check engine MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 236 of 1273

13-94 FUEL SYSTEM

1

Idle speed control

motor connector

Idle speed control

motor connector6FUO750

6FUO9&

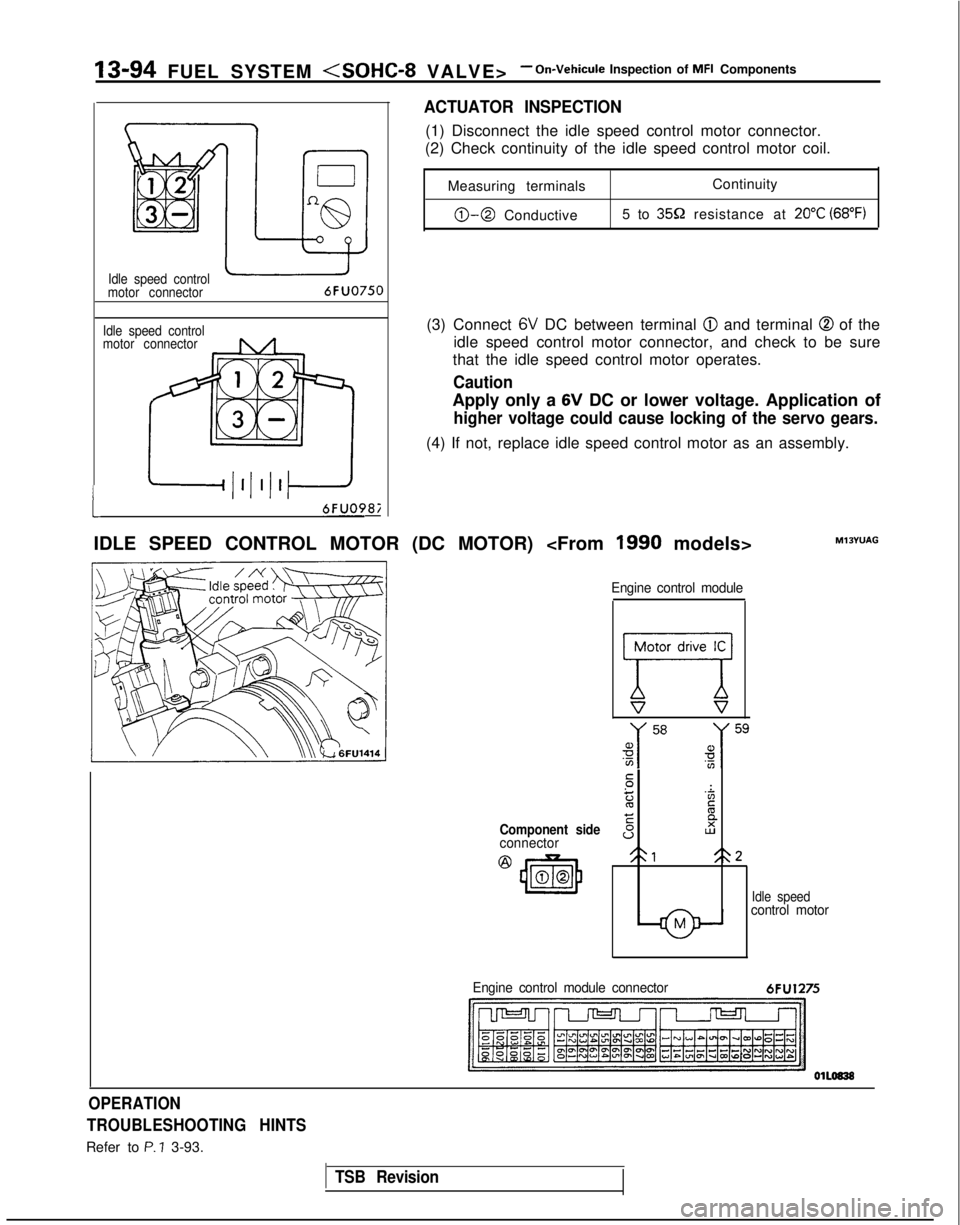

ACTUATOR INSPECTION

(1) Disconnect the idle speed control motor connector.

(2) Check continuity of the idle speed control motor coil.

Measuring terminals Continuity

0-0 Conductive

5 to 359 resistance at 20°C (68°F)

(3) Connect 6V DC between terminal @I and terminal @ of the

idle speed control motor connector, and check to be sure

that the idle speed control motor operates.

Caution

Apply only a 6V DC or lower voltage. Application of

higher voltage could cause locking of the servo gears.

(4) If not, replace idle speed control motor as an assembly.

IDLE SPEED CONTROL MOTOR (DC MOTOR)

Component sideconnector

@

43m00

Engine control module

77V s

.-:

z'Zc

EE

sI2

21<\2

Idle speedcontrol motor

MlOYUAG

Engine control module connector

6FU1275

OPERATION

TROUBLESHOOTING HINTS

Refer to P. ? 3-93.

