check engine MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 752 of 1273

23-46AUTOMATIC TRANSAXLE - Troubleshootincl

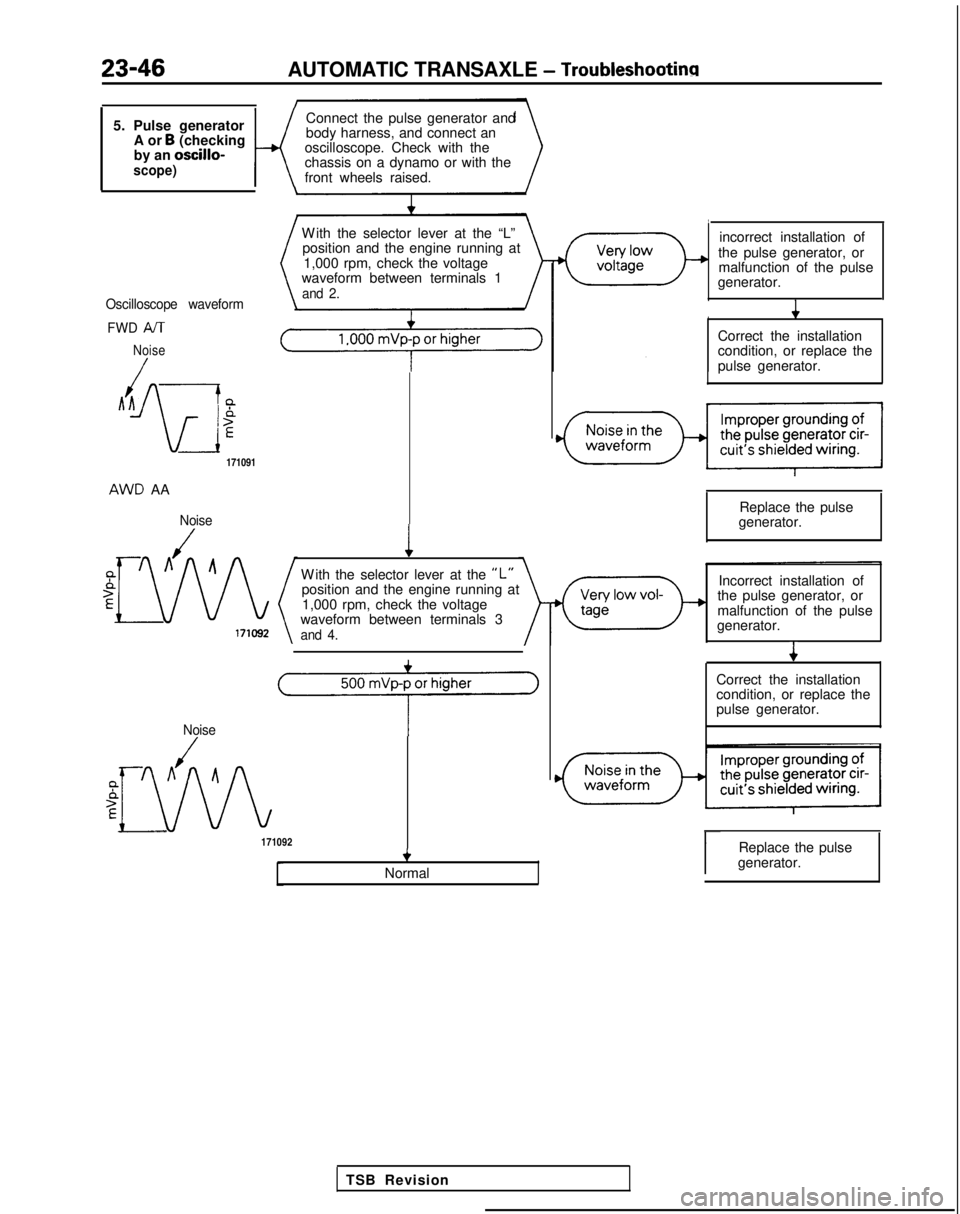

5. Pulse generatorA or B (checking

by an oscillo-

scope)K

Connect the pulse generator and

body harness, and connect an

oscilloscope. Check with the

chassis on a dynamo or with the

front wheels raised.

Oscilloscope waveform

FWD

/VT

Noise

/Ah --L

Ar

IP

-iE

171091 AWD

AA

Noise

W

ith the selector lever at the “L”

position and the engine running at

1,000 rpm, check the voltage

waveform between terminals 1

and 2.

1

W

ith the selector lever at the

“L”position and the engine running at

1,000 rpm, check the voltage

waveform between terminals 3

and 4.

Noise

A

(6

171092+

Normal incorrect installation of

the pulse generator, or malfunction of the pulse

generator. 4

Correct the installation

condition, or replace the

pulse generator.

Replace the pulse

generator.

Incorrect installation of

the pulse generator, or

malfunction of the pulse

generator. 4

Correct the installation

condition, or replace the

pulse generator.r

Replace the pulse

generator.

