MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 121 of 1273

ENGINE

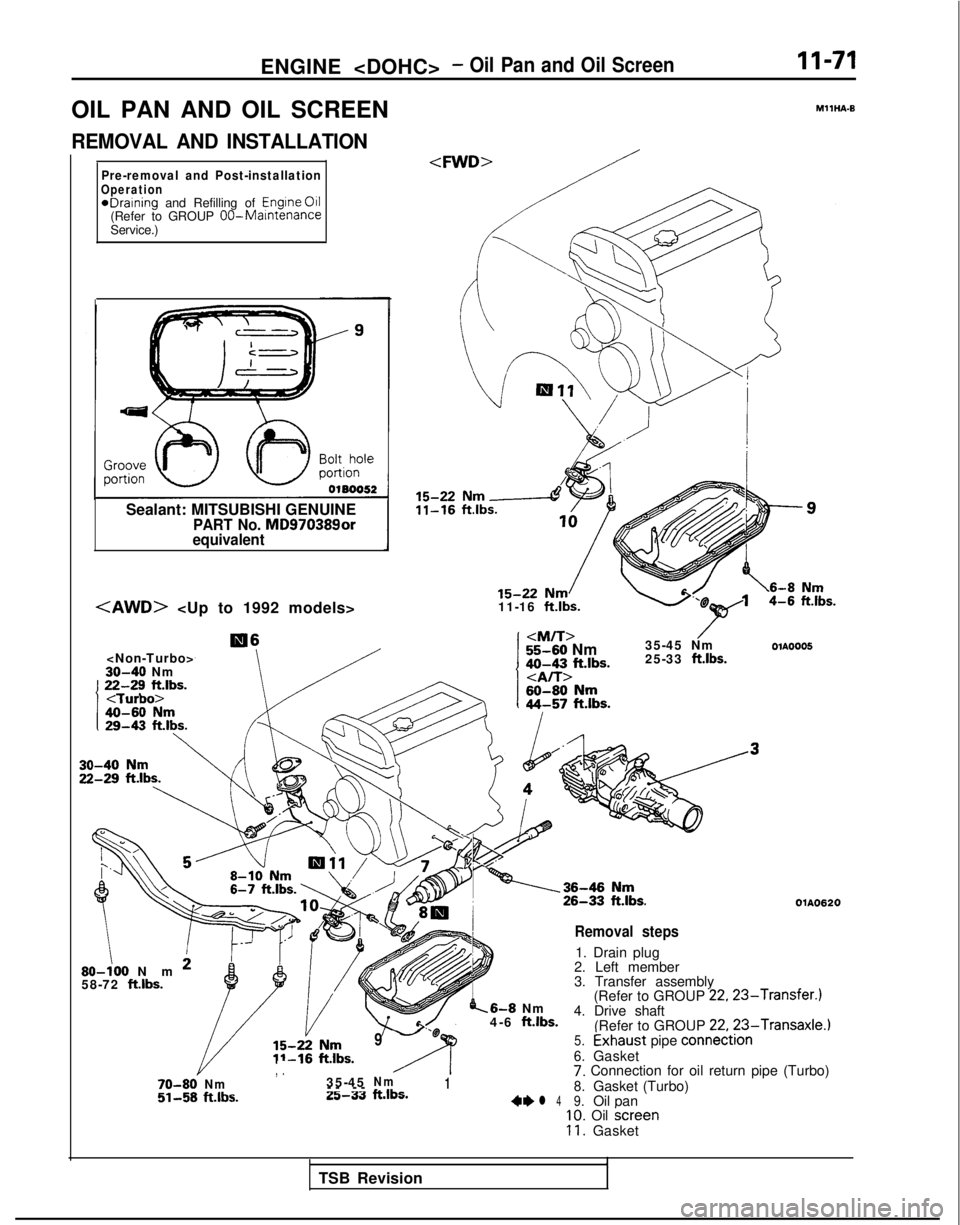

OIL PAN AND OIL SCREEN

REMOVAL AND INSTALLATION

Pre-removal and Post-installationOperation*Draining and Refilling of

Engine

011(Refer to GROUP OO-MamtenanceService.)

Sealant: MITSUBISHI GENUINE

PART No. MD970389or

equivalent

30-40 Nm1 22-28 Fibs.I

/

11-16 ft.lbs.

I

55-60 Nm

35-45 NmOlA0005

do-43 ft.lbs.25-33 ft.lbs.

Removal steps

1. Drain plug

2. Left member

3. Transfer assembly (Refer to GROUP

22,23-Transfer.)6-8 Nm

4-6 ft.lbs.4. Drive shaft

(Refer to GROUP 22.23-Transaxle.)

OlA0620

SO-:00 Nm *58-72 ft.lbs. 70-80’

Nm

51-58

ft.lbs.

/ - -e

95.ixhaust pipe connedtion

, .A6.Gasket

Nm17. Connection for oil return pipe (Turbo)

25-33ft.lbs.8.Gasket (Turbo)4*l 49.Oil pan

35-45

-- -

-

10. Oil

screen11. Gasket

TSB Revision

Page 122 of 1273

11-72

ENGINE

1

OlR0606

Sealant

Groove 4 m

m

(.I 6

in.)

