check engine MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 646 of 1273

17-26EMISSION CONTROL SYSTEMS- Exhaust Gas Recirculation (EGR) System

~

I6EM0224 1

(3) Disconnect the three-way terminal and connect the manual

vacuum pump directly to the exhaust gas recirculation

(EGR) valve.

(4) Check whether the engine stalls or the idling is unstable

when a vacuum of 155 mmHg (5.9 in.Hg) or higher is

applied during idling.

EGR VALVE CONTROL VACUUM

INSPECTION M17WBB

Engine coolant temperature: 85-95°C

(185-205°F)

(1) Disconnect the vacuum hose from the throttle body EGR

vacuum nipple and connect a hand vacuum pump to the

nipple.

TSB Revision

Page 647 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual EMISSION CONTROL SYSTEMS -Exhaust Gas Recirculation (EGR) System1 T-27

1 <DOHC (From 1990 models)>/]

LEngine speed (rpm)

lFU446

4zJ -6EM159

(2) Start the engine and check to see that, after raising th MITSUBISHI GALANT 1989 Service Repair Manual EMISSION CONTROL SYSTEMS -Exhaust Gas Recirculation (EGR) System1 T-27

1 <DOHC (From 1990 models)>/]

LEngine speed (rpm)

lFU446

4zJ -6EM159

(2) Start the engine and check to see that, after raising th](/img/19/57312/w960_57312-646.png)

EMISSION CONTROL SYSTEMS -Exhaust Gas Recirculation (EGR) System1 T-27

1

LEngine speed (rpm)

lFU446

4zJ -6EM159

(2) Start the engine and check to see that, after raising the

engine speed by racing the engine, vacuum raises prop-

ortionately with the rise in engine speed.

NOTE

if there is a problem with the change in vacuum, it is

possible that the throttle body port may be clogged and

require cleaning.

EGR VALVE

INSPECTION MI’IICKF

(1) Remove the EGR valve and check it for sticking, deposit of

carbon, etc.

If such condition exists, clean with adequate solvent to en-

sure tight valve seat contact.

(2) Connect a hand vacuum pump to the EGR valve.

(3) Apply a vacuum of 500 mmHg (19.6 in.Hg.) and check air

tightness.

(4)Blow in air from one passage of the EGR to check condition

as follows.

INSTALLATION

(1) Install a new gasket and EGR valve, tighten bolts to

specified torque.

Specified tightening torque: 17-26 Nm (12-19 ft.lbs.1

THERMAL VACUUM VALVE

INSPECTION

(1)Disconnect the vacuum hoses from the thermal vacuum

valve, and connect a hand vacuum pump to nipple of the

thermal vacuum valve.

(2) Apply a vacuum and check the air passage through the

thermal vacuum valve.

Page 649 of 1273

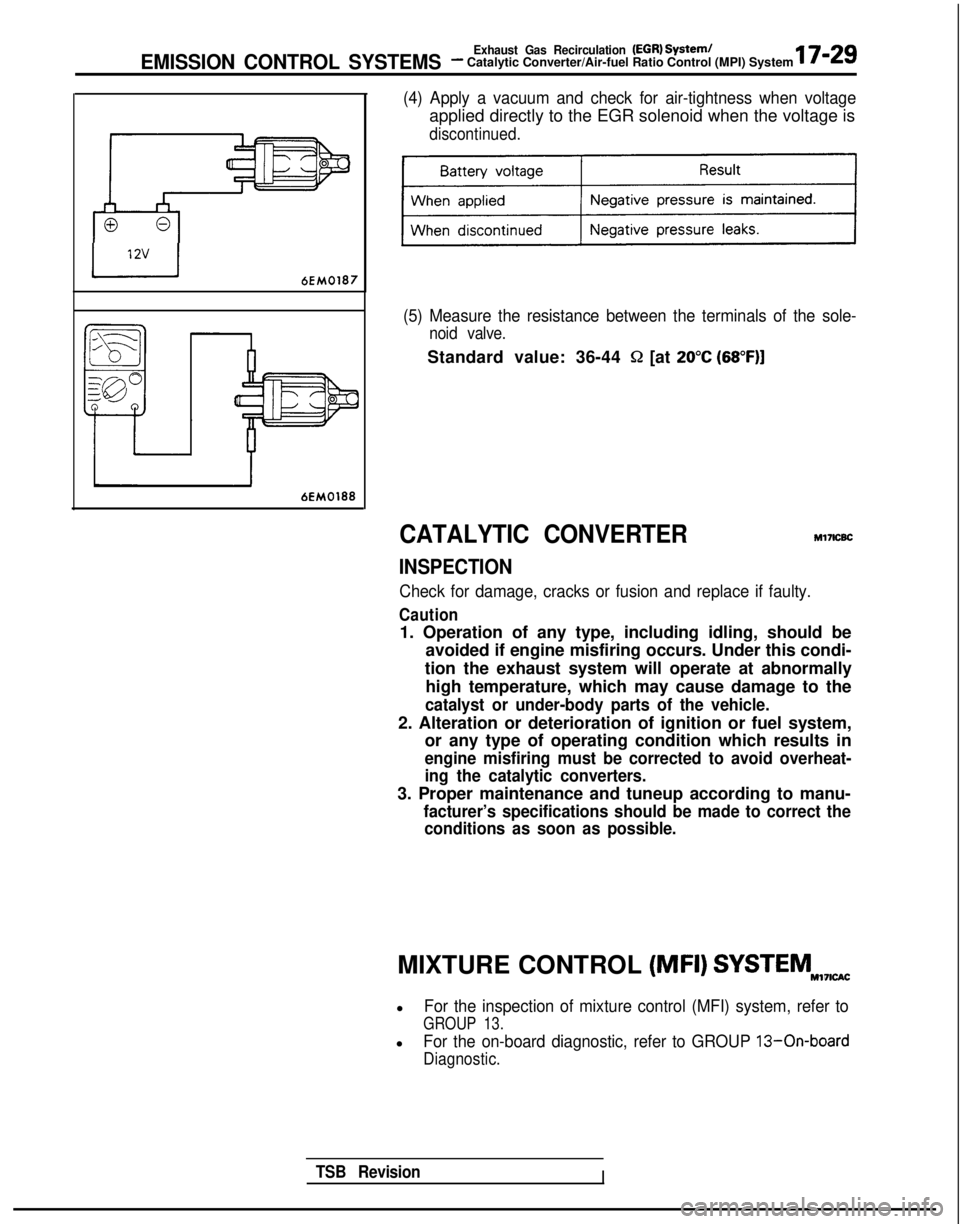

I6EM0187

EMISSION CONTROL SYSTEMSExhaust Gas Recirculation (EGR) System/- Catalytic Converter/Air-fuel Ratio Control (MPI) System17-29

(4) Apply a vacuum and check for air-tightness when voltage

applied directly to the EGR solenoid when the voltage is

discontinued.