TSB Revision

Page 758 of 1273

23-52AUTOMATIC TRANSAXLE - Troubleshooting

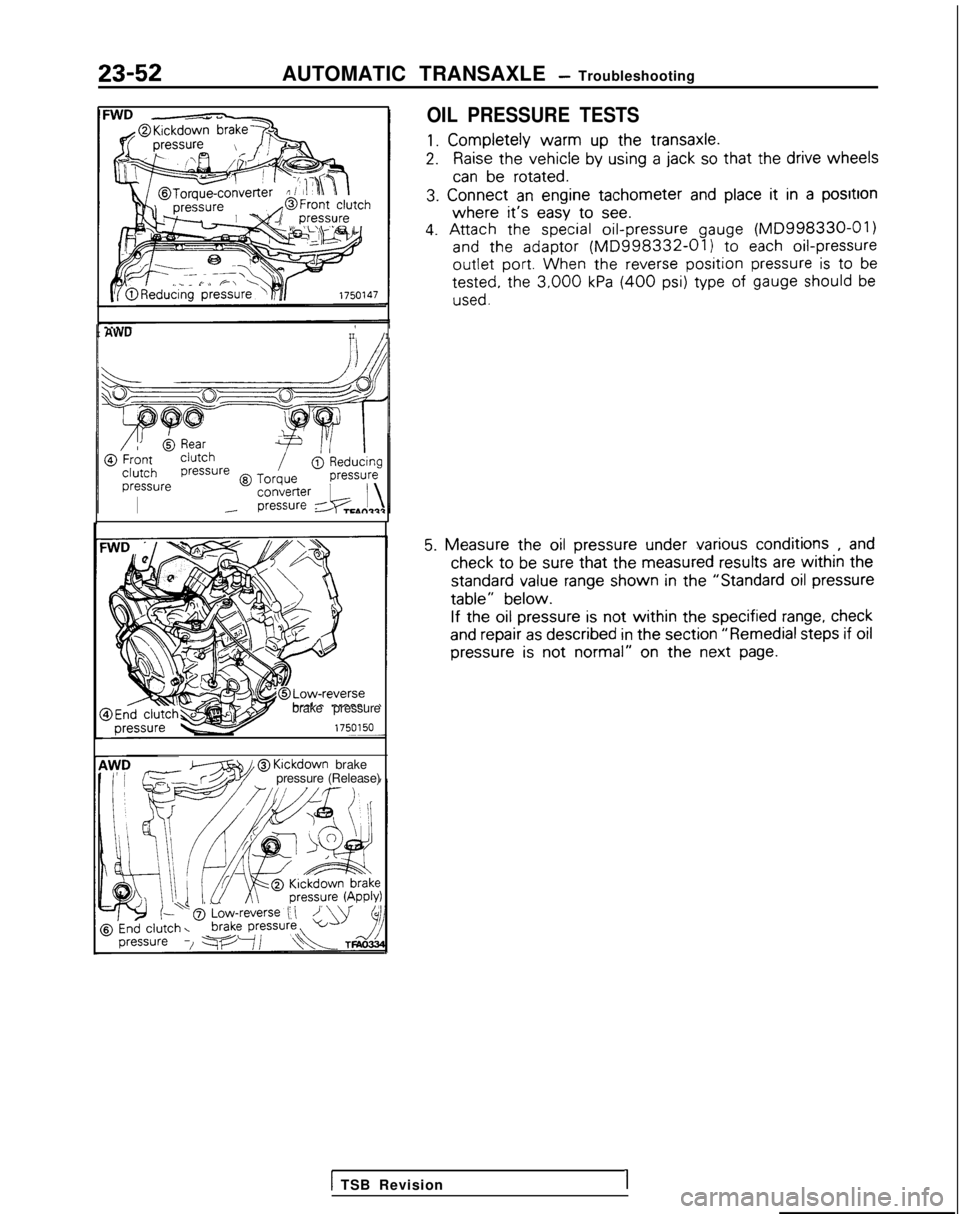

OIL PRESSURE TESTS

1. Completely

warm

up the

transaxle.

2.Raise the

vehicle

by

using

a jack so that the

drive

wheels

can be

rotated.

3.

Connect

an engine

tachometer

and place it

in a positron

where it’s easy

to

see.

4. Attach

the

special oil-pressure

gauge (MD998330-01)

and

the

adaptor

(MD998332-01) to

each oil-pressure

outlet

port. When

the

reverse position pressure is to

be tested,

the

3,000 kPa (400 psi) type

of gauge should be

used.

I AWUII/I

brake pressure

zT?ziw@

Klckdown

brake

pressure (Release)

5. Measure

the

oil pressure

under

various

conditions

, and check

to be sure that the

measured

results

are within the

standard

value

range shown

in the

“Standard

oil pressure

table”

below.

If the

oil pressure

is not

within the

specified

range, check

and repair

as described

in the

section

“Remedial

steps

if oil

pressure

is not

normal”

on the next

page.

