check engine MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 968 of 1273

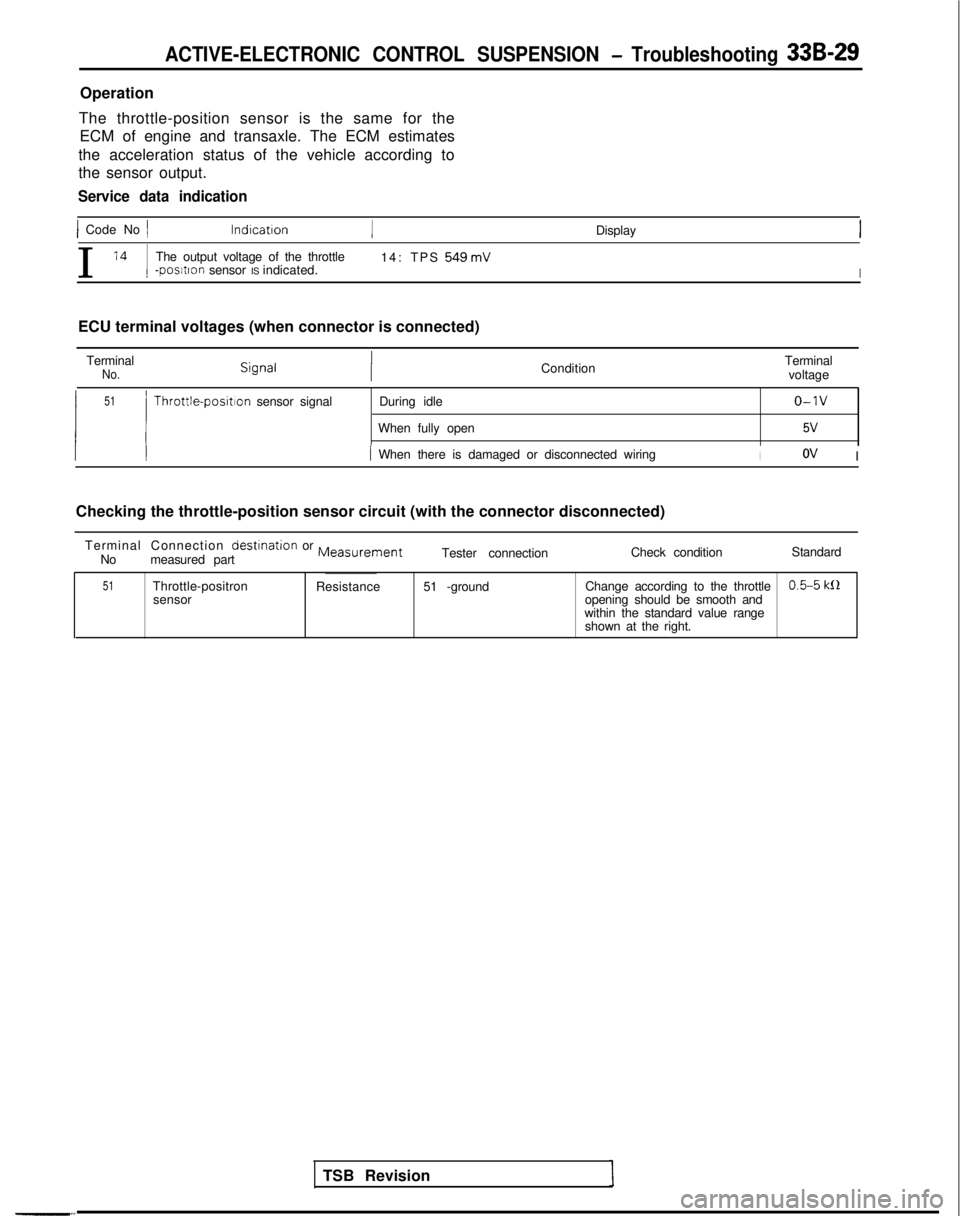

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-29

Operation

The throttle-position sensor is the same for the ECM of engine and transaxle. The ECM estimates

the acceleration status of the vehicle according to

the sensor output.

Service data indication

) Code No 1 lndrcatron

Display

I

l4 1

The output voltage of the throttle 14: TPS 549mV-postron sensor IS indicated.I

ECU terminal voltages (when connector is connected)

Terminal

No.Condition Terminal

voltage

51

1 !

Throttle-posrtlon sensor signal During idleo-1v

When fully open5v

/ When there is damaged or disconnected wiringIov I

Checking the throttle-position sensor circuit (with the connector disco\

nnected) Terminal Connection

destrnation or MeasurementNo measured part Tester connection

Check condition

Standard

51Throttle-positron

sensor Resistance

51 -ground Change according to the throttle0.5-5 k0opening should be smooth and

within the standard value range shown at the right.