TSB Revision

Page 237 of 1273

FUEL SYSTEM

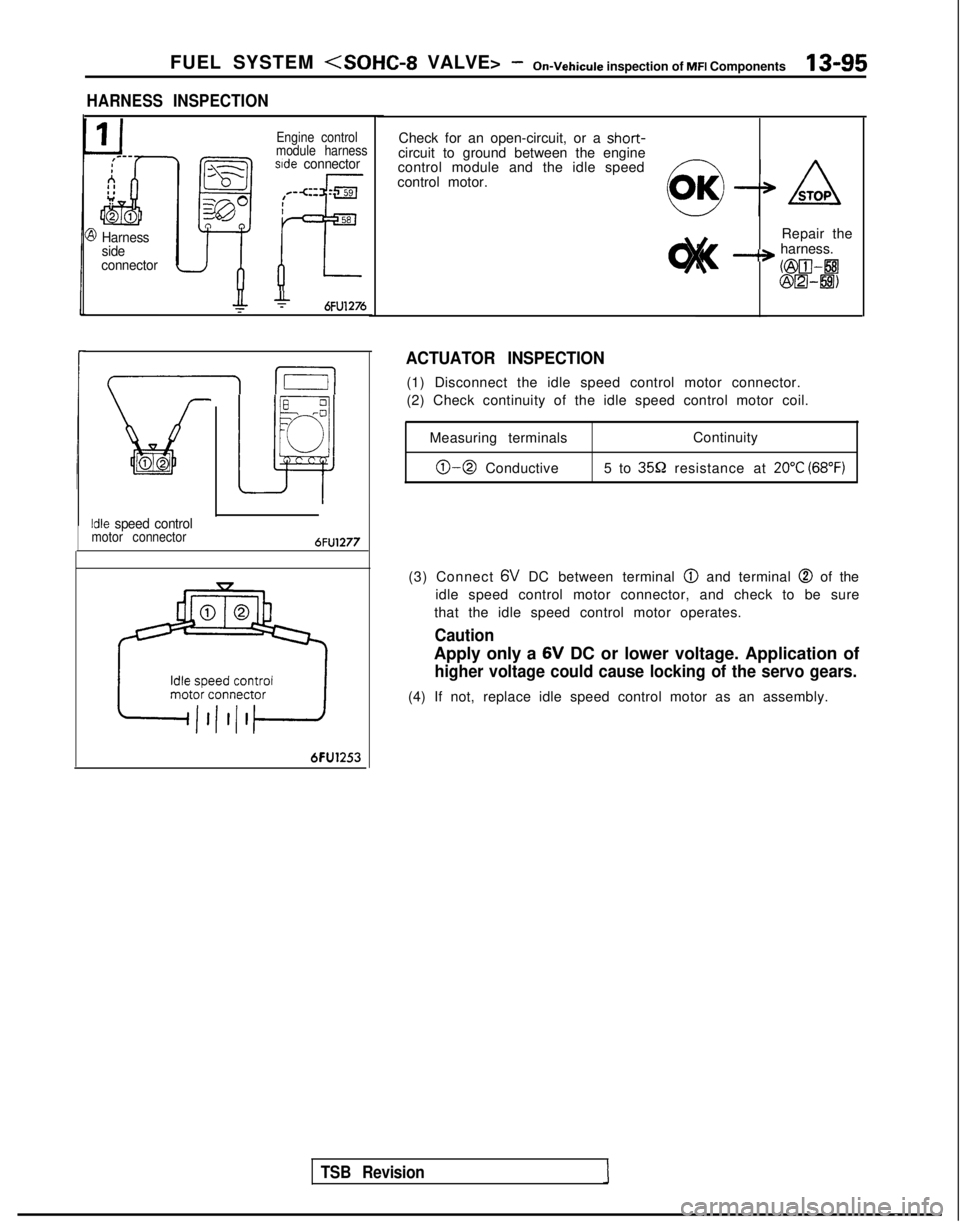

HARNESS INSPECTION

3 Harness

side

connector

Engine control

module harness

sde connector

+6FU1276

I I

Lit02

Idle speed controlmotor connector6FU1277

6FU1253

Check for an open-circuit, or a short-circuit to ground between the engine

control module and the idle speed

control motor.

Repair the

-+ harness.

OZGII-8@m-8)

TSB Revision

ACTUATOR INSPECTION

(1) Disconnect the idle speed control motor connector.

(2) Check continuity of the idle speed control motor coil.Measuring terminals Continuity

0-0 Conductive

5 to 3552 resistance at 20°C (68°F)

(3) Connect 6V

DC between terminal @

and terminal @ of the

idle speed control motor connector, and check to be sure

that the idle speed control motor operates.

Caution

Apply only a 6V

DC or lower voltage. Application of

higher voltage could cause locking of the servo gears.

(4) If not, replace idle speed control motor as an assembly.

Page 238 of 1273

13-96 FUEL SYSTEM

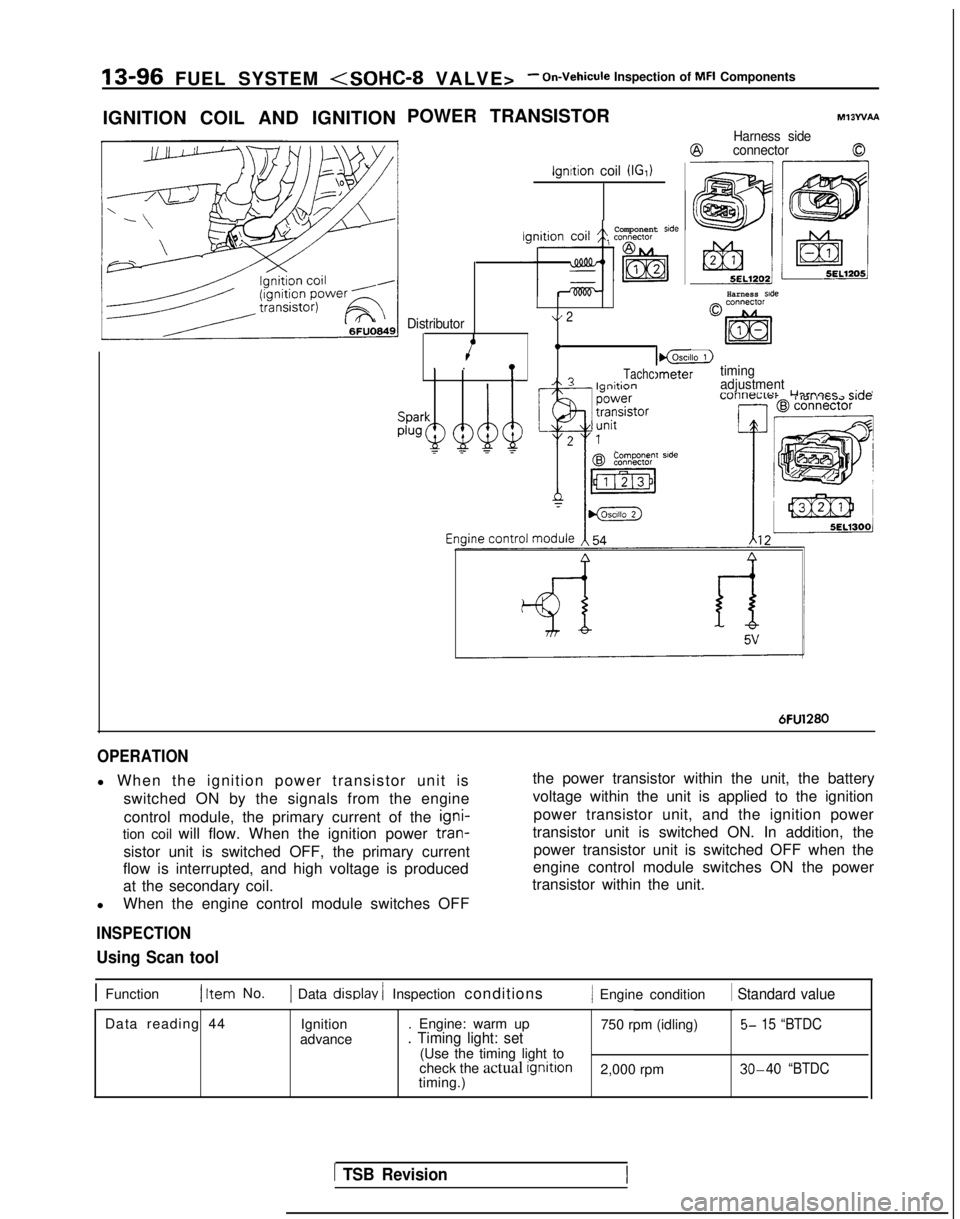

IGNITION COIL AND IGNITION POWER TRANSISTOR

ignition coil (IGI)

