check engine MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 247 of 1273

FUEL SYSTEM

fine probe7FU1264 1

(15) Reduce the internal pressure of the fuel pipes and hoses.

(Refer to

P.13-102.)

(16) Disconnect the fuel pressure gauge and the special toolsfrom the fuel rail.

Caution

Because there will be some residual pressure in the fuel

pipe line, use a shop towel to cover so that fuel doesn’t

splatter.

(17)Replace the O-ring at the end of the fuel high-pressure

hose with a new one. (18)After

connecting the fuel high-pressure hose to the fuel

rail, tighten the installation bolt.

(19)Check to be sure that there is no fuel leakage.

@ Apply battery voltage to the terminal for activation of the fuel pump so as to activate the fuel pump.

@ With fuel pressure applied, check for leakage of the fuel

line.

INSPECTION OF ENGINE CONTROL MODULE

TERMINAL VOLTAGEMl 3ZALBa

(1) Connect the extremely fine probe (paper clip, etc.) to the probe of the voltmeter.

(2) At each terminal of the engine control module connector,

insert the extremely fine probe from the wire side, and

measure the voltage referring to the check chart.

NOTE

1. In the state in which the connector of the engine

control module is connected, measure the voltage.

2. Measure the voltage across each terminal to the

terminal No. 106.

(ground terminal).

3. You may find it convenient to pull out the engine control module to make it easier to reach the connector

terminals.

4.Inspection need not be executed in the chart’s sequence.

Caution

Short-circuiting the positive

(+) probe between a con-

nector terminal and ground could damage the vehicle

wiring, the sensor, the engine control module, or all

there. Use care to prevent this!

(3) If voltmeter shows any deviation from standard value, check the corresponding sensor, actuator and related

electrical wiring, then repair or replace.

(4) After repair or replacement, recheck with the voltmeter to confirm that the repair has corrected the problem.

Page 248 of 1273

13-106

FUEL SYSTEM

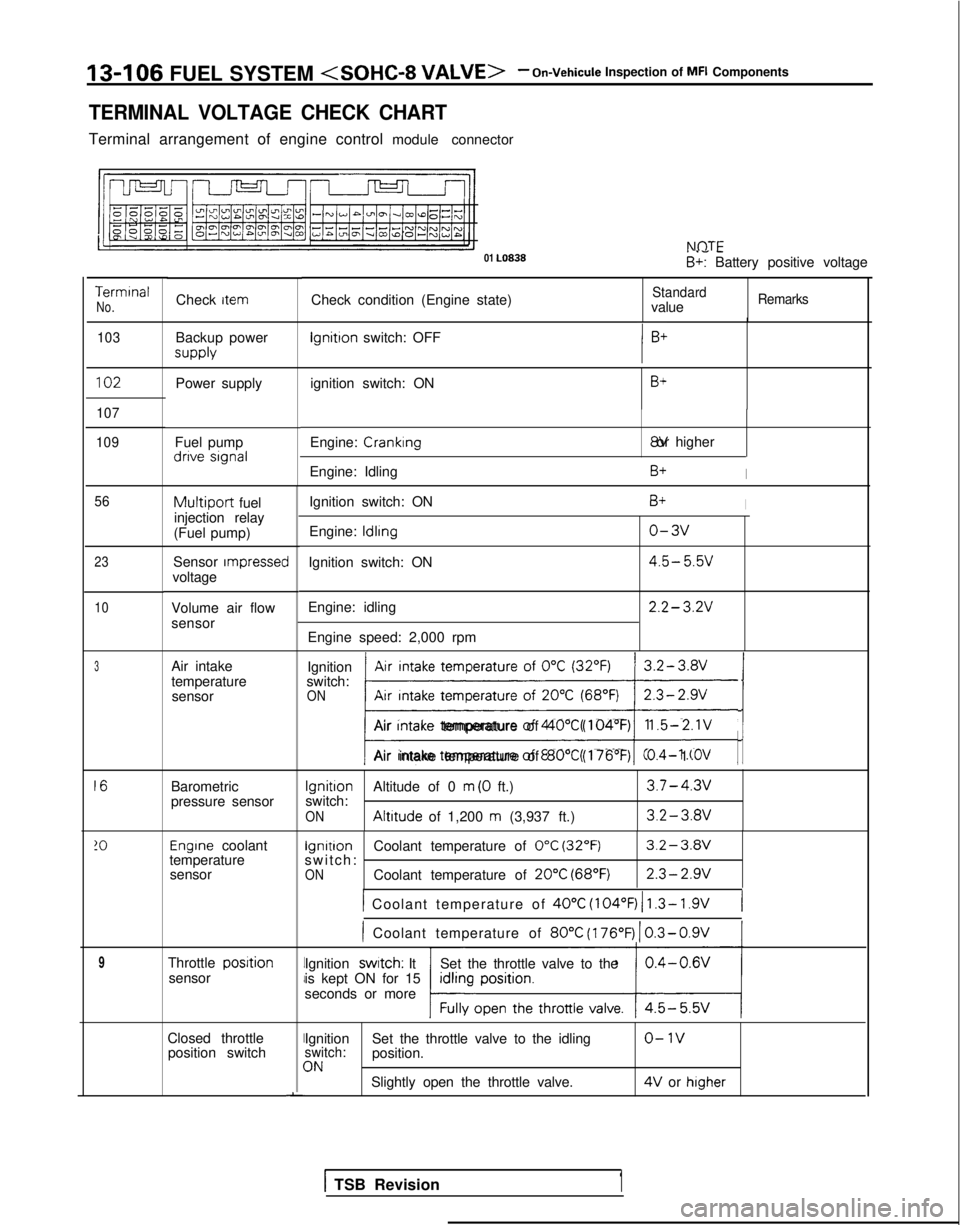

TERMINAL VOLTAGE CHECK CHART

Terminal arrangement of engine control module connector NflTF

01 LO838

. .- -B+: Battery positive voltage

Terminal

No.Check condition (Engine state)StandardvalueRemarksCheck item

103

Backup power supply lgnitron

switch: OFF

102Power supply ignition switch: ONB+

107

109

Fuel pump dnve signal

Engine: Cranking 8V or higher

Engine: Idling

B+I

Ignition switch: ON

Engine:

ldlrng

Ignition switch: ON

Engine: idling

Engine speed: 2,000 rpm

B+I

o-3v

4.5- 5.5v

2.2- 3.2V

56

23

10

Multiport fuel

injection relay

(Fuel pump)