TSB Revision

Page 982 of 1273

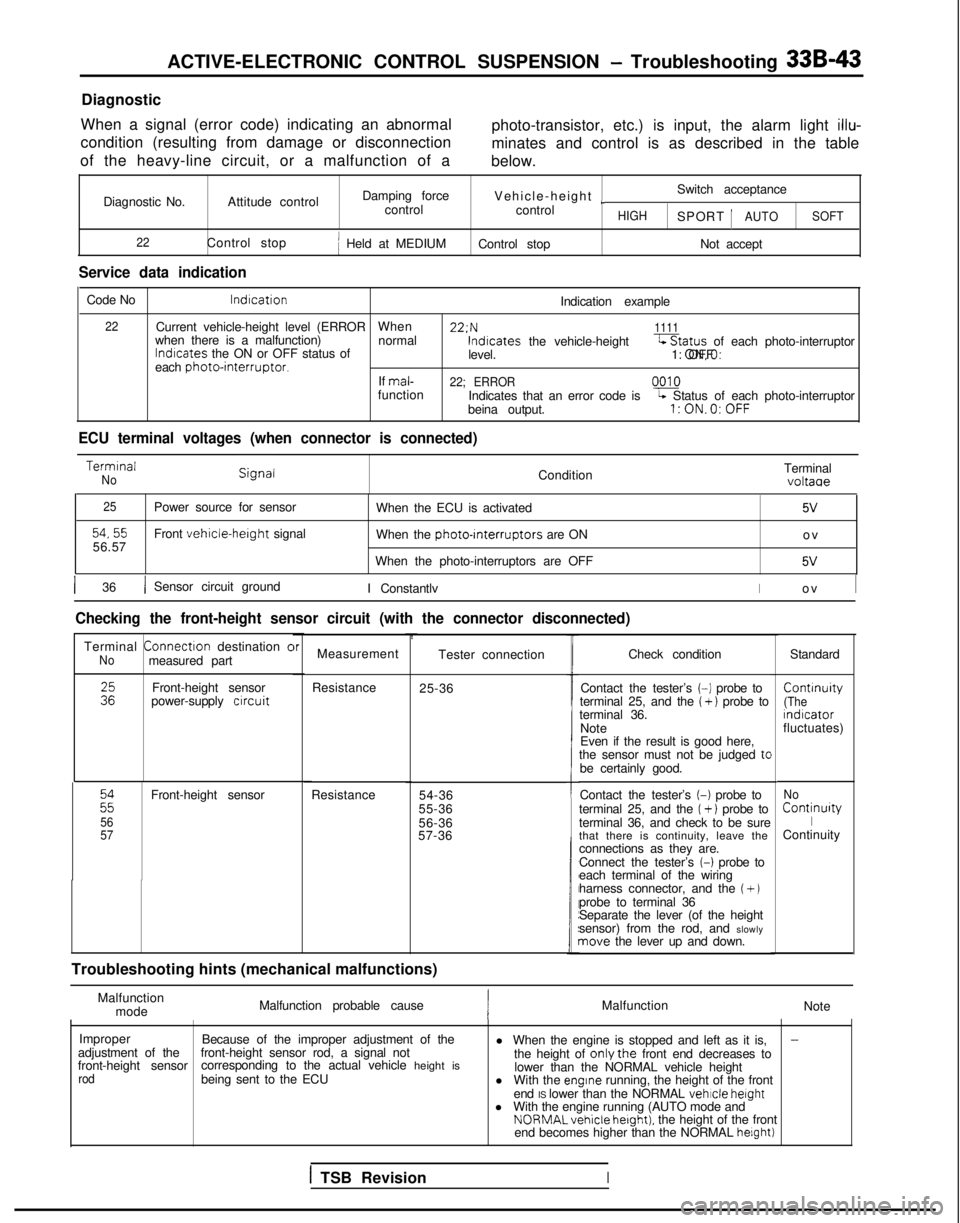

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-43

Diagnostic

When a signal (error code) indicating an abnormal

condition (resulting from damage or disconnection

of the heavy-line circuit, or a malfunction of a photo-transistor, etc.) is input, the alarm light

illu-

minates and control is as described in the table

below.

Diagnostic No. Attitude control Damping force

Vehicle-height

~Switch acceptance

control control

HIGHSPORT 1AUTOSOFT

22

Control stopj Held at MEDIUM Control stop Not accept

Service data indication

Code No lndrcation

Indication example

22Current vehicle-height level (ERRORWhen 22:N1111when there is a malfunction)

normallndrcates

the ON or OFF status of lndtcates

the vehicle-height-Status of each photo-interruptor

level. 1: ON,O: OFF

each

photointerruptor.If mal-22; ERRORfunction

0010

Indicates that an error code isL Status of each photo-interruptor

beina output.l:ON.O:OFF

ECU terminal voltages (when connector is connected) Termrnal

NoCondition

Terminalvoltaae

25

54,5556.57Power source for sensor

Front vehicle-herght signal

When the ECU is activated

5V

When the photo-rnterruptors are ON

o

v

When the photo-interruptors are OFF

5V

1 36/ Sensor circuit ground I ConstantlvIo

v

I

Checking the front-height sensor circuit (with the connector disconnect\

ed)

Terminal

Connectron

destination cNomeasured part

:zFront-height sensor

power-supply crrcuit

22

56

57

Front-height sensor

Resistance

brMeasurement

Resistance 25-36Tester connection

54-36

55-36

56-36

57-36

t

Troubleshooting hints (mechanical malfunctions) Check condition

Standard

Contact the tester’s

(-1 probe to Contrnuity

terminal 25, and the ( + ) probe to(Theterminal 36.

rndrcator

Note fluctuates)

Even if the result is good here,

the sensor must not be judged

tcbe certainly good.

Contact the tester’s

(-1 probe to

terminal 25, and the (+ 1 probe to

terminal 36, and check to be sure

that there is continuity, leave the

connections as they are.

Connect the tester’s

(-1 probe to

each terminal of the wiring

harness connector, and the

(+ Jprobe to terminal 36

Separate the lever (of the height

sensor) from the rod, and slowly

nave the lever up and down.

No Continurty

IContinuity

Malfunction mode Malfunction probable cause

Malfunction

Note

Improper Because of the improper adjustment of the

-adjustment of the

front-height sensorfront-height sensor rod, a signal not

l When the engine is stopped and left as it is,

corresponding to the actual vehicle height is the height of onlythe front end decreases to

rodbeing sent to the ECU lower than the NORMAL vehicle height

l With the engrne running, the height of the front

end IS lower than the NORMAL vehicle

height

l With the engine running (AUTO mode and NORMALvehicle

hetght). the height of the front

end becomes higher than the NORMAL helght)

1 TSB RevisionI

Page 984 of 1273

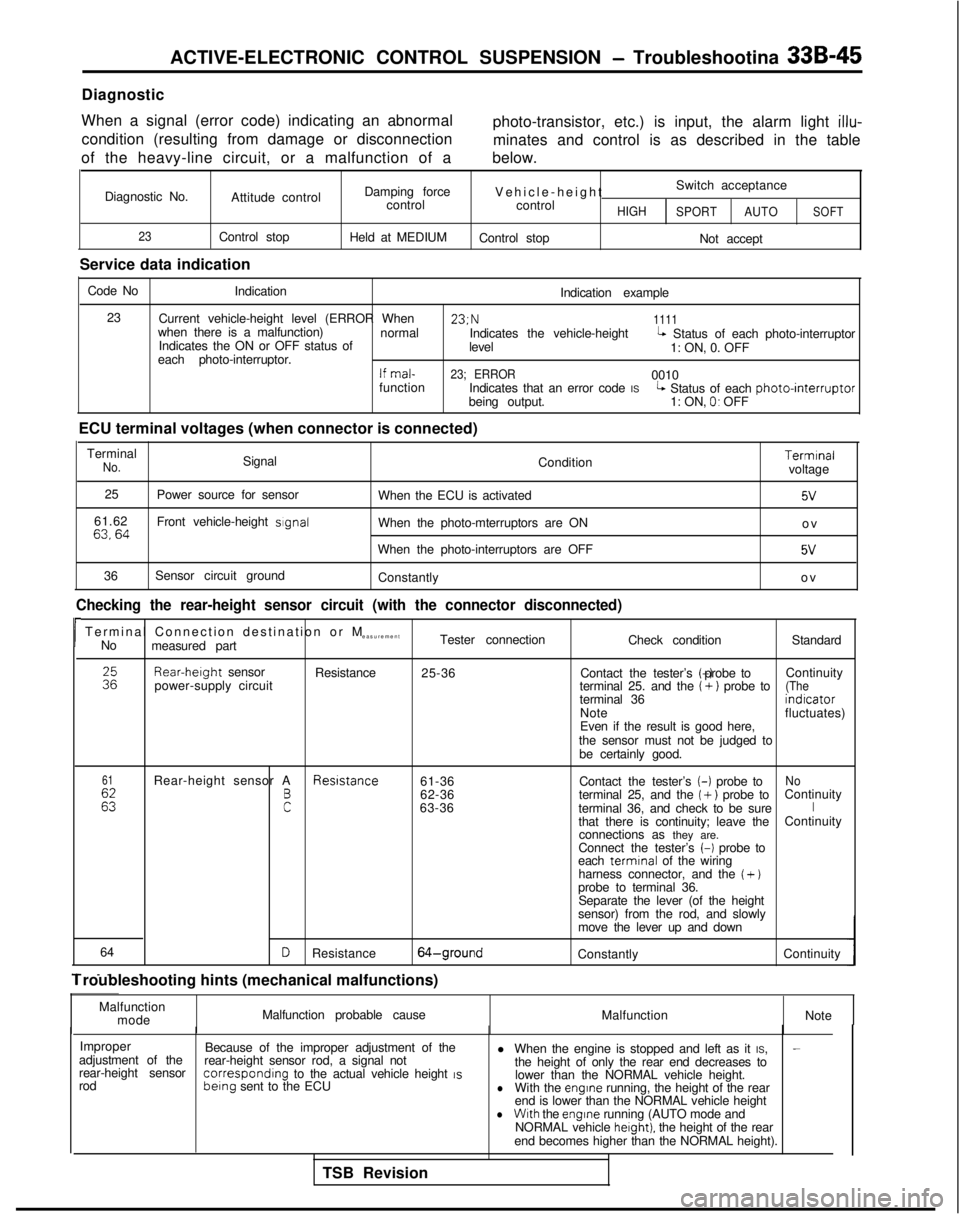

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshootina 33B-45

Diagnostic

When a signal (error code) indicating an abnormal condition (resulting from damage or disconnection

of the heavy-line circuit, or a malfunction of a photo-transistor, etc.) is input, the alarm light

illu-

minates and control is as described in the table

below.

