check engine MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 275 of 1273

FUEL SYSTEM

FUEL TANK AND FUEL LINEMIBEAAB

Symptom

Probable cause Remedy

Engine malfunctions

due to insufficient

fuel supply Bent or kinked fuel pipe or hose

Clogged fuel pipe or hose

Clogged fuel filter or in-tank fuel filter

Water in fuel filter Repair or replace

Clean or replace

Replace

Replace the fuel filter or clean the

fuel tank and fuel line

Dirty or rusted fuel tank interior

Clean or replace

Malfunctioning fuel pump

(Clogged filter in the pump)Replace

Evaporative emission

control system

malfunctions

[When fuel tank filler

tube cap is removed,

pressure releasingnoise is heard) Mispiping of vapor line

Disconnected vapor line piping joint

Folded, bent, cracked or clogged vapor line

Faulty fuel tank filler tube cap

Malfunctioning fuel tank pressure control valve Correct

Correct

Replace

Replace

Replace

SERVICE ADJUSTMENT

PROCEDURES

CURB IDLE SPEED INSPECTIONhll3MAE

(1) The vehicle should be prepared as follows before th

e

inspection.

lEngine coolant temperature: 85-95°C (185-203°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: Neutral (P for vehicles with an automatic

transaxle)

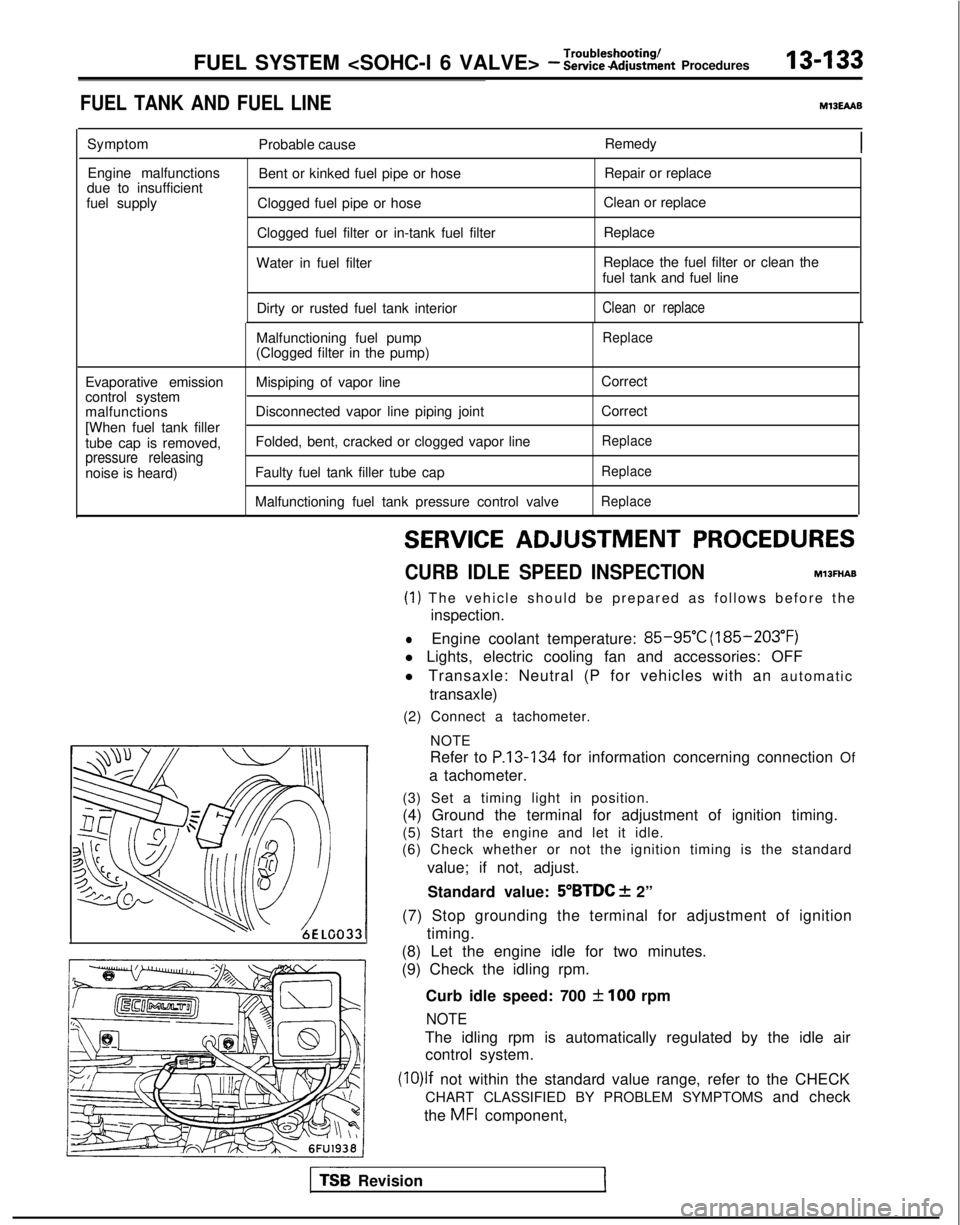

(2) Connect a tachometer.

NOTE

Refer to

P.13-134 for information concerning connection Of

a tachometer.

(3) Set a timing light in position.

(4) Ground the terminal for adjustment of ignition timing.

(5) Start the engine and let it idle.

(6) Check whether or not the ignition timing is the standard

value; if not, adjust.

Standard value:

5”BTDC f 2”

(7) Stop grounding the terminal for adjustment of ignition timing.

(8) Let the engine idle for two minutes.

(9) Check the idling rpm.

Curb idle speed: 700

31100 rpm

NOTE

The idling rpm is automatically regulated by the idle aircontrol system.