Ml3WAA

Harness side

@connector0

Harness side

Component side

Distributor\/ 2

4.I_lgnltion. .!

I@LZ)

TachcImetertimingA? I--:*:^^adjustment-_

Lllrnacr

r;rlnI 101 i IG.72 Jl”F

Componenr side

6FU1280

OPERATION

l When the ignition power transistor unit is

switched ON by the signals from the engine

control module, the primary current of the igni-

tion coil will flow. When the ignition power tran-

sistor unit is switched OFF, the primary current

flow is interrupted, and high voltage is produced

at the secondary coil.

l When the engine control module switches OFF

INSPECTION

the power transistor within the unit, the battery

voltage within the unit is applied to the ignition

power transistor unit, and the ignition power

transistor unit is switched ON. In addition, the power transistor unit is switched OFF when the

engine control module switches ON the power

transistor within the unit.

Using Scan tool

1 Function1 Item No.1 Data display / Inspection conditions/ Engine condition 1 Standard value

Data reading 44

Ignition

advance . Engine: warm up

750 rpm (idling)5- 15 “BTDC. Timing light: set(Use the timing light to

check the actual ignition

2,000 rpm 30-40 “BTDCtiming.)

1 TSB Revision

Page 239 of 1273

FUEL SYSTEM (SOHC-8 VALVE> -On-Vehicule Inspection of MFI Components13-97

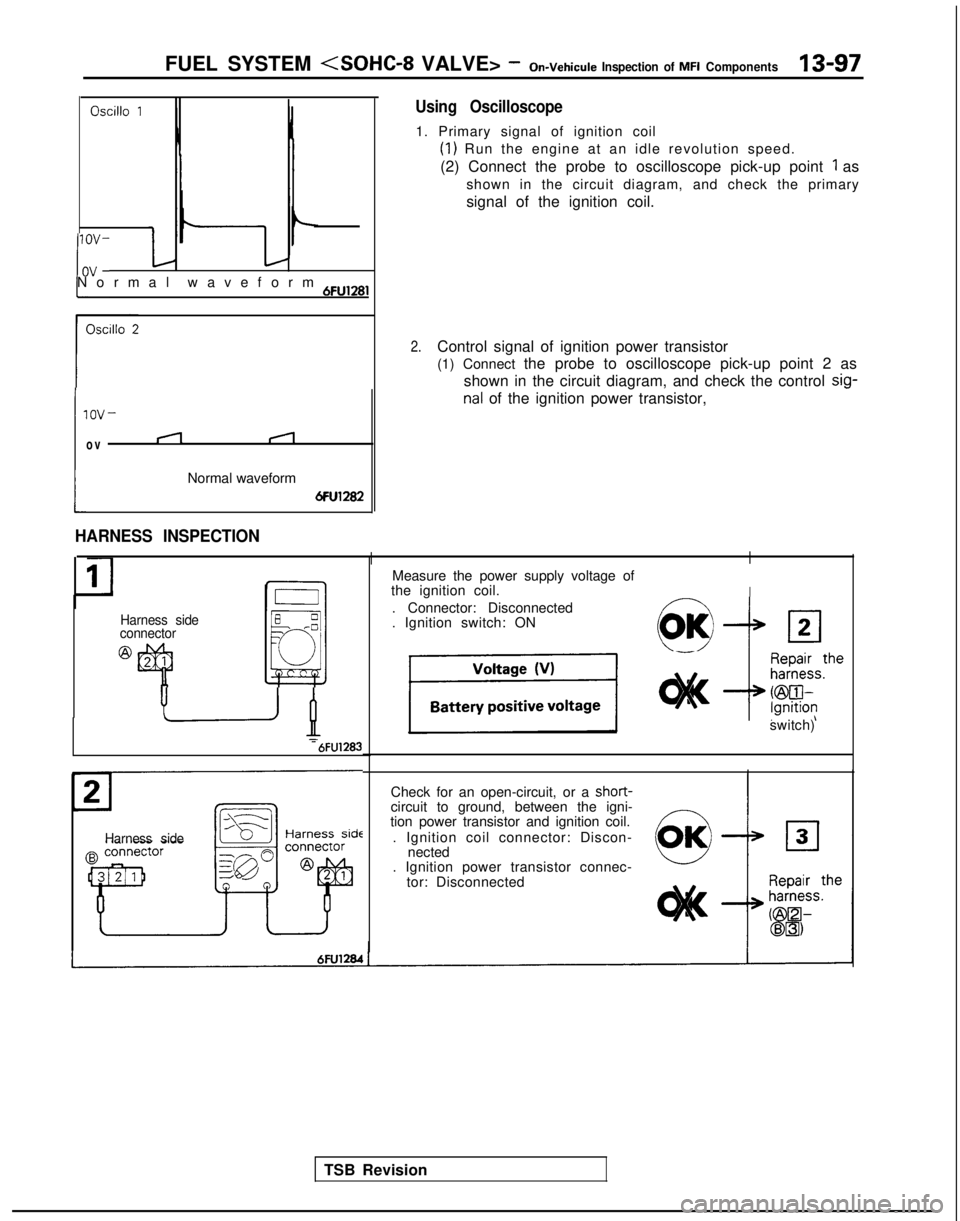

Oscillo 1

If-Normal waveform 6Fu,28,

lOV-

ov

i

nal of the ignition power transistor,

(1

Normal waveform

6Fu1282

Using Oscilloscope

1. Primary signal of ignition coil

(1) Run the engine at an idle revolution speed.