Diagnostic No. Attitude control

23Control stop

Service data indication Damping force

control

Held at MEDIUM Vehicle-heigh

t

Switch acceptance

control

HIGH SPORT AUTOSOFT

Control stop

Not accept

Code No Indication

Indication example

23 Current vehicle-height level (ERROR When 23;N

1111when there is a malfunction)

normal

Indicates the ON or OFF status of Indicates the vehicle-height

levelL Status of each photo-interruptor

each photo-interruptor. 1: ON, 0. OFF

If mal-23; ERROR0010

function Indicates that an error code IS

being output.L Status of each photointerruptor1: ON, 0. OFF

ECU terminal voltages (when connector is connected) Terminal

No.Signal Condition

25 Power source for sensor

When the ECU is activated

61.62

63,64Front vehicle-height sIgnalWhen the photo-mterruptors are ON

When the photo-interruptors are OFF

36 Sensor circuit ground

Constantly Terminal

voltage

5v

o

v

5V

o

v

Checking the rear-height sensor circuit (with the connector disconnecte\

d)

rTerminal Connection destination or

M

easurement

No measured part Tester connection

Check conditionStandardRear-herght

sensor

power-supply circuit Resistance

25-36 Contact the tester’s (-) probe to

Continuity

terminal 25. and the

(+) probe to(Theterminal 36 indrcator

Note fluctuates)

Even if the result is good here,

the sensor must not be judged to be certainly good.

61

Es

Rear-height sensor A Resrstance

61-36No

F

Contact the tester’s (-)

probe to

62-36 terminal 25, and the ( +) probe toContinuity

63-36 terminal 36, and check to be sureIthat there is continuity; leave the Continuity

connections as they are.

Connect the tester’s

(-1 probe to

each termrnal

of the wiring

harness connector, and the

( +)probe to terminal 36. Separate the lever (of the height

sensor) from the rod, and slowly

move the lever up and down

64

- _. .

DResistance64-groundConstantly Continuity

1 roubleshooting hints (mechanical malfunctions)

Malfunctionmode Malfunction probable cause

MalfunctionNote

Improper Because of the improper adjustment of the l When the engine is stopped and left as it IS,

-adjustment of the

rear-height sensorrear-height sensor rod, a signal not

the height of only the rear end decreases to

rod correspondrng

to the actual vehicle height IS berng

sent to the ECU lower than the NORMAL vehicle height.lWith the engrne running, the height of the rear

end is lower than the NORMAL vehicle height

lWith the engine

running (AUTO mode and

NORMAL vehicle herght). the height of the rear

end becomes higher than the NORMAL height).

TSB Revision

Page 986 of 1273

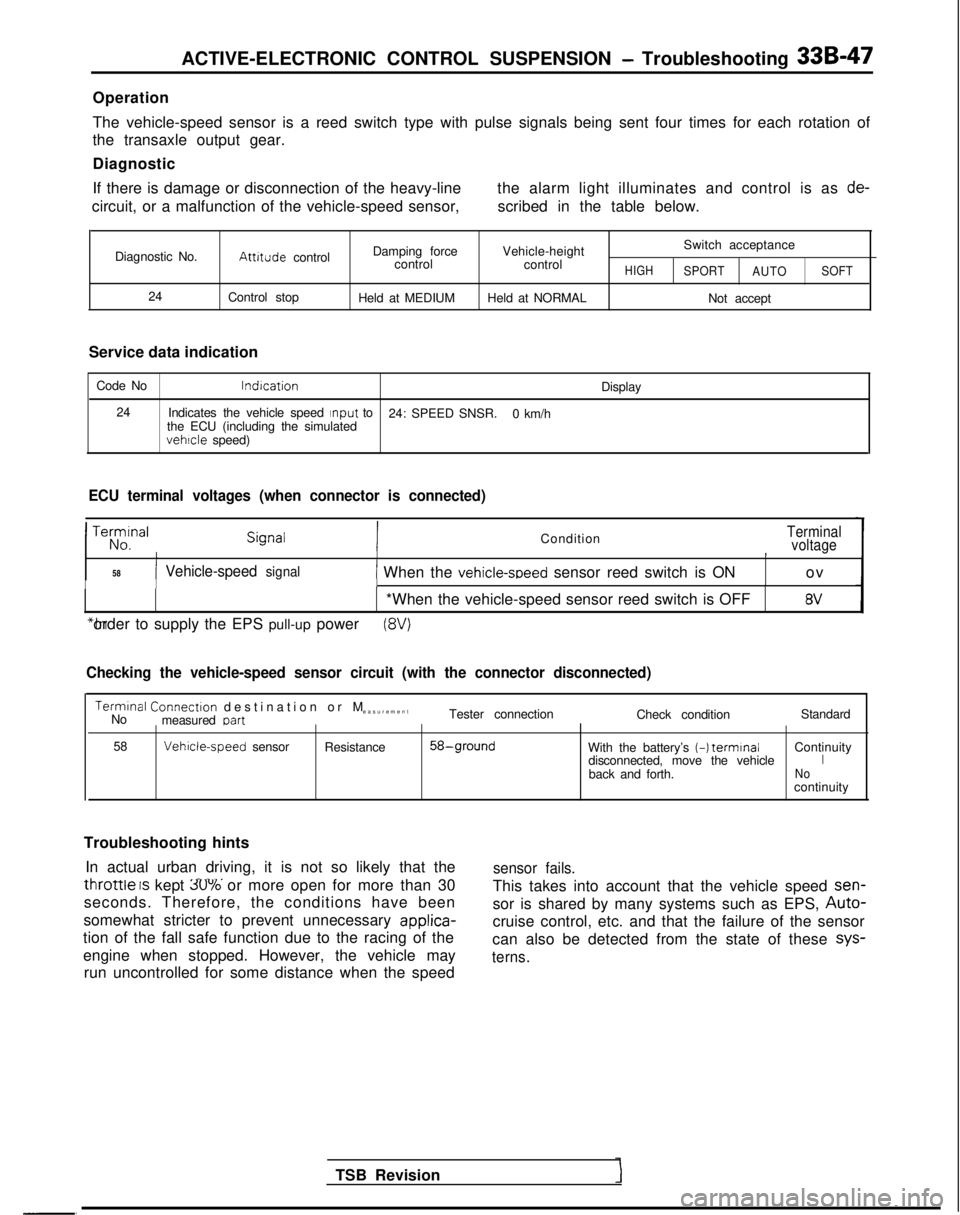

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-47

Operation

The vehicle-speed sensor is a reed switch type with pulse signals being \

sent four times for each rotation of

the transaxle output gear.

