MITSUBISHI GALANT 1989 Service Owners Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 91 of 1273

ENGINE

I

I

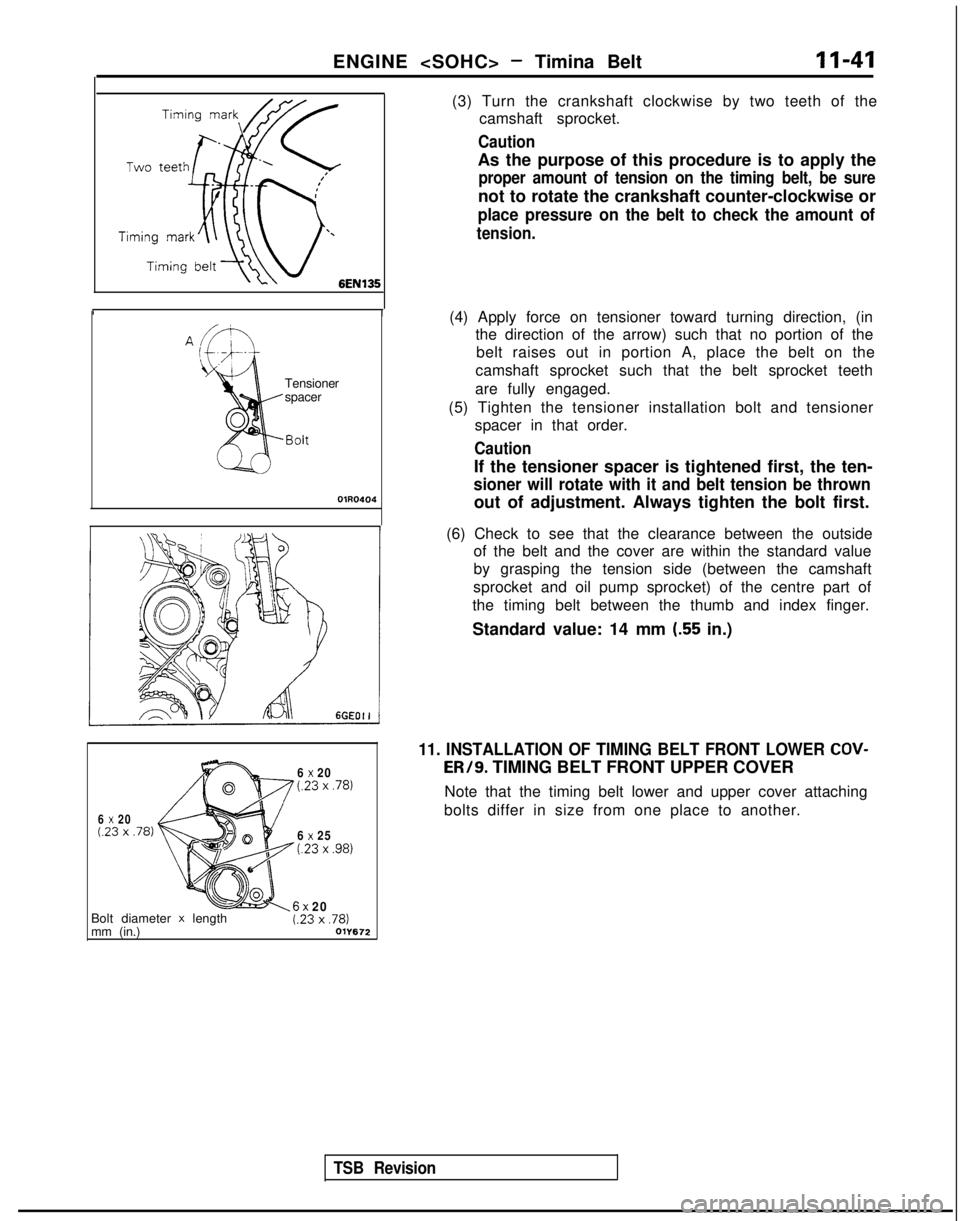

(3) Turn the crankshaft clockwise by two teeth of the

camshaft sprocket.

Caution

As the purpose of this procedure is to apply the

proper amount of tension on the timing belt, be sure

not to rotate the crankshaft counter-clockwise or

place pressure on the belt to check the amount of

tension.

Tensioner

spacer

OlR0404

(4) Apply force on tensioner toward turning direction, (inthe direction of the arrow) such that no portion of the

belt raises out in portion A, place the belt on the

camshaft sprocket such that the belt sprocket teeth

are fully engaged.

(5) Tighten the tensioner installation bolt and tensioner spacer in that order.

Caution

If the tensioner spacer is tightened first, the ten-

sioner will rotate with it and belt tension be thrown

out of adjustment. Always tighten the bolt first.

TSB Revision

(6) Check to see that the clearance between the outside of the belt and the cover are within the standard value

by grasping the tension side (between the camshaft

sprocket and oil pump sprocket) of the centre part of

the timing belt between the thumb and index finger.

Standard value: 14 mm

(.55 in.)

6 x 20(23 x .78)

6 x 20(23 x .78)

6 x 25t.23 x ,981

11. INSTALLATION OF TIMING BELT FRONT LOWER COV- ER/9.

TIMING BELT FRONT UPPER COVER

Note that the timing belt lower and upper cover attaching

bolts differ in size from one place to another.