(2) Connect the probe to oscilloscope pick-up point

1 as

shown in the circuit diagram, and check the primary

signal of the ignition coil.

2.Control signal of ignition power transistor

(1) Connect the probe to oscilloscope pick-up point 2 as shown in the circuit diagram, and check the control sig-

Harness side

connector

@

HARNESS INSPECTION

II

I I

I

Measure the power supply voltage of

the ignition coil.

. Connector: Disconnected

. Ignition switch: ON

c--vOK/III2

-‘B-6FU1283

TSB Revision

Harness side

switch)

Check for an open-circuit, or a short-

circuit to ground, between the igni-

tion power transistor and ignition coil.

. Ignition coil connector: Discon- nected

. Ignition power transistor connec-

tor: Disconnected

Page 241 of 1273

FUEL SYSTEM

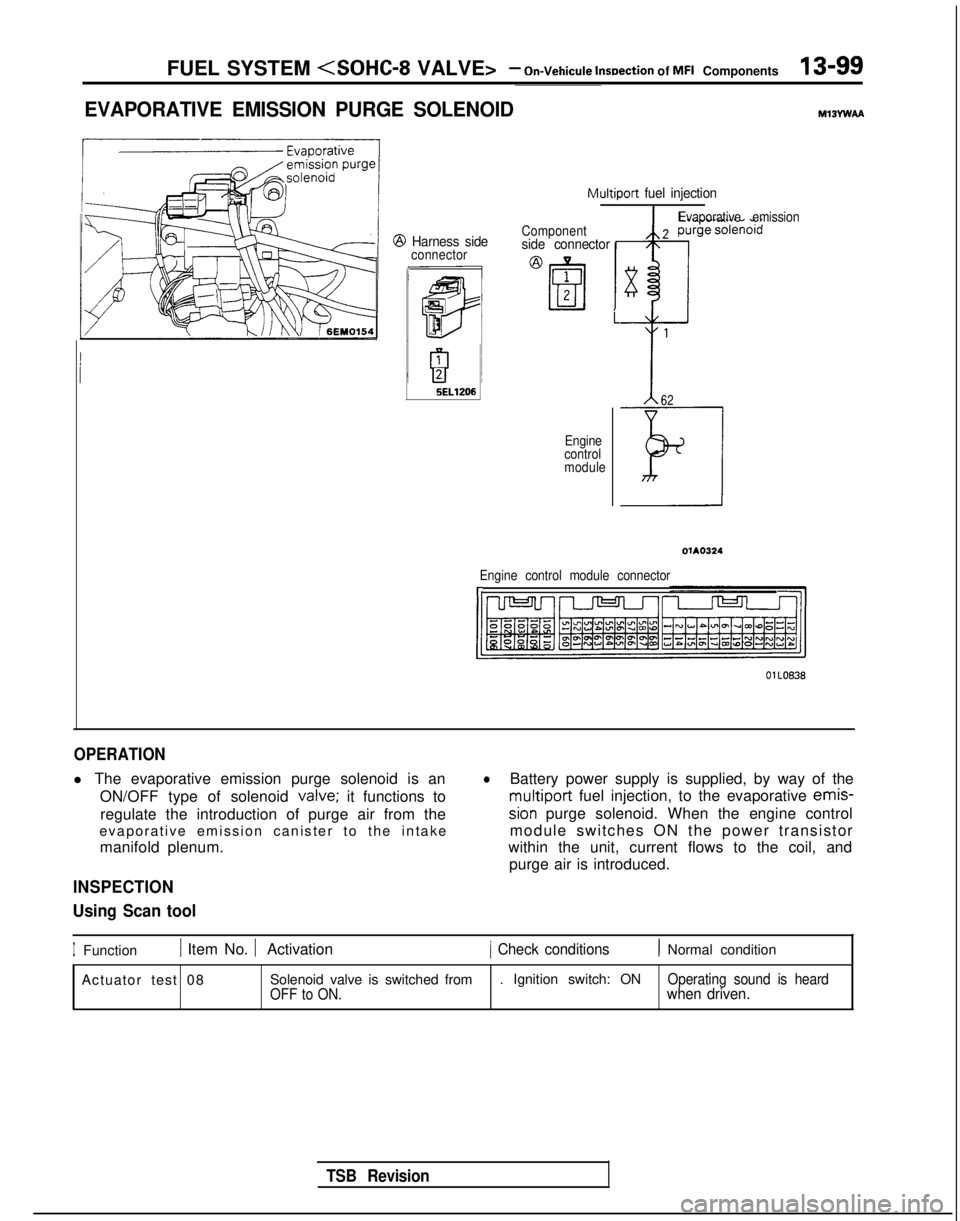

EVAPORATIVE EMISSION PURGE SOLENOIDMlBYwAA

Multiport fuel injection

@ Harness sideconnector Componentside connector

i

5EL1206

Engine

control

module

TSB Revision

Evaporative emission

62

Engine control module connectorI,

OlLO838

OPERATION

l The evaporative emission purge solenoid is an

ON/OFF type of solenoid valve;

it functions to

regulate the introduction of purge air from the

evaporative emission canister to the intake

manifold plenum.

INSPECTION

Using Scan tool

lBattery power supply is supplied, by way of the multiport

fuel injection, to the evaporative emis-

sion purge solenoid. When the engine control

module switches ON the power transistor

within the unit, current flows to the coil, and

purge air is introduced.

IFunction1 Item No. 1 Activation1 Check conditions1 Normal condition

Actuator test 08 Solenoid valve is switched from . Ignition switch: ON

Operating sound is heard

OFF to ON.when driven.

