check engine MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 585 of 1273

COOLING -Engine Coolant Temperature Gauge Unit, Engine Coolant

Temperature Sensor and Engine Coolant Temperature Switch14-33

20R0586

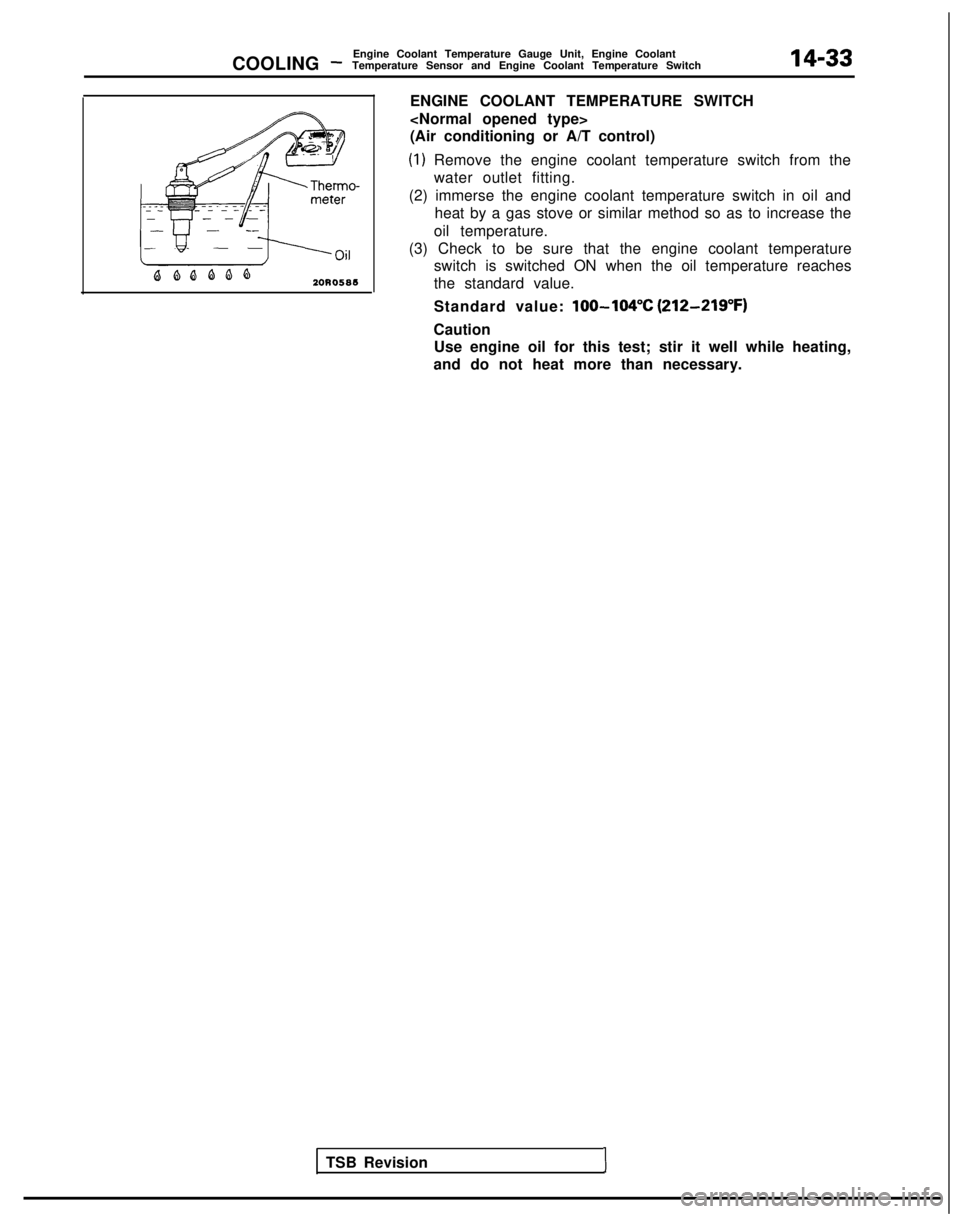

ENGINE COOLANT TEMPERATURE SWITCH

(Air conditioning or A/T control)

(1) Remove the engine coolant temperature switch from the

water outlet fitting.

(2) immerse the engine coolant temperature switch in oil and heat by a gas stove or similar method so as to increase the

oil temperature.

(3) Check to be sure that the engine coolant temperature switch is switched ON when the oil temperature reaches

the standard value.

Standard value:

lOO-104% (212-219°F)

CautionUse engine oil for this test; stir it well while heating,

and do not heat more than necessary.