(5) Measure the resistance between the terminals of the sole-

noid valve.

Standard value: 36-44 Q [at 20°C (68”F)]

CATALYTIC CONVERTERMl7lcBc

INSPECTION

Check for damage, cracks or fusion and replace if faulty.

Caution

1. Operation of any type, including idling, should be

avoided if engine misfiring occurs. Under this condi-

tion the exhaust system will operate at abnormally high temperature, which may cause damage to the

catalyst or under-body parts of the vehicle.

2. Alteration or deterioration of ignition or fuel system, or any type of operating condition which results in

engine misfiring must be corrected to avoid overheat-

ing the catalytic converters.

3. Proper maintenance and tuneup according to manu-

facturer’s specifications should be made to correct theconditions as soon as possible.

TSB RevisionI

MIXTURE CONTROL (MFI) SYSTEMNI,I,w

lFor the inspection of mixture control (MFI) system, refer to

GROUP 13.

lFor the on-board diagnostic, refer to GROUP 13-On-board

Diagnostic.

Page 674 of 1273

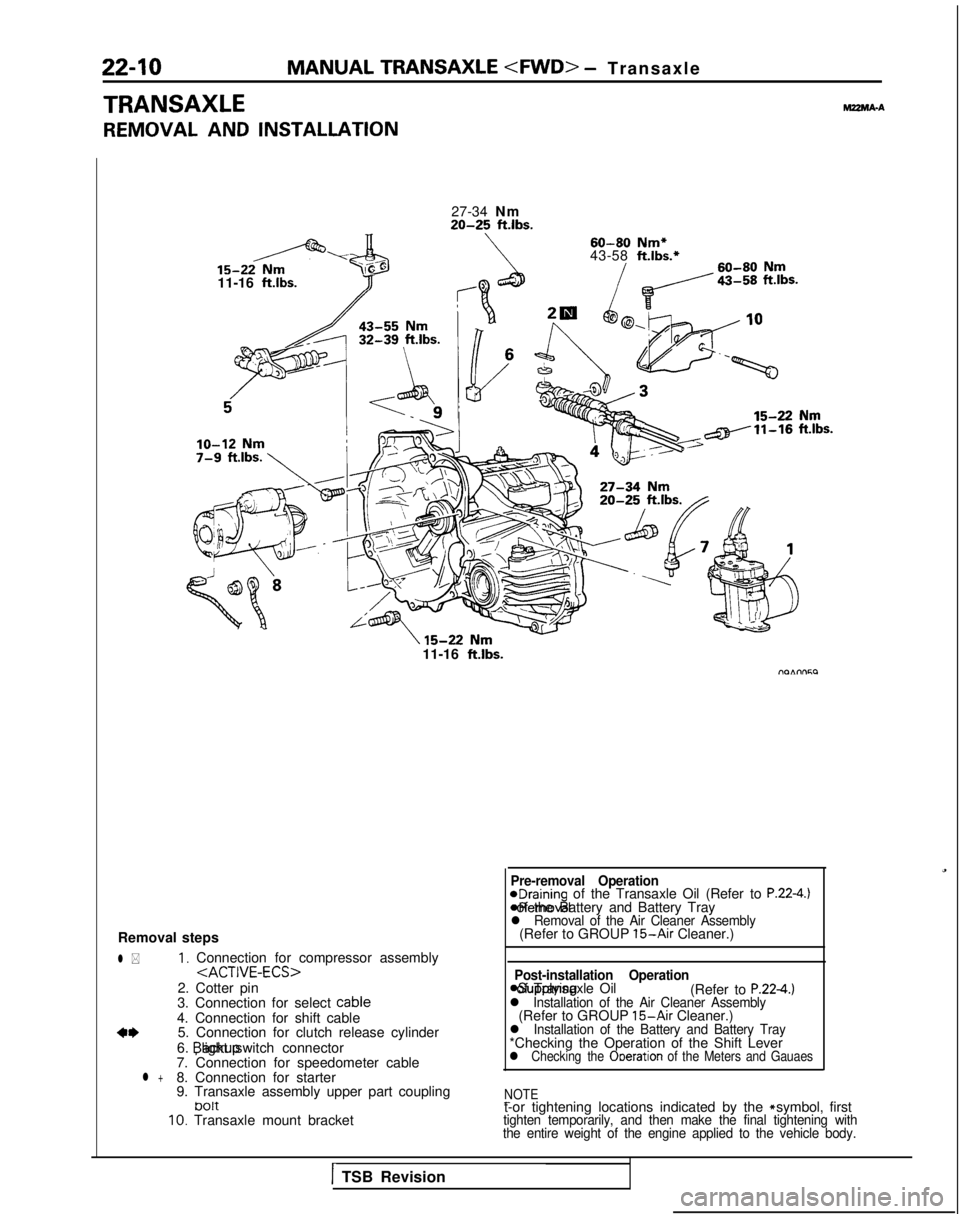

22-10MANUAL TRANSAXLE

e

TRANSAXLE

REMOVAL AND INSTALLATION

MZMA-A

27-34 Nm20-25 ft.lbs.

60-80

Nm*

43-58 ft.lbs.*

11-16

ft.lbs.71

11-16 ftlbs.