p4L

cut off

-01 BOOS1e

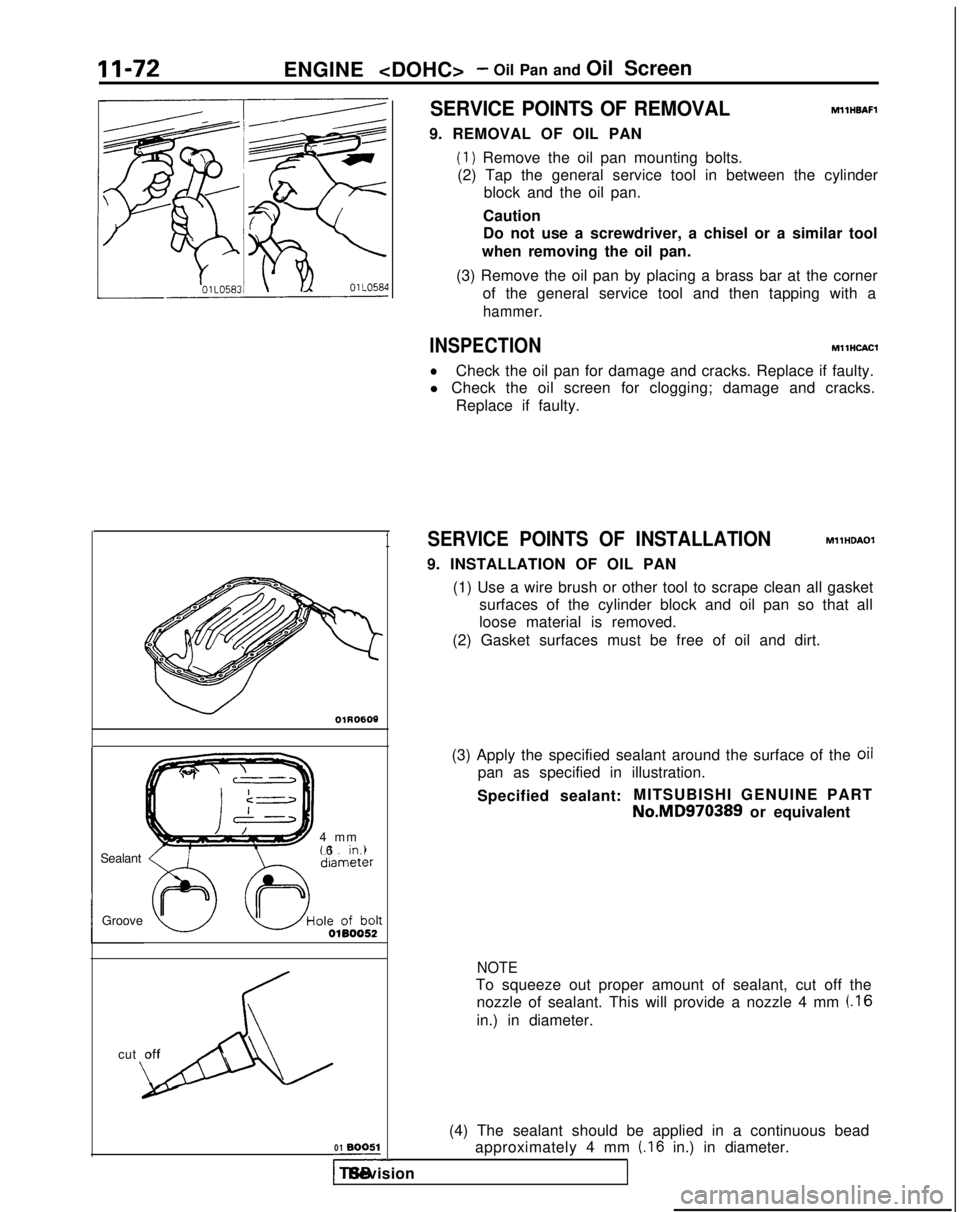

SERVICE POINTS OF REMOVALMllHBAFl

9. REMOVAL OF OIL PAN

(1) Remove the oil pan mounting bolts.

(2) Tap the general service tool in between the cylinder block and the oil pan.

Caution

Do not use a screwdriver, a chisel or a similar tool

when removing the oil pan.

(3) Remove the oil pan by placing a brass bar at the corner of the general service tool and then tapping with a

hammer.

INSPECTIONMllHCACl

lCheck the oil pan for damage and cracks. Replace if faulty.

l Check the oil screen for clogging; damage and cracks.

Replace if faulty.

SERVICE POINTS OF INSTALLATIONMllHDAOl

9. INSTALLATION OF OIL PAN

(1) Use a wire brush or other tool to scrape clean all gasket surfaces of the cylinder block and oil pan so that all

loose material is removed.

(2) Gasket surfaces must be free of oil and dirt.

(3) Apply the specified sealant around the surface of the

oil

pan as specified in illustration.

Specified sealant: MITSUBISHI GENUINE PART

No.MD970389 or equivalent

NOTE

To squeeze out proper amount of sealant, cut off the

nozzle of sealant. This will provide a nozzle 4 mm

(.I6

in.) in diameter.

(4) The sealant should be applied in a continuous bead approximately 4 mm

(.I6 in.) in diameter.