TSB Revision

1

Page 593 of 1273

INTAKE AND EXHAUST - Service Adjustment Procedures15-7

Turbocharger waste

gate actuator

05A0150

OSAOlSl

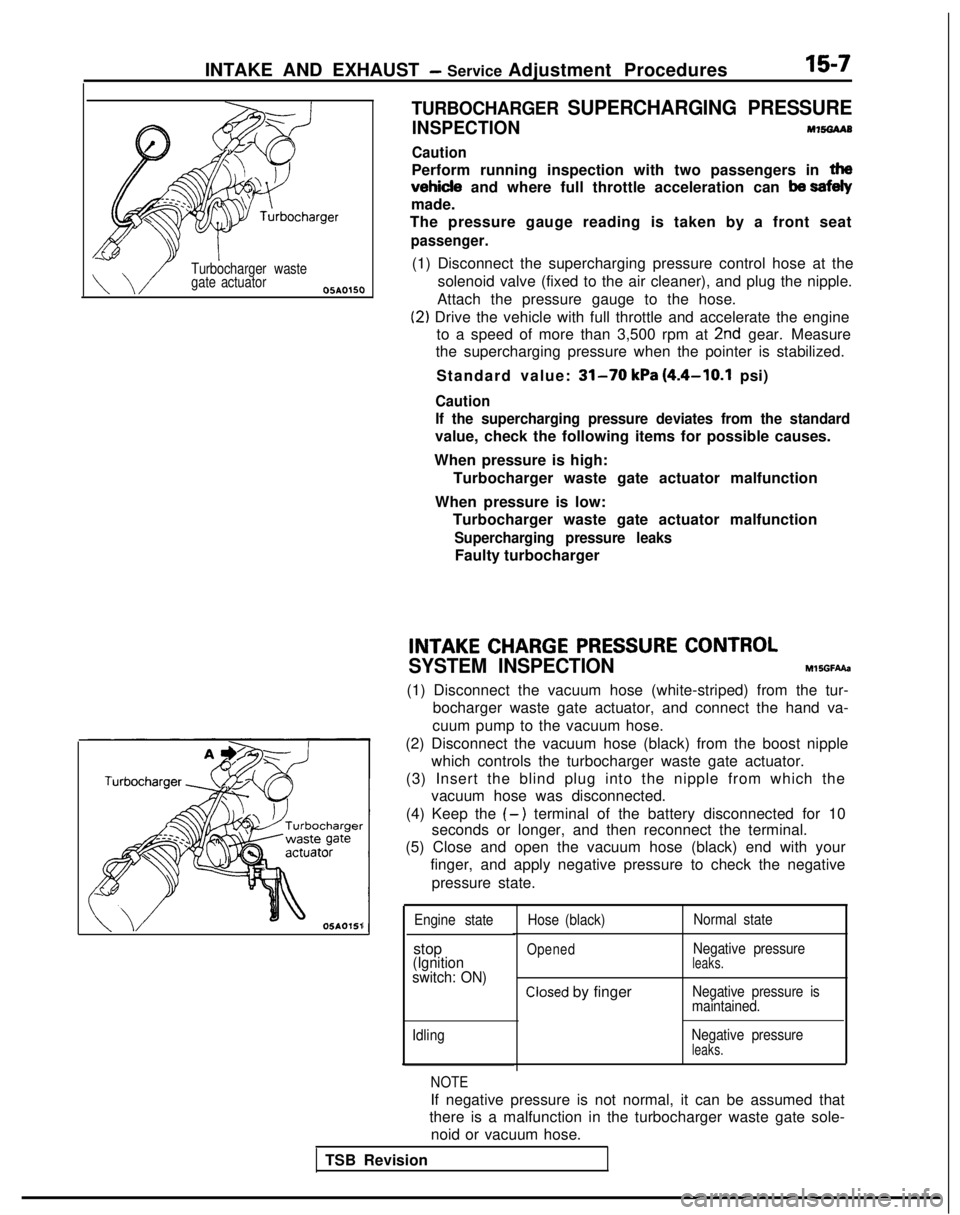

TURBOCHARGER SUPERCHARGING PRESSURE

INSPECTIONM7!%3AAB

Caution

Perform running inspection with two passengers in tha

vehicle and where full throttle acceleration can ba sefely

made.

The pressure gauge reading is taken by a front seat

passenger.

(1) Disconnect the supercharging pressure control hose at the

solenoid valve (fixed to the air cleaner), and plug the nipple.

Attach the pressure gauge to the hose.

(2) Drive the vehicle with full throttle and accelerate the engine to a speed of more than 3,500 rpm at

2nd gear. Measure

the supercharging pressure when the pointer is stabilized.

Standard value:

31-70 kPa (4.4-10.1 psi)

Caution

If the supercharging pressure deviates from the standard

value, check the following items for possible causes.

When pressure is high: Turbocharger waste gate actuator malfunction

When pressure is low: Turbocharger waste gate actuator malfunction

Supercharging pressure leaks

Faulty turbocharger

INTAKECHARGEPRESSURECONTROL

SYSTEM INSPECTION

MlSGFAAa

(1) Disconnect the vacuum hose (white-striped) from the tur- bocharger waste gate actuator, and connect the hand va-

cuum pump to the vacuum hose.

(2) Disconnect the vacuum hose (black) from the boost nipple which controls the turbocharger waste gate actuator.

(3) Insert the blind plug into the nipple from which the vacuum hose was disconnected.

(4) Keep the

(-) terminal of the battery disconnected for 10

seconds or longer, and then reconnect the terminal.

(5) Close and open the vacuum hose (black) end with your

finger, and apply negative pressure to check the negative

pressure state.

Engine state

stop(Ignition

switch: ON)

Idling Hose (black)

Opened

Normal state

Negative pressure

leaks.

Closed by fingerNegative pressure is

maintained.

Negative pressure

leaks.

NOTE

If negative pressure is not normal, it can be assumed that

there is a malfunction in the turbocharger waste gate sole-

noid or vacuum hose.

