MITSUBISHI GALANT 1989 Service Owner's Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 21 of 1273

GENERAL - Towing and Hoisting

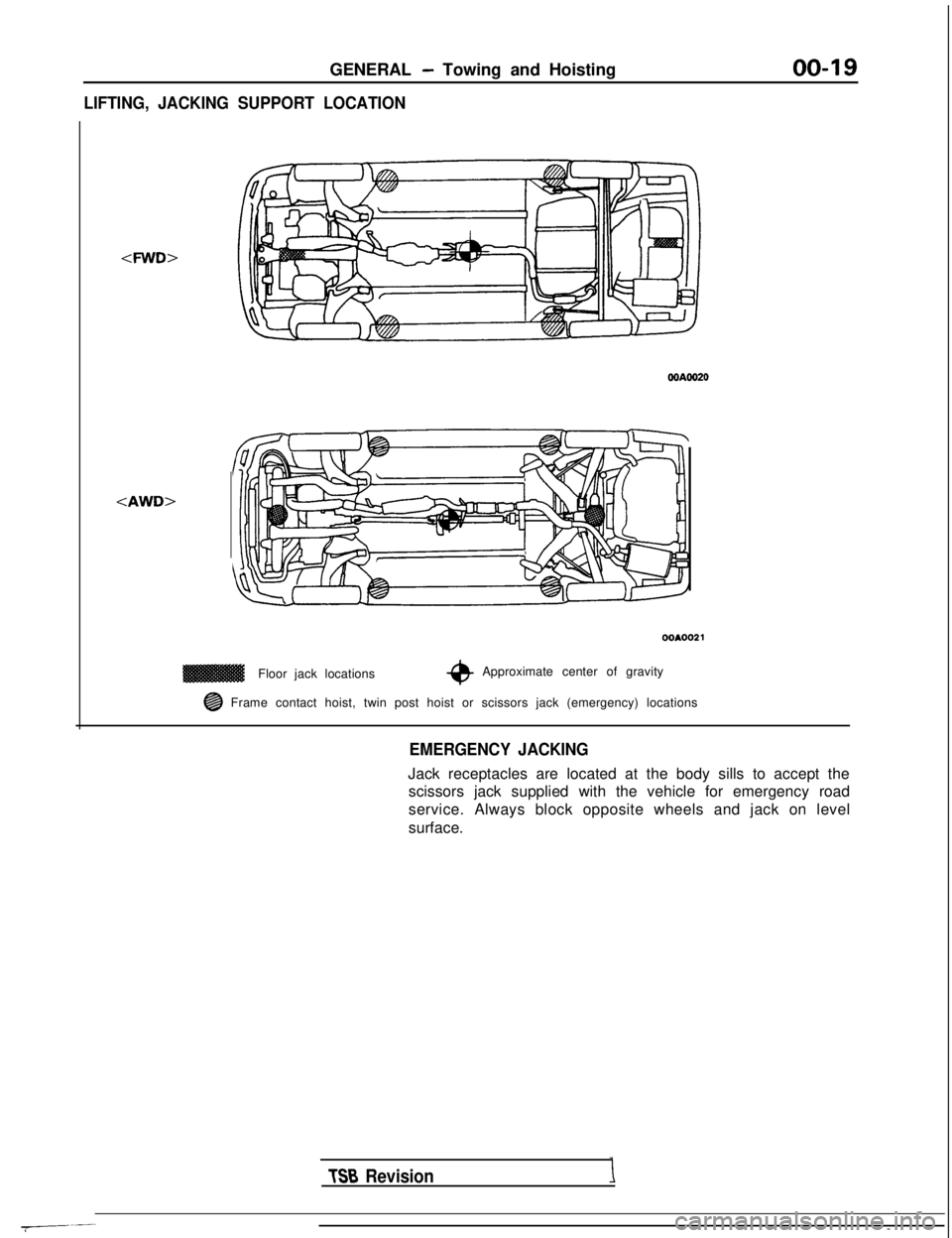

LIFTING, JACKING SUPPORT LOCATION

00-19

WA0020

00A0021

Floor jack locations-eApproximate center of gravity

@ Frame contact hoist, twin post hoist or scissors jack (emergency) loc\

ations

EMERGENCY JACKING

Jack receptacles are located at the body sills to accept the

scissors jack supplied with the vehicle for emergency road

service. Always block opposite wheels and jack on level

surface.