Sensor

rmpressecvoltage

Volume air flow

sensor

Air intake

temperature sensor Ignition

Air intake temperature of

0°C (32°F)switch:ONAir Intake temperature of 20°C (68°F); ji/

Air Intake temperature of 40°C (104°F)1.5-2.1V

Air intake temperature of 80°C (176’F)0.4- 1 .OV

Barometric

pressure sensor

Ignition

Altitude of 0 m (0 ft.)3.7-4.3vswitch:ON Altitude

of 1,200 m (3,937 ft.)3.2-3.av

Engrne coolant lgnitron

Coolant temperature of 0°C (32°F)3.2-3.Wtemperature switch: -sensorONCoolant temperature of 20°C (68°F)2.3-2.9v

1 Coolant temperature of 40°C

(104°F) 1 1.3- 1.9V(

) Coolant temperature of 80°C

(176’F)

1 0.3-0.9V

Throttle posrtionsensor Ignition swatch: It

Set the throttle valve to the

is kept ON for 15

seconds or more

Closed throttle position switchII

I

I

-

Ignition Set the throttle valve to the idlingo-1vswitch:position.3NSlightly open the throttle valve. 4V

or higher

3

16

!O

9

1 TSB Revision1

Page 249 of 1273

FUEL SYSTEM

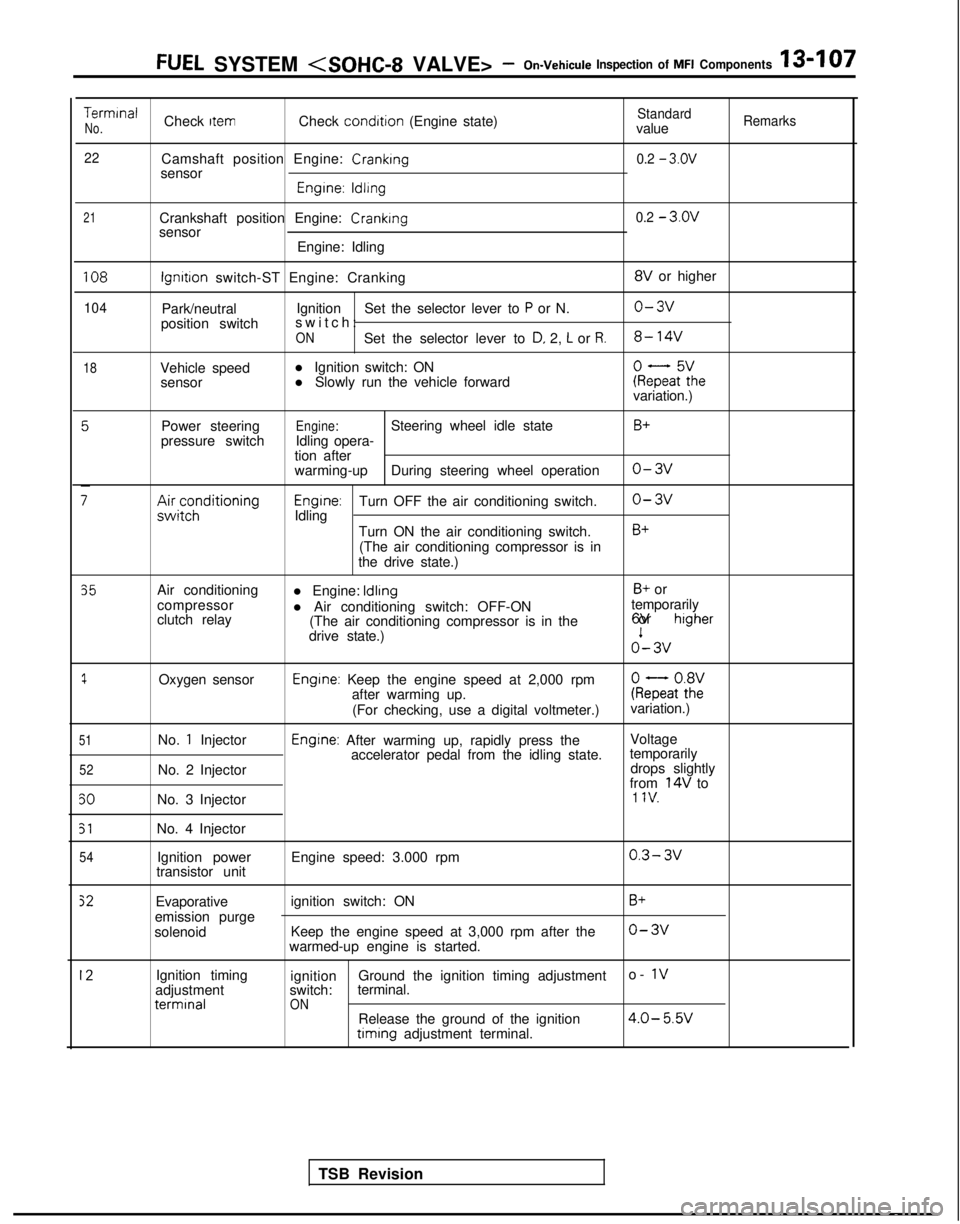

TerminalCheck ItemCheck condition

(Engine state)StandardNo.valueRemarks

22

Camshaft position Engine: Cranking0.2 - 3.ov

sensor

Engrne: ldllng

21Crankshaft position Engine: Crankingsensor

Engine: Idling0.2 - 3.ov

108

104

18

lgnrtron switch-ST Engine: Cranking 8V

or higher

Park/neutral Ignition

Set the selector lever to

P or N.o-3v

position switch switch

:

ONSet the selector lever to D, 2, L or R.8- 14V

Vehicle speed

l Ignition switch: ON

sensor l Slowly run the vehicle forwardkeFaF:hevariation.)

Power steering

pressure switch

;;ir;z;ditioning

Engine:Steering wheel idle state

Idling opera-

tion after

warming-up During steering wheel operation

Engrne:Turn OFF the air conditioning switch.

Idling

Turn ON the air conditioning switch.(The air conditioning compressor is in

the drive state.)

B+

o-3v

o-3v

B+

35

1

51

52

50

51

54

Air conditioning

compressor

clutch relay

Oxygen sensor

No.

1 Injector

No. 2 Injector

No. 3 Injector

No. 4 Injector Ignition power

transistor unit l Engine: Idling

B+ or

l Air conditioning switch: OFF-ON temporarily

(The air conditioning compressor is in the 6V or

higher

drive state.)o’- 3v

Engine: Keep the engine speed at 2,000 rpm

after warming up. kQatot8h2:

(For checking, use a digital voltmeter.) variation.)