Diagnostic

If there is damage or disconnection of the heavy-line

the alarm light illuminates and control is as

de-

circuit, or a malfunction of the vehicle-speed sensor, scribed in the table below.

Diagnostic No. 24

Attitude control Damping force

Vehicle-height Switch acceptance

control controlHIGHSPORTAUTO SOFT

Control stop

Held at MEDIUMHeld at NORMAL

Not accept

Service data indication Code No lndrcation

Display

24 Indicates the vehicle speed Input

to

24: SPEED SNSR. 0 km/h

the ECU (including the simulated

vehicle speed)

ECU terminal voltages (when connector is connected)

ITerNmo_na’ConditionTerminal

voltage

I I

58 /

I

Vehicle-speed signal1 When the vehicle-speed sensor reed switch is ONo

v

IIII

*When the vehicle-speed sensor reed switch is OFF8V

TSB Revision

*In order to supply the EPS pull-up power

(8V)

Checking the vehicle-speed sensor circuit (with the connector disconnec\

ted)

Termrnal

Connectron

destination or M

easurement

No measured part

Tester connection

Check conditionStandard

58 Vehrcle-speed

sensor

Resistance

58-groundWith the battery’s (-1 termrnal

Continuity

disconnected, move the vehicleIback and forth.Nocontinuity

Troubleshooting hints In actual urban driving, it is not so likely that the

sensor fails.., ^_^.tnrottle IS kept 3U% or more open for more than 30

seconds. Therefore, the conditions have been This takes into account that the vehicle speed sen-

somewhat stricter to prevent unnecessary applica-

sor is shared by many systems such as EPS,

Auto-

tion of the fall safe function due to the racing of the cruise control, etc. and that the failure of the sensor

engine when stopped. However, the vehicle may can also be detected from the state of these sys-

terns.run uncontrolled for some distance when the speed

Page 1026 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSIONService Adjustment- Procedures33B-87

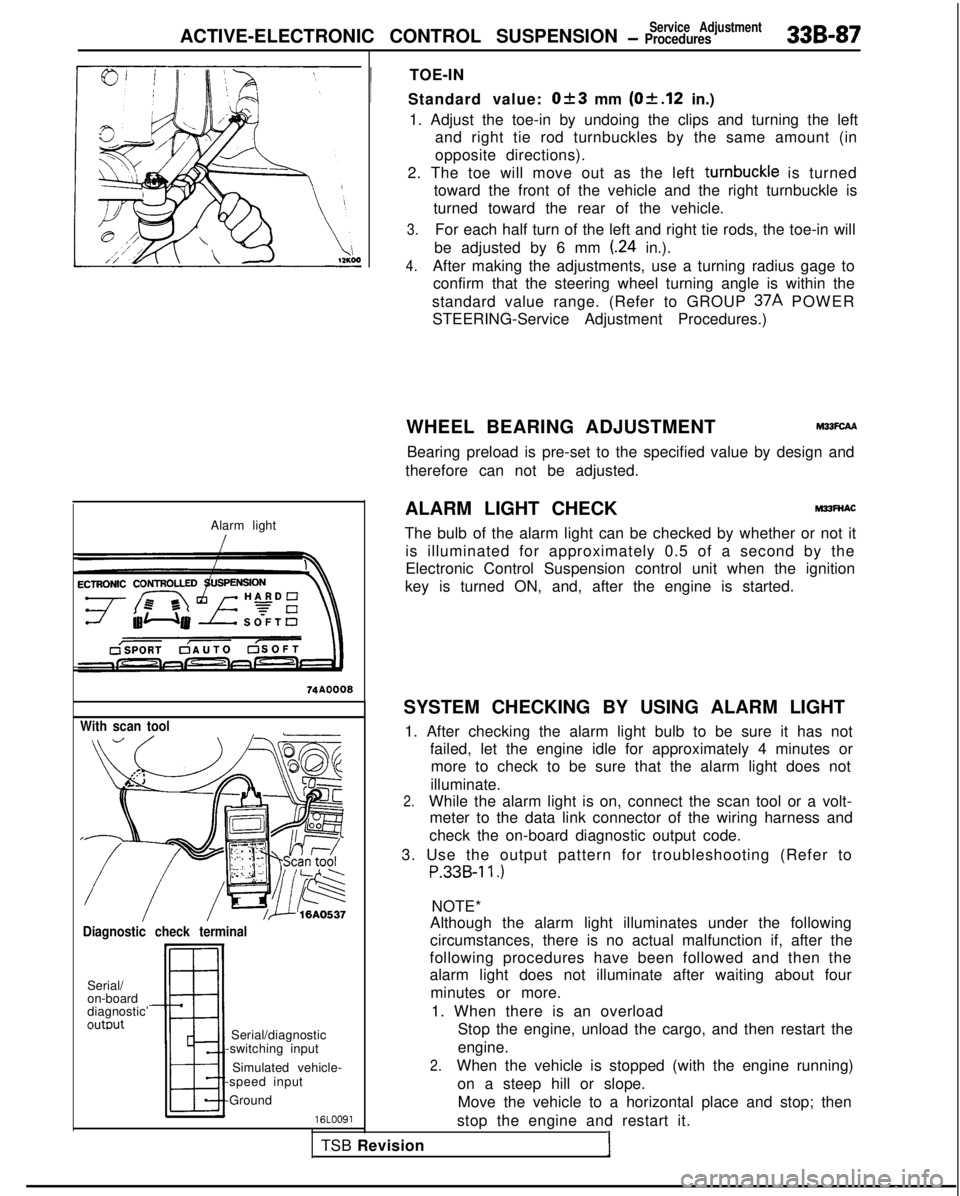

Alarm light

With scan tool

Diagnostic check terminal

Serial/

on-board

diagnostic’

outwt

TSB RevisionI

Serial/diagnostic

-switching input

Simulated vehicle-

-speed input

-Ground

16LOO91

!

TOE-IN

Standard value:

Ok3 mm (Of.12 in.)

1. Adjust the toe-in by undoing the clips and turning the left and right tie rod turnbuckles by the same amount (in

opposite directions).

2. The toe will move out as the left turnbuckle

is turned

toward the front of the vehicle and the right turnbuckle is

turned toward the rear of the vehicle.

3.For each half turn of the left and right tie rods, the toe-in will

be adjusted by 6 mm

(.24 in.).

4.After making the adjustments, use a turning radius gage to confirm that the steering wheel turning angle is within the

standard value range. (Refer to GROUP 37A

POWER

STEERING-Service Adjustment Procedures.)

WHEEL BEARING ADJUSTMENT

M33FcAA

Bearing preload is pre-set to the specified value by design and

therefore can not be adjusted.

ALARM LIGHT CHECK

MPFNAC

The bulb of the alarm light can be checked by whether or not it is illuminated for approximately 0.5 of a second by the

Electronic Control Suspension control unit when the ignition

key is turned ON, and, after the engine is started.

SYSTEM CHECKING BY USING ALARM LIGHT 1. After checking the alarm light bulb to be sure it has not failed, let the engine idle for approximately 4 minutes ormore to check to be sure that the alarm light does not

illuminate.

2.While the alarm light is on, connect the scan tool or a volt- meter to the data link connector of the wiring harness and

check the on-board diagnostic output code.

3. Use the output pattern for troubleshooting (Refer to

P.33B-11.)