TSB Revision

Page 22 of 1273

00-20GENERAL - Special Handling Instructions for AWD Models

SPECIAL HANDLING INSTRUCTIONS

FOR AWD MODELS

TOWIN

G

MomMA

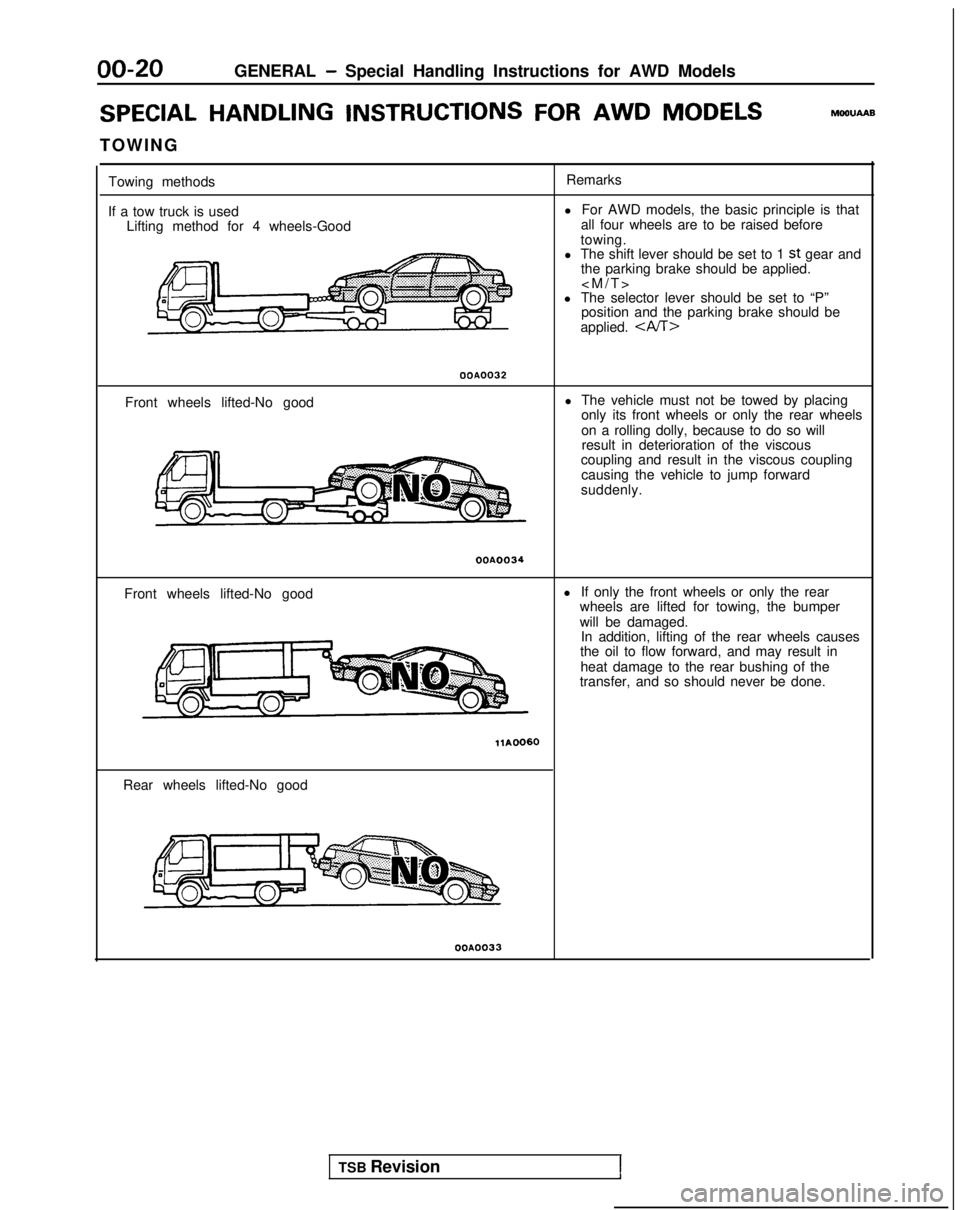

Towing methods

If a tow truck is used Lifting method for 4 wheels-Good Remarks

l For AWD models, the basic principle is that

all four wheels are to be raised before

towing.

l The shift lever should be set to 1

st gear and

the parking brake should be applied.

l The selector lever should be set to “P” position and the parking brake should be

applied.

OOA0032

Front wheels lifted-No good l The vehicle must not be towed by placing

only its front wheels or only the rear wheels

on a rolling dolly, because to do so willresult in deterioration of the viscous

coupling and result in the viscous coupling

causing the vehicle to jump forward

suddenly.

OOA0034

Front wheels lifted-No good l

If only the front wheels or only the rear

wheels are lifted for towing, the bumper

will be damaged. In addition, lifting of the rear wheels causes

the oil to flow forward, and may result in

heat damage to the rear bushing of the

transfer, and so should never be done.

Rear wheels lifted-No good

OOA0033

TSB Revision1

Page 23 of 1273

GENERAL - Special Handling Instructions for AWD Models00-21

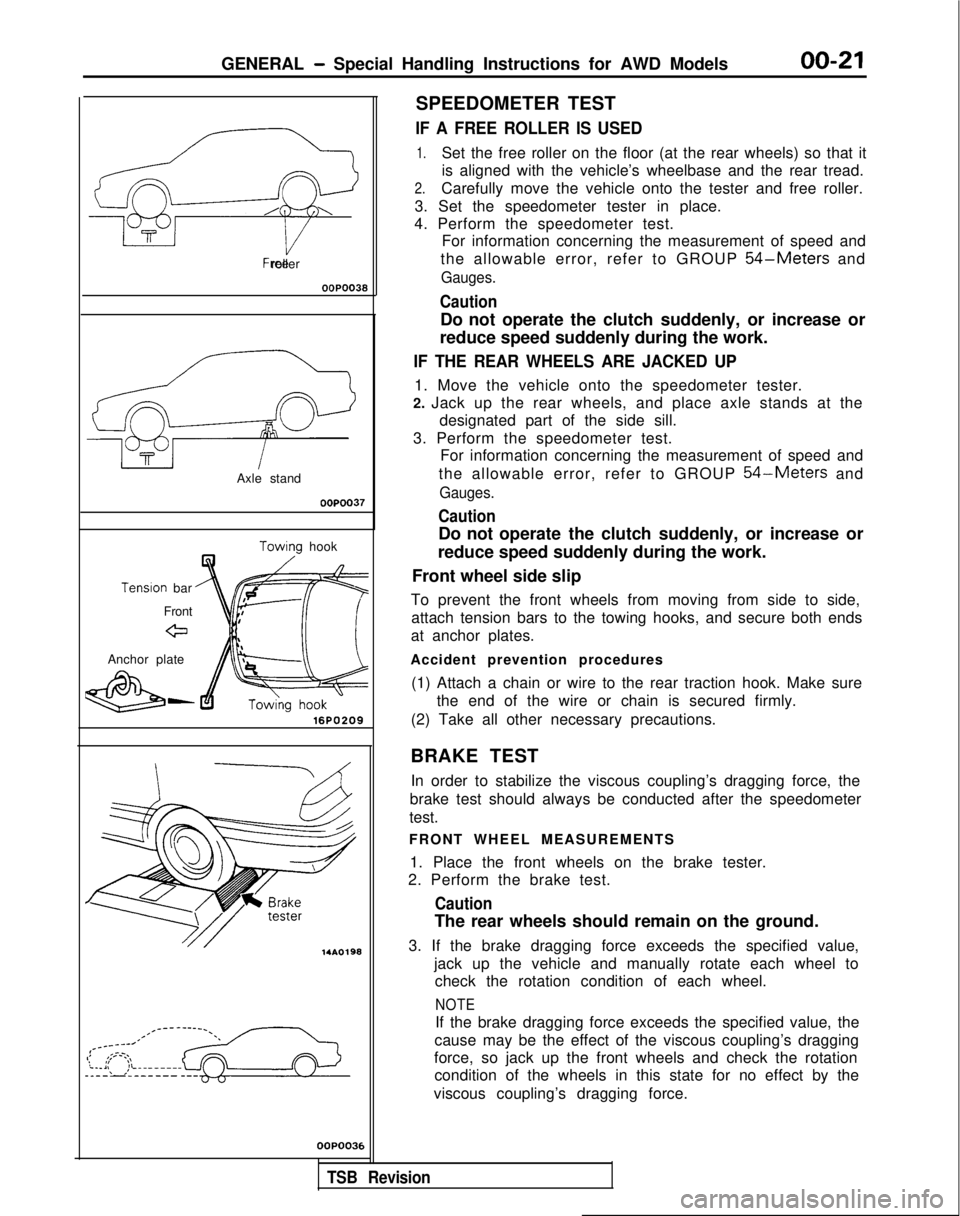

Free roller

OOPO038

Axle stand

OOPOO37

Towino hook

Tenslon

bar

Front

eJ

Anchor plate

&-16PO209 14AO198

OOP003E

SPEEDOMETER TEST

IF A FREE ROLLER IS USED

1.Set the free roller on the floor (at the rear wheels) so that it

is aligned with the vehicle’s wheelbase and the rear tread.