1 TSB Revision1

Page 765 of 1273

AUTOMATIC TRANSAXLE - Troubleshooting23-59

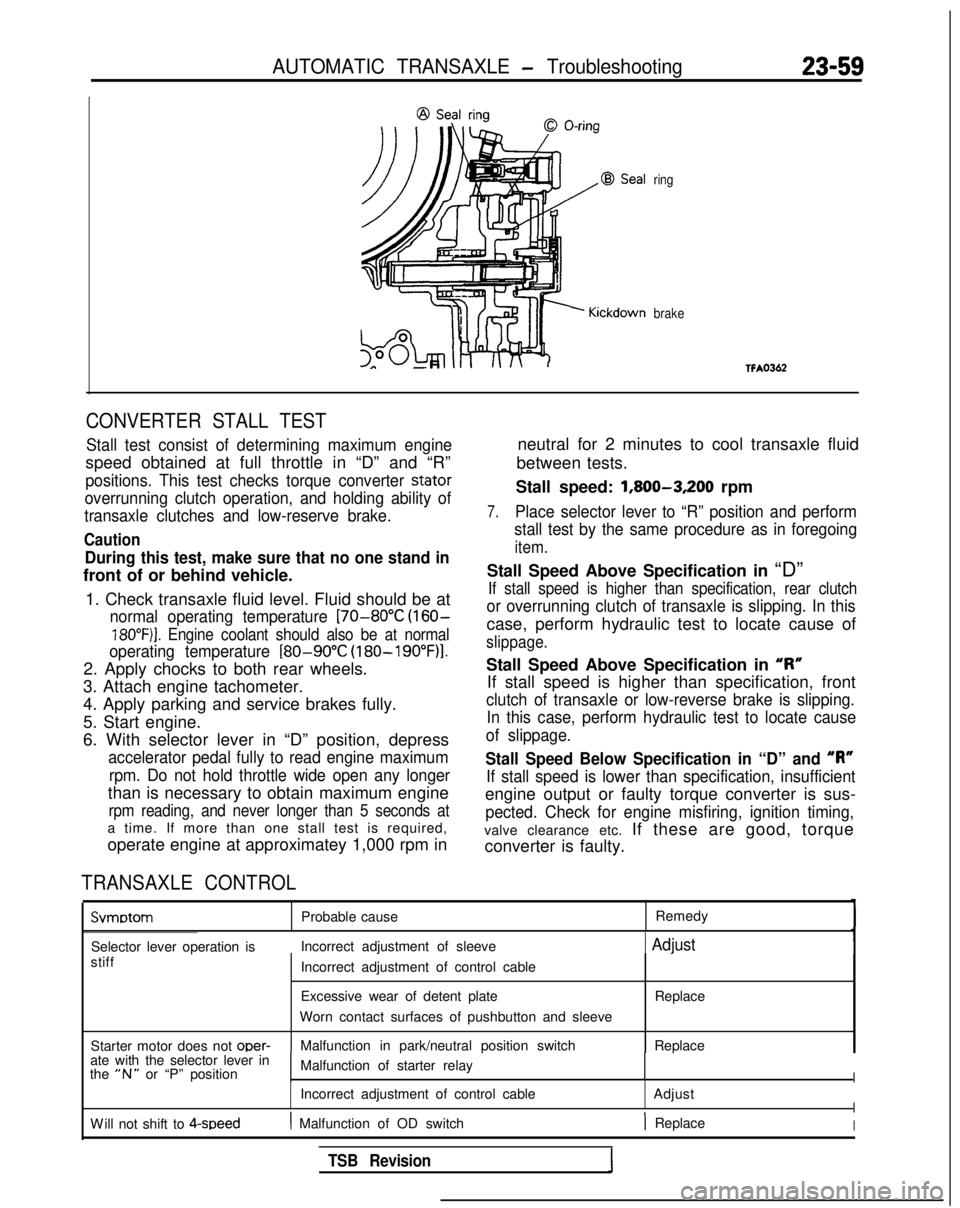

ring

brake

CONVERTER STALL TEST

Stall test consist of determining maximum engine

speed obtained at full throttle in “D” and “R”

positions. This test checks torque converter stator

overrunning clutch operation, and holding ability of

transaxle clutches and low-reserve brake.

Caution

During this test, make sure that no one stand in

front of or behind vehicle.

1. Check transaxle fluid level. Fluid should be at

normal operating temperature [70-80°C (160-

18O”F)j. Engine coolant should also be at normal

operating temperature

[80-90°C (180-19O”F)l.

2. Apply chocks to both rear wheels.

3. Attach engine tachometer.

4. Apply parking and service brakes fully.

5. Start engine.

6. With selector lever in “D” position, depress

accelerator pedal fully to read engine maximum

rpm. Do not hold throttle wide open any longer

than is necessary to obtain maximum engine

rpm reading, and never longer than 5 seconds at

a time. If more than one stall test is required,

operate engine at approximatey 1,000 rpm in

TRANSAXLE CONTROL

neutral for 2 minutes to cool transaxle fluid

between tests.

Stall speed: 1,800-3,200

rpm

7.Place selector lever to “R” position and perform

stall test by the same procedure as in foregoing

item.

Stall Speed Above Specification in “D”

If stall speed is higher than specification, rear clutch

or overrunning clutch of transaxle is slipping. In this

case, perform hydraulic test to locate cause of

slippage.

Stall Speed Above Specification in “I?”

If stall speed is higher than specification, front

clutch of transaxle or low-reverse brake is slipping. In this case, perform hydraulic test to locate cause

of slippage.

Stall Speed Below Specification in “D” and “R”