Bolt diameter

x length

mm (in.)6x 20t.23 x ,781011672

Page 92 of 1273

11-42

ENGINE

TIMING BELT

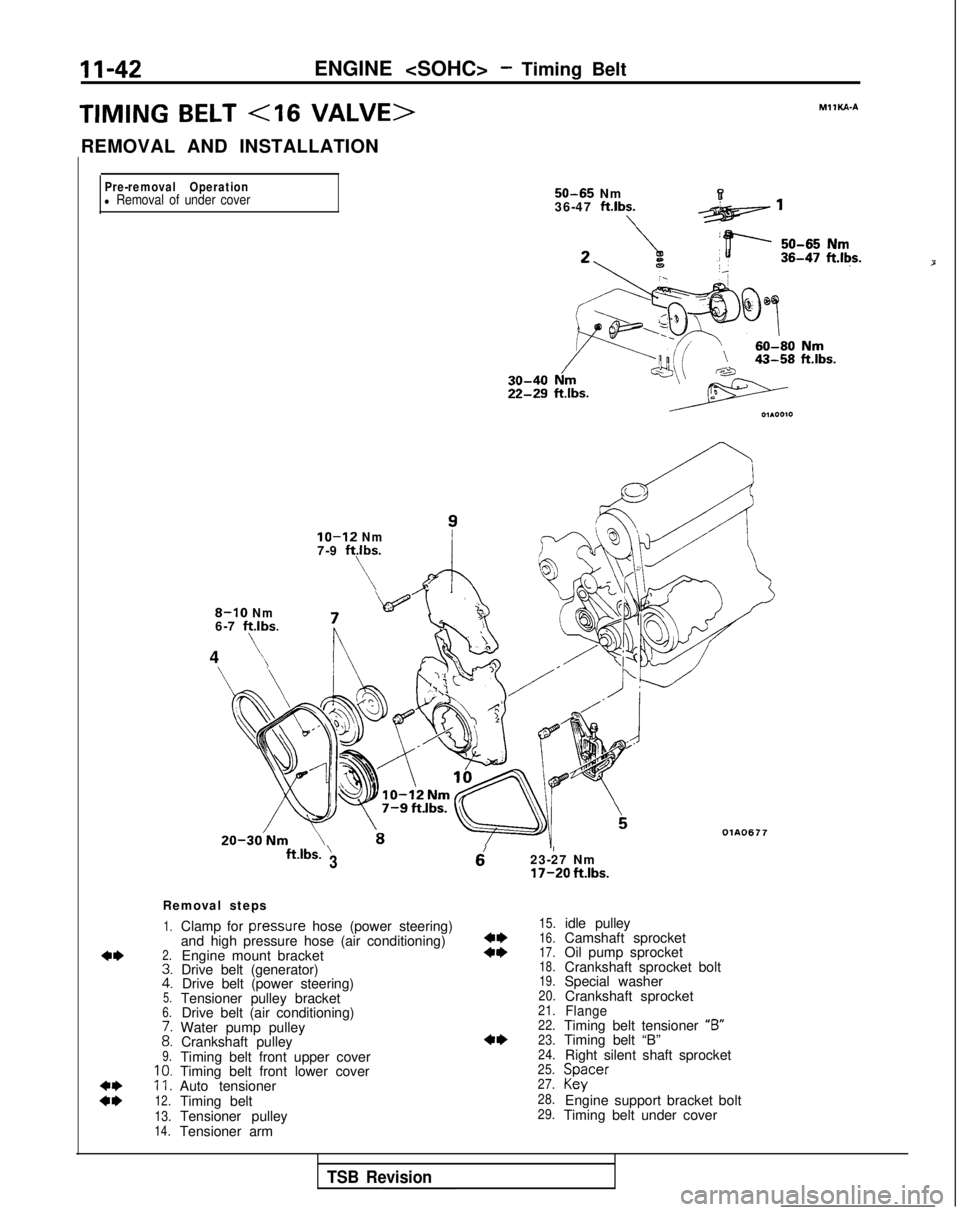

REMOVAL AND INSTALLATION

MIlKA-A

Pre-removal Operation

l Removal of under cover

8-10 Nm6-7 ftlbs.

4

’‘\ 50-65

Nm

36-47

ft.lbs.\

IO-12 Nm7-9 ftlbs.

\

\

ft.lbs.’3Q ’23-27 Nm

17-20 ft.lbs.

Removal steps

1.

2.

Clamp for

pressure

hose (power steering)

and high pressure hose (air conditioning) Engine mount bracket

Drive belt (generator) Drive belt (power steering)

Tensioner pulley bracket Drive belt (air conditioning)

Water pump pulley Crankshaft pulley

Timing belt front upper cover

Timing belt front lower cover

Auto tensioner

Timing belt OlA0677

::5.6.

i:9.10.11.

12.

13.14.Tensioner pulley

Tensioner arm

15.

::16.

17.

18.

19.

20.

21.

22.

4*23.

24.

25.

27.

28.

29.

idle pulley

Camshaft sprocket

Oil pump sprocket

Crankshaft sprocket bolt

Special washer Crankshaft sprocket

FlangeTiming belt tensioner “B”

Timing belt “B”

Right silent shaft sprocket Spacer

Kky

Engine support bracket bolt

Timing belt under cover

P

TSB Revision

Page 93 of 1273

ENGINE

+/@Service Adjustment Procedures

24?5

20-;7 Nmio

14-20 ft.lbs.\ is\ i7

Nm50-60 Nm80-94 ft.lbs.36-43 ft.lbs.

