check engine MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 502 of 1273

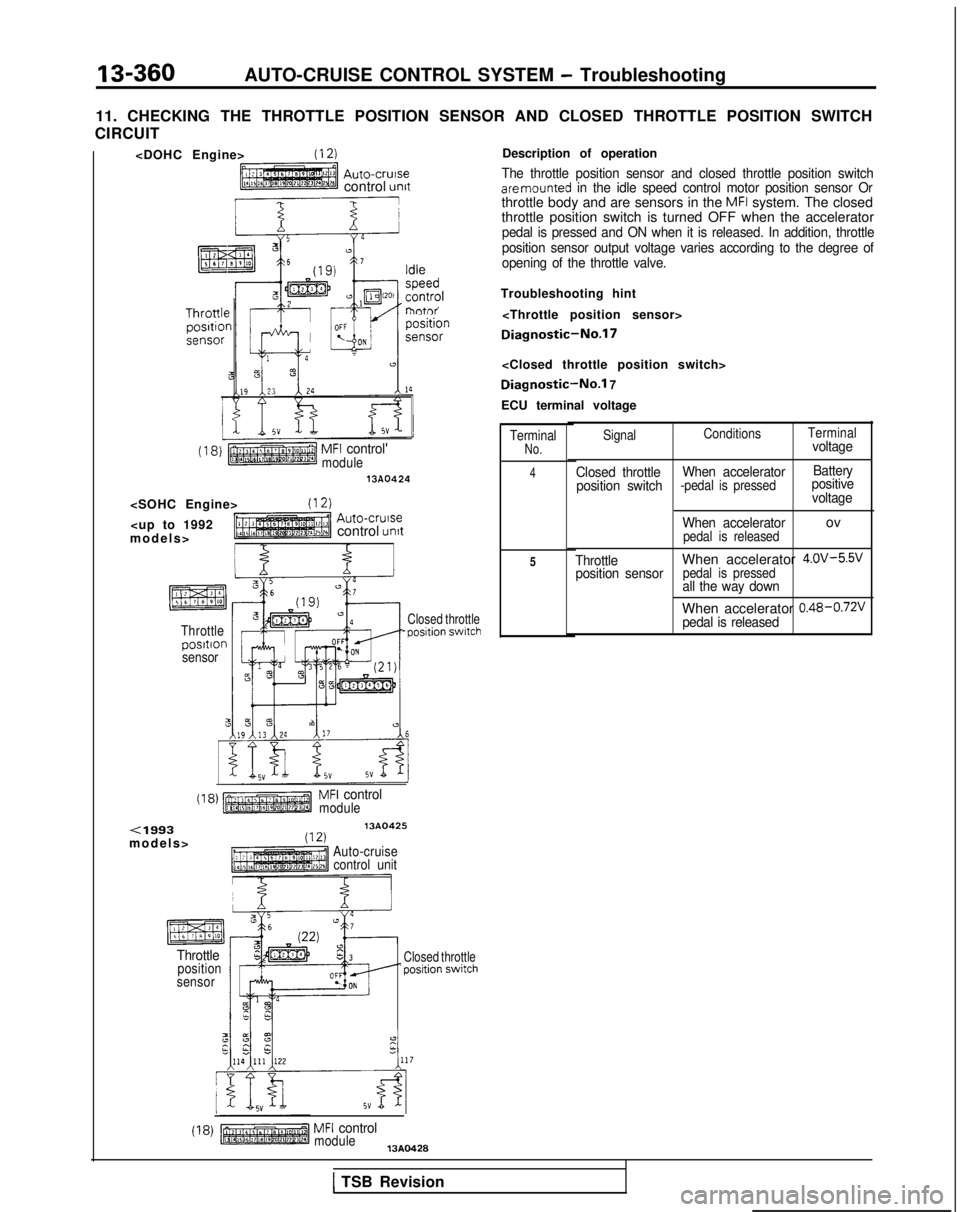

13-360AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

11. CHECKING THE THROTTLE POSITION SENSOR AND CLOSED THROTTLE POSITION S\

WITCH

CIRCUIT

Auto-crursecontrol unit

I 2EB16 I

lntr’

(18)

MFI controlmodule1380424

>

control

unrt

I f

Throttleposrtronsensor

Closed throttle-position swrtch

(18)MFI controlmodule

<1993models

>

13A0425(12)Auto-cruise

control unit

Throttleposition

sensorClosed throttle ‘position

switch

(18)MFI controlmodule13A0428

Description of operation

The throttle position sensor and closed throttle position switchare mounted in the idle speed control motor position sensor Orthrottle body and are sensors in the MFI system. The closed

throttle position switch is turned OFF when the accelerator

pedal is pressed and ON when it is released. In addition, throttle

position sensor output voltage varies according to the degree of

opening of the throttle valve.

Troubleshooting hint

Diagnostic-No.17

Diagnostic-No.1 7

ECU terminal voltage

TerminalNo.