NOTE*

Although the alarm light illuminates under the following

circumstances, there is no actual malfunction if, after the

following procedures have been followed and then the

alarm light does not illuminate after waiting about four

minutes or more.

1. When there is an overload Stop the engine, unload the cargo, and then restart the

engine.

2.When the vehicle is stopped (with the engine running)

on a steep hill or slope.Move the vehicle to a horizontal place and stop; then

stop the engine and restart it.

Page 1027 of 1273

338-88 ACTIVE-ELECTRONIC CONTROL SUSPENSION - ~~~%.,~Rment

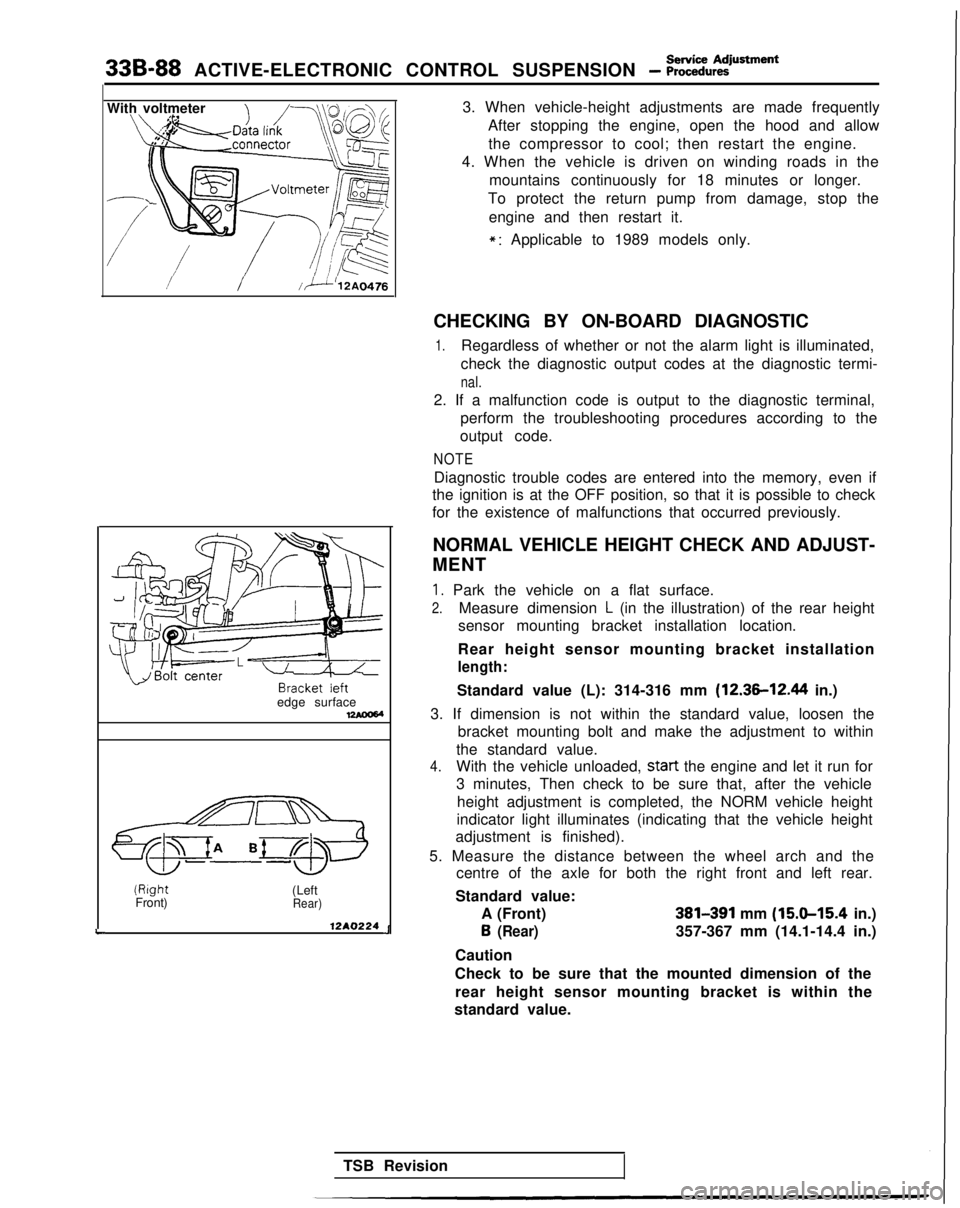

With voltmeter

!//ii’12A0476

L

edge surface17AOOW(Right

Front) (Left

Rear)

12A0224 J3. When vehicle-height adjustments are made frequently

After stopping the engine, open the hood and allowthe compressor to cool; then restart the engine.

4. When the vehicle is driven on winding roads in the

mountains continuously for 18 minutes or longer.

To protect the return pump from damage, stop the

engine and then restart it.

*: Applicable to 1989 models only.

CHECKING BY ON-BOARD DIAGNOSTIC

1.Regardless of whether or not the alarm light is illuminated,

check the diagnostic output codes at the diagnostic termi-

nal.

2. If a malfunction code is output to the diagnostic terminal, perform the troubleshooting procedures according to the

output code.

NOTE

Diagnostic trouble codes are entered into the memory, even if

the ignition is at the OFF position, so that it is possible to check

for the existence of malfunctions that occurred previously.

NORMAL VEHICLE HEIGHT CHECK AND ADJUST-

MENT

1. Park the vehicle on a flat surface.

2.Measure dimension L (in the illustration) of the rear height

sensor mounting bracket installation location.

Rear height sensor mounting bracket installation

length:

Standard value (L): 314-316 mm (12.36-12.44 in.)

3. If dimension is not within the standard value, loosen the bracket mounting bolt and make the adjustment to within

the standard value.

4.With the vehicle unloaded, start

the engine and let it run for

3 minutes, Then check to be sure that, after the vehicle

height adjustment is completed, the NORM vehicle height

indicator light illuminates (indicating that the vehicle height

adjustment is finished).

5. Measure the distance between the wheel arch and the centre of the axle for both the right front and left rear.

Standard value: A (Front)

381391 mm (15.9-15.4 in.) 6

(Rear)357-367 mm (14.1-14.4 in.)

Caution

Check to be sure that the mounted dimension of the rear height sensor mounting bracket is within the

standard value.

TSB Revision

Page 1028 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - ~~:i%,~:iustment 33B-89