TSB Revision

Page 594 of 1273

15-8INTAKE AND EXHAUST - Service Adjustment Procedures

u--05A0155

61 N006C

6 I NO056

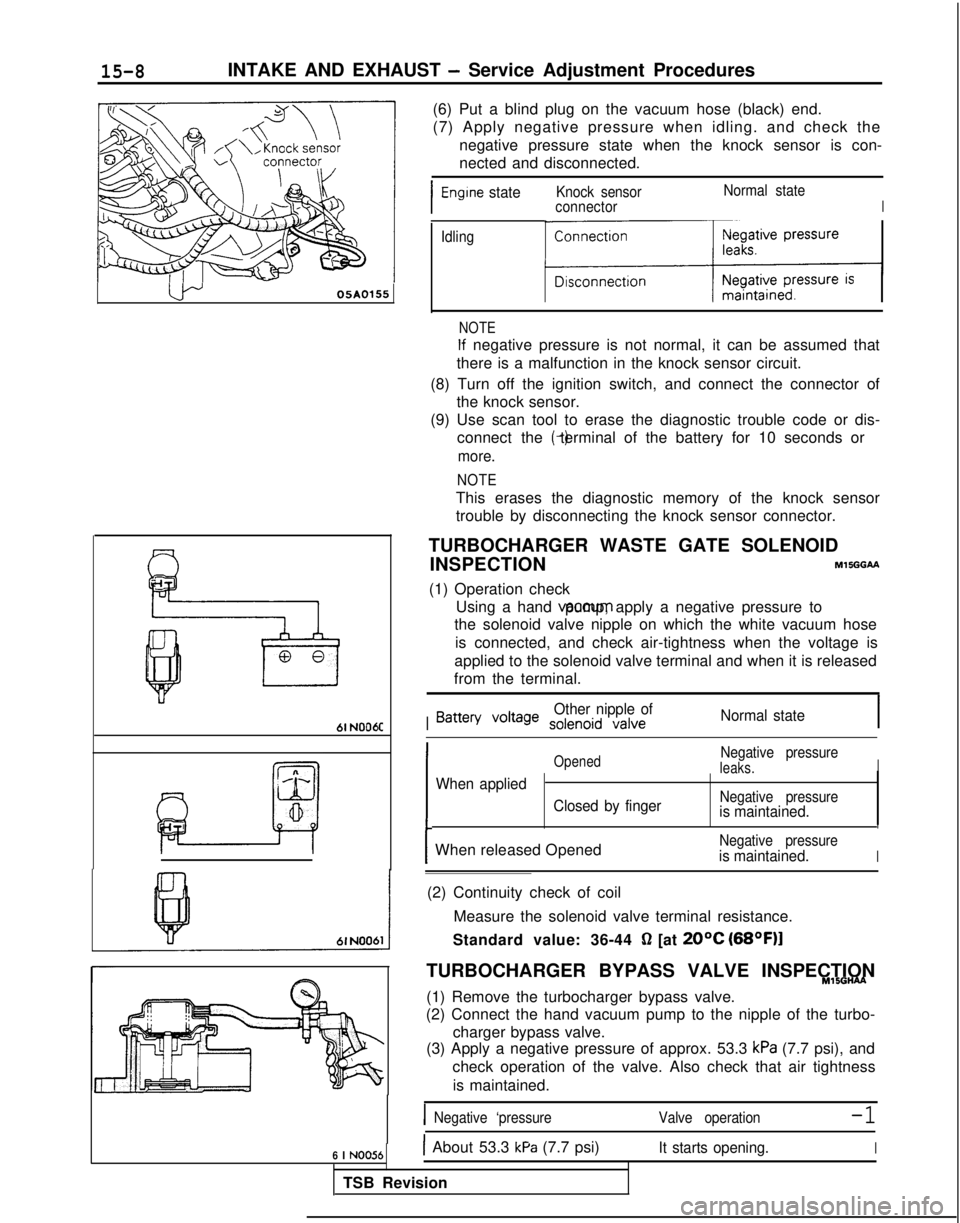

(6) Put a blind plug on the vacuum hose (black) end.

(7) Apply negative pressure when idling. and check thenegative pressure state when the knock sensor is con-

nected and disconnected.

I

Engine stateKnock sensor Normal state

connectorI

Idling

ml

NOTE

If negative pressure is not normal, it can be assumed that

there is a malfunction in the knock sensor circuit.

(8) Turn off the ignition switch, and connect the connector of the knock sensor.

(9) Use scan tool to erase the diagnostic trouble code or dis- connect the (-) terminal of the battery for 10 seconds or

more.

NOTE

This erases the diagnostic memory of the knock sensor

trouble by disconnecting the knock sensor connector.

TURBOCHARGER WASTE GATE SOLENOID INSPECTION

MlSGGM

(1) Operation check Using a hand vaccum pump, apply a negative pressure to

the solenoid valve nipple on which the white vacuum hose

is connected, and check air-tightness when the voltage is

applied to the solenoid valve terminal and when it is released

from the terminal.

I

Other nipple ofBattery Voltage solenoid valveNormal state

OpenedNegative pressureleaks.I

When applied

Closed by fingerNegative pressureis maintained.LIII

Negative pressureis maintained.IIWhen released Opened

(2) Continuity check of coil Measure the solenoid valve terminal resistance.

Standard value: 36-44

0 [at 20°C (68OF)l

TURBOCHARGER BYPASS VALVE INSPECTIONMlSGHAA

(1) Remove the turbocharger bypass valve.

(2) Connect the hand vacuum pump to the nipple of the turbo-

charger bypass valve.

(3) Apply a negative pressure of approx. 53.3

kPa (7.7 psi), and

check operation of the valve. Also check that air tightness

is maintained.