Engine: After warming up, rapidly press the

Voltage

accelerator pedal from the idling state. temporarily

drops slightly

from

14V to1 IV.

Engine speed: 3.000 rpm0.3- 3v

Evaporative

emission purge

solenoid ignition switch: ON

Keep the engine speed at 3,000 rpm after the

warmed-up engine is started.B+

o-3v

12Ignition timing

adjustment terminal

ignition

Ground the ignition timing adjustment o- 1vswitch:

terminal.ONRelease the ground of the ignition4.0- 5.W timing

adjustment terminal.

TSB Revision

Page 250 of 1273

13-108 FUEL SYSTEM

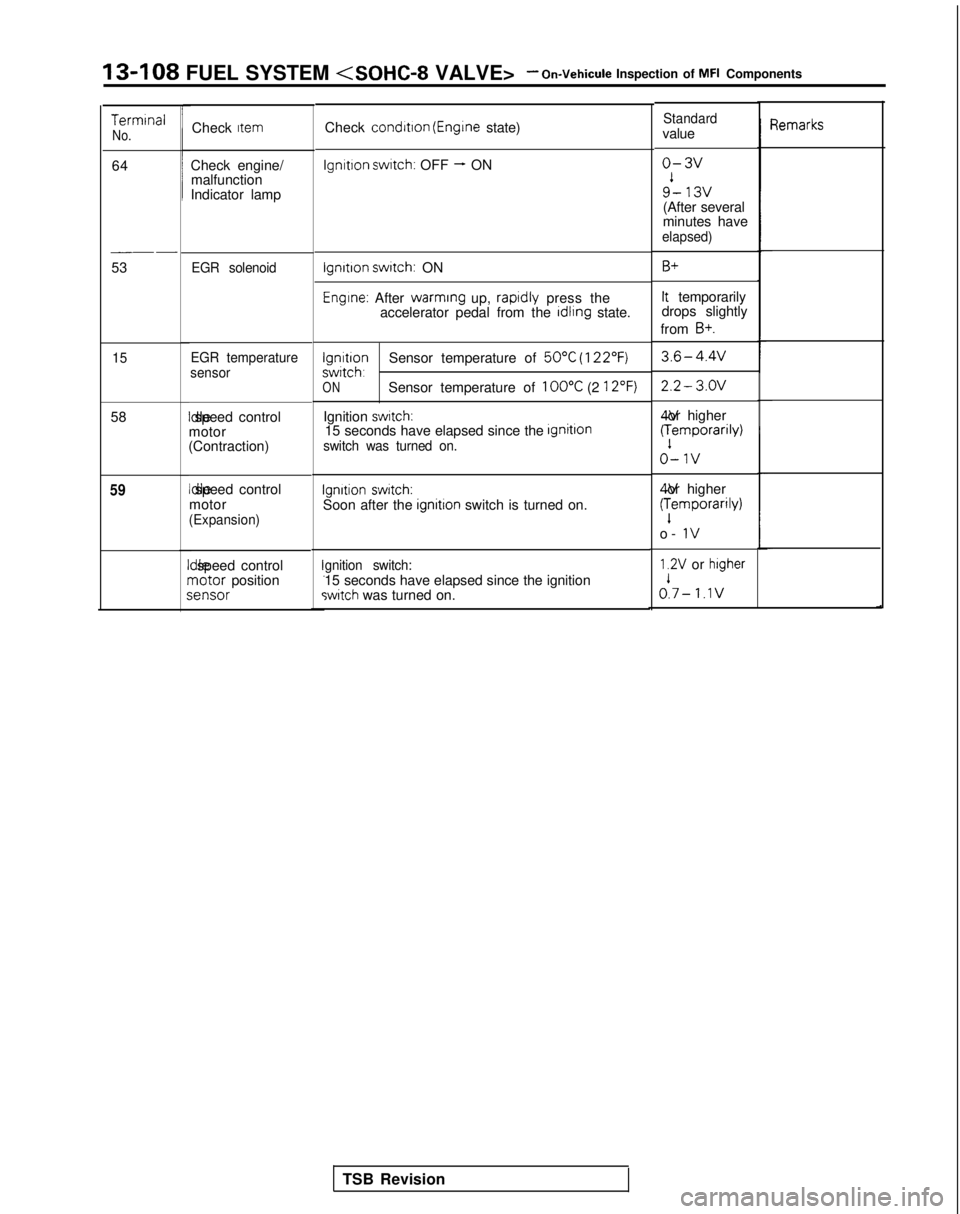

TermrnalNo.

64

__-

53

15

58

59

Check Item

Check engine/

malfunction

Indicator lamp

EGR solenoid

EGR temperature

sensor Idle speed control

motor

(Contraction) Idle speed control

motor

(Expansion)

II

dle speed controlrnotor positions

;ensor

Check

condrtron (Engrne state)

lgnrtron swatch: OFF - ON

lgnrtron swatch: ON

Engine: After warming

up, raprdly press the

accelerator pedal from the rdlrng state.

lgnrtronSensor temperature of 50°C (122°F)swrtch,ONSensor temperature of 100°C (2 12°F)

Ignition swatch:15 seconds have elapsed since the IgnitlOnswitch was turned on.

Ignition switch:Soon after the ignitron switch is turned on.

gnition switch:15 seconds have elapsed since the ignitionswitch was turned on.

Standardvalue

o-3v

9’- 13v(After several

minutes have

elapsed)

B+

It temporarily

drops slightly

from

B+.

3.6-4.4v

2.2- 3.OV 4V or higher

(:emporarily)

o-1v

4V or higher

(:emporarily)