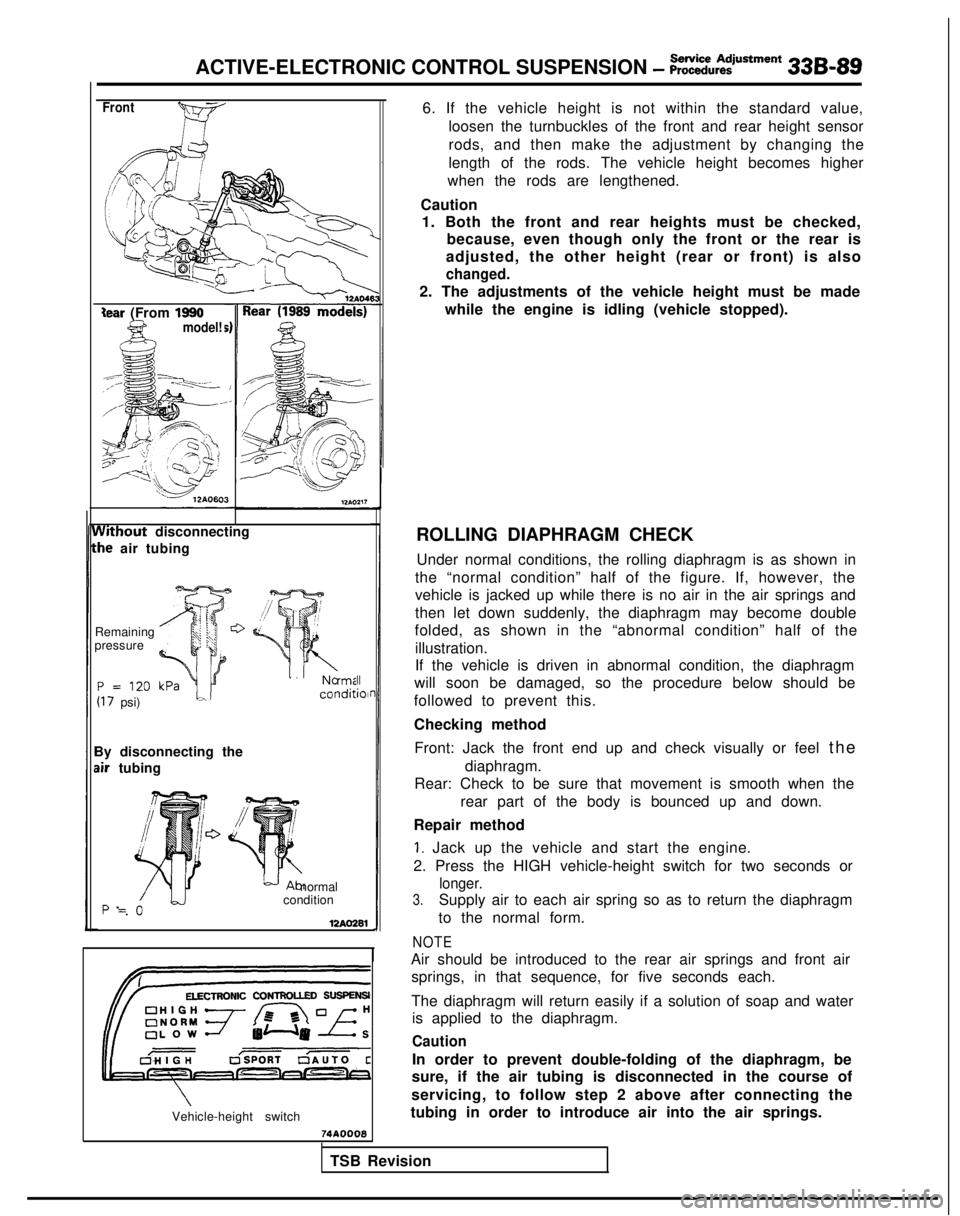

Without

disconnecting

:he air tubing

Remaining

pressure

P =

120 kPa

(17 psi)

By disconnecting the

fir tubing

normal

condition

P ‘=.0

Front

tear (From 1990

model!

rmzIIconditlui

12AO281

Vehicle-height switch 6. If the vehicle height is not within the standard value,

loosen the turnbuckles of the front and rear height sensor

rods, and then make the adjustment by changing the

length of the rods. The vehicle height becomes higher

when the rods are lengthened.

Caution 1. Both the front and rear heights must be checked, because, even though only the front or the rear is

adjusted, the other height (rear or front) is also

changed.

2. The adjustments of the vehicle height must be made

while the engine is idling (vehicle stopped).

ROLLING DIAPHRAGM CHECK Under normal conditions, the rolling diaphragm is as shown in

the “normal condition” half of the figure. If, however, the

vehicle is jacked up while there is no air in the air springs and

then let down suddenly, the diaphragm may become double

folded, as shown in the “abnormal condition” half of the

illustration.

If the vehicle is driven in abnormal condition, the diaphragm

will soon be damaged, so the procedure below should be

followed to prevent this.

Checking method

Front: Jack the front end up and check visually or feel th

e

diaphragm.

Rear: Check to be sure that movement is smooth when the

rear part of the body is bounced up and down.

Repair method

1. Jack up the vehicle and start the engine.

2. Press the HIGH vehicle-height switch for two seconds or

longer.

3.Supply air to each air spring so as to return the diaphragm

to the normal form.

NOTE

Air should be introduced to the rear air springs and front air springs, in that sequence, for five seconds each.

The diaphragm will return easily if a solution of soap and water is applied to the diaphragm.

Caution

In order to prevent double-folding of the diaphragm, be

sure, if the air tubing is disconnected in the course of

servicing, to follow step 2 above after connecting the

tubing in order to introduce air into the air springs.

74AOOQ8

TSB Revision

Page 1030 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - %ii%:justment 33B-91