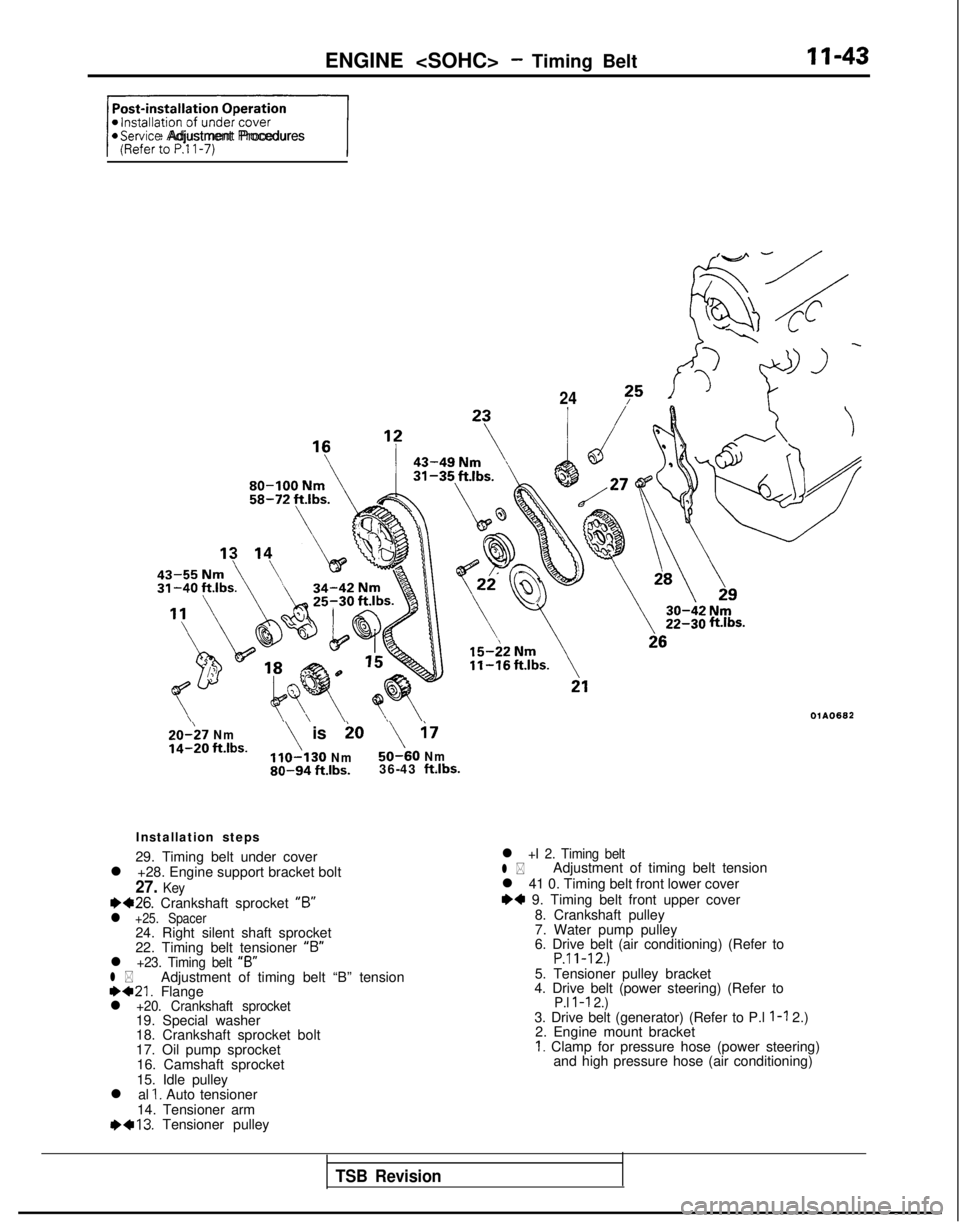

Installation steps

29. Timing belt under cover

l +28. Engine support bracket bolt

27. Keyea26. Crankshaft sprocket “6”l +25. Spacer24. Right silent shaft sprocket

22. Timing belt tensioner “B”

l +23. Timing belt

“B”l *Adjustment of timing belt “B” tension1)421. Flangel +20. Crankshaft sprocket19. Special washer

18. Crankshaft sprocket bolt

17. Oil pump sprocket

16. Camshaft sprocket

15. Idle pulley

l al

1. Auto tensioner

14. Tensioner arm 1)+13.

Tensioner pulley

ftlbs.

OlAO682

l +I 2. Timing beltl *Adjustment of timing belt tension

l 41 0. Timing belt front lower cover

I)+ 9. Timing belt front upper cover 8. Crankshaft pulley

7. Water pump pulley

6. Drive belt (air conditioning) (Refer to

P.ll-12.)5. Tensioner pulley bracket

4. Drive belt (power steering) (Refer to

P.l l-l 2.)3. Drive belt (generator) (Refer to P.l l-l 2.)

2. Engine mount bracket

I. Clamp for pressure hose (power steering) and high pressure hose (air conditioning)

TSB Revision

Page 94 of 1273

ENGINE

A Timing

mark

Timingmark

mark

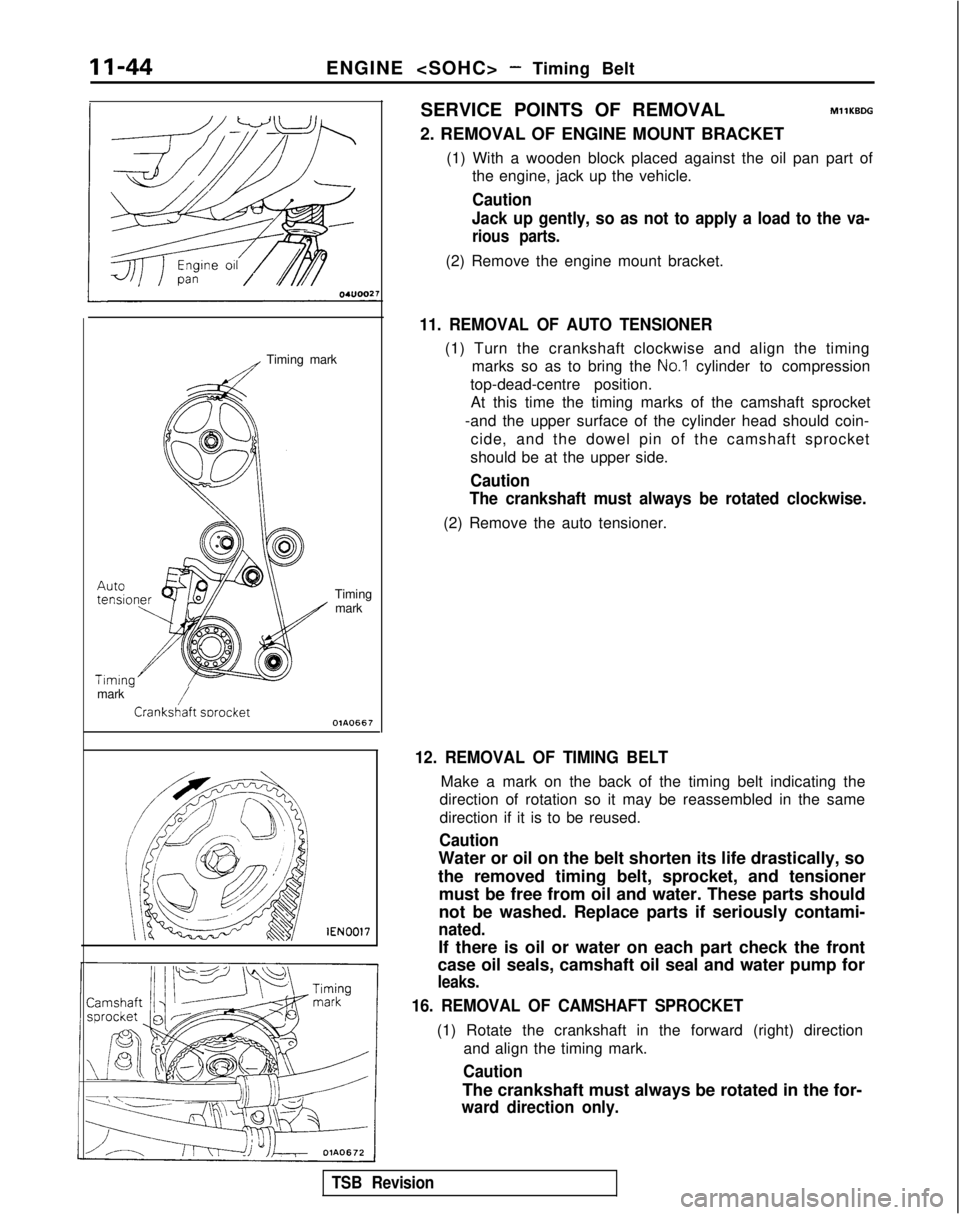

-/Crank&aft swocketOlA0667 lEN0017SERVICE POINTS OF REMOVAL

MllKBDG

2. REMOVAL OF ENGINE MOUNT BRACKET

(1) With a wooden block placed against the oil pan part ofthe engine, jack up the vehicle.