(lO)lf not within the standard value range, refer to the CHECK

CHART CLASSIFIED BY PROBLEM SYMPTOMS and check

the

MFI component,

TS6 Revision1

Page 277 of 1273

FUEL SYSTEM

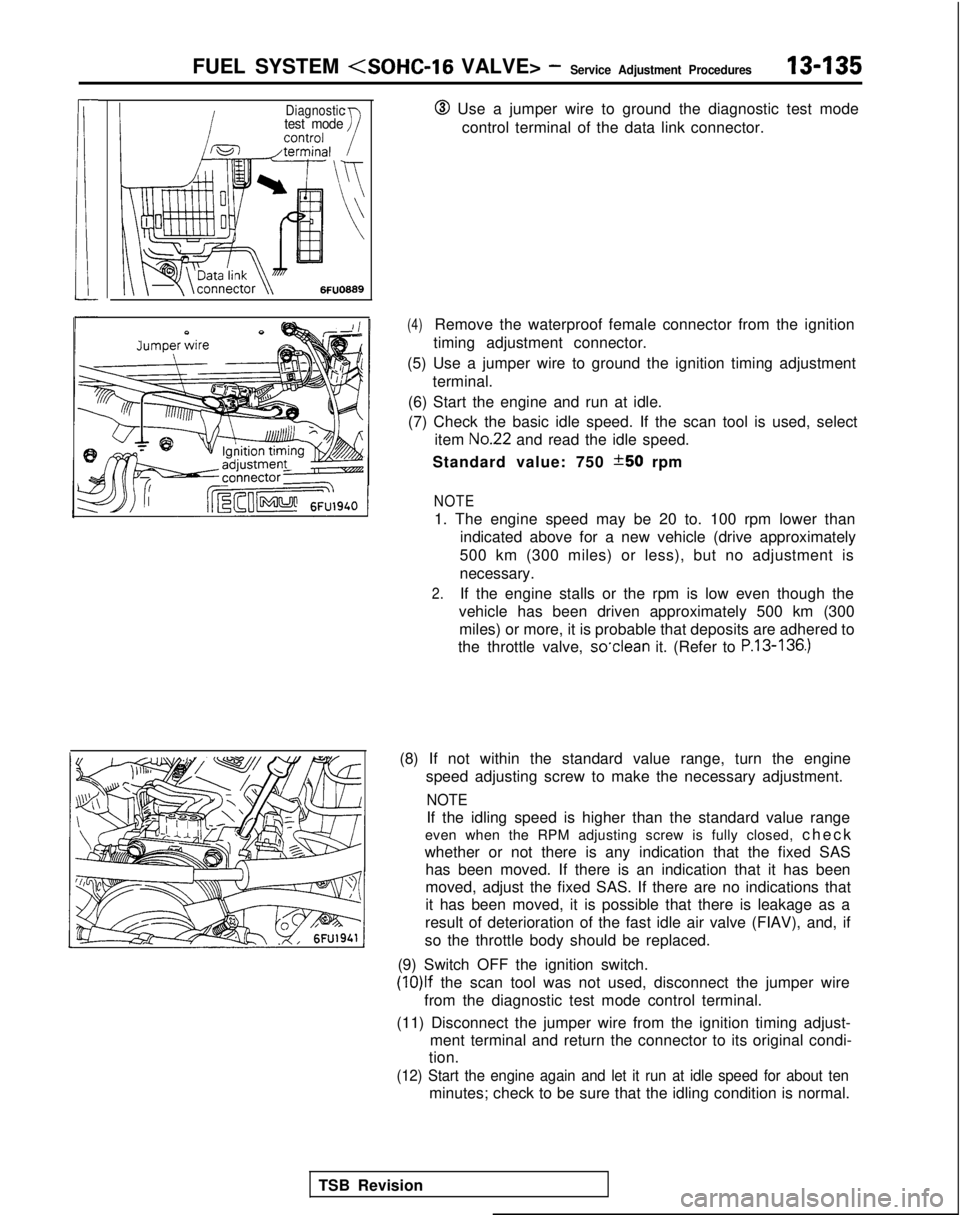

Diagnostictest mode@ Use a jumper wire to ground the diagnostic test mode

control terminal of the data link connector.

TSB Revision

(4)Remove the waterproof female connector from the ignition

timing adjustment connector.

(5) Use a jumper wire to ground the ignition timing adjustment terminal.

(6) Start the engine and run at idle.

(7) Check the basic idle speed. If the scan tool is used, select item

No.22 and read the idle speed.

Standard value: 750

*50 rpm

NOTE

1. The engine speed may be 20 to. 100 rpm lower than indicated above for a new vehicle (drive approximately

500 km (300 miles) or less), but no adjustment is

necessary.

2.If the engine stalls or the rpm is low even though the

vehicle has been driven approximately 500 km (300 miles) or more, it is probable that deposits are adhered to

the throttle valve, so’clean

it. (Refer to

P.13-136.)

(8) If not within the standard value range, turn the engine

speed adjusting screw to make the necessary adjustment.

NOTE

If the idling speed is higher than the standard value range

even when the RPM adjusting screw is fully closed, chec

k

whether or not there is any indication that the fixed SAS has been moved. If there is an indication that it has been

moved, adjust the fixed SAS. If there are no indications that

it has been moved, it is possible that there is leakage as a

result of deterioration of the fast idle air valve (FIAV), and, if

so the throttle body should be replaced.

(9) Switch OFF the ignition switch. (lO)lf

the scan tool was not used, disconnect the jumper wire

from the diagnostic test mode control terminal.

(11) Disconnect the jumper wire from the ignition timing adjust- ment terminal and return the connector to its original condi-

tion.

(12) Start the engine again and let it run at idle speed for about ten\

minutes; check to be sure that the idling condition is normal.