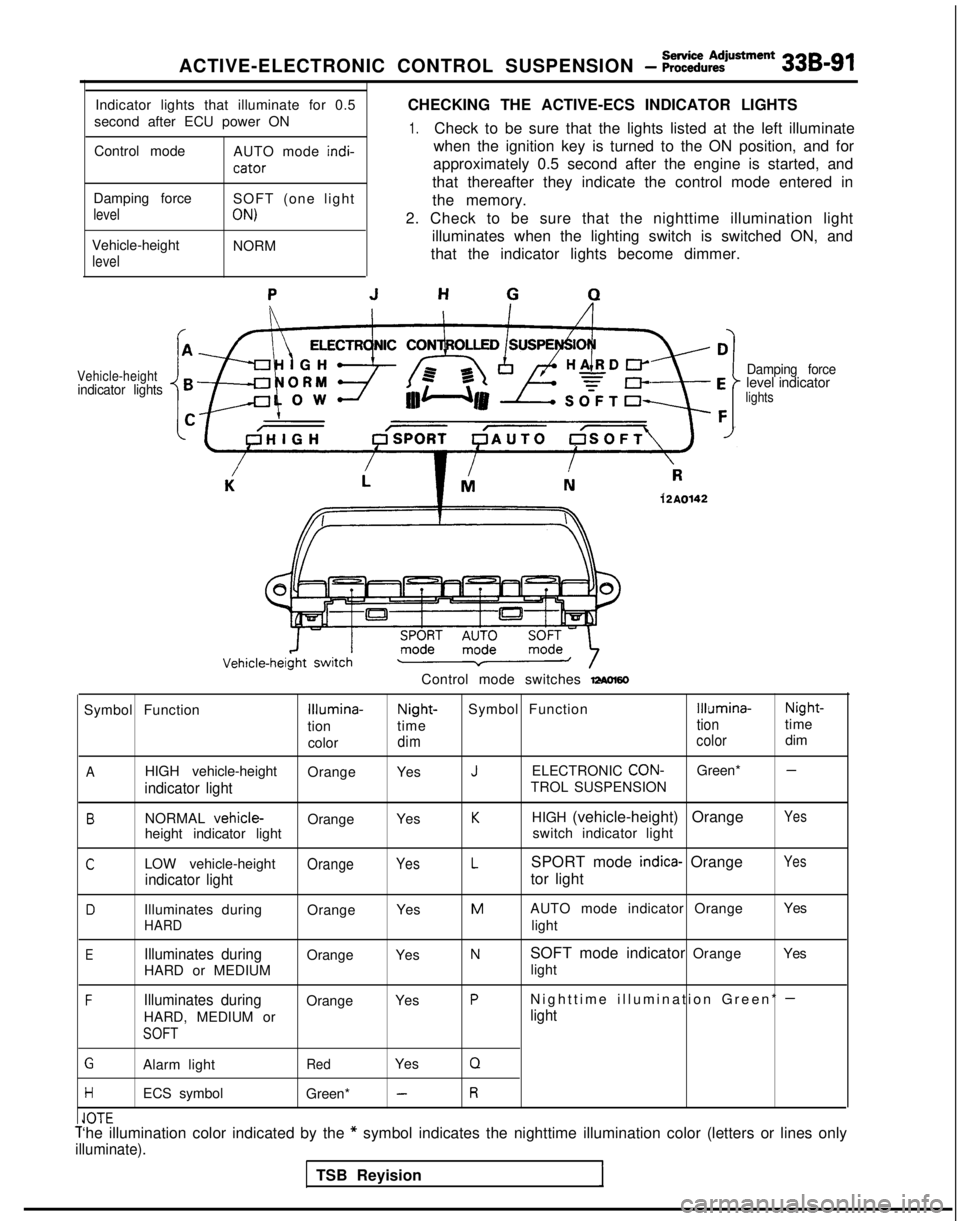

Indicator lights that illuminate for 0.5

second after ECU power ON

Control mode AUTO mode indi-

cator

CHECKING THE ACTIVE-ECS INDICATOR LIGHTS

1.Check to be sure that the lights listed at the left illuminate

when the ignition key is turned to the ON position, and for

approximately 0.5 second after the engine is started, and

that thereafter they indicate the control mode entered in

Damping force

level

Vehicle-height

level

SOFT (one light

ON)

NORM the memory.

2. Check to be sure that the nighttime illumination light illuminates when the lighting switch is switched ON, and

that the indicator lights become dimmer.

Vehicle-heightindicator lights Damping forcelevel indicatorlights

12A0142

Control mode switches -60

Symbol FunctionIllumina-Night-

Symbol FunctionIllumina- Night-

tion time

tiontime

color

dim colordim

AHIGH vehicle-height

OrangeYesJELECTRONIC CON-Green* -

indicator lightTROL SUSPENSION

BNORMAL vehicle-OrangeYesKHIGH (vehicle-height) OrangeYes

height indicator light switch indicator light

CLOW vehicle-heightOrangeYesLSPORT mode indica- OrangeYes

indicator lighttor light

DIlluminates during

OrangeYesMAUTO mode indicator Orange Yes

HARDlight

EIlluminates duringOrange

YesNSOFT mode indicator Orange Yes

HARD or MEDIUM light

FIlluminates duringOrange

YesPNighttime illumination Green* -

HARD, MEDIUM orlight

SOFT

GAlarm lightRedYesQ

HECS symbol

Green* -R

IA-r-Cl”lCT‘he illumination color indicated by the * symbol indicates the nighttime illumination color (letters or lines on\

ly

illuminate).

TSB Reyision

Page 1031 of 1273

33B-92 ACTIVE-ELECTRONIC CONTROL SUSPENSION - ~~:%:?stment

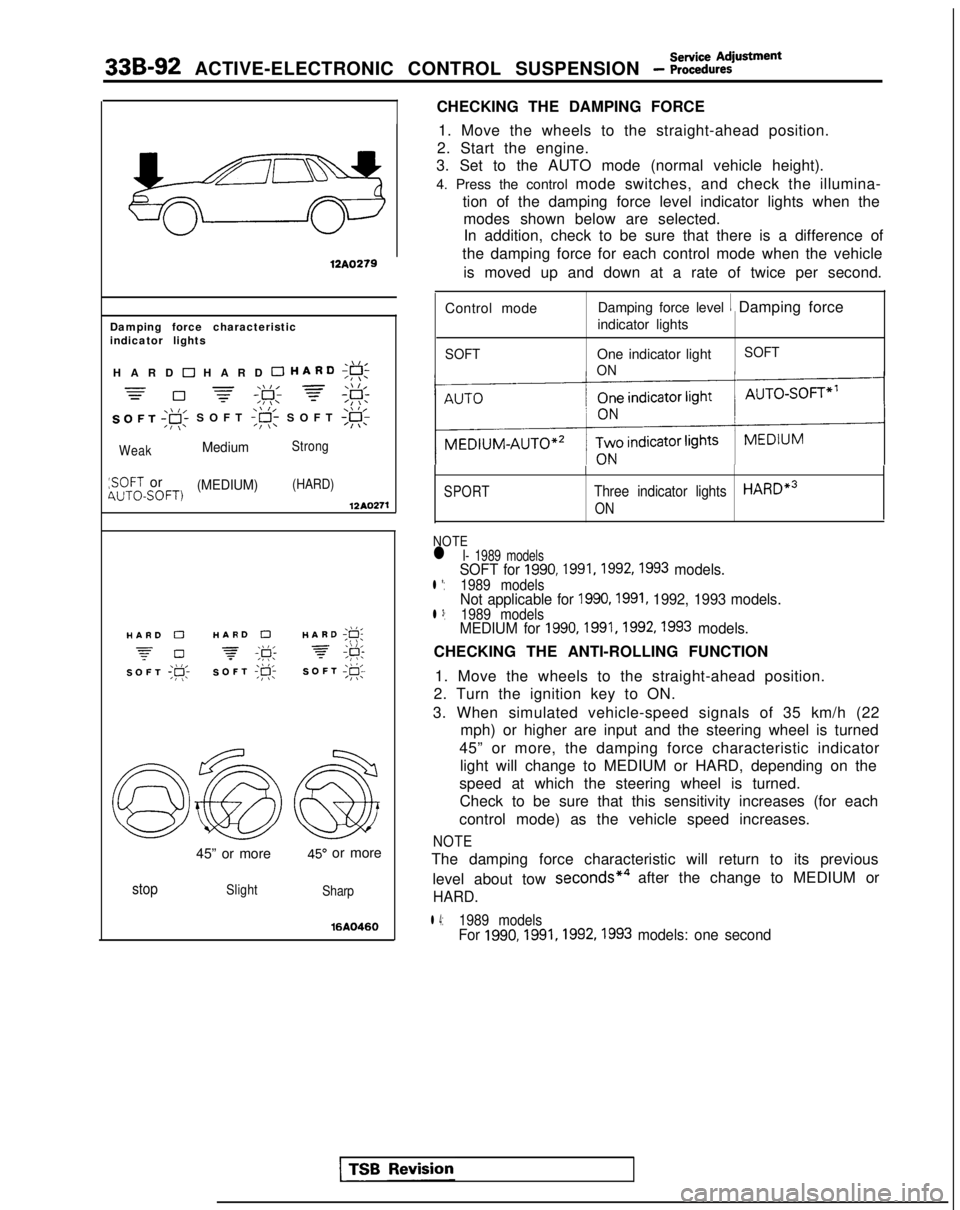

CHECKING THE DAMPING FORCE

12A0279

Damping force characteristic

indicator lights

,\,IHARD 0 HARD 0 HARD;g!;

=-\\I, =\\ l,=0 -=-,F; f;F:

SOFT ,gi SOFT

:SOFT or(MEDIUM)(HARD)4UTOSOFT)12AQ271

./I,HARD 0HARD 0HARD ;g;

z-0 -\k 3,\I I,SOFT ;p;SOFT ;R-SOFT I@;

45” or more45” or more

stopSlight

Sharp

16AQ460

1. Move the wheels to the straight-ahead position.

2. Start the engine.

3. Set to the AUTO mode (normal vehicle height).

4. Press the control mode switches, and check the illumina-

tion of the damping force level indicator lights when themodes shown below are selected.In addition, check to be sure that there is a difference of

the damping force for each control mode when the vehicle

is moved up and down at a rate of twice per second.