Removal steps

l *1, Connection for compressor assembly

2. Cotter pin

3. Connection for select cable

4. Connection for shift cable

a*5. Connection for clutch release cylinder

6. backup light switch connector

7. Connection for speedometer cable

l +8. Connection for starter

9. Transaxle assembly upper part coupling

tJ01t10. Transaxle mount bracket

Pre-removal Operation@Draining of the Transaxle Oil (Refer to P.22-4.) *Removal of the Battery and Battery Tray

l Removal of the Air Cleaner Assembly(Refer to GROUP 15-Air Cleaner.)

Post-installation Operation

asupplying of Transaxle Oil

(Refer to P.224.)l Installation of the Air Cleaner Assembly(Refer to GROUP 15-Air Cleaner.)l Installation of the Battery and Battery Tray*Checking the Operation of the Shift Leverl Checking the Ooeration of the Meters and Gauaes

NOTE

-t-or tightening locations indicated by the * symbol, firsttighten temporarily, and then make the final tightening with

the entire weight of the engine applied to the vehicle body.

1TSB Revision

Page 684 of 1273

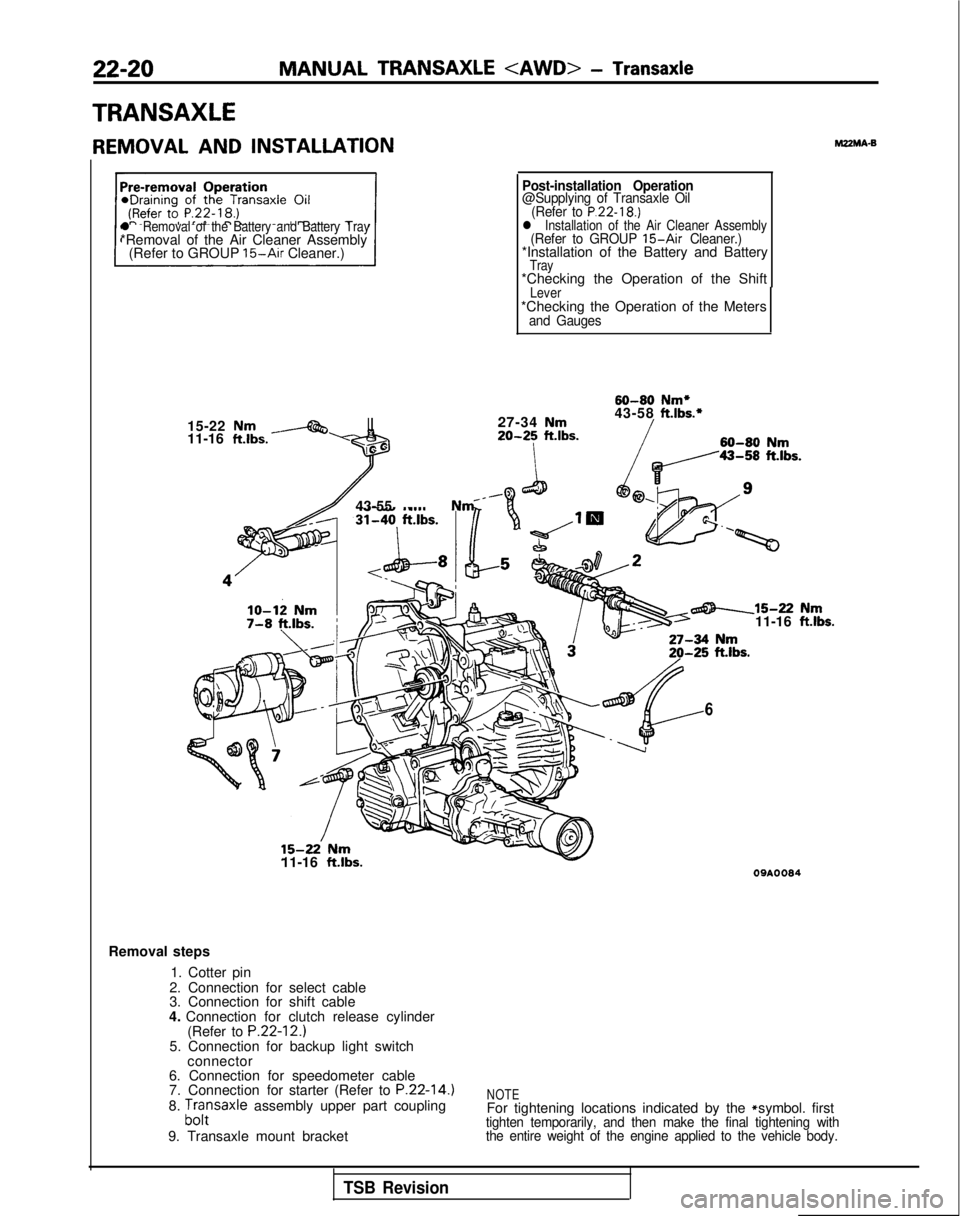

22-20MANUAL TRANSAXLE

TRANSAXLE

REMOVAL AND INSTALLATIONMZMA-B

l Removal of the Battery and Battery Tray*Removal of the Air Cleaner Assembly

(Refer to GROUP 15-Air Cleaner.)

15-22

Nm11-16 ft.lbs.-

lo-12 Nm7-8 ft.lbs.;

Post-installation Operation@Supplying of Transaxle Oil (Refer to P.22-18.)l Installation of the Air Cleaner Assembly(Refer to GROUP 15-Air Cleaner.)*Installation of the Battery and BatteryTray*Checking the Operation of the ShiftLever*Checking the Operation of the Metersand Gauges

60-80

Nm*

27-34

Nm43-58ft.lbs.*

20-25ft.lbs.60-80Nm

43-55 Nm _

15-22’ Nm11-16 ft.lbs.

6

-15-22 Nm11-16 ftlbs.

09AOOS4

Removal steps

1. Cotter pin

2. Connection for select cable

3. Connection for shift cable

4. Connection for clutch release cylinder (Refer to

P.22-12.)5. Connection for backup light switchconnector

6. Connection for speedometer cable

7. Connection for starter (Refer to

P.22-14.)8. ;,,:saxle assembly upper part coupling

9. Transaxle mount bracketNOTEFor tightening locations indicated by the * symbol. firsttighten temporarily, and then make the final tightening with

the entire weight of the engine applied to the vehicle body.