1 TSB Revision

Page 123 of 1273

ENGINE

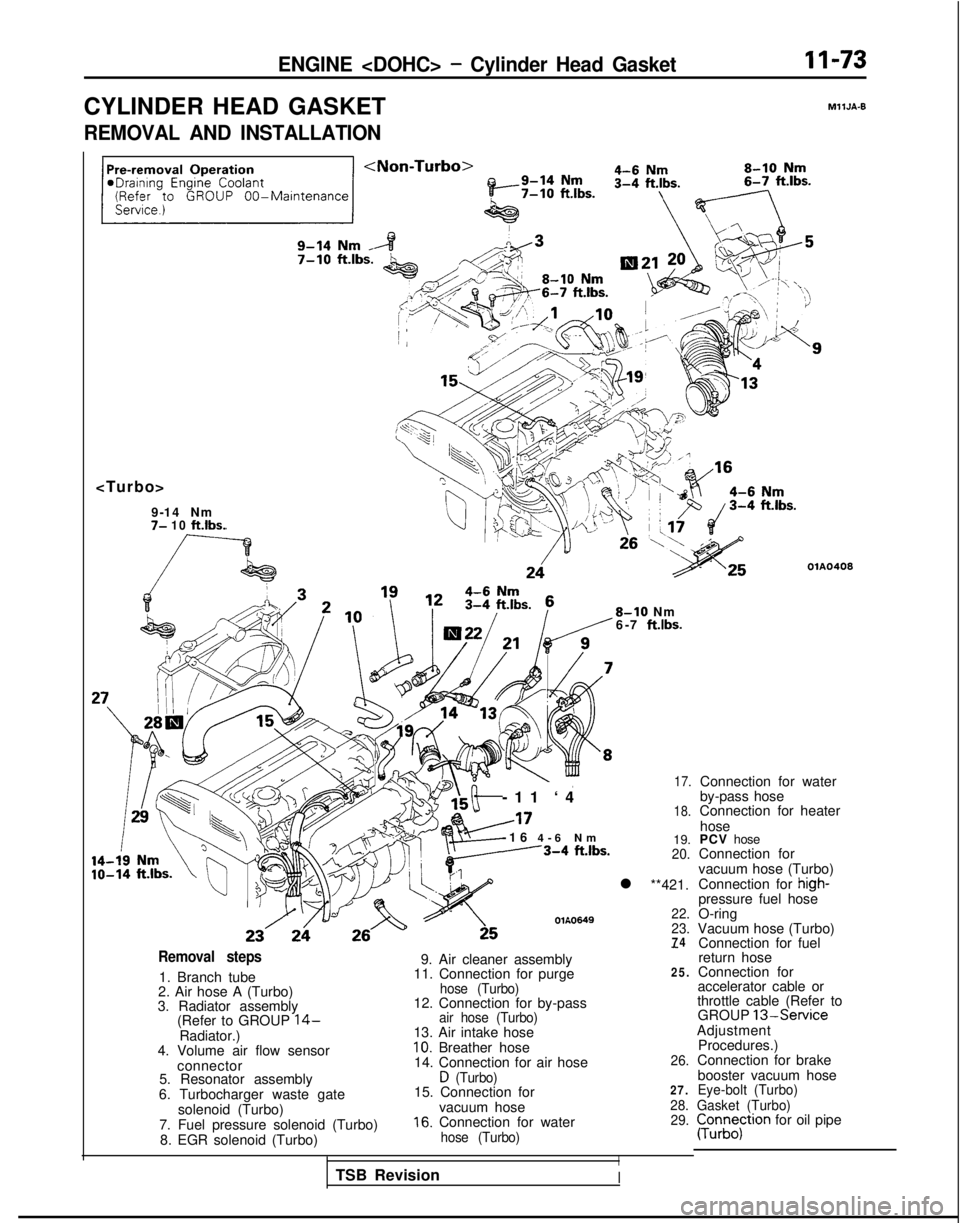

CYLINDER HEAD GASKET

MllJA-9

REMOVAL AND INSTALLATION

7- 10 ft.lbs.

OlA0408

8-10 Nm

6-7 ft.lbs.

-11 ‘

4

A17

-16

4-6 N

m

---3-4

ftlbs.

OlA0649

17.

18.

19.20.

l **421.

22.

23.

74Removal steps

1. Branch tube

2. Air hose A (Turbo)

3. Radiator assembly (Refer to GROUP

14-Radiator.)

4. Volume air flow sensor

connector

5. Resonator assembly

6. Turbocharger waste gate solenoid (Turbo)

7. Fuel pressure solenoid (Turbo) 8. EGR solenoid (Turbo)

-

9. Air cleaner assembly

11. Connection for purge25.

hose (Turbo)12. Connection for by-passair hose (Turbo)13. Air intake hose10. Breather hose

14. Connection for air hose26.

D (Turbo)15. Connection for27.

vacuum hose28.

16. Connection for water29.

hose (Turbo)

I

Connection for water

by-pass hose

Connection for heater

hose

PCV hose

Connection for

vacuum hose (Turbo)

Connection for

high-pressure fuel hose

O-ring

Vacuum hose (Turbo) Connection for fuel

return hose

Connection for

accelerator cable or

throttle cable (Refer to GROUP

13-ServiceAdjustment

Procedures.)

Connection for brake

booster vacuum hose

Eye-bolt (Turbo)

Gasket (Turbo)