Caution

Jack up gently, so as not to apply a load to the va-

rious parts.

(2) Remove the engine mount bracket.

11. REMOVAL OF AUTO TENSIONER

(1) Turn the crankshaft clockwise and align the timing marks so as to bring the

No.1 cylinder to compression

top-dead-centre position. At this time the timing marks of the camshaft sprocket

-and the upper surface of the cylinder head should coin- cide, and the dowel pin of the camshaft sprocket

should be at the upper side.

Caution

The crankshaft must always be rotated clockwise.

(2) Remove the auto tensioner.

12. REMOVAL OF TIMING BELT

Make a mark on the back of the timing belt indicating the

direction of rotation so it may be reassembled in the same

direction if it is to be reused.

Caution

Water or oil on the belt shorten its life drastically, so

the removed timing belt, sprocket, and tensioner must be free from oil and water. These parts should

not be washed. Replace parts if seriously contami-

nated.

If there is oil or water on each part check the front

case oil seals, camshaft oil seal and water pump for

leaks.

16. REMOVAL OF CAMSHAFT SPROCKET

(1) Rotate the crankshaft in the forward (right) direction

and align the timing mark.

Caution

The crankshaft must always be rotated in the for-

ward direction only.

TSB Revision

Page 95 of 1273

ENGINE

11-45

sprocket

vlGVO001 MD998754

vlB990767-01

-

&

00B00°

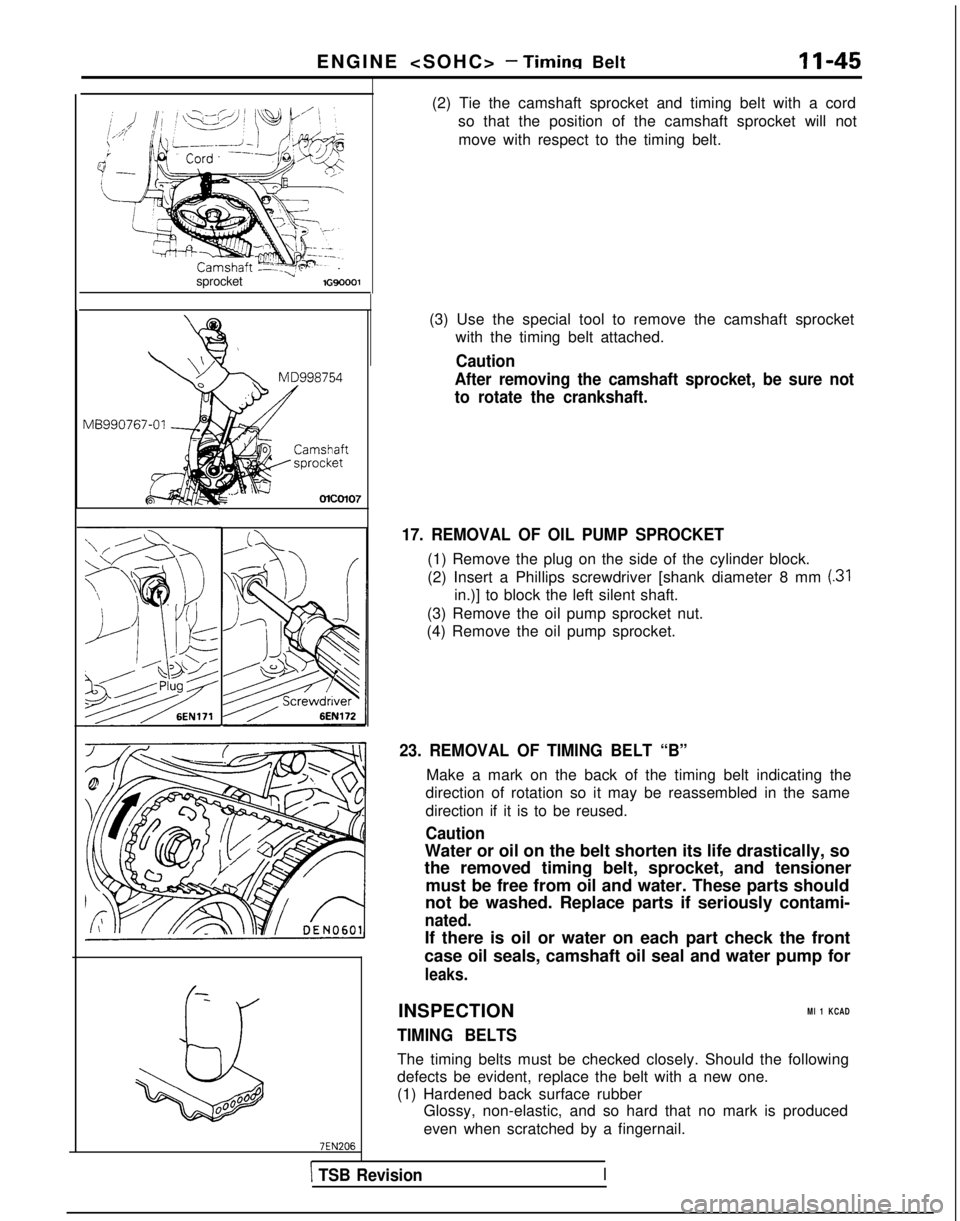

(2) Tie the camshaft sprocket and timing belt with a cord

so that the position of the camshaft sprocket will not

move with respect to the timing belt.

(3) Use the special tool to remove the camshaft sprocket with the timing belt attached.

Caution

After removing the camshaft sprocket, be sure not

to rotate the crankshaft.

17. REMOVAL OF OIL PUMP SPROCKET

(1) Remove the plug on the side of the cylinder block.

(2) Insert a Phillips screwdriver [shank diameter 8 mm

(31

in.)] to block the left silent shaft.

(3) Remove the oil pump sprocket nut.

(4) Remove the oil pump sprocket.

23. REMOVAL OF TIMING BELT “B”

Make a mark on the back of the timing belt indicating the

direction of rotation so it may be reassembled in the same

direction if it is to be reused.

Caution

Water or oil on the belt shorten its life drastically, so

the removed timing belt, sprocket, and tensioner

must be free from oil and water. These parts should

not be washed. Replace parts if seriously contami-

nated.

If there is oil or water on each part check the front

case oil seals, camshaft oil seal and water pump for

leaks.