Page 279 of 1273

FUEL SYSTEM

I;gFixed SAS

Terminal @Terminal @(sensor output) (sensor ground) /

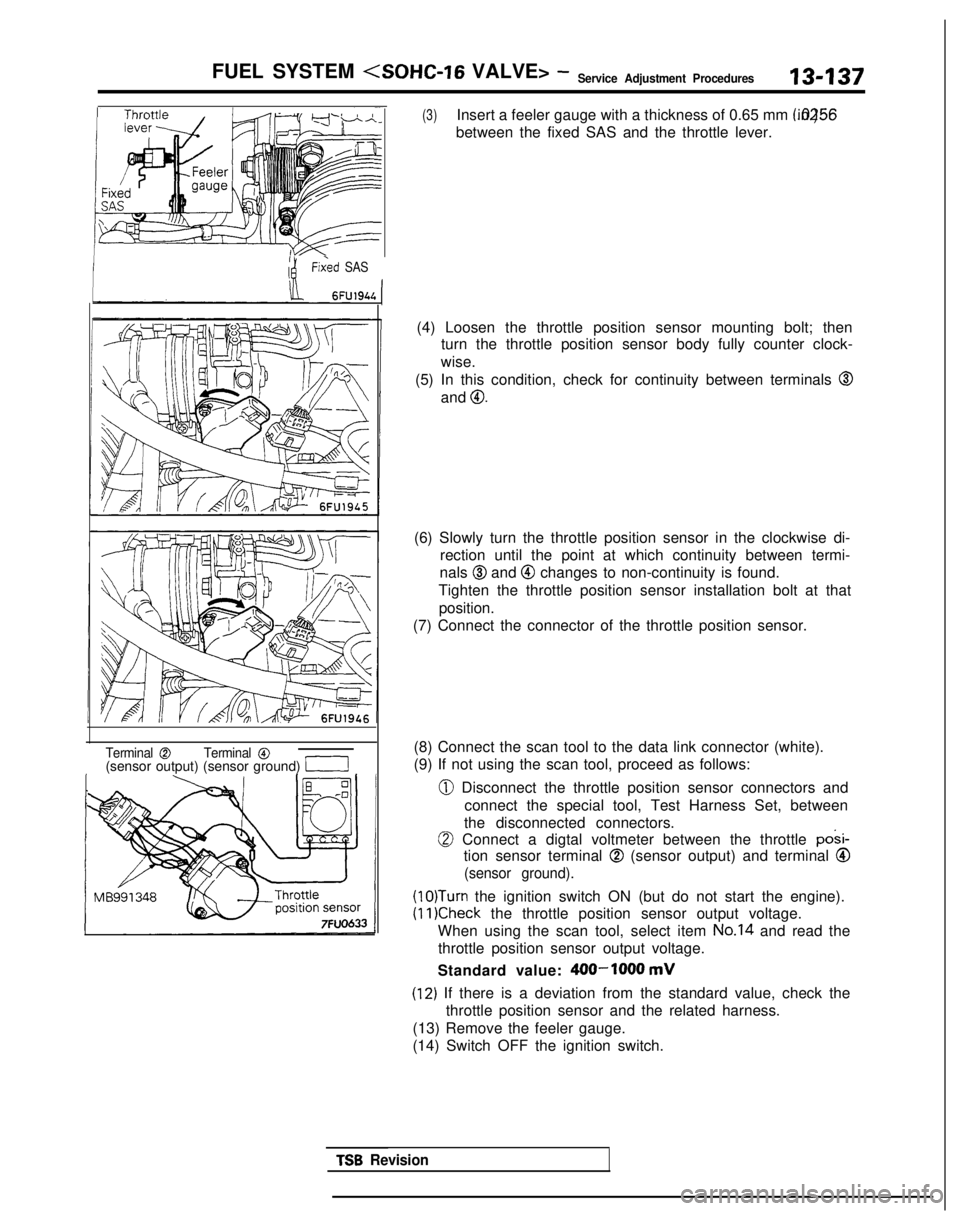

(3)Insert a feeler gauge with a thickness of 0.65 mm (.0256 in.)

between the fixed SAS and the throttle lever.

(4) Loosen the throttle position sensor mounting bolt; then turn the throttle position sensor body fully counter clock-

wise.

(5) In this condition, check for continuity between terminals

@

and 0.

(6) Slowly turn the throttle position sensor in the clockwise di- rection until the point at which continuity between termi-

nals

@I and @ changes to non-continuity is found.

Tighten the throttle position sensor installation bolt at that position.

(7) Connect the connector of the throttle position sensor.

(8) Connect the scan tool to the data link connector (white).

(9) If not using the scan tool, proceed as follows:

0 Disconnect the throttle position sensor connectors and connect the special tool, Test Harness Set, between

the disconnected connectors.

0 Connect a digtal voltmeter between the throttle posi-

tion sensor terminal

@ (sensor output) and terminal Q

(sensor ground).

(lO)Turn the ignition switch ON (but do not start the engine).

(11)Check the throttle position sensor output voltage.

When using the scan tool, select item

No.14 and read the

throttle position sensor output voltage.

Standard value:

400-1000 mV

(12) If there is a deviation from the standard value, check the throttle position sensor and the related harness.

(13) Remove the feeler gauge.

(14) Switch OFF the ignition switch.