pun;;;tron for oil pipe

TSB Revision

I

Page 124 of 1273

11-74ENGINE

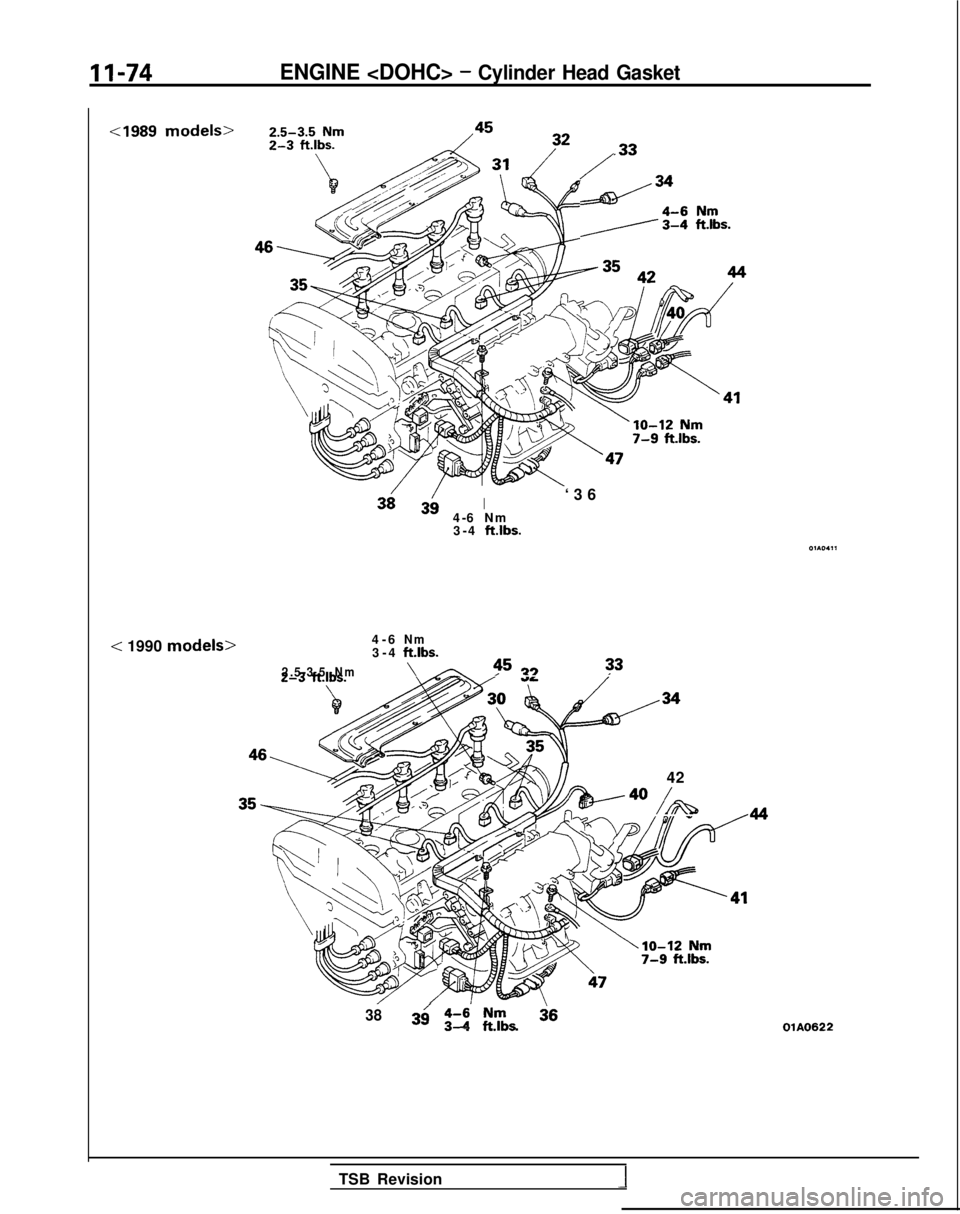

< 1990 models>

/

d34

/./At %L.

I4-6 Nm

3-4 ftlbs.

‘36

4-6

Nm3-

4 ftlbs.

2.5-3.5Nm\45

13 33

42

/A

3839/ z-i ,“g,- . .OlA0622

TSB Revision

Page 125 of 1273

ENGINE

Z&-y,bfm

‘\ .

,,\:.,.s.

46

4-6

‘Nm $7

3-4 ftlbs.

41

43

42

IO-12 Nm

7-9 ft.lbs.

05A0199

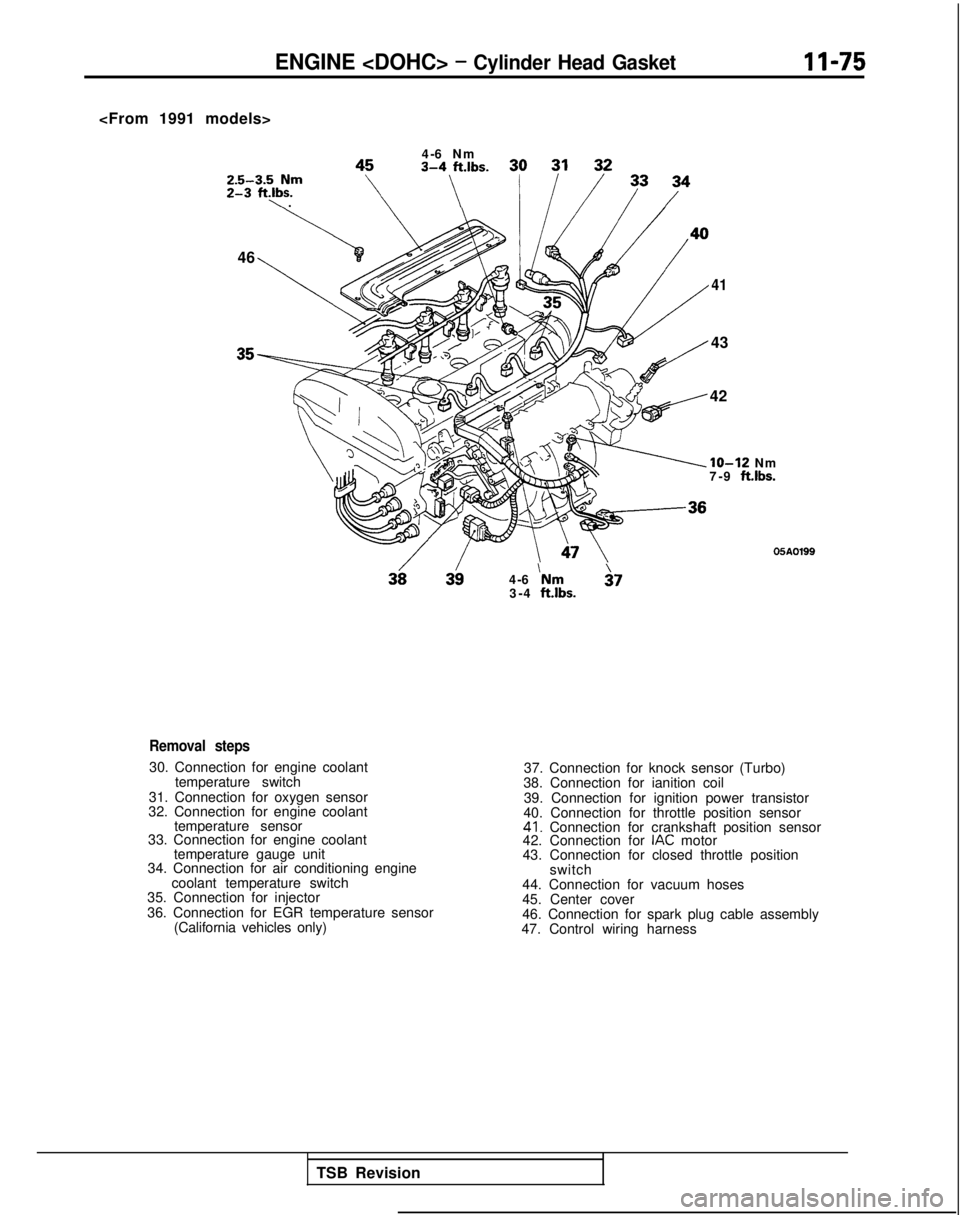

Removal steps

30. Connection for engine coolant

temperature switch

31. Connection for oxygen sensor

32. Connection for engine coolant temperature sensor

33. Connection for engine coolant

temperature gauge unit

34. Connection for air conditioning engine

coolant temperature switch

35. Connection for injector

36. Connection for EGR temperature sensor

(California vehicles only) 37. Connection for knock sensor (Turbo)