TSB Revision

Page 726 of 1273

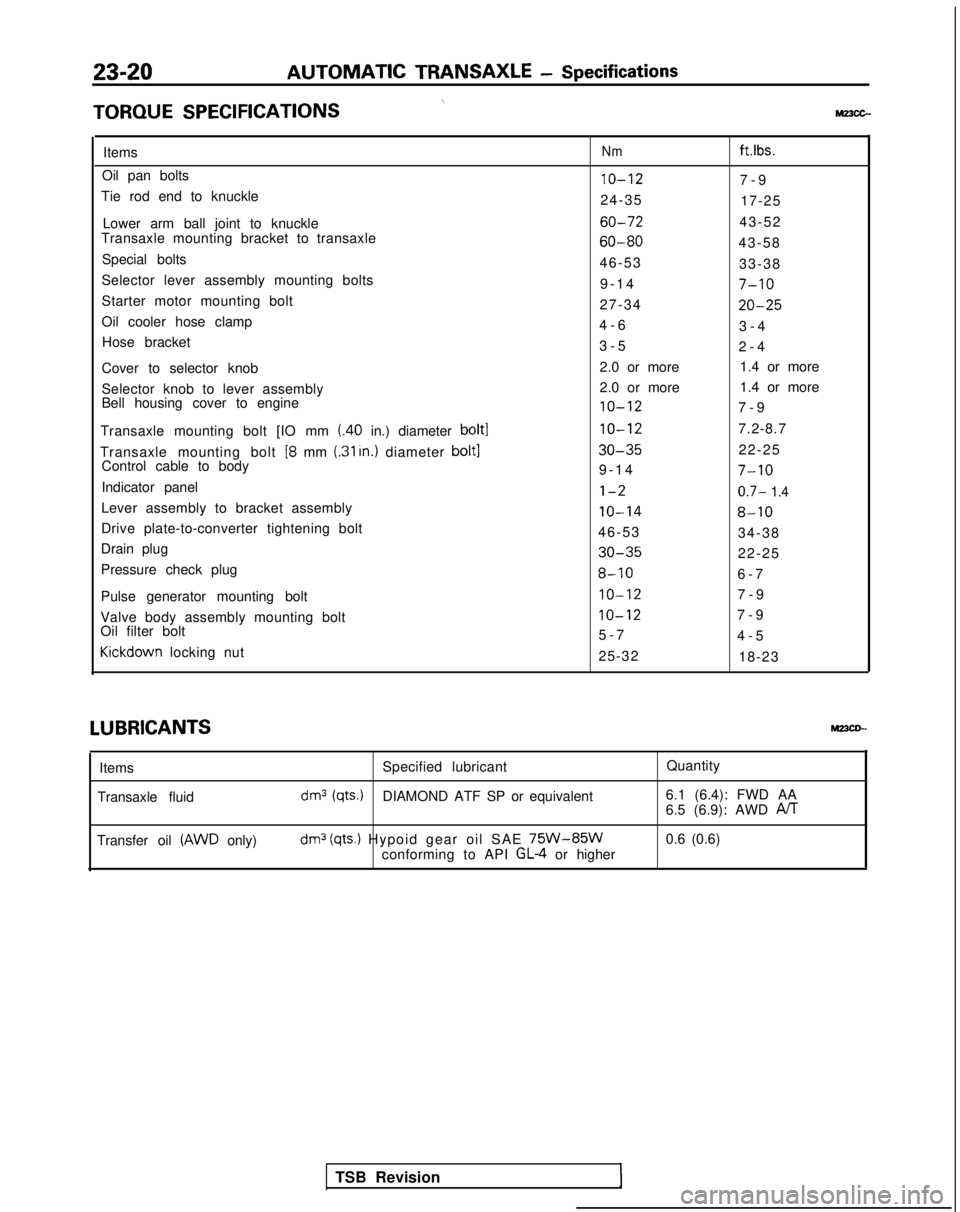

23-20AUTOMATIC TRANSAXLE

- Specifications

\TORQUE

SPECIFICATIONSMz3cc-

ItemsNmft.lbs.

Oil pan bolts10-127-

9

Tie rod end to knuckle 24-3517-25

Lower arm ball joint to knuckle

60-7243-52

Transaxle mounting bracket to transaxle

60-8043-58

Special bolts 46-5333-38

Selector lever assembly mounting bolts 9-1

4

7-10

Starter motor mounting bolt

27-3420-25

Oil cooler hose clamp4-

6

3-4

Hose bracket 3-52-4

Cover to selector knob 2.0 or more

1.4 or more

Selector knob to lever assembly 2.0 or more

1.4 or more

Bell housing cover to engine

10-127-

9

Transaxle mounting bolt [IO mm

(.40 in.) diameter bolt110-127.2-8.7

Transaxle mounting bolt

[8 mm (.31 In.) diameter bolt130-3522-25

Control cable to body 9-1

4

7-10

Indicator panell-20.7- 1.4

Lever assembly to bracket assembly10-148-10

Drive plate-to-converter tightening bolt

46-5334-38

Drain plug

30-3522-25

Pressure check plug

8-106-

7

Pulse generator mounting bolt

IO-127-

9

Valve body assembly mounting bolt

IO-127-

9

Oil filter bolt 5-74-5Kickdown

locking nut

25-3218-23LUBRICANTS

MPCD--

Items

Transaxle fluid Specified lubricant

Quantity

dm3 (qts.)DIAMOND ATF SP or equivalent6.1 (6.4): FWD AA

6.5 (6.9): AWD PJT

Transfer oil (AWD only)dm3 (qts.) Hypoid gear oil SAE 75W-85Wconforming to API GL-4 or higher0.6 (0.6)