INSPECTIONMl 1 KCAD

TIMING BELTS

The timing belts must be checked closely. Should the following

defects be evident, replace the belt with a new one.

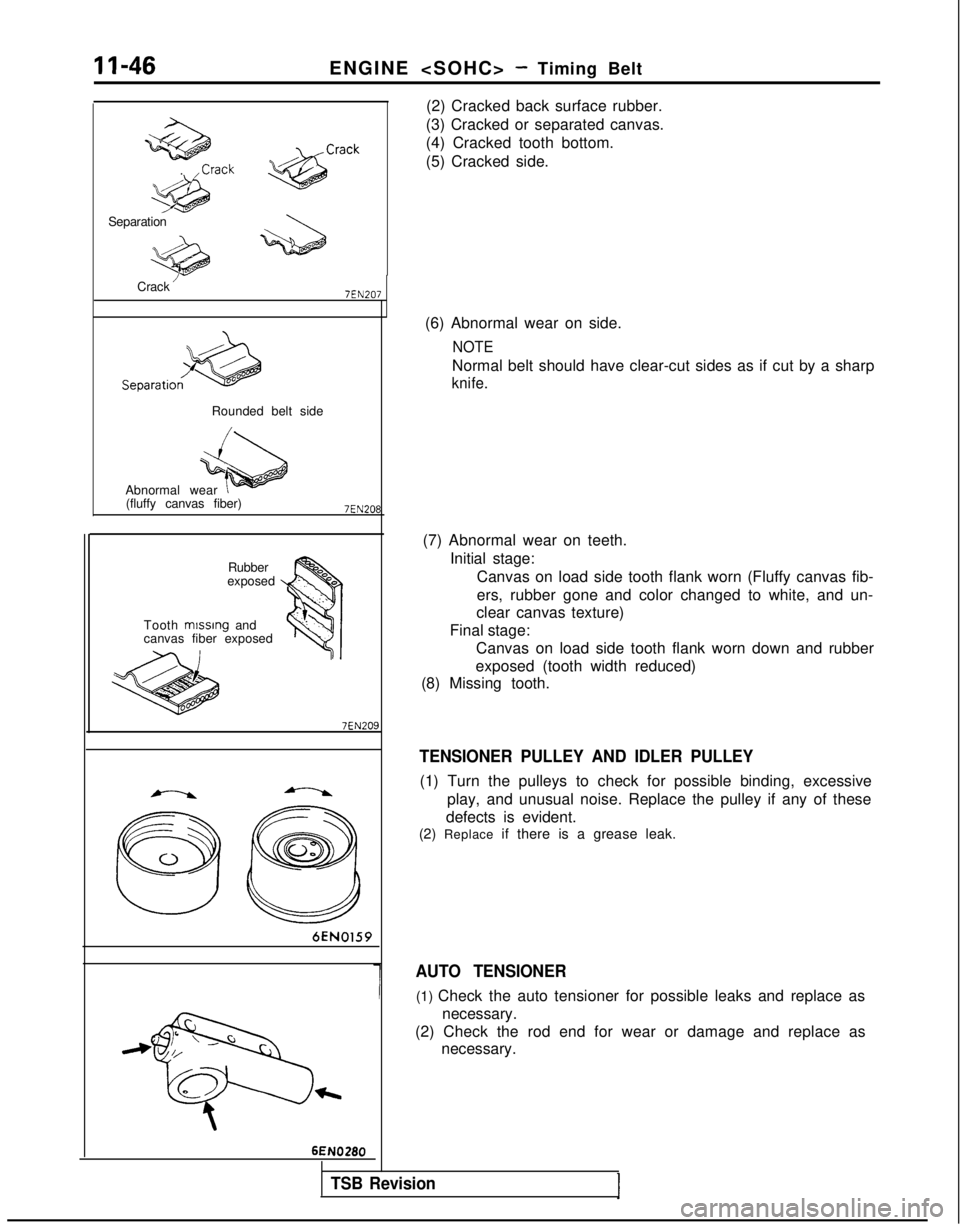

(1) Hardened back surface rubber Glossy, non-elastic, and so hard that no mark is produced

even when scratched by a fingernail.

\ TSB RevisionI

Page 96 of 1273

. .CrackII-46ENGINE

(2) Cracked back surface rubber.

(3) Cracked or separated canvas.

(4) Cracked tooth bottom.

(5) Cracked side.

Separation

Crack

’7EN207

Rounded belt side

Abnormal wear (fluffy canvas fiber)

7EN208

Rubber

exposed

Tooth mlsslng

and

canvas fiber exposed

7EN209

6EN0159

c \/Ga//

@E3%00

t 6EN0280(6) Abnormal wear on side.

NOTE

Normal belt should have clear-cut sides as if cut by a sharp

knife.

(7) Abnormal wear on teeth.

Initial stage:Canvas on load side tooth flank worn (Fluffy canvas fib-

ers, rubber gone and color changed to white, and un-

clear canvas texture)

Final stage: Canvas on load side tooth flank worn down and rubber

exposed (tooth width reduced)

(8) Missing tooth.

TENSIONER PULLEY AND IDLER PULLEY

(1) Turn the pulleys to check for possible binding, excessive

play, and unusual noise. Replace the pulley if any of these

defects is evident.

(2) Replace if there is a grease leak.

AUTO TENSIONER

(1) Check the auto tensioner for possible leaks and replace as

necessary.

(2) Check the rod end for wear or damage and replace as necessary.

TSB Revision

Page 97 of 1273

ENGINE

~7 12

rym

I

(.47 In.)-0

io

‘0

6EN0161

/

AL

@

Plug

6EN0281

Crankshaft

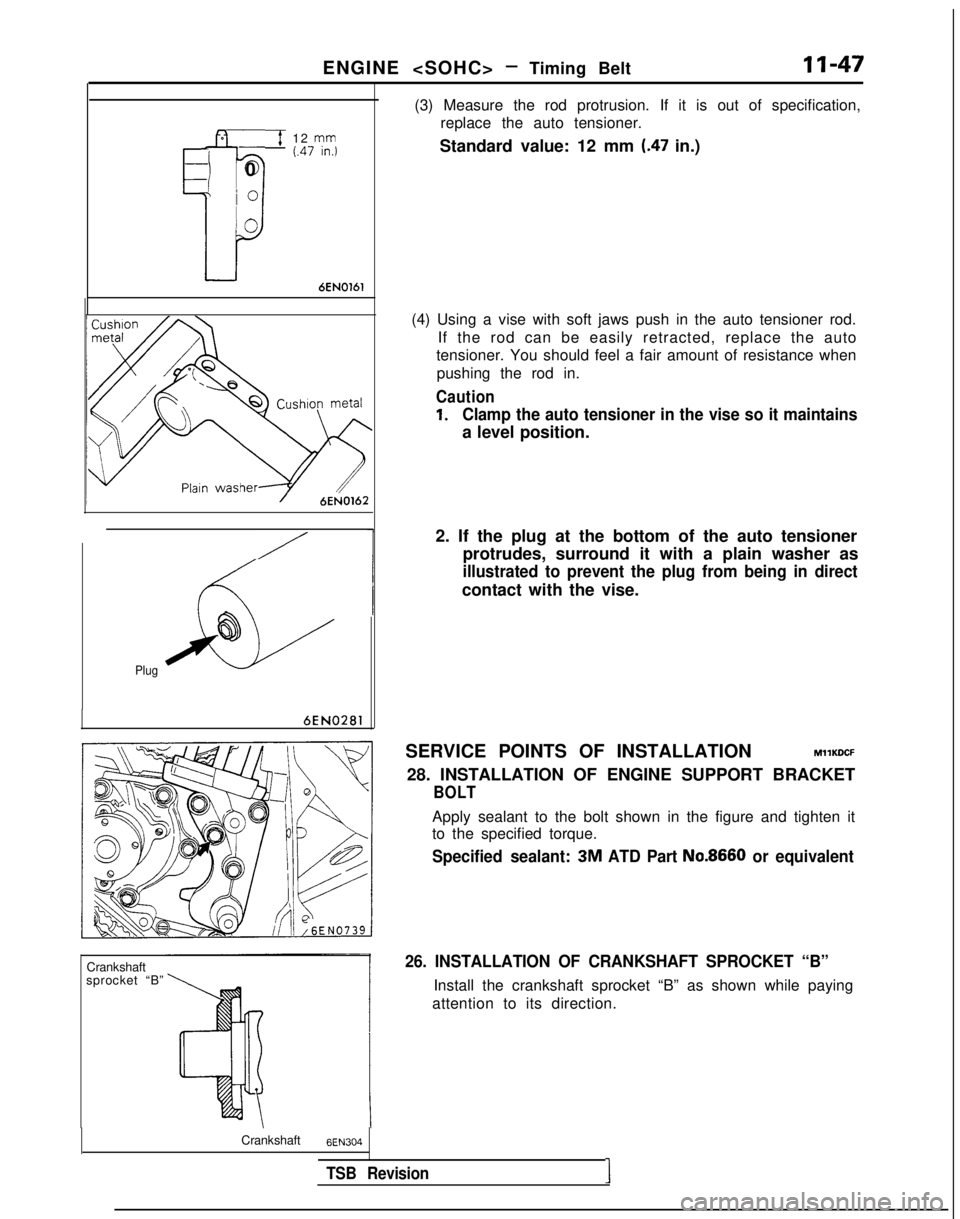

sprocket “B” (3) Measure the rod protrusion. If it is out of specification,

replace the auto tensioner.

Standard value: 12 mm

(.47 in.)

(4) Using a vise with soft jaws push in the auto tensioner rod. If the rod can be easily retracted, replace the auto

tensioner. You should feel a fair amount of resistance when

pushing the rod in.

Caution

1.Clamp the auto tensioner in the vise so it maintains

a level position.

2. If the plug at the bottom of the auto tensioner protrudes, surround it with a plain washer as

illustrated to prevent the plug from being in direct

contact with the vise.

SERVICE POINTS OF INSTALLATION

M1lKDCF

28. INSTALLATION OF ENGINE SUPPORT BRACKET

BOLT

Apply sealant to the bolt shown in the figure and tighten it

to the specified torque.

Specified sealant: 3M ATD Part No.8660

or equivalent

26. INSTALLATION OF CRANKSHAFT SPROCKET “B”

Install the crankshaft sprocket “B” as shown while paying

attention to its direction.

Crankshaft

6EN304

TSB RevisionI

Page 98 of 1273

II-48ENGINE

ChaAfered

Silent shaftnsprocket

Center of

tensioner

pulley

Center of

installation bolt

installation bolt

01Aoo39-

1

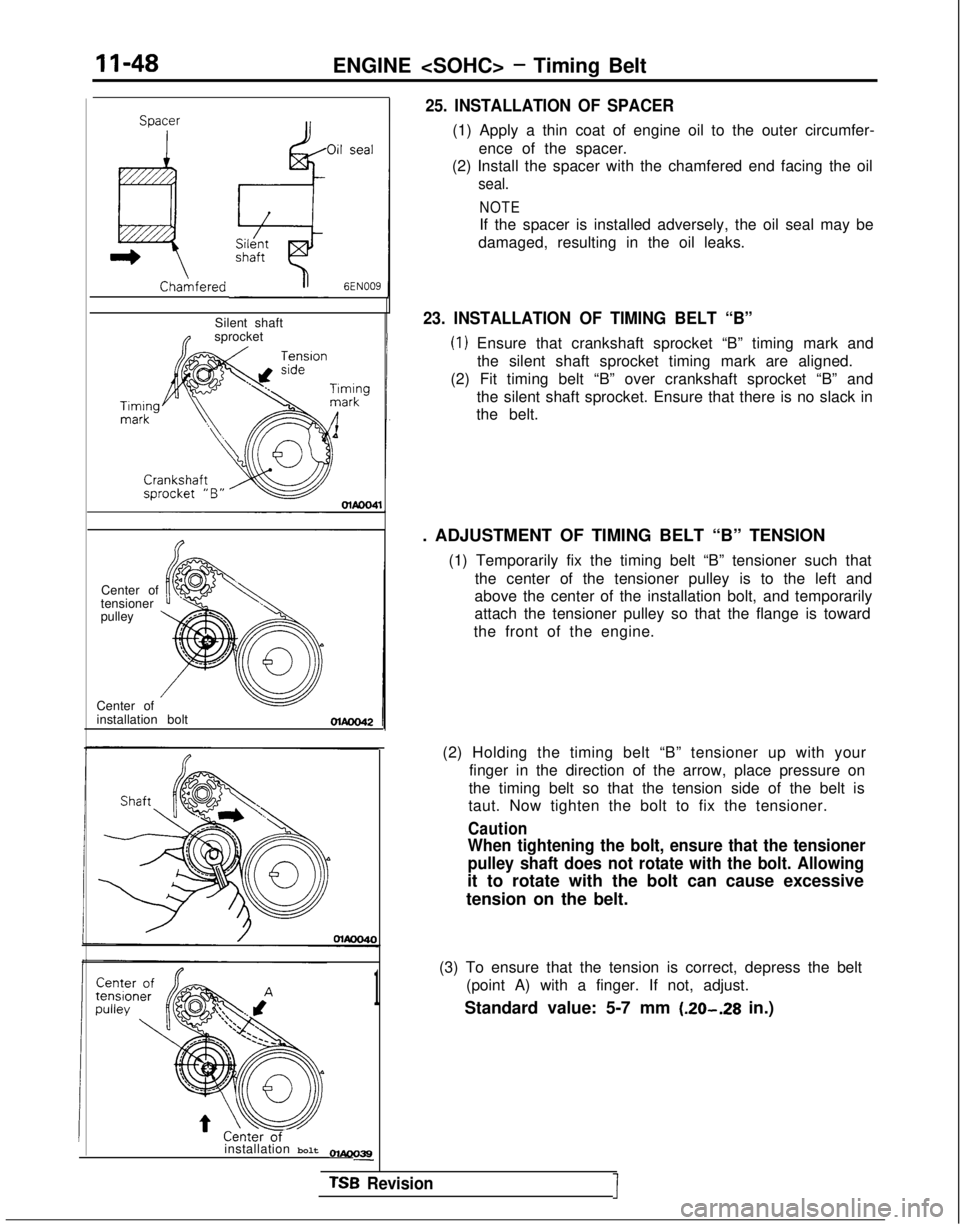

25. INSTALLATION OF SPACER

(1) Apply a thin coat of engine oil to the outer circumfer-

ence of the spacer.

(2) Install the spacer with the chamfered end facing the oil

seal.

NOTE

If the spacer is installed adversely, the oil seal may be

damaged, resulting in the oil leaks.

23. INSTALLATION OF TIMING BELT “B”

(1) Ensure that crankshaft sprocket “B” timing mark and the silent shaft sprocket timing mark are aligned.

(2) Fit timing belt “B” over crankshaft sprocket “B” and the silent shaft sprocket. Ensure that there is no slack in

the belt.

. ADJUSTMENT OF TIMING BELT “B” TENSION (1) Temporarily fix the timing belt “B” tensioner such thatthe center of the tensioner pulley is to the left and

above the center of the installation bolt, and temporarily

attach the tensioner pulley so that the flange is toward

the front of the engine.

(2) Holding the timing belt “B” tensioner up with your finger in the direction of the arrow, place pressure on

the timing belt so that the tension side of the belt is

taut. Now tighten the bolt to fix the tensioner.

Caution

When tightening the bolt, ensure that the tensioner

pulley shaft does not rotate with the bolt. Allowing

it to rotate with the bolt can cause excessive

tension on the belt.

(3) To ensure that the tension is correct, depress the belt (point A) with a finger. If not, adjust.

Standard value: 5-7 mm (.20-.28

in.)

TSB Revision1

Page 99 of 1273

ENGINE

Crankshaft

sprocket “B”

/

Crankshaft/\ \sprocket Flange Crankshaft 6~~~72

Plain washer-J

26

@

Plug

6EN0281

I

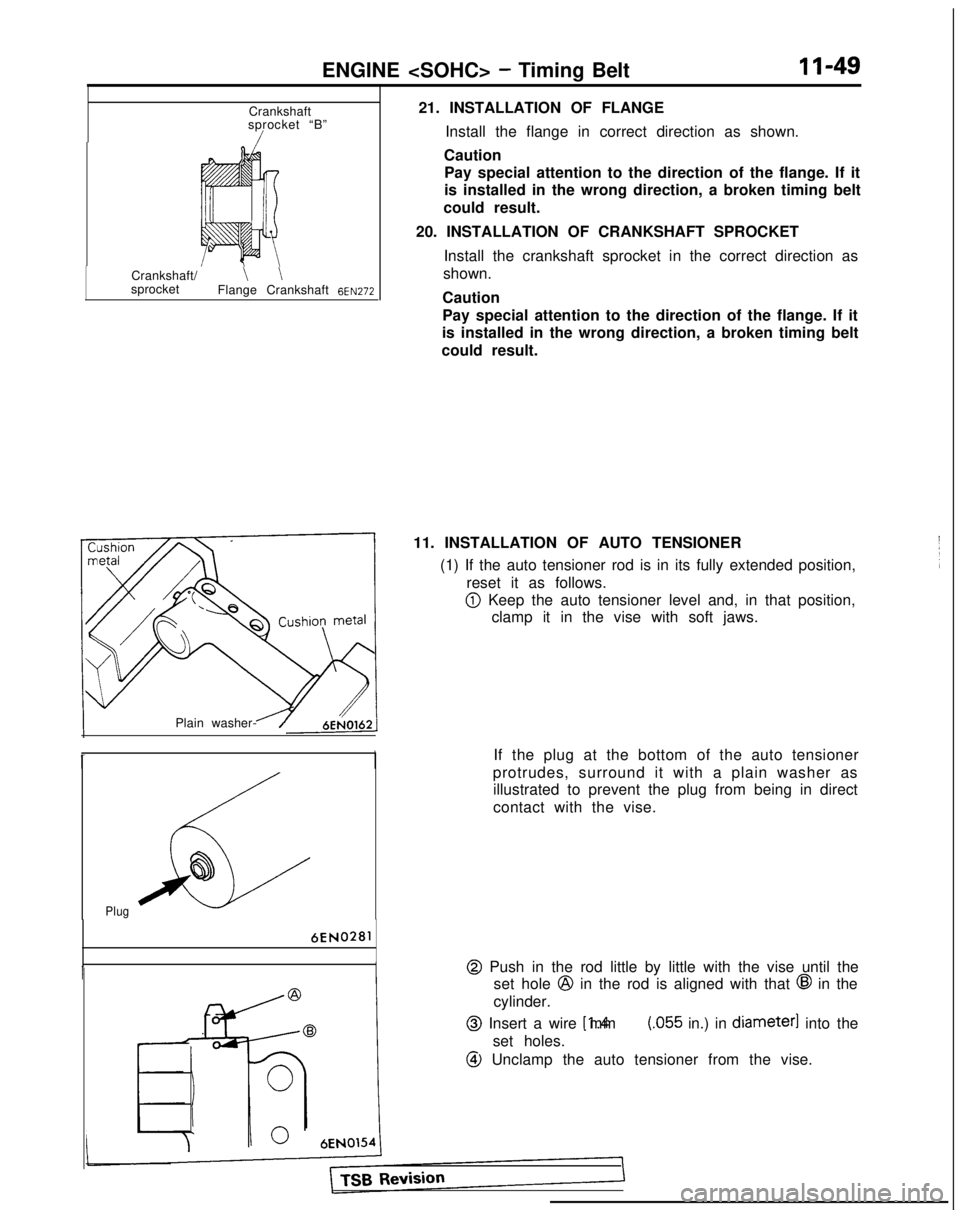

21. INSTALLATION OF FLANGE

Install the flange in correct direction as shown.

Caution Pay special attention to the direction of the flange. If it

is installed in the wrong direction, a broken timing belt

could result.

20. INSTALLATION OF CRANKSHAFT SPROCKET Install the crankshaft sprocket in the correct direction as

shown.

Caution

Pay special attention to the direction of the flange. If it

is installed in the wrong direction, a broken timing belt

could result.

11. INSTALLATION OF AUTO TENSIONER (1) If the auto tensioner rod is in its fully extended position,reset it as follows.

@ Keep the auto tensioner level and, in that position,clamp it in the vise with soft jaws.

If the plug at the bottom of the auto tensioner

protrudes, surround it with a plain washer as illustrated to prevent the plug from being in direct

contact with the vise.

@ Push in the rod little by little with the vise until the set hole

@ in the rod is aligned with that @ in the

cylinder.

@ Insert a wire [1.4 mm (055 in.) in diameter]

into the

set holes.

@ Unclamp the auto tensioner from the vise.

Page 100 of 1273

ENGINE

Center bolt i\ \

6EN028:

Timina mark

Timingmark

Timing mark

Crankshaft sprocket

OlAO668

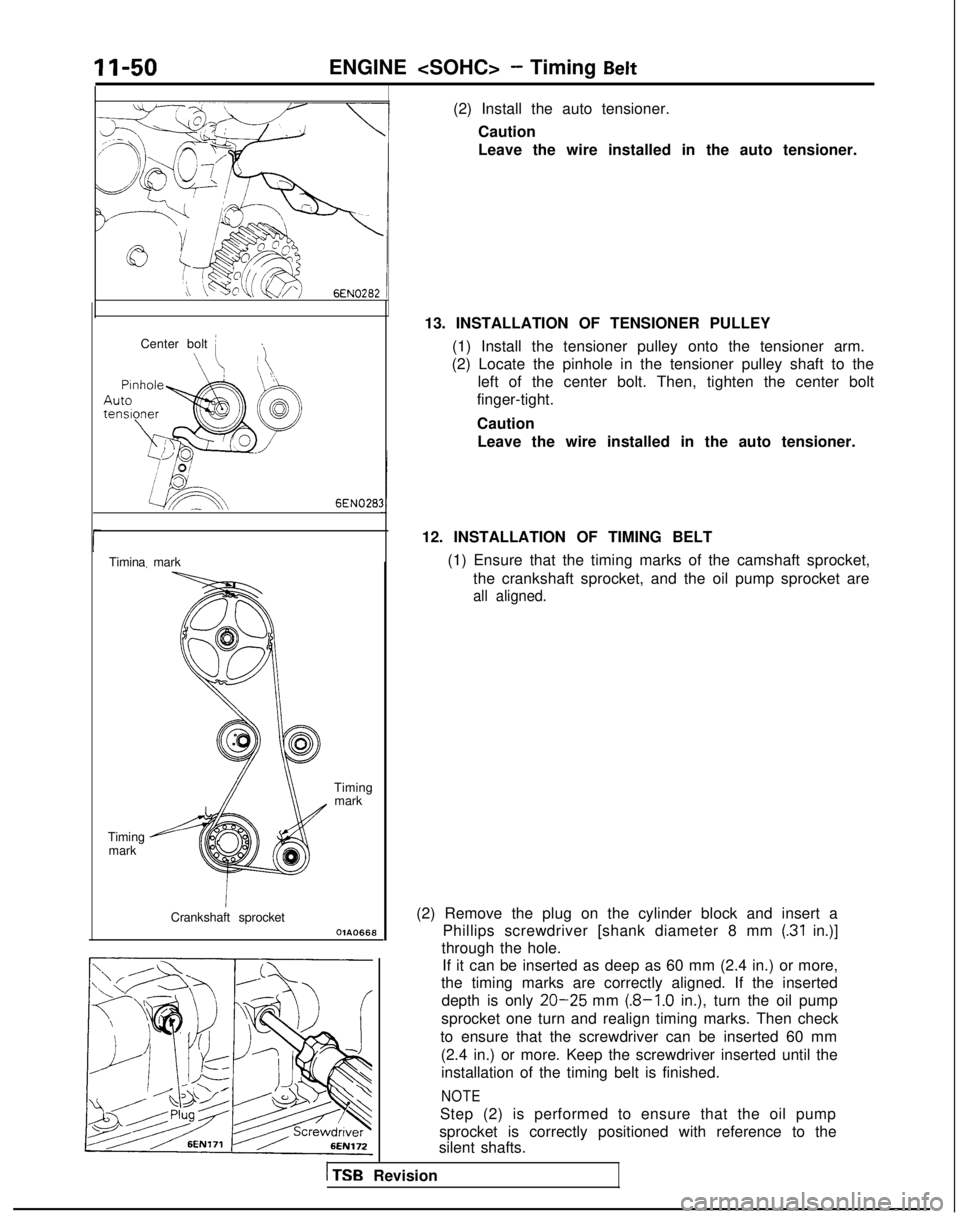

(2) Install the auto tensioner.Caution

Leave the wire installed in the auto tensioner.

13. INSTALLATION OF TENSIONER PULLEY (1) Install the tensioner pulley onto the tensioner arm.

(2) Locate the pinhole in the tensioner pulley shaft to the left of the center bolt. Then, tighten the center bolt

finger-tight.

Caution

Leave the wire installed in the auto tensioner.

12. INSTALLATION OF TIMING BELT (1) Ensure that the timing marks of the camshaft sprocket,the crankshaft sprocket, and the oil pump sprocket are

all aligned.

(2) Remove the plug on the cylinder block and insert a Phillips screwdriver [shank diameter 8 mm

(.31 in.)]

through the hole. If it can be inserted as deep as 60 mm (2.4 in.) or more,

the timing marks are correctly aligned. If the inserted

depth is only

20-25 mm (.8-1.0 in.), turn the oil pump

sprocket one turn and realign timing marks. Then check

to ensure that the screwdriver can be inserted 60 mm (2.4 in.) or more. Keep the screwdriver inserted until theinstallation of the timing belt is finished.

NOTE

Step (2) is performed to ensure that the oil pump

sprocket is correctly positioned with reference to the

silent shafts.

1 TSB Revision