2.Carefully move the vehicle onto the tester and free roller.

3. Set the speedometer tester in place.

4. Perform the speedometer test. For information concerning the measurement of speed and

the allowable error, refer to GROUP

54-Meters and

Gauges.

Caution

Do not operate the clutch suddenly, or increase or

reduce speed suddenly during the work.

IF THE REAR WHEELS ARE JACKED UP

1. Move the vehicle onto the speedometer tester.

2. Jack up the rear wheels, and place axle stands at the designated part of the side sill.

3. Perform the speedometer test. For information concerning the measurement of speed and

the allowable error, refer to GROUP

54-Meters and

Gauges.

Caution

Do not operate the clutch suddenly, or increase or

reduce speed suddenly during the work.

Front wheel side slip

To prevent the front wheels from moving from side to side, attach tension bars to the towing hooks, and secure both ends

at anchor plates.

Accident prevention procedures (1) Attach a chain or wire to the rear traction hook. Make sure the end of the wire or chain is secured firmly.

(2) Take all other necessary precautions.

BRAKE TEST In order to stabilize the viscous coupling’s dragging force, the

brake test should always be conducted after the speedometer

test.

FRONT WHEEL MEASUREMENTS

1. Place the front wheels on the brake tester.

2. Perform the brake test.

Caution

The rear wheels should remain on the ground.

3. If the brake dragging force exceeds the specified value, jack up the vehicle and manually rotate each wheel tocheck the rotation condition of each wheel.

NOTE

If the brake dragging force exceeds the specified value, the

cause may be the effect of the viscous coupling’s dragging

force, so jack up the front wheels and check the rotation condition of the wheels in this state for no effect by the

viscous coupling’s dragging force.

,

TSB Revision

Page 24 of 1273

00-22GENERAL - Special Handling Instructions for AWD Models

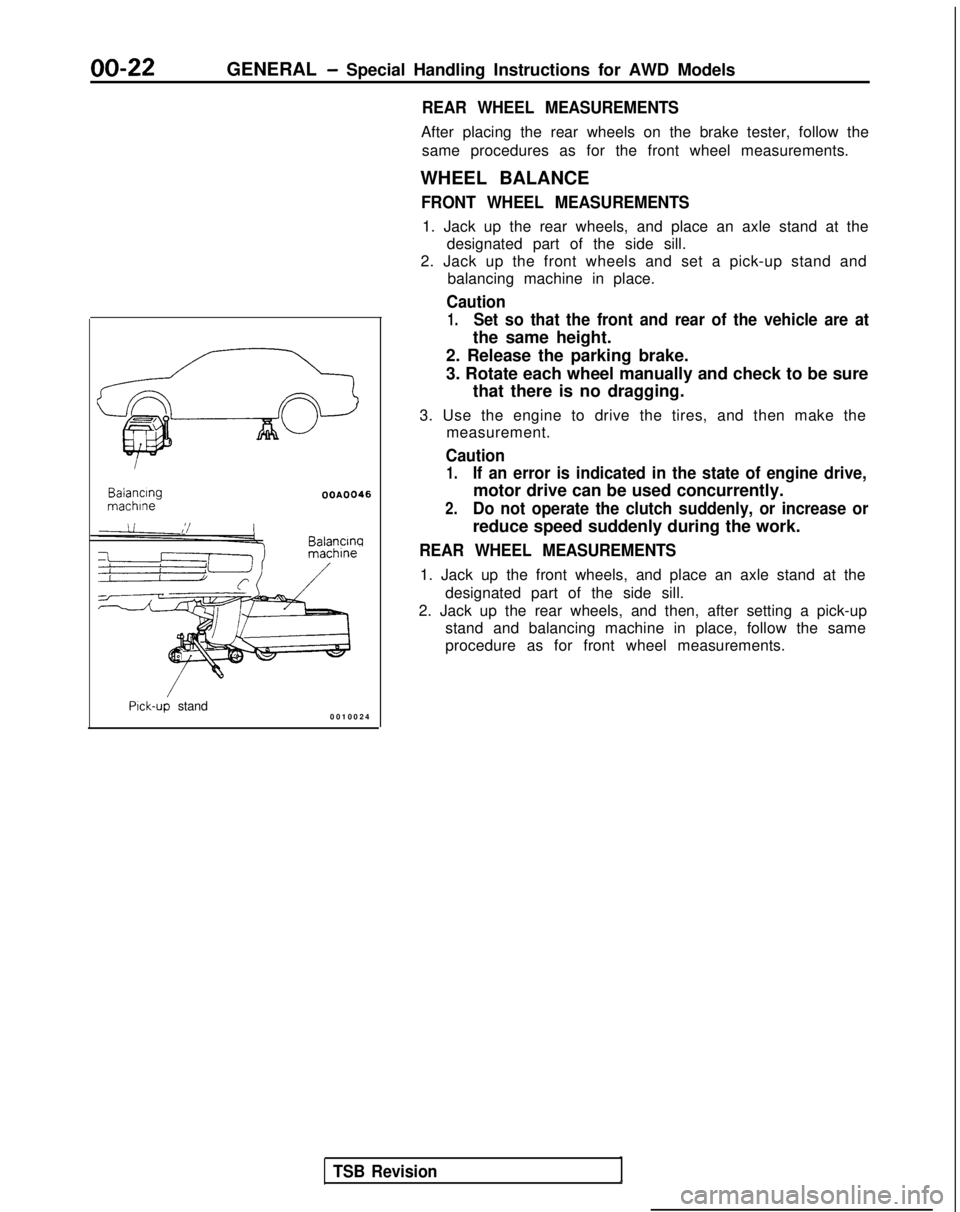

REAR WHEEL MEASUREMENTS

After placing the rear wheels on the brake tester, follow thesame procedures as for the front wheel measurements.