TSB Revision

Page 281 of 1273

FUEL SYSTEM

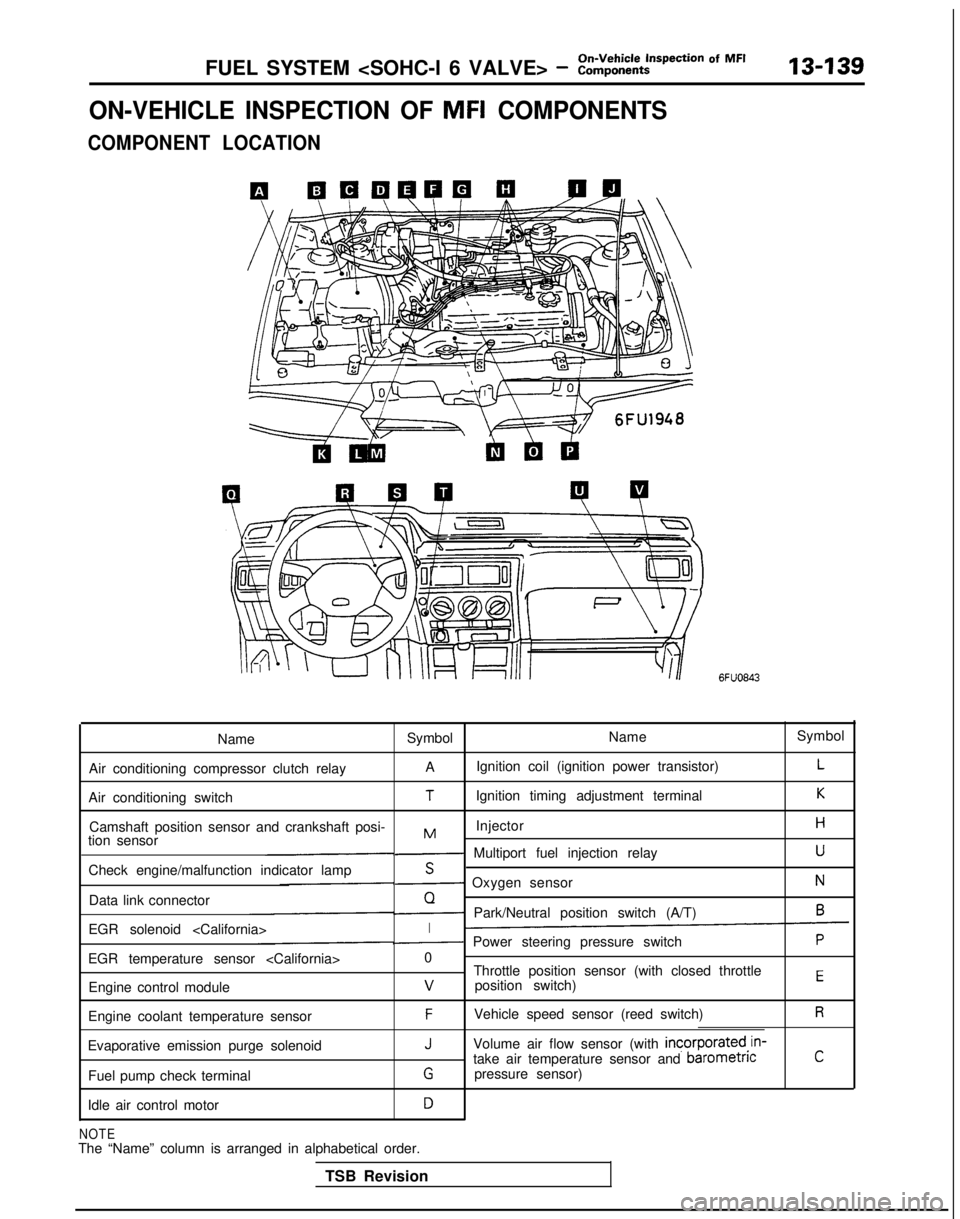

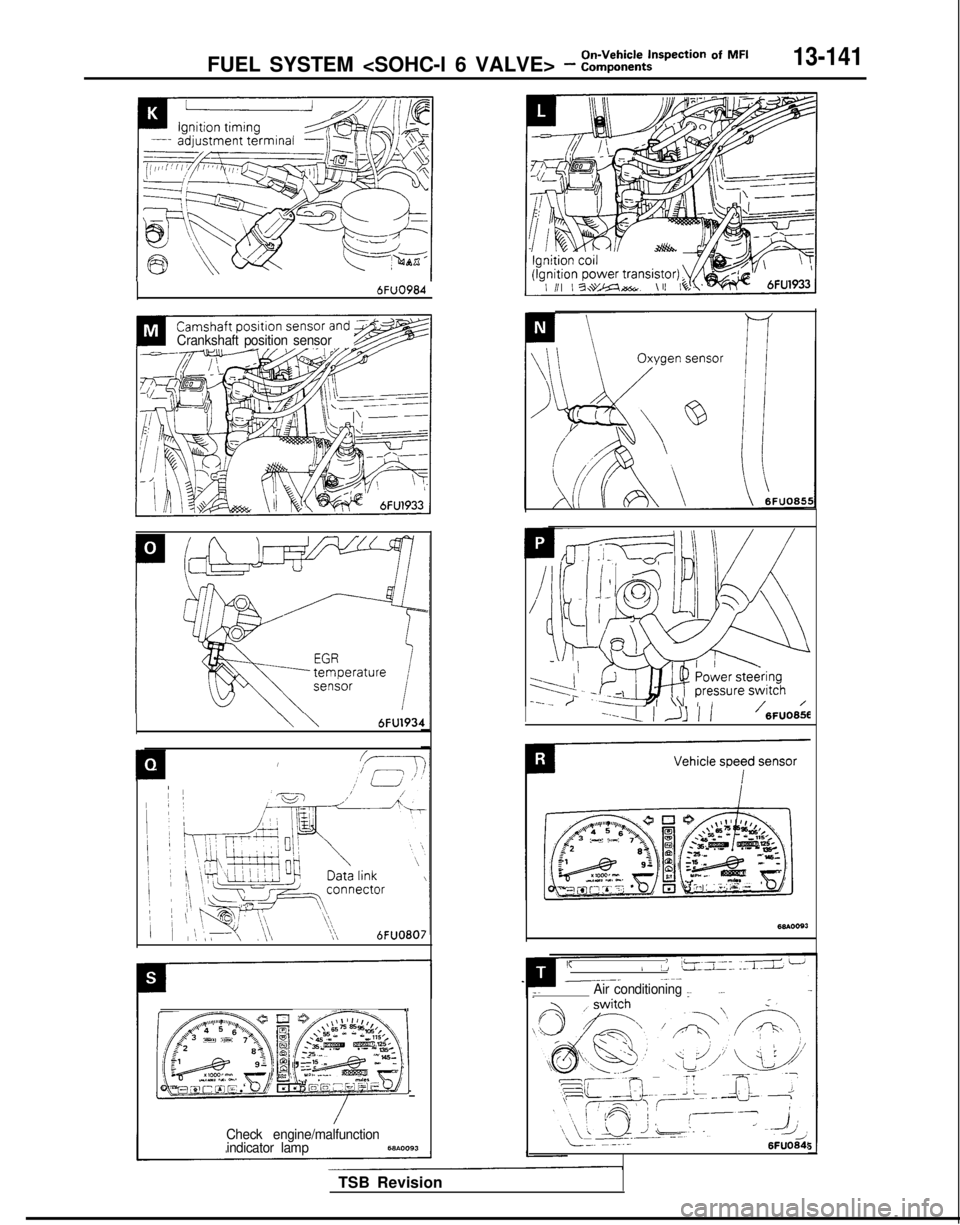

ON-VEHICLE INSPECTION OF MFI COMPONENTS

COMPONENT LOCATION

6FUO843

Name Symbol NameSymbol

Air conditioning compressor clutch relay A

Ignition coil (ignition power transistor)

L

Air conditioning switchTIgnition timing adjustment terminalK

Camshaft position sensor and crankshaft posi- InjectorHMtion sensor- Multiport fuel injection relayU

Check engine/malfunction indicator lampS- Oxygen sensorN

Data link connectorQ- Park/Neutral position switch (A/T)6

EGR solenoid

EGR temperature sensor

Throttle position sensor (with closed throttle

position switch)

EEngine control modulev

Engine coolant temperature sensorFVehicle speed sensor (reed switch)R

Evaporative emission purge solenoidJVolume air flow sensor (with incorporated,in-

take air temperature sensor and barometncC

Fuel pump check terminalGpressure sensor)

Idle air control motor

D

NOTEThe “Name” column is arranged in alphabetical order. TSB Revision

Page 283 of 1273

FUEL SYSTEM

6FuO984

Crankshaft position sensor

\\6FU193~

I(7-T

I;.’ E

,/ii

;

i

; ~&qqLk~

)

’ [,,“\,k@$&b;,,,“\

I’

/ \, pQi, >{,

1; /

‘\l>,

/\\\6FUO8Oi

,<,$+$GgT

z Jp$j&& ‘\

,

“2$---8%\.35 Fqp2; ,I <,, cLTgg.&~.