INegative ‘pressure Valve operation-1

IAbout 53.3 kPa (7.7 psi)It starts opening.I

TSB Revision

Page 613 of 1273

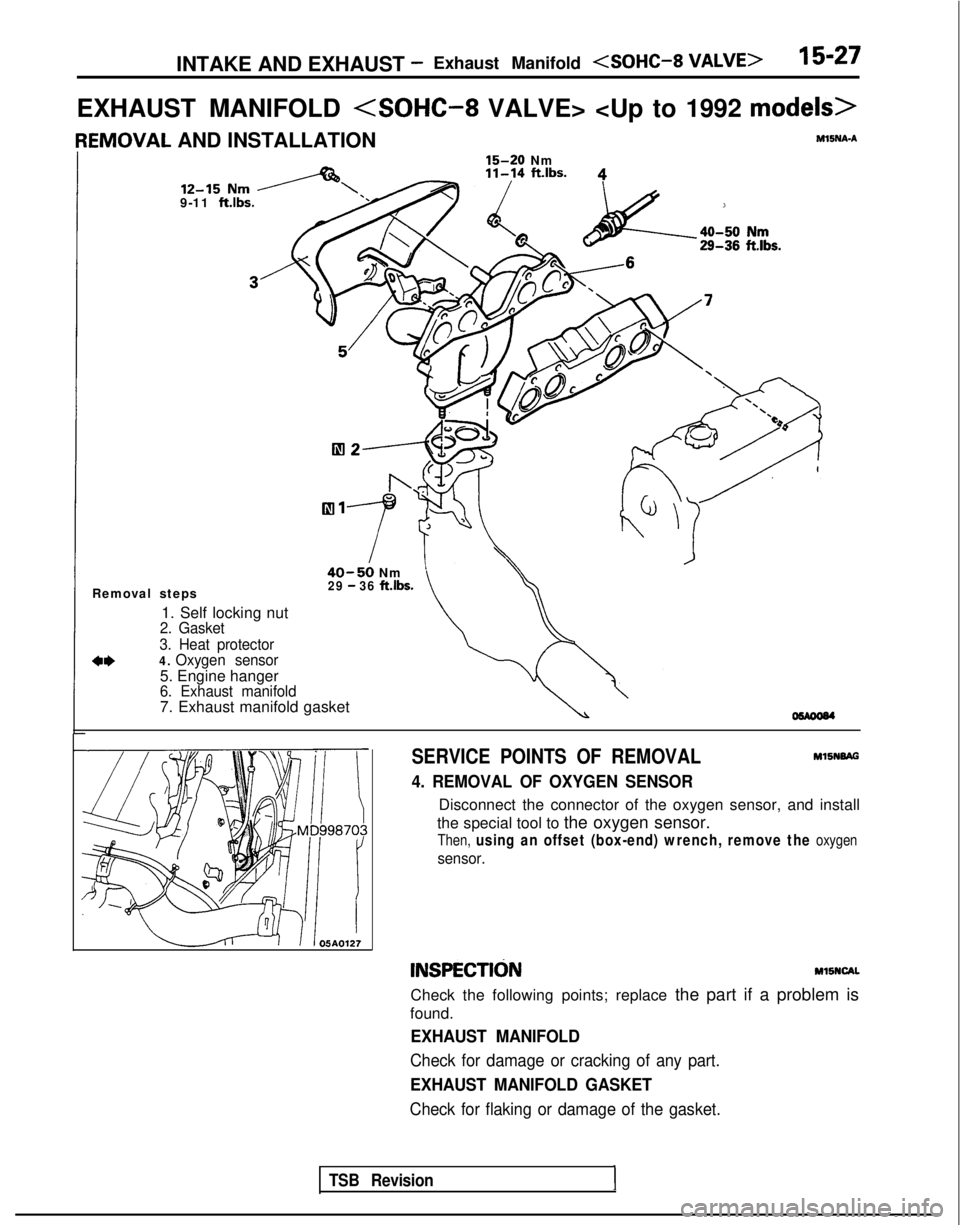

INTAKE AND EXHAUST -Exhaust Manifold (SOHC-8 VALVE>15-27

EXHAUST MANIFOLD

IEMOVAL AND INSTALLATIONYSNA-A

15-20

Nm

9-11 ftlbs.

40-50 Nm

Removal steps29 - 36 ft.lbs.

1. Self locking nut2. Gasket

3. Heat protector

a*4. Oxygen sensor

5. Engine hanger6. Exhaust manifold7. Exhaust manifold gasket

SERVICE POINTS OF REMOVAL MlSNBAG

4. REMOVAL OF OXYGEN SENSOR

Disconnect the connector of the oxygen sensor, and install

the special tool to the oxygen sensor.

Then, using an offset (box-end) wrench, remove the oxygen

sensor.

INSPECTldNMllNCAL

Check the following points; replace the part if a problem is

found.

EXHAUST MANIFOLD

Check for damage or cracking of any part.

EXHAUST MANIFOLD GASKET

Check for flaking or damage of the gasket.