If stall speed is lower than specification, insufficient

engine output or faulty torque converter is sus-

pected. Check for engine misfiring, ignition timing,

valve clearance etc. If these are good, torque

converter is faulty. Svmotom

Probable cause

Remedy

Selector lever operation is Incorrect adjustment of sleeve

1 Adjust

stiff

Starter motor does not oper-

Incorrect adjustment of control cable

Excessive wear of detent plate

Worn contact surfaces of pushbutton and sleeve

Malfunction in park/neutral position switch Replace

Replace

ate with the selector lever in

the

“N” or “P” position Malfunction of starter relayI

Incorrect adjustment of control cable

AdjustI

W

ill not shift to 4-speed

( Malfunction of OD switch) ReplaceI

TSB Revision

Page 789 of 1273

AUTOMATIC TRANSAXLE - Service Adjustment Procedures23-83

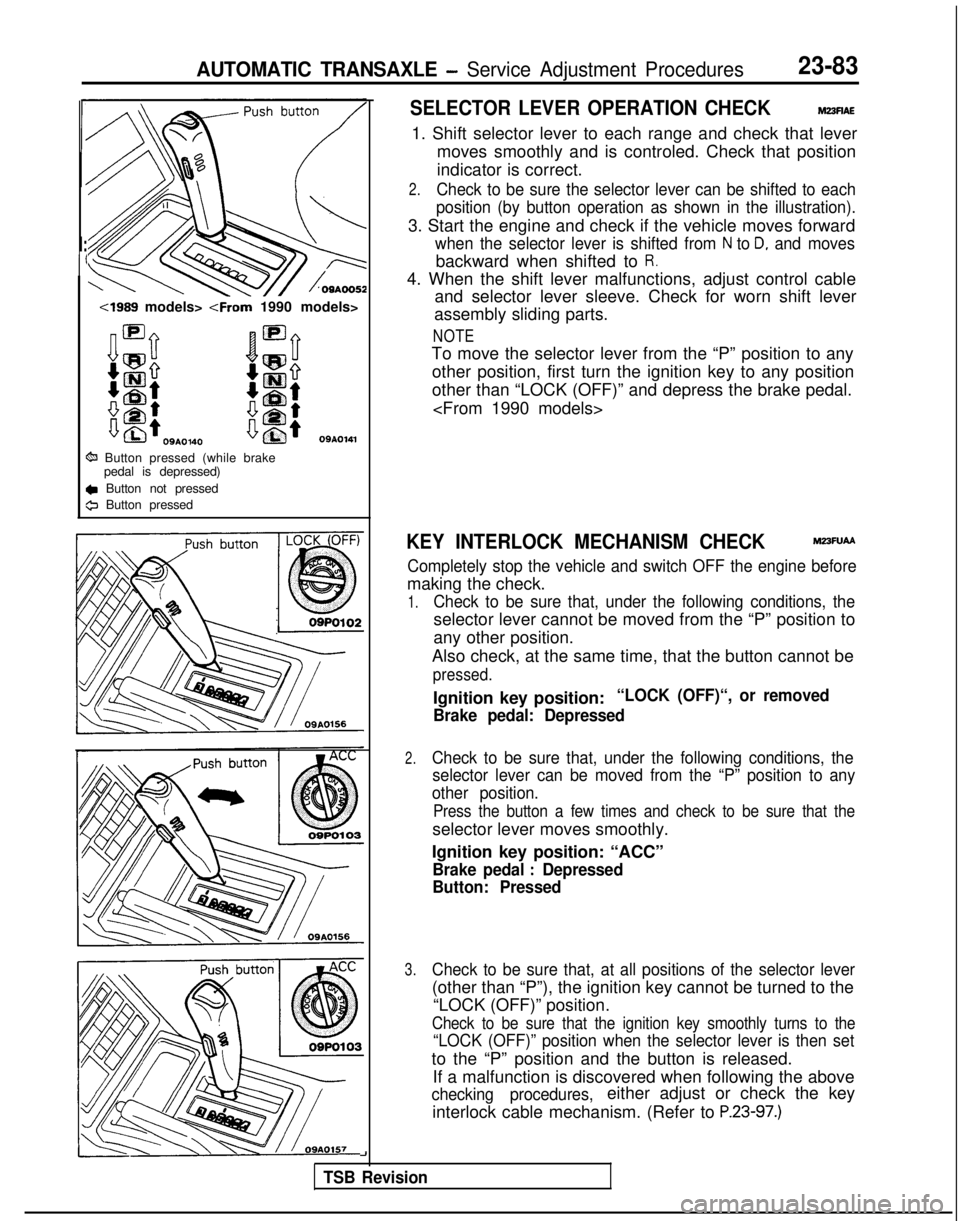

I:

I’

4989 models>

09A0140

6% Button pressed (while brakepedal is depressed)

c Button not pressed

0 Button pressed

SELECTOR LEVER OPERATION CHECKM23flAE

1. Shift selector lever to each range and check that lever

moves smoothly and is controled. Check that position

indicator is correct.

2.Check to be sure the selector lever can be shifted to each

position (by button operation as shown in the illustration).

3. Start the engine and check if the vehicle moves forward

when the selector lever is shifted from N to D, and moves

backward when shifted to R.

4. When the shift lever malfunctions, adjust control cable and selector lever sleeve. Check for worn shift lever

assembly sliding parts.

NOTE

To move the selector lever from the “P” position to any

other position, first turn the ignition key to any position

other than “LOCK (OFF)” and depress the brake pedal.

KEY INTERLOCK MECHANISM CHECKM23FUAA

Completely stop the vehicle and switch OFF the engine before

making the check.

1.Check to be sure that, under the following conditions, the

selector lever cannot be moved from the “P” position to

any other position.

Also check, at the same time, that the button cannot be

pressed.

Ignition key position:“LOCK (OFF)“, or removed

Brake pedal: Depressed

2.Check to be sure that, under the following conditions, the selector lever can be moved from the “P” position to any

other position.

Press the button a few times and check to be sure that the

selector lever moves smoothly.

Ignition key position: “ACC”

Brake pedal : Depressed

Button: Pressed

3.Check to be sure that, at all positions of the selector lever

(other than “P”), the ignition key cannot be turned to the

“LOCK (OFF)” position.

Check to be sure that the ignition key smoothly turns to the

“LOCK (OFF)” position when the selector lever is then set

to the “P” position and the button is released.

If a malfunction is discovered when following the above

checking procedures,either adjust or check the key

interlock cable mechanism. (Refer to

P.23-97.)

-I

TSB Revision

Page 909 of 1273

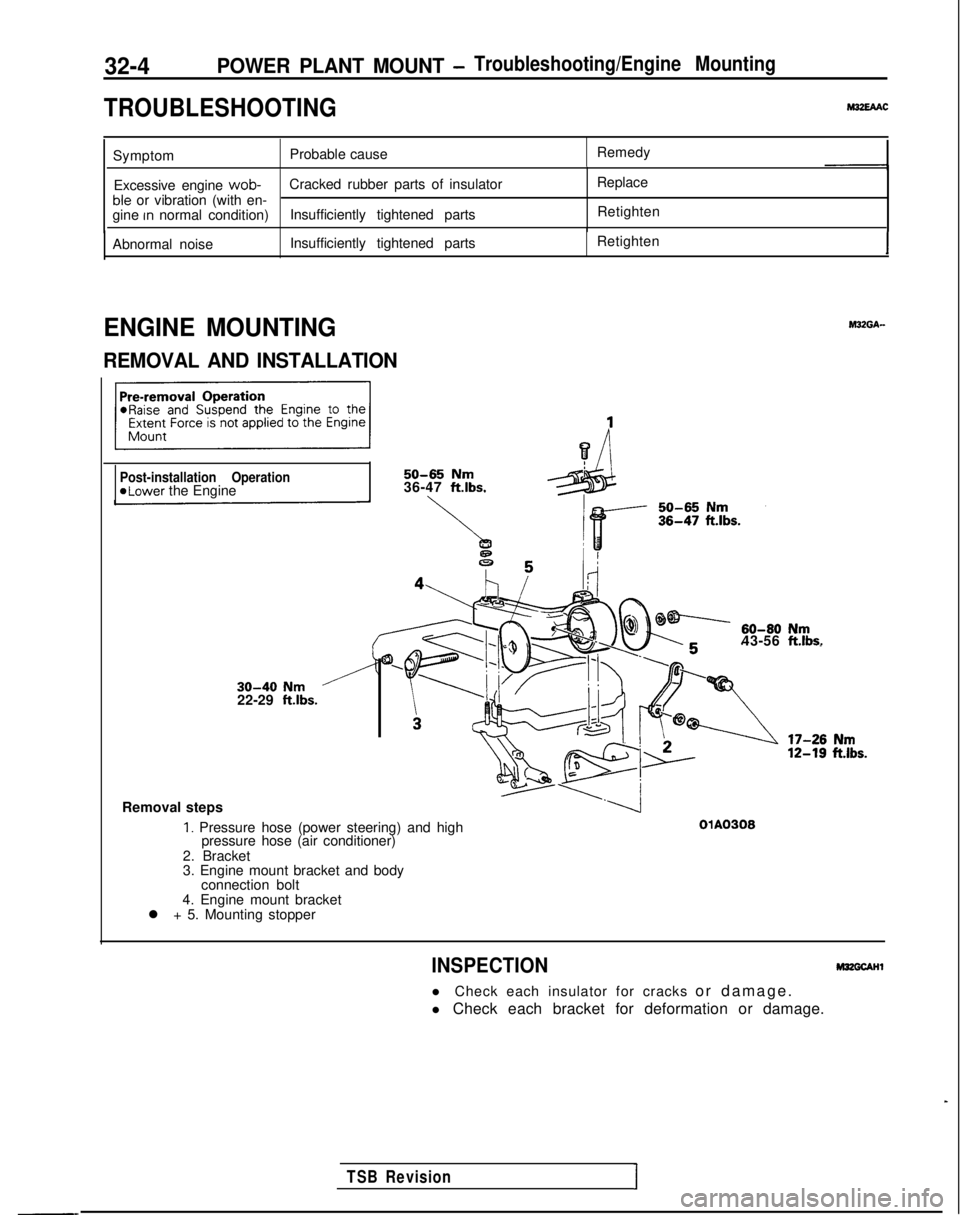

32-4POWER PLANT MOUNT -Troubleshooting/Engine Mounting

TROUBLESHOOTING

SymptomProbable cause Remedy

Excessive engine wob-

Cracked rubber parts of insulator Replace

ble or vibration (with en-

gine rn normal condition) Insufficiently tightened parts Retighten

Abnormal noise Insufficiently tightened parts Retighten

ENGINE MOUNTING

REMOVAL AND INSTALLATION

.