,D~~,

1sl ) g , a&&iI& I.“: :

(;-omd!gs?~ 5, gt : .“*I-- L l2,, m ‘IFiTb;qF

/Check engine/malfunction

indicator lamp68b.0093

B :iG i 1

,i mIl-

11

’ 0_;

3

(1P

I”;l-i-yCL, ,\i / ,---_ /

’ - ’ +-+j$p2E~~;:c9h

/ /I----4 ) Jj 1 1’ 6FU0656

68mosJ

I(>/

!,ij”_II. .:a L-2__--. ~-~-Air conditioning I~.~ ~..

LT. --..-6FUO64!

TSB Revision

Page 286 of 1273

On-Vehicle Inspection of MFI

13-144FUEL SYSTEM

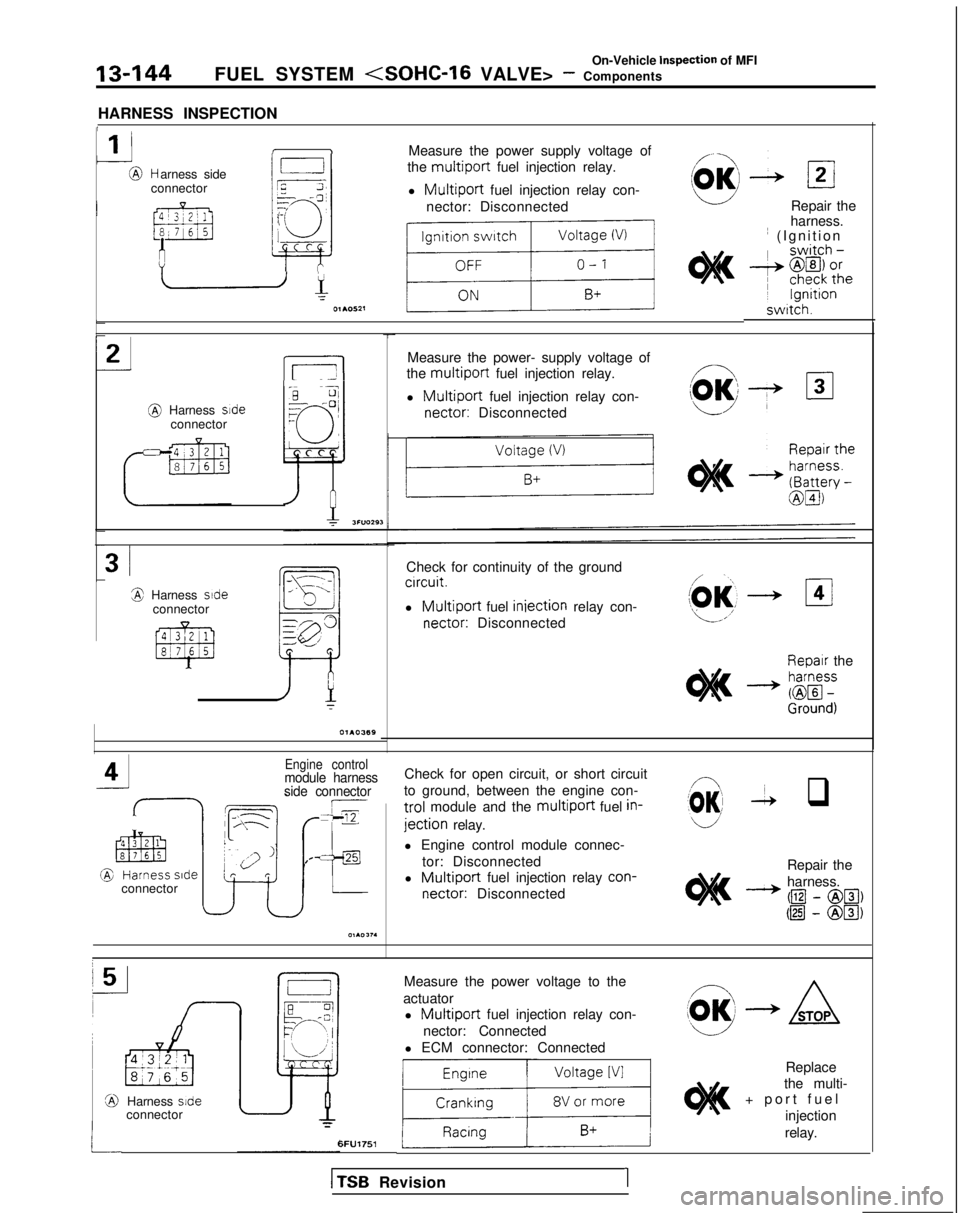

HARNESS INSPECTION

1

1 IMeasure the power supply voltage of

the

multiport fuel injection relay.

l

Multiport fuel injection relay con-

nector: Disconnected

r,

L

NC;Jr=--cl7

I

?-i3I+- c

-@ Harness side

connector

Repair the

harness. ~

(Ignition swrtch.

_J2

L5-l

Measure the power- supply voltage of

the

multiport fuel injection relay.

l

Multiport fuel injection relay con- nectar:

Disconnected @

Harness sdeconnector

3iCheck for continuity of the groundcrrcuit.

l Multiport fuel iniection

relay con- nectar:

Disconnected3 Harness side

connector

Repair theI

M.- zf$

Engine controlmodule harness

side connectorCheck for open circuit, or short circuit

to ground, between the engine con-

trol module and the multiport fuel in-

jection relay.

(03 -2 q

l Engine control module connec-

tor: Disconnected

l

Multiport fuel injection relay con-

nectar:

Disconnected Repair the

harness.