o-

IV

1.2V or higher

A- 1.1v

qemarks

TSB Revision

Page 261 of 1273

Specifications/Special Tools/FUEL SYSTEM

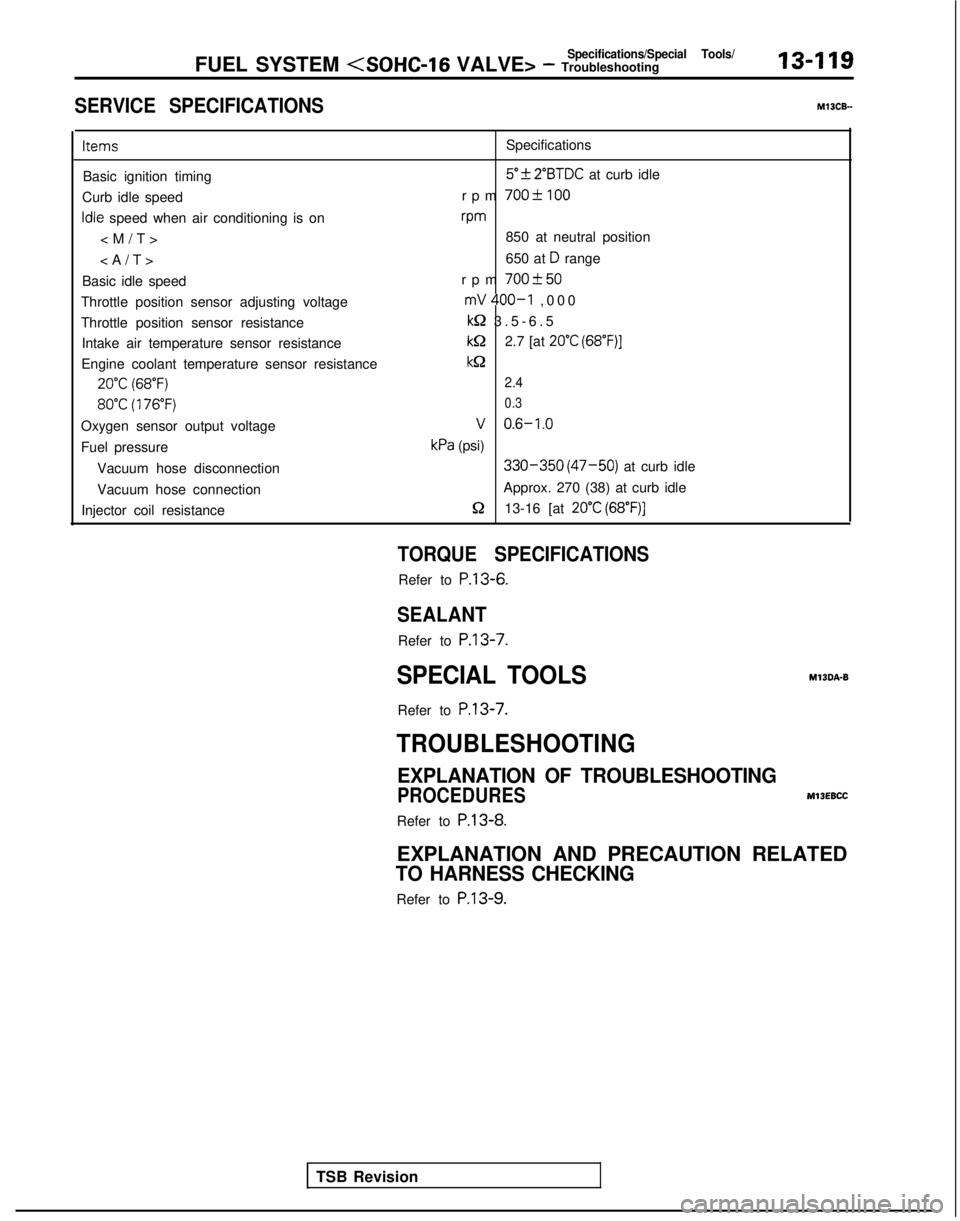

SERVICE SPECIFICATIONS

13-119 MlOCB-

Items

Specifications

Basic ignition timing

5”f 2”BTDC at curb idle

Curb idle speed rpm

700-C 100

Idle speed when air conditioning is onvm

850 at neutral position

650 at

D range

Basic idle speed rpm

700+50

Throttle position sensor adjusting voltagemV 400-I ,00

0

Throttle position sensor resistance

kQ 3.5-6.

5

Intake air temperature sensor resistance

kQ2.7 [at 20°C (68”F)]

Engine coolant temperature sensor resistancekQ

20°C (68°F)2.4

80°C (176°F) 0.3

Oxygen sensor output voltageV 0.6-1.0

Fuel pressurekPa (psi)

Vacuum hose disconnection

330-350 (47-50) at curb idle

Vacuum hose connection Approx. 270 (38) at curb idle

Injector coil resistance

5213-16 [at 20°C (68”F)]

TSB Revision

TORQUE SPECIFICATIONS

Refer to P.13-6.

SEALANT

Refer to

P.13-7.

SPECIAL TOOLS

Refer to

P.13-7.

MlBDA-B

TROUBLESHOOTING

EXPLANATION OF TROUBLESHOOTING

PROCEDURES

MllEBCC

Refer to P.13-8.

EXPLANATION AND PRECAUTION RELATED

TO HARNESS CHECKING

Refer to P.13-9.