TSB Revision

Page 728 of 1273

23-22 AUTOMATIC

TRANSAXLE

- Troubleshooting

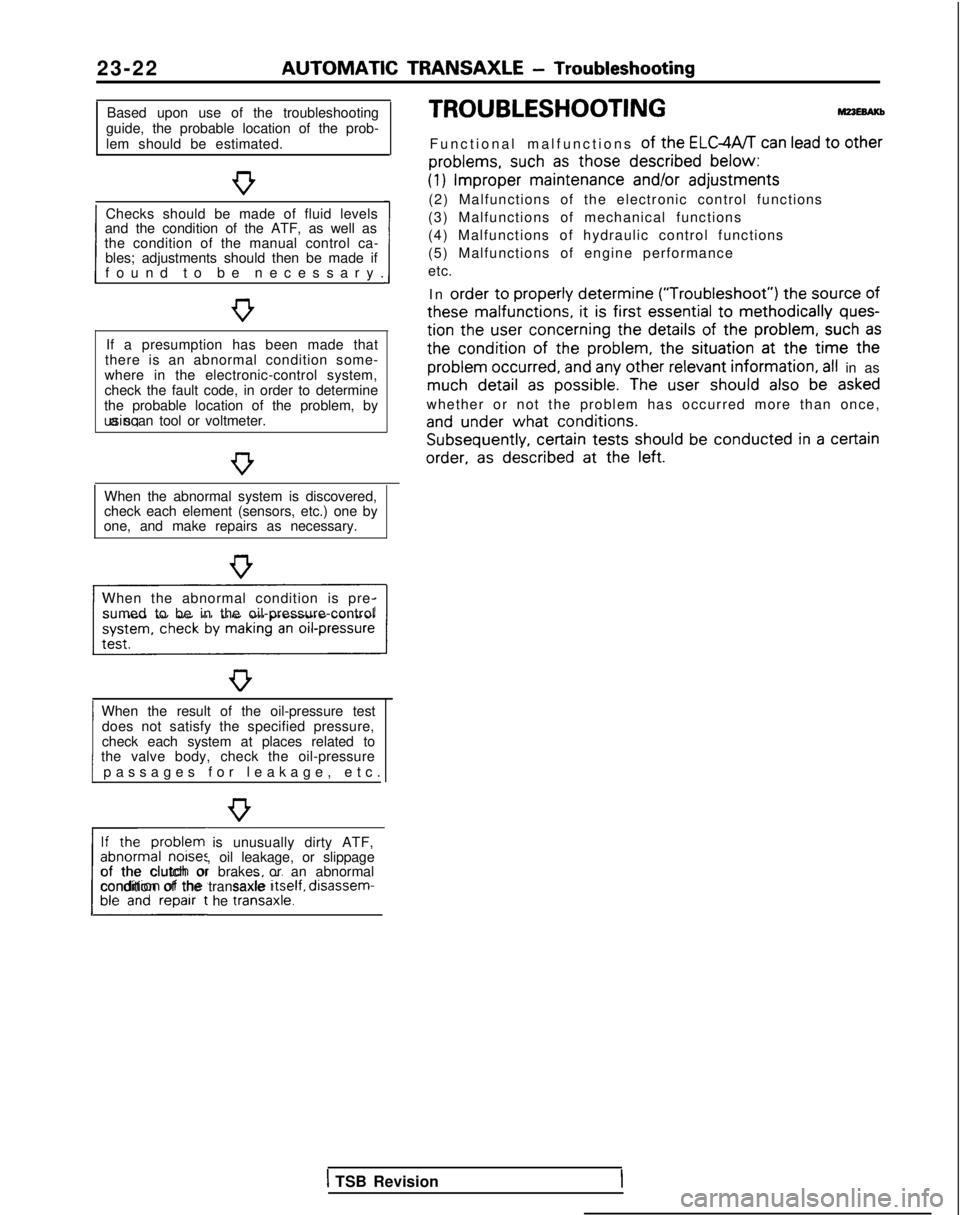

Based upon use of the troubleshooting

guide, the probable location of the prob-

lem should be estimated.

Checks should be made of fluid levels

and the condition of the ATF, as well as

1 found to be necessary

.

the condition of the manual control ca-

bles; adjustments should then be made if

If a presumption has been made that

there is an abnormal condition some-

where in the electronic-control system,

check the fault code, in order to determine

the probable location of the problem, by using a scan tool or voltmeter.

When the abnormal system is discovered,

check each element (sensors, etc.) one by

one, and make repairs as necessary.

When the abnormal condition is pre- sumed to be in the oil-pressure-control

When the result of the oil-pressure test does not satisfy the specified pressure,

1 passages for leakage, etc

.

check each system at places related to

the valve body, check the oil-pressure

If the problem is unusually dirty ATF,

abnormal noises, oil leakage, or slippage

L##t he traniaxle.1

of the clutch or brakes or an abnormal

condition of the transaxle Itself,

disassem-

TROUBLESHOOTING

Functional malfunctions of the ELGWT can lead to other

problems,

such

as those described

below:

(1) Improper

maintenance

and/or

adjustments

(2) Malfunctions of the electronic control functions

(3) Malfunctions of mechanical functions

(4) Malfunctions of hydraulic control functions

(5) Malfunctions of engine performance

etc.

In order

to properly

determine (“Troubleshoot”)

the

source

of

these

malfunctions,

it is first essential

to methodically ques-

tion

the

user

concerning

the details

of the problem,

such as

the

condition of

the

problem,

the

situation at

the

time the

problem

occurred,

and any other relevant

information, all in as much detail

as possible.

The user

should

also be asked

whether or not the problem has occurred more than once,

and under

what conditions. Subsequently,

certain

tests should

be conducted in a certain

order,

as described

at

the

left.