TSB Revision1

Page 623 of 1273

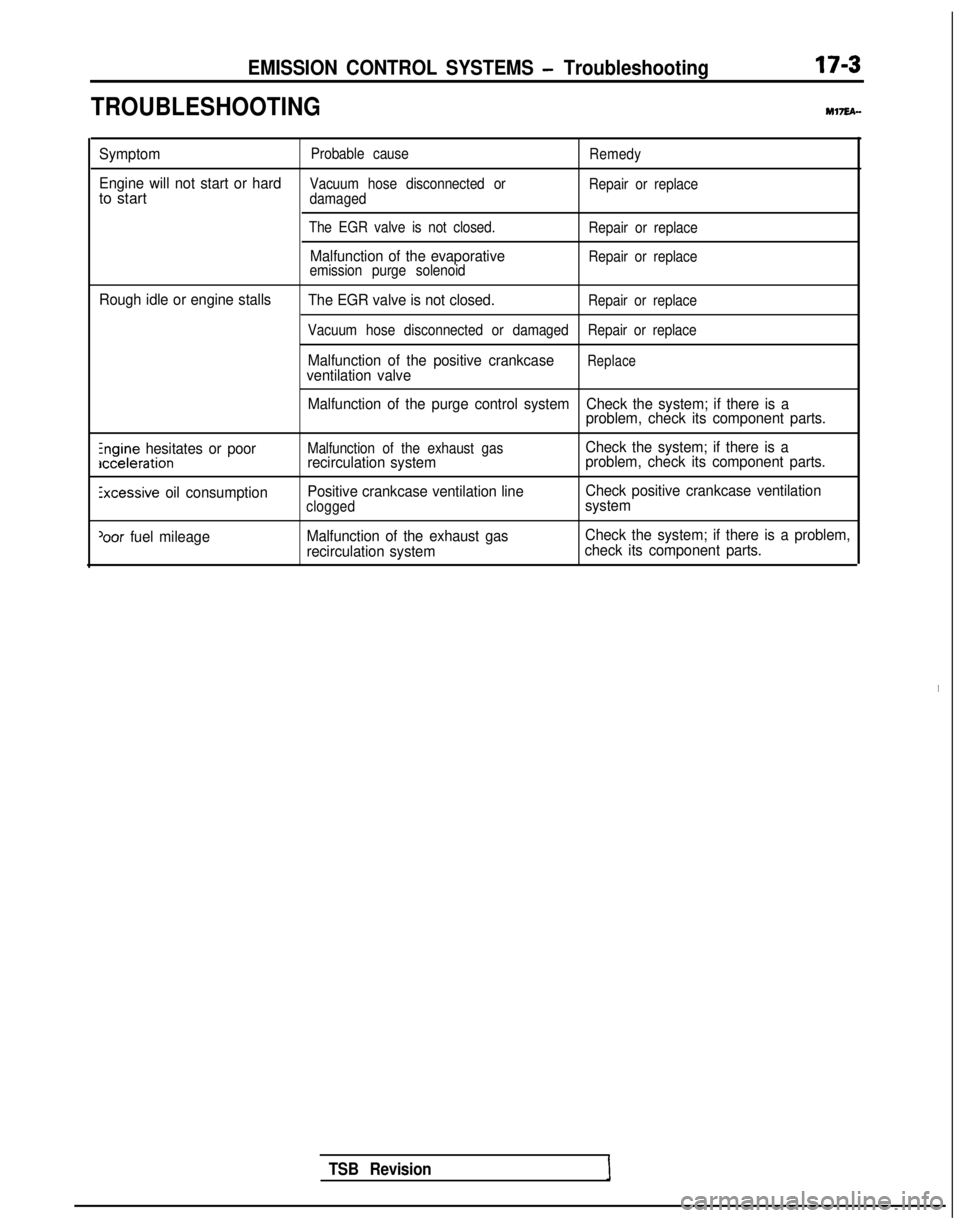

EMISSION CONTROL SYSTEMS - Troubleshooting17-3

TROUBLESHOOTINGMVEA-

SymptomProbable causeRemedy

Engine will not start or hardVacuum hose disconnected or Repair or replaceto startdamaged

The EGR valve is not closed. Repair or replace

Malfunction of the evaporativeRepair or replace

emission purge solenoid

Rough idle or engine stalls The EGR valve is not closed.Repair or replace

Vacuum hose disconnected or damaged Repair or replace

Malfunction of the positive crankcaseReplaceventilation valve

Malfunction of the purge control system Check the system; if there is a

problem, check its component parts.

Engine hesitates or poorIcceleration

Zxcessive oil consumption

)oor fuel mileage

Malfunction of the exhaust gasrecirculation system

Positive crankcase ventilation line

clogged

Malfunction of the exhaust gas

recirculation system Check the system; if there is a

problem, check its component parts.

Check positive crankcase ventilation

system

Check the system; if there is a problem,

check its component parts.