- @I

- @El, @I

- @Ia

connector

Measure the power voltage to the

actuator l

Multiport fuel injection relay con-

nector: Connected

l ECM connector: Connected

1li

Replace

the multi-

+ port fue

l

injection

Harness side

connector

relay.6FU1751

1

TSB

Revision1

Page 288 of 1273

13-146FUEL SYSTEM

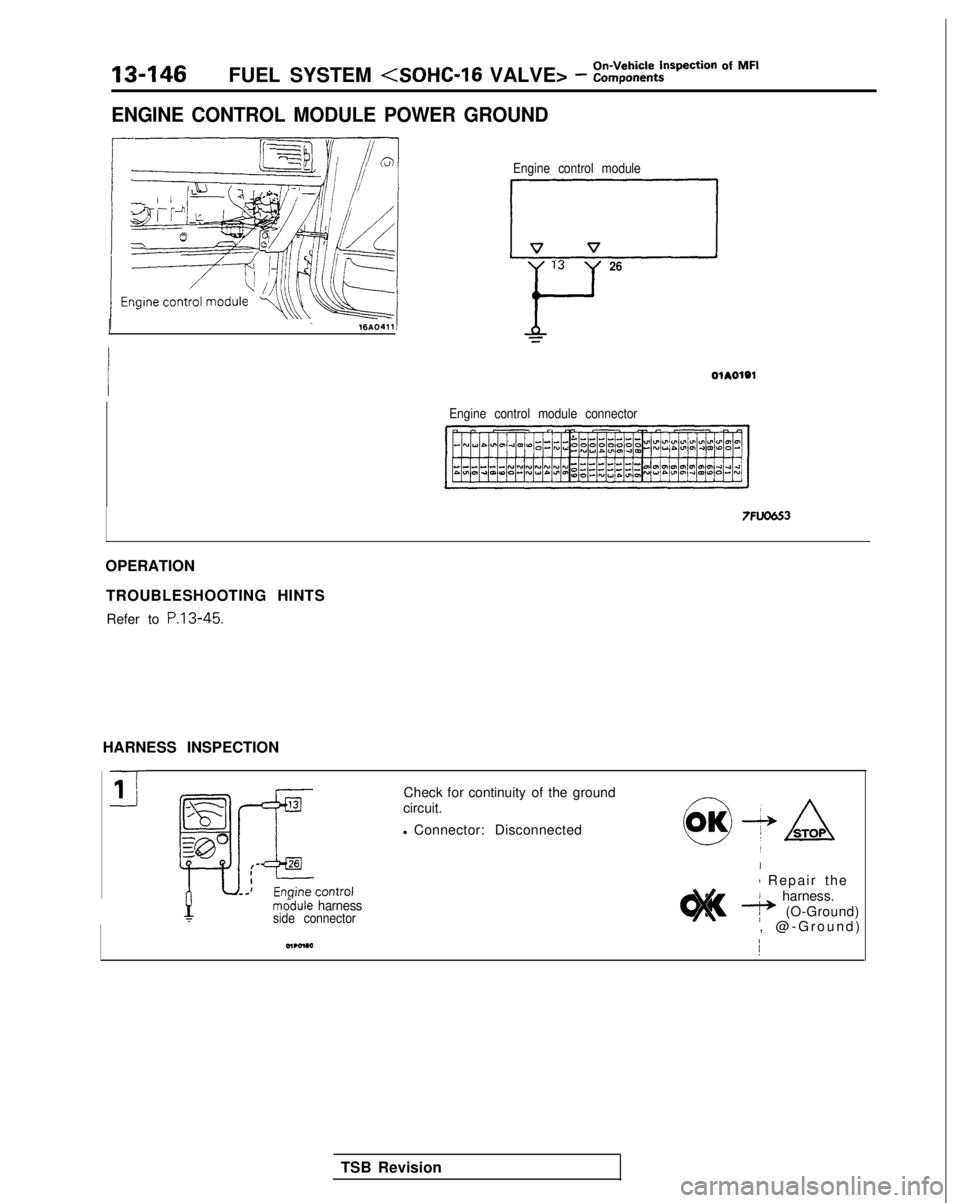

ENGINE CONTROL MODULE POWER GROUND

Engine control module

LIirzl13

Y

26

Engine control module connector

7FU06.53

OPERATION

TROUBLESHOOTING HINTSRefer to P.13-45.

HARNESS INSPECTION

mddule harnessside connector

Check for continuity of the ground

circuit.

l Connector: Disconnected

I

1 Repair th

e

harness.

e (O-Ground)

, @-Ground

)