4

5 Signal

Conditions

Terminal

voltage

Closed throttle When accelerator Battery

position switch

-pedal is pressedpositive voltage

When accelerator

pedal is releasedov

ThrottleWhen accelerator 4.0v-5%’position sensorpedal is pressedall the way down

When accelerator 0.48~0.72v

pedal is released

1 TSB Revision

Page 540 of 1273

13-398

AUTO-CRUISE CONTROL SYSTEM - Setice Adjustment procedures

03*02.5*

1

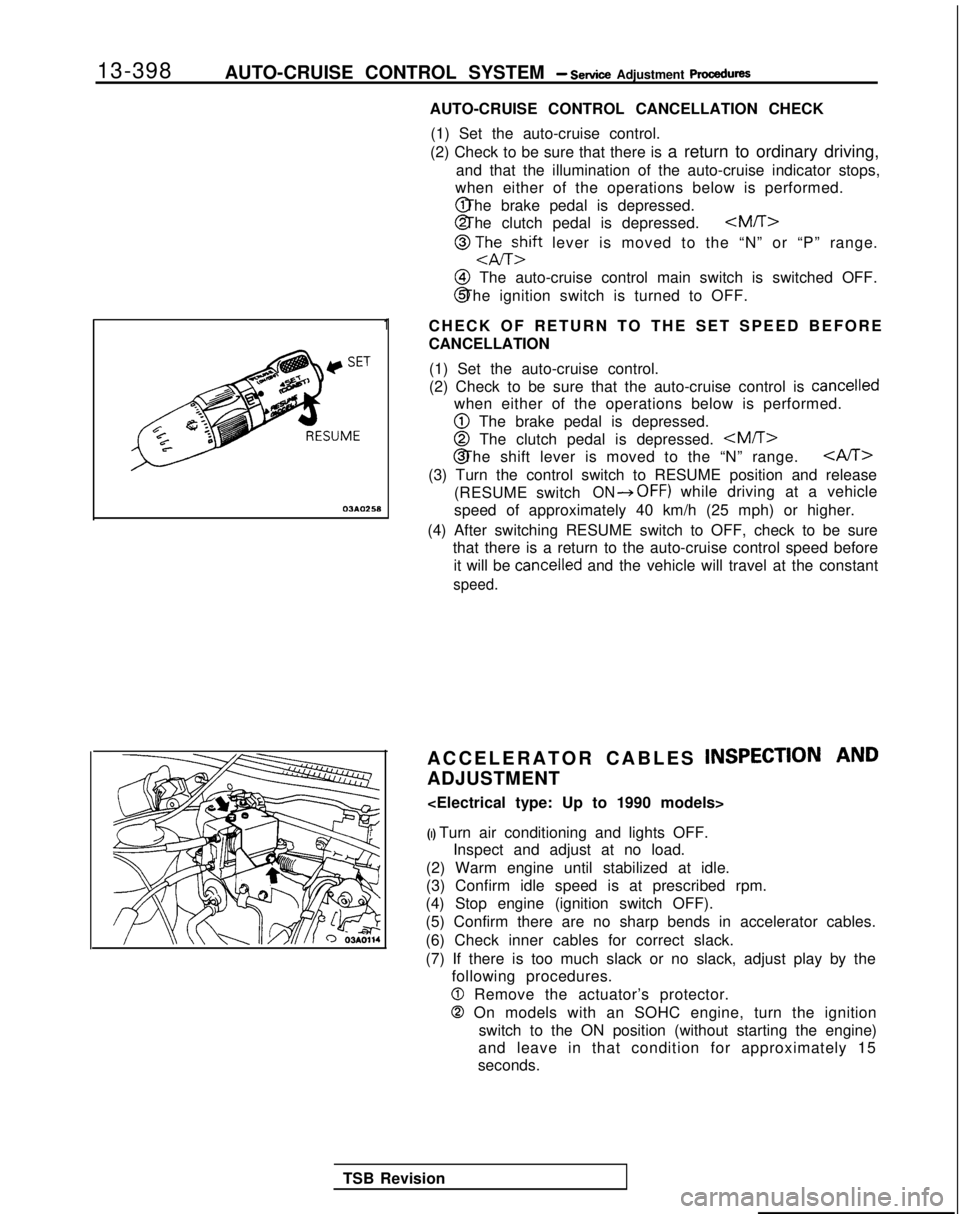

AUTO-CRUISE CONTROL CANCELLATION CHECK

(1) Set the auto-cruise control.

(2) Check to be sure that there is a return to ordinary driving,

and that the illumination of the auto-cruise indicator stops,

when either of the operations below is performed. @ The brake pedal is depressed.

@ The clutch pedal is depressed.

@ TJhEzift lever is moved to the “N” or “P” range.

@I The auto-cruise control main switch is switched OFF.

@ The ignition switch is turned to OFF.

CHECK OF RETURN TO THE SET SPEED BEFORE

CANCELLATION (1) Set the auto-cruise control.

(2) Check to be sure that the auto-cruise control is

cancelled

when either of the operations below is performed.

@ The brake pedal is depressed.

@ The clutch pedal is depressed.

CAST>

(3) Turn the control switch to RESUME position and release

(RESUME switch

ON*OFF) while driving at a vehicle

speed of approximately 40 km/h (25 mph) or higher.

(4) After switching RESUME switch to OFF, check to be sure that there is a return to the auto-cruise control speed before

it will be

cancelled and the vehicle will travel at the constant

speed.