WHEEL BALANCE

FRONT WHEEL MEASUREMENTS

1. Jack up the rear wheels, and place an axle stand at the designated part of the side sill.

2. Jack up the front wheels and set a pick-up stand and balancing machine in place.

Caution

1.Set so that the front and rear of the vehicle are at

the same height. Balancing

machlne

OOA0046

Balancw

Pick-up stand

0010024

TSB Revision

2. Release the parking brake.

3. Rotate each wheel manually and check to be sure

that there is no dragging.

3. Use the engine to drive the tires, and then make the measurement.

Caution

1.If an error is indicated in the state of engine drive,

motor drive can be used concurrently.

2.Do not operate the clutch suddenly, or increase or

reduce speed suddenly during the work.

REAR WHEEL MEASUREMENTS

1. Jack up the front wheels, and place an axle stand at the

designated part of the side sill.

2. Jack up the rear wheels, and then, after setting a pick-up stand and balancing machine in place, follow the same

procedure as for front wheel measurements.

Page 25 of 1273

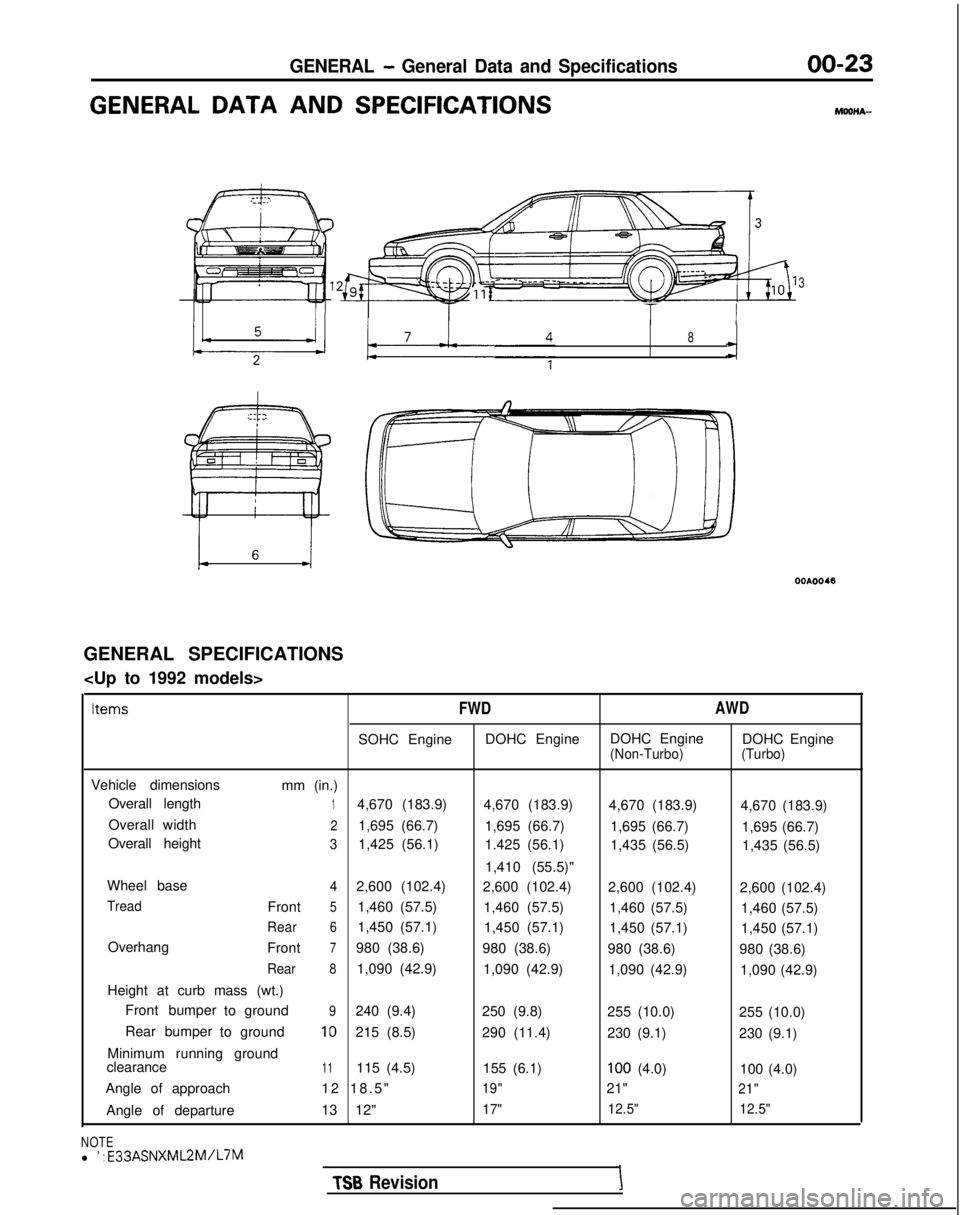

GENERAL - General Data and Specifications00-23

GENERAL DATA AND SPECIFICATIONSMOOHA-

3

I TT I

8

GENERAL SPECIFICATIONS

FWD

AWD

SOHC EngineDOHC EngineDOHC Engine

DOHC Engine(Non-Turbo) (Turbo)

Vehicle dimensions

mm (in.)

Overall length

14,670 (183.9) 4,670 (183.9)4,670 (183.9) 4,670 (183.9)

Overall width

21,695 (66.7) 1,695 (66.7)1,695 (66.7) 1,695 (66.7)

Overall height

31,425 (56.1) 1.425 (56.1)1,435 (56.5) 1,435 (56.5)

1,410 (55.5)"

Wheel base

42,600 (102.4) 2,600 (102.4)2,600 (102.4) 2,600 (102.4)

TreadFront51,460 (57.5)1,460 (57.5)1,460 (57.5) 1,460 (57.5)

Rear61,450 (57.1)1,450 (57.1)1,450 (57.1) 1,450 (57.1)

Overhang Front

7980 (38.6)980 (38.6)980 (38.6) 980 (38.6)

Rear81,090 (42.9)1,090 (42.9)1,090 (42.9) 1,090 (42.9)

Height at curb mass (wt.) Front bumper toground

9240 (9.4)

250 (9.8)255 (10.0) 255 (10.0)