1 TSB Revision

Page 740 of 1273

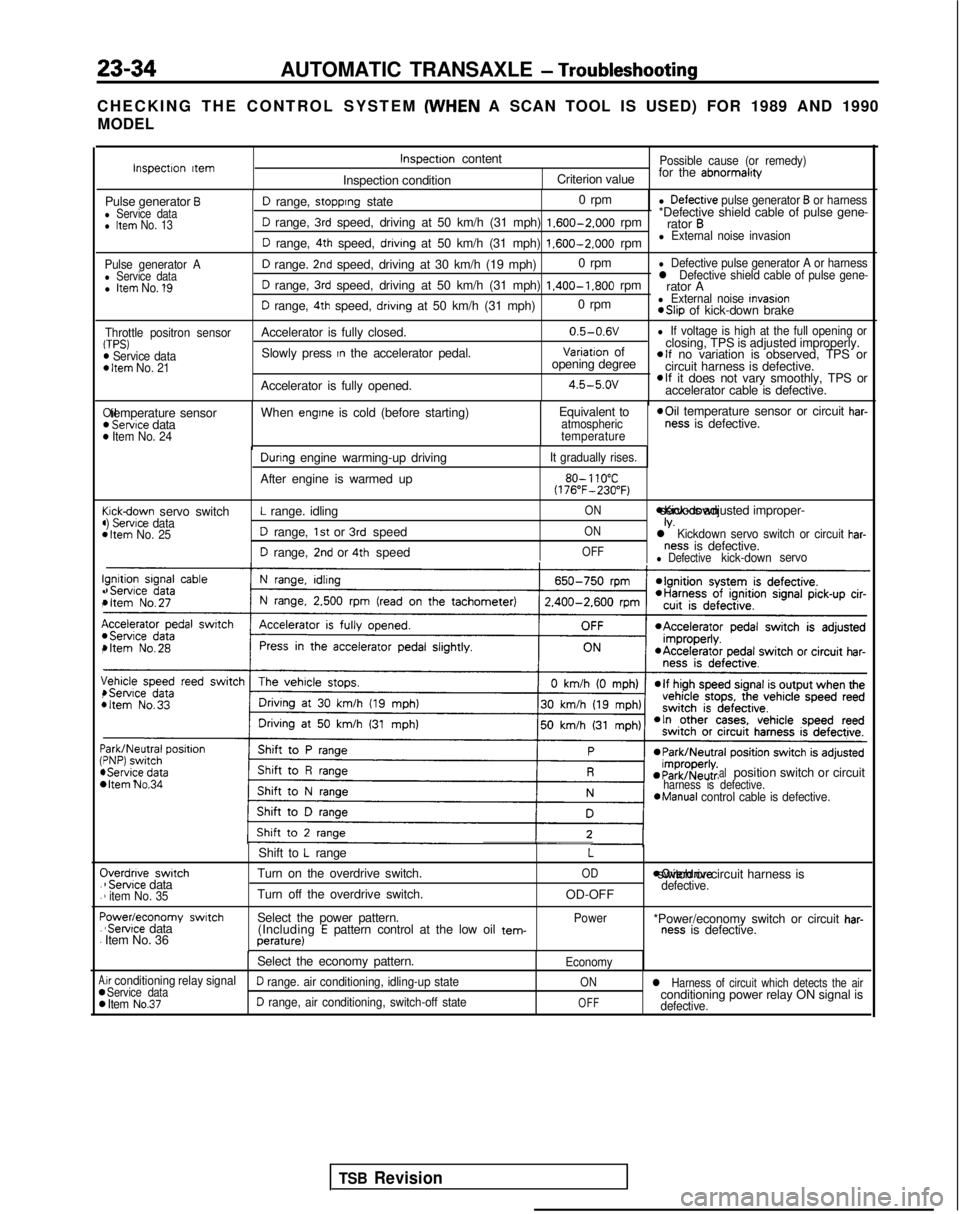

23-34AUTOMATIC TRANSAXLE - Troubleshooting

CHECKING THE CONTROL SYSTEM (WHEN

A SCAN TOOL IS USED) FOR 1989 AND 1990

MODEL

Pulse generator Al Service datal Item No. 1’9

Throttle positron sensorTPS)m Service dataD Item No. 21

I!(

(44

c44

I!.,

I(,

\,4

:44 C

.

.

F.

.

A00

D range, stopprng state 0 rpml Defectrve pulse generator B or harness

D range, 3rd speed, driving at 50 km/h (31 mph) 1.600-2.000

rpm*Defective shield cable of pulse gene-

rator B

D range, 4th speed, drivrng at 50 km/h (31 mph) 1.600-2.000

rpml External noise invasion

D range. 2nd speed, driving at 30 km/h (19 mph) 0 rpml Defective pulse generator A or harness

D range, 3rd speed, driving at 50 km/h (31 mph) 1.400-1.800

rpml Defective shield cable of pulse gene-rator A

D range, 4th speed, drivrng at 50 km/h (31 mph) 0 rpml External noise Invasion *Slip

of kick-down brake

Accelerator is fully closed. 0.5-0.6V

l If voltage is high at the full opening or

Slowly press In the accelerator pedal.Variatron of

closing, TPS is adjusted improperly.

opening degreeelf no variation is observed, TPS or

circuit harness is defective.

Accelerator is fully opened.

4.5-5.ovelf it does not vary smoothly, TPS or

accelerator cable is defective. Xl temperature sensor

) Servtce data) Item No. 24

When engtne is cold (before starting)

Equivalent toatmospheric

temperature *Oil

temperature sensor or circuit har-ness is defective.

cickdown servo switch) Servrce data1 Item No. 25

Durrng engine warming-up driving

After engine is warmed up

L range. idling

D range, 1st or 3rd speed

D range, 2nd or 4th speed

It gradually rises.

80- 110°C(176”F-230°F)

ON *Kick-down servo IS adjusted improper-

ONIV.l Kickdown servo switch or circuit har-

OFFness is defective.l Defectivekick-down

servo

bItem No.34 alposition switch or circuitharness is defective.*Manual

control cable is defective.

Iverdnve switch1 Servrce data1 item No. 35

‘owedeconomy swatch‘Servrce data

Item No. 36 Shift to

L range

Turn on the overdrive switch.

Turn off the overdrive switch.

Select the power pattern. (Including

E pattern control at the low oil tem-perature)

L

OD

OD-OFF

Power moverdrive switch or circuit harness is

defective.

*Power/economy switch or circuit har-ness is defective.

Select the economy pattern.