TSB Revision

Page 637 of 1273

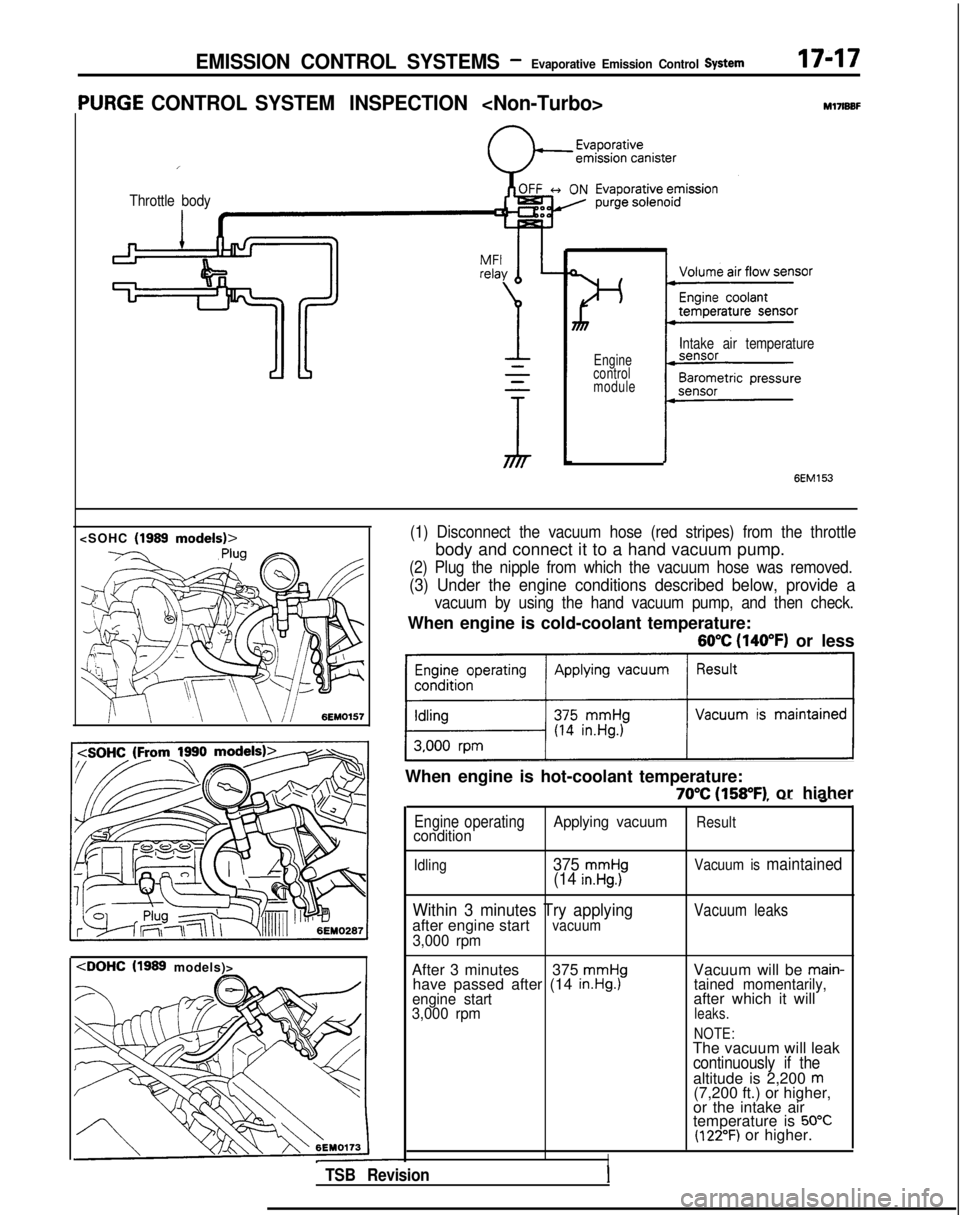

EMISSION CONTROL SYSTEMS -Evaporative Emission Control System17-17

‘URGE CONTROL SYSTEM INSPECTION

I

Throttle body

M17lBBF

Engine

control

module

Intake air temperature

models)>

6EM153

(1) Disconnect the vacuum hose (red stripes) from the throttle

body and connect it to a hand vacuum pump.

(2) Plug the nipple from which the vacuum hose was removed.

(3) Under the engine conditions described below, provide a

vacuum by using the hand vacuum pump, and then check.

When engine is cold-coolant temperature:

60°C (140°F) or less

~1

When engine is hot-coolant temperature:

70°C (158°F) or hiaher, -- ---~“----

Engine operatingApplying vacuumResultcondition

Idling375 mmHg(14 in.Hg.)Vacuum is maintained

Within 3 minutes Try applyingafter engine startvacuum3,000 rpm

Vacuum leaks

After 3 minutes 375 mmHghave passed after (14 in.Hg.)engine start

3,000 rpm

Vacuum will be main-tained momentarily,after which it willleaks.

NOTE:

The vacuum will leakcontinuously if thealtitude is 2,200 m(7,200 ft.) or higher,

or the intake air

temperature is

50°C(122°F) or higher.