Rear bumper toground

10215 (8.5)

290 (11.4)230 (9.1) 230 (9.1)

Minimum running ground

clearance

11115 (4.5) 155 (6.1)100 (4.0)100 (4.0)

Angle of approach 12 18.5

"

19"21"21"

Angle of departure

13 12"17"12.5"

12.5"

NOTEl ’ : E33ASNXML2M/L7M

TSB RevisionI

Page 26 of 1273

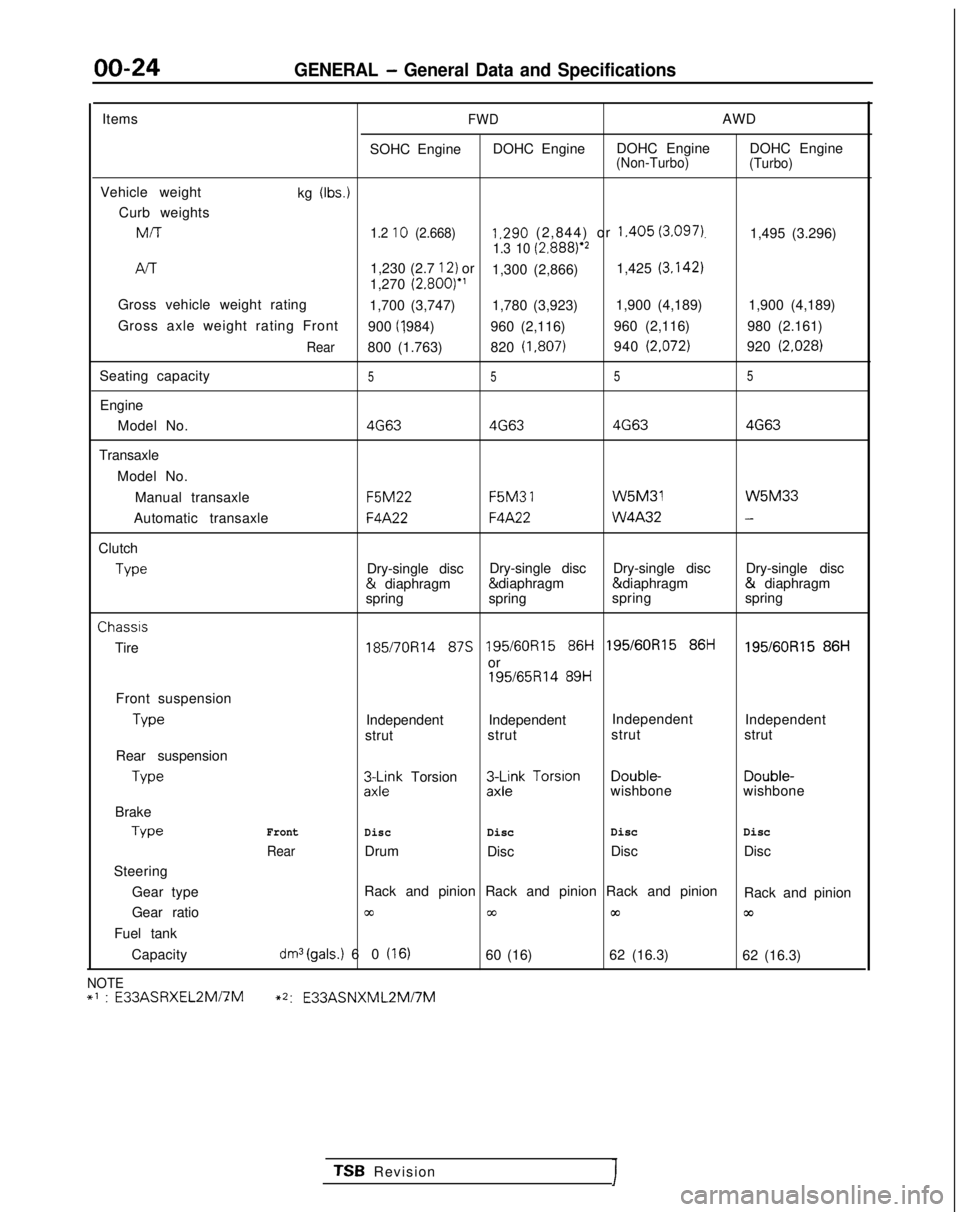

00-24GENERAL - General Data and Specifications

ItemsFWDAWD

SOHC Engine DOHC Engine DOHC Engine DOHC Engine

(Non-Turbo)

(Turbo)

Vehicle weight

kg (Ibs.)

Curb weightsMIT

1.2 10 (2.668)1.290 (2,844) or 1.405 (3.097).1,495 (3.296)1.3 10 (2.8881e2

/-v-r1,230 (2.7 12) or

1,300 (2,866) 1,425 (3.142)

1,270

(2.800)”

Gross vehicle weight rating 1,700 (3,747) 1,780 (3,923)1,900 (4,189)

1,900 (4,189)

Gross axle weight rating Front 900 (I ,984)

960 (2,116) 960 (2,116)

980 (2.161)

Rear800 (1.763)820 (1,807)940 (2.072)920 (2.028)

Seating capacity5 55 5

Engine

Model No.

4G634G63 4G634G63

Transaxle

Model No.Manual transaxle F5M22 F5M3

1 W5M31 W5M33

Automatic transaxle

F4A22F4A22 W4A32-

Clutch

Type

Dry-single disc

Dry-single disc

Dry-single disc Dry-single disc &

diaphragm & diaphragm & diaphragm &

diaphragm

spring spring spring

springChassis

Tire

185/7OR14 87s 195/60R15 86i-i 195/60R15 86ti195/60R15 86H

or

195/65R14 89H

Front suspension Type

Independent Independent

Independent

Independent

strut strut strut

strut

Rear suspension Type

3L$k Torsion3$k Torsion Double-

Double-

wishbone wishbone

Brake Type

Front

DiscDisc Disc

Disc

RearDrum

Disc Disc

Disc

Steering

Gear type Rack and pinion Rack and pinion Rack and pinion

Rack and pinion

Gear ratio

cc00m03

Fuel tank

Capacity

dm3(gals.) 60 (16)60 (16) 62 (16.3)

62 (16.3)

NOTE+’ : E33ASRXEL2Mi7M~2:

E33ASNXML2Mi7M

TSB RevisionI

Page 27 of 1273

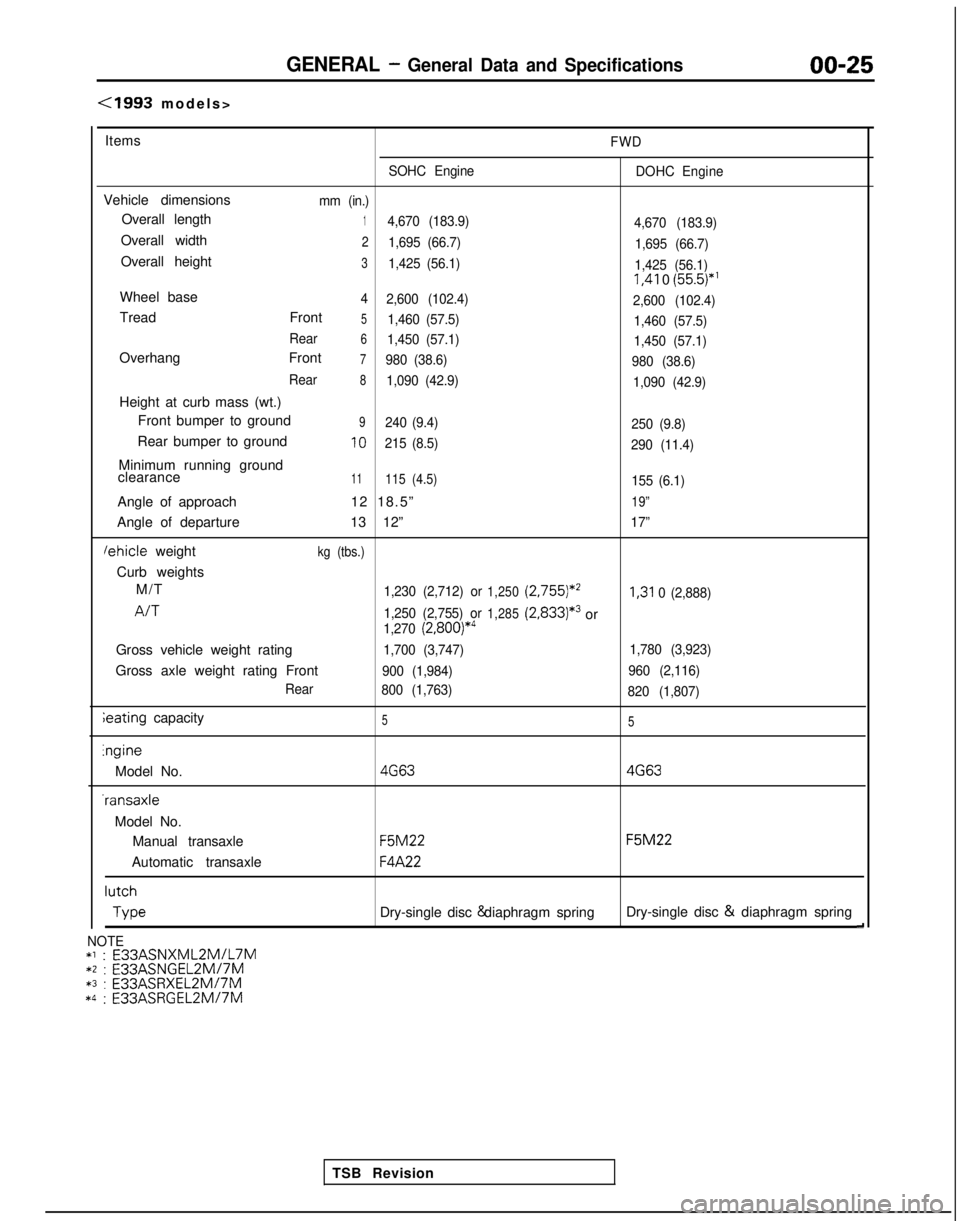

GENERAL - General Data and Specifications00-25

(1993 models

>

Items

FWD

SOHC Engine DOHC Engine

Vehicle dimensionsmm (in.)

Overall length14,670 (183.9)

4,670 (183.9)

Overall width21,695 (66.7)1,695 (66.7)

Overall height31,425 (56.1)1,425 (56.1) I,41

0

(55.5)*’

Wheel base4

2,600 (102.4)

2,600 (102.4)

Tread Front51,460 (57.5)1,460 (57.5)

Rear

61,450 (57.1) 1,450 (57.1)

Overhang Front7980 (38.6)980 (38.6)

Rear

81,090 (42.9) 1,090 (42.9)

Height at curb mass (wt.)

Front bumper to ground

9240 (9.4) 250 (9.8)

Rear bumper to ground10215 (8.5)290 (11.4)

Minimum running ground

clearance11115 (4.5)155 (6.1)

Angle of approach 12 18.5”19”

Angle of departure13 12”17”

lehicle weightkg (tbs.)

Curb weights

M/T

1,230 (2,712) or1,250 (2,755)*’I,31

0 (2,888)

A/T1,250 (2,755) or1,285(2,833)*3or1,270 (2,800)*4

Gross vehicle weight rating1,700 (3,747) 1,780 (3,923)

Gross axle weight rating Front900 (1,984)960 (2,116)

Rear 800 (1,763)

820 (1,807)

ieating capacity55lngine

Model No.

4G634G63 -ransaxle

Model No. Manual transaxle

F5M22 F5M22

Automatic transaxle

F4A22 lutch

Type

Dry-single disc & diaphragm spring

Dry-single disc &

diaphragm spring

d

TSB Revision

NOTE*l : E33ASNXML2MlL7M*2 : E33ASNGEL2MI7M*3 :

E33ASRXEL2M/7M*4 :