38. Connection for ianition coil

39. Connection for ignition power transistor

40. Connection for throttle position sensor

41. Connection for crankshaft position sensor

42. Connection for IAC motor

43. Connection for closed throttle position

switch

44. Connection for vacuum hoses

45. Center cover

46. Connection for spark plug cable assembly

47. Control wiring harness

TSB Revision

Page 126 of 1273

11-76

ENGINE

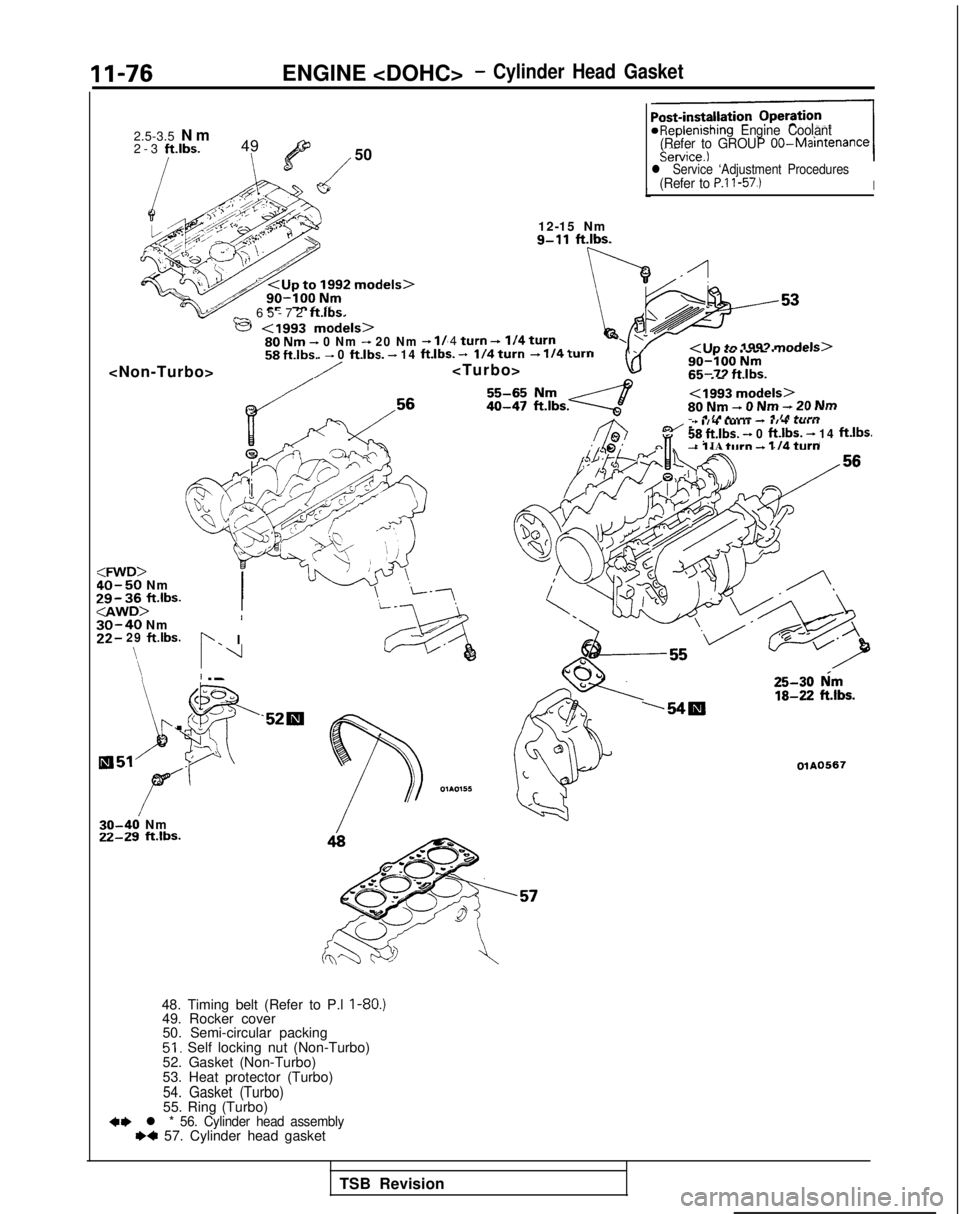

2.5-3.5

N

m

2-3 ft.lbs.

49

l’/

50

_ 65-72 ftlbs.

e

- 14 ft.lbs. -4 turn +I/4 turna ,a _..--/I In +n lQQ3 mnrimls>- II ~

i/4wrn + 114xurnrAVJ

.vp .” .““L . ..-..-.I-^^ -^^I.~1-_ _- .-..-YU-IUU NIT5.

<199” ---I-‘-’80 Nn, - v ,.lll - Lw .-...II I” I.._^

66-77 ft Ih!

* IA +.*r..

*Replenishing

Engine Coolant

(Refer to GROUP OO-Maintenance

l Service ‘Adjustment Procedures(Refer to P.l l-57.)I

12-15 Nm

9-11

ft.lbs.