Page 242 of 1273

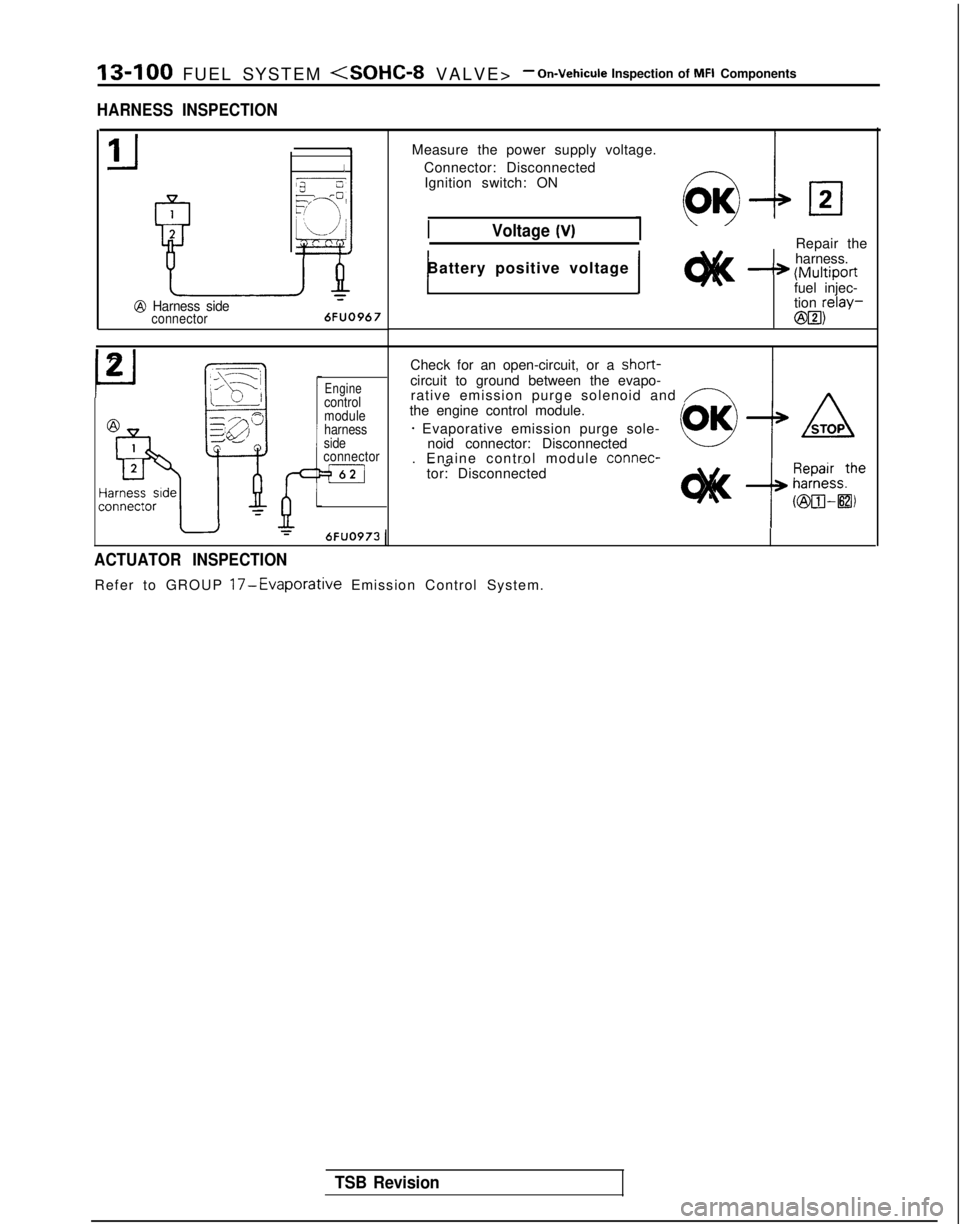

13-100 FUEL SYSTEM

- On-Vehicule Inspection of MFI Components

HARNESS INSPECTION

1

2

P

Izj----=2T !r/

‘3“L j

k&

-&@ Harness sideconnector

6FUO967

Measure

the power supply voltage.

Connector: Disconnected Ignition switch: ON

Voltage (V)Repair the

harness.

-* (Multiportfuel injec-

tion relay-

@B3)

1Battery positive voltage 1

P

2_Fq,/-\i-1- /-

F

&--

Y

Enginecontrol

module

harness

side

connector

=m

Check for an open-circuit, or a short-circuit to ground between the evapo-

rative emission purge solenoid and /-Athe engine control module.

* Evaporative emission purge sole- noid connector: Disconnected

. Enaine control module connec-

-a ~~tor: Disconnected

6FUO973

1

ACTUATOR INSPECTION

Refer to GROUP 17-Evaporative Emission Control System.