Economy

.ir conditioning relay signalService dataD range. air conditioning, idling-up stateONl Harness of circuit which detects the air

Item No.37D range, air conditioning, switch-off stateOFFconditioning power relay ON signal isdefective.

Inspectron ttemInspectron content

Inspection conditionPossible cause (or remedy)

Criterion value for the abnormalrty

Pulse generator Bl Service datal Item No. 13

TSB Revision

Page 741 of 1273

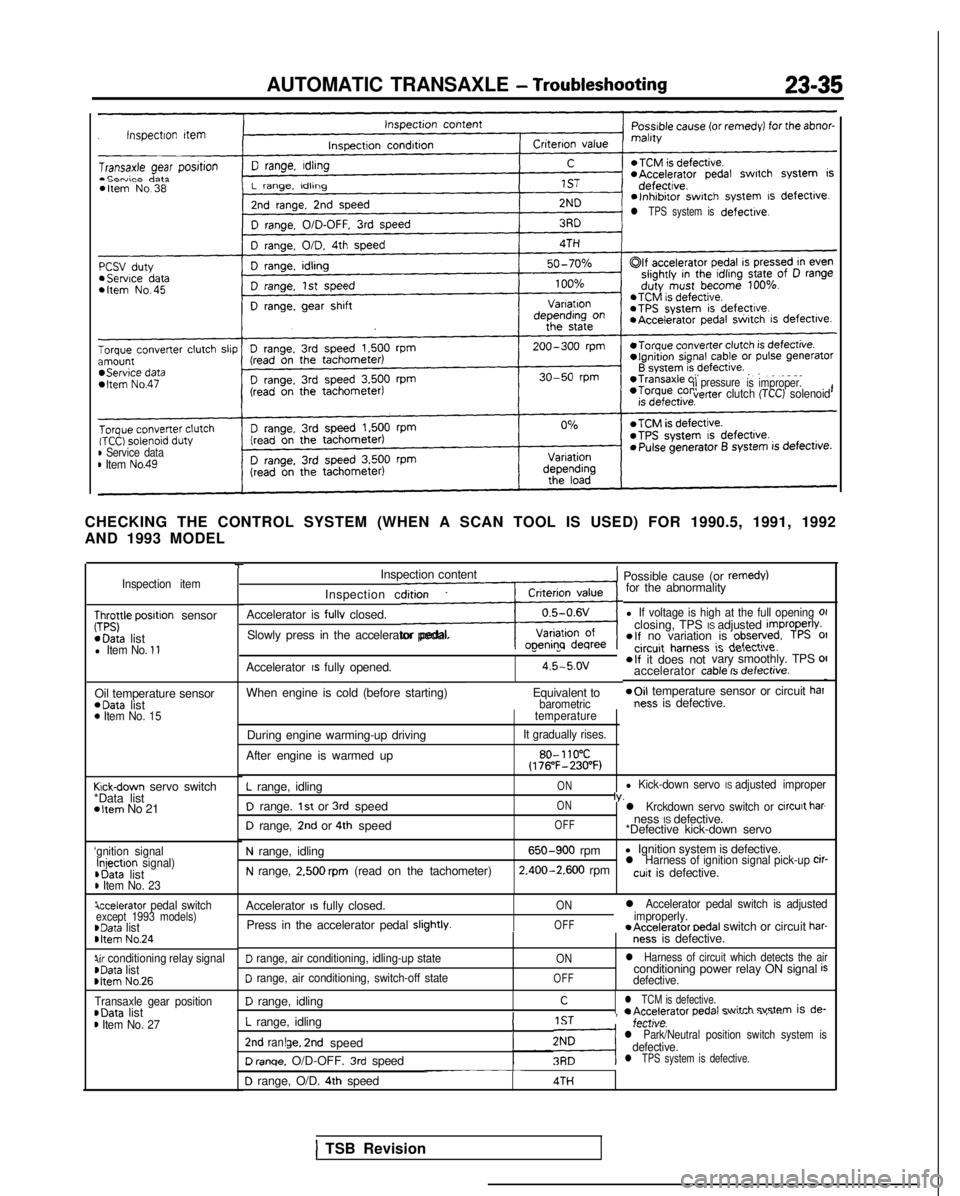

AUTOMATIC TRANSAXLE - Troubleshooting23-35

l TPS system isdefective.

ilpressure

is improper.verter clutch (TCC) solenoid

B Service datam Item No.49

CHECKING THE CONTROL SYSTEM (WHEN A SCAN TOOL IS USED) FOR 1990.5, 199\

1, 1992

AND 1993 MODEL

Inspection item

;;;yle posrtion sensor *Data

list

l Item No. 11

Oil temperature sensor *Data

list

0 Item No. 15

Krck-down servo switch

*Data list

*Item No 21

‘gnition signalInjectron signal) ,Data

list

D Item No. 23

iccelerator pedal switchexcept 1993 models)~Data listbItem No.24

Qr conditioning relay signalrData list rltem

No.26

Transaxle gear position~Data listm Item No. 27

-rInspection content

Inspection condition

Accelerator is

fullv closed.

LSlowly press in the accelerator pedal.

1 Possible cause (or remedy)for the abnormality

l If voltage is high at the full opening 01closing, TPS IS adjusted improperlv.elf no variation is observed. TPS 01

Accelerator IS fully opened.

--circuit harness ic r(afndi

O,a “ClrULIIu.

4.5-5.ov*If it does not vary smoothly. TPS OII- .-d-L__.:__accelerator cable IS oerectrve.

When engine is cold (before starting)

Equivalent to*Oil temperature sensor or circuit barbarometricness is defective.

During engine warming-up driving

After engine is warmed uptemperature

It gradually rises.

80- 110°C(176”F-230°F)

L range, idling

D range. 1st or 3rd speed

D range, 2nd or 4th speed

ON

ON

OFFl Kick-down servo IS adjusted improperIv.l Krckdown servo switch or circurt barness IS defective.

*Defective kick-down servo

N range, idling

N range, 2.500 rpm (read on the tachometer)

650-900 rpm l Ignition system is defective. 2.400-2.600

rpml Harness of ignition signal pick-up cir-cuit is defective.

Accelerator

IS fully closed.