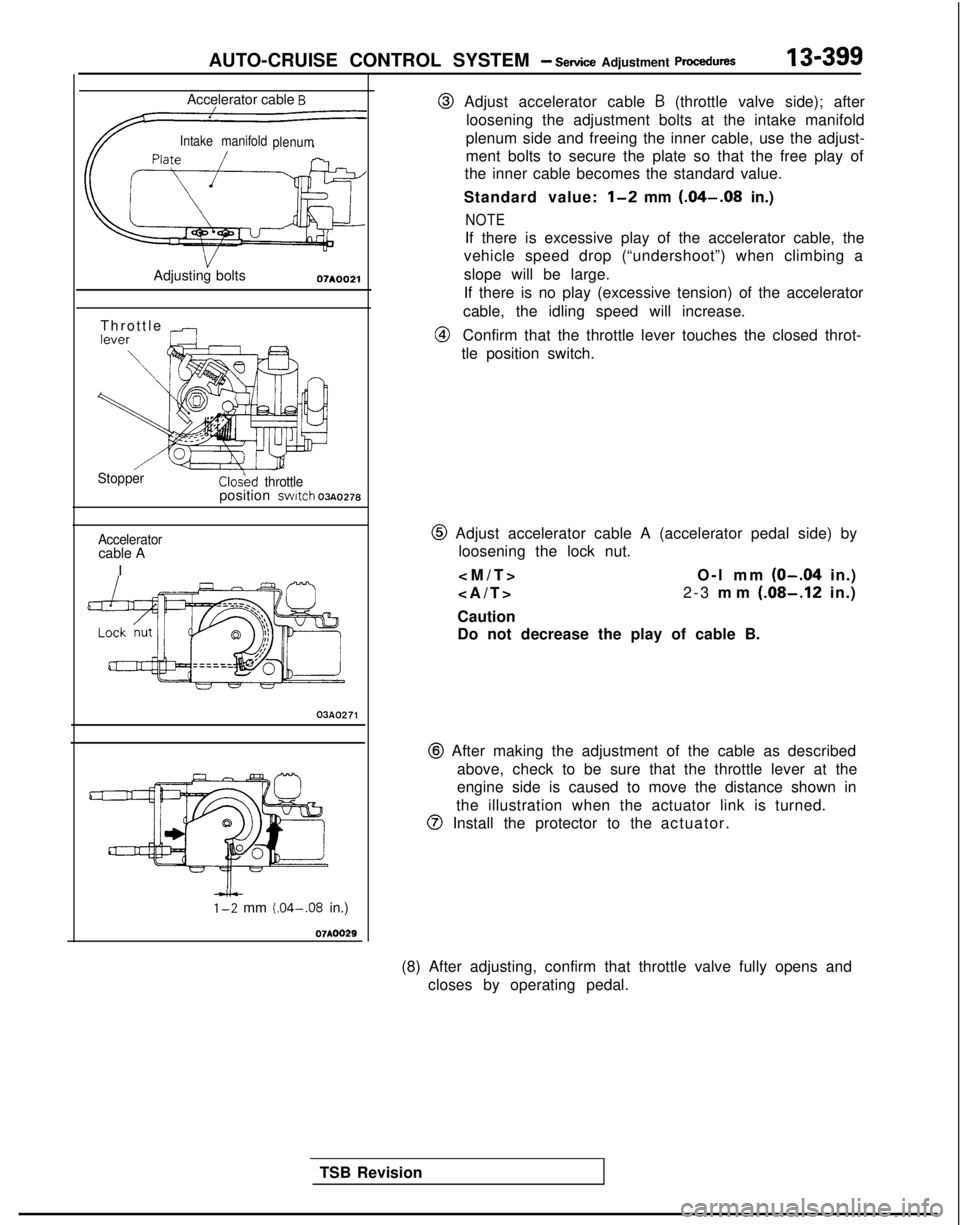

ACCELERATOR CABLES INSPECTION AND

ADJUSTMENT

(I) Turn air conditioning and lights OFF. Inspect and adjust at no load.

(2) Warm engine until stabilized at idle.

(3) Confirm idle speed is at prescribed rpm.

(4) Stop engine (ignition switch OFF).

(5) Confirm there are no sharp bends in accelerator cables.

(6) Check inner cables for correct slack.

(7) If there is too much slack or no slack, adjust play by the following procedures.

0 Remove the actuator’s protector.

0 On models with an SOHC engine, turn the ignition

switch to the ON position (without starting the engine)

and leave in that condition for approximately 15

seconds.

TSB Revision

Page 541 of 1273

AUTO-CRUISE CONTROL SYSTEM - Setice Adjustment ~rccedures13-399

Accelerator cable B

Intake manifold

plenum

VAdjusting bolts07A0021

Throttle -.--

StopperCloskd throttleposition swrtch 03~0278

Acceleratorcable A

I

03A0271

-Ai+1-2 mm (.04-.08

in.)

TSB Revision

@ Adjust accelerator cable B (throttle valve side); after

loosening the adjustment bolts at the intake manifold

plenum side and freeing the inner cable, use the adjust-

ment bolts to secure the plate so that the free play of

the inner cable becomes the standard value.

Standard value:

l-2 mm (.04-.08 in.)

NOTE

If there is excessive play of the accelerator cable, the

vehicle speed drop (“undershoot”) when climbing a

slope will be large.

If there is no play (excessive tension) of the accelerator

cable, the idling speed will increase.

@Confirm that the throttle lever touches the closed throt-

tle position switch.

@ Adjust accelerator cable A (accelerator pedal side) by loosening the lock nut.

O-l mm

(O-.04 in.)

>

2-3

mm

(.08-.12 in.)

Caution

Do not decrease the play of cable B.

@ After making the adjustment of the cable as described above, check to be sure that the throttle lever at the

engine side is caused to move the distance shown in

the illustration when the actuator link is turned.

@ Install the protector to the actuator.

(8) After adjusting, confirm that throttle valve fully opens and closes by operating pedal.