TSB Revision

Page 243 of 1273

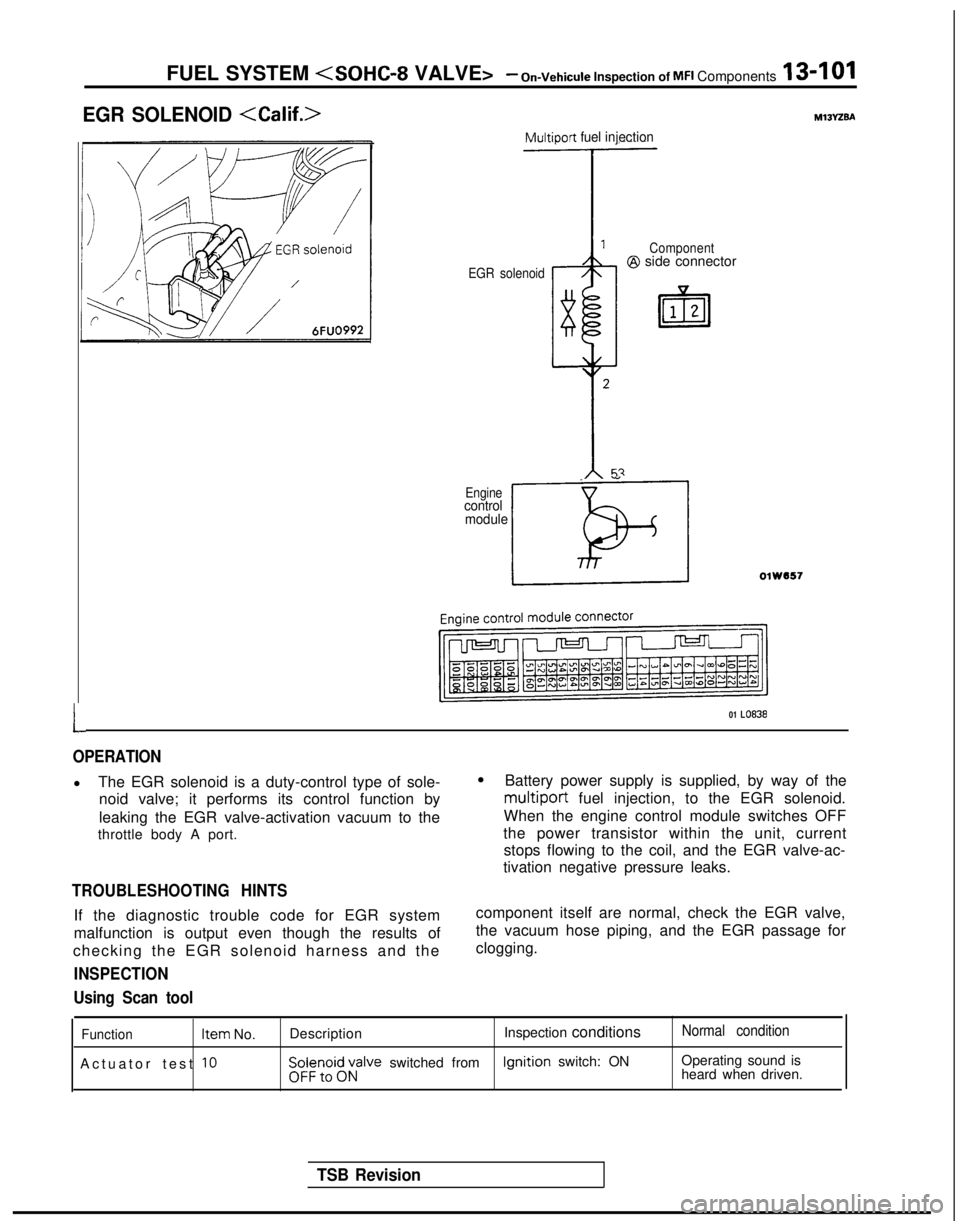

FUEL SYSTEM

EGR SOLENOID

L

Multiport fuel injection

EGR solenoid Component@I side connector

_ ”

Enginecontrol

module

LOlW557

01 LO838

OPERATION

l The EGR solenoid is a duty-control type of sole-

noid valve; it performs its control function by

leaking the EGR valve-activation vacuum to the

throttle body A port.

TROUBLESHOOTING HINTS

If the diagnostic trouble code for EGR system

malfunction is output even though the results of

checking the EGR solenoid harness and the

INSPECTION

l Battery power supply is supplied, by way of the

multiport fuel injection, to the EGR solenoid.

When the engine control module switches OFF

the power transistor within the unit, current stops flowing to the coil, and the EGR valve-ac-

tivation negative pressure leaks.

component itself are normal, check the EGR valve,

the vacuum hose piping, and the EGR passage for

clogging.

Using Scan tool

Function Item

No.

Actuator test

10

Description Inspection conditionsNormal condition

$i;;,oi$;;alve switched from Ignition

switch: ON Operating sound is

heard when driven.

TSB Revision

Page 244 of 1273

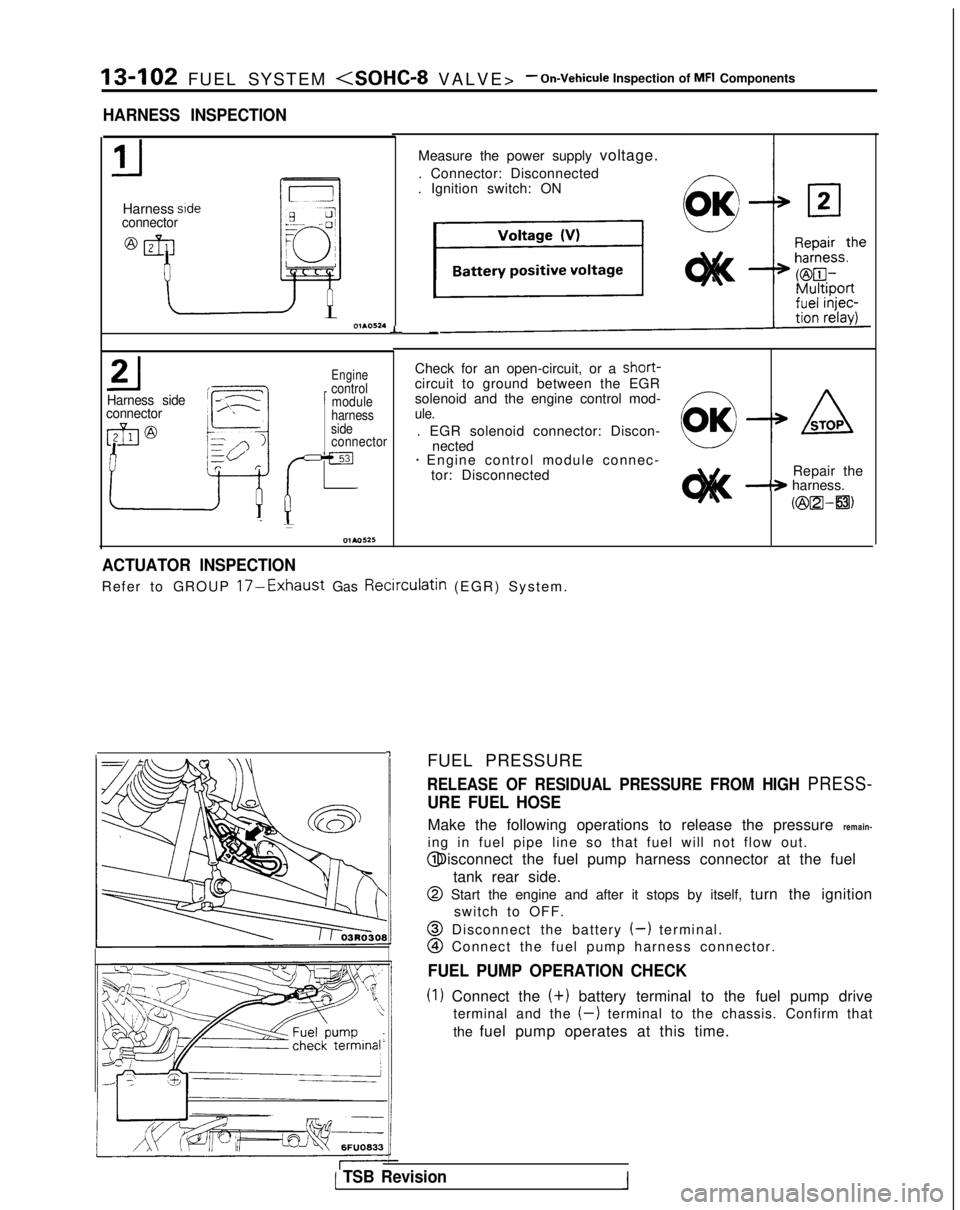

13-102 FUEL SYSTEM

- On-Vehicule Inspection of MFI Components

HARNESS INSPECTION

Harness sideconnector

L

Harness side

connector

Engine

1

control module

Check for an open-circuit, or a short-

circuit to ground between the EGR

solenoid and the engine control mod-

harnessule.side. EGR solenoid connector: Discon-connectornected+ Engine control module connec- tor: Disconnected Repair the

-+ harness.