Press in the accelerator pedal

sliphtlv.I

ON

OFF

l Accelerator pedal switch is adjusted

improperly. *Accelerator

oedal switch or circuit har-ness is defective.

D range, air conditioning, idling-up state

D range, air conditioning, switch-off state

ON

OFF

l Harness of circuit which detects the airconditioning power relay ON signal isdefective.

D range, idling

L range, idling

Cl TCM is defective.r A~d~r~tnr nednl +witch svstem is de-

!IST, -;,,tl;;..- r..--. -.-.--..

-,---,.,.,.,.v.l Park/Neutral position switch system isdefective.2nd ran!ge. 2nd speed

D renqe. O/D-OFF. 3rd speedl TPS system is defective.-~~~~~D range, O/D. 4th speed4TH

1 TSB Revision

Page 751 of 1273

AlJTCMVlATlC TRANSAXLE - Troubleshooting23-45

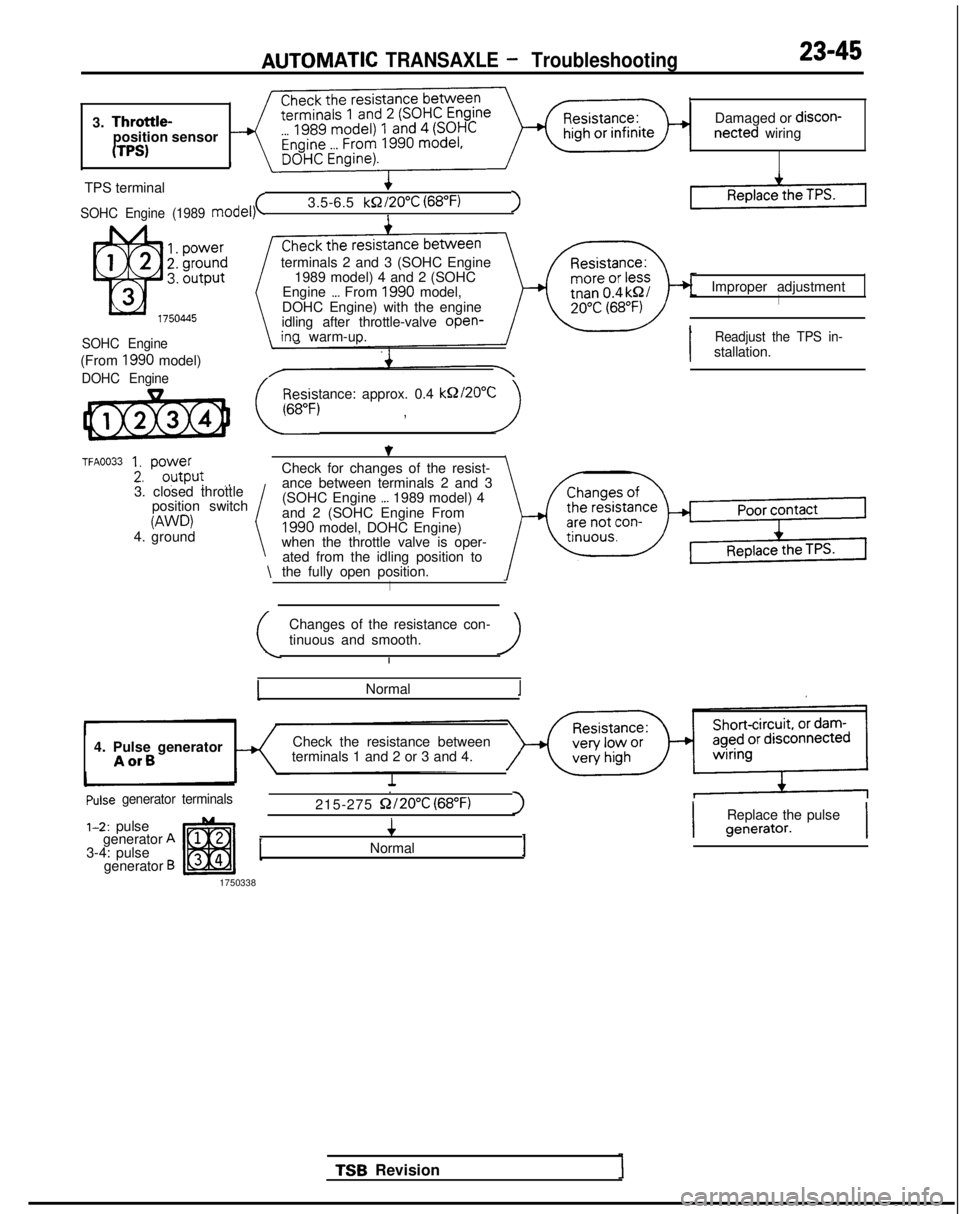

3. Throttle-position sensor

UPS)

Damaged or discon-netted wiring

TPS terminal

SOHC Engine (1989 model)(3.5-6.5 kQ/20”C

(68°F)1I

SOHC Engine

(From 1990 model)

DOHC Engine

TFA0033 1. power

2. outpur.,

terminals 2 and 3 (SOHC Engine

1989 model) 4 and 2 (SOHC

Engine

_._ From 1990 model,

DOHC Engine) with the engine

idling after throttle-valve open-

ina warm-up.

Resistance: approx. 0.4

kQZ20”C

(,6,, , )

3. closed throttle position switch

W’D)4. ground \

Check for changes of the resist-

ance between terminals 2 and 3

(SOHC Engine

,._ 1989 model) 4

and 2 (SOHC Engine From

1990 model, DOHC Engine)

when the throttle valve is oper-

ated from the idling position to

the fully open position.

I

Changes of the resistance con-

tinuous and smooth.

Normal

4. Pulse generator

AorB

Check the resistance between

terminals 1 and 2 or 3 and 4.

Pulse generator terminals.

215-275

Q/20% (68°F)I

1-2: pulse

generator A3-4: pulse

generator B

4

Normal1

1750338 Improper adjustment

I

I

Readjust the TPS in-stallation.

TSB Revision

I

Replace the pulsegenerator.I