TSB RevisionI

30-40 Nm22-29 ft.lbs.

Removal steps

Post-installation Operation@Lower the Engine

50-65 Nm36-47 ftlbs.

43-56 ft.lbs.

1. Pressure hose (power steering) and high

pressure hose (air conditioner)

2. BracketOIA0306

3. Engine mount bracket and body connection bolt

4. Engine mount bracket

l + 5. Mounting stopper

INSPECTION

l Check each insulator for cracks or damage

.

l Check each bracket for deformation or damage.

Page 910 of 1273

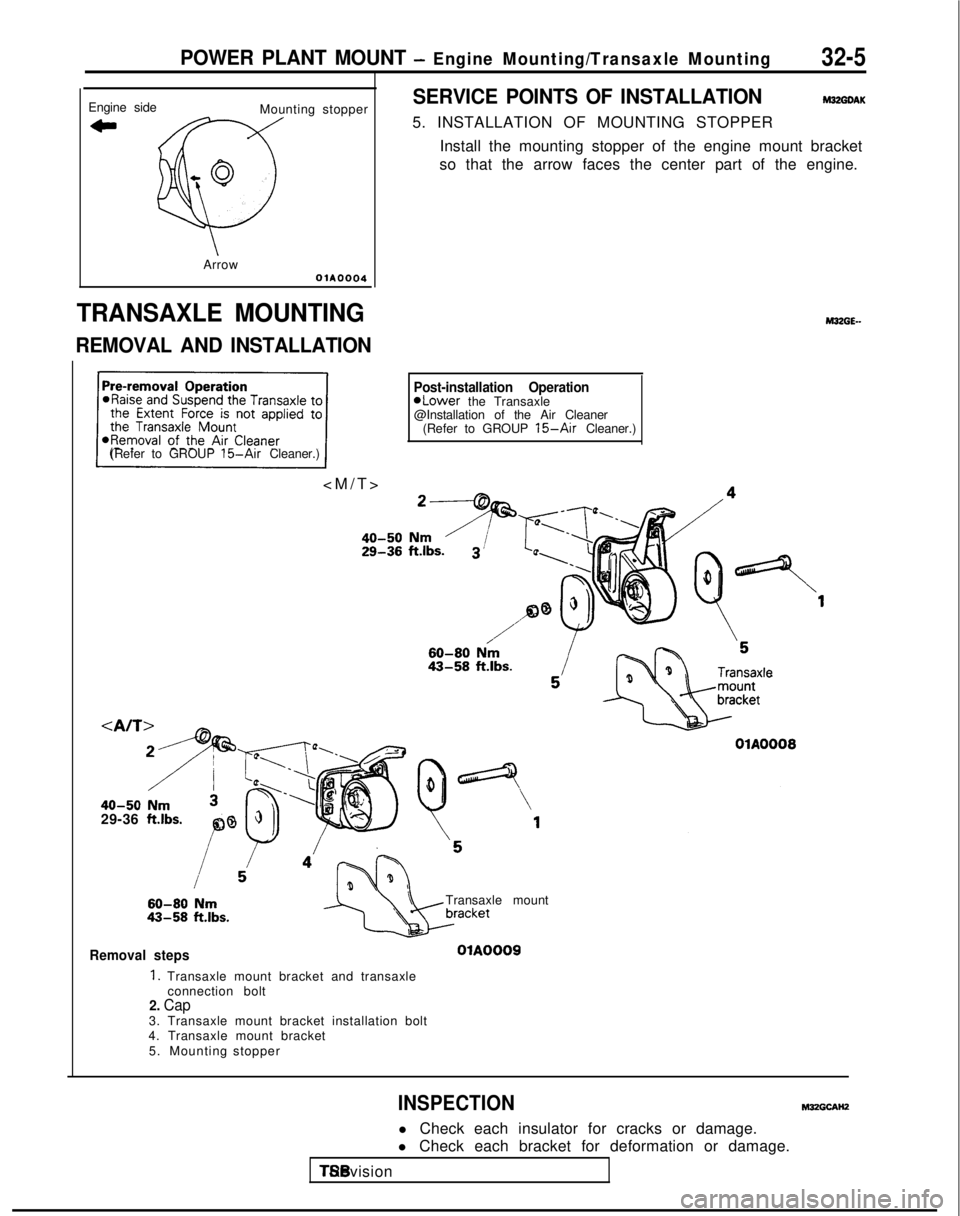

POWER PLANT MOUNT - Engine Mounting/Transaxle Mounting32-5

Engine side

1

Mounting stopper

Arrow 01AQOO4

TRANSAXLE MOUNTING

REMOVAL AND INSTALLATION

(Refer to GROUP 15-Air Cleaner.)

SERVICE POINTS OF INSTALLATIONM32GDAK

5. INSTALLATION OF MOUNTING STOPPER

Install the mounting stopper of the engine mount bracket

so that the arrow faces the center part of the engine.

Post-installation Operation @Lower

the Transaxle

@Installation of the Air Cleaner

(Refer to GROUP

15-Air Cleaner.)

60-60Nm43-58ft.lbs.

40-50Nm29-36ft.lbs.

60-80 Nm43-58 ft.lbs.