Kzix2l-a)

-I

Measure the power supply voltage.

. Connector: Disconnected

. Ignition switch: ON

-

ACTUATOR INSPECTION

Refer to GROUP 17-Exhaust Gas Recirculatin (EGR) System

.

FUEL PRESSURE

RELEASE OF RESIDUAL PRESSURE FROM HIGH PRESS-

URE FUEL HOSE

Make the following operations to release the pressure remain-

ing in fuel pipe line so that fuel will not flow out. @ Disconnect the fuel pump harness connector at the fuel

tank rear side.

@ Start the engine and after it stops by itself, turn the ignitionswitch to OFF.

@ Disconnect the battery (-) terminal.

@I Connect the fuel pump harness connector.

FUEL PUMP OPERATION CHECK

(1) Connect the (+)

battery terminal to the fuel pump drive

terminal and the

(-) terminal to the chassis. Confirm that

the fuel pump operates at this time.

( TSB Revision1

Page 245 of 1273

FUEL SYSTEM

TSB Revision

---

I g$qfq, tcJ-s6FUO633

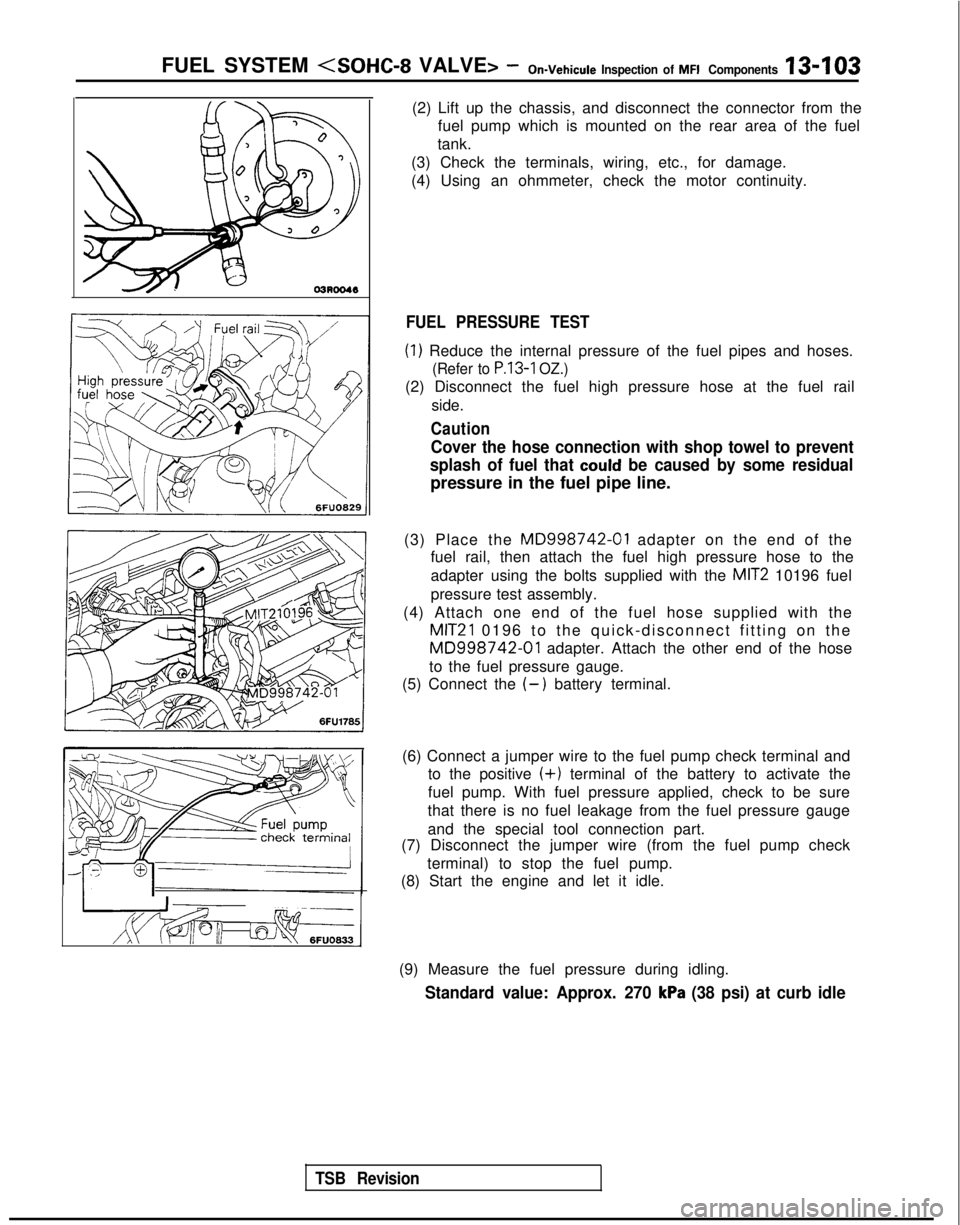

(2) Lift up the chassis, and disconnect the connector from the

fuel pump which is mounted on the rear area of the fuel

tank.

(3) Check the terminals, wiring, etc., for damage.

(4) Using an ohmmeter, check the motor continuity.

FUEL PRESSURE TEST

(1) Reduce the internal pressure of the fuel pipes and hoses.

(Refer to P.13-1 OZ.)

(2) Disconnect the fuel high pressure hose at the fuel rail

side.

Caution

Cover the hose connection with shop towel to prevent

splash of fuel that

could be caused by some residual

pressure in the fuel pipe line.

(3) Place the

MD998742-01 adapter on the end of the

fuel rail, then attach the fuel high pressure hose to the

adapter using the bolts supplied with the

MIT2 10196 fuel

pressure test assembly.

(4) Attach one end of the fuel hose supplied with the

MIT21 0196 to the quick-disconnect fitting on the

MD998742-01 adapter. Attach the other end of the hose

to the fuel pressure gauge.

(5) Connect the

(-) battery terminal.

(6) Connect a jumper wire to the fuel pump check terminal and to the positive

(+) terminal of the battery to activate the

fuel pump. With fuel pressure applied, check to be sure

that there is no fuel leakage from the fuel pressure gauge

and the special tool connection part.