/

:WD>40-50 NmW3i,ft.lbs...,....I,30-40 NmI

3_2- 29 ftlbs.b. I\

\$ 1

‘\I

L. I

Q51 ,-,?/*

r

r

30-46 Nm22-29 ft.lbs. I.5

rrl”“els~n .nNm-7nNm

48. Timing belt (Refer to P.l I-80.)49. Rocker cover

50. Semi-circular packing

51. Self locking nut (Non-Turbo)

52. Gasket (Non-Turbo)

53. Heat protector (Turbo)

54. Gasket (Turbo)55. Ring (Turbo)+, l * 56. Cylinder head assembly~~ 57. Cylinder head gasket

+ I,4 L”,,, - #l-t L”lllj8 ft.lbs. - 0 ft.lbs. - 14 ft.lbs.,J -1 IA turn + 1 IO turn

25-30 him

18-22

ft.lbs.‘54m

OlA0567

TSB Revision

Page 127 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual ENGINE <DOHC>- Cylinder Head GasketII-77

SFAI ING

POINTSGaln

OlA0155

J

Front of engine I)Intake side

]

Exhaust side

SERVICE POINTS OF REMOVALMllJBAUa

21. DISCONNECTION OF HIGH-PRESSURE FUEL HOSE

Cauti MITSUBISHI GALANT 1989 Service Repair Manual ENGINE <DOHC>- Cylinder Head GasketII-77

SFAI ING

POINTSGaln

OlA0155

J

Front of engine I)Intake side

]

Exhaust side

SERVICE POINTS OF REMOVALMllJBAUa

21. DISCONNECTION OF HIGH-PRESSURE FUEL HOSE

Cauti](/img/19/57312/w960_57312-126.png)

ENGINE

SFAI ING

POINTSGaln

OlA0155

J

Front of engine I)Intake side

]

Exhaust side

SERVICE POINTS OF REMOVALMllJBAUa

21. DISCONNECTION OF HIGH-PRESSURE FUEL HOSE

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressure

in the fuel pipe line.

For information concerning the bleeding of the residualpressure, refer to GROUP

13-On-vehicle Inspection of MFI Components.

56. REMOVAL OF CYLINDER HEAD ASSEMBLY Using the tool, loosen the bolts in the order shown in the

figure (in 2 or 3 cycles) and remove. Then remove the cylin-

der head assembly.

TSB Revision

I

Page 128 of 1273

ENGINE

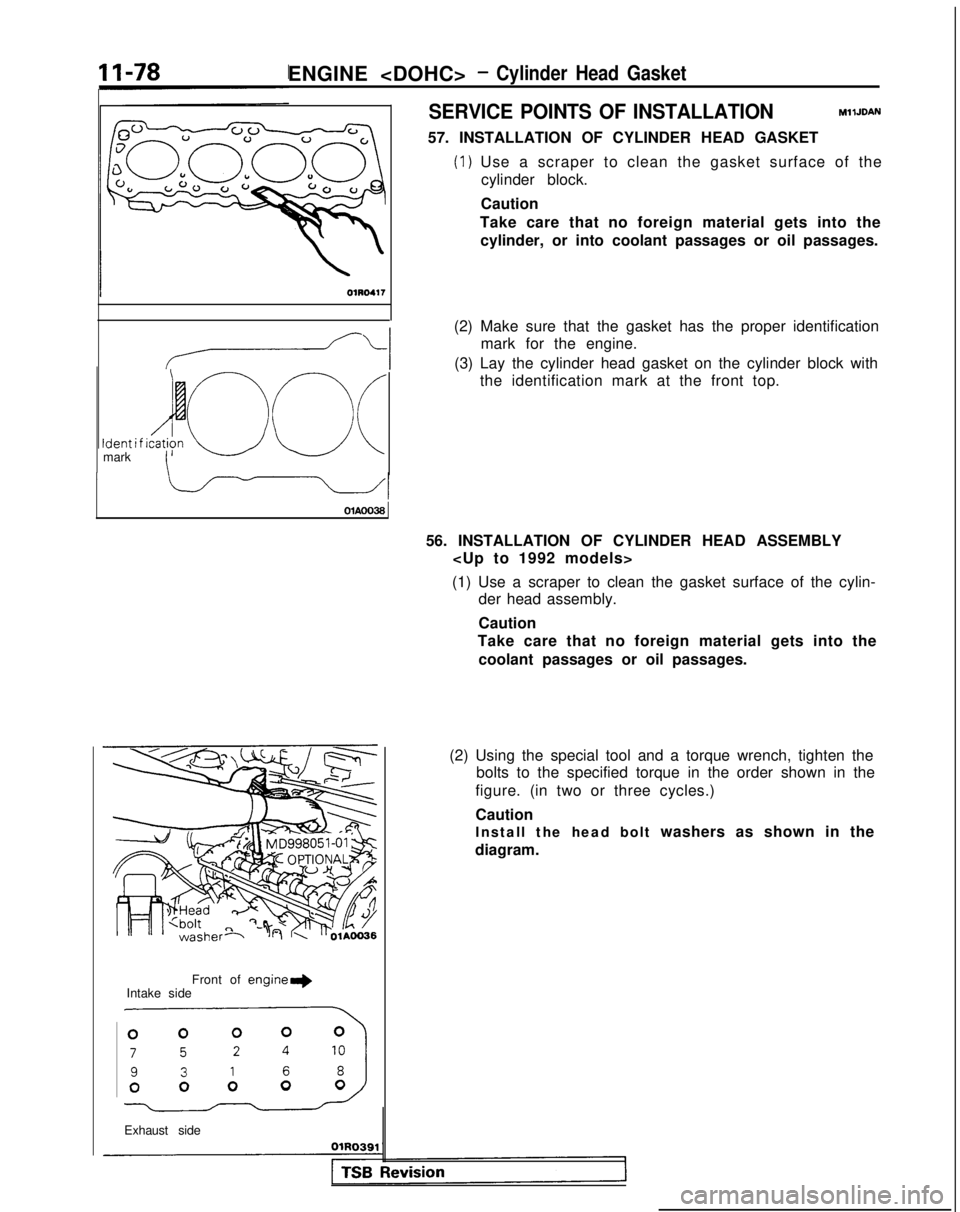

SERVICE POINTS OF INSTALLATIONMllJDAN

57. INSTALLATION OF CYLINDER HEAD GASKET

(1) Use a scraper to clean the gasket surface of the

cylinder block.