Transaxle mount

Removal steps

1. Transaxle mount bracket and transaxle

connection bolt

2. Cap3. Transaxle mount bracket installation bolt

4. Transaxle mount bracket

5. Mounting stopper

OlA0009

INSPECTIONNUZGCAHZ

l Check each insulator for cracks or damage.

l Check each bracket for deformation or damage. TSB Revision

Page 911 of 1273

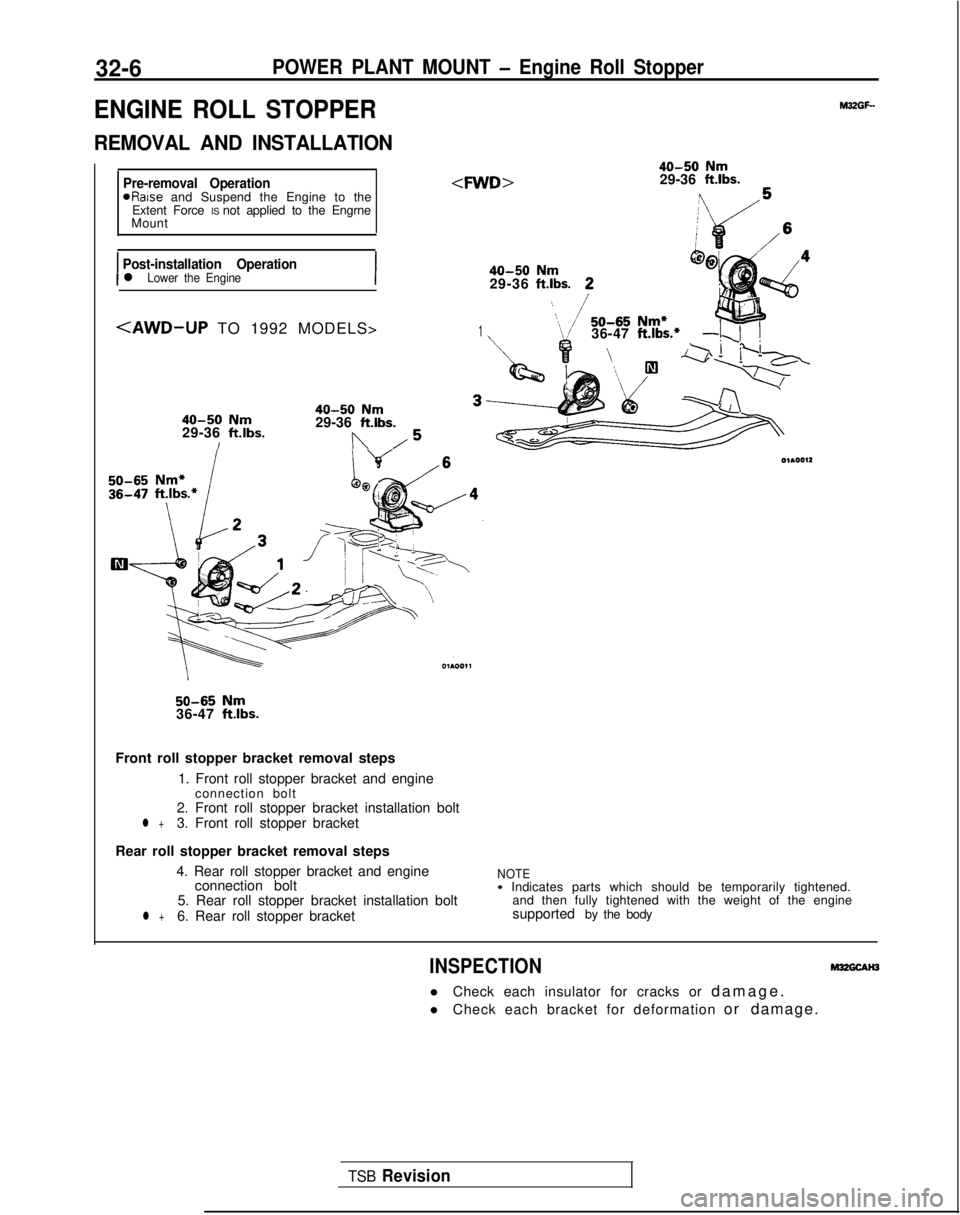

32-6POWER PLANT MOUNT - Engine Roll Stopper

ENGINE ROLL STOPPER

REMOVAL AND INSTALLATION

M32GF-

Pre-removal Operation*Raise and Suspend the Engine to the

Extent Force IS not applied to the Engrne

Mount

I

Post-installation Operationl Lower the EngineI

40-50 Nm29-36 ftlbs.I

40-50 Nm29-36 ft.lbs.

nA5

40-50 Nm29-36 ft.lbs.

40-50Nm29-36ft.lbs. 2

136-47

ft.lbs.*

50-65 Nm36-47 ft.lbs.

Front roll stopper bracket removal steps

1. Front roll stopper bracket and engineconnection bolt

2. Front roll stopper bracket installation bolt

l +3. Front roll stopper bracket

Rear roll stopper bracket removal steps 4. Rear roll stopper bracket and engineconnection bolt

5. Rear roll stopper bracket installation bolt

l +6. Rear roll stopper bracket

NOTE+ Indicates parts which should be temporarily tightened. and then fully tightened with the weight of the engine

supported by the body

INSPECTIONM32GcAH3

l Check each insulator for cracks or damage

.

l Check each bracket for deformation or damage.

TSB Revision

Page 956 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-17

CHECKING ACCORDING TO CHARTS CLASSIFIED BY THE MALFUNCTION SYMPTOM

[A] DIAGNOSTIC TROUBLE CODE NO.54

No

Yes

b Excessive vehicle-height ad- MITSUBISHI GALANT 1989 Service Repair Manual ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-17

CHECKING ACCORDING TO CHARTS CLASSIFIED BY THE MALFUNCTION SYMPTOM

[A] DIAGNOSTIC TROUBLE CODE NO.54

No

Yes

b Excessive vehicle-height ad-](/img/19/57312/w960_57312-955.png)

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-17

CHECKING ACCORDING TO CHARTS CLASSIFIED BY THE MALFUNCTION SYMPTOM

[A] DIAGNOSTIC TROUBLE CODE NO.54

No

Yes

b Excessive vehicle-height ad-justment

(overload) overload). time (due to -Unload the vehicle and turn* the ignition key to OFF; then

restart the engine and check

whether or not the system

functions normally.

Is the installation position of Nothe height sensor correct?

Yes Improper setting of the heightc sensor, or malfunction of the

height sensor. l Correct the installationcposition of the height sen-

sor, or adjust the vehicle

-height sensor rod.

l Check the height sensor. Refer to troubleshooting

hints [IO] and

[ll]classified by circuit.