Page 542 of 1273

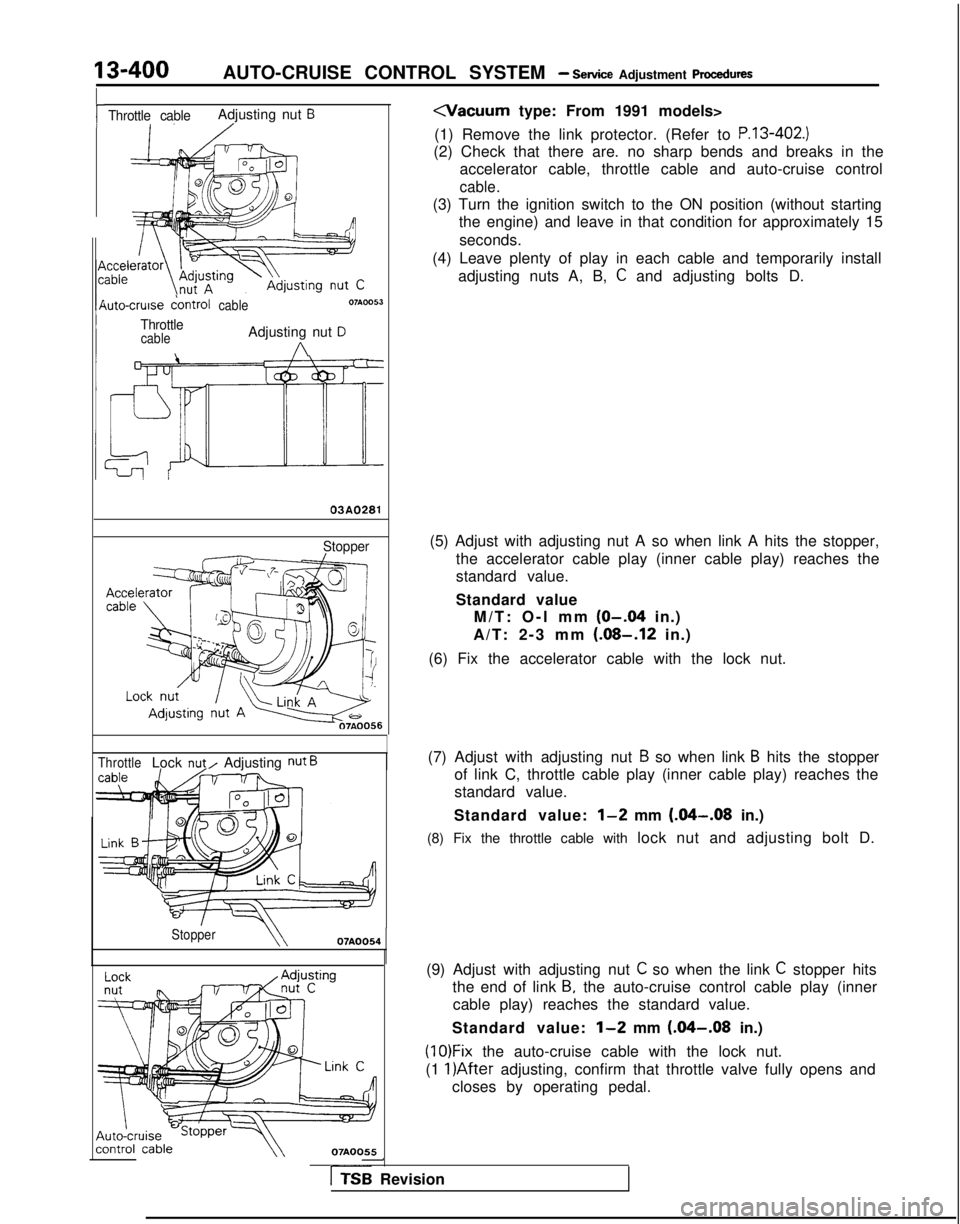

13-400AUTO-CRUISE CONTROL SYSTEM - Service Adjustment procedures

rThrottle cableAdjusting nut B

\uto-cruise dontrolcable

ThrottlecableAdjusting nut D

A

03A0281

Stopper

ThrottleLock nut/ Adjusting nut B

Stopper07AOO54

07AOO55

(1) Remove the link protector. (Refer to

P.13-402.)

(2) Check that there are. no sharp bends and breaks in the accelerator cable, throttle cable and auto-cruise control

cable.

(3) Turn the ignition switch to the ON position (without startingthe engine) and leave in that condition for approximately 15

seconds.

(4) Leave plenty of play in each cable and temporarily install adjusting nuts A, B,

C and adjusting bolts D.

(5) Adjust with adjusting nut A so when link A hits the stopper, the accelerator cable play (inner cable play) reaches the

standard value.

Standard valueM/T: O-l mm

(O-.04 in.)

A/T: 2-3 mm

(.08-.12 in.)

(6) Fix the accelerator cable with the lock nut.

(7) Adjust with adjusting nut

B so when link B hits the stopper

of link C, throttle cable play (inner cable play) reaches the

standard value.

Standard value:

l-2 mm (&I-.08 in.)

(8) Fix the throttle cable with lock nut and adjusting bolt D.

(9) Adjust with adjusting nut

C so when the link C stopper hits

the end of link

B, the auto-cruise control cable play (inner

cable play) reaches the standard value.

Standard value:

l-2 mm (.04-.08 in.)

(1O)Fix the auto-cruise cable with the lock nut.

(1

l)After adjusting, confirm that throttle valve fully opens and

closes by operating pedal.

-

rTSB Revision

Page 553 of 1273

14-1

COOLING

ENGINE COOLANT TEMPERATURE GAUGE

UNIT, ENGINE COOLANT

TEMPERATURE SENSOR AND ENGINE

COOLANT TEMPERATURE

SWITCH.............

31

RADIATOR ....................................................... 9

RADIATOR FAN MOTOR ASSEMBLY ..........

12

SERVICE ADJUSTMENT PROCEDURES..

.....

8

Engine Coolant Concentration Test .............

8

Engine Coolant LeakCheck

........................8

Engine Coolant

Replacement .......................

8

Radiator Cap Pressure Test .........................

8

SPECIAL TOOL................................................5

SPECIFICATIONS .............................................

2

General Specifications ..................................

2

Lubricant

....................................................... 4

CONTENTS

IM14AA-

Sealant. . . . . . . . . . . . . ..__...........’ . . . . . . . . . . . . . \

. . . . . .._.........4

ServiceSpecifications . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Torque