ITSB RevisionI

Page 638 of 1273

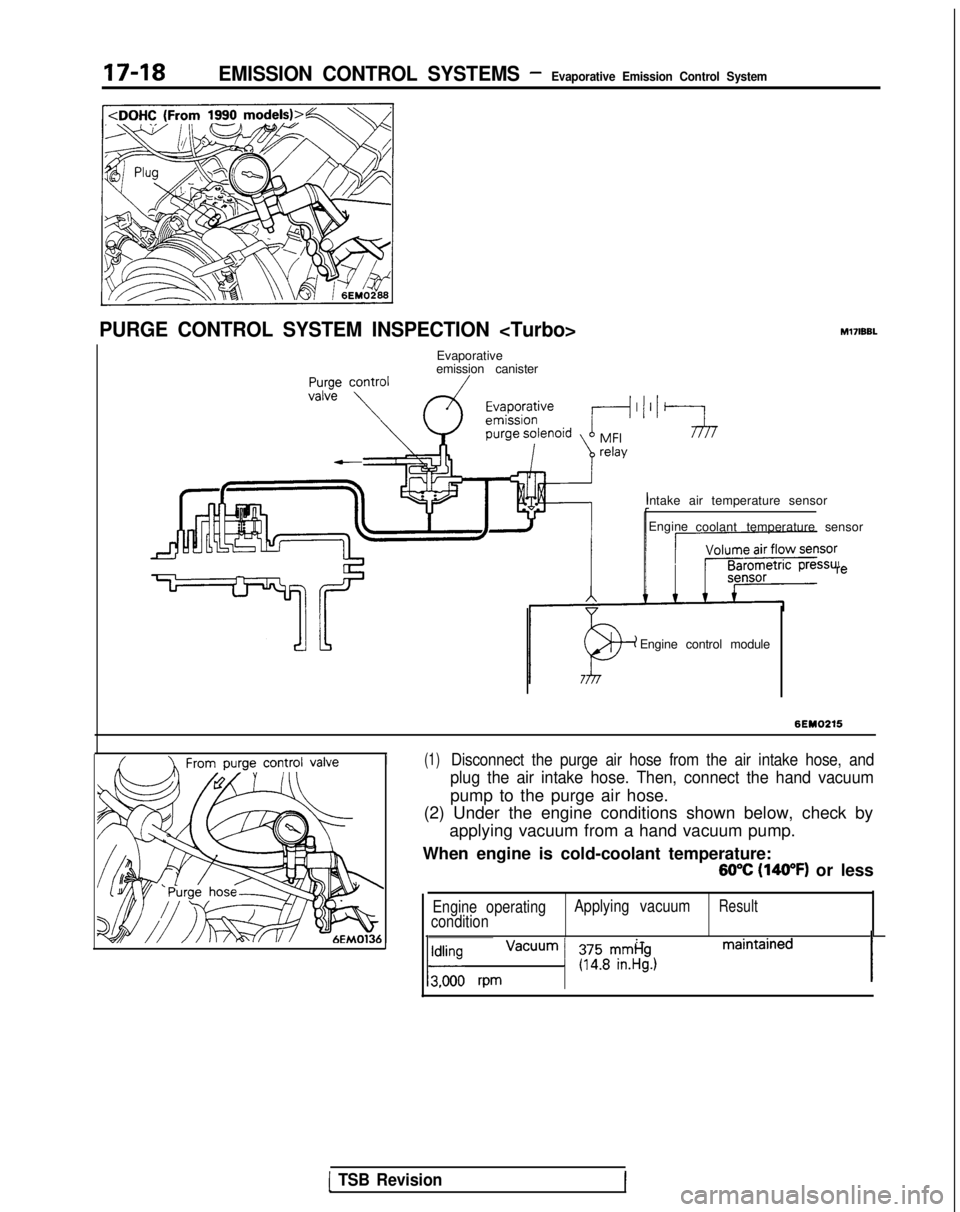

EMISSION CONTROL SYSTEMS -Evaporative Emission Control System

PURGE CONTROL SYSTEM INSPECTION

Evaporative

emission canister

Intake air temperature sensorEngine coolant temperature sensor re

Engine control module

I(1)Disconnect the purge air hose from the air intake hose, and

plug the air intake hose. Then, connect the hand vacuum

pump to the purge air hose.

(2) Under the engine conditions shown below, check by

applying vacuum from a hand vacuum pump.

When engine is cold-coolant temperature:

60°C (140°F) or less

Engine operating Applying vacuumResultcondition

1 vacuum is maintained 1ldldl rpm1 gy?r$y)