Control mode Damping force level

1 Damping force

indicator lights

SOFTOne indicator light

ON SOFT

SPORT

I

Three indicator lightsHARDe3

ON

NOTEl I- 1989 modelsSOFT for 1990,1991,1992,1993 models.l *:1989 modelsNot applicable for 1990,1991, 1992, 1993 models.l 3:1989 modelsMEDIUM for 1990,1991,1992,1993 models.

CHECKING THE ANTI-ROLLING FUNCTION

1. Move the wheels to the straight-ahead position.

2. Turn the ignition key to ON.

3. When simulated vehicle-speed signals of 35 km/h (22 mph) or higher are input and the steering wheel is turned

45” or more, the damping force characteristic indicator light will change to MEDIUM or HARD, depending on the

speed at which the steering wheel is turned. Check to be sure that this sensitivity increases (for each

control mode) as the vehicle speed increases.

NOTE

The damping force characteristic will return to its previous

level about tow seconds*4

after the change to MEDIUM or

HARD.

l 4:1989 modelsFor 1990,1991,1992,1993

models: one second

Page 1032 of 1273

Service AdjustmentACTIVE-ELECTRONIC CONTROL SUSPENSION - Procedures33B-93

\\ I/HARD ;g;

7 #

SOFT;#c

\\ I/HARD ;F;

7 ;&

SOFT;@;

I12AO399

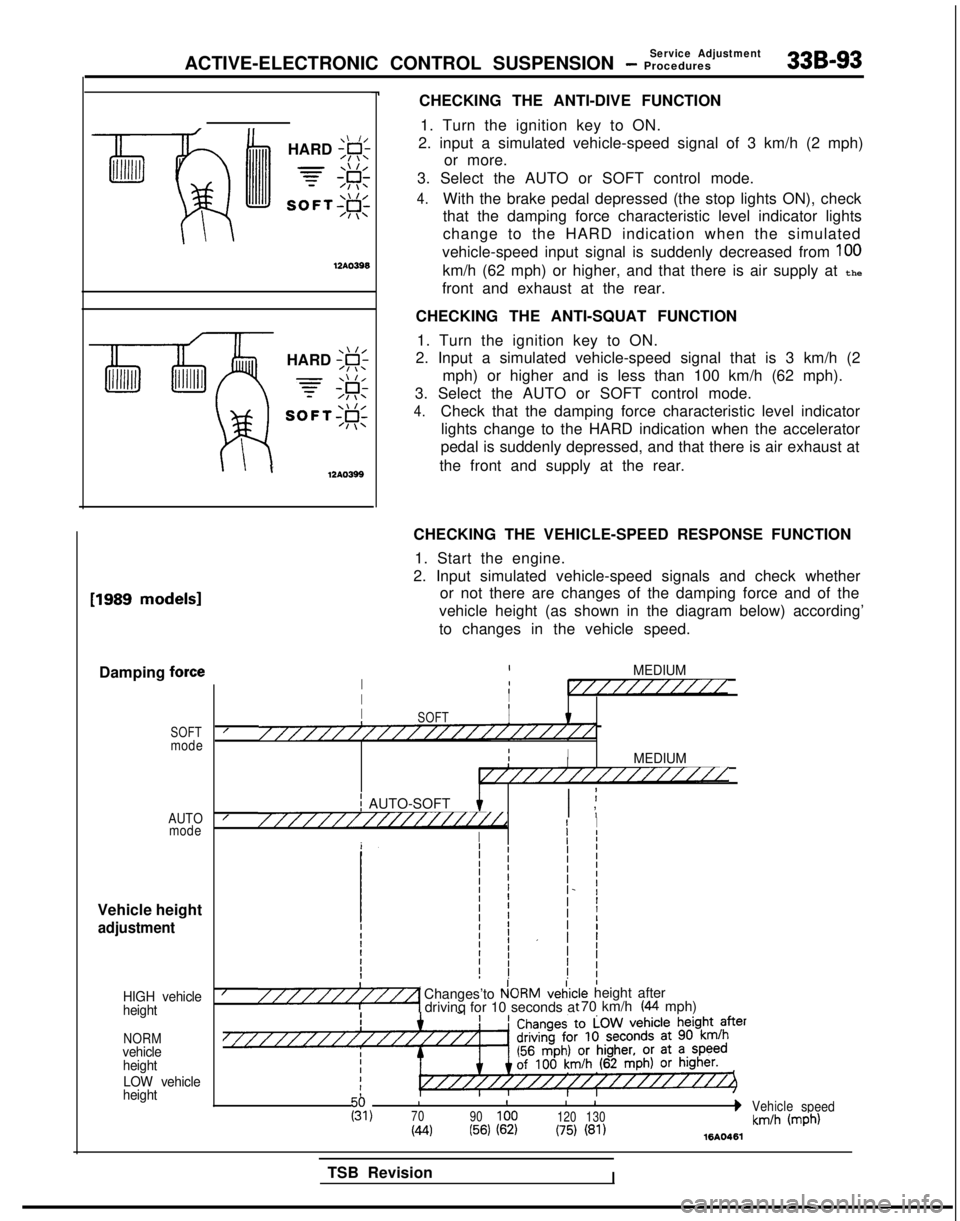

CHECKING THE ANTI-DIVE FUNCTION1. Turn the ignition key to ON.

2. input a simulated vehicle-speed signal of 3 km/h (2 mph) or more.

3. Select the AUTO or SOFT control mode.

4.With the brake pedal depressed (the stop lights ON), check

that the damping force characteristic level indicator lights

change to the HARD indication when the simulated

vehicle-speed input signal is suddenly decreased from

100

km/h (62 mph) or higher, and that there is air supply at the

front and exhaust at the rear.

CHECKING THE ANTI-SQUAT FUNCTION 1. Turn the ignition key to ON.

2. Input a simulated vehicle-speed signal that is 3 km/h (2

mph) or higher and is less than 100 km/h (62 mph).

3. Select the AUTO or SOFT control mode.

4.Check that the damping force characteristic level indicator lights change to the HARD indication when the accelerator

pedal is suddenly depressed, and that there is air exhaust at

the front and supply at the rear. [1989

models1

Damping force

SOFTmode

AUTO mode

Vehicle height

adjustment

HIGH vehicle

height

NORMvehicle

height

LOW vehicle

height

CHECKING THE VEHICLE-SPEED RESPONSE FUNCTION

1. Start the engine.

2. Input simulated vehicle-speed signals and check whether or not there are changes of the damping force and of the

vehicle height (as shown in the diagram below) according’

to changes in the vehicle speed.

IMEDIUMI1I//////////IIIII8SOFTI////////////////////////IIIIMEDIUMI////////////////

j AUTO-SOFT I ;I ,////////////////i//dI I

I

Ij I

I/Changes’to P!ORMveiic“““““1 drivinq for 10 seconds a:le height after t 70 km/h (44 mph)

III

I 1g,70

90100 120130bVehicle

speed

(44(56) (62)(75) (81)km/h (mph)1610461

TSB RevisionI