(7) Disconnect the jumper wire (from the fuel pump check

terminal) to stop the fuel pump.

(8) Start the engine and let it idle.

(9) Measure the fuel pressure during idling.

Standard value: Approx. 270 kPa (38 psi) at curb idle

Page 246 of 1273

13-I 04 FUEL SYSTEM

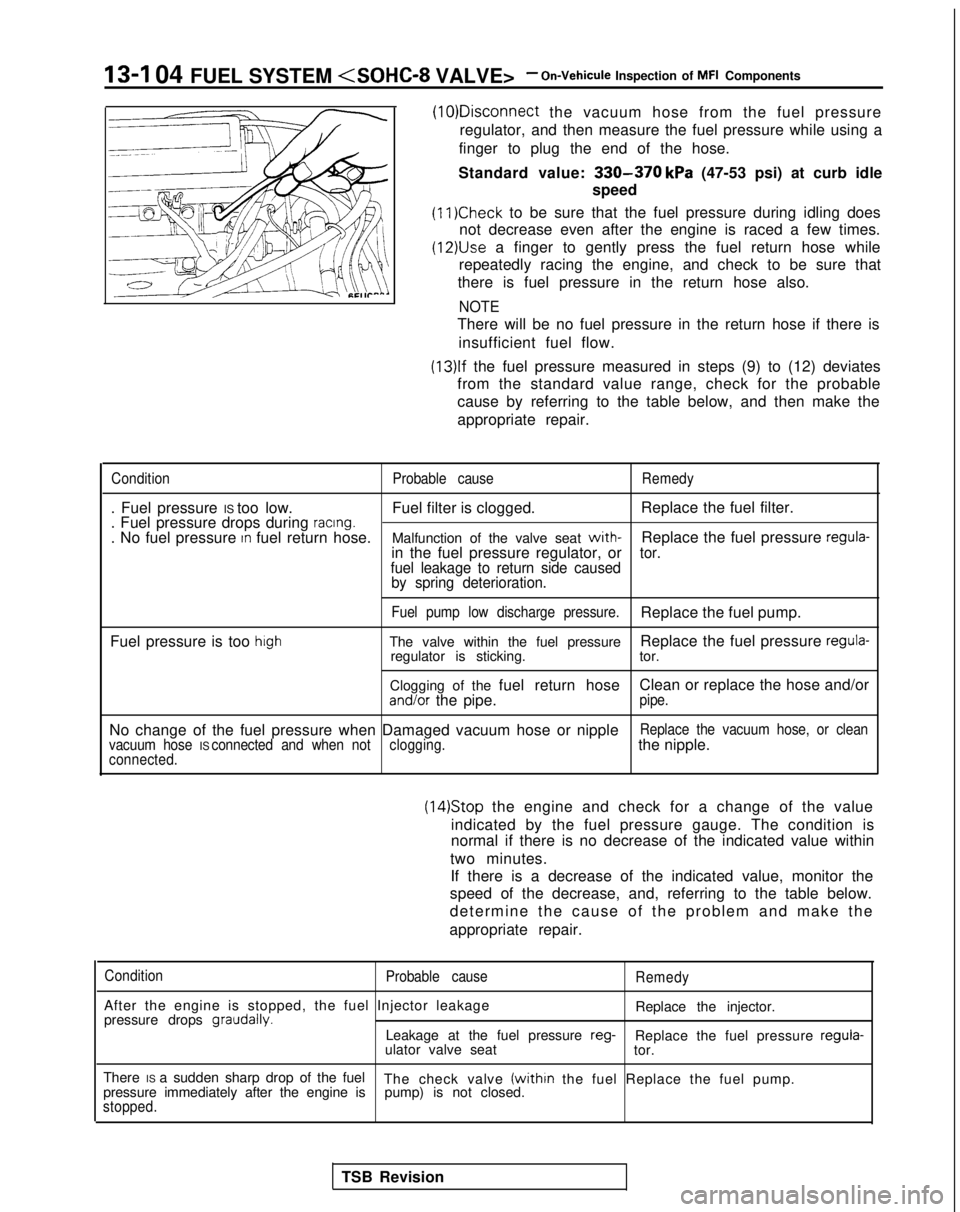

the vacuum hose from the fuel pressure

regulator, and then measure the fuel pressure while using a

finger to plug the end of the hose.

Standard value:

330-370 kPa (47-53 psi) at curb idle

speed

(11)Check to be sure that the fuel pressure during idling does

not decrease even after the engine is raced a few times.

(12)&e a finger to gently press the fuel return hose while

repeatedly racing the engine, and check to be sure that

there is fuel pressure in the return hose also.

NOTE

There will be no fuel pressure in the return hose if there is

insufficient fuel flow.

(13)lf the fuel pressure measured in steps (9) to (12) deviates

from the standard value range, check for the probable

cause by referring to the table below, and then make the

appropriate repair.

Condition Probable causeRemedy

. Fuel pressure IS too low. Fuel filter is clogged.Replace the fuel filter.

. Fuel pressure drops during racing.. No fuel pressure In fuel return hose. Malfunction of the valve seat with-Replace the fuel pressure regula-in the fuel pressure regulator, ortor.

fuel leakage to return side caused by spring deterioration.

Fuel pump low discharge pressure.Replace the fuel pump.

Fuel pressure is too

highThe valve within the fuel pressure Replace the fuel pressure regula-regulator is sticking.

tor.

Clogging of the fuel return hose Clean or replace the hose and/or

and/or the pipe.pipe.

No change of the fuel pressure when Damaged vacuum hose or nippleReplace the vacuum hose, or clean

vacuum hose IS connected and when not clogging.the nipple.connected.

(14)Stop the engine and check for a change of the value

indicated by the fuel pressure gauge. The condition is

normal if there is no decrease of the indicated value within

two minutes. If there is a decrease of the indicated value, monitor the

speed of the decrease, and, referring to the table below.

determine the cause of the problem and make the

appropriate repair.

Condition Probable cause

After the engine is stopped, the fuel Injector leakage

pressure drops graudally.

Remedy

Replace the injector.

Leakage at the fuel pressure reg-

Replace the fuel pressure regula-

ulator valve seat tor.

There IS a sudden sharp drop of the fuel The check valve

(within the fuel Replace the fuel pump.

pressure immediately after the engine is pump) is not closed.

stopped.

TSB Revision