Page 262 of 1273

13-120FUEL SYSTEM

CHH;K

ENGINE/MALFUNCTION INDICATOR

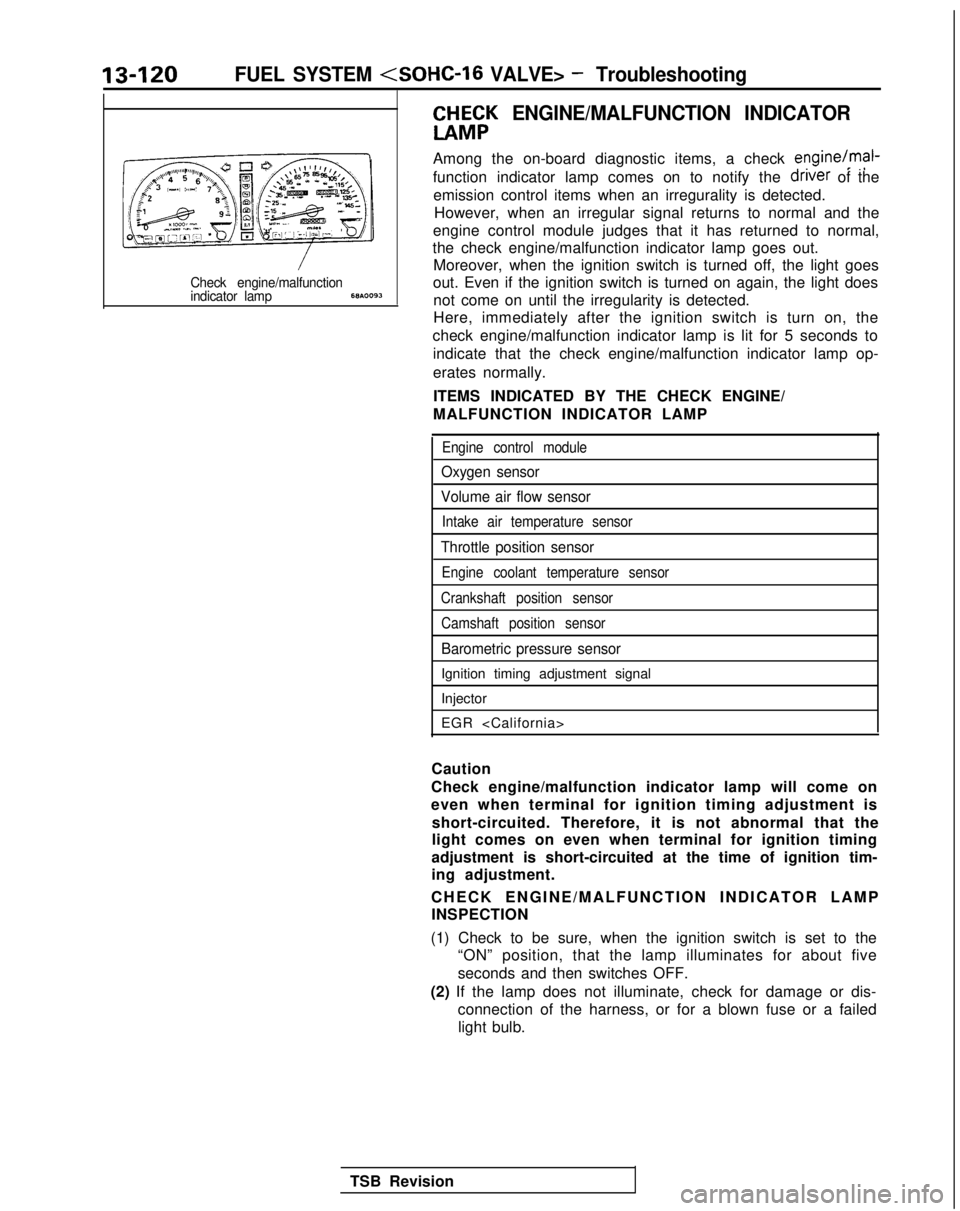

Among the on-board diagnostic items, a check engine/mal-

function indicator lamp comes on to notify the driver

of the

emission control items when an irregurality is detected. However, when an irregular signal returns to normal and the

engine control module judges that it has returned to normal,

the check engine/malfunction indicator lamp goes out. Moreover, when the ignition switch is turned off, the light goes

Check engine/malfunctionout. Even if the ignition switch is turned on again, the light doesindicator lamp68A.0093not come on until the irregularity is detected.

Here, immediately after the ignition switch is turn on, the

check engine/malfunction indicator lamp is lit for 5 seconds to indicate that the check engine/malfunction indicator lamp op-

erates normally.

ITEMS INDICATED BY THE CHECK ENGINE/

MALFUNCTION INDICATOR LAMP

Engine control module

Oxygen sensor

Volume air flow sensor

Intake air temperature sensor

Throttle position sensor

Engine coolant temperature sensor

Crankshaft position sensor Camshaft position sensor

Barometric pressure sensor

Ignition timing adjustment signal

Injector

EGR

Caution

Check engine/malfunction indicator lamp will come on

even when terminal for ignition timing adjustment is short-circuited. Therefore, it is not abnormal that the

light comes on even when terminal for ignition timing

adjustment is short-circuited at the time of ignition tim-

ing adjustment.

CHECK ENGINE/MALFUNCTION INDICATOR LAM

P

INSPECTION

(1) Check to be sure, when the ignition switch is set to the “ON” position, that the lamp illuminates for about five

seconds and then switches OFF.

(2) If the lamp does not illuminate, check for damage or dis- connection of the harness, or for a blown fuse or a failedlight bulb.

TSB Revision

Page 263 of 1273

FUEL SYSTEM

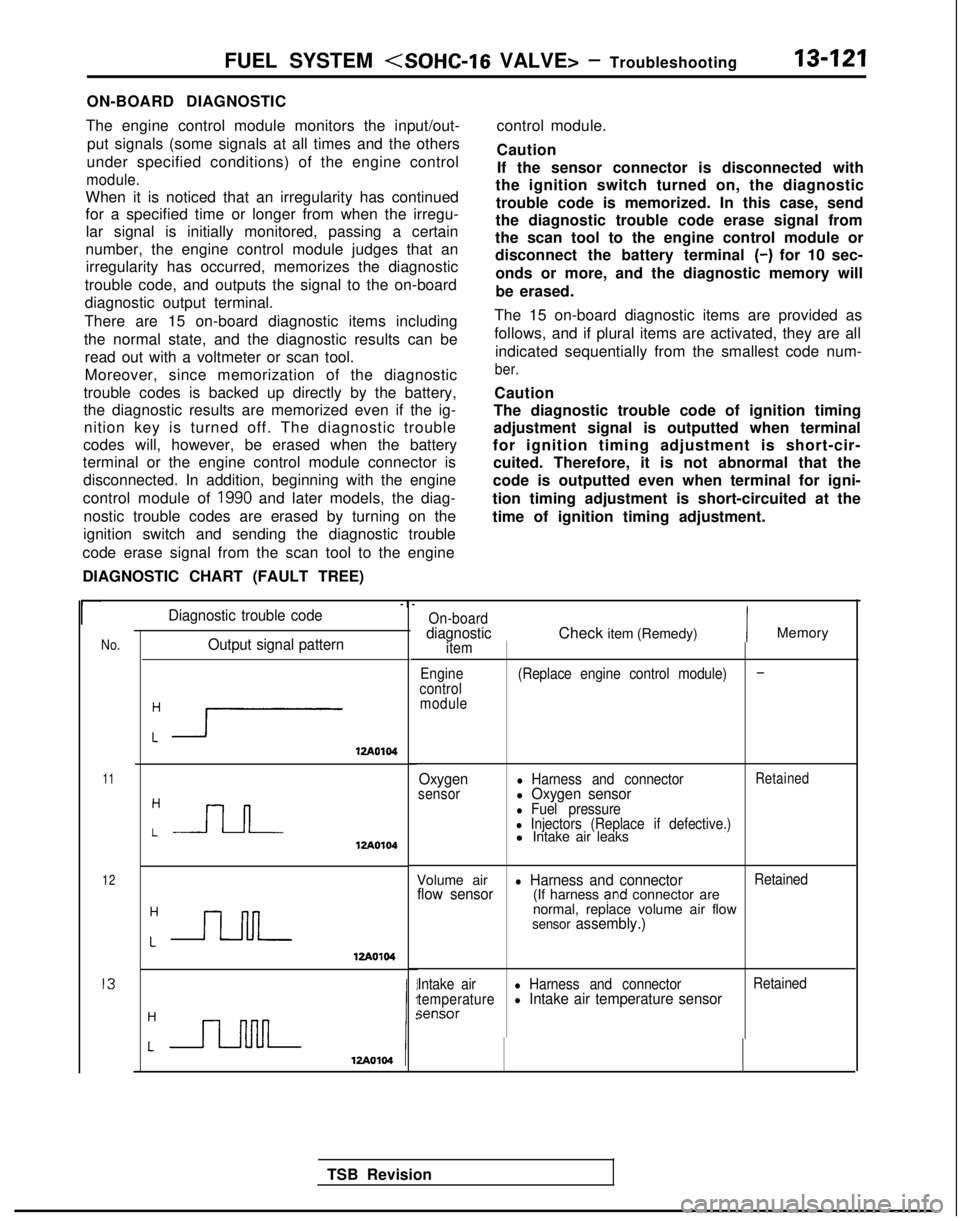

ON-BOARD DIAGNOSTIC

The engine control module monitors the input/out- put signals (some signals at all times and the others