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

THERMOSTAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . .13

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. .5

No rise in temperature

Overheat

WATER HOSE AND WATER PIPE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

WATER HOSE AND WATER PIPE

WATER HOSE AND WATER PIPE

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..a.....23

WATER PUMP

WATER PUMP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Page 560 of 1273

14-8

COOLING -Service Adjustment Procedures T210863

SERVICE ADJUSTMENT PROCEDUl$t&

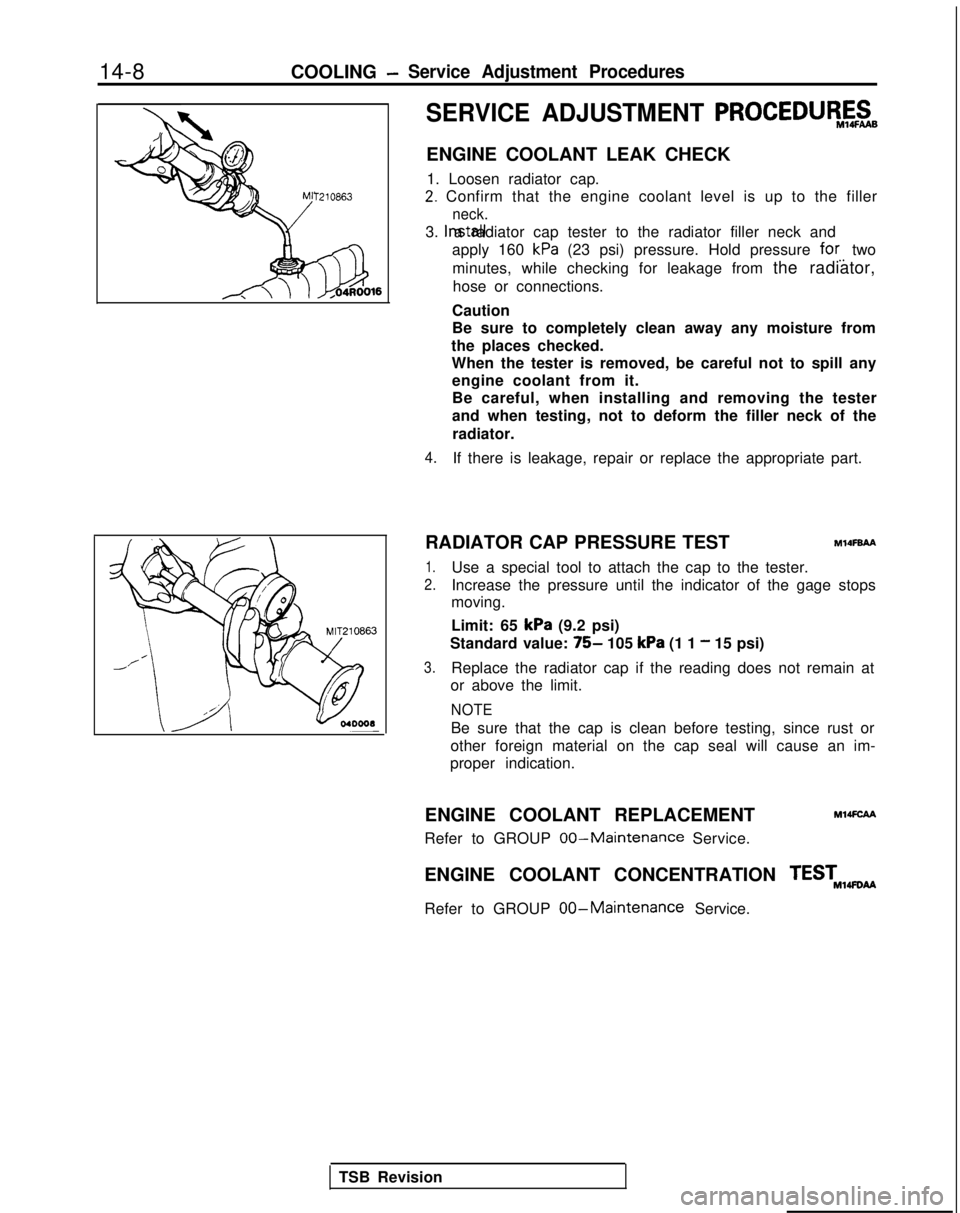

ENGINE COOLANT LEAK CHECK

1. Loosen radiator cap.

2. Confirm that the engine coolant level is up to the filler

neck.

3. Install a radiator cap tester to the radiator filler neck and

apply 160

kPa (23 psi) pressure. Hold pressure for. two

minutes, while checking for leakage from the radiator, hose or connections.

Caution

Be sure to completely clean away any moisture from

the places checked. When the tester is removed, be careful not to spill anyengine coolant from it.

Be careful, when installing and removing the tester

and when testing, not to deform the filler neck of the

radiator.

4.If there is leakage, repair or replace the appropriate part.

RADIATOR CAP PRESSURE TEST

MlOFBAA

1.Use a special tool to attach the cap to the tester.

2.Increase the pressure until the indicator of the gage stops

moving.

Limit: 65

kPa (9.2 psi)

Standard value:

75- 105 kPa (1 1 - 15 psi)

3.Replace the radiator cap if the reading does not remain at

or above the limit.

NOTE

Be sure that the cap is clean before testing, since rust or

other foreign material on the cap seal will cause an im-

proper indication.

ENGINE COOLANT REPLACEMENT

MMFCAA

Refer to GROUP 00-Maintenance Service.

ENGINE COOLANT CONCENTRATION TEST,,wti

Refer to GROUP

00-Maintenance Service.