E33ASRGEL2M/7M

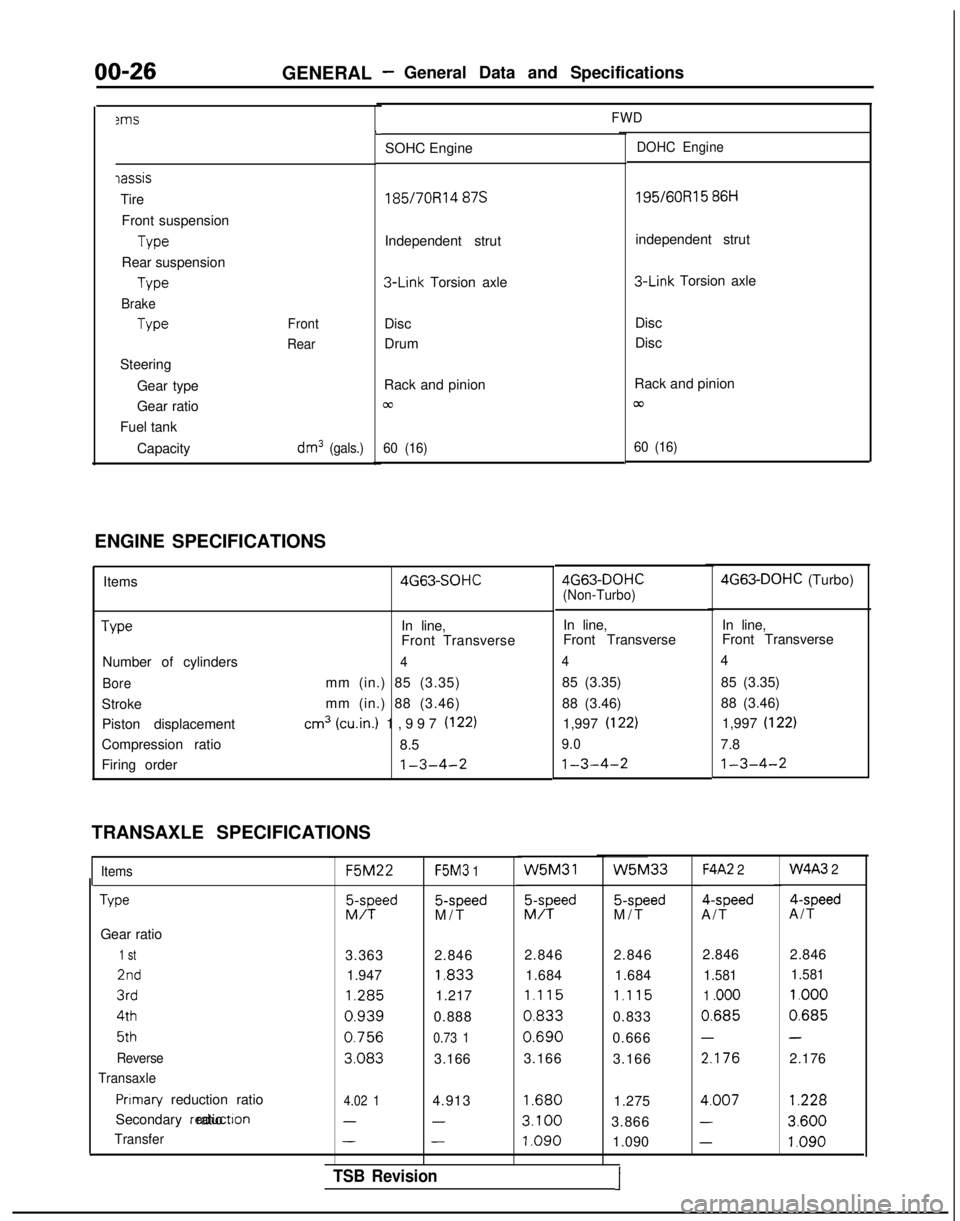

Page 28 of 1273

00-263ms

GENERAL -General Data and Specifications

FWD

iassis

Tire

Front suspension Type

Rear suspension Type

Brake

Type

Steering Gear type

Gear ratio

Fuel tank

Capacity

Front

Rear

dm3 (gals.)

L

SOHC EngineDOHC Engine

185/7ORl4 87s 195/60R15

86H

Independent strut independent strut 3-Link

Torsion axle 3-Link

Torsion axle

Disc

Drum Disc

Disc

Rack and pinion

cc

60 (16)

Rack and pinion

/cu

60 (16)

ENGINE SPECIFICATIONS Items Type

Number of cylinders

Bore

StrokePiston displacement

Compression ratio

Firing order 4G63-SOHC

In line,

Front Transverse

4

mm (in.) 85 (3.35)

mm (in.) 88 (3.46)

cm3 (win.) 1,997 (122)

8.5

1-3-4-2

TRANSAXLE SPECIFICATIONS

Items

Type

Gear ratio

1 st

2nd

3rd 4th

5th

Reverse

Transaxle

Pnmary reduction ratio

Secondary reductron ratio

Transfer F5M22

F5M3

1 5-speed

M/T W5M31

EFd

5-speed

M/T

F4A2 2 4-speed

A/T 4-speed

A/T

3.363 2.846 2.846 2.846

1.947 1.833

1.684 1.684 1.285

1.217

1.115 1.115

0.9390.8880.8330.833

0.7560.73 10.6900.666

3.0833.166

3.166

3.166 2.846 2.846

1.581

1.581

1 .ooo 1.000

0.6850.685

--

2.1762.176

4.02 14.9131.6801.2754.007

1.228

---3.1003.8663.600

---1.0901.090

1.0904G63-DOHC

(Non-Turbo) 4G63-DOHC

(Turbo)

In line, In line,

Front Transverse Front Transverse

44

85 (3.35) 85 (3.35)

88 (3.46) 88 (3.46)

1,997 (I

22)1,997 (I 22)

9.0

7.8

1-3-4-21-3-4-2

W5M33W4A3 2

TSB Revision1

Page 29 of 1273

GENERAL - Tightening Torque00-27

TIGHTENING TORQUE

Each torque value in the table is a standard value for tightening under \

the following conditions.

(1) Bolts, nuts and washers are all mode of steel and plated with zinc\

.

(2) The threads and bearing surface of bolts and nuts are all in dry c\

ondition.

The values in the table are not applicable:

(1) If toothed washers are inserted.

(2) If plastic parts are fastened.

(3) If bolts are tightened to plastic or die-cast inserted nuts.

(4) If self-tapping screws or self-locking nuts are used.