under specified conditions) of the engine control

module.

When it is noticed that an irregularity has continued

for a specified time or longer from when the irregu- lar signal is initially monitored, passing a certain

number, the engine control module judges that an irregularity has occurred, memorizes the diagnostic

trouble code, and outputs the signal to the on-board

diagnostic output terminal.

There are 15 on-board diagnostic items including

the normal state, and the diagnostic results can be read out with a voltmeter or scan tool.

Moreover, since memorization of the diagnostic

trouble codes is backed up directly by the battery,

the diagnostic results are memorized even if the ig- nition key is turned off. The diagnostic trouble

codes will, however, be erased when the battery

terminal or the engine control module connector is

disconnected. In addition, beginning with the engine

control module of

1990 and later models, the diag-

nostic trouble codes are erased by turning on the

ignition switch and sending the diagnostic trouble

code erase signal from the scan tool to the engine

DIAGNOSTIC CHART (FAULT TREE) control module.

Caution

If the sensor connector is disconnected with

the ignition switch turned on, the diagnostic

trouble code is memorized. In this case, send

the diagnostic trouble code erase signal from

the scan tool to the engine control module or

disconnect the battery terminal

(-) for 10 sec-

onds or more, and the diagnostic memory will

be erased.

The 15 on-board diagnostic items are provided as

follows, and if plural items are activated, they are all indicated sequentially from the smallest code num-

ber.

Caution

The diagnostic trouble code of ignition timing

adjustment signal is outputted when terminal

for ignition timing adjustment is short-cir- cuited. Therefore, it is not abnormal that the

code is outputted even when terminal for igni-

tion timing adjustment is short-circuited at the

time of ignition timing adjustment.

r

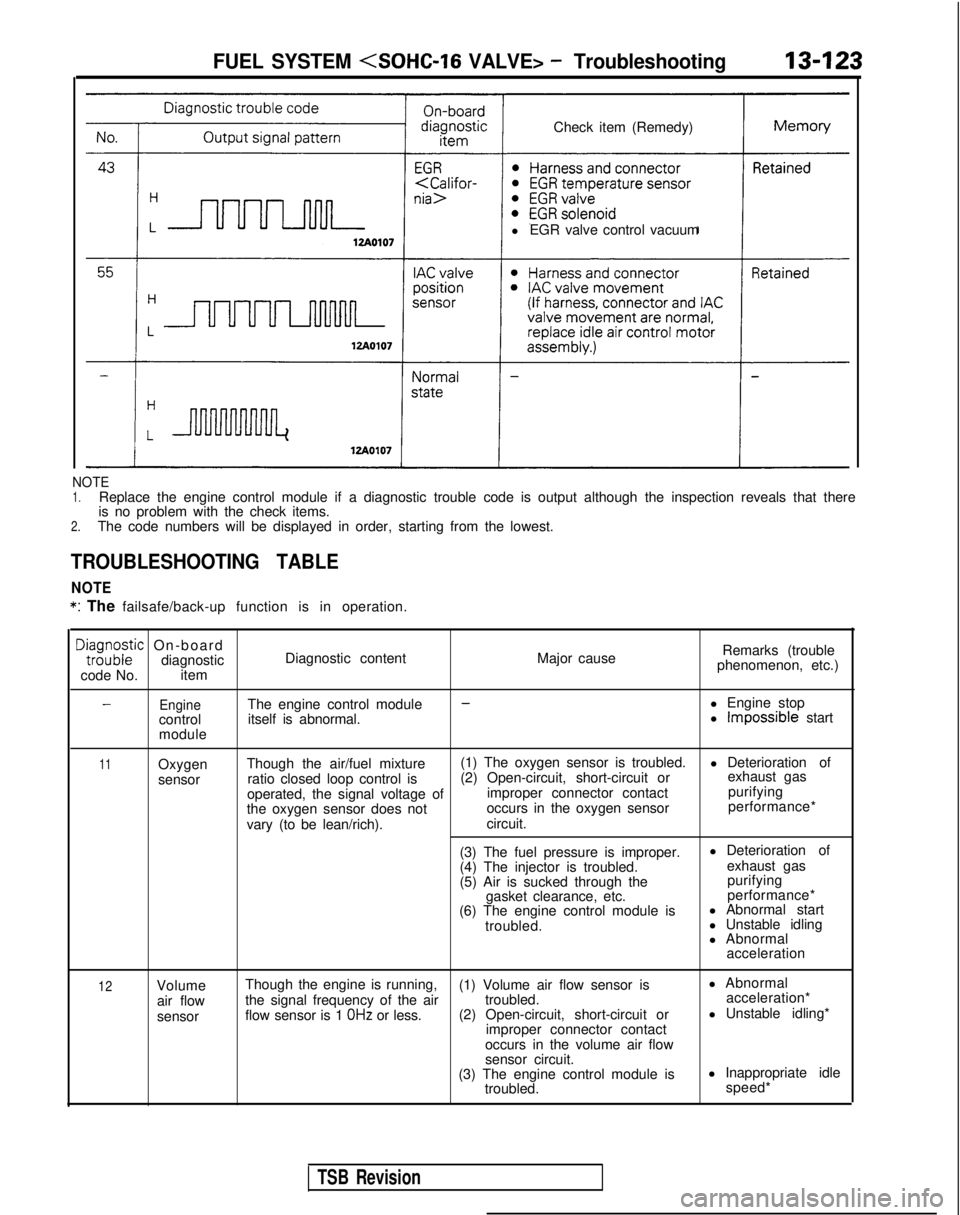

No.Output signal pattern

:i1zA0104

11

12

I3

:-J-l-J-12Ao104

Diagnostic trouble code-I

-

On-boarddiagnosticitem

Engine

control moduleCheck item (Remedy)IMemory

(Replace engine control module)-

Oxygensensorl Harness and connectorRetainedl Oxygen sensorl Fuel pressurel Injectors (Replace if defective.)l Intake air leaks

Volume air

l Harness and connectorRetainedflow sensor(If harness and connector are

normal, replace volume air flow

sensor assembly.)

