DOJ Boot/BJ Boot

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

ASSEMBLY SERVICE POINTS >>A<< BJ BOOT/DOJ BOOT INSTALLATION 1. Wrap the tape around the spline of the shaft, then install BJ boot and DOJ boot

in order.

2. Fill the inside of BJ and BJ boot with specified grease.

Specified grease: Repair kit grease

Used amount: 75 +/- 10 g (2.6 +/- 0.3 oz)

CAUTION: Do not mix old and new or different types of

grease, as a special grease is used in the joint.

NOTE: The grease in the repair kit should be divided in half for

use, respectively, at the joint and inside the boot.

2004 Mitsubishi Endeavor LS

2004 SUSPENSION Rear Axle < AWD > - Endeavor

Page 2975 of 3870

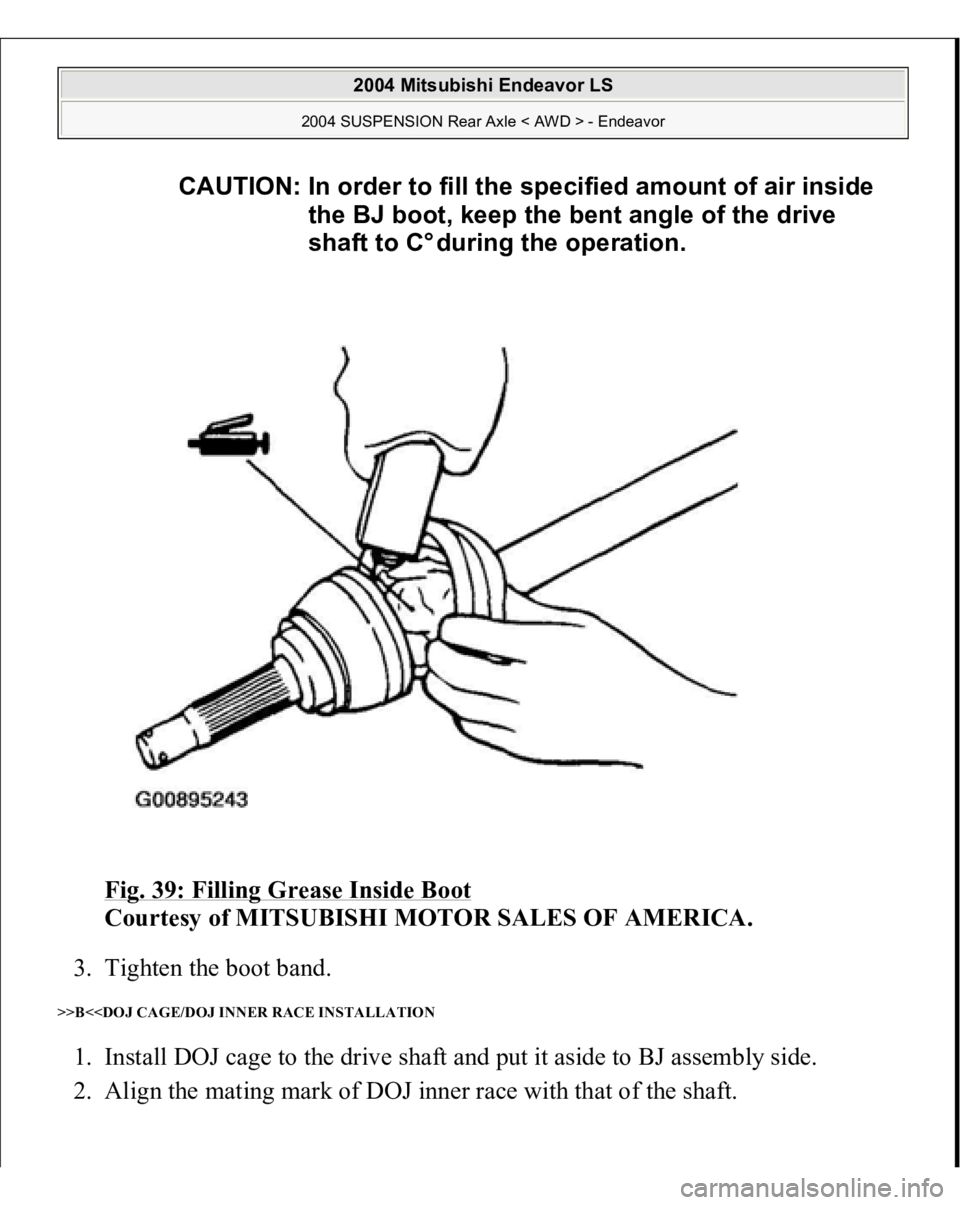

Fig. 39: Filling Grease Inside Boot

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Tighten the boot band.

>>B<

CAUTION: In order to fill the specified amount of air inside

the BJ boot, keep the bent angle of the drive

shaft to C° during the operation.

2004 Mitsubishi Endeavor LS

2004 SUSPENSION Rear Axle < AWD > - Endeavor