Are the front strut and rear

NoMalfunction of the rolling

shock absorber unit air spr-* diaphragm.

Repair the rolling diaphragm,

or replace the shock absorber

ings in normal condition?Lunit.

(become folded)

Yes

Is the sound of operation

NoThe solenoid valves remain

heard from each solenoid closed, or there is air leakage

valve necessary for th

e

’ due to a malfunction of the

vehicle-height adjustment? valve seat.

Yes

Is the air pressure in the

vehicle-height adjustment

Nopressure line 950 kPa (135

psi) or higher?

I

Yes Damaged or disconnected

wiring of the high-pressure

switch, or incorrect vehicle

-height adjustment pressureline.

l Check the high-pressure switch circuit.

* Refer to troubleshooting hint [5] classified by circuit.

l Correct the clogging pro-

blem, or replace the air

tube.

Control unit malfunction.

[B] DIAGNOSTIC TROUBLE CODE NO.55

- No

Does the compressor func-

tion normally?

Yes Replace the control unit.c l Power is not supplied to

the compressor.Refer to troubleshooting

hint

[18] classified by cir-

cuit.

0 Improper compressor com- pression.

Is the air pressure in the

Novehicle-height adjustment

pressure line 760 kPa (108psi) or lower? High-pressure

switch

isRefer to troubleshooting hint

shorted____* [5] classified by circuit.

Yes Air leakage.

TSB RevisionI

Page 957 of 1273

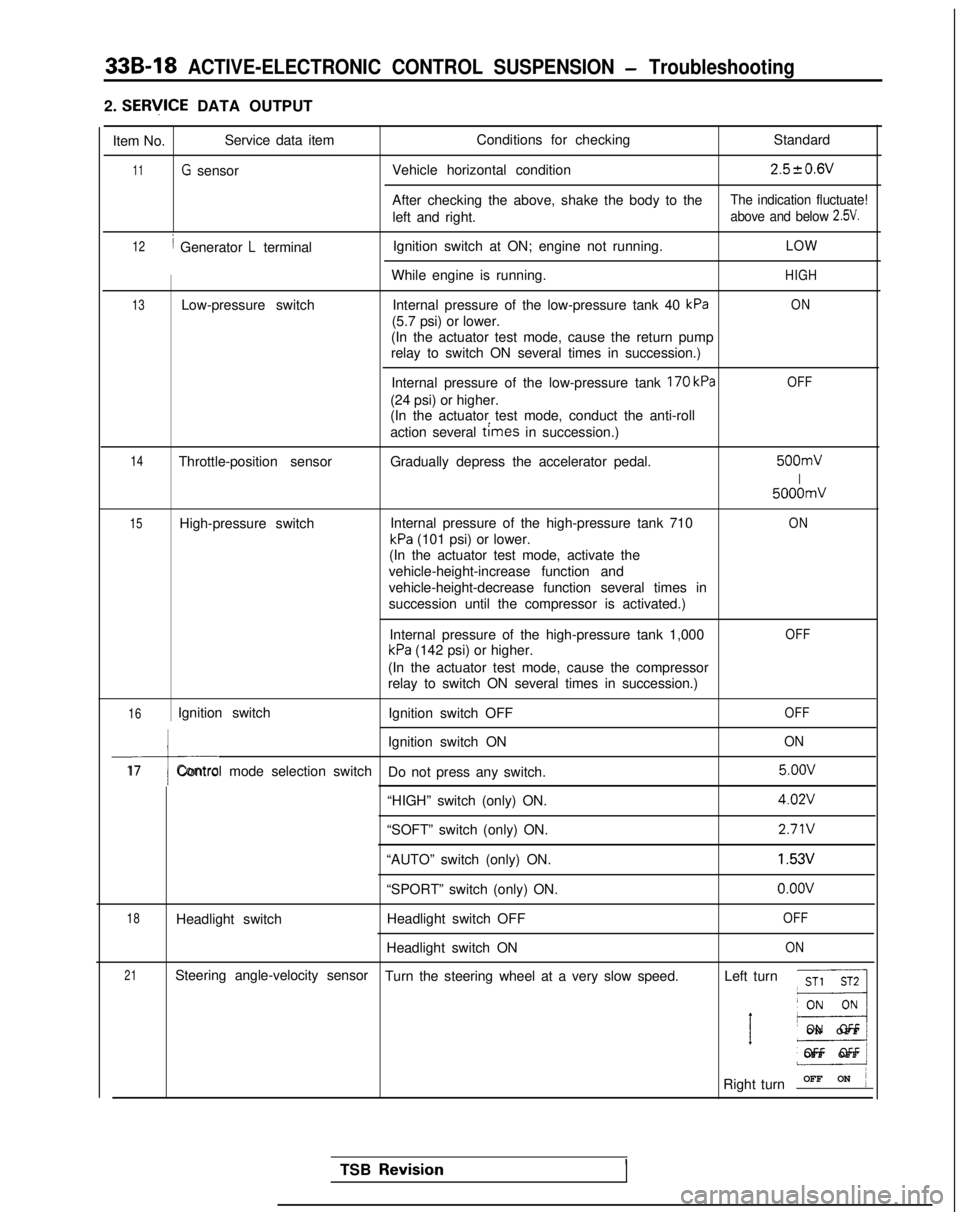

33B-18 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

2. SERlflCE DATA OUTPUT

Item No. Service data item

Conditions for checking

Standard

11G sensorVehicle horizontal condition2.520.6V

After checking the above, shake the body to theThe indication fluctuate!

left and right.above and below 2.5V.

12/ Generator L terminalIgnition switch at ON; engine not running.LOW

While engine is running.HIGH

13Low-pressure switch

Internal pressure of the low-pressure tank 40 kPaON

(5.7 psi) or lower.

(In the actuator test mode, cause the return pump

relay to switch ON several times in succession.)

Internal pressure of the low-pressure tank

170 kPa

(24 psi) or higher.

(In the actuator test mode, conduct the anti-roll

action several

times in succession.)

OFF

14Throttle-position sensor Gradually depress the accelerator pedal. 500mV

I

5000mV

15High-pressure switch

Internal pressure of the high-pressure tank 710ON

kPa (101 psi) or lower.

(In the actuator test mode, activate the

vehicle-height-increase function and

vehicle-height-decrease function several times in

succession until the compressor is activated.)

Internal pressure of the high-pressure tank 1,000

kPa (142 psi) or higher.