Intake airl Harness and connector Retained

temperaturel Intake air temperature sensorsensor

TSB Revision

Page 264 of 1273

13-122FUEL SYSTEM

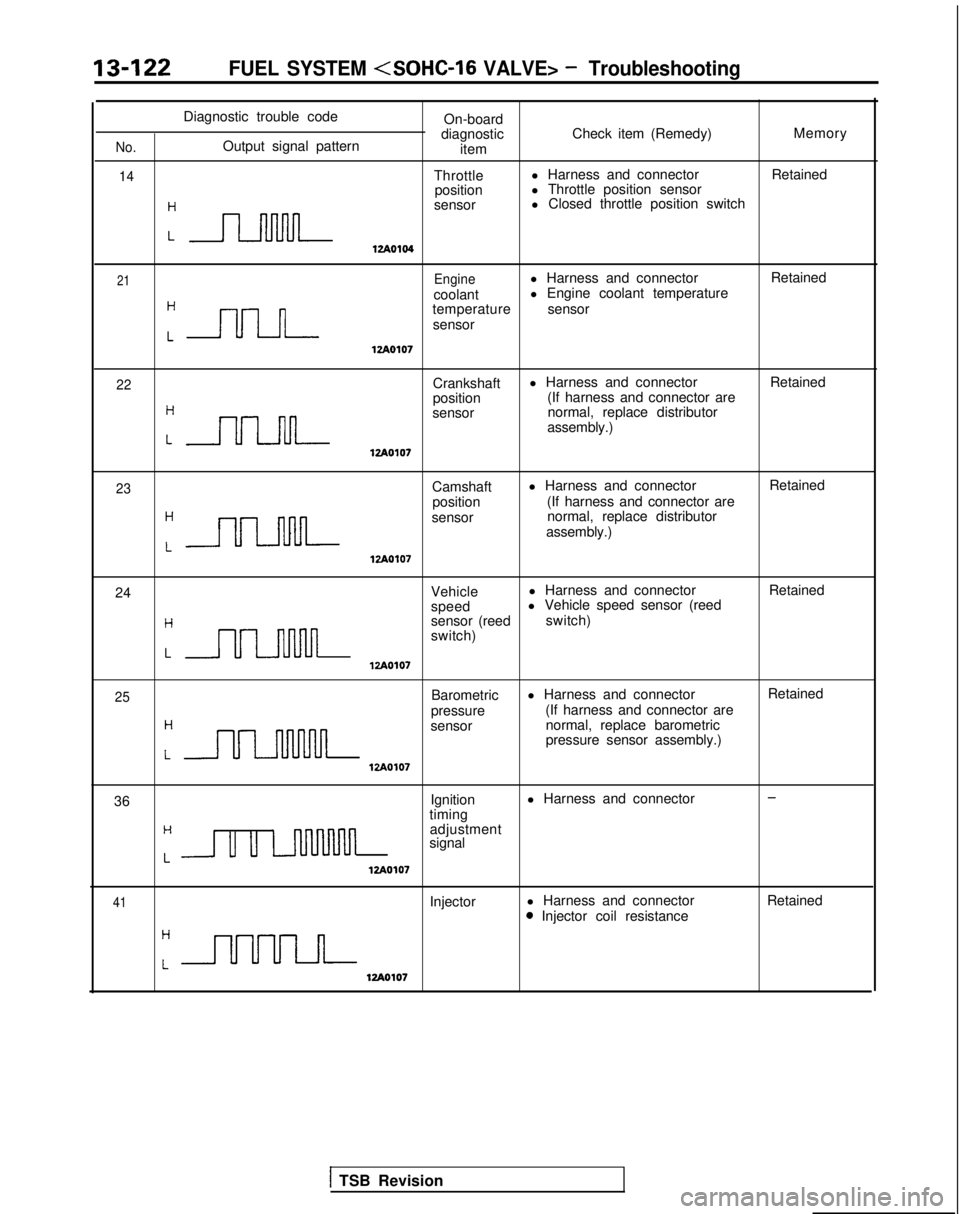

Diagnostic trouble codeOn-board

diagnostic Check item (Remedy) Memory

No.Output signal pattern

item

14Throttlel Harness and connector

Retained

position l Throttle position sensor

:n

sensor l Closed throttle position switch

12Ao104

21Enginel Harness and connector

Retained

coolant l Engine coolant temperature

Cnn

temperature

sensor

sensor

lzAO107

22Crankshaft l Harness and connector

Retained

position (If harness and connector are

:nn

sensor normal, replace distributor

assembly.)

lzAOlO7

23Camshaft l Harness and connector

Retained

position (If harness and connector are

:-

sensor normal, replace distributor

assembly.)

12Ao107

24 Vehiclel Harness and connector

Retained

speed l Vehicle speed sensor (reed

Hsensor (reed

switch)

switch)

LULl-uulnlzAO107

25

H

Barometric

pressure l Harness and connector

(If harness and connector are

LULMlvul

sensor normal, replace barometric

pressure sensor assembly.)

VA0107

Retained

36 Ignition

l Harness and connector

-

timingH

Lu u LnllMnn

adjustment

signal

12Ao107

41Injector l Harness and connector0 Injector coil resistance Retained

12Ao107

1 TSB Revision

Page 265 of 1273

Check item (Remedy)

l EGR valve control vacuumFUEL SYSTEM

NOTE1.Replace the engine control module if a diagnostic trouble code is output\

although the inspection reveals that there

is no problem with the check items.

2.The code numbers will be displayed in order, starting from the lowest.

TROUBLESHOOTING TABLE

NOTE *:

The failsafe/back-up function is in operation.

DE;;;zic On-board

diagnostic

code No. item Diagnostic content

Major causeRemarks (trouble

phenomenon, etc.)

EngineThe engine control module--l Engine stop

control itself is abnormal. l Impossible start

module

11Oxygen

sensor Though the air/fuel mixture

(1) The oxygen sensor is troubled.

l Deterioration of

ratio closed loop control is (2) Open-circuit, short-circuit or exhaust gas

operated, the signal voltage of improper connector contact purifying

the oxygen sensor does not occurs in the oxygen sensor performance*

vary (to be lean/rich). circuit.