TSB Revision

Page 563 of 1273

COOLING - Radiator14-11

04A0020

A

B’ -WaterI

423°C (725°F)temperature

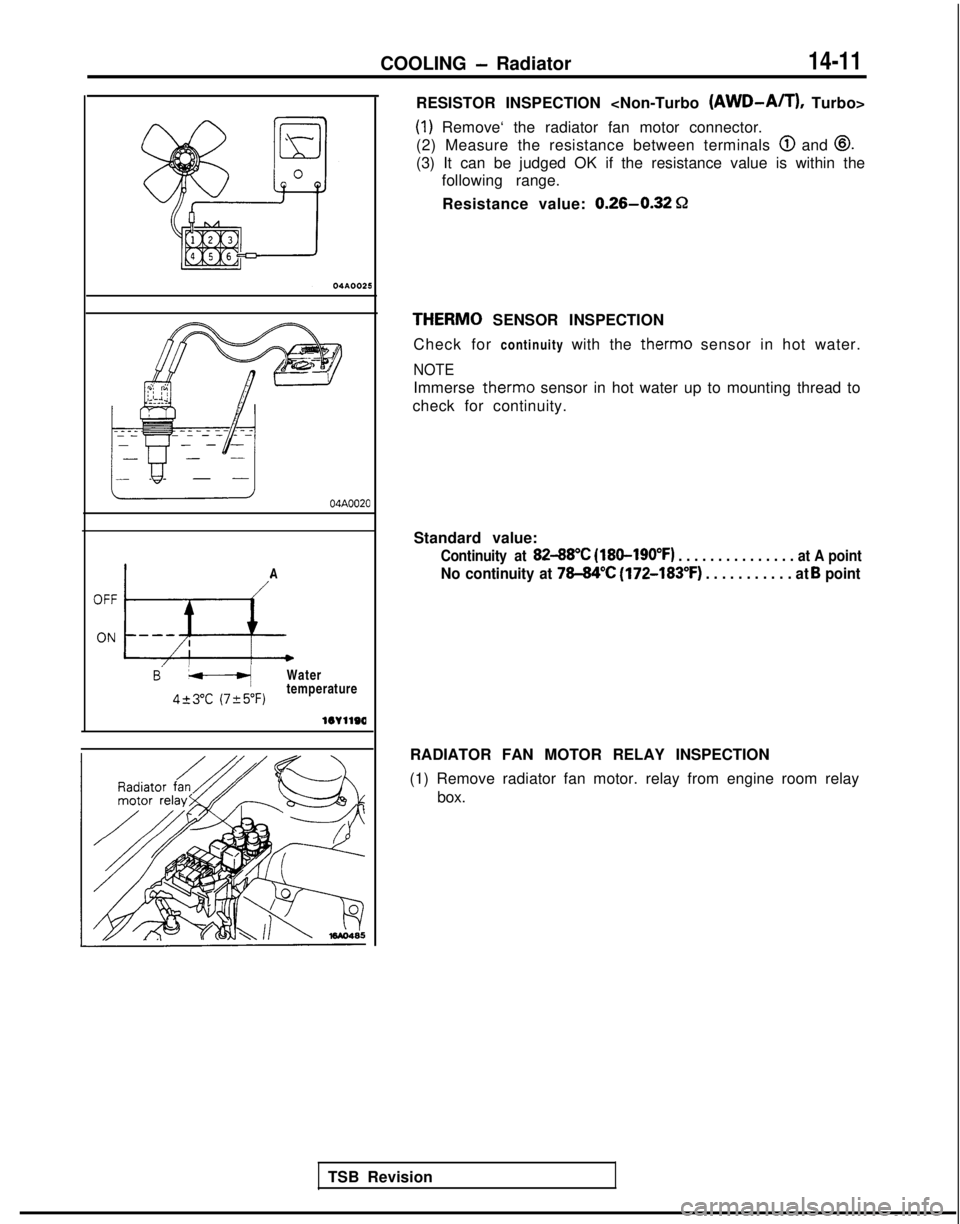

TSB Revision RESISTOR INSPECTION

(1) Remove‘ the radiator fan motor connector.

(2) Measure the resistance between terminals

0 and @.

(3) It can be judged OK if the resistance value is within the following range.

Resistance value:

0.26-0.32 Q

THERM0 SENSOR INSPECTION

Check for continuity with the therm0

sensor in hot water.

NOTE

Immerse therm0

sensor in hot water up to mounting thread to

check for continuity.

Standard value:

Continuity at 82-88”C (180-190°F) . . . . . . . . . . . . . . . at A point

No continuity at 7844°C (172-183°F) . . . . . . . . . . . at B point

RADIATOR FAN MOTOR RELAY INSPECTION

(1) Remove radiator fan motor. relay from engine room relay box.

Page 570 of 1273

14-18COOLING - Water Pump

Quality canvas Core wire

\\Adhesive rubber

\Rib rubberlCOO29

W

ater pump

J--iLi+

O-ring

W

ater pipe

I I

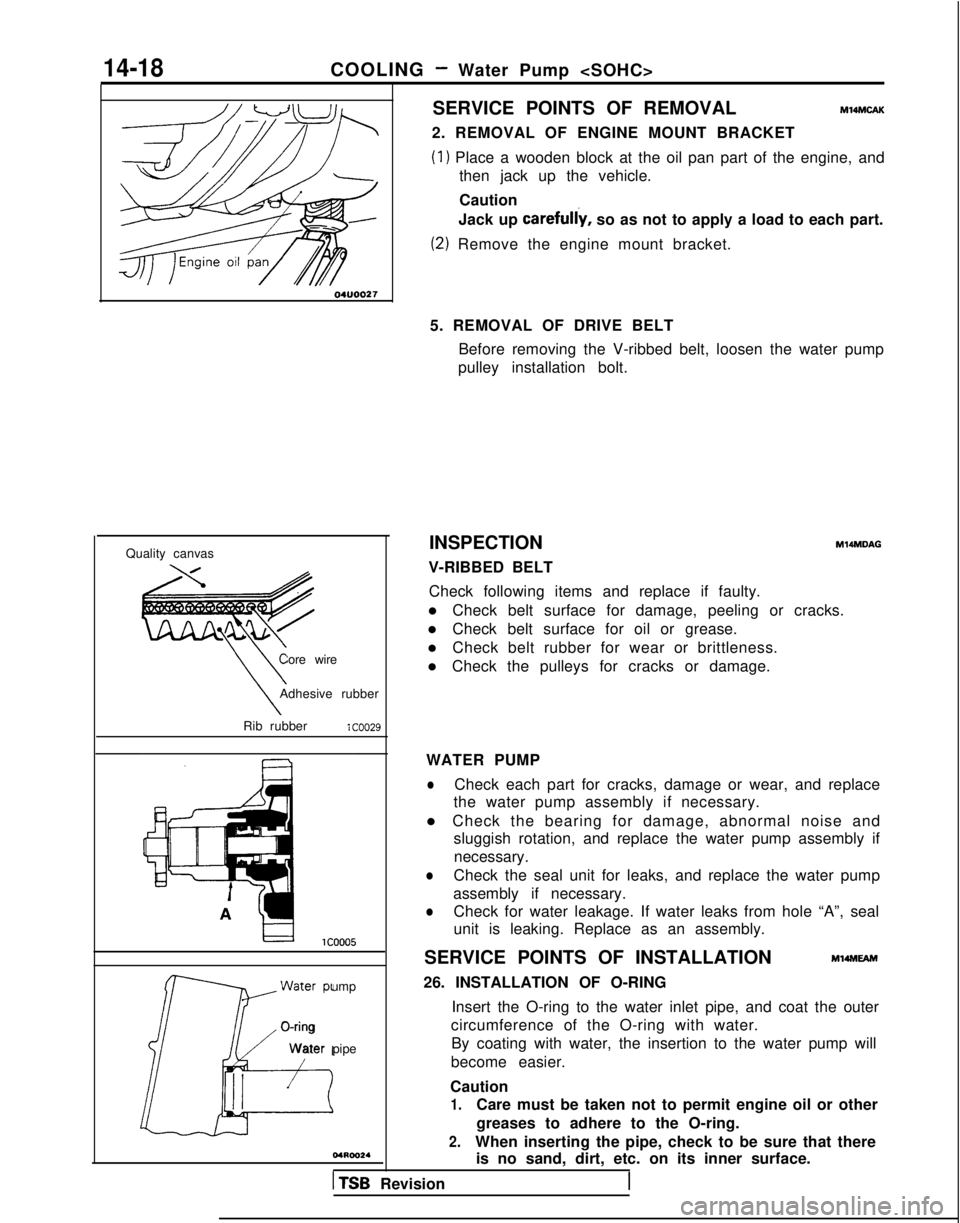

SERVICE POINTS OF REMOVALMl4MCAK

2. REMOVAL OF ENGINE MOUNT BRACKET

(1) Place a wooden block at the oil pan part of the engine, and

then jack up the vehicle.