OFF

(In the actuator test mode, cause the compressor

relay to switch ON several times in succession.)

16Ignition switch Ignition switch OFFOFF

I

Ignition switch ONON

17Control mode selection switch

Do not press any switch. 5.oov

“HIGH” switch (only) ON.

4.02V

“SOFT” switch (only) ON.2.71V

“AUTO” switch (only) ON.1.53V

“SPORT” switch (only) ON.o.oov

18Headlight switch Headlight switch OFFOFF

Headlight switch ONON

21Steering angle-velocity sensor

Turn the steering wheel at a very slow speed. Left turnST1 ST2

__I

’ E3

ON OF

F

OFF OFF

Right turn OFF ON

j

TSB Revisio.nI

Page 964 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-25

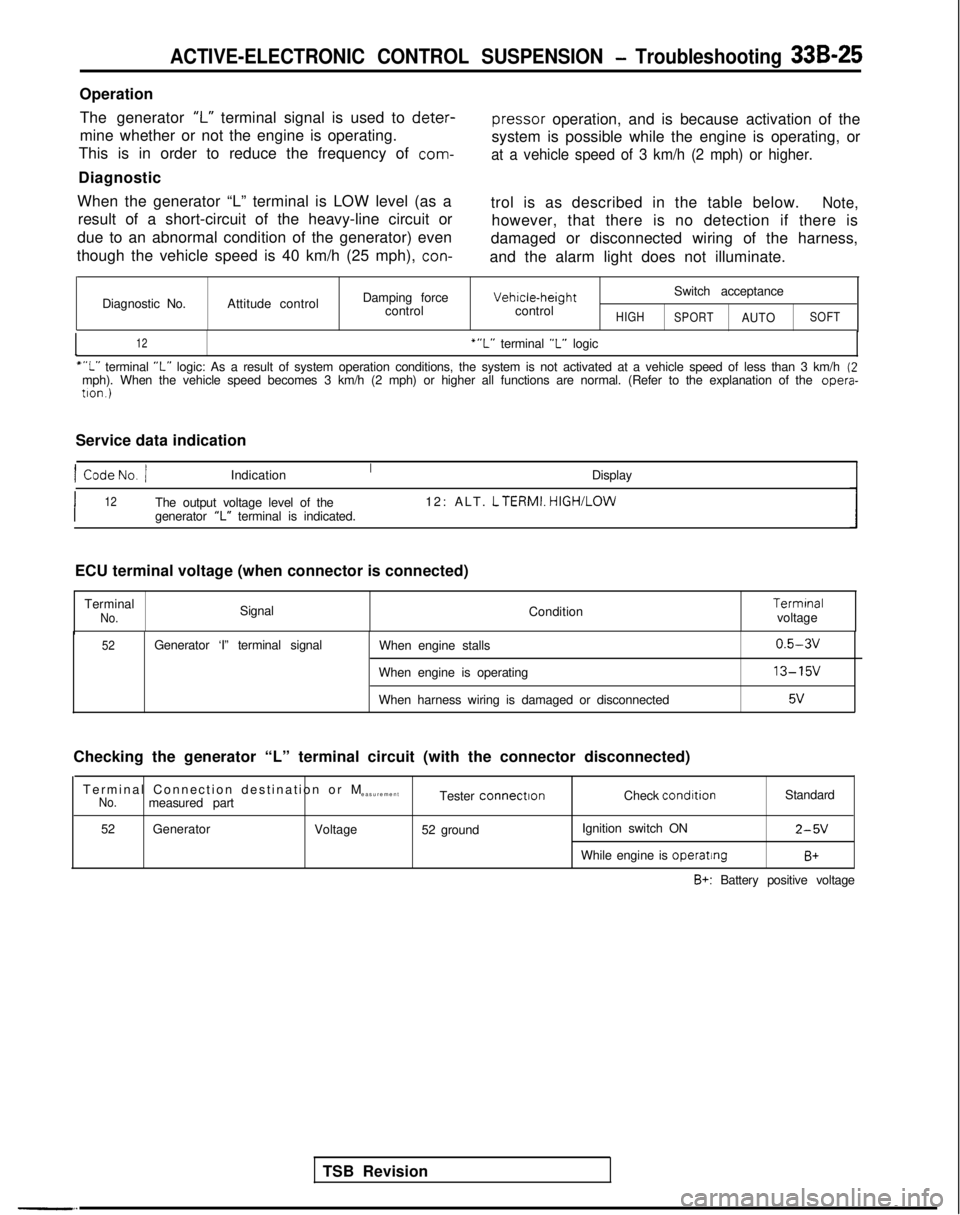

OperationThe generator

‘I-” terminal signal is used to deter-

pressor

operation, and is because activation of the

mine whether or not the engine is operating.

This is in order to reduce the frequency of

com-

system is possible while the engine is operating, or

at a vehicle speed of 3 km/h (2 mph) or higher.

Diagnostic

When the generator “L” terminal is LOW level (as a result of a short-circuit of the heavy-line circuit or

due to an abnormal condition of the generator) even

though the vehicle speed is 40 km/h (25 mph),

con-

trol is as described in the table below.Note,

however, that there is no detection if there is

damaged or disconnected wiring of the harness,

and the alarm light does not illuminate.

Diagnostic No. Attitude control Damping force

control Vehrcle-height

control

HIGH

Switch acceptance

SPORTAUTOSOFT

I12‘“L” terminal “L” logic

““L” terminal “L” logic: As a result of system operation conditions, the system is not ac\

tivated at a vehicle speed of less than 3 km/h (2mph). When the vehicle speed becomes 3 km/h (2 mph) or higher all fun\

ctions are normal. (Refer to the explanation of the opera-

tron.)

Service data indication

1 CodeNo. /Indication Display

I12The output voltage level of the12: ALT. LTERMI.

HIGH/LOW

generator “L” terminal is indicated.

TSB Revision

ECU terminal voltage (when connector is connected)

Terminal

No.Signal Condition Termrnal

voltage

52Generator ‘I” terminal signal When engine stalls

When engine is operating

When harness wiring is damaged or disconnected0.5-3v

13-15v

5v

Checking the generator “L” terminal circuit (with the connector d\

isconnected)

Terminal Connection destination or

M

easurement

No.measured part Tester connectronCheck condrtion

Standard

52 Generator

Voltage52 ground Ignition switch ON

2-5V

While engine is operatingB+

B+: Battery positive voltage