(3) The fuel pressure is improper. l Deterioration of

(4) The injector is troubled. exhaust gas

(5) Air is sucked through the purifying

gasket clearance, etc. performance*

(6) The engine control module is l Abnormal start

troubled. l Unstable idling

l Abnormal

acceleration

12Volume

air flow

sensor Though the engine is running,

(1) Volume air flow sensor is l Abnormal

the signal frequency of the air troubled. acceleration*

flow sensor is 1

OHz or less. (2) Open-circuit, short-circuit or l Unstable idling*

improper connector contact

occurs in the volume air flow

sensor circuit.

(3) The engine control module is l Inappropriate idle

troubled. speed*

TSB Revision

Page 269 of 1273

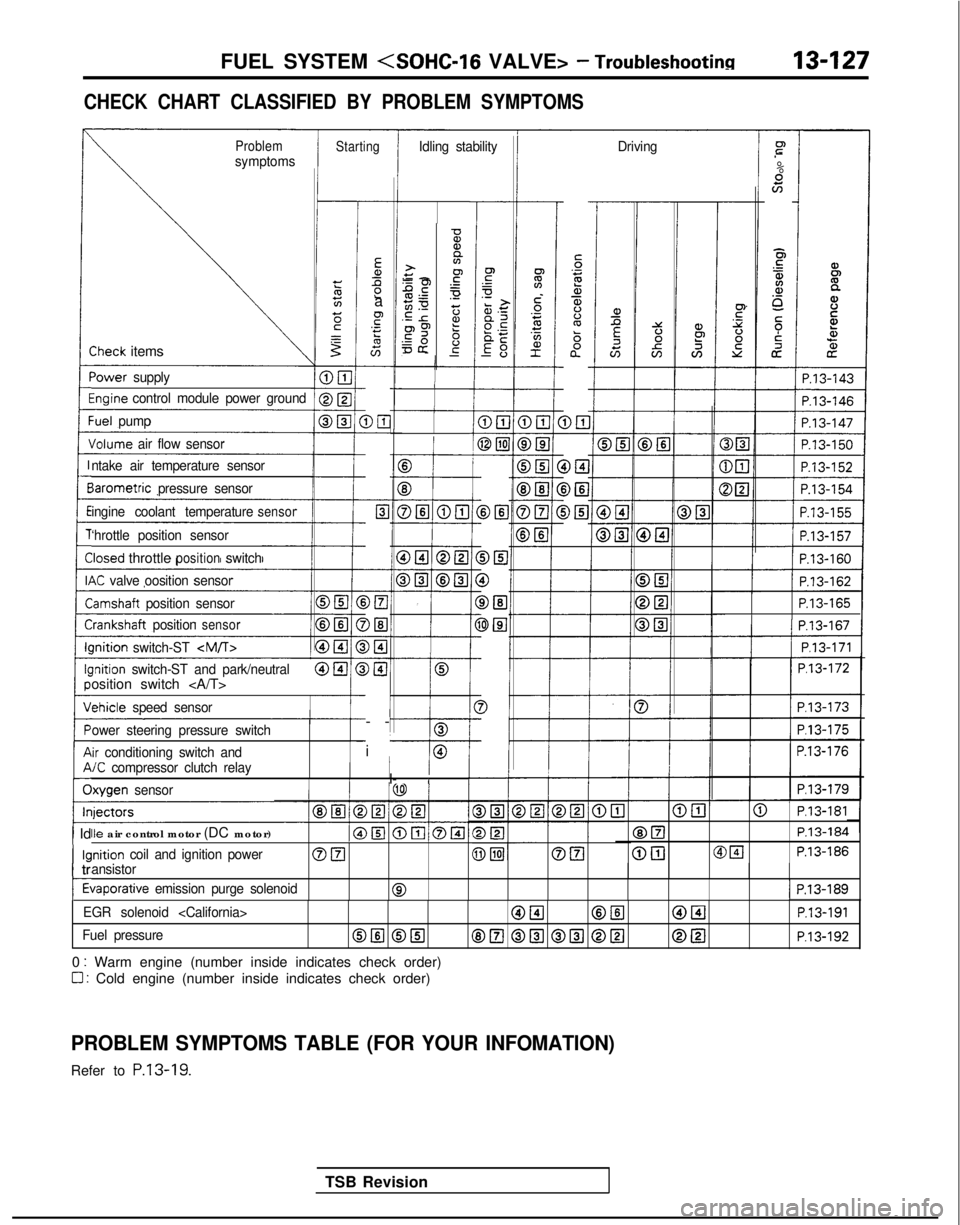

FUEL SYSTEM

CHECK CHART CLASSIFIED BY PROBLEM SYMPTOMS

ProblemsymptomsStartingIdling stability Drivingr”

.-

%scn

E5

$4.a,o_

5;i

cz

iP.13-143

-

Ea,Ll2a

F.- s

G-

DE-

c-

Elc

-

-

>El

)El-

)I3-

)@I

I-

-

i

-

5‘32a,$%ba”

D&l DEI

i>El

-0%,a>+y -2.gPE.-50 z.E r2?p9 6=& g-

-

-Sheck items

‘ower

supply

%ginecontrol module power groundI

1 P.13-146

:uel pump

Jolume air flow sensor

B

f

E3

DELI @El

cP.13-162

P.13-165III P.13-167I

1/ P.l3-171 1

P.l3-172

P.l3-173

P.l3-175

P.13-176

P.l3-179

ntake air temperature sensor

BIB

DEI

0

DEl

3El

3

-I

iarometric

pressure sensor

ingine coolant temperature

sensor

‘hrottle position sensor

Iosed throttlepositionswitch

K valve oosition sensor

lamshaft position sensor

i-:rankshaft positionsensorIIlnition

switch-ST

-I---0lnition switch-ST and park/neutralosition switch

chicle

speed sensor

ower steering pressure switch

ir conditioning switch and/C compressor clutch relayI/I- IIlxygen sensor

@El@ P.l3-181

@ElP.13-184

@[email protected]

Ile air control motor (DC motor)

inition coil and ignition powerOFI@piJOEIansistor

tiaporative emission purge solenoid01 P.13-189

1 Id

kl

c

tr

t

EGR solenoid

Fuel pressureOIlI @El8E.l @El @El @[email protected]

0 : Warm engine (number inside indicates check order)

0 : Cold engine (number inside indicates check order)

PROBLEM SYMPTOMS TABLE (FOR YOUR INFOMATION)

Refer to P.13-19.

TSB Revision