Caution

Jack up carefully,

so as not to apply a load to each part.

(2) Remove the engine mount bracket.

5. REMOVAL OF DRIVE BELT Before removing the V-ribbed belt, loosen the water pump

pulley installation bolt.

INSPECTION

V-RIBBED BELT

M14MDAG

Check following items and replace if faulty.

l Check belt surface for damage, peeling or cracks.

l Check belt surface for oil or grease.

l Check belt rubber for wear or brittleness.

l Check the pulleys for cracks or damage.

WATER PUMP

lCheck each part for cracks, damage or wear, and replace

the water pump assembly if necessary.

l Check the bearing for damage, abnormal noise and sluggish rotation, and replace the water pump assembly if

necessary.

lCheck the seal unit for leaks, and replace the water pump

assembly if necessary.

lCheck for water leakage. If water leaks from hole “A”, seal

unit is leaking. Replace as an assembly.

SERVICE POINTS OF INSTALLATION

Ml4MEAm

26. INSTALLATION OF O-RING Insert the O-ring to the water inlet pipe, and coat the outer

circumference of the O-ring with water. By coating with water, the insertion to the water pump will

become easier.

Caution

1.Care must be taken not to permit engine oil or other

greases to adhere to the O-ring.

2.When inserting the pipe, check to be sure that there is no sand, dirt, etc. on its inner surface.

1 TSB Revision

Page 575 of 1273

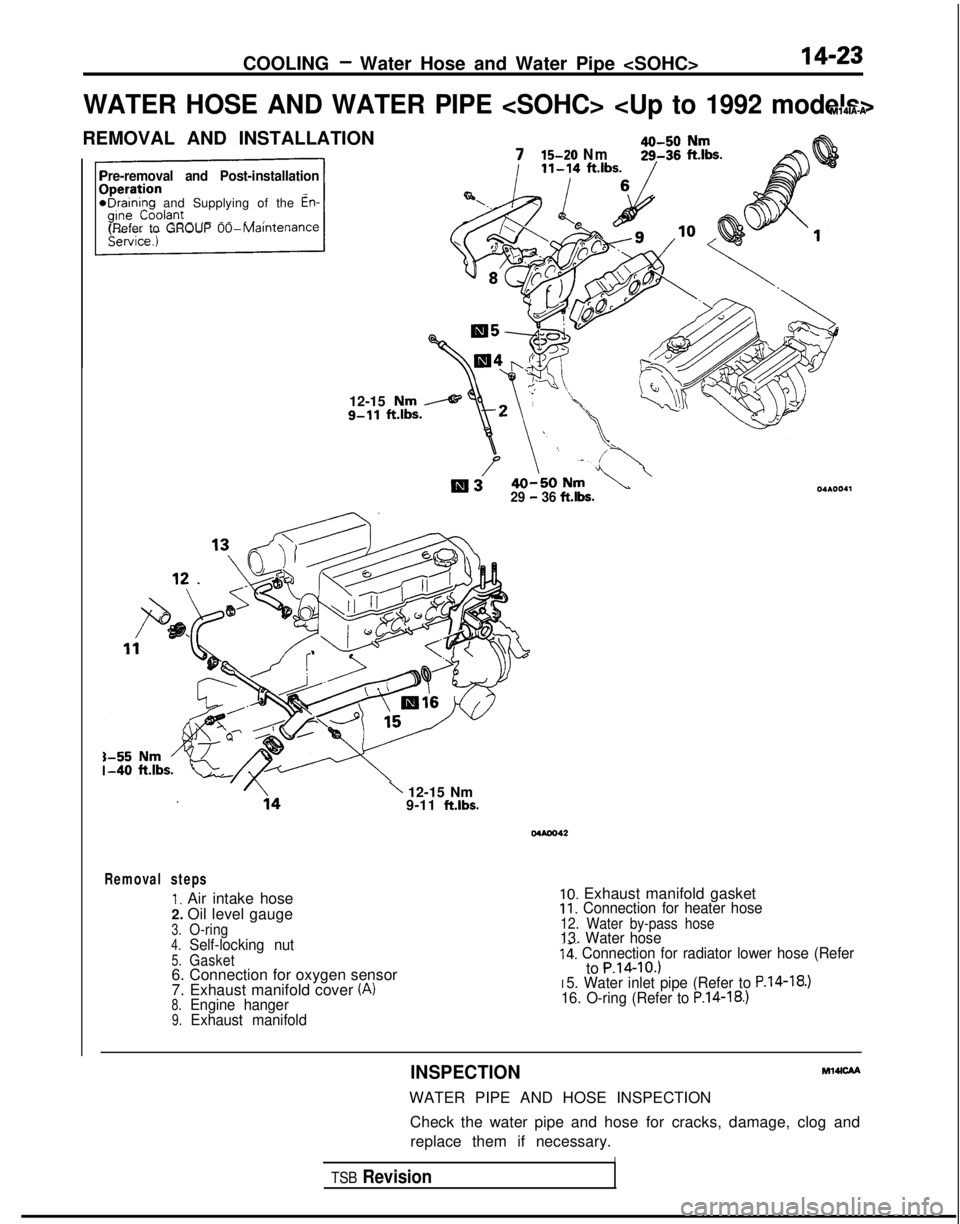

COOLING - Water Hose and Water Pipe

WATER HOSE AND WATER PIPE

REMOVAL AND INSTALLATION

Pre-removal and Post-installation

*Draining and Supplying of the En-

(Refer to GROUP 00-Maintenance

12-15 Nm

g-11

ft.lbs.

715-20 Nm

Ill329 - 36 fths.

\ 12-15 Nm

9-11 ft.lbs.