TSB Revision

Page 290 of 1273

On-Vehicle Inspection of MFI

13-148FUEL SYSTEM (SOHC-16 VALVE> - Components

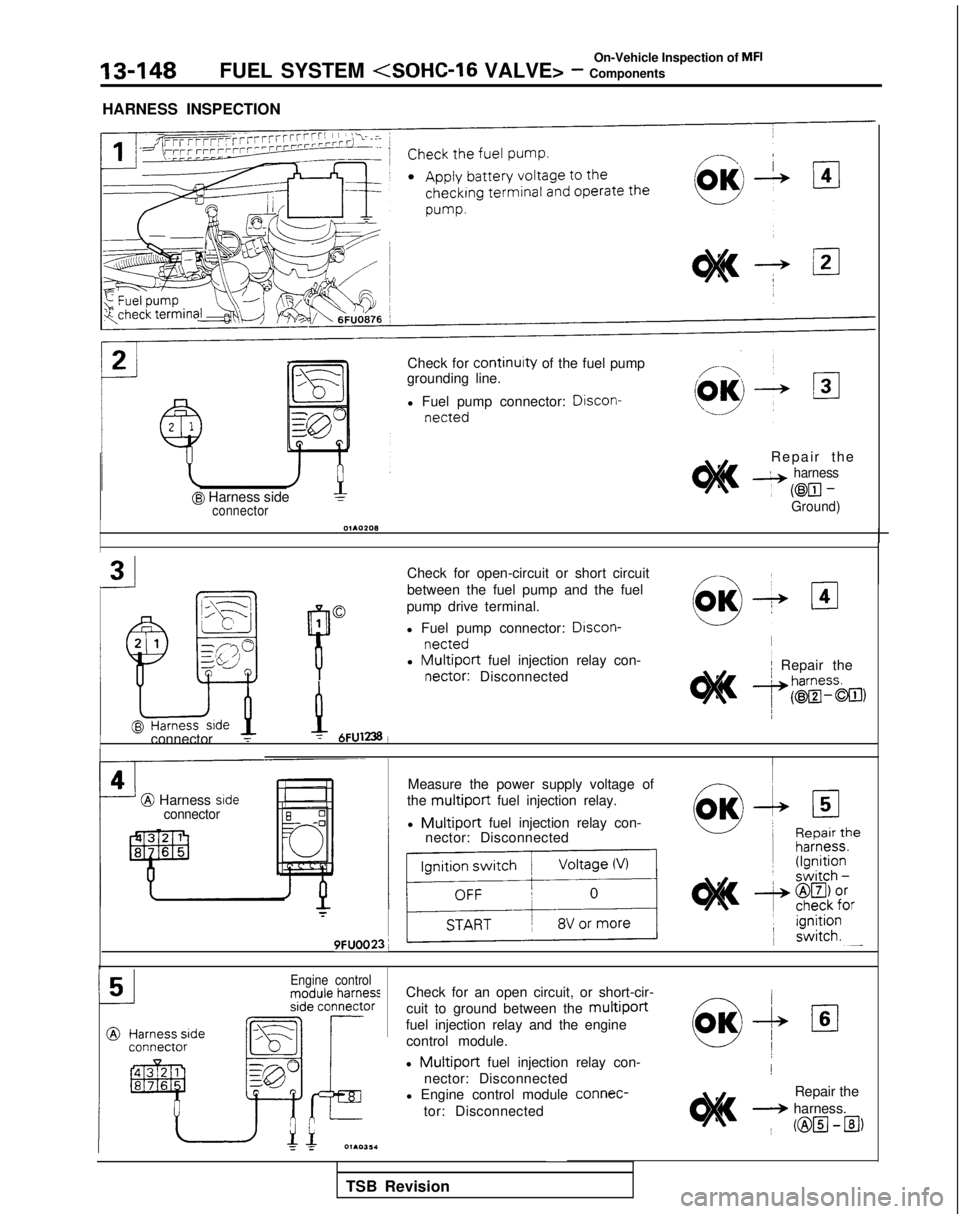

HARNESS INSPECTION

@ Harness sideconnector

Check for continuity of the fuel pump

grounding line.

l Fuel pump connector: Discon-

netted

Repair th

e

4 harness

~

@El-Ground)

Check for open-circuit or short circuit

between the fuel pump and the fuel

pump drive terminal.

l Fuel pump connector:

Drscon-

nettedl Multiport fuel injection relay con- nectar:

Disconnected

I/

2 .lr/ Repair theL^Srr,-..-r

P

9vh

connector T-y 6FU1238!

I

@ Harness srdeconnector

Measure the power supply voltage of

the

multiport fuel injection relay.

l

Multiport fuel injection relay con-

nector: Disconnected

r

9FUOO23;

IIIEngine controlCheck for an open circuit, or short-cir-

cuit to ground between the

multiport

fuel injection relay and the enginecontrol module.

l

Multiport fuel injection relay con-

nector: Disconnected

l Engine control module connec-

tor: Disconnected!

Repair the

+ harness. ~

@H-B)

TSB Revision

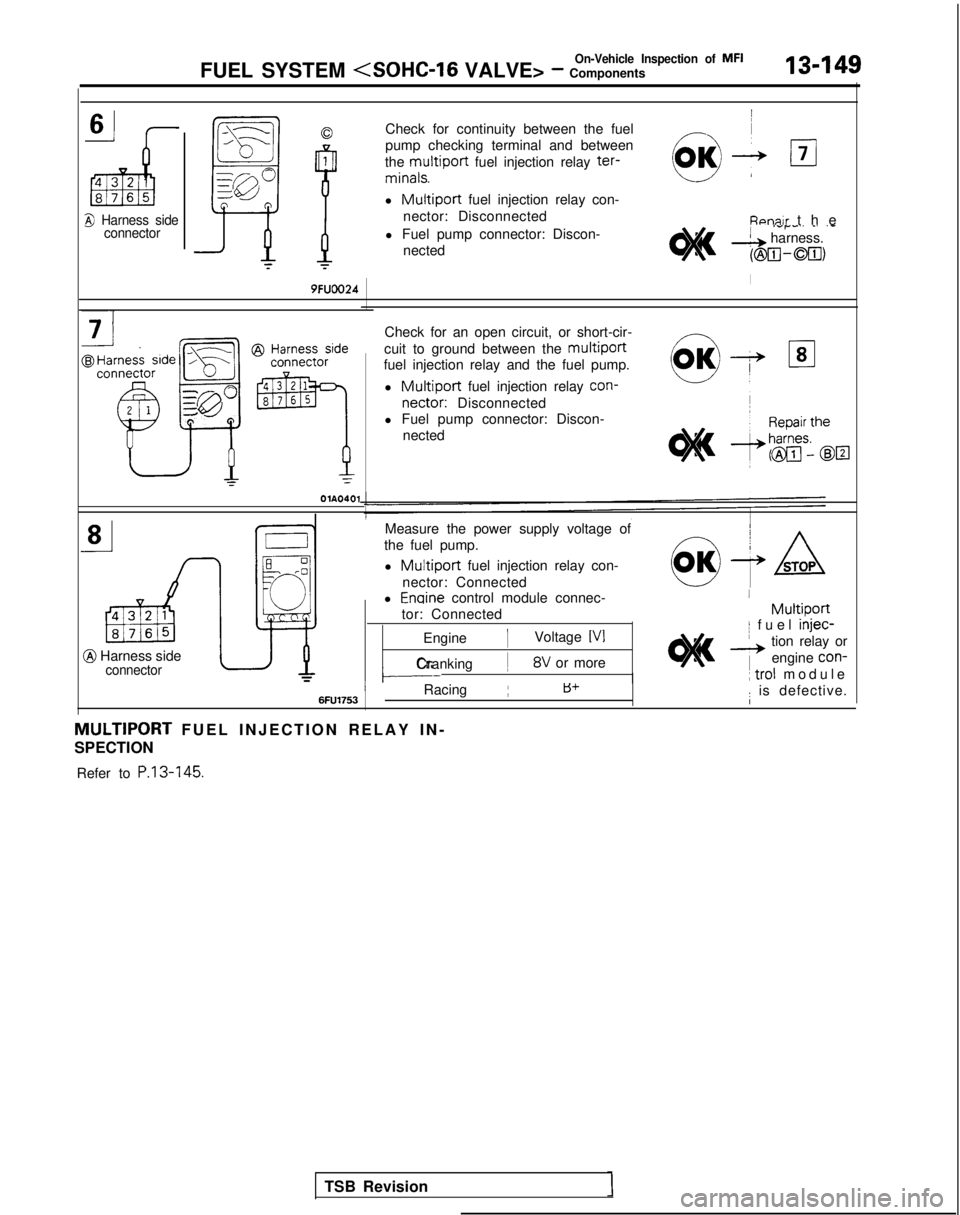

Page 291 of 1273

On-Vehicle Inspection of MFIFUEL SYSTEM

a Harness side

connector

--------

m

J-----k

N

qp

CI

F

Check for continuity between the fuel

pump checking terminal and between

the

multiport fuel injection relay ter- minals.

l

Multiport fuel injection relay con-

nector: Disconnected Fipnn~r

the

l Fuel pump connector: Discon-

nected

.-P-” _’ ‘-& harness.