[ TSB Revision

Page 640 of 1273

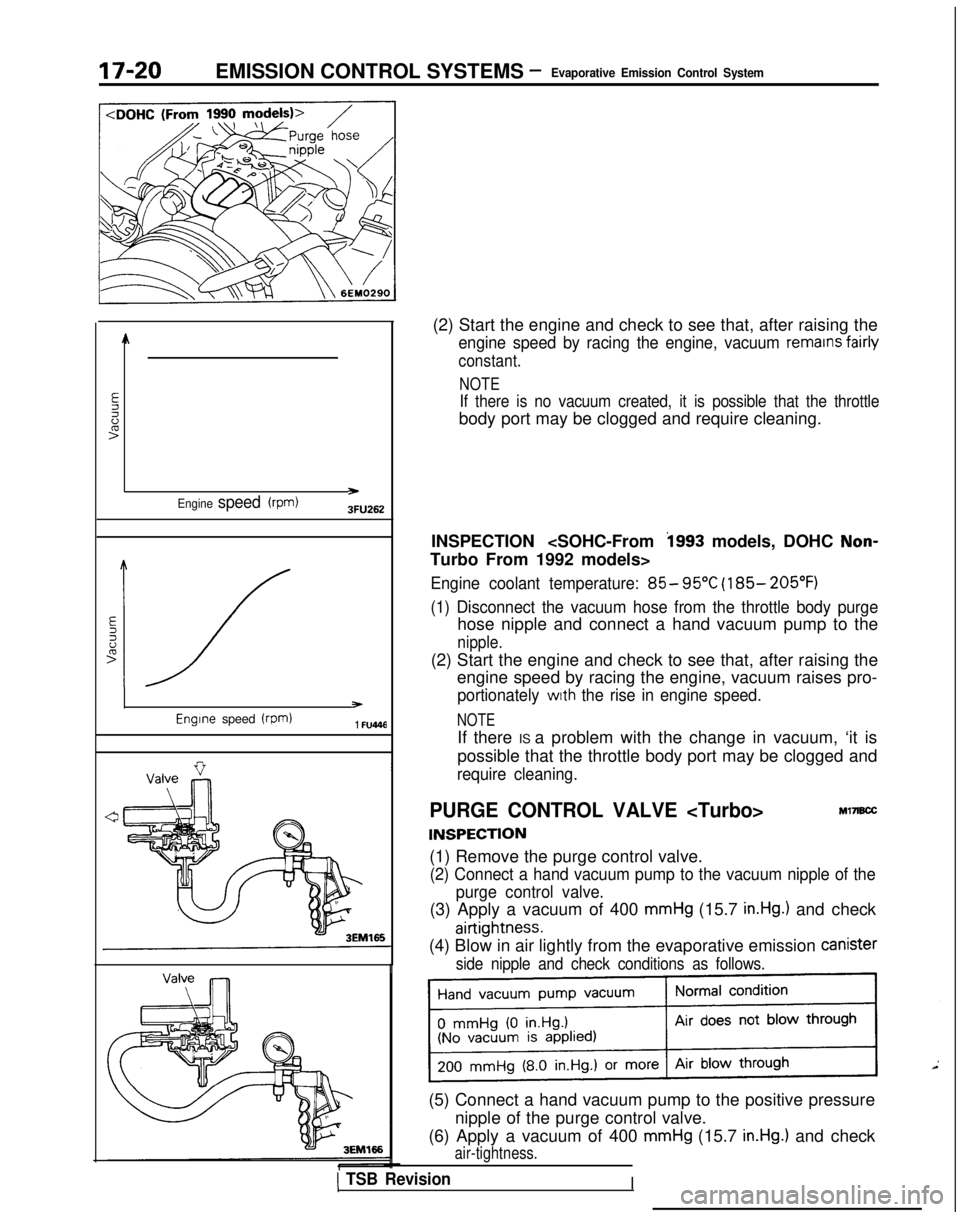

17-20EMISSION CONTROL SYSTEMS -Evaporative Emission Control System

Engine speed (rpm)>

3FU262

E2id>

‘_/- )Engine

speed

(rpm)1 FU446

1 TSB Revision

(2) Start the engine and check to see that, after raising the

engine speed by racing the engine, vacuum remains fairly

constant.

NOTE

If there is no vacuum created, it is possible that the throttle

body port may be clogged and require cleaning.

INSPECTION

Turbo From 1992 models>

Engine coolant temperature: 85- 95°C (185- 205°F)

(1) Disconnect the vacuum hose from the throttle body purge

hose nipple and connect a hand vacuum pump to the

nipple.

(2) Start the engine and check to see that, after raising the engine speed by racing the engine, vacuum raises pro-

portionately with the rise in engine speed.

NOTE

If there IS a problem with the change in vacuum, ‘it is

possible that the throttle body port may be clogged and

require cleaning.

PURGE CONTROL VALVE

INSPECTION

Ml7B.X

(1) Remove the purge control valve.

(2) Connect a hand vacuum pump to the vacuum nipple of the

purge control valve.

(3) Apply a vacuum of 400 mmHg (15.7 in.Hg.) and check

airtightness.

(4) Blow in air lightly from the evaporative emission Canister

side nipple and check conditions as follows.

(5) Connect a hand vacuum pump to the positive pressure

nipple of the purge control valve.

(6) Apply a vacuum of 400

mmHg (15.7 in.Hg.) and check

air-tightness.

I

Page 641 of 1273

EMISSION CONTROL SYSTEMS -Evaporative Emission Control System17-21EC1510

6EM137

EVAPORATIVE EMlS$lON

PURGE SOLENOID

INSPECTIONM17lBFD

NOTE

When disconnecting the vacuum hose, make an identification

mark on it so that it can be reconnected to the original posi-

tion.

(1) Disconnect the vacuum hoses (non stripe and red stripe

hoses) from the solenoid valve

(2) Disconnect the harness connector from solenoid valve.

(3) Connect a hand vacuum pump to the nipple to which the red-striped vacuum hose was connected.

(4) Apply a vacuum and check for air-tightness when voltage applied directly to the evaporative emission purge solenoid

when the voltage is discontinued.

Battery voltageResult

Non-Turbo When appliedVacuum leaks

When discontinued Vacuum is maintained

TurboWhen appliedVacuum is maintained

When discontinued Vacuum leaks

(5) Measure the resistance between the terminals of the sole-

noid valve.

Standard value: 36-44 Q [at 20°C (68”F)l

VOLUME AIR FLOW SENSOR, ENGINE

COOLANT TEMPERATURE SENSOR AND

INTAKE AIR TEMPERATURE SENSOR

M17IBGB

To inspect these parts, refer to GROUP 13-On-Vehicle Inspec-

tion of

MFI Components.

AIR CONDITIONING SWITCH Ml7IBHB

To inspect the air conditioning switch, refer to GROUP

55-Air

Conditioning Switch.

FUEL TANK PRESSURE CONTROL VALVE MI’IIBEB

To inspect the fuel tank pressure control valve, refer to GROUP

13-Fuel

Tank.

EVAPORATIVE EMISSION CANISTERM17lBlB

To inspect the evaporative emission canister, refer to GROUP

13-Fuel Line and Vapor Line.

FUEL TANK FILLER TUBE CAP INSPECTIONM,7,w~

Check the gasket of the fuel tank filler tube cap, and the filler

cap itself, for damage or deformation; replace the

cap if neces-

sary.

TSB RevisionI

Page 645 of 1273

EMISSION CONTROL SYSTEMS -Exhaust Gas Recirculation (EGR) System17-25

.

EGR SYSTEM INSPECTION

(1) Disconnect the vacuum hose (green stripe) from the throttle body, and connect a hand vacuum pump to the

vacuum hose.

(2) Under the engine conditions described below, provide a

vacuum by using the hand vacuum pump, and then check.

WhenEngine is Cold-

coolant temperature 50°C (122°F) or below

Engine operatingconditionApplying vacuumResul

t

IdlingTry applying vacuum Vacuum leaks

When Engine is Hot-

coolant temperature 85”-95°C (185”-205°F) or higher

Engine operatingconditionApplying vacuumResult

Idling45 mmHg(1.7 in.Hg.1Vacuum is maintained

Changes from

idling to slightlyunstable

Vacuum is maintained

EGR SYSTEM INSPECTION

(1) Disconnect the vacuum hose (green striped hose) from the exhaust gas recirculation

(EGR) valve, and then connect a

manual vacuum pump via the three-way terminal.

(2) Check the following points when the engine is cold [enginecoolant temperature is

20°C (68°F) or below] and when the

engine is warm [engine coolant temperature is

70°C (158°F)

or higher].

116EMOZW

TSB Revision