Standard bolt and nut tightening torque Bolt nominal

PitchTorque Nm (ft.lbs.1diameterb-m-dh-n)Head mark@Head mark@Head mark@

M50.8 2-3 (1.4-2.2) 4-6 (2.9-4.3)

5-7 (3.6-5.1)M6

1 .o4-6 (2.9-4.3)7-11 (5.1-8.0)8-12 (5.8-8.7)

M8

1.259-14 (6.5-10)17-26 (12-19)20-30 (14-22)

Ml01.2519-28(14-20)35-5

5

(25-40)45-60 (33-43)

Ml21.2534-50(25-36)70-95(51-69)85-110 (61-80)

Ml41.560-85 (43-61)120-160(87-116)130-180(94-130)

Ml61.595-130 (69-94)180-240(130-174)200-270(145-195)

Ml81.5140-190 (101-137)260-350(188-253)300-400(217-289)

Bolt nominal

Pitch Torque Nm (ft.lbs.1

diameterh-n)b-m-dHead mark@Head mark0Head mark@

M61 .o4-6 (2.9-4.3)8-12 (5.8-8.7)9-14 (6.5-10)

M81.25lo-15 (7.2-11)19-28 (14-20)22-33 (16-24)

Ml01.2521-31 (15-22)39-60 (28-43)50-65 (36-47)

Ml01.519-29 (14-21)

36-54 (26-39)45-65 (33-47)

Ml21.2538-55 (27-40)80-1'10 (58-80)90-120 (65-87)

Ml21.7534-52 (25-38)70-95 (51-69)85-110 (61-80)

.

TSB RevisionM20

1.5190-260(137-188)

M22

1.5260-350(188-253)M24

1.5340-460(246-333)630-860(456-622)

Flange bolt and nut tightening torque

Page 30 of 1273

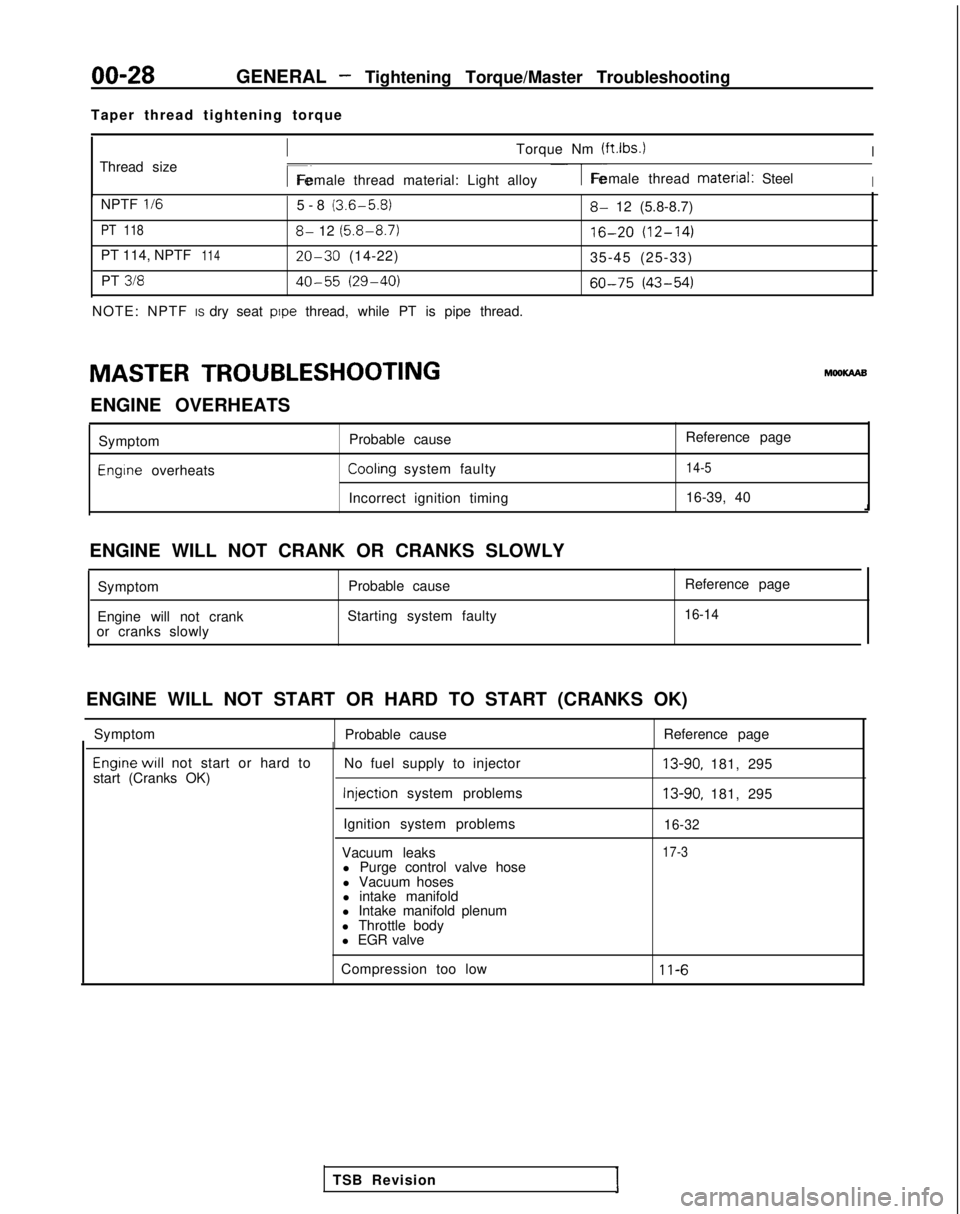

00-28GENERAL - Tightening Torque/Master Troubleshooting

Taper thread tightening torque

Thread size

ITorque Nm (ftlbs.)I

r~Female thread material: Light alloy1-Female thread material: SteelI

NPTF II65-8 (3.6-5.8)

PT 1188- 12 (5.8-8.7)

PT 114, NPTF11420-30 (14-22)

PT

31840-55 (29-40)

NOTE: NPTF IS dry seat pope thread, while PT is pipe thread.

8- 12 (5.8-8.7)

16-20 (12-14)

35-45 (25-33)

60-75 (43-54)

MASTER TROUBLESHOOTING hlooKAAB

ENGINE OVERHEATS Symptom

Engine overheats Probable cause

Reference pageCoolrng system faulty14-5

Incorrect ignition timing

16-39, 40

ENGINE WILL NOT CRANK OR CRANKS SLOWLY Symptom Probable cause

Engine will not crank Starting system faulty

or cranks slowly Reference page

16-14

ENGINE WILL NOT START OR HARD TO START (CRANKS OK)

Symptom Probable cause Reference page

Engrne WIII not start or hard to

start (Cranks OK) No fuel supply to injector Injection

system problems

Ignition system problems

Vacuum leaks l Purge control valve hose

l Vacuum hoses

l intake manifold

l Intake manifold plenum

l Throttle body

l EGR valve13-90, 181, 295

13-90, 181, 295

16-32

17-3

Compression too low11-6

TSB Revision