(@m-00,

I9FUOO24

OlA0401

Check for an open circuit, or short-cir-

cuit to ground between the

multiport

fuel injection relay and the fuel pump.

l

Multiport fuel injection relay con-

nectar:

Disconnected

l Fuel pump connector: Discon-

nected

@ Harness sideconnector

Measure the power supply voltage of

the fuel pump.

l

Multiport fuel injection relay con-

nector: Connected

l

Enoine control module connec-

tor: Connected

Engine

1Voltage IV1

cCranking ~8V or more-

I

MultiportI fuel injec-

__, tion relay or

1

engine con-

~

trol

module

TSB Revision

IRacing Iid+: is defective.6FU175.3I

MULTIPORT FUEL INJECTION RELAY IN

-

SPECTION

Refer to P.13-145.

Page 293 of 1273

On-Vehicle Inspection of MFIFUEL SYSTEM

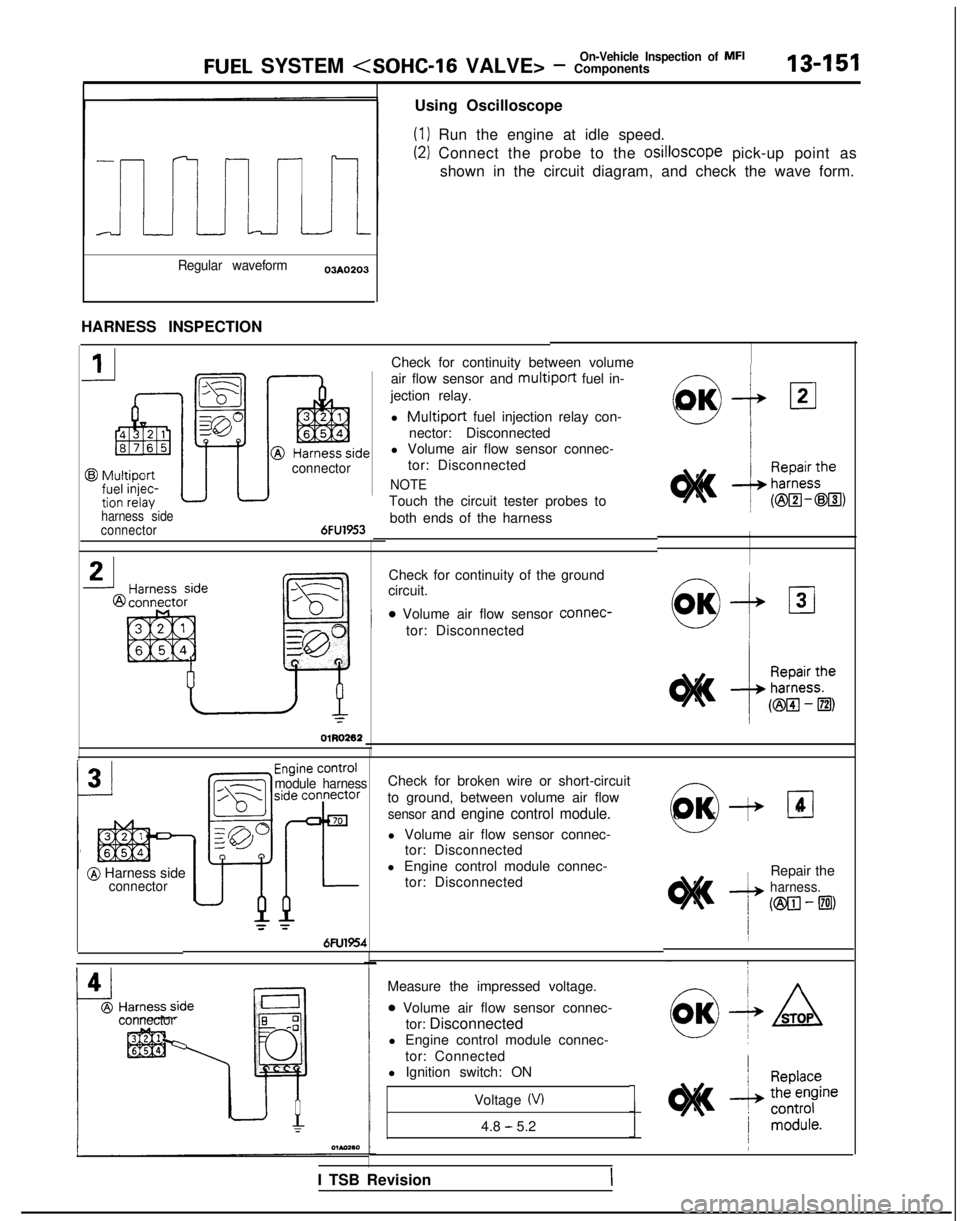

Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the osilloscope

pick-up point as

shown in the circuit diagram, and check the wave form.

Regular waveform03AO203

HARNESS INSPECTION

Check for continuity between volume

air flow sensor and

multiport fuel in-

jection relay.

l

Multiport fuel injection relay con-

nector: Disconnected

l Volume air flow sensor connec-

tor: Disconnected

NOTE

Touch the circuit tester probes to

both ends of the harness

a+

OK 121

harness side

connector6FU1953

connector

Check for continuity of the ground-Icircuit.

0 Volume air flow sensor connec-WI+ 131tor: DisconnectedL-l I

OlR0262

/I

module harness

@ Harness sideconnector

= =

6FU1954

0O

K

-I+

Check for broken wire or short-circuit

to ground, between volume air flow

sensor and engine control module.

l Volume air flow sensor connec- tor: Disconnected

l Engine control module connec- tor: Disconnected

El4

Repair the

harness.

(ml-El)

Measure the impressed voltage.

0 Volume air flow sensor connec- tor: Disconnected

l Engine control module connec-

tor: Connected

l Ignition switch: ONconnector

Voltage (V)

4.8 - 5.2

I TSB Revision