Mbm42

Removal steps

1. Air intake hose

2. Oil level gauge

3.O-ring4.Self-locking nut5.Gasket6. Connection for oxygen sensor

7. Exhaust manifold cover (A)

8.Engine hanger9.Exhaust manifold

10. Exhaust manifold gasket11. Connection for heater hose12. Water by-pass hose13. Water hosei41 Connection for radiator lower hose (Referto P.14-IO.)I 5. Water inlet pipe (Refer to P.14-18.)16. O-ring (Refer to P.14-18.)

INSPECTIONMl4lcAA

WATER PIPE AND HOSE INSPECTION

Check the water pipe and hose for cracks, damage, clog andreplace them if necessary.

ITSB Revision

Page 584 of 1273

14-32COOLING -Engine Coolant Temperature Gauge Unit, Engine Coolant

Temperature Sensor and Engine Coolant Temperature Switch

/

Sensor

J

046003

3

04GOO32

9FUO156

---

--I ‘Oi

l

QQQQQQ2cmn99

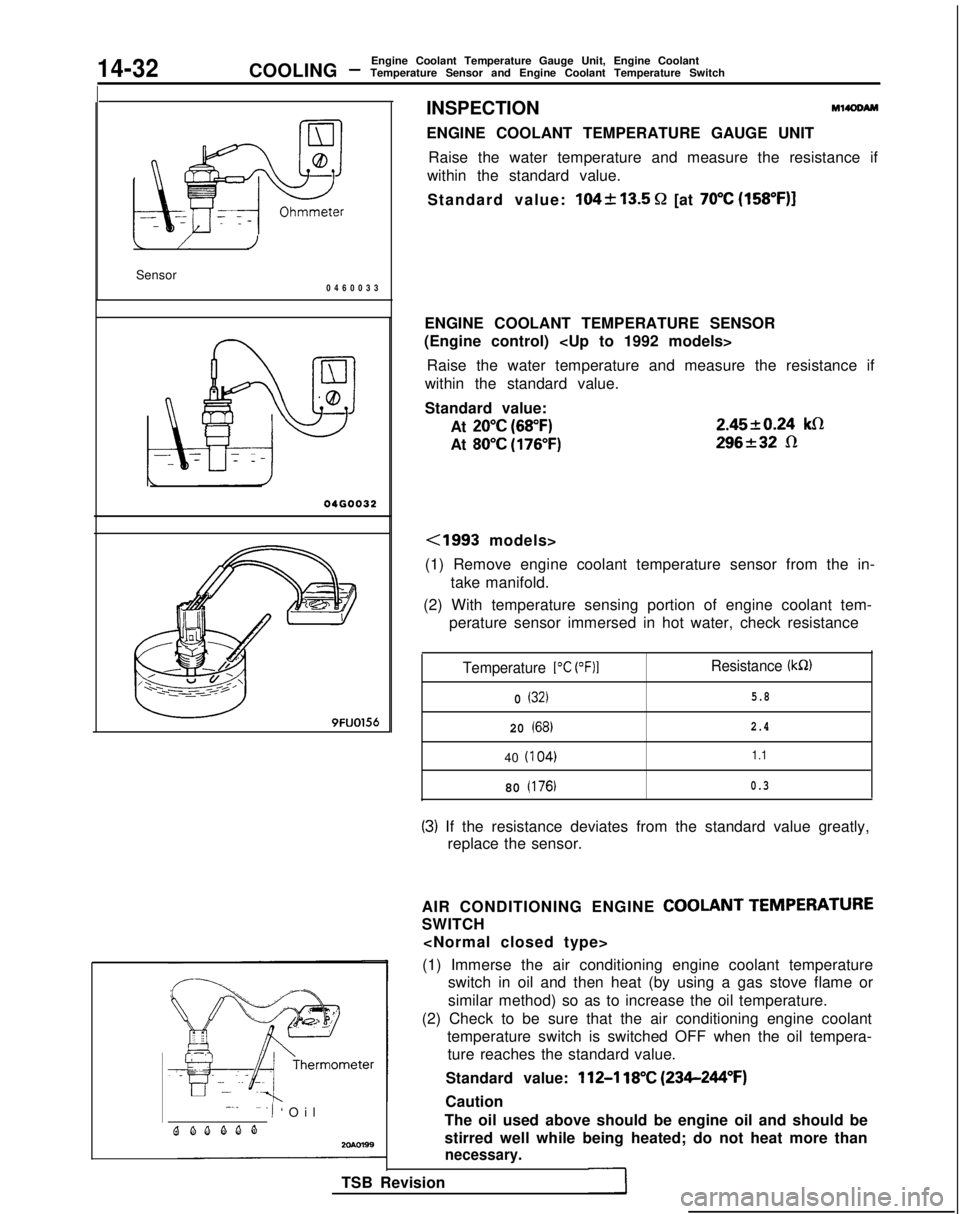

INSPECTIONM14OOAM

ENGINE COOLANT TEMPERATURE GAUGE UNIT

Raise the water temperature and measure the resistance if

within the standard value.

Standard value:

104k13.5 Q [at 70°C (158”F)]

ENGINE COOLANT TEMPERATURE SENSOR

(Engine control)

Raise the water temperature and measure the resistance if

within the standard value.

Standard value:

At

20°C (68°F)

At 80°C (176°F) 2.4520.24

klR

296232 R

<1993 models>

(1) Remove engine coolant temperature sensor from the in- take manifold.

(2) With temperature sensing portion of engine coolant tem- perature sensor immersed in hot water, check resistance

Temperature 1°C (OF)1Resistance (kR)

0 (32)5.8

20 (68)2.4

40

(I

04)1.1

80 (176)0.3

(3) If the resistance deviates from the standard value greatly,

replace the sensor.

AIR CONDITIONING ENGINE

COOLANT TEMPERATURE

SWITCH

(1) Immerse the air conditioning engine coolant temperature switch in oil and then heat (by using a gas stove flame or

similar method) so as to increase the oil temperature.

(2) Check to be sure that the air conditioning engine coolant temperature switch is switched OFF when the oil tempera-ture reaches the standard value.

Standard value:

112-l 18°C (234-244°F)

Caution

The oil used above should be engine oil and should be

stirred well while being heated; do not heat more than

necessary.

TSB Revision