Ident i f ido c\ (Imark\ OlAOO38

Front of

engine+Intake side

.miJ

Exhaust side Caution

Take care that no foreign material gets into the cylinder, or into coolant passages or oil passages.

(2) Make sure that the gasket has the proper identification mark for the engine.

(3) Lay the cylinder head gasket on the cylinder block with the identification mark at the front top.

56. INSTALLATION OF CYLINDER HEAD ASSEMBLY

(1) Use a scraper to clean the gasket surface of the cylin- der head assembly.

Caution

Take care that no foreign material gets into the

coolant passages or oil passages.

(2) Using the special tool and a torque wrench, tighten the bolts to the specified torque in the order shown in the

figure. (in two or three cycles.)

Caution

Install the head bolt washers as shown in the

diagram.

Page 129 of 1273

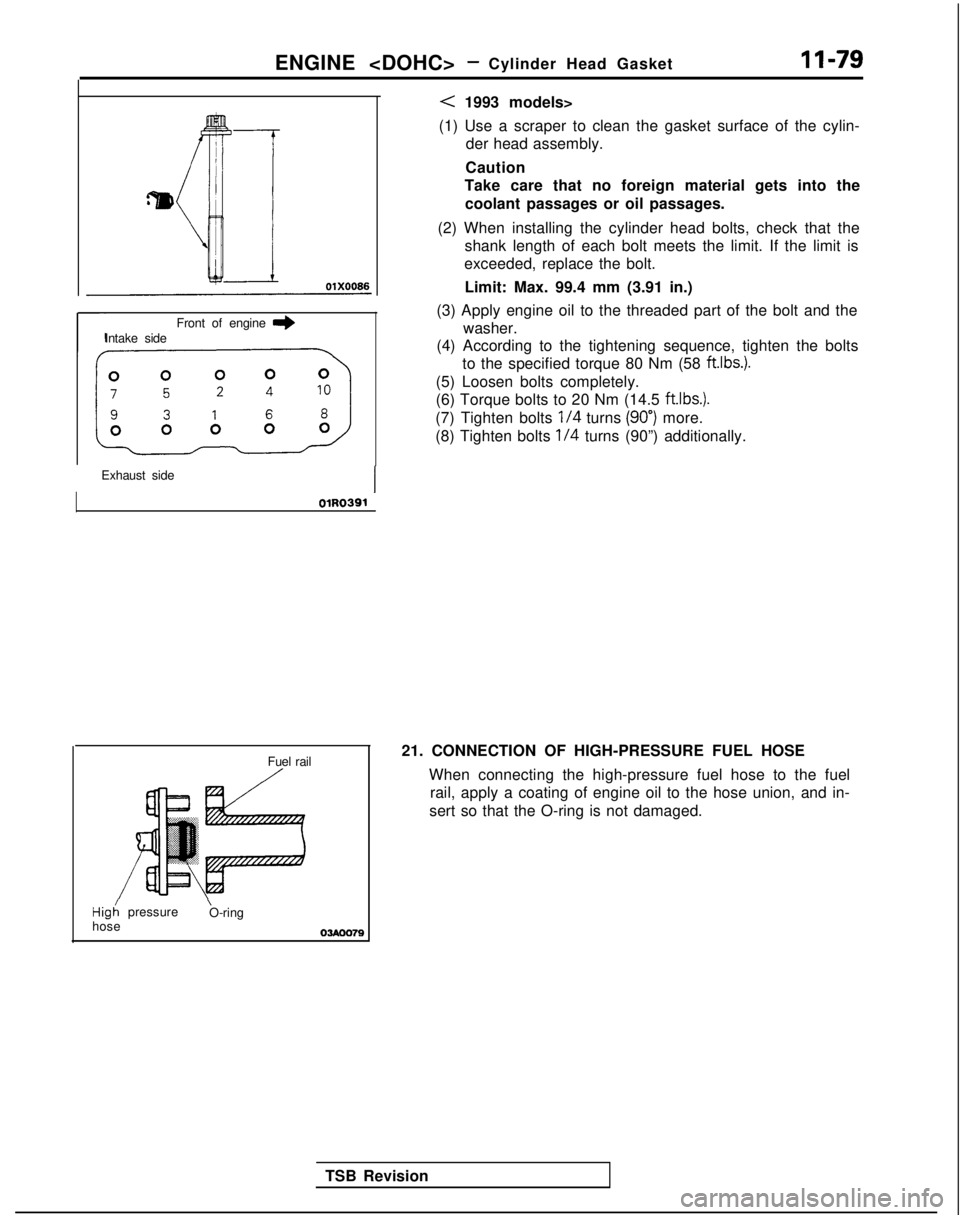

ENGINE

Front of engine I)Intake side

Exhaust side

OlR0391

Fuel rail/

Hig; pressure \

O-ring

hose

03Aoo79

< 1993 models>

(1) Use a scraper to clean the gasket surface of the cylin- der head assembly.

Caution

Take care that no foreign material gets into the

coolant passages or oil passages.

(2) When installing the cylinder head bolts, check that the shank length of each bolt meets the limit. If the limit is

exceeded, replace the bolt.

Limit: Max. 99.4 mm (3.91 in.)

(3) Apply engine oil to the threaded part of the bolt and the washer.

(4) According to the tightening sequence, tighten the bolts

to the specified torque 80 Nm (58 ftlbs.).

(5) Loosen bolts completely.

(6) Torque bolts to 20 Nm (14.5 ftlbs.).

(7) Tighten bolts

l/4 turns (90”) more.

(8) Tighten bolts

l/4 turns (90”) additionally.

TSB Revision 21. CONNECTION OF HIGH-PRESSURE FUEL HOSE

When connecting the high-pressure fuel hose to the fuelrail, apply a coating of engine oil to the hose union, and in-

sert so that the O-ring is not damaged.

Page 130 of 1273

II-80ENGINE

TIMING BELT

REMOVAL AND INSTALLATION 50-65

Nm

36-47 ftlbs.

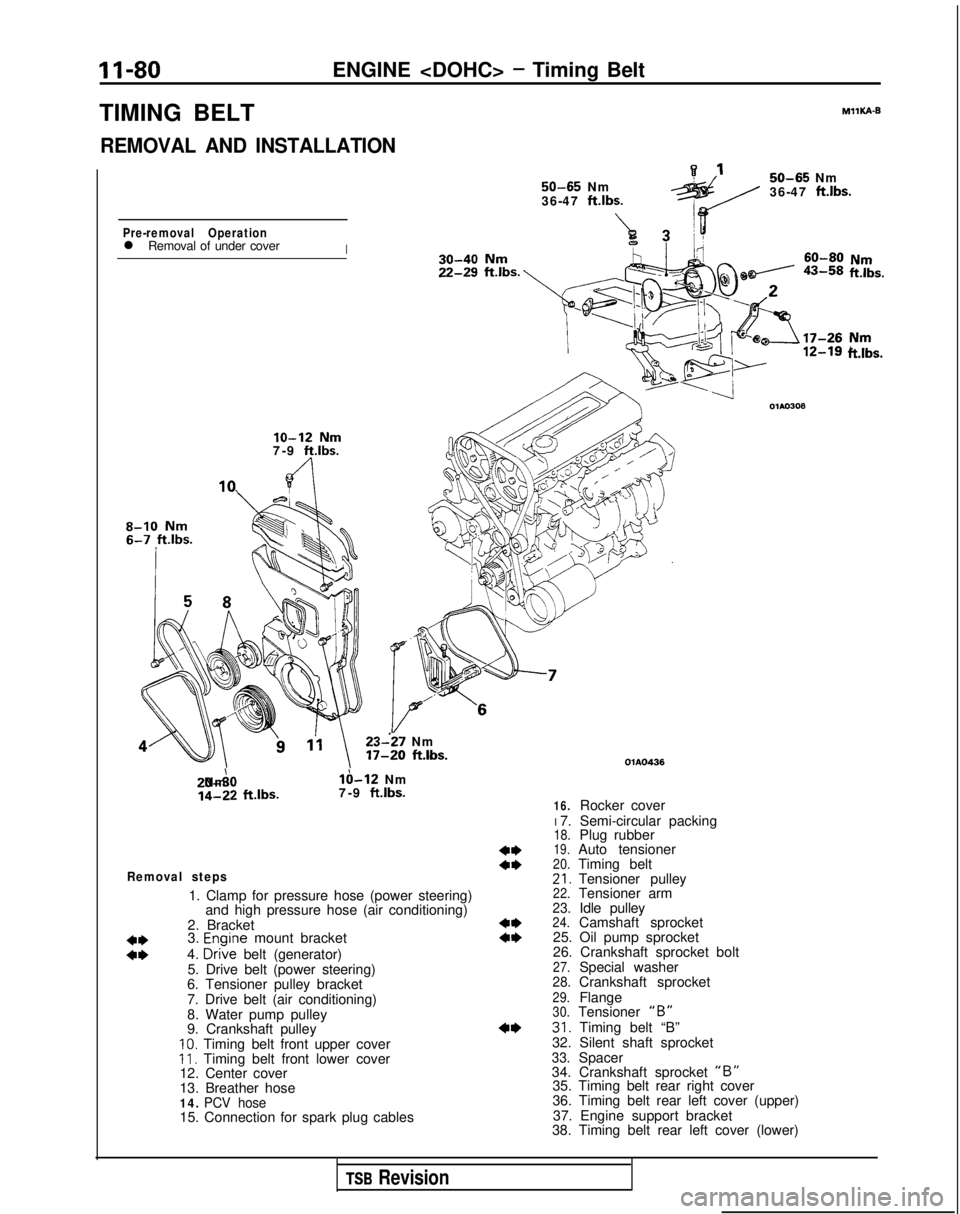

A7Pre-removal Operationl Removal of under coverI MIlKA-B

50-65

Nm

36-47

ft.lbs.

ii!&.

lo-12 Nm7-9 ft.lbs.

8-10 Nm

23--27 Nm 17-20

ft.lbs. 20-A0 Nm

lb-12 Nm

14-22

ftlbs.

7-9 ft.lbs.

Removal steps

1. Clamp for pressure hose (power steering)

and high pressure hose (air conditioning)

2. Bracket

3.

Enoine mount bracket

ii4. D&e belt (generator)

5. Drive belt (power steering)

6. Tensioner pulley bracket

7. Drive belt (air conditioning)

8. Water pump pulley

9. Crankshaft pulley

10. Timing belt front upper coverII. Timing belt front lower cover

12. Center cover

13. Breather hose

14. PCV hose15. Connection for spark plug cables

ft.lbs.

4*a*

4**I)

4* OlAO436

16.Rocker cover

I 7. Semi-circular packing

18.Plug rubber19.Auto tensioner20.Timing belt21.Tensioner pulley22.Tensioner arm23.Idle pulley24.Camshaft sprocket

25. Oil pump sprocket

26. Crankshaft sprocket bolt

27.Special washer28.Crankshaft sprocket29.Flange30.Tensioner “B”31. Timing belt “B”

32. Silent shaft sprocket

33.Spacer

34. Crankshaft sprocket “B”35. Timing belt rear right cover

36. Timing belt rear left cover (upper)

37. Engine support bracket

38. Timing belt rear left cover